automatic transmission SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 746 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-102 Automatic Transmission/Transaxle:

Operation Check

Check pressure control solenoid valves (Pressure

control solenoid and TCC pressure control solenoid)

operation in the either manner of the following.

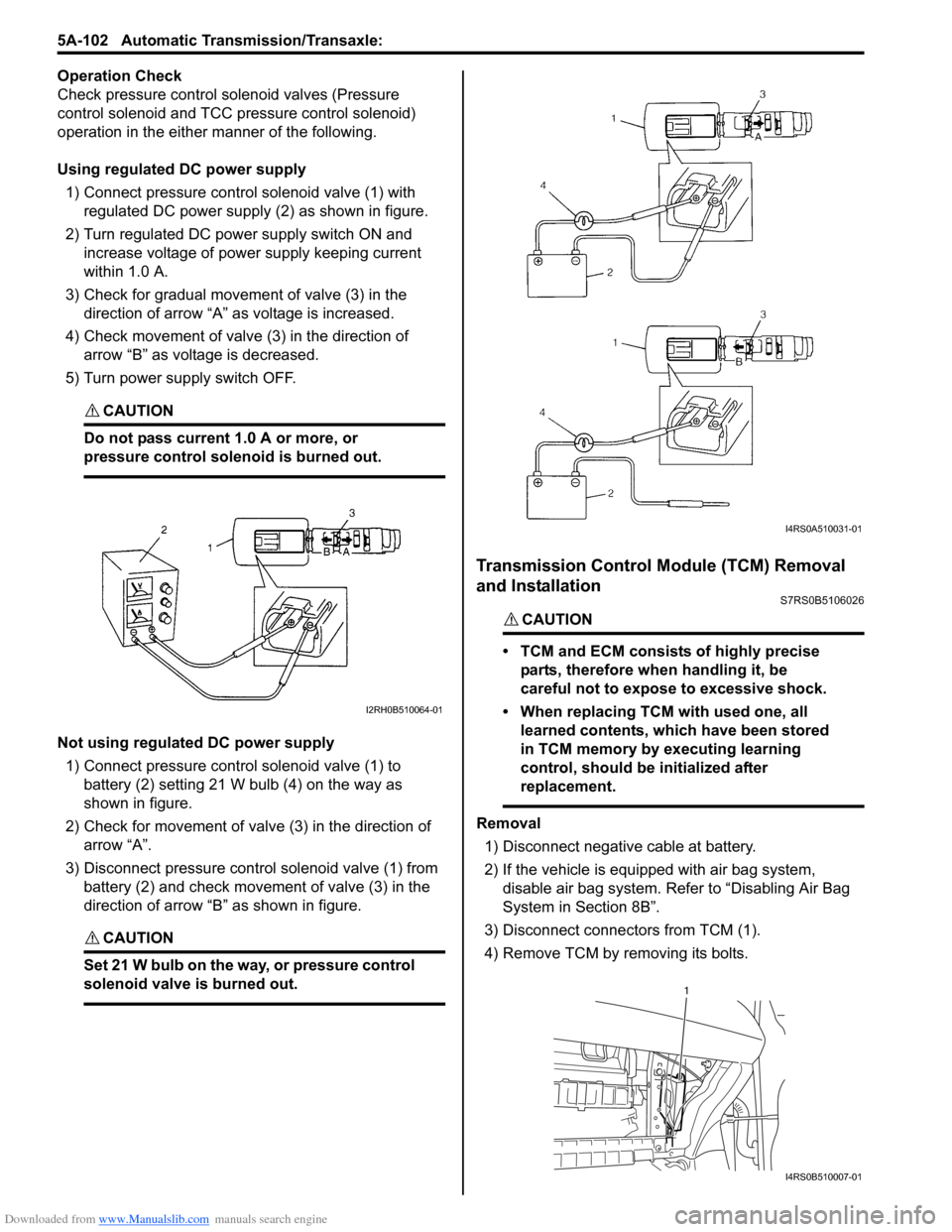

Using regulated DC power supply

1) Connect pressure contro l solenoid valve (1) with

regulated DC power supply (2) as shown in figure.

2) Turn regulated DC power supply switch ON and increase voltage of power supply keeping current

within 1.0 A.

3) Check for gradual movement of valve (3) in the direction of arrow “A” as voltage is increased.

4) Check movement of valve (3) in the direction of arrow “B” as voltage is decreased.

5) Turn power supply switch OFF.

CAUTION!

Do not pass current 1.0 A or more, or

pressure control solenoid is burned out.

Not using regulated DC power supply 1) Connect pressure control solenoid valve (1) to battery (2) setting 21 W bulb (4) on the way as

shown in figure.

2) Check for movement of valve (3) in the direction of arrow “A”.

3) Disconnect pressure control solenoid valve (1) from battery (2) and check movement of valve (3) in the

direction of arrow “B” as shown in figure.

CAUTION!

Set 21 W bulb on the way, or pressure control

solenoid valve is burned out.

Transmission Control Module (TCM) Removal

and Installation

S7RS0B5106026

CAUTION!

• TCM and ECM consists of highly precise

parts, therefore when handling it, be

careful not to expose to excessive shock.

• When replacing TCM with used one, all learned contents, which have been stored

in TCM memory by executing learning

control, should be initialized after

replacement.

Removal

1) Disconnect negative cable at battery.

2) If the vehicle is equipped with air bag system, disable air bag system. Refer to “Disabling Air Bag

System in Section 8B”.

3) Disconnect connectors from TCM (1).

4) Remove TCM by removing its bolts.

I2RH0B510064-01

I4RS0A510031-01

1

I4RS0B510007-01

Page 747 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-103

Installation

Reverse removal procedure noting the following.

• Connect TCM connectors securely.

• If the vehicle is equipped with air bag system, be sure to enable air bag system after TCM is back in place.

Refer to “Enabling Air Bag System in Section 8B”.

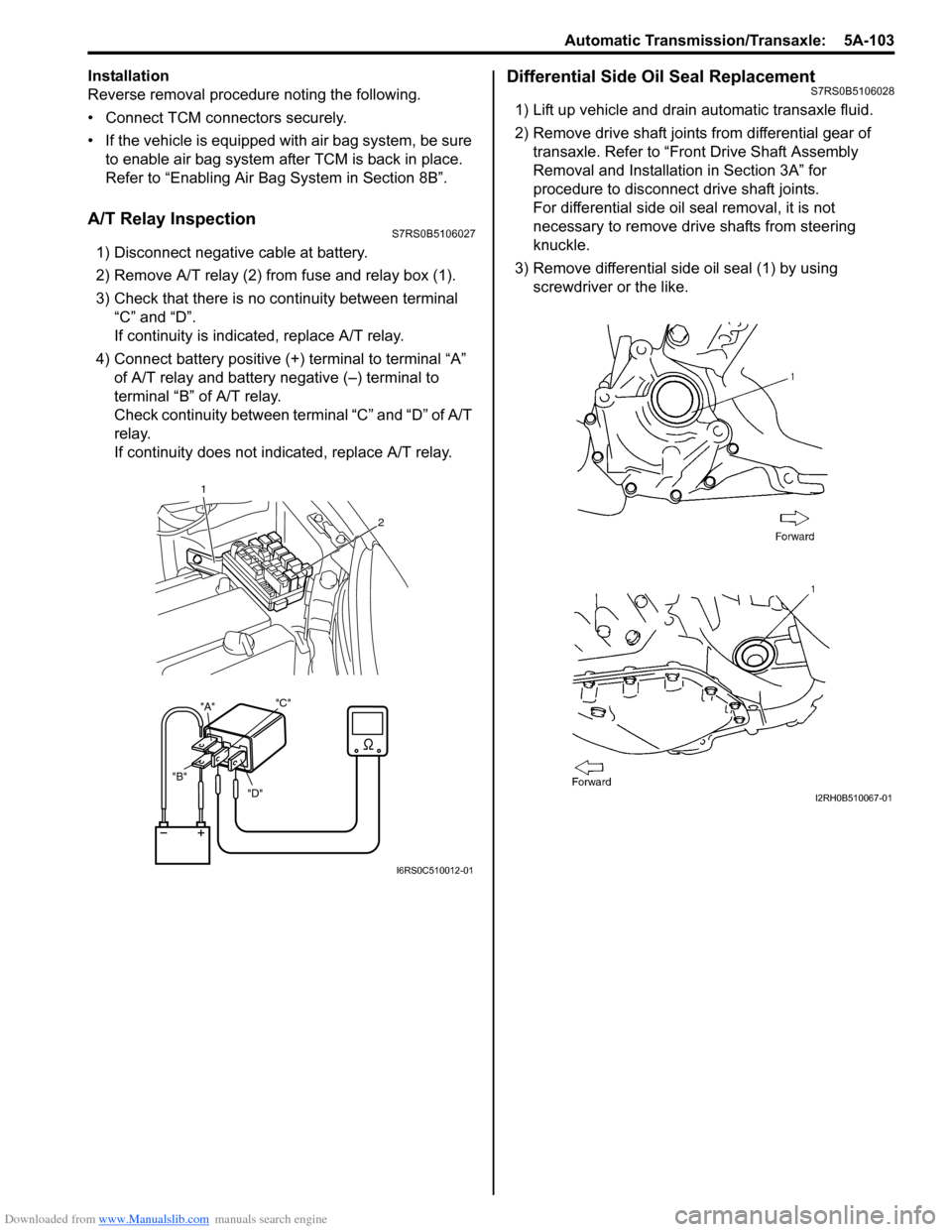

A/T Relay InspectionS7RS0B5106027

1) Disconnect negative cable at battery.

2) Remove A/T relay (2) from fuse and relay box (1).

3) Check that there is no continuity between terminal “C” and “D”.

If continuity is indicated, replace A/T relay.

4) Connect battery positive (+ ) terminal to terminal “A”

of A/T relay and battery negative (–) terminal to

terminal “B” of A/T relay.

Check continuity between terminal “C” and “D” of A/T

relay.

If continuity does not indicated, replace A/T relay.

Differential Side Oil Seal ReplacementS7RS0B5106028

1) Lift up vehicle and drain automatic transaxle fluid.

2) Remove drive shaft joints from differential gear of transaxle. Refer to “Front Drive Shaft Assembly

Removal and Installation in Section 3A” for

procedure to disconnect drive shaft joints.

For differential side oil seal removal, it is not

necessary to remove drive shafts from steering

knuckle.

3) Remove differential side oil seal (1) by using screwdriver or the like.

"D"

"B" "A"

"C"

1

2

I6RS0C510012-01

I2RH0B510067-01

Page 748 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-104 Automatic Transmission/Transaxle:

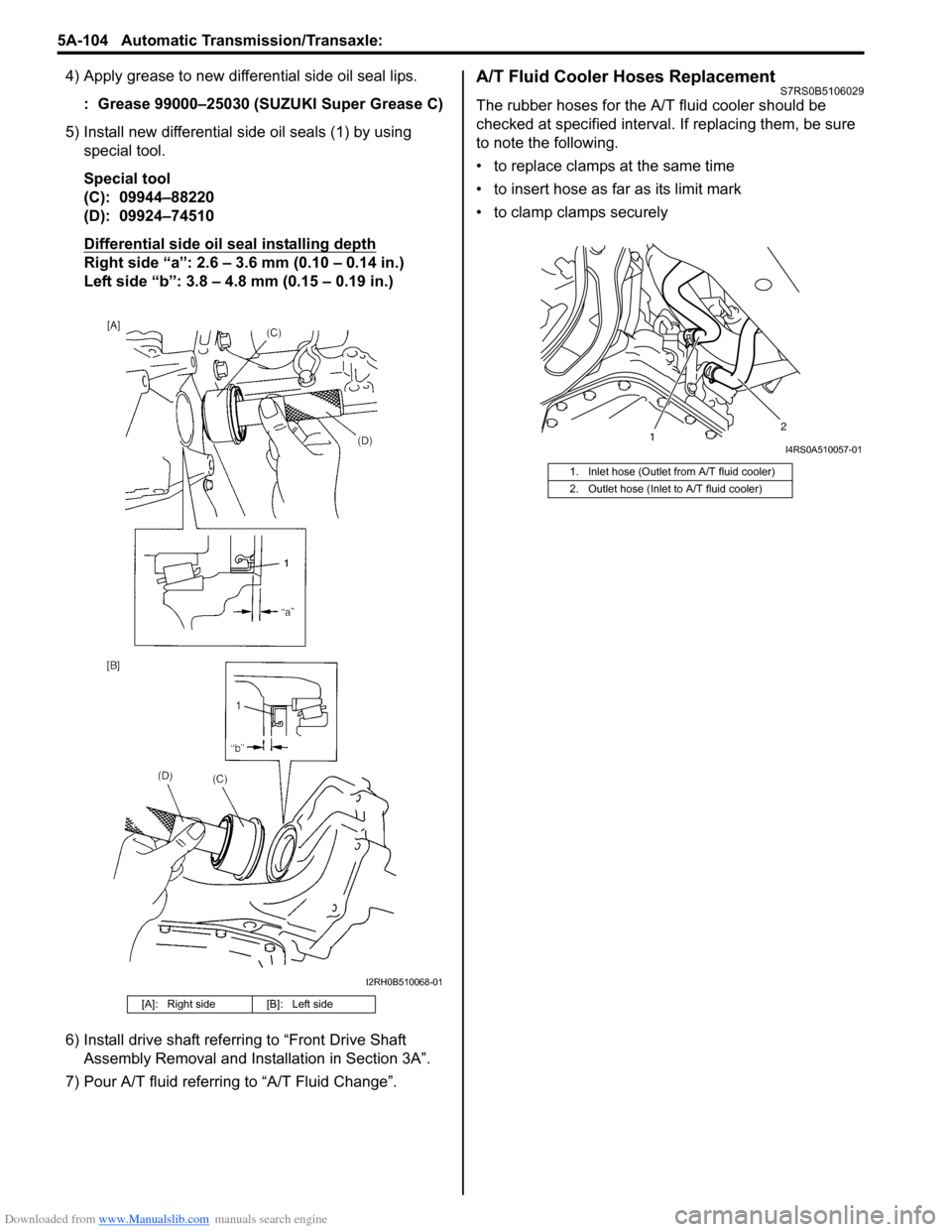

4) Apply grease to new differential side oil seal lips.: Grease 99000–25030 (SUZUKI Super Grease C)

5) Install new differential side oil seals (1) by using special tool.

Special tool

(C): 09944–88220

(D): 09924–74510

Differential side oil seal installing depth

Right side “a”: 2.6 – 3.6 mm (0.10 – 0.14 in.)

Left side “b”: 3.8 – 4.8 mm (0.15 – 0.19 in.)

6) Install drive shaft referring to “Front Drive Shaft Assembly Removal and Installation in Section 3A”.

7) Pour A/T fluid referring to “A/T Fluid Change”.

A/T Fluid Cooler Hoses ReplacementS7RS0B5106029

The rubber hoses for the A/T fluid cooler should be

checked at specified interval. If replacing them, be sure

to note the following.

• to replace clamps at the same time

• to insert hose as far as its limit mark

• to clamp clamps securely

[A]: Right side [B]: Left side

I2RH0B510068-01

1. Inlet hose (Outlet from A/T fluid cooler)

2. Outlet hose (Inlet to A/T fluid cooler)

1 2I4RS0A510057-01

Page 749 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-105

Automatic Transaxle Unit ComponentsS7RS0B5106030

I4RS0A510035-01

1. Drive plate4. Torque converter7. Transaxle and engine fastening nut

2. Drive plate bolt : Apply sealant 99000-31230 to thread. 5. Transaxle stiffener bolt

: Tightening torque

3. Drive plate to torque converter bolt 6. Transaxle and engine fastening bolt

Page 750 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-106 Automatic Transmission/Transaxle:

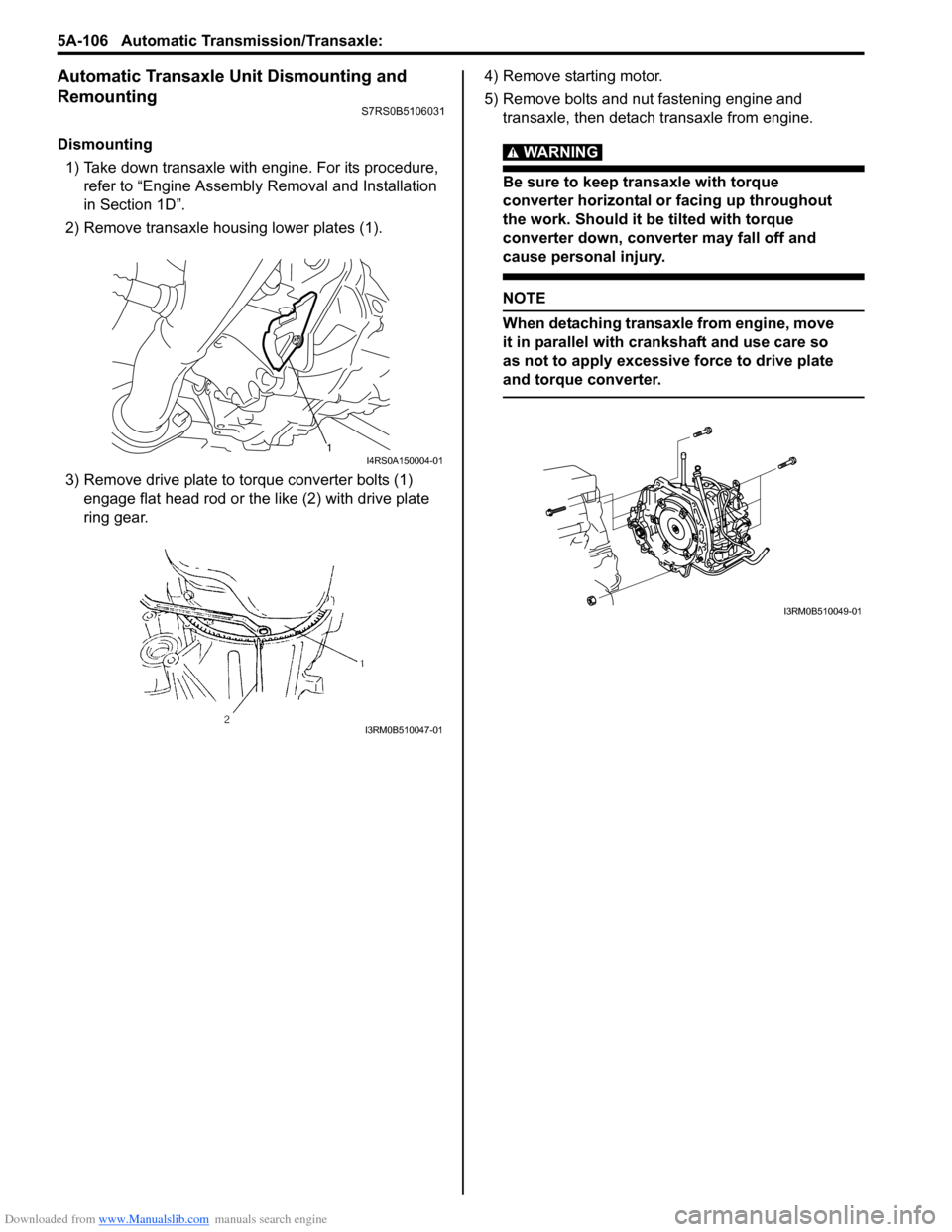

Automatic Transaxle Unit Dismounting and

Remounting

S7RS0B5106031

Dismounting1) Take down transaxle with engine. For its procedure, refer to “Engine Assembly Removal and Installation

in Section 1D”.

2) Remove transaxle housing lower plates (1).

3) Remove drive plate to torque converter bolts (1) engage flat head rod or the like (2) with drive plate

ring gear. 4) Remove starting motor.

5) Remove bolts and nut fastening engine and

transaxle, then detach transaxle from engine.WARNING!

Be sure to keep transaxle with torque

converter horizontal or facing up throughout

the work. Should it be tilted with torque

converter down, converter may fall off and

cause personal injury.

NOTE

When detaching transaxle from engine, move

it in parallel with cranks haft and use care so

as not to apply excessive force to drive plate

and torque converter.

1I4RS0A150004-01

I3RM0B510047-01

I3RM0B510049-01

Page 751 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-107

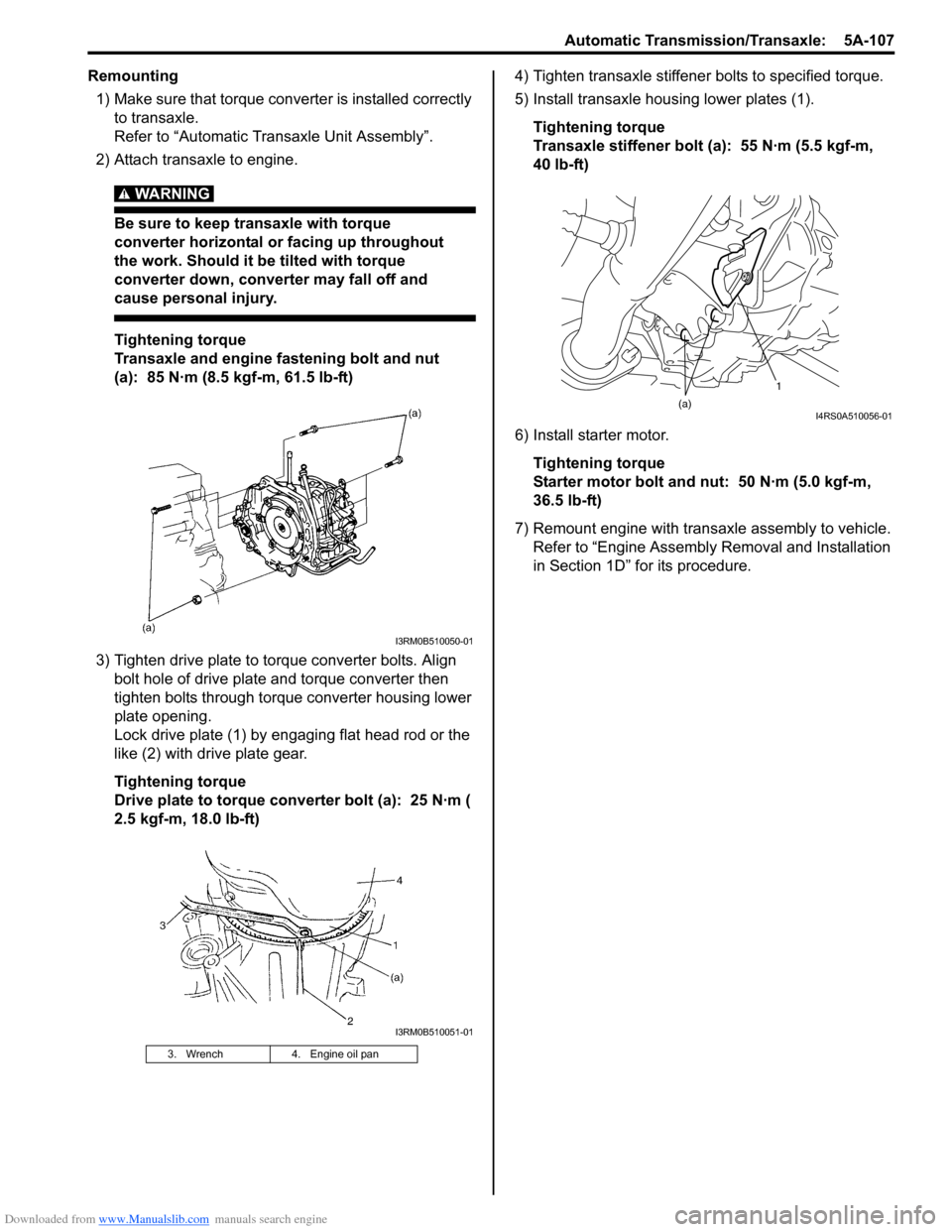

Remounting1) Make sure that torque converter is installed correctly to transaxle.

Refer to “Automatic Transaxle Unit Assembly”.

2) Attach transaxle to engine.

WARNING!

Be sure to keep transaxle with torque

converter horizontal or facing up throughout

the work. Should it be tilted with torque

converter down, converter may fall off and

cause personal injury.

Tightening torque

Transaxle and engine fastening bolt and nut

(a): 85 N·m (8.5 kgf-m, 61.5 lb-ft)

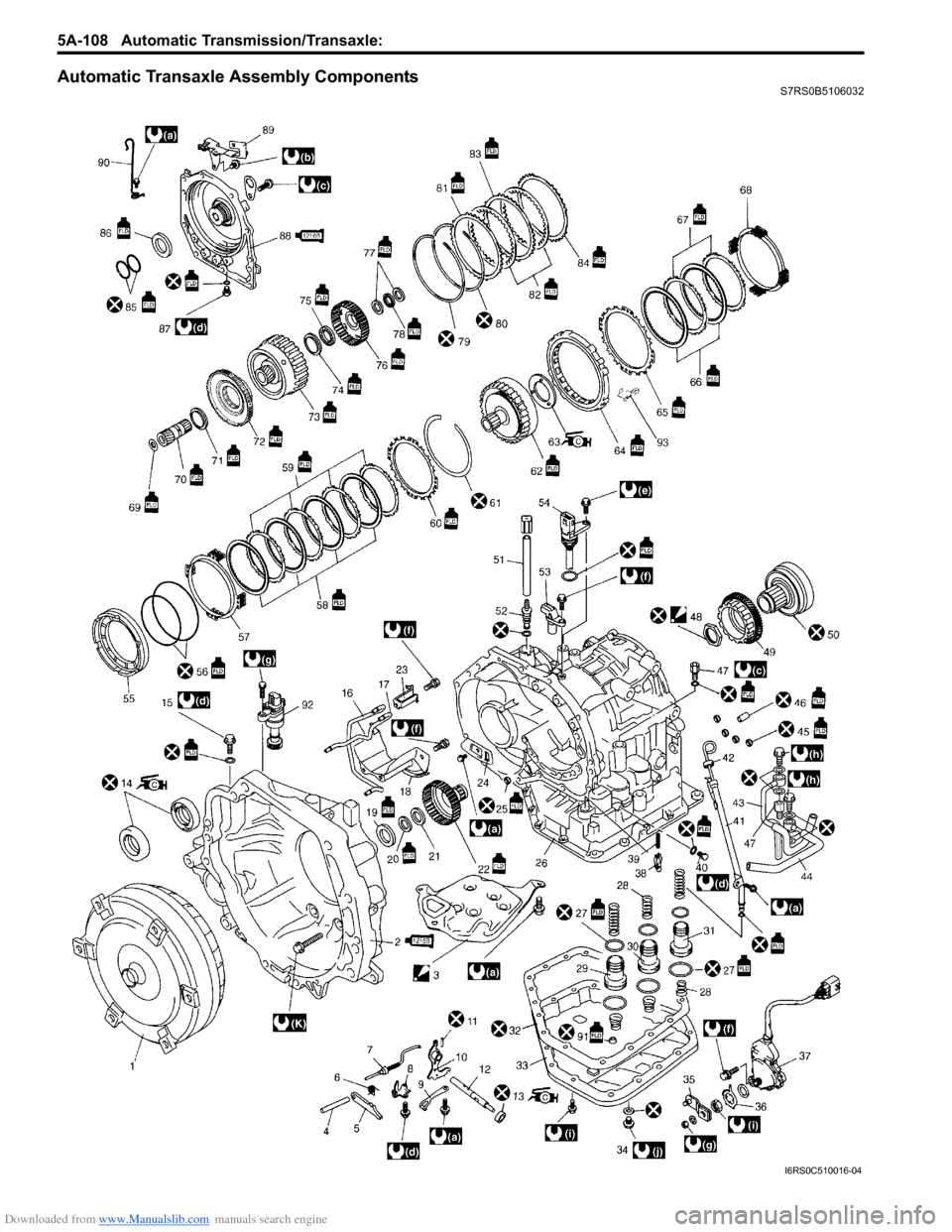

3) Tighten drive plate to torque converter bolts. Align bolt hole of drive plate and torque converter then

tighten bolts through torque converter housing lower

plate opening.

Lock drive plate (1) by engaging flat head rod or the

like (2) with drive plate gear.

Tightening torque

Drive plate to torque converter bolt (a): 25 N·m (

2.5 kgf-m, 18.0 lb-ft) 4) Tighten transaxle stiffener bolts to specified torque.

5) Install transaxle housing lower plates (1).

Tightening torque

Transaxle stiffener bolt (a): 55 N·m (5.5 kgf-m,

40 lb-ft)

6) Install starter motor. Tightening torque

Starter motor bolt and nut: 50 N·m (5.0 kgf-m,

36.5 lb-ft)

7) Remount engine with transaxle assembly to vehicle. Refer to “Engine Assembly Removal and Installation

in Section 1D” for its procedure.

3. Wrench 4. Engine oil pan

I3RM0B510050-01

I3RM0B510051-01

1

(a)

I4RS0A510056-01

Page 752 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-108 Automatic Transmission/Transaxle:

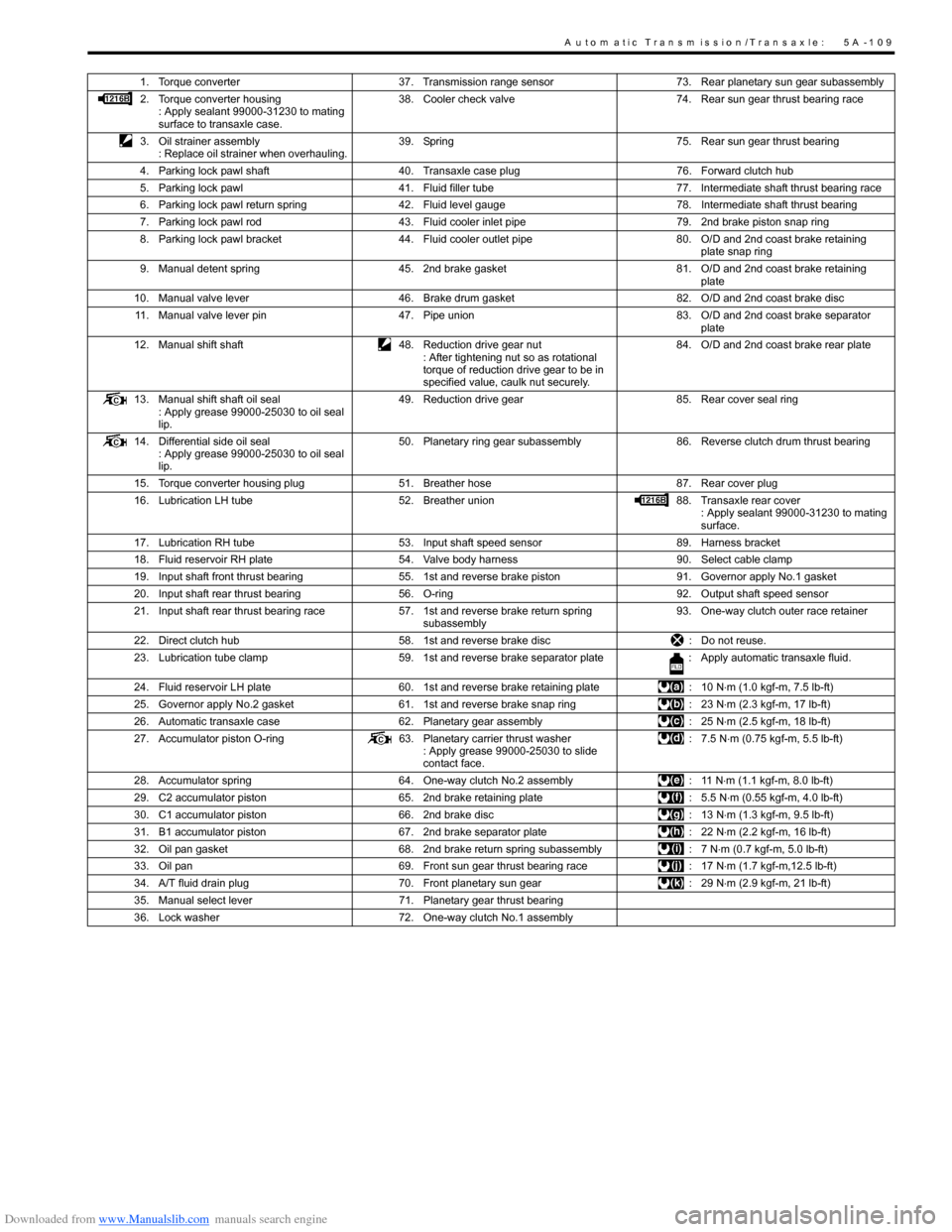

Automatic Transaxle Assembly ComponentsS7RS0B5106032

I6RS0C510016-04

Page 753 of 1496

Downloaded from www.Manualslib.com manuals search engine A u to m a tic Tra n s m is s io n /Tra n s a x le : 5 A -1 0 9

1. Torque converter37. Transmission range sensor 73. Rear planetary sun gear subassembly

2. Torque converter housing : Apply sealant 99000-31230 to mating

surface to transaxle case. 38. Cooler check valve

74. Rear sun gear thrust bearing race

3. Oil strainer assembly : Replace oil strainer when overhauling. 39. Spring

75. Rear sun gear thrust bearing

4. Parking lock pawl shaft 40. Transaxle case plug 76. Forward clutch hub

5. Parking lock pawl 41. Fluid filler tube 77. Intermediate shaft thrust bearing race

6. Parking lock pawl return spring 42. Fluid level gauge 78. Intermediate shaft thrust bearing

7. Parking lock pawl rod 43. Fluid cooler inlet pipe 79. 2nd brake piston snap ring

8. Parking lock pawl bracket 44. Fluid cooler outlet pipe 80. O/D and 2nd coast brake retaining

plate snap ring

9. Manual detent spring 45. 2nd brake gasket 81. O/D and 2nd coast brake retaining

plate

10. Manual valve lever 46. Brake drum gasket 82. O/D and 2nd coast brake disc

11. Manual valve lever pin 47. Pipe union 83. O/D and 2nd coast brake separator

plate

12. Manual shift shaft 48. Reduction drive gear nut

: After tightening nut so as rotational

torque of reduction drive gear to be in

specified value, caulk nut securely. 84. O/D and 2nd coast brake rear plate

13. Manual shift shaft oil seal : Apply grease 99000-25030 to oil seal

lip. 49. Reduction drive gear

85. Rear cover seal ring

14. Differential side oil seal : Apply grease 99000-25030 to oil seal

lip. 50. Planetary ring gear subassembly

86. Reverse clutch drum thrust bearing

15. Torque converter housing plug 51. Breather hose 87. Rear cover plug

16. Lubrication LH tube 52. Breather union 88. Transaxle rear cover

: Apply sealant 99000-31230 to mating

surface.

17. Lubrication RH tube 53. Input shaft speed sensor 89. Harness bracket

18. Fluid reservoir RH plate 54. Valve body harness 90. Select cable clamp

19. Input shaft front thrust bearing 55. 1st and reverse brake piston 91. Governor apply No.1 gasket

20. Input shaft rear thrust bearing 56. O-ring 92. Output shaft speed sensor

21. Input shaft rear thrust bearing race 57. 1st and reverse brake return spring

subassembly 93. One-way clutch outer race retainer

22. Direct clutch hub 58. 1st and reverse brake disc : Do not reuse.

23. Lubrication tube clamp 59. 1st and reverse brake separator plate : Apply automatic transaxle fluid.

24. Fluid reservoir LH plate 60. 1st and reverse brake retaining plate : 10 N⋅m (1.0 kgf-m, 7.5 lb-ft)

25. Governor apply No.2 gasket 61. 1st and reverse brake snap ring : 23 N⋅m (2.3 kgf-m, 17 lb-ft)

26. Automatic transaxle case 62. Planetary gear assembly : 25 N⋅m (2.5 kgf-m, 18 lb-ft)

27. Accumulator piston O-ring 63. Planetary carrier thrust washer

: Apply grease 99000-25030 to slide

contact face. : 7.5 N

⋅m (0.75 kgf-m, 5.5 lb-ft)

28. Accumulator spring 64. One-way clutch No.2 assembly : 11 N⋅m (1.1 kgf-m, 8.0 lb-ft)

29. C2 accumulator piston 65. 2nd brake retaining plate : 5.5 N⋅m (0.55 kgf-m, 4.0 lb-ft)

30. C1 accumulator piston 66. 2nd brake disc : 13 N⋅m (1.3 kgf-m, 9.5 lb-ft)

31. B1 accumulator piston 67. 2nd brake separator plate : 22 N⋅m (2.2 kgf-m, 16 lb-ft)

32. Oil pan gasket 68. 2nd brake return spring subassembly : 7 N⋅m (0.7 kgf-m, 5.0 lb-ft)

33. Oil pan 69. Front sun gear thrust bearing race : 17 N⋅m (1.7 kgf-m,12.5 lb-ft)

34. A/T fluid drain plug 70. Front planetary sun gear : 29 N⋅m (2.9 kgf-m, 21 lb-ft)

35. Manual select lever 71. Planetary gear thrust bearing

36. Lock washer 72. One-way clutch No.1 assembly

Page 754 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-110 Automatic Transmission/Transaxle:

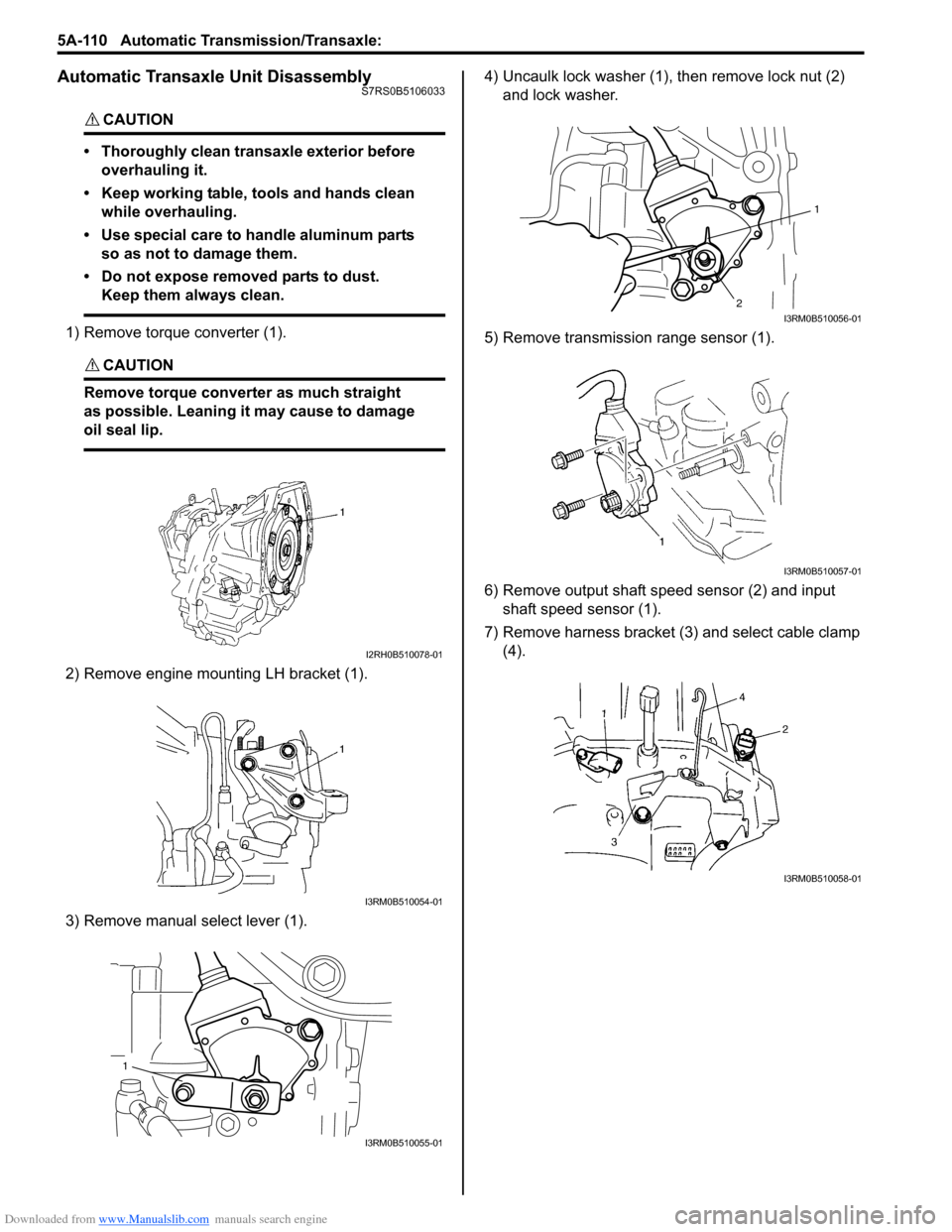

Automatic Transaxle Unit DisassemblyS7RS0B5106033

CAUTION!

• Thoroughly clean transaxle exterior before overhauling it.

• Keep working table, tools and hands clean while overhauling.

• Use special care to handle aluminum parts so as not to damage them.

• Do not expose removed parts to dust. Keep them always clean.

1) Remove torque converter (1).

CAUTION!

Remove torque converte r as much straight

as possible. Leaning it may cause to damage

oil seal lip.

2) Remove engine mounting LH bracket (1).

3) Remove manual select lever (1). 4) Uncaulk lock washer (1),

then remove lock nut (2)

and lock washer.

5) Remove transmission range sensor (1).

6) Remove output shaft speed sensor (2) and input shaft speed sensor (1).

7) Remove harness bracket (3) and select cable clamp (4).

I2RH0B510078-01

I3RM0B510054-01

1

I3RM0B510055-01

1

2

I3RM0B510056-01

I3RM0B510057-01

I3RM0B510058-01

Page 755 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-111

8) Remove fluid cooler pipes (1) and pipe union (2).

9) Remove fluid level gauge (3) and fluid filler tube (4).

10) Remove oil pan (1) and oil pan gasket (2).

NOTE

• For removal of oil pan, do not turn transaxle over as this will contaminate

valve body with foreign materials in

bottom of oil pan.

• When removing oil pan, tap around it lightly with plastic ha mmer. Do not force it

off by using screwdriver or the like.

11) Remove oil strain er assembly (1). 12) Disconnect connectors (2) from solenoid valves and

transmission fluid temperature sensor (1).

13) Remove valve body assembly bolts.

CAUTION!

Be careful not to let manual valve fall off

when removing valve body assembly.

NOTE

There are five kinds of bolts (bolts A (1), B (2),

C (3), D (4) and E (5)) fixing valve body

assembly.

14) Remove manual valve rod (1) from manual valve lever (2), then remove valve body assembly (3).

1 2

4

3

I3RM0B510059-01

I2RH0B510086-01

I2RH0B510087-01

1 2I4RS0A510027-01

I2RH0B510089-01

I2RH0B510090-01