intermittent and poor connection SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 1129 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-91

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

DTC Will Set when

The voltage measured at side curtain-air bag (driver or passenger) initiator circuit is above a specified value for

specified time.

Flow Test Description

Step 1: Check whether malfunction is in side curtain-air bag (inflator) module.

Step 2: Check side curtain-air bag initiator circuit.

DTC Troubleshooting

Step Action YesNo

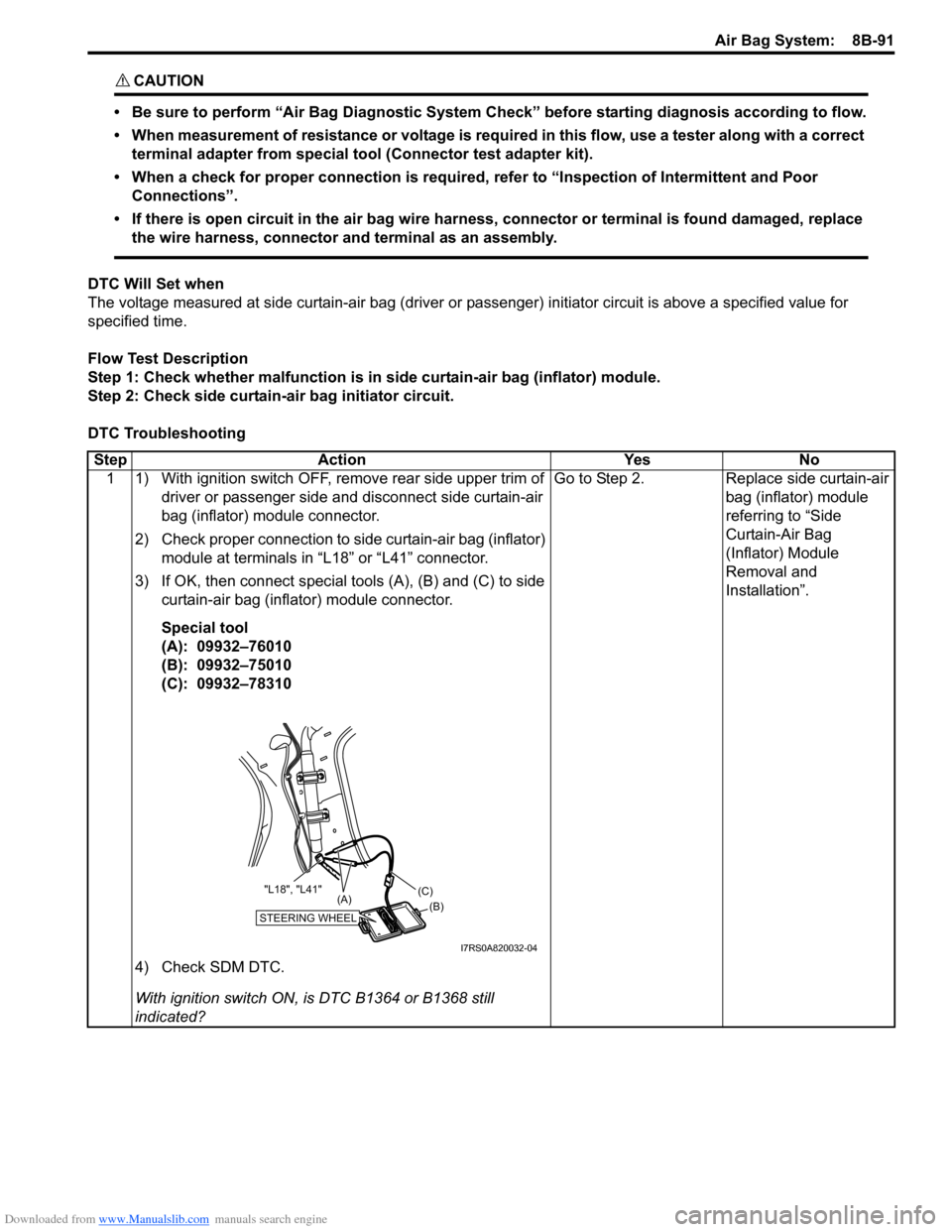

1 1) With ignition switch OFF, remove rear side upper trim of driver or passenger side and disconnect side curtain-air

bag (inflator) module connector.

2) Check proper connection to side curtain-air bag (inflator) module at terminals in “L18” or “L41” connector.

3) If OK, then connect special tools (A), (B) and (C) to side curtain-air bag (inflator) module connector.

Special tool

(A): 09932–76010

(B): 09932–75010

(C): 09932–78310

4) Check SDM DTC.

With ignition switch ON, is DTC B1364 or B1368 still

indicated? Go to Step 2.

Replace side curtain-air

bag (inflator) module

referring to “Side

Curtain-Air Bag

(Inflator) Module

Removal and

Installation”.

STEERING WHEEL(B)

(C)

(A)

"L18", "L41"

I7RS0A820032-04

Page 1133 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-95

Inspection of Intermittent and Poor

Connections

S7RS0B8204048

Most intermittents are caused by faulty electrical

connections or wiring. When a check for proper

connection is requested in a diagnostic flow, perform

careful check of suspect circuits.

If any abnormality is found, repair or replace as a wire

harness assembly.

• Poor mating of connector halves, or terminals not fully seated in the connector body (backed out).

• Dirt or corrosion on the terminals. The terminals must be clean and free of any foreign material which could

impede proper terminal contact.

However, cleaning the terminal with a sand paper or

the like is prohibited.

• Damaged connector body, exposing the terminals to moisture and dirt, as well as not maintaining proper

terminal orientation with the component or mating

connector.

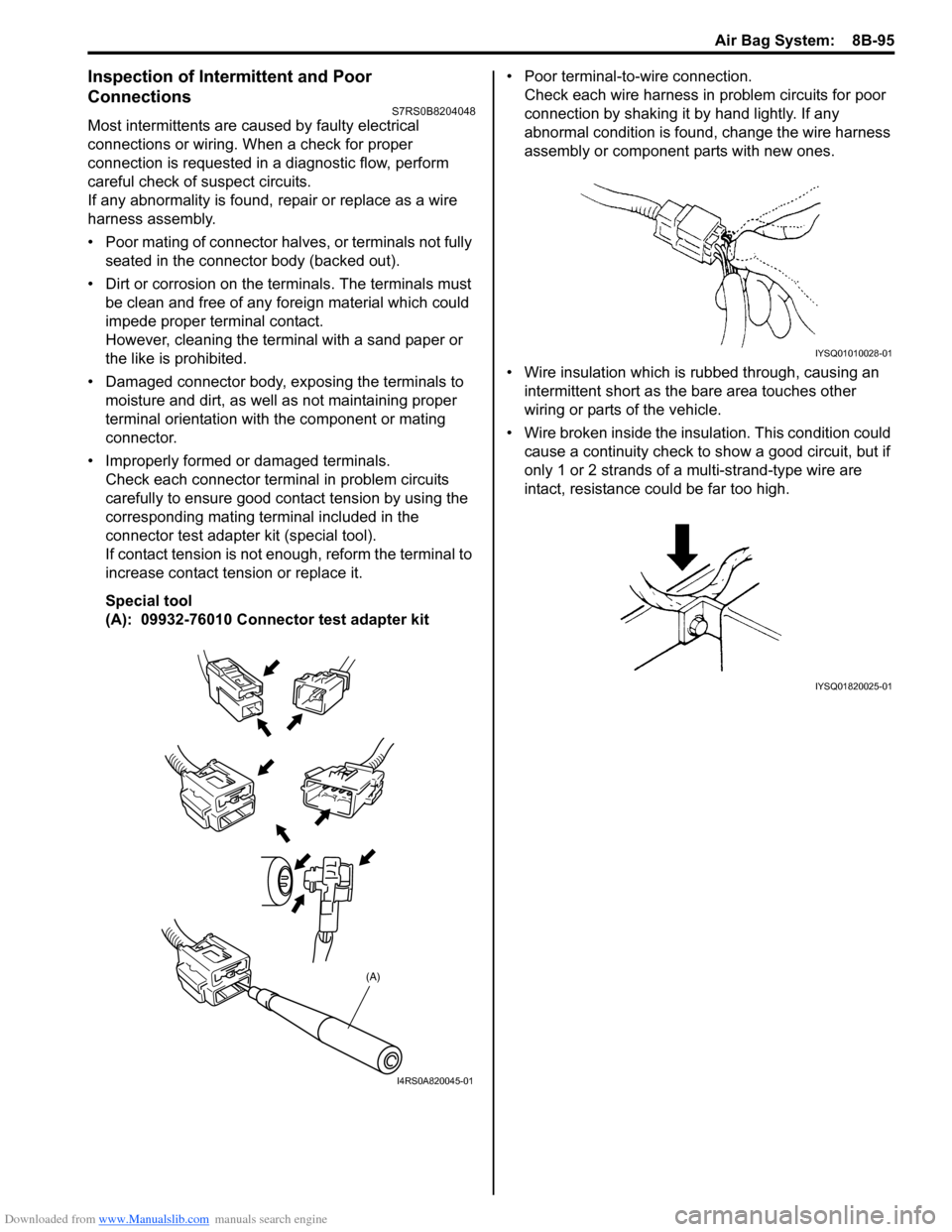

• Improperly formed or damaged terminals. Check each connector terminal in problem circuits

carefully to ensure good contact tension by using the

corresponding mating terminal included in the

connector test adapter kit (special tool).

If contact tension is not e nough, reform the terminal to

increase contact tension or replace it.

Special tool

(A): 09932-76010 Connector test adapter kit • Poor terminal-to-wire connection.

Check each wire harness in problem circuits for poor

connection by shaking it by hand lightly. If any

abnormal condition is found, change the wire harness

assembly or component parts with new ones.

• Wire insulation which is rubbed through, causing an intermittent short as the bare area touches other

wiring or parts of the vehicle.

• Wire broken inside the insulation. This condition could cause a continuity check to show a good circuit, but if

only 1 or 2 strands of a multi-strand-type wire are

intact, resistance could be far too high.

(A)

I4RS0A820045-01

IYSQ01010028-01

IYSQ01820025-01

Page 1135 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-97

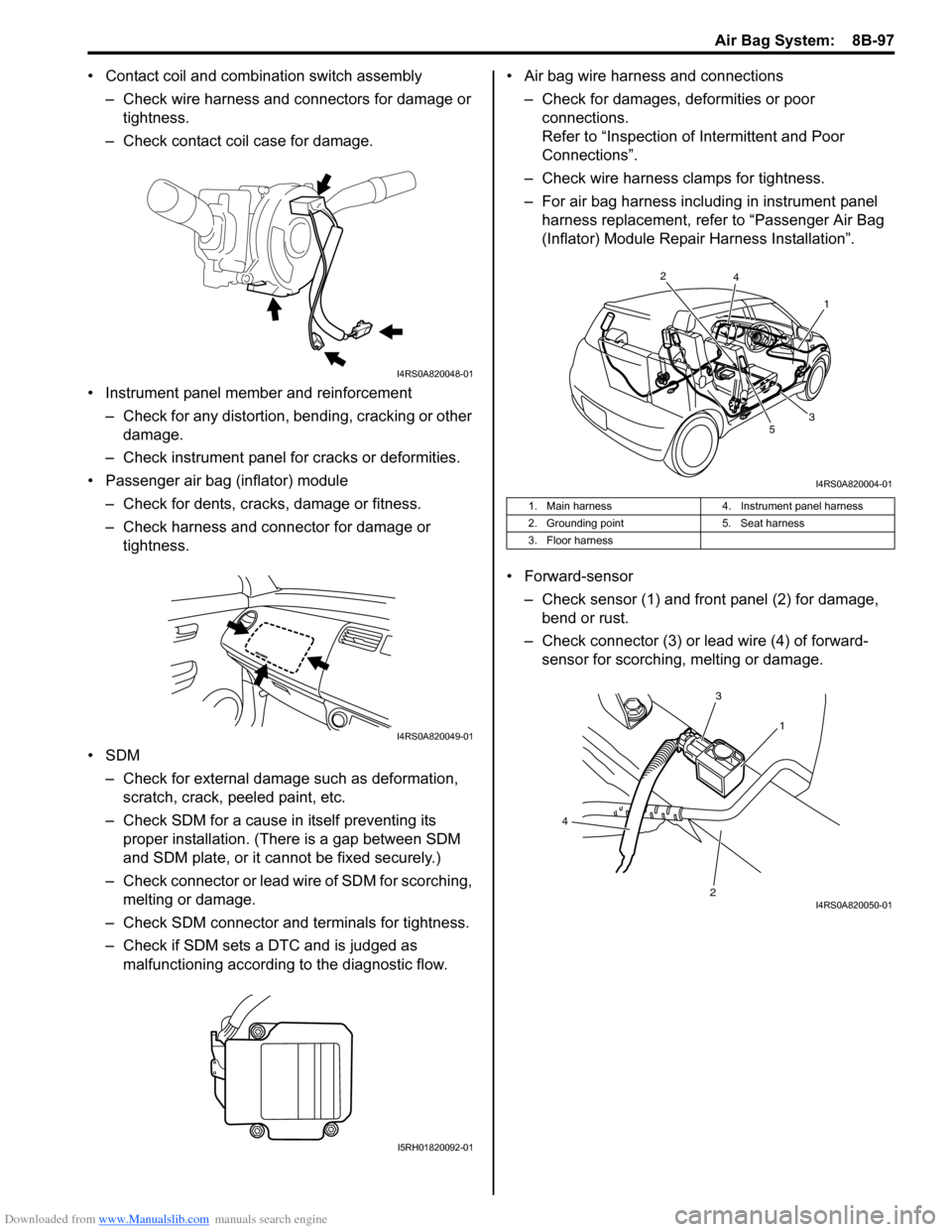

• Contact coil and combination switch assembly

– Check wire harness and connectors for damage or tightness.

– Check contact coil case for damage.

• Instrument panel member and reinforcement – Check for any distortion, bending, cracking or other damage.

– Check instrument panel fo r cracks or deformities.

• Passenger air bag (inflator) module

– Check for dents, cracks, damage or fitness.

– Check harness and connector for damage or tightness.

•SDM – Check for external damage such as deformation, scratch, crack, peeled paint, etc.

– Check SDM for a cause in itself preventing its proper installation. (There is a gap between SDM

and SDM plate, or it cannot be fixed securely.)

– Check connector or lead wire of SDM for scorching, melting or damage.

– Check SDM connector and terminals for tightness.

– Check if SDM sets a DTC and is judged as malfunctioning according to the diagnostic flow. • Air bag wire harness and connections

– Check for damages, deformities or poor connections.

Refer to “Inspection of Intermittent and Poor

Connections”.

– Check wire harness clamps for tightness.

– For air bag harness including in instrument panel harness replacement, refer to “Passenger Air Bag

(Inflator) Module Repair Harness Installation”.

• Forward-sensor – Check sensor (1) and front panel (2) for damage, bend or rust.

– Check connector (3) or lead wire (4) of forward- sensor for scorching, melting or damage.

I4RS0A820048-01

I4RS0A820049-01

I5RH01820092-01

1. Main harness 4. Instrument panel harness

2. Grounding point 5. Seat harness

3. Floor harness

1

2

3

4

5

I4RS0A820004-01

1

3

2

4

I4RS0A820050-01

Page 1426 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-23 Body Electrical Control System:

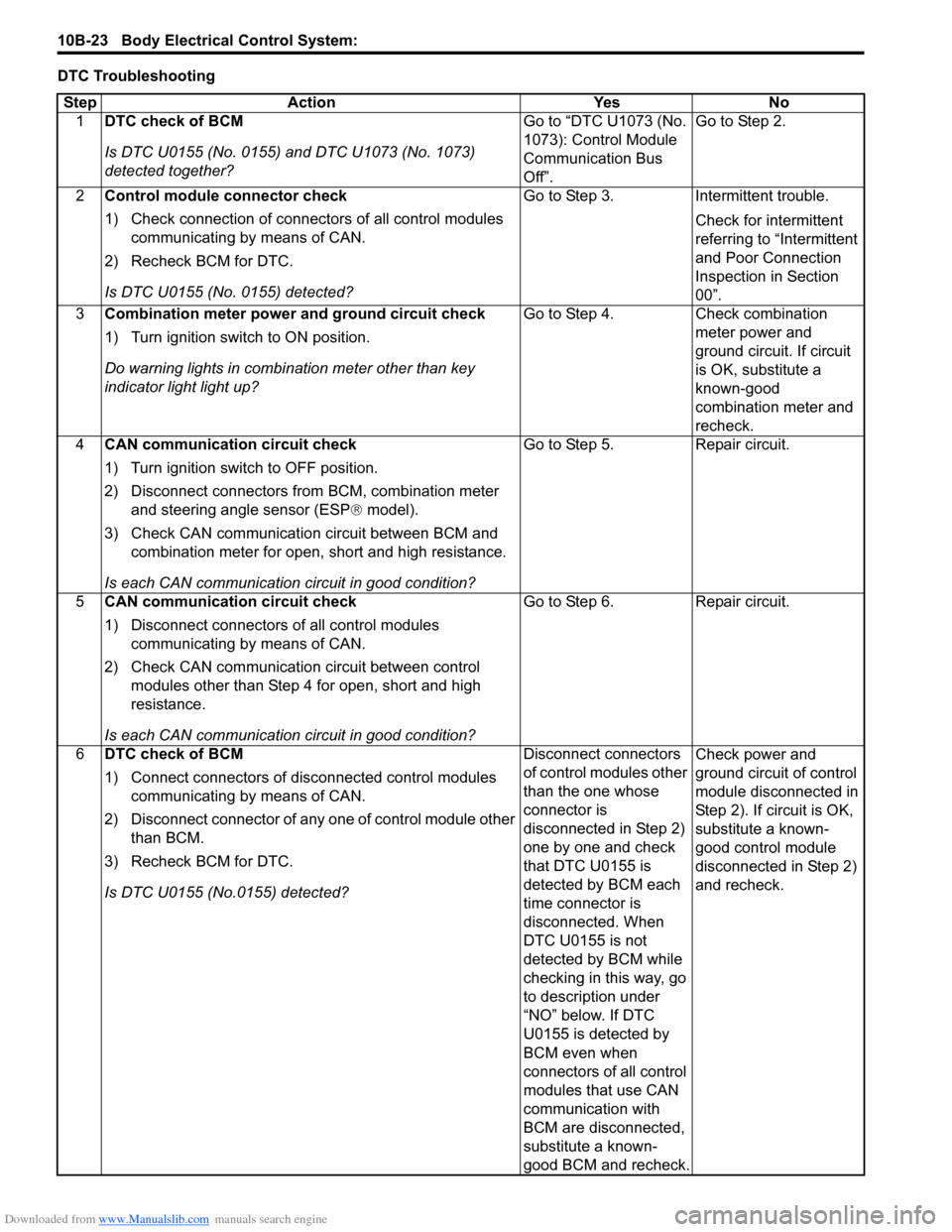

DTC TroubleshootingStep Action YesNo

1 DTC check of BCM

Is DTC U0155 (No. 0155) and DTC U1073 (No. 1073)

detected together? Go to “DTC U1073 (No.

1073): Control Module

Communication Bus

Off”.Go to Step 2.

2 Control module connector check

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck BCM for DTC.

Is DTC U0155 (No. 0155) detected? Go to Step 3.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

3 Combination meter power and ground circuit check

1) Turn ignition switch to ON position.

Do warning lights in combi nation meter other than key

indicator light light up? Go to Step 4.

Check combination

meter power and

ground circuit. If circuit

is OK, substitute a

known-good

combination meter and

recheck.

4 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors from BCM, combination meter

and steering angle sensor (ESP ® model).

3) Check CAN communication circuit between BCM and combination meter for open, short and high resistance.

Is each CAN communication circuit in good condition? Go to Step 5.

Repair circuit.

5 CAN communication circuit check

1) Disconnect connectors of all control modules

communicating by means of CAN.

2) Check CAN communication circuit between control modules other than Step 4 for open, short and high

resistance.

Is each CAN communication circuit in good condition? Go to Step 6.

Repair circuit.

6 DTC check of BCM

1) Connect connectors of disconnected control modules

communicating by means of CAN.

2) Disconnect connector of any one of control module other than BCM.

3) Recheck BCM for DTC.

Is DTC U0155 (No.0155) detected? Disconnect connectors

of control modules other

than the one whose

connector is

disconnected in Step 2)

one by one and check

that DTC U0155 is

detected by BCM each

time connector is

disconnected. When

DTC U0155 is not

detected by BCM while

checking in this way, go

to description under

“NO” below. If DTC

U0155 is detected by

BCM even when

connectors of all control

modules that use CAN

communication with

BCM are disconnected,

substitute a known-

good BCM and recheck.Check power and

ground circuit of control

module disconnected in

Step 2). If circuit is OK,

substitute a known-

good control module

disconnected in Step 2)

and recheck.

Page 1427 of 1496

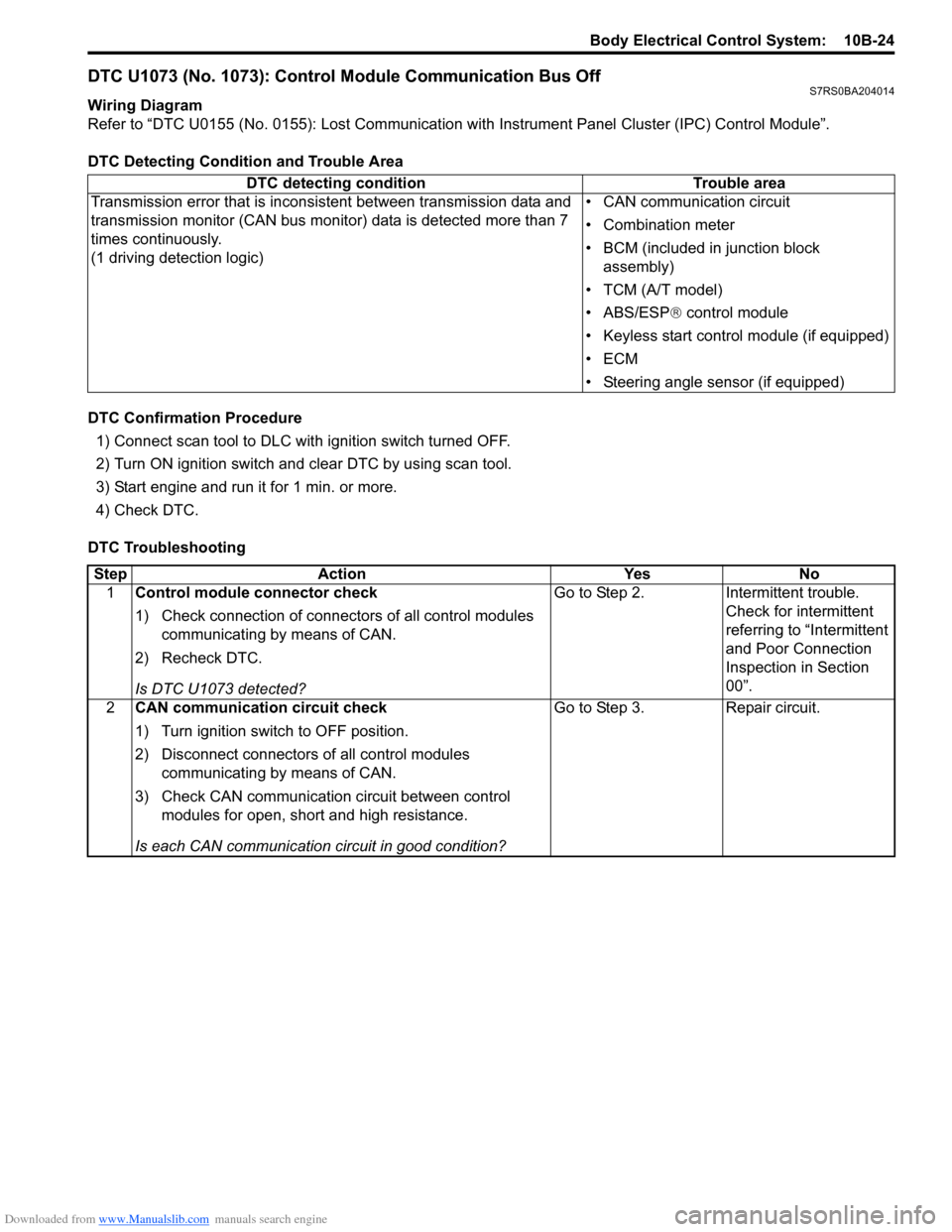

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-24

DTC U1073 (No. 1073): Control Module Communication Bus OffS7RS0BA204014

Wiring Diagram

Refer to “DTC U0155 (No. 0155): Lost Communication with Instrument Panel Cluster (IPC) Control Module”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure 1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC by using scan tool.

3) Start engine and run it for 1 min. or more.

4) Check DTC.

DTC Troubleshooting DTC detecting condition Trouble area

Transmission error that is inconsistent between transmission data and

transmission monitor (CAN bus monitor) data is detected more than 7

times continuously.

(1 driving detection logic) • CAN communication circuit

• Combination meter

• BCM (included in junction block

assembly)

• TCM (A/T model)

• ABS/ESP ® control module

• Keyless start control module (if equipped)

•ECM

• Steering angle sensor (if equipped)

Step Action YesNo

1 Control module connector check

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck DTC.

Is DTC U1073 detected? Go to Step 2.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

2 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by means of CAN.

3) Check CAN communication circuit between control modules for open, short and high resistance.

Is each CAN communication circuit in good condition? Go to Step 3.

Repair circuit.

Page 1429 of 1496

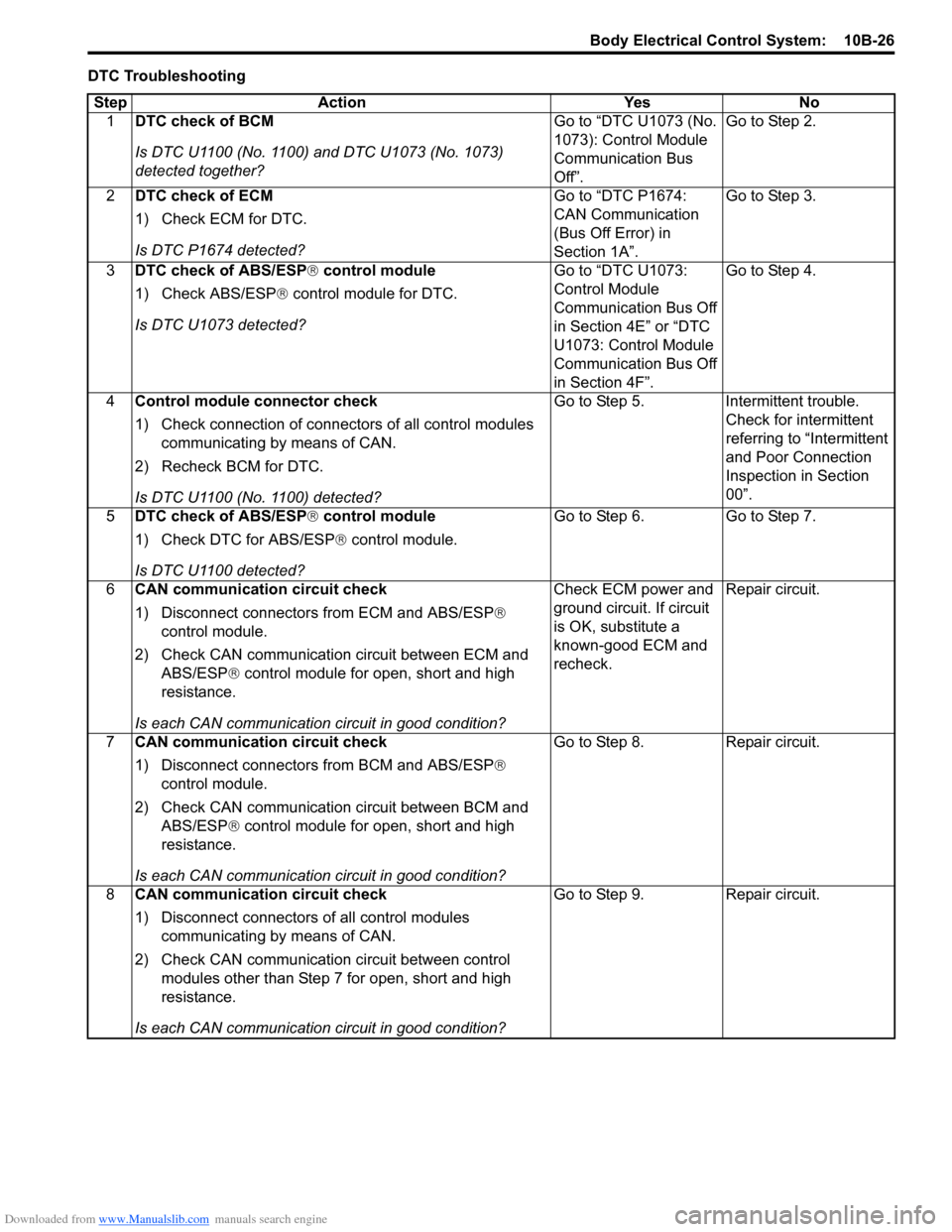

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-26

DTC TroubleshootingStep Action Yes No 1 DTC check of BCM

Is DTC U1100 (No. 1100) and DTC U1073 (No. 1073)

detected together? Go to “DTC U1073 (No.

1073): Control Module

Communication Bus

Off”.Go to Step 2.

2 DTC check of ECM

1) Check ECM for DTC.

Is DTC P1674 detected? Go to “DTC P1674:

CAN Communication

(Bus Off Error) in

Section 1A”.Go to Step 3.

3 DTC check of ABS/ESP ® control module

1) Check ABS/ESP ® control module for DTC.

Is DTC U1073 detected? Go to “DTC U1073:

Control Module

Communication Bus Off

in Section 4E” or “DTC

U1073: Control Module

Communication Bus Off

in Section 4F”.Go to Step 4.

4 Control module connector check

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck BCM for DTC.

Is DTC U1100 (No. 1100) detected? Go to Step 5. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

5 DTC check of ABS/ESP ® control module

1) Check DTC for ABS/ESP ® control module.

Is DTC U1100 detected? Go to Step 6. Go to Step 7.

6 CAN communication circuit check

1) Disconnect connector s from ECM and ABS/ESP ®

control module.

2) Check CAN communication circuit between ECM and ABS/ESP ® control module for open, short and high

resistance.

Is each CAN communication circuit in good condition? Check ECM power and

ground circuit. If circuit

is OK, substitute a

known-good ECM and

recheck.

Repair circuit.

7 CAN communication circuit check

1) Disconnect connector s from BCM and ABS/ESP ®

control module.

2) Check CAN communication circuit between BCM and ABS/ESP ® control module for open, short and high

resistance.

Is each CAN communication circuit in good condition? Go to Step 8. Repair circuit.

8 CAN communication circuit check

1) Disconnect connectors of all control modules

communicating by means of CAN.

2) Check CAN communication circuit between control modules other than Step 7 for open, short and high

resistance.

Is each CAN communication circuit in good condition? Go to Step 9. Repair circuit.

Page 1431 of 1496

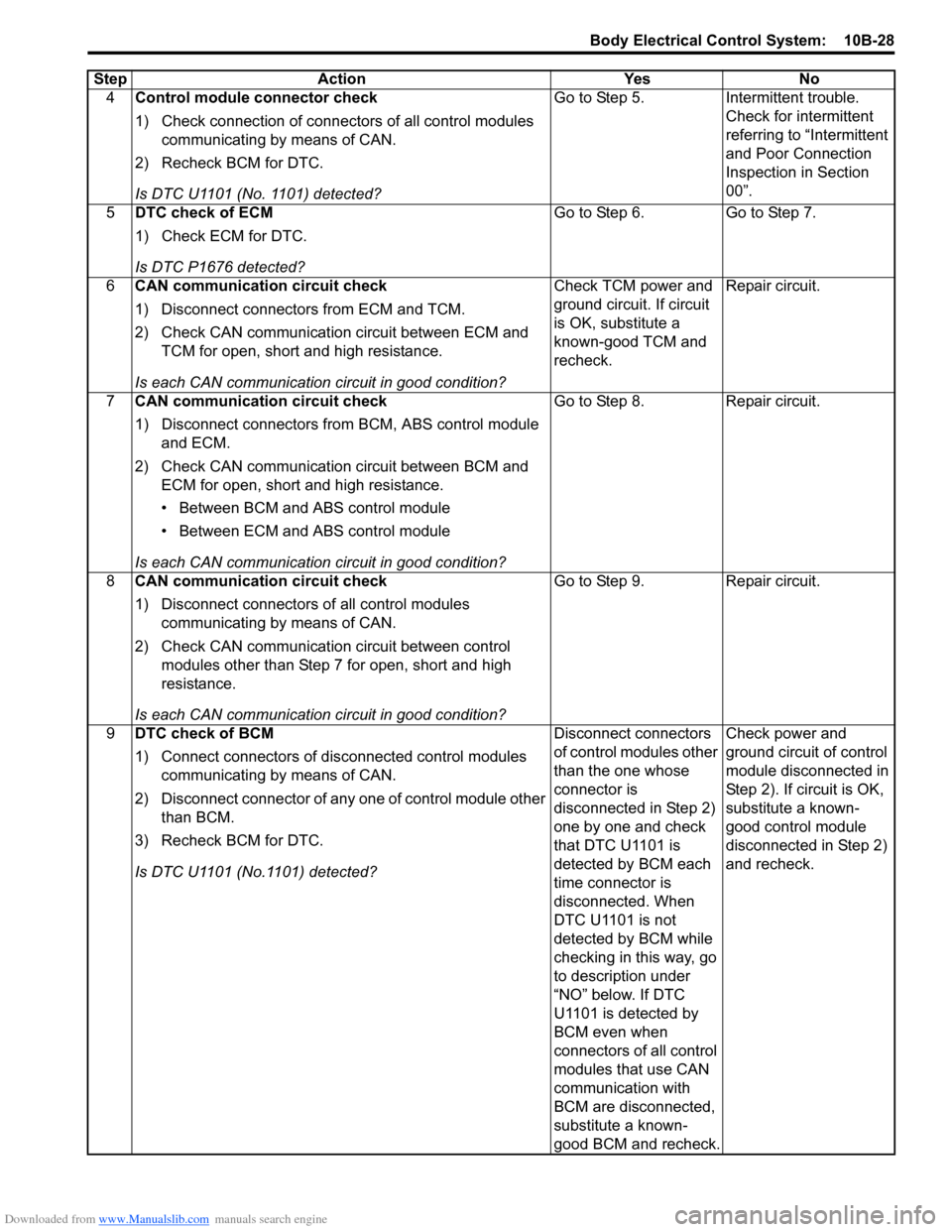

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-28

4Control module connector check

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck BCM for DTC.

Is DTC U1101 (No. 1101) detected? Go to Step 5. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

5 DTC check of ECM

1) Check ECM for DTC.

Is DTC P1676 detected? Go to Step 6. Go to Step 7.

6 CAN communication circuit check

1) Disconnect connectors from ECM and TCM.

2) Check CAN communication circuit between ECM and

TCM for open, short and high resistance.

Is each CAN communication circuit in good condition? Check TCM power and

ground circuit. If circuit

is OK, substitute a

known-good TCM and

recheck.

Repair circuit.

7 CAN communication circuit check

1) Disconnect connectors from BCM, ABS control module

and ECM.

2) Check CAN communication circuit between BCM and ECM for open, short and high resistance.

• Between BCM and ABS control module

• Between ECM and ABS control module

Is each CAN communication circuit in good condition? Go to Step 8. Repair circuit.

8 CAN communication circuit check

1) Disconnect connectors of all control modules

communicating by means of CAN.

2) Check CAN communication circuit between control modules other than Step 7 for open, short and high

resistance.

Is each CAN communication circuit in good condition? Go to Step 9. Repair circuit.

9 DTC check of BCM

1) Connect connectors of disconnected control modules

communicating by means of CAN.

2) Disconnect connector of any one of control module other than BCM.

3) Recheck BCM for DTC.

Is DTC U1101 (No.1101) detected? Disconnect connectors

of control modules other

than the one whose

connector is

disconnected in Step 2)

one by one and check

that DTC U1101 is

detected by BCM each

time connector is

disconnected. When

DTC U1101 is not

detected by BCM while

checking in this way, go

to description under

“NO” below. If DTC

U1101 is detected by

BCM even when

connectors of all control

modules that use CAN

communication with

BCM are disconnected,

substitute a known-

good BCM and recheck.Check power and

ground circuit of control

module disconnected in

Step 2). If circuit is OK,

substitute a known-

good control module

disconnected in Step 2)

and recheck.

Step Action Yes No

Page 1432 of 1496

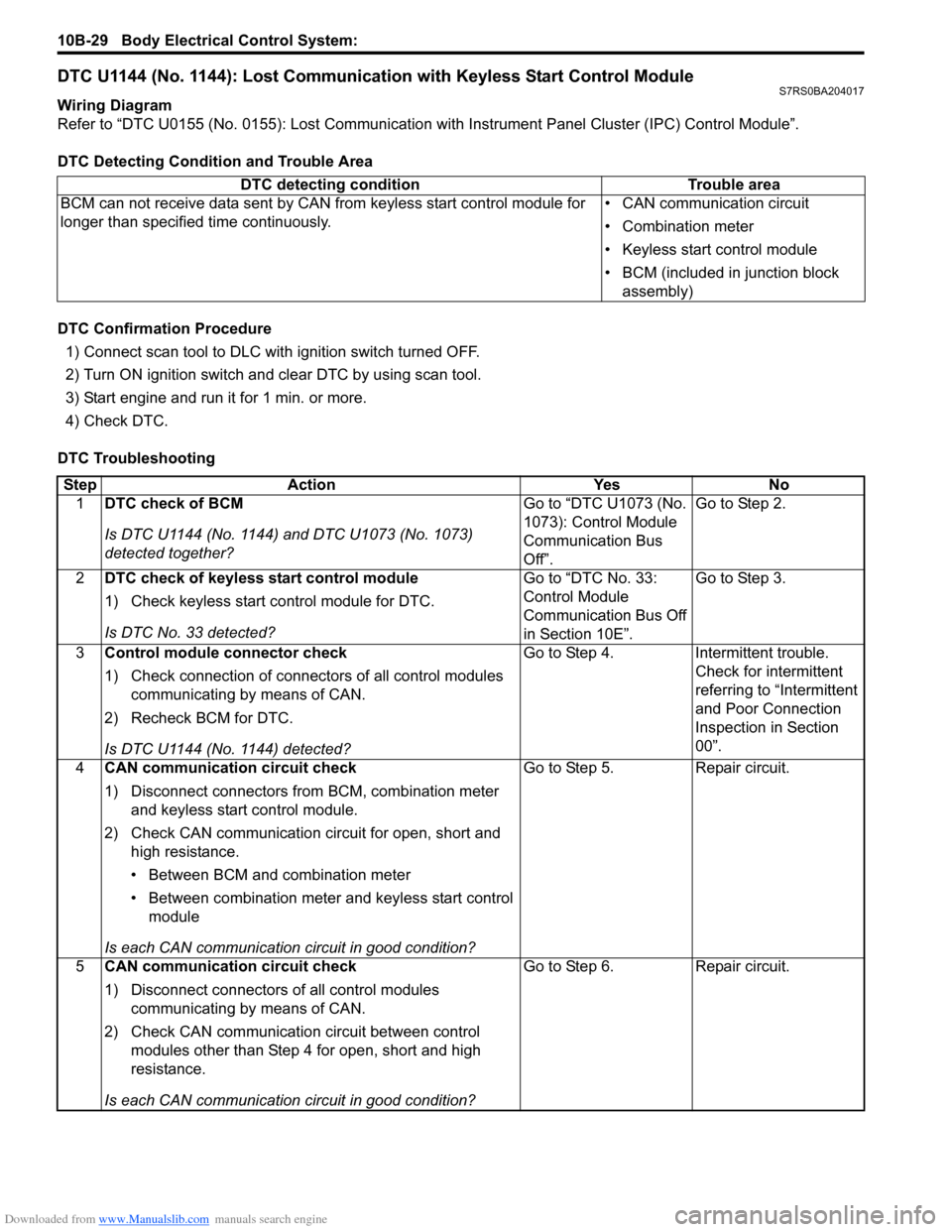

Downloaded from www.Manualslib.com manuals search engine 10B-29 Body Electrical Control System:

DTC U1144 (No. 1144): Lost Communication with Keyless Start Control ModuleS7RS0BA204017

Wiring Diagram

Refer to “DTC U0155 (No. 0155): Lost Communication with Instrument Panel Cluster (IPC) Control Module”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure 1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC by using scan tool.

3) Start engine and run it for 1 min. or more.

4) Check DTC.

DTC Troubleshooting DTC detecting condition Trouble area

BCM can not receive data sent by CAN from keyless start control module for

longer than specified time continuously. • CAN communication circuit

• Combination meter

• Keyless start control module

• BCM (included in junction block

assembly)

Step Action YesNo

1 DTC check of BCM

Is DTC U1144 (No. 1144) and DTC U1073 (No. 1073)

detected together? Go to “DTC U1073 (No.

1073): Control Module

Communication Bus

Off”.Go to Step 2.

2 DTC check of keyless start control module

1) Check keyless start co ntrol module for DTC.

Is DTC No. 33 detected? Go to “DTC No. 33:

Control Module

Communication Bus Off

in Section 10E”.Go to Step 3.

3 Control module connector check

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck BCM for DTC.

Is DTC U1144 (No. 1144) detected? Go to Step 4.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

4 CAN communication circuit check

1) Disconnect connectors from BCM, combination meter

and keyless start control module.

2) Check CAN communication circuit for open, short and high resistance.

• Between BCM and combination meter

• Between combination meter and keyless start control module

Is each CAN communication circuit in good condition? Go to Step 5.

Repair circuit.

5 CAN communication circuit check

1) Disconnect connectors of all control modules

communicating by means of CAN.

2) Check CAN communication circuit between control modules other than Step 4 for open, short and high

resistance.

Is each CAN communication circuit in good condition? Go to Step 6.

Repair circuit.

Page 1453 of 1496

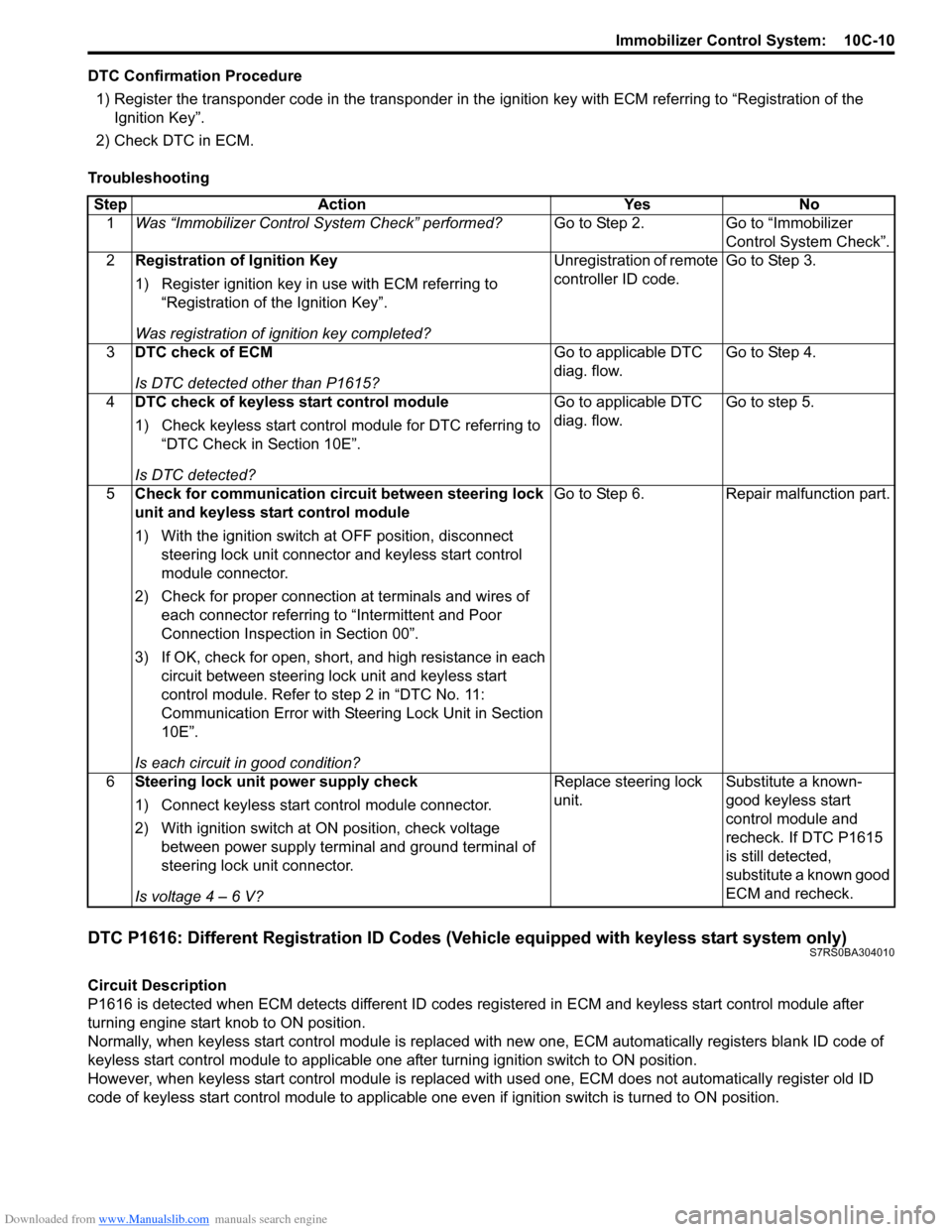

Downloaded from www.Manualslib.com manuals search engine Immobilizer Control System: 10C-10

DTC Confirmation Procedure1) Register the transponder code in the transponder in the ignition key with ECM referring to “Registration of the

Ignition Key”.

2) Check DTC in ECM.

Troubleshooting

DTC P1616: Different Registration ID Codes (Vehicle equipped with keyless start system only)S7RS0BA304010

Circuit Description

P1616 is detected when ECM detects different ID codes registered in ECM and keyless start control module after

turning engine start knob to ON position.

Normally, when keyless start control module is replaced with new one, ECM automatically registers blank ID code of

keyless start control module to applicable one after turning ignition switch to ON position.

However, when keyless start control module is replaced wit h used one, ECM does not automatically register old ID

code of keyless start control module to applicable one ev en if ignition switch is turned to ON position.

Step Action Yes No

1 Was “Immobilizer Control S ystem Check” performed? Go to Step 2. Go to “Immobilizer

Control System Check”.

2 Registration of Ignition Key

1) Register ignition key in use with ECM referring to

“Registration of the Ignition Key”.

Was registration of ignition key completed? Unregistration of remote

controller ID code.

Go to Step 3.

3 DTC check of ECM

Is DTC detected other than P1615? Go to applicable DTC

diag. flow.

Go to Step 4.

4 DTC check of keyless start control module

1) Check keyless start control module for DTC referring to

“DTC Check in Section 10E”.

Is DTC detected? Go to applicable DTC

diag. flow.

Go to step 5.

5 Check for communication circuit between steering lock

unit and keyless start control module

1) With the ignition switch at OFF position, disconnect

steering lock unit connector and keyless start control

module connector.

2) Check for proper connection at terminals and wires of

each connector referring to “Intermittent and Poor

Connection Inspection in Section 00”.

3) If OK, check for open, short, and high resistance in each circuit between steering lock unit and keyless start

control module. Refer to step 2 in “DTC No. 11:

Communication Error with Steeri ng Lock Unit in Section

10E”.

Is each circuit in good condition? Go to Step 6. Repair malfunction part.

6 Steering lock unit power supply check

1) Connect keyless start control module connector.

2) With ignition switch at ON position, check voltage

between power supply terminal and ground terminal of

steering lock unit connector.

Is voltage 4 – 6 V? Replace steering lock

unit.

Substitute a known-

good keyless start

control module and

recheck. If DTC P1615

is still detected,

substitute a known good

ECM and recheck.

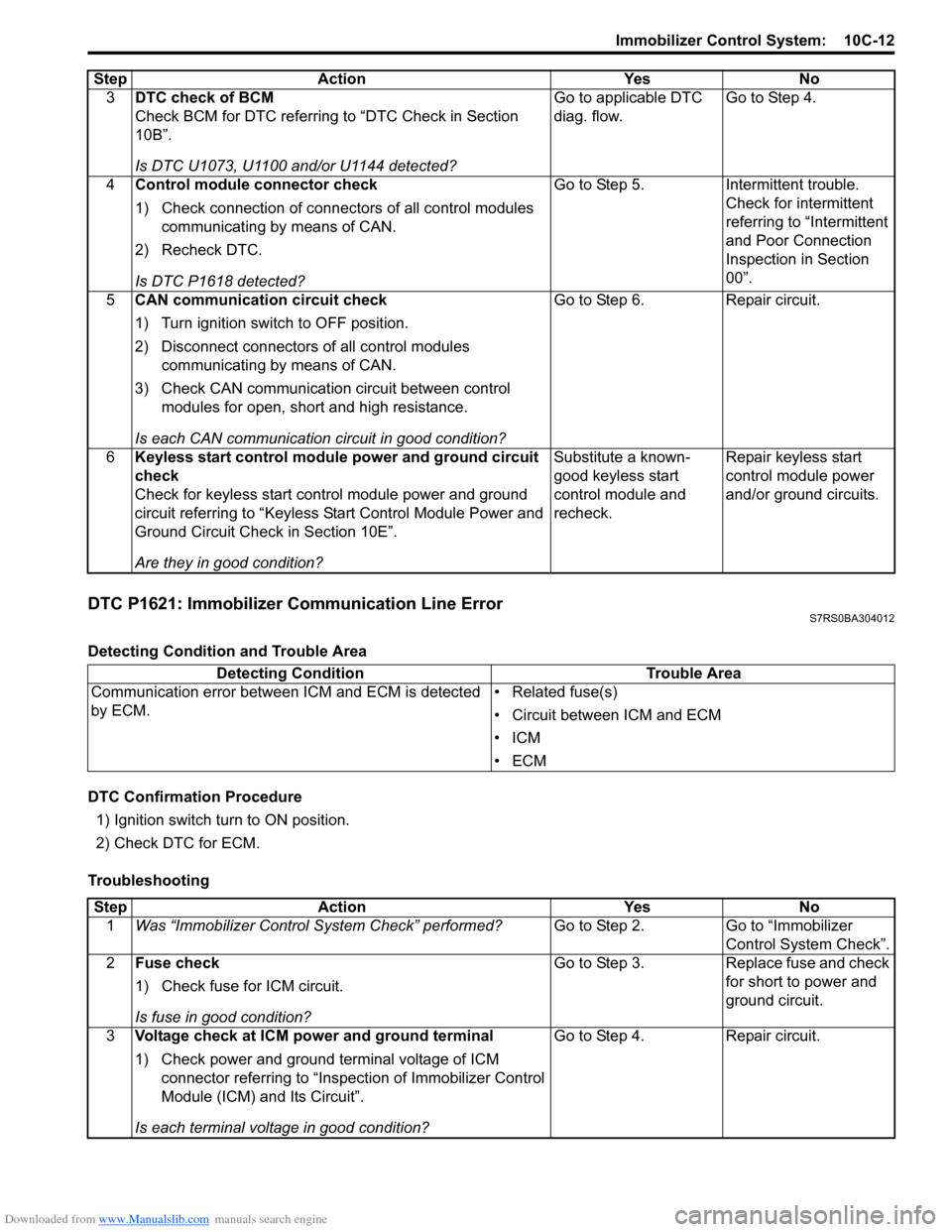

Page 1455 of 1496

Downloaded from www.Manualslib.com manuals search engine Immobilizer Control System: 10C-12

DTC P1621: Immobilizer Communication Line ErrorS7RS0BA304012

Detecting Condition and Trouble Area

DTC Confirmation Procedure1) Ignition switch turn to ON position.

2) Check DTC for ECM.

Troubleshooting 3

DTC check of BCM

Check BCM for DTC referring to “DTC Check in Section

10B”.

Is DTC U1073, U1100 and/or U1144 detected? Go to applicable DTC

diag. flow.

Go to Step 4.

4 Control module connector check

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck DTC.

Is DTC P1618 detected? Go to Step 5. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

5 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by means of CAN.

3) Check CAN communication circuit between control modules for open, short and high resistance.

Is each CAN communication circuit in good condition? Go to Step 6. Repair circuit.

6 Keyless start control module power and ground circuit

check

Check for keyless start control module power and ground

circuit referring to “Keyless St art Control Module Power and

Ground Circuit Check in Section 10E”.

Are they in good condition? Substitute a known-

good keyless start

control module and

recheck.

Repair keyless start

control module power

and/or ground circuits.

Step Action Yes No

Detecting Condition

Trouble Area

Communication error between ICM and ECM is detected

by ECM. • Related fuse(s)

• Circuit between ICM and ECM

•ICM

•ECM

Step

Action YesNo

1 Was “Immobilizer Control S ystem Check” performed? Go to Step 2.Go to “Immobilizer

Control System Check”.

2 Fuse check

1) Check fuse for ICM circuit.

Is fuse in good condition? Go to Step 3.

Replace fuse and check

for short to power and

ground circuit.

3 Voltage check at ICM power and ground terminal

1) Check power and ground terminal voltage of ICM

connector referring to “Inspe ction of Immobilizer Control

Module (ICM) and Its Circuit”.

Is each terminal voltage in good condition? Go to Step 4.

Repair circuit.