automatic transmission SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 736 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-92 Automatic Transmission/Transaxle:

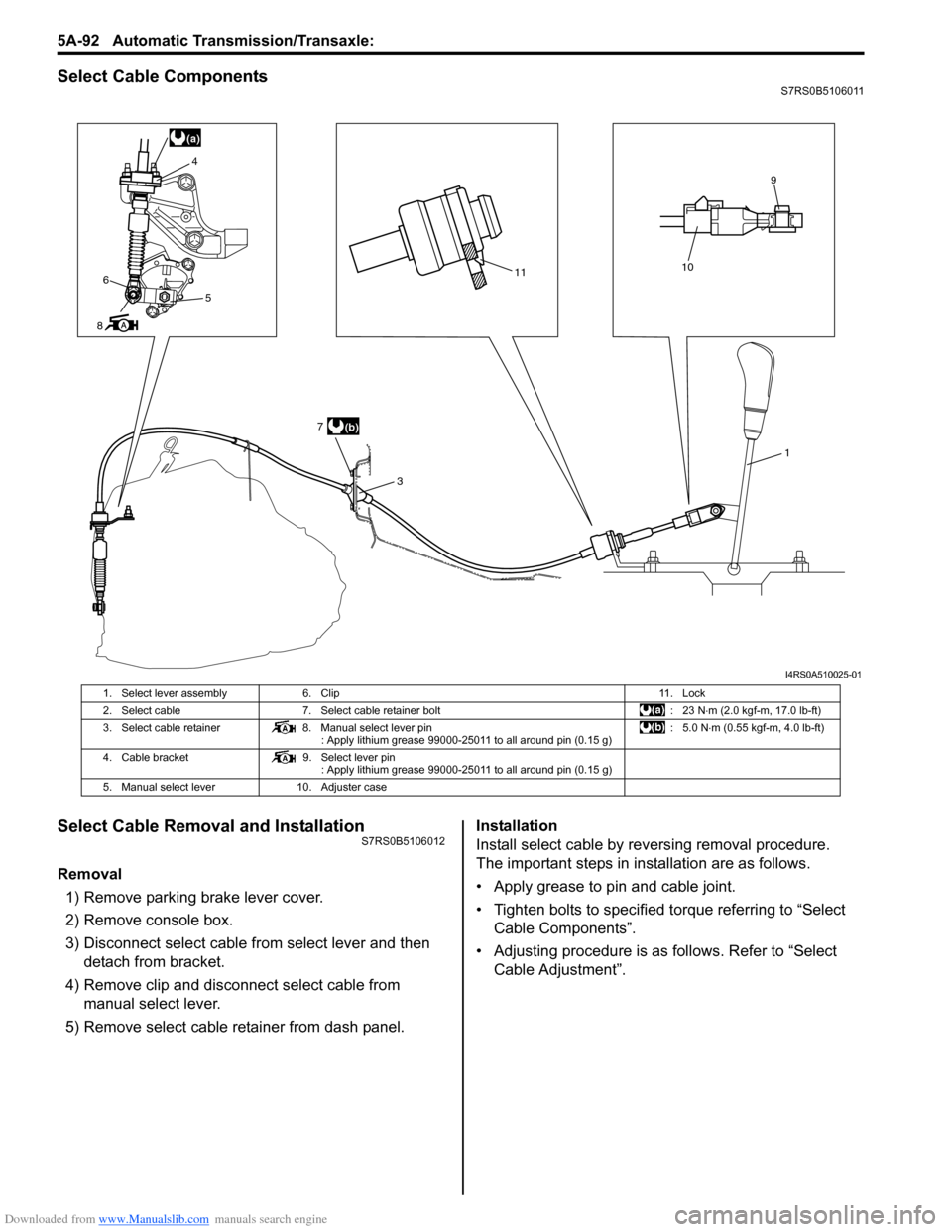

Select Cable ComponentsS7RS0B5106011

Select Cable Removal and InstallationS7RS0B5106012

Removal

1) Remove parking brake lever cover.

2) Remove console box.

3) Disconnect select cable from select lever and then detach from bracket.

4) Remove clip and disconnect select cable from manual select lever.

5) Remove select cable retainer from dash panel. Installation

Install select cable by reversing removal procedure.

The important steps in inst

allation are as follows.

• Apply grease to pin and cable joint.

• Tighten bolts to specified torque referring to “Select Cable Components”.

• Adjusting procedure is as follows. Refer to “Select Cable Adjustment”.

(a)

11

3

10

9

6

8 4

5

(b)

7

1

I4RS0A510025-01

1. Select lever assembly

6. Clip 11. Lock

2. Select cable 7. Select cable retainer bolt : 23 N⋅m (2.0 kgf-m, 17.0 lb-ft)

3. Select cable retainer 8. Manual select lever pin

: Apply lithium grease 99000-25011 to all around pin (0.15 g) :5.0 N

⋅m (0.55 kgf-m, 4.0 lb-ft)

4. Cable bracket 9. Select lever pin

: Apply lithium grease 99000-25011 to all around pin (0.15 g)

5. Manual select lever 10. Adjuster case

Page 737 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-93

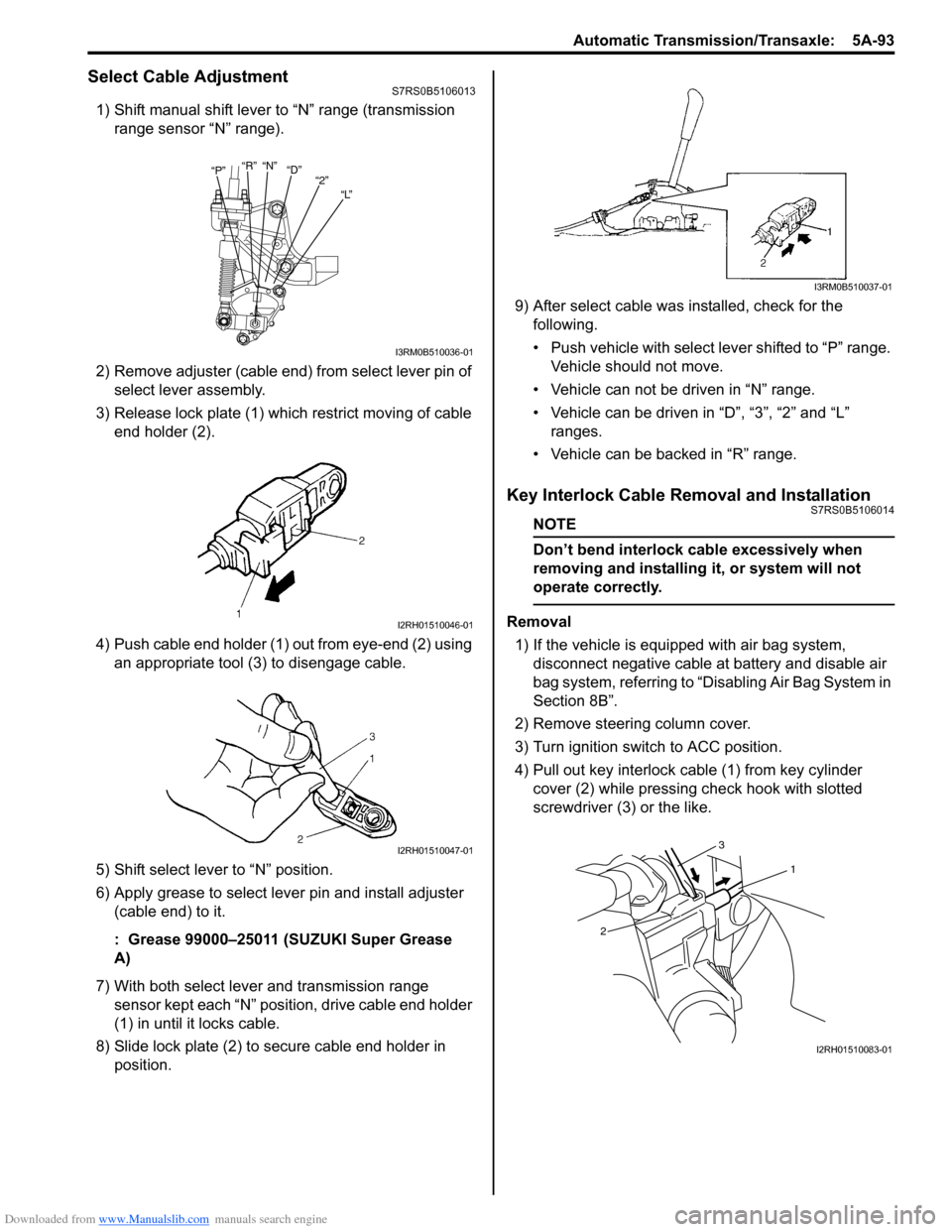

Select Cable AdjustmentS7RS0B5106013

1) Shift manual shift lever to “N” range (transmission range sensor “N” range).

2) Remove adjuster (cable end) from select lever pin of select lever assembly.

3) Release lock plate (1) which restrict moving of cable end holder (2).

4) Push cable end holder (1) out from eye-end (2) using an appropriate tool (3) to disengage cable.

5) Shift select lever to “N” position.

6) Apply grease to select lever pin and install adjuster (cable end) to it.

: Grease 99000–25011 (SUZUKI Super Grease

A)

7) With both select lever and transmission range sensor kept each “N” position, drive cable end holder

(1) in until it locks cable.

8) Slide lock plate (2) to secure cable end holder in position. 9) After select cable was

installed, check for the

following.

• Push vehicle with select lever shifted to “P” range. Vehicle should not move.

• Vehicle can not be driven in “N” range.

• Vehicle can be driven in “D”, “3”, “2” and “L” ranges.

• Vehicle can be backed in “R” range.

Key Interlock Cable Removal and InstallationS7RS0B5106014

NOTE

Don’t bend interlock cable excessively when

removing and installing it, or system will not

operate correctly.

Removal

1) If the vehicle is equipped with air bag system, disconnect negative cable at battery and disable air

bag system, referring to “Disabling Air Bag System in

Section 8B”.

2) Remove steering column cover.

3) Turn ignition switch to ACC position.

4) Pull out key interlock cable (1) from key cylinder cover (2) while pressing check hook with slotted

screwdriver (3) or the like.

“P” “R”

“N”

“D”

“2”

“L”

I3RM0B510036-01

I2RH01510046-01

I2RH01510047-01

I3RM0B510037-01

1

2 3

I2RH01510083-01

Page 738 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-94 Automatic Transmission/Transaxle:

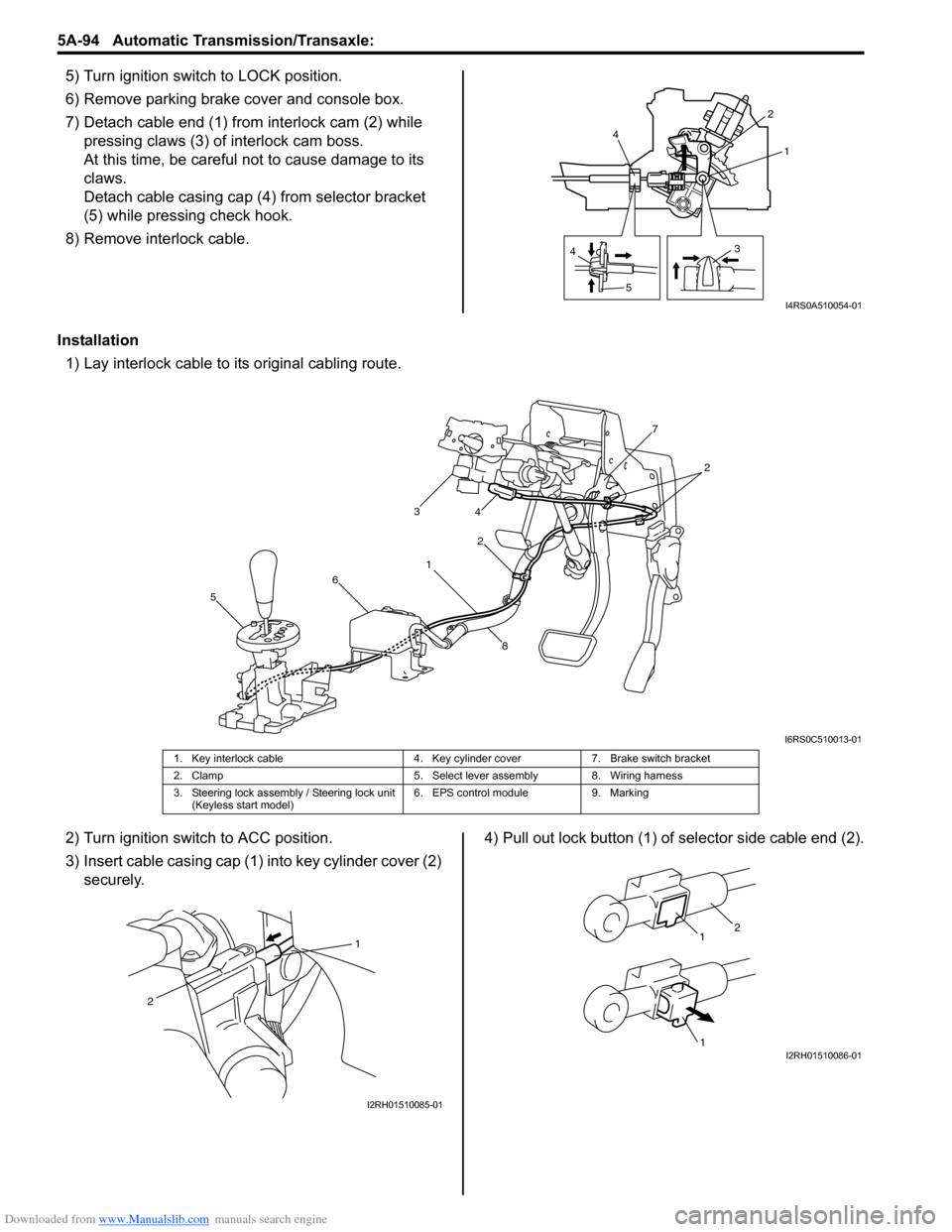

5) Turn ignition switch to LOCK position.

6) Remove parking brake cover and console box.

7) Detach cable end (1) from interlock cam (2) while

pressing claws (3) of interlock cam boss.

At this time, be careful no t to cause damage to its

claws.

Detach cable casing cap (4 ) from selector bracket

(5) while pressing check hook.

8) Remove interlock cable.

Installation 1) Lay interlock cable to its original cabling route.

2) Turn ignition switch to ACC position.

3) Insert cable casing cap (1) into key cylinder cover (2) securely. 4) Pull out lock button (1) of selector side cable end (2).

4

5 31

2

4

I4RS0A510054-01

1 2

3

4

5 6 7

8

2

I6RS0C510013-01

1. Key interlock cable 4. Key cylinder cover7. Brake switch bracket

2. Clamp 5. Select lever assembly 8. Wiring harness

3. Steering lock assembly / Steering lock unit (Keyless start model) 6. EPS control module

9. Marking

1

2

I2RH01510085-01

1

1

2

I2RH01510086-01

Page 739 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-95

5) Shift select lever to “N” position.

NOTE

If select lever is in “P” position, shift select

lever referring to “Select Lever Inspection”.

6) Install cable casing cap (3) to selector bracket (4).

7) Connect cable end (1) to interlock cam (2) with ignition switch turned to ACC position.

8) Drive lock button (5) in cable end until it locks cable expansion and contraction.

9) With select lever set at “P ” position, turn ignition key

to ACC position and then check for the following

conditions.

• With knob button released, ignition key can be turned from ACC position to LOCK position.

• With knob button pressed, ignition key cannot be

turned from ACC position to LOCK position.

10) Install steering column cover. 11) If the vehicle is equipped with air bag system, connect negative cable at battery and enable air bag

system, referring to “Enabling Air Bag System in

Section 8B”.

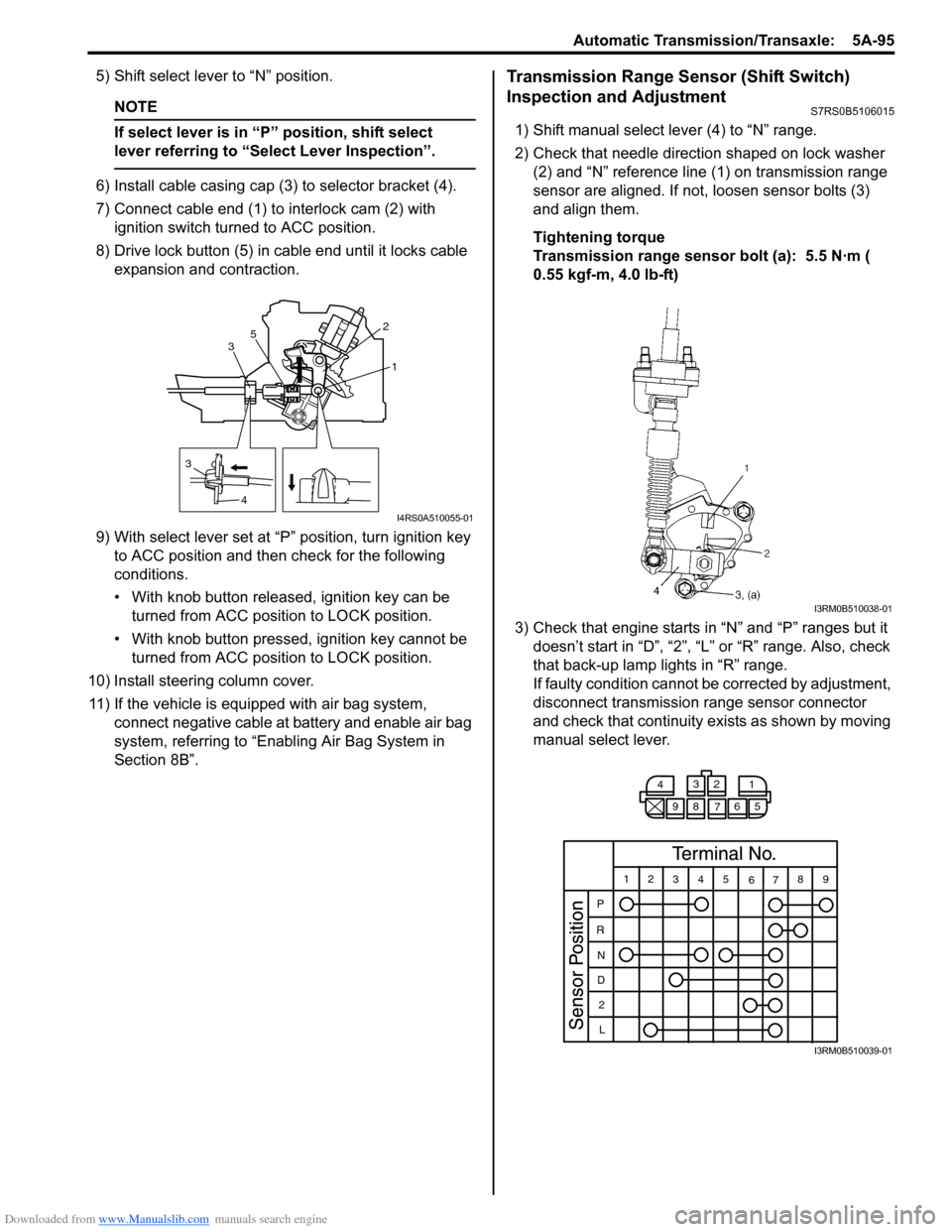

Transmission Range Sensor (Shift Switch)

Inspection and Adjustment

S7RS0B5106015

1) Shift manual select lever (4) to “N” range.

2) Check that needle direction shaped on lock washer (2) and “N” reference line (1) on transmission range

sensor are aligned. If not, loosen sensor bolts (3)

and align them.

Tightening torque

Transmission range sensor bolt (a): 5.5 N·m (

0.55 kgf-m, 4.0 lb-ft)

3) Check that engine starts in “N” and “P” ranges but it doesn’t start in “D”, “2”, “L” or “R” range. Also, check

that back-up lamp lights in “R” range.

If faulty condition cannot be corrected by adjustment,

disconnect transmission range sensor connector

and check that continuity ex ists as shown by moving

manual select lever.

3

4 1

2

3 5

I4RS0A510055-01

I3RM0B510038-01

4

3

2

1

98 76 5

12 345

6789

P

R N

D 2

L

I3RM0B510039-01

Page 740 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-96 Automatic Transmission/Transaxle:

Output Shaft Speed Sensor Removal and

Installation

S7RS0B5106016

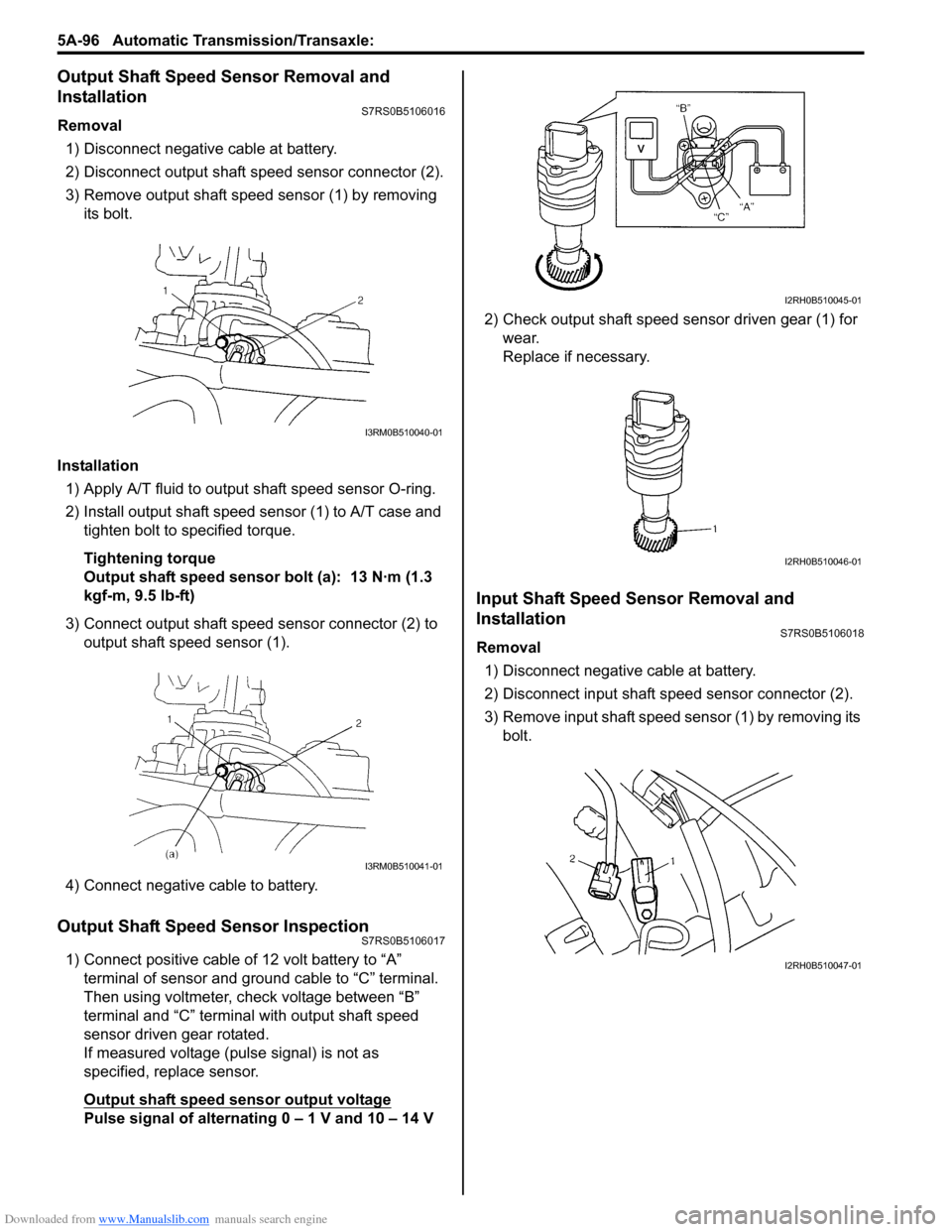

Removal

1) Disconnect negative cable at battery.

2) Disconnect output shaft speed sensor connector (2).

3) Remove output shaft speed sensor (1) by removing its bolt.

Installation 1) Apply A/T fluid to output shaft speed sensor O-ring.

2) Install output shaft speed sensor (1) to A/T case and tighten bolt to specified torque.

Tightening torque

Output shaft speed sensor bolt (a): 13 N·m (1.3

kgf-m, 9.5 lb-ft)

3) Connect output shaft speed sensor connector (2) to output shaft speed sensor (1).

4) Connect negative cable to battery.

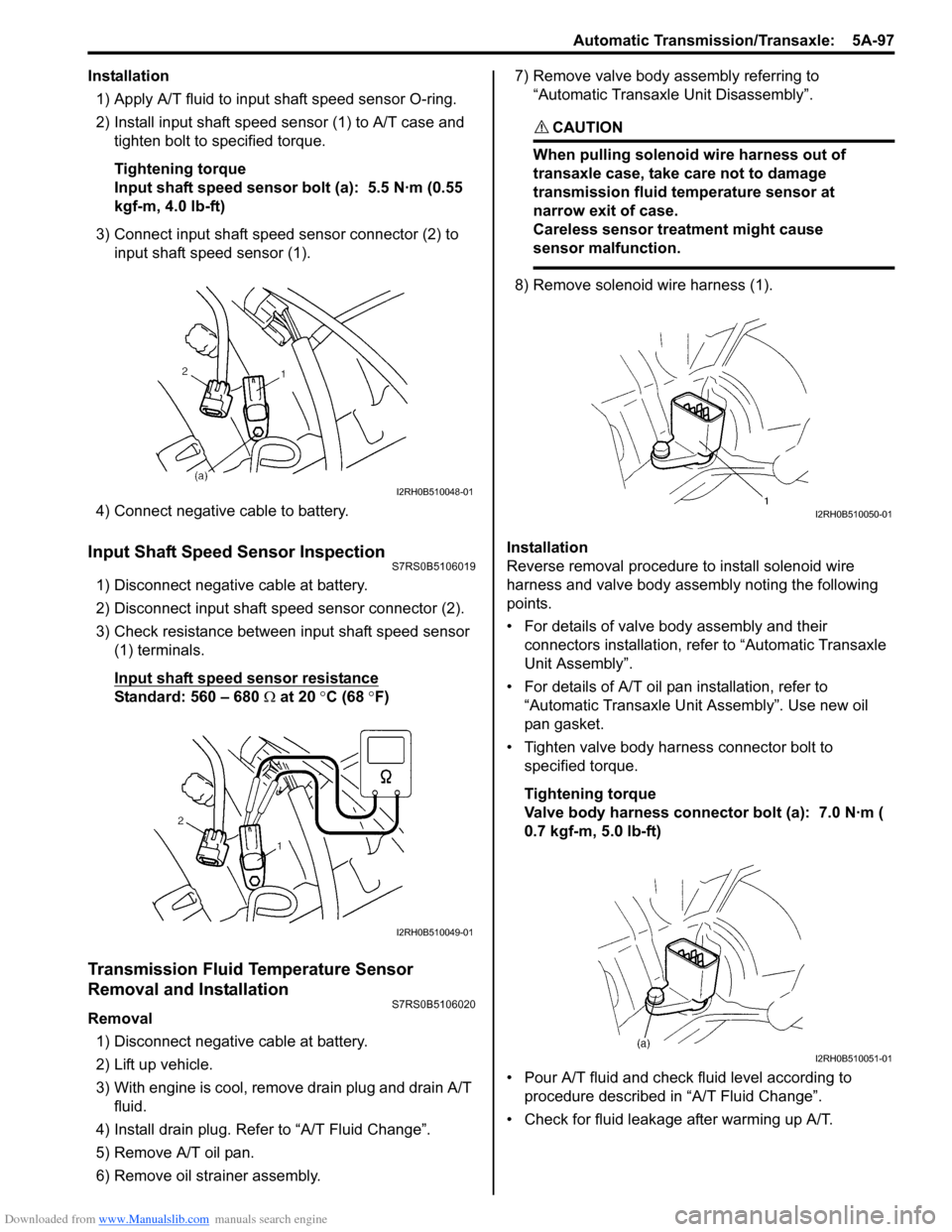

Output Shaft Speed Sensor InspectionS7RS0B5106017

1) Connect positive cable of 12 volt battery to “A” terminal of sensor and ground cable to “C” terminal.

Then using voltmeter, check voltage between “B”

terminal and “C” terminal with output shaft speed

sensor driven gear rotated.

If measured voltage (pulse signal) is not as

specified, replace sensor.

Output shaft speed sensor output voltage

Pulse signal of alternating 0 – 1 V and 10 – 14 V 2) Check output shaft speed sensor driven gear (1) for

wear.

Replace if necessary.

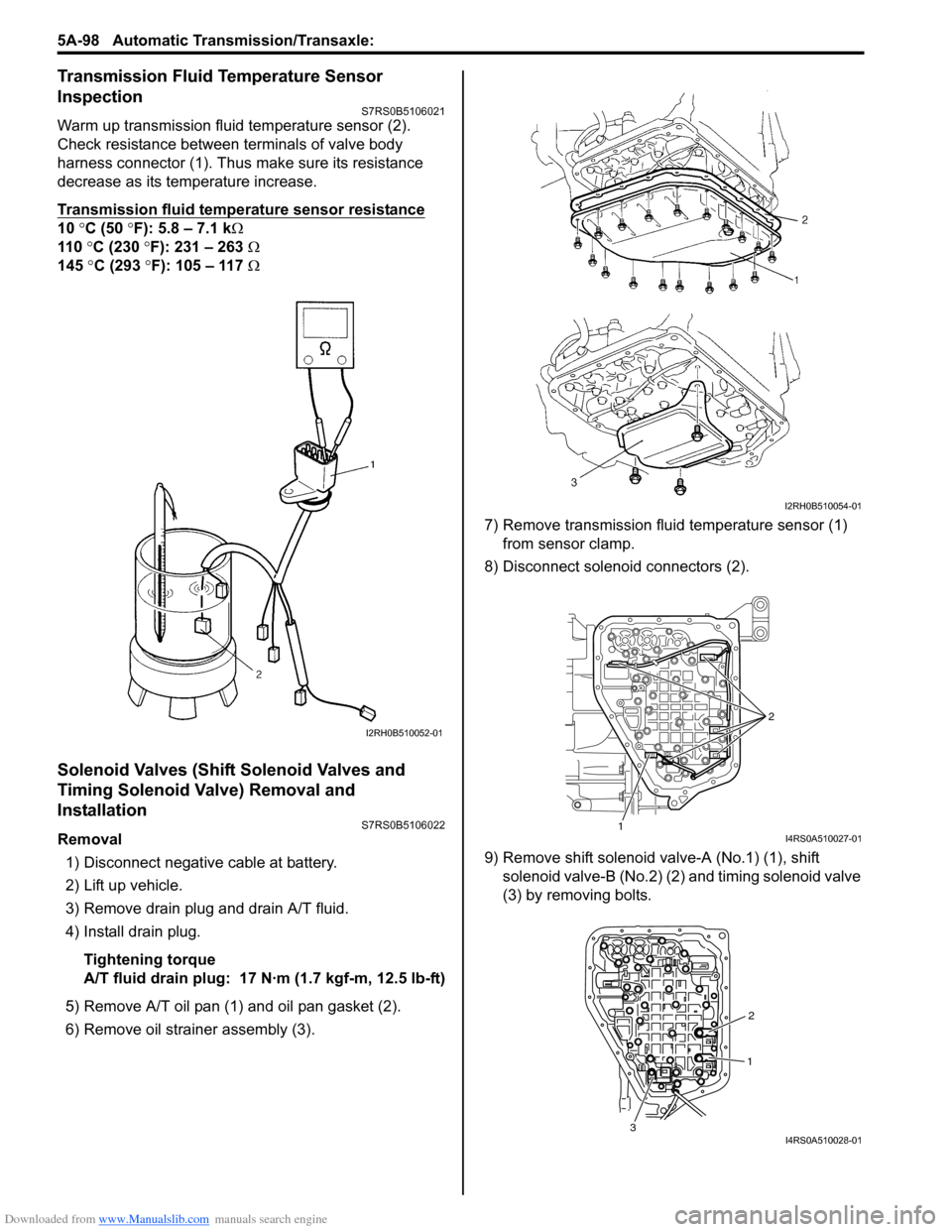

Input Shaft Speed Sensor Removal and

Installation

S7RS0B5106018

Removal

1) Disconnect negative cable at battery.

2) Disconnect input shaft speed sensor connector (2).

3) Remove input shaft speed sensor (1) by removing its bolt.

I3RM0B510040-01

I3RM0B510041-01

I2RH0B510045-01

I2RH0B510046-01

I2RH0B510047-01

Page 741 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-97

Installation1) Apply A/T fluid to input shaft speed sensor O-ring.

2) Install input shaft speed se nsor (1) to A/T case and

tighten bolt to specified torque.

Tightening torque

Input shaft speed sensor bolt (a): 5.5 N·m (0.55

kgf-m, 4.0 lb-ft)

3) Connect input shaft speed sensor connector (2) to input shaft speed sensor (1).

4) Connect negative cable to battery.

Input Shaft Speed Sensor InspectionS7RS0B5106019

1) Disconnect negative cable at battery.

2) Disconnect input shaft speed sensor connector (2).

3) Check resistance between input shaft speed sensor (1) terminals.

Input shaft speed sensor resistance

Standard: 560 – 680 Ω at 20 °C (68 °F)

Transmission Fluid Temperature Sensor

Removal and Installation

S7RS0B5106020

Removal

1) Disconnect negative cable at battery.

2) Lift up vehicle.

3) With engine is cool, remove drain plug and drain A/T fluid.

4) Install drain plug. Refer to “A/T Fluid Change”.

5) Remove A/T oil pan.

6) Remove oil stra iner assembly. 7) Remove valve body assembly referring to

“Automatic Transaxl e Unit Disassembly”.

CAUTION!

When pulling solenoid wire harness out of

transaxle case, take care not to damage

transmission fluid temperature sensor at

narrow exit of case.

Careless sensor treatment might cause

sensor malfunction.

8) Remove solenoid wire harness (1).

Installation

Reverse removal procedure to install solenoid wire

harness and valve body assembly noting the following

points.

• For details of valve body assembly and their connectors installation, refer to “Automatic Transaxle

Unit Assembly”.

• For details of A/T oil pa n installation, refer to

“Automatic Transaxle Unit Assembly”. Use new oil

pan gasket.

• Tighten valve body harness connector bolt to specified torque.

Tightening torque

Valve body harness connector bolt (a): 7.0 N·m (

0.7 kgf-m, 5.0 lb-ft)

• Pour A/T fluid and check fluid level according to procedure described in “A/T Fluid Change”.

• Check for fluid leakage after warming up A/T.

I2RH0B510048-01

I2RH0B510049-01

I2RH0B510050-01

I2RH0B510051-01

Page 742 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-98 Automatic Transmission/Transaxle:

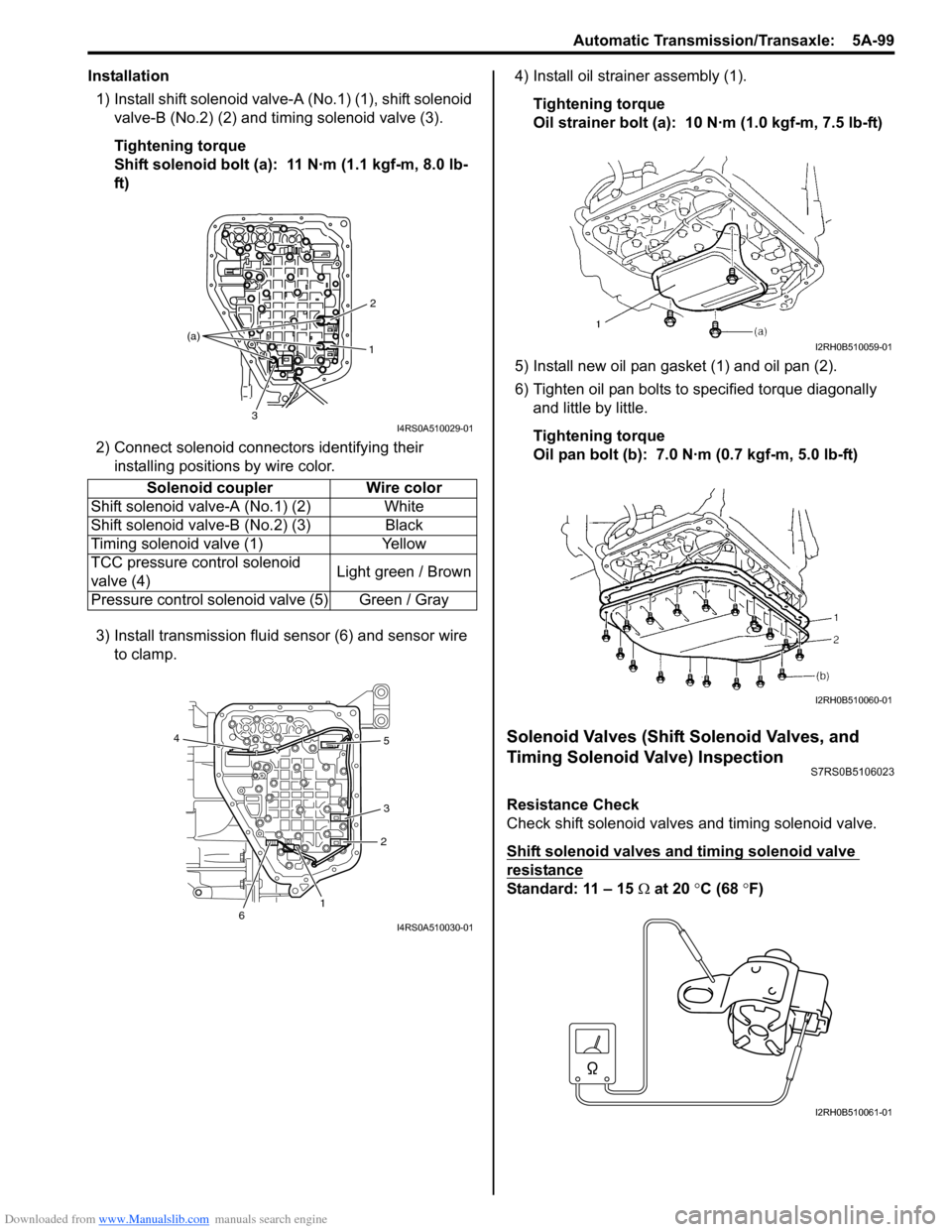

Transmission Fluid Temperature Sensor

Inspection

S7RS0B5106021

Warm up transmission fluid temperature sensor (2).

Check resistance between terminals of valve body

harness connector (1). Thus make sure its resistance

decrease as its temperature increase.

Transmission fluid temperature sensor resistance

10 °C (50 °F): 5.8 – 7.1 k Ω

110 °C (230 °F): 231 – 263 Ω

145 °C (293 °F): 105 – 117 Ω

Solenoid Valves (Shift Solenoid Valves and

Timing Solenoid Valve) Removal and

Installation

S7RS0B5106022

Removal

1) Disconnect negative cable at battery.

2) Lift up vehicle.

3) Remove drain plug and drain A/T fluid.

4) Install drain plug.

Tightening torque

A/T fluid drain plug: 17 N· m (1.7 kgf-m, 12.5 lb-ft)

5) Remove A/T oil pan (1) and oil pan gasket (2).

6) Remove oil strain er assembly (3). 7) Remove transmission fluid temperature sensor (1)

from sensor clamp.

8) Disconnect solenoid connectors (2).

9) Remove shift solenoid va lve-A (No.1) (1), shift

solenoid valve-B (No.2) (2) and timing solenoid valve

(3) by removing bolts.

I2RH0B510052-01

I2RH0B510054-01

1 2I4RS0A510027-01

1

2

3

I4RS0A510028-01

Page 743 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-99

Installation1) Install shift solenoid valve- A (No.1) (1), shift solenoid

valve-B (No.2) (2) and timing solenoid valve (3).

Tightening torque

Shift solenoid bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-

ft)

2) Connect solenoid connectors identifying their installing positions by wire color.

3) Install transmission fluid sensor (6) and sensor wire to clamp. 4) Install oil strain

er assembly (1).

Tightening torque

Oil strainer bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft)

5) Install new oil pan gasket (1) and oil pan (2).

6) Tighten oil pan bolts to specified torque diagonally and little by little.

Tightening torque

Oil pan bolt (b): 7.0 N·m (0.7 kgf-m, 5.0 lb-ft)

Solenoid Valves (Shift Solenoid Valves, and

Timing Solenoid Valve) Inspection

S7RS0B5106023

Resistance Check

Check shift solenoid valves and timing solenoid valve.

Shift solenoid valves and timing solenoid valve

resistance

Standard: 11 – 15 Ω at 20 °C (68 ° F)

Solenoid coupler Wire color

Shift solenoid valv e-A (No.1) (2) White

Shift solenoid valv e-B (No.2) (3) Black

Timing solenoid valve (1) Yellow

TCC pressure control solenoid

valve (4) Light green / Brown

Pressure control solenoid valve (5) Green / Gray

1 2

3

(a)

I4RS0A510029-01

1

2

3 5

4

6

I4RS0A510030-01

I2RH0B510059-01

I2RH0B510060-01

I2RH0B510061-01

Page 744 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-100 Automatic Transmission/Transaxle:

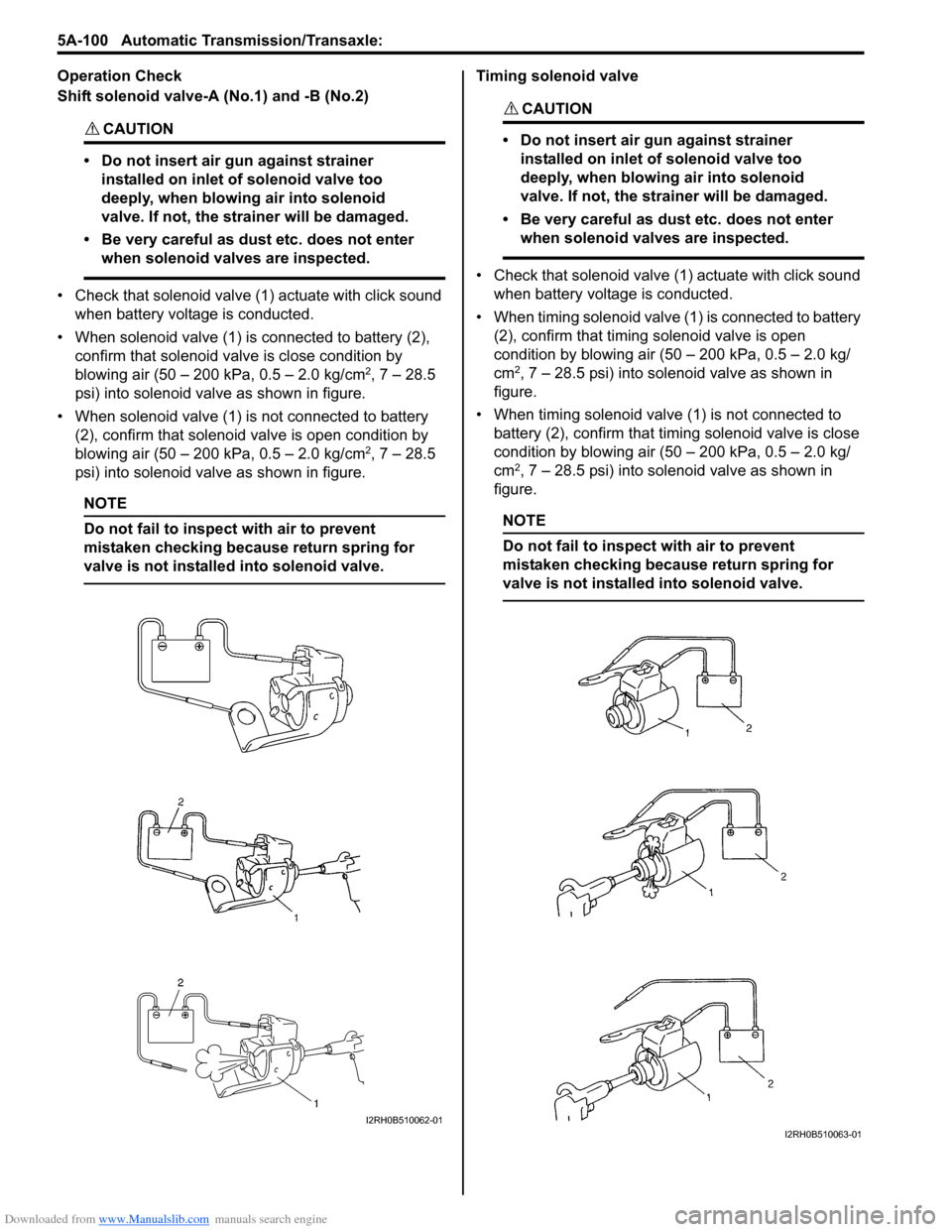

Operation Check

Shift solenoid valve-A (No.1) and -B (No.2)

CAUTION!

• Do not insert air gun against strainer installed on inlet of solenoid valve too

deeply, when blowing air into solenoid

valve. If not, the strainer will be damaged.

• Be very careful as dust etc. does not enter when solenoid valves are inspected.

• Check that solenoid valve (1) actuate with click sound when battery voltage is conducted.

• When solenoid valve (1) is connected to battery (2), confirm that solenoid valve is close condition by

blowing air (50 – 200 kPa, 0.5 – 2.0 kg/cm

2, 7 – 28.5

psi) into solenoid valve as shown in figure.

• When solenoid valve (1) is not connected to battery (2), confirm that solenoid valve is open condition by

blowing air (50 – 200 kPa, 0.5 – 2.0 kg/cm

2, 7 – 28.5

psi) into solenoid valve as shown in figure.

NOTE

Do not fail to inspect with air to prevent

mistaken checking because return spring for

valve is not installe d into solenoid valve.

Timing solenoid valve

CAUTION!

• Do not insert air gun against strainer

installed on inlet of solenoid valve too

deeply, when blowing air into solenoid

valve. If not, the strainer will be damaged.

• Be very careful as dust etc. does not enter when solenoid valves are inspected.

• Check that solenoid valve (1) actuate with click sound

when battery voltage is conducted.

• When timing solenoid valve (1 ) is connected to battery

(2), confirm that timing solenoid valve is open

condition by blowing air (50 – 200 kPa, 0.5 – 2.0 kg/

cm

2, 7 – 28.5 psi) into solenoid valve as shown in

figure.

• When timing solenoid valve (1) is not connected to battery (2), confirm that timi ng solenoid valve is close

condition by blowing air (50 – 200 kPa, 0.5 – 2.0 kg/

cm

2, 7 – 28.5 psi) into solenoid valve as shown in

figure.

NOTE

Do not fail to inspect with air to prevent

mistaken checking because return spring for

valve is not installed into solenoid valve.

I2RH0B510062-01I2RH0B510063-01

Page 745 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-101

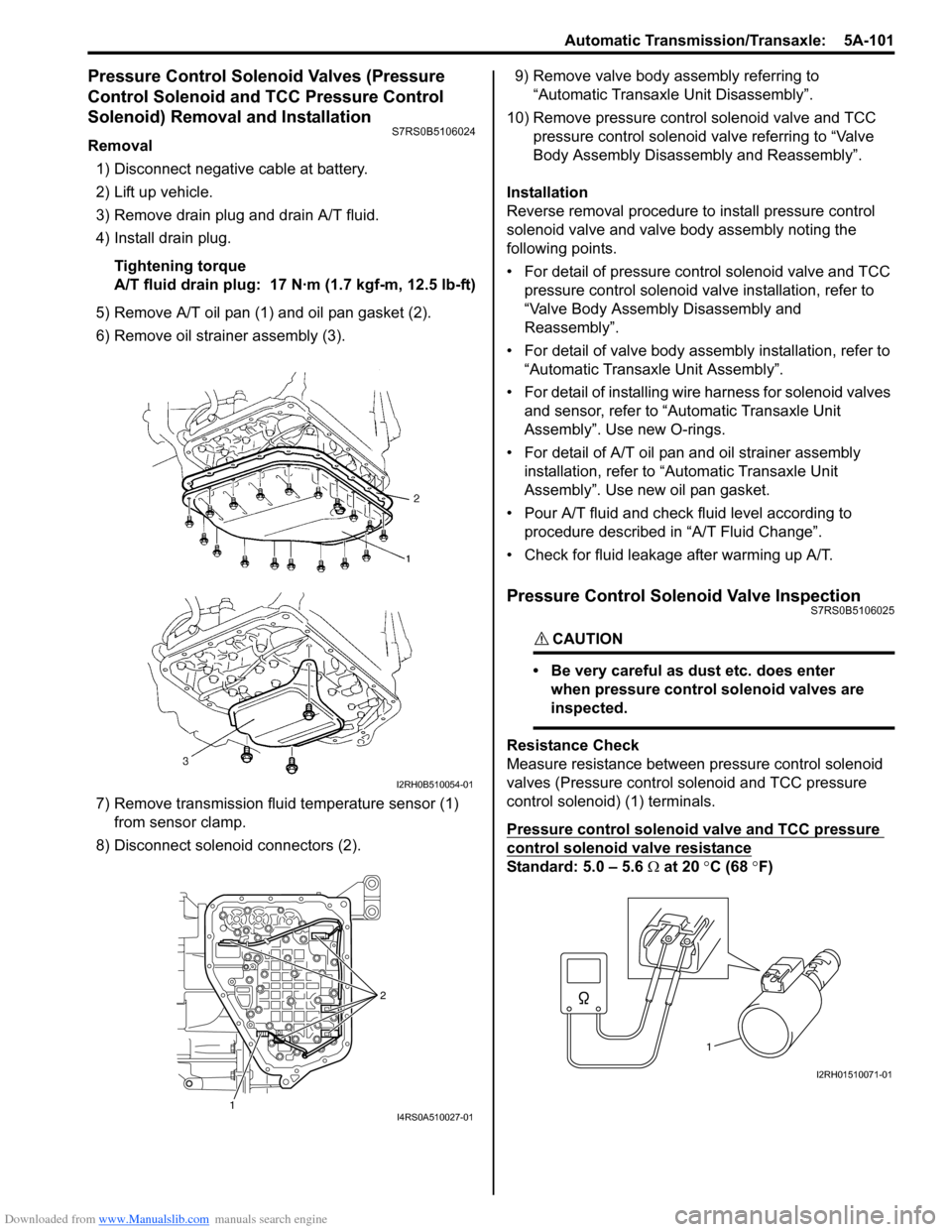

Pressure Control Solenoid Valves (Pressure

Control Solenoid and TCC Pressure Control

Solenoid) Removal and Installation

S7RS0B5106024

Removal1) Disconnect negative cable at battery.

2) Lift up vehicle.

3) Remove drain plug and drain A/T fluid.

4) Install drain plug.

Tightening torque

A/T fluid drain plug: 17 N·m (1.7 kgf-m, 12.5 lb-ft)

5) Remove A/T oil pan (1) and oil pan gasket (2).

6) Remove oil strain er assembly (3).

7) Remove transmission fluid temperature sensor (1) from sensor clamp.

8) Disconnect solenoid connectors (2). 9) Remove valve body assembly referring to

“Automatic Transaxl e Unit Disassembly”.

10) Remove pressure control solenoid valve and TCC pressure control solenoid valve referring to “Valve

Body Assembly Disassembly and Reassembly”.

Installation

Reverse removal procedure to install pressure control

solenoid valve and valve body assembly noting the

following points.

• For detail of pressure control solenoid valve and TCC pressure control solenoid va lve installation, refer to

“Valve Body Assembly Disassembly and

Reassembly”.

• For detail of valve body asse mbly installation, refer to

“Automatic Transaxle Unit Assembly”.

• For detail of installing wire harness for solenoid valves and sensor, refer to “Automatic Transaxle Unit

Assembly”. Use new O-rings.

• For detail of A/T oil pan and oil strainer assembly

installation, refer to “A utomatic Transaxle Unit

Assembly”. Use new oil pan gasket.

• Pour A/T fluid and check fluid level according to procedure described in “A/T Fluid Change”.

• Check for fluid leakage after warming up A/T.

Pressure Control Solenoid Valve InspectionS7RS0B5106025

CAUTION!

• Be very careful as dust etc. does enter when pressure control solenoid valves are

inspected.

Resistance Check

Measure resistance between pressure control solenoid

valves (Pressure control solenoid and TCC pressure

control solenoid) (1) terminals.

Pressure control solenoid valve and TCC pressure

control solenoid valve resistance

Standard: 5.0 – 5.6 Ω at 20 °C (68 °F)

I2RH0B510054-01

1 2I4RS0A510027-01

1

I2RH01510071-01