Ect SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 1359 of 1496

Downloaded from www.Manualslib.com manuals search engine Security and Locks: 9F-13

Replacement of Transmitter Battery S7RS0B9606014

If transmitter becomes unreliable, replace transmitter

battery as follows.

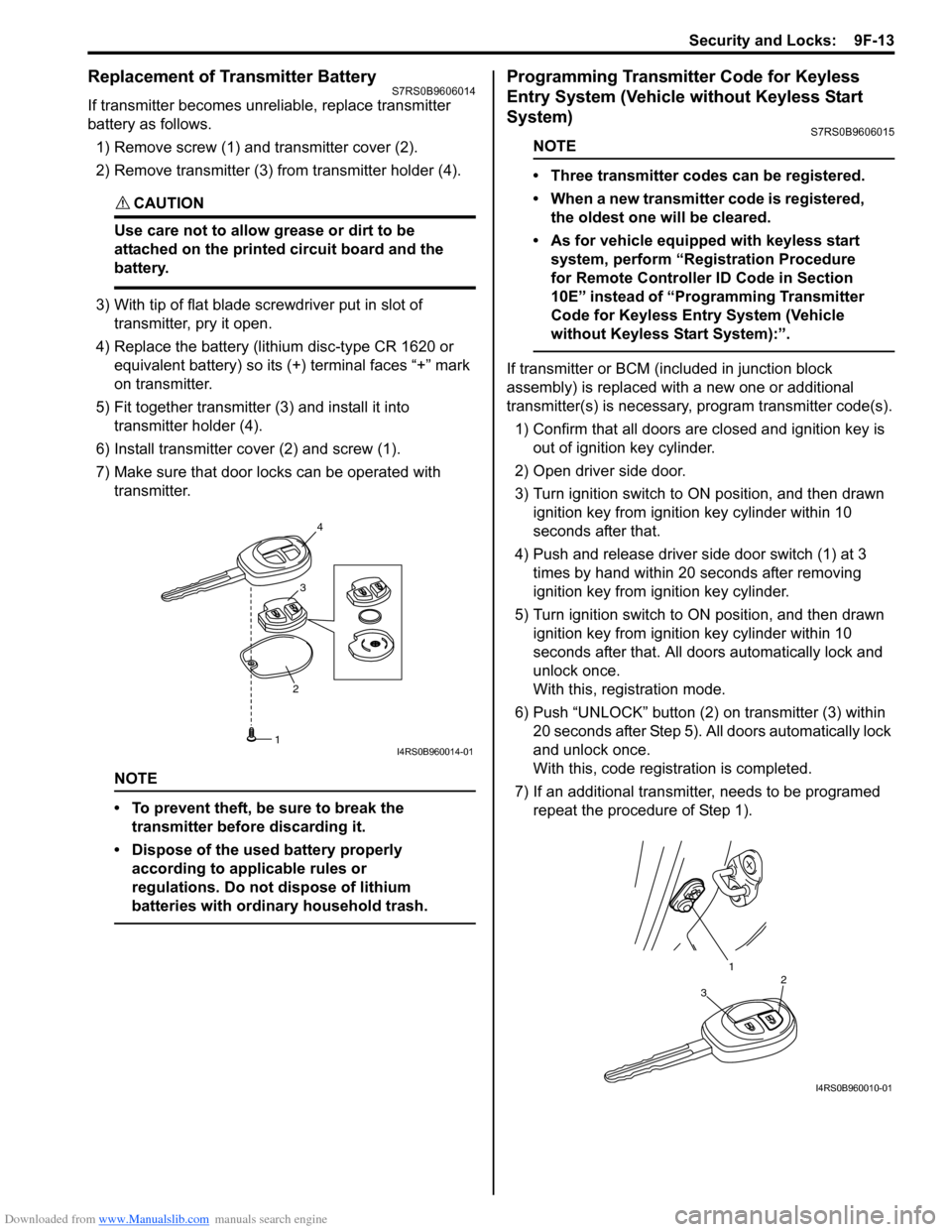

1) Remove screw (1) and transmitter cover (2).

2) Remove transmitter (3) from transmitter holder (4).

CAUTION!

Use care not to allow grease or dirt to be

attached on the printed circuit board and the

battery.

3) With tip of flat blade screwdriver put in slot of transmitter, pry it open.

4) Replace the battery (lithium disc-type CR 1620 or equivalent battery) so its (+) terminal faces “+” mark

on transmitter.

5) Fit together transmitter (3) and install it into

transmitter holder (4).

6) Install transmitter co ver (2) and screw (1).

7) Make sure that door locks can be operated with transmitter.

NOTE

• To prevent theft, be sure to break the transmitter before discarding it.

• Dispose of the used battery properly according to applicable rules or

regulations. Do not dispose of lithium

batteries with ordinary household trash.

Programming Transmitter Code for Keyless

Entry System (Vehicle without Keyless Start

System)

S7RS0B9606015

NOTE

• Three transmitter codes can be registered.

• When a new transmitter code is registered, the oldest one will be cleared.

• As for vehicle equipped with keyless start system, perform “Registration Procedure

for Remote Controller ID Code in Section

10E” instead of “Programming Transmitter

Code for Keyless Entry System (Vehicle

without Keyless Start System):”.

If transmitter or BCM (included in junction block

assembly) is replaced with a new one or additional

transmitter(s) is necessary, program transmitter code(s).

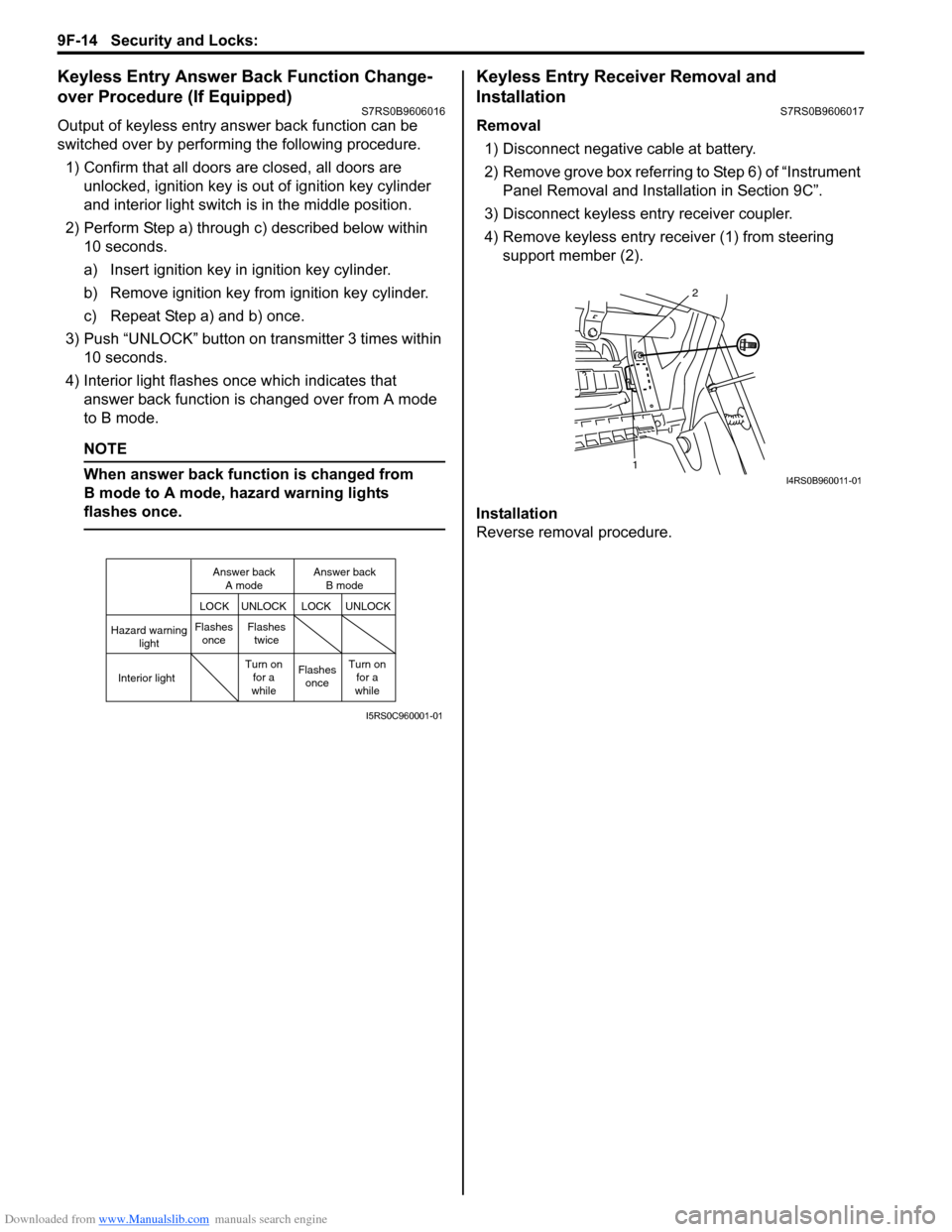

1) Confirm that all doors are closed and ignition key is

out of ignition key cylinder.

2) Open driver side door.

3) Turn ignition switch to ON position, and then drawn ignition key from igniti on key cylinder within 10

seconds after that.

4) Push and release driver side door switch (1) at 3 times by hand within 20 seconds after removing

ignition key from ig nition key cylinder.

5) Turn ignition switch to ON position, and then drawn ignition key from igniti on key cylinder within 10

seconds after that. All d oors automatically lock and

unlock once.

With this, registration mode.

6) Push “UNLOCK” button (2) on transmitter (3) within

20 seconds after Step 5). All doors automatically lock

and unlock once.

With this, code registration is completed.

7) If an additional transmitter, needs to be programed repeat the procedure of Step 1).

23

4

1I4RS0B960014-01

1

32

I4RS0B960010-01

Page 1360 of 1496

Downloaded from www.Manualslib.com manuals search engine 9F-14 Security and Locks:

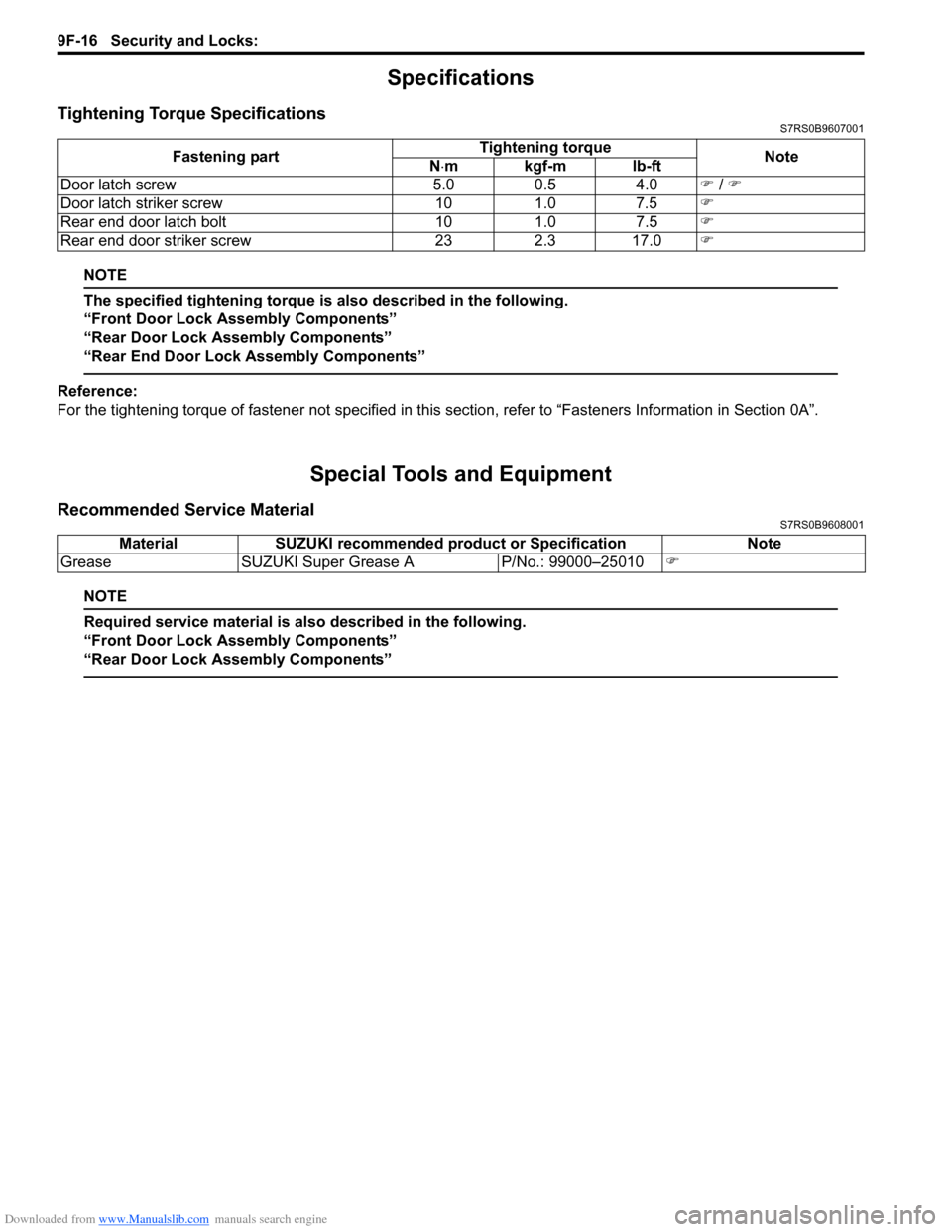

Keyless Entry Answer Back Function Change-

over Procedure (If Equipped)

S7RS0B9606016

Output of keyless entry answer back function can be

switched over by performing the following procedure.

1) Confirm that all doors are closed, all doors are unlocked, ignition key is out of ignition key cylinder

and interior light switch is in the middle position.

2) Perform Step a) through c) described below within 10 seconds.

a) Insert ignition key in ignition key cylinder.

b) Remove ignition key from ignition key cylinder.

c) Repeat Step a) and b) once.

3) Push “UNLOCK” button on transmitter 3 times within 10 seconds.

4) Interior light flashes once which indicates that answer back function is changed over from A mode

to B mode.

NOTE

When answer back function is changed from

B mode to A mode, hazard warning lights

flashes once.

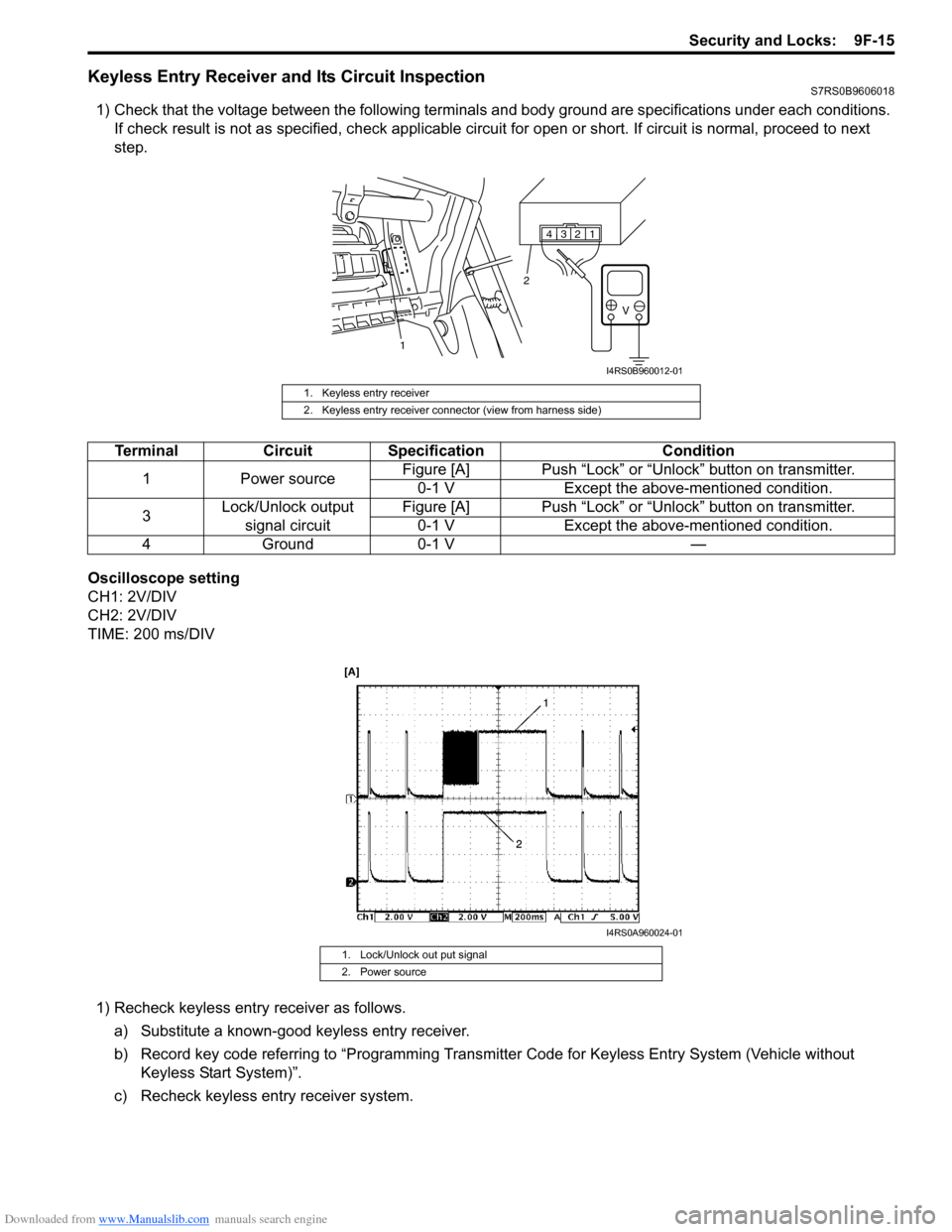

Keyless Entry Receiver Removal and

Installation

S7RS0B9606017

Removal

1) Disconnect negative cable at battery.

2) Remove grove box referring to Step 6) of “Instrument Panel Removal and Installation in Section 9C”.

3) Disconnect keyless entry receiver coupler.

4) Remove keyless entry receiver (1) from steering support member (2).

Installation

Reverse removal procedure.

Hazard warning light

LOCK LOCK

UNLOCK UNLOCK

Interior lightFlashes

once Flashes

twice

Flashesonce

Turn on

for a

while Turn on

for a

while

Answer back

A mode Answer back

B mode

I5RS0C960001-01

1 2I4RS0B960011-01

Page 1361 of 1496

Downloaded from www.Manualslib.com manuals search engine Security and Locks: 9F-15

Keyless Entry Receiver and Its Circuit InspectionS7RS0B9606018

1) Check that the voltage between the following terminals and body ground are specifications under each conditions.

If check result is not as specified, ch eck applicable circuit for open or short. If circuit is normal, proceed to next

step.

Oscilloscope setting

CH1: 2V/DIV

CH2: 2V/DIV

TIME: 200 ms/DIV 1) Recheck keyless entry receiver as follows.

a) Substitute a known-good keyless entry receiver.

b) Record key code referring to “Programming Transmit ter Code for Keyless Entry System (Vehicle without

Keyless Start System)”.

c) Recheck keyless entry receiver system.

1. Keyless entry receiver

2. Keyless entry receiver connector (view from harness side)

1234

V

1 2

I4RS0B960012-01

Terminal

Circuit Specification Condition

1 Power source Figure [A] Push “Lock” or “Unlock” button on transmitter.

0-1 V Except the above-mentioned condition.

3 Lock/Unlock output

signal circuit Figure [A] Push “Lock” or “Unlock” button on transmitter.

0-1 V Except the above-mentioned condition.

4G ro un d0 -1 V —

1. Lock/Unlock out put signal

2. Power source

I4RS0A960024-01

Page 1362 of 1496

Downloaded from www.Manualslib.com manuals search engine 9F-16 Security and Locks:

Specifications

Tightening Torque SpecificationsS7RS0B9607001

NOTE

The specified tightening torque is also described in the following.

“Front Door Lock Assembly Components”

“Rear Door Lock Assembly Components”

“Rear End Door Lock Assembly Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Service MaterialS7RS0B9608001

NOTE

Required service material is also described in the following.

“Front Door Lock Assembly Components”

“Rear Door Lock Assembly Components”

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Door latch screw 5.0 0.5 4.0 �) / �)

Door latch striker screw 10 1.0 7.5 �)

Rear end door latch bolt 10 1.0 7.5 �)

Rear end door striker screw 23 2.3 17.0 �)

MaterialSUZUKI recommended product or Specification Note

Grease SUZUKI Super Grease A P/No.: 99000–25010�)

Page 1364 of 1496

Downloaded from www.Manualslib.com manuals search engine 9G-2 Seats:

Front Seat Removal and InstallationS7RS0B9706002

WARNING!

Refer to “Air Bag Warning in Section 00” before starting service work.

Removal1) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

2) Disconnect couplers for seat harness and side air bag, if equipped.

3) Remove 4 mounting bolts to remove seat assembly.

4) Disassemble and repair seat if necessary.

Installation

Reverse removal procedure to install front seat.

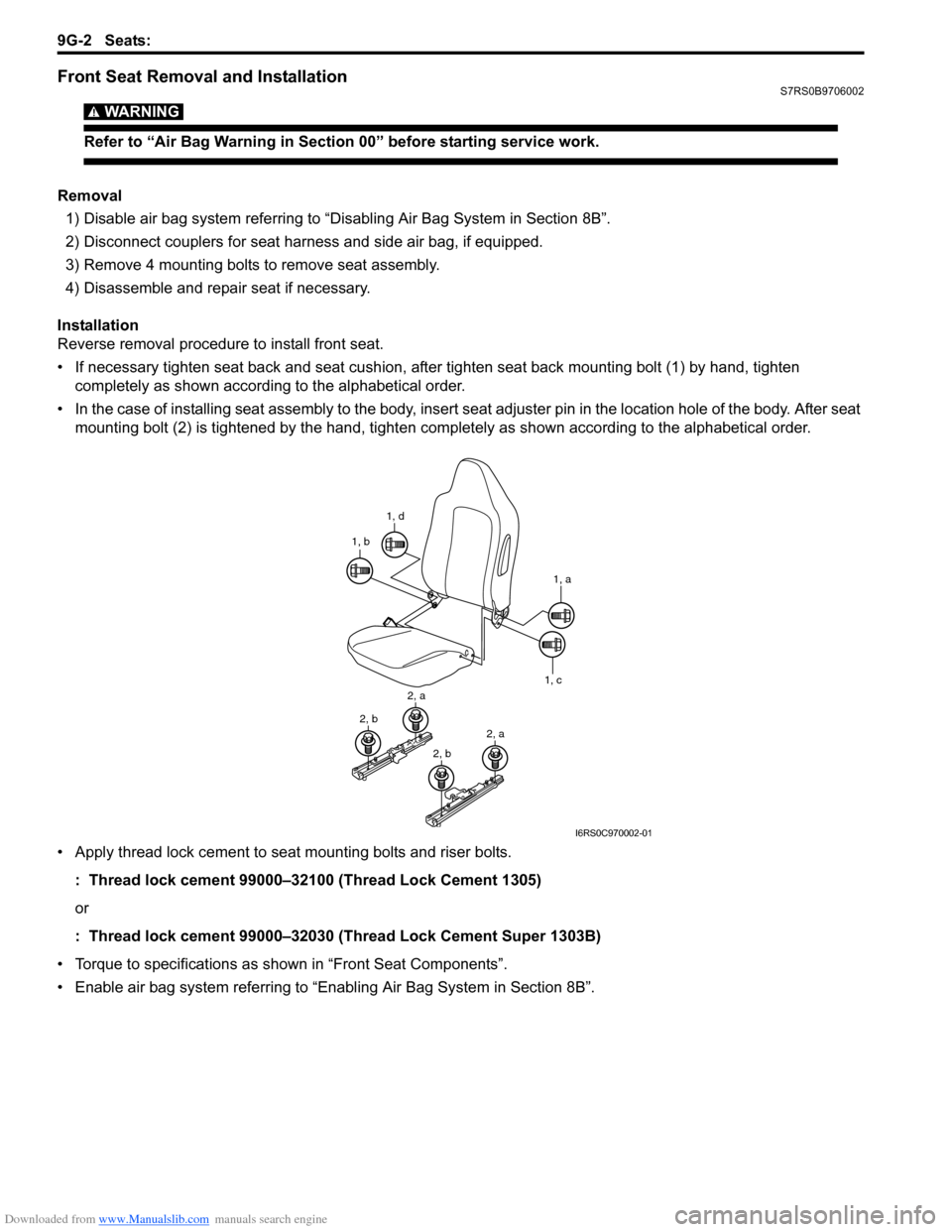

• If necessary tighten seat back and seat cushion, after tighten seat back mounting bolt (1) by hand, tighten completely as shown according to the alphabetical order.

• In the case of installing seat assembly to the body, insert se at adjuster pin in the location hole of the body. After seat

mounting bolt (2) is tightened by t he hand, tighten completely as shown according to the alphabetical order.

• Apply thread lock cement to seat mounting bolts and riser bolts. : Thread lock cement 99000–32100 (Thread Lock Cement 1305)

or

: Thread lock cement 99000–32030 (Thread Lock Cement Super 1303B)

• Torque to specifications as shown in “Front Seat Components”.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

1, d

1, b

1, a

1, c

2, a

2, b2, a

2, b

I6RS0C970002-01

Page 1366 of 1496

Downloaded from www.Manualslib.com manuals search engine 9G-4 Seats:

Rear Seat Removal and InstallationS7RS0B9706004

Removal1) Fold rear seat back forward.

2) Remove seat mounting bolts and nuts to remove seat assembly.

3) Disassemble and repair seat as necessary.

Installation

Reverse removal procedure to install rear seat.

• Tighten seat back striker mounting bolts according to “Rear Seat Components”.

• Torque to specifications in “Rear Seat Components”.

• When installing seat cushion, align seat cushion hook with center hinge bracket.

Specifications

Tightening Torque SpecificationsS7RS0B9707001

NOTE

The specified tightening torque is also described in the following.

“Front Seat Components”

“Rear Seat Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Service MaterialS7RS0B9708001

NOTE

Required service material is also described in the following.

“Front Seat Components”

Material SUZUKI recommended product or Specification Note

Thread lock cement Thread Lock Cement Super 1303B P/No.: 99000–32030 �)

Thread Lock Cement 1305 P/No.: 99000–32100 �)

Page 1367 of 1496

Downloaded from www.Manualslib.com manuals search engine Interior Trim: 9H-1

Body, Cab and Accessories

Interior Trim

Repair Instructions

Floor Carpet Removal and InstallationS7RS0B9806001

WARNING!

Refer to “Air Bag Warning in Section 00”

before starting service work.

Removal1) Remove front seats and rear seats referring to “Front Seat Removal and Installa tion in Section 9G” and

“Rear Seat Removal and Installation in Section 9G”.

2) Remove seat belt lower anchor bolt.

3) Remove dash side trims, fr ont side sill scuffs, center

pillar inner lower trims, qu arter inner front trims and

rear side sill scuffs.

4) Remove console box.

5) Remove floor carpet.

Installation

Reverse removal sequence to install floor carpet, noting

the following instruction.

• For tightening torque of rear seat mounting bolt, refer to “Rear Seat Components in Section 9G”.

• For tightening torque of front seat mounting bolt, refer to “Front Seat Components in Section 9G”.

Head Lining Removal and InstallationS7RS0B9806002

WARNING!

Refer to “Air Bag Warning in Section 00”

before starting service work.

Removal

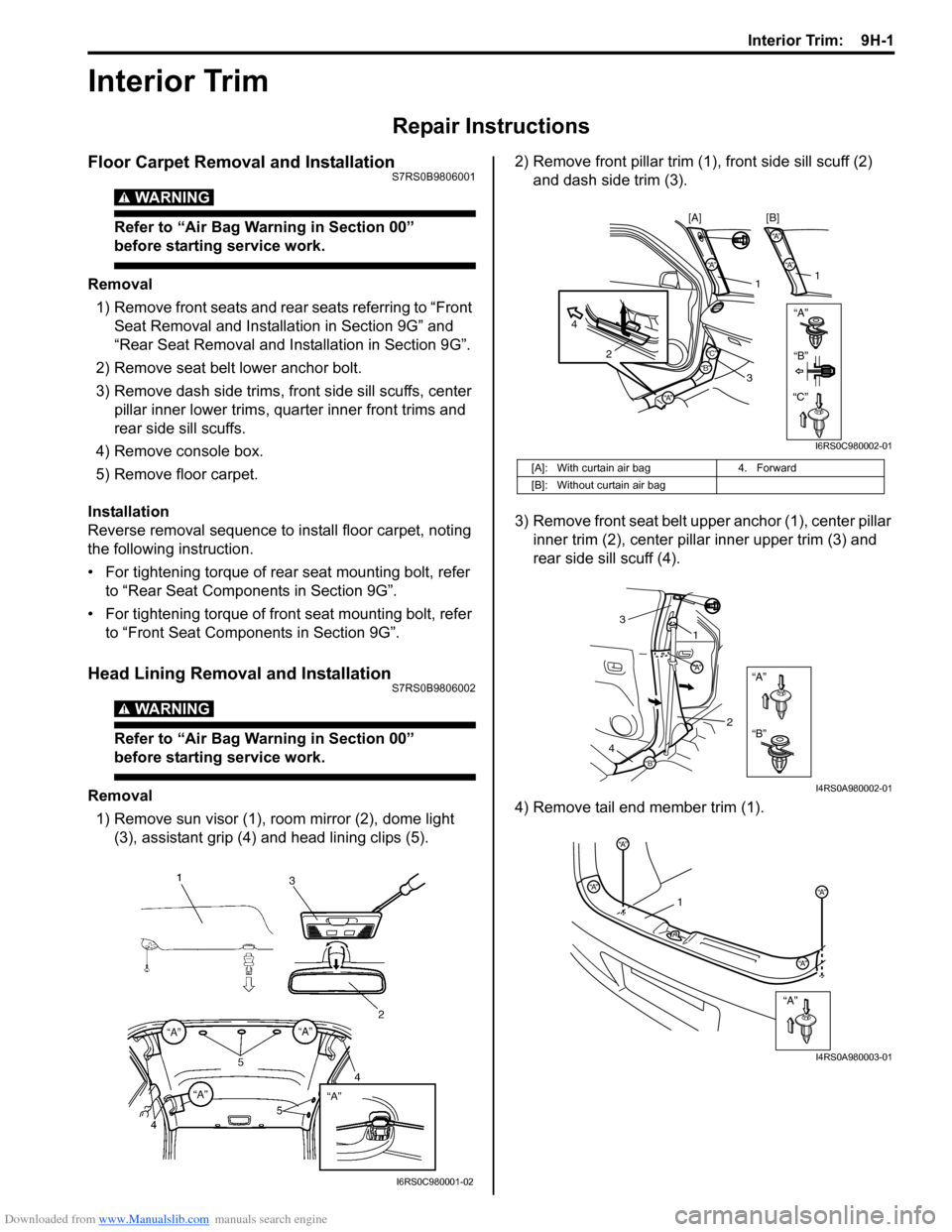

1) Remove sun visor (1), room mirror (2), dome light (3), assistant grip (4) and head lining clips (5). 2) Remove front pillar trim (1

), front side sill scuff (2)

and dash side trim (3).

3) Remove front seat belt u pper anchor (1), center pillar

inner trim (2), center pillar inner upper trim (3) and

rear side sill scuff (4).

4) Remove tail end member trim (1).

I6RS0C980001-02

[A]: With curtain air bag 4. Forward

[B]: Without curtain air bag

“A”“A”

“A”

2

4

1

3

“A”

“A”

1

[B]

[A]

“B”“B”

“C”“C”

I6RS0C980002-01

“A”

“B”

“A”

“B”

1

3

2

4

I4RS0A980002-01

“A”

“A”

“A”

“A”“A”1

I4RS0A980003-01

Page 1369 of 1496

Downloaded from www.Manualslib.com manuals search engine Interior Trim: 9H-3

Specifications

Tightening Torque SpecificationsS7RS0B9807001

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Sun visor screw 40.4 3.0 �)

Page 1370 of 1496

Downloaded from www.Manualslib.com manuals search engine 9J-1 Hood / Fenders / Doors:

Body, Cab and Accessories

Hood / Fenders / Doors

Repair Instructions

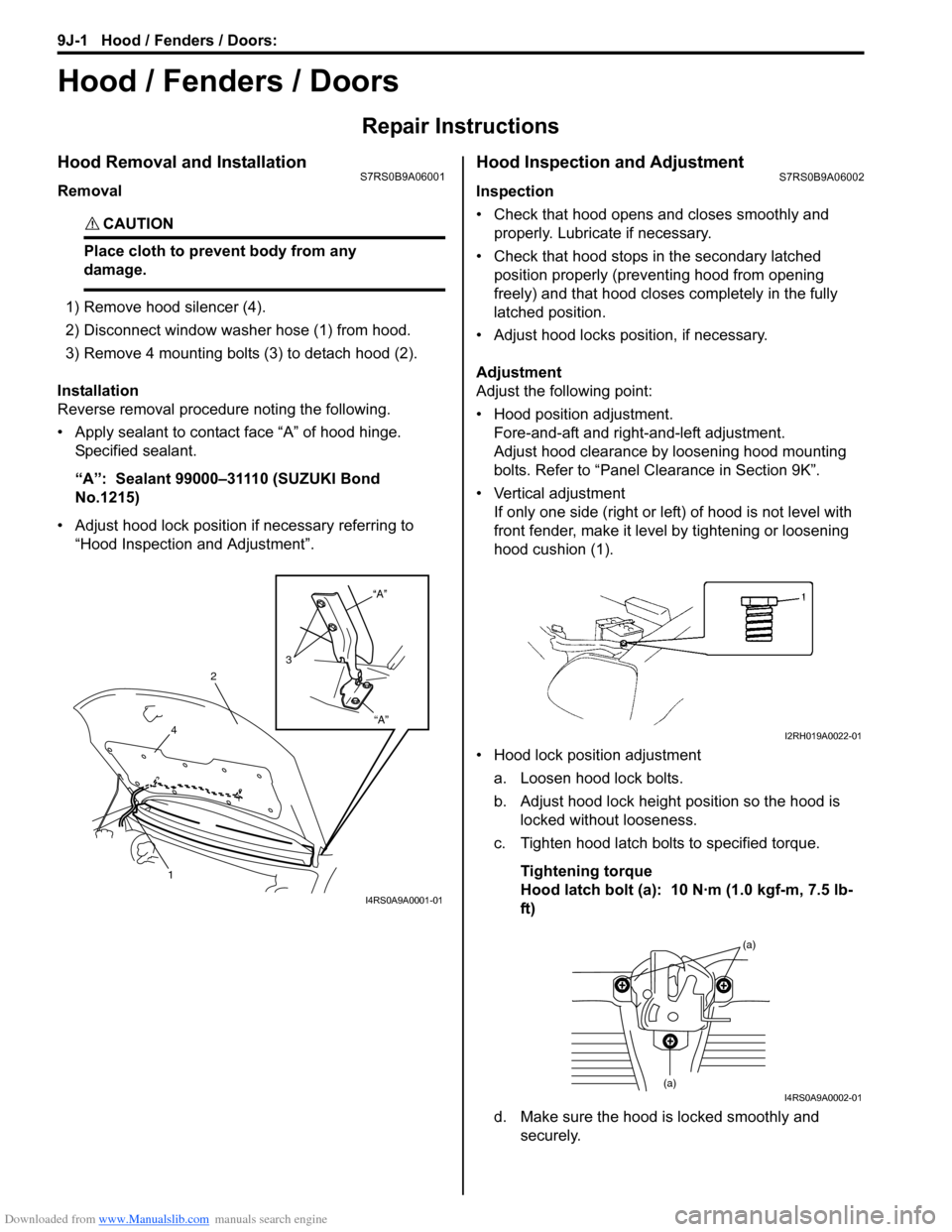

Hood Removal and InstallationS7RS0B9A06001

Removal

CAUTION!

Place cloth to prevent body from any

damage.

1) Remove hood silencer (4).

2) Disconnect window washer hose (1) from hood.

3) Remove 4 mounting bolts (3) to detach hood (2).

Installation

Reverse removal procedure noting the following.

• Apply sealant to contact face “A” of hood hinge. Specified sealant.

“A”: Sealant 99000–31110 (SUZUKI Bond

No.1215)

• Adjust hood lock position if necessary referring to “Hood Inspection and Adjustment”.

Hood Inspection and AdjustmentS7RS0B9A06002

Inspection

• Check that hood opens and closes smoothly and properly. Lubricate if necessary.

• Check that hood stops in the secondary latched position properly (preventing hood from opening

freely) and that hood closes completely in the fully

latched position.

• Adjust hood locks position, if necessary.

Adjustment

Adjust the following point:

• Hood position adjustment. Fore-and-aft and right-and-left adjustment.

Adjust hood clearance by loosening hood mounting

bolts. Refer to “Panel Clearance in Section 9K”.

• Vertical adjustment If only one side (right or left) of hood is not level with

front fender, make it level by tightening or loosening

hood cushion (1).

• Hood lock position adjustment a. Loosen hood lock bolts.

b. Adjust hood lock height position so the hood is locked without looseness.

c. Tighten hood latch bolts to specified torque.

Tightening torque

Hood latch bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-

ft)

d. Make sure the hood is locked smoothly and securely.

“A”

“A”

3

2

4

1

I4RS0A9A0001-01

I2RH019A0022-01

(a)

(a)I4RS0A9A0002-01

Page 1371 of 1496

Downloaded from www.Manualslib.com manuals search engine Hood / Fenders / Doors: 9J-2

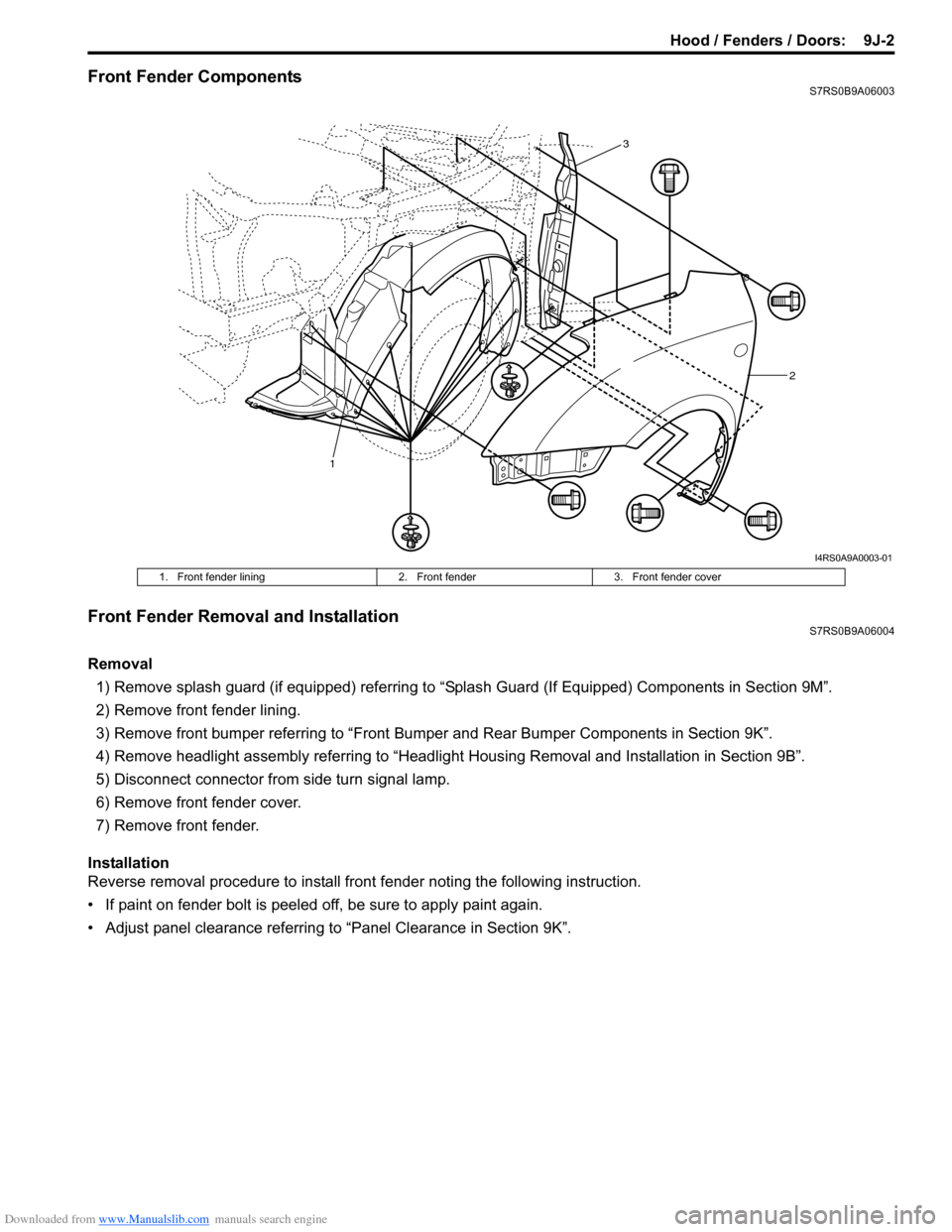

Front Fender ComponentsS7RS0B9A06003

Front Fender Removal and InstallationS7RS0B9A06004

Removal1) Remove splash guard (if equipped) referring to “Splash Guard (If Equipped) Components in Section 9M”.

2) Remove front fender lining.

3) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

4) Remove headlight assembly referring to “Headlig ht Housing Removal and Installation in Section 9B”.

5) Disconnect connector from side turn signal lamp.

6) Remove front fender cover.

7) Remove front fender.

Installation

Reverse removal procedure to install fron t fender noting the following instruction.

• If paint on fender bolt is peeled off, be sure to apply paint again.

• Adjust panel clearance referring to “Panel Clearance in Section 9K”.

1 2

3

I4RS0A9A0003-01

1. Front fender lining

2. Front fender3. Front fender cover