intermittent and poor connection SUZUKI SWIFT 2008 2.G Service Manual PDF

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 723 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-79

2Check TCC solenoid valve circuit for IG short

1) Connect valve body harness connector.

2) Disconnect TCM connectors.

3) Check for proper connection to TCM at terminal “C34-3”

and “C34-5”.

4) If connection is OK, turn ignition switch ON and measure voltage between terminal “C34-3” of disconnected

harness side TCM connector and ground between

terminal “C34-5” of disconnected harness side TCM

connector and ground.

Are voltage 1 V or less? Go to Step 3. “WHT/BLU” or “WHT/

BLK” circuit shorted to

power circuit.

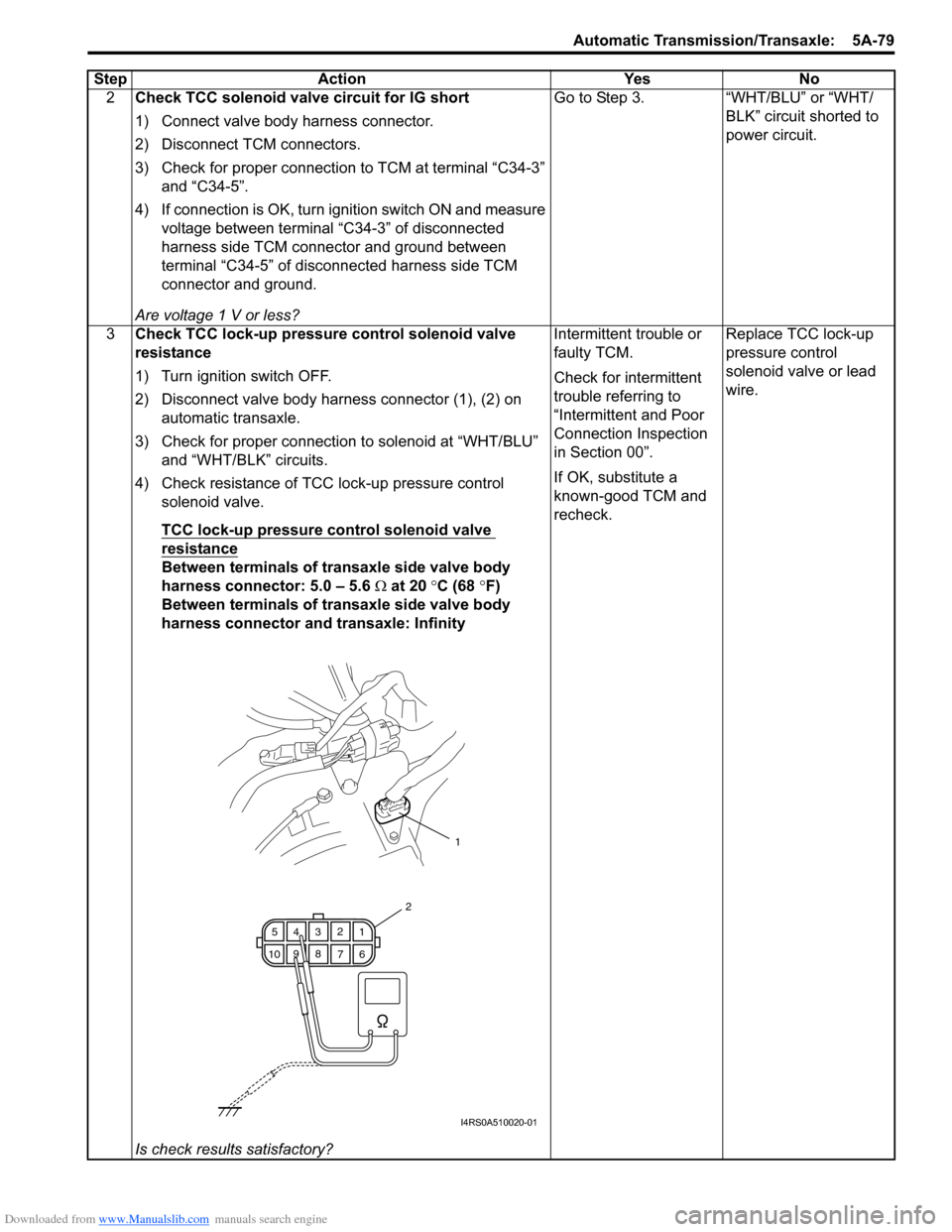

3 Check TCC lock-up pressure control solenoid valve

resistance

1) Turn ignition switch OFF.

2) Disconnect valve body harness connector (1), (2) on

automatic transaxle.

3) Check for proper connection to solenoid at “WHT/BLU” and “WHT/BLK” circuits.

4) Check resistance of TCC lock-up pressure control

solenoid valve.

TCC lock-up pressure control solenoid valve

resistance

Between terminals of transaxle side valve body

harness connector: 5.0 – 5.6 Ω at 20 °C (68 °F)

Between terminals of transaxle side valve body

harness connector and transaxle: Infinity

Is check results satisfactory? Intermittent trouble or

faulty TCM.

Check for intermittent

trouble referring to

“Intermittent and Poor

Connection Inspection

in Section 00”.

If OK, substitute a

known-good TCM and

recheck.

Replace TCC lock-up

pressure control

solenoid valve or lead

wire.

Step Action Yes No

1

6

7

89

10 5

43 2

1

2

I4RS0A510020-01

Page 725 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-81

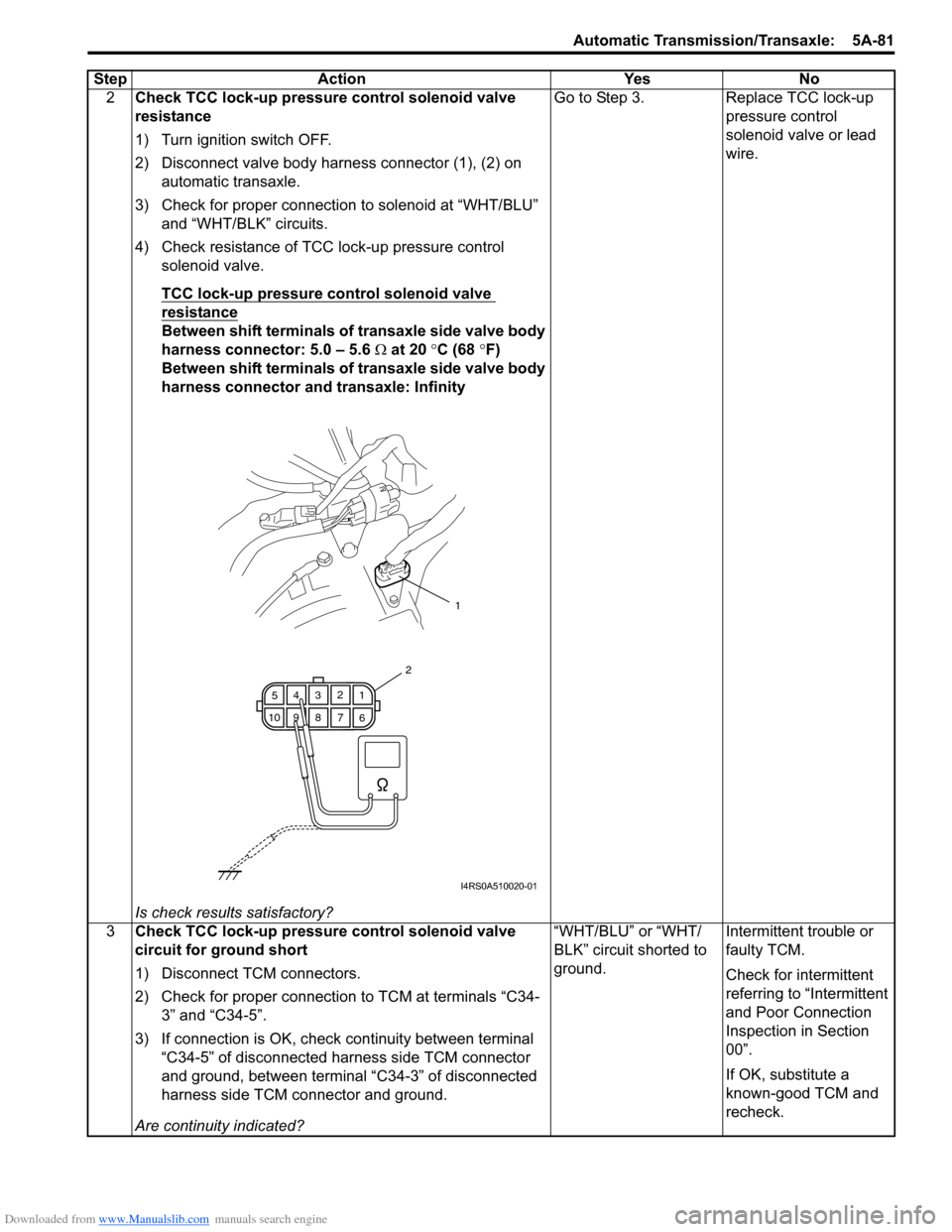

2Check TCC lock-up pressure control solenoid valve

resistance

1) Turn ignition switch OFF.

2) Disconnect valve body harness connector (1), (2) on

automatic transaxle.

3) Check for proper connection to solenoid at “WHT/BLU” and “WHT/BLK” circuits.

4) Check resistance of TCC lock-up pressure control

solenoid valve.

TCC lock-up pressure control solenoid valve

resistance

Between shift terminals of transaxle side valve body

harness connector: 5.0 – 5.6 Ω at 20 °C (68 °F)

Between shift terminals of transaxle side valve body

harness connector and transaxle: Infinity

Is check results satisfactory? Go to Step 3. Replace TCC lock-up

pressure control

solenoid valve or lead

wire.

3 Check TCC lock-up pressure control solenoid valve

circuit for ground short

1) Disconnect TCM connectors.

2) Check for proper connection to TCM at terminals “C34-

3” and “C34-5”.

3) If connection is OK, check continuity between terminal

“C34-5” of disconnected harness side TCM connector

and ground, between terminal “C34-3” of disconnected

harness side TCM connector and ground.

Are continuity indicated? “WHT/BLU” or “WHT/

BLK” circuit shorted to

ground.

Intermittent trouble or

faulty TCM.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

If OK, substitute a

known-good TCM and

recheck.

Step Action Yes No

1

6

7

89

10 5

43 2

1

2

I4RS0A510020-01

Page 890 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-8 Power Assisted Steering System:

Step 2: DTC Check, Record and Clearance

First, check DTC, referring to “DTC Check”. If DTC is

indicated, print it or write them down and then clear them

by referring to “DTC Clearance”. DTC indicates

malfunction that occurred in the system but does not

indicate whether it exists now or it occurred in the past

and the normal condition has been restored now. To

check which case applies, check the symptom in

question according to Step 5 and recheck DTC

according to Step 6 and 7.

Attempt to diagnose a trouble based on DTC in this step

only or failure to clear the DTC in this step will lead to

incorrect diagnosis, trouble diagnosis of a normal circuit

or difficulty in troubleshooting.

Step 3 and 4: Visual Inspection

As a preliminary step, be sure to perform visual check of

the items that support proper function of the P/S system

referring to “Visual Inspection”.

Step 5: Trouble Symptom Confirmation

Based on information obtained in “Step 1: Customer

Complaint Analysis: ” and “S tep 2: DTC Check, Record

and Clearance: ”, confirm trouble symptoms. Also,

reconfirm trouble symptom by performing test drive and

turning steering wheel fully to right and left at stopped

vehicle.

Step 6 and 7: Rechecking and Record of DTC

Refer to “DTC Check” for checking procedure.

Step 8: Steering Symptom Diagnosis and P/S

System Symptom Diagnosis

Perform basic steering system check according to

“Steering Symptom Diagnosis in Section 6A” first. When

the end of the flow has been reached, check the parts of

the system suspected as a possible cause referring to

“P/S System Symptom Diagnosis” and based on

symptoms appearing on the vehicle (symptoms obtained

through steps of customer complaint analysis, trouble

symptom confirmation and/or basic P/S system check)

and repair or replace faulty parts, if any.

Step 9: Troubleshooting for DTC (See each DTC

Diag. Flow)

Based on the DTC indicated in Step 6 or 7 and referring

to the applicable DTC diag. flow, locate the cause of the

trouble, namely in a sensor, switch, wire harness,

connector, actuator, P/S control module or other part and

repair or replace faulty parts.

Step 10: Intermittent Problems Check

Check parts where an intermittent trouble is easy to

occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connection Inspection in Section

00” and related circuit of DTC recorded in Step 2. Step 11: Final Confirmation Test

Confirm that the problem symptom has gone and the P/

S system is free from any abnormal conditions. If what

has been repaired is related to the DTC, clear the DTC

once, perform DTC confirmation procedure and confirm

that no DTC is indicated.

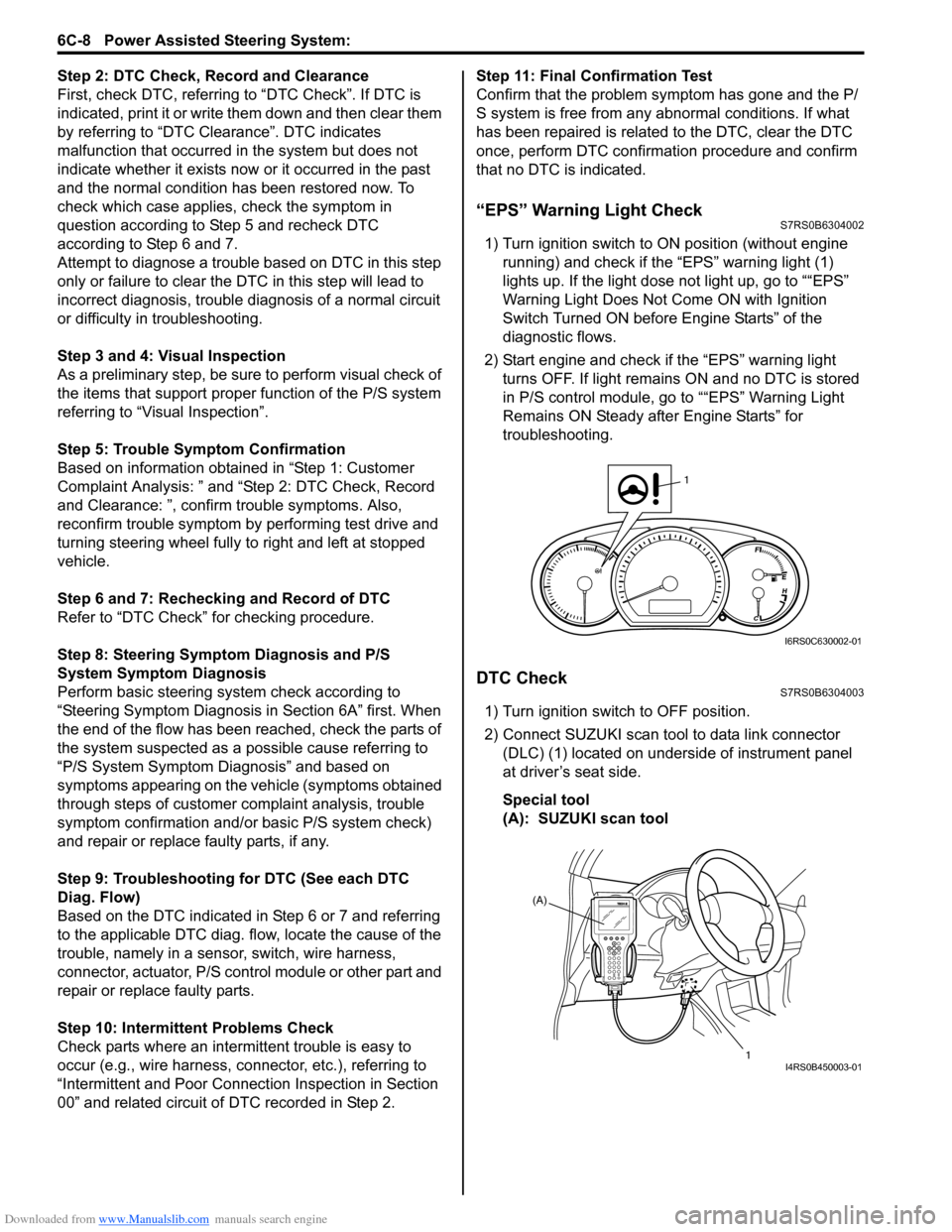

“EPS” Warning Light CheckS7RS0B6304002

1) Turn ignition switch to ON position (without engine

running) and chec k if the “EPS” warning light (1)

lights up. If the light dose not light up, go to ““EPS”

Warning Light Does Not Come ON with Ignition

Switch Turned ON before Engine Starts” of the

diagnostic flows.

2) Start engine and check if the “EPS” warning light turns OFF. If light remains ON and no DTC is stored

in P/S control module, go to ““EPS” Warning Light

Remains ON Steady after Engine Starts” for

troubleshooting.

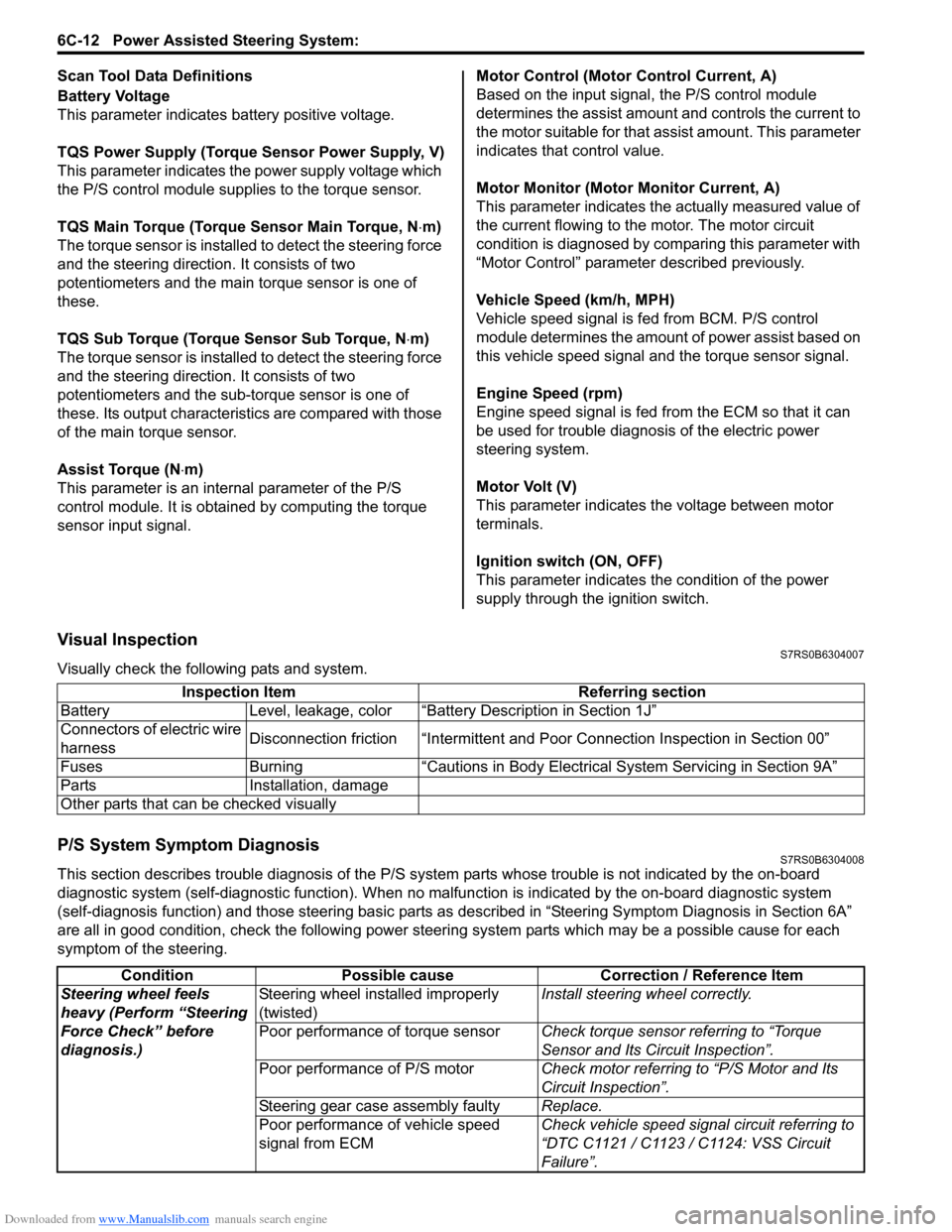

DTC CheckS7RS0B6304003

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (DLC) (1) located on underside of instrument panel

at driver’s seat side.

Special tool

(A): SUZUKI scan tool

1

I6RS0C630002-01

(A)

1

I4RS0B450003-01

Page 894 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-12 Power Assisted Steering System:

Scan Tool Data Definitions

Battery Voltage

This parameter indicates battery positive voltage.

TQS Power Supply (Torque Sensor Power Supply, V)

This parameter indicates the power supply voltage which

the P/S control module supplies to the torque sensor.

TQS Main Torque (Torque Sensor Main Torque, N ⋅m)

The torque sensor is installed to detect the steering force

and the steering directio n. It consists of two

potentiometers and the main torque sensor is one of

these.

TQS Sub Torque (Torque Sensor Sub Torque, N ⋅m)

The torque sensor is installed to detect the steering force

and the steering directio n. It consists of two

potentiometers and the sub-torque sensor is one of

these. Its output characteristics are compared with those

of the main torque sensor.

Assist Torque (N ⋅m)

This parameter is an internal parameter of the P/S

control module. It is obtained by computing the torque

sensor input signal. Motor Control (Motor Control Current, A)

Based on the input signal, the P/S control module

determines the assist amount

and controls the current to

the motor suitable for that a ssist amount. This parameter

indicates that control value.

Motor Monitor (Motor Monitor Current, A)

This parameter indicates the actually measured value of

the current flowing to the motor. The motor circuit

condition is diagnosed by co mparing this parameter with

“Motor Control” parameter described previously.

Vehicle Speed (km/h, MPH)

Vehicle speed signal is fed from BCM. P/S control

module determines the amount of power assist based on

this vehicle speed signal and the torque sensor signal.

Engine Speed (rpm)

Engine speed signal is fed from the ECM so that it can

be used for trouble diagnos is of the electric power

steering system.

Motor Volt (V)

This parameter indicates the voltage between motor

terminals.

Ignition switch (ON, OFF)

This parameter indicates the condition of the power

supply through the ignition switch.

Visual InspectionS7RS0B6304007

Visually check the following pats and system.

P/S System Symptom DiagnosisS7RS0B6304008

This section describes trouble diagnosis of the P/S system parts whose trouble is not indicated by the on-board

diagnostic system (self-diagnostic functi on). When no malfunction is indicated by the on-board diagnostic system

(self-diagnosis function) and those stee ring basic parts as described in “Steering Symptom Diagnosis in Section 6A”

are all in good condition, check the following power steer ing system parts which may be a possible cause for each

symptom of the steering. Inspection Item Referring section

Battery Level, leakage, color “Batte ry Description in Section 1J”

Connectors of electric wire

harness Disconnection friction “Intermittent and Poor

Connection Inspection in Section 00”

Fuses Burning “Cautions in Body Electric al System Servicing in Section 9A”

Parts Installation, damage

Other parts that can be checked visually

Condition Possible cause Correction / Reference Item

Steering wheel feels

heavy (Perform “Steering

Force Check” before

diagnosis.) Steering wheel installed improperly

(twisted)

Install steering wheel correctly.

Poor performance of torque sensor Check torque sensor referring to “Torque

Sensor and Its Circuit Inspection”.

Poor performance of P/S motor Check motor referring to “P/S Motor and Its

Circuit Inspection”.

Steering gear case assembly faulty Replace.

Poor performance of vehicle speed

signal from ECM Check vehicle speed signal circuit referring to

“DTC C1121 / C1123 / C1124: VSS Circuit

Failure”.

Page 911 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-29

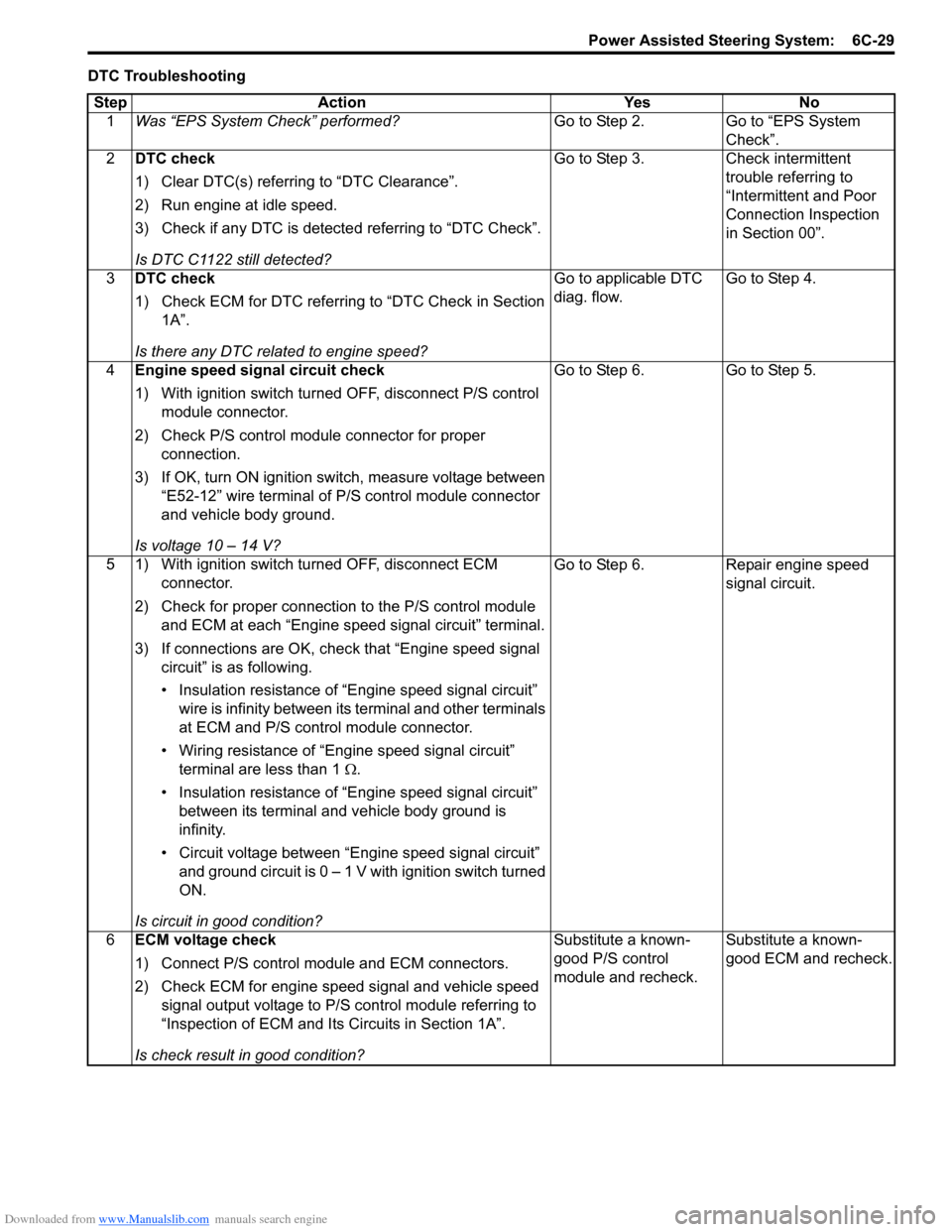

DTC TroubleshootingStep Action Yes No 1 Was “EPS System Check” performed? Go to Step 2. Go to “EPS System

Check”.

2 DTC check

1) Clear DTC(s) referring to “DTC Clearance”.

2) Run engine at idle speed.

3) Check if any DTC is detecte d referring to “DTC Check”.

Is DTC C1122 still detected? Go to Step 3. Check intermittent

trouble referring to

“Intermittent and Poor

Connection Inspection

in Section 00”.

3 DTC check

1) Check ECM for DTC referring to “DTC Check in Section

1A”.

Is there any DTC related to engine speed? Go to applicable DTC

diag. flow.

Go to Step 4.

4 Engine speed signal circuit check

1) With ignition switch turned OFF, disconnect P/S control

module connector.

2) Check P/S control module connector for proper connection.

3) If OK, turn ON ignition switch, measure voltage between “E52-12” wire terminal of P/S control module connector

and vehicle body ground.

Is voltage 10 – 14 V? Go to Step 6.

Go to Step 5.

5 1) With ignition switch turned OFF, disconnect ECM connector.

2) Check for proper connection to the P/S control module and ECM at each “Engine speed signal circuit” terminal.

3) If connections are OK, chec k that “Engine speed signal

circuit” is as following.

• Insulation resistance of “Engine speed signal circuit” wire is infinity between its terminal and other terminals

at ECM and P/S control module connector.

• Wiring resistance of “Engine speed signal circuit” terminal are less than 1 Ω.

• Insulation resistance of “Engine speed signal circuit” between its terminal and vehicle body ground is

infinity.

• Circuit voltage between “Engine speed signal circuit” and ground circuit is 0 – 1 V with ignition switch turned

ON.

Is circuit in good condition? Go to Step 6.

Repair engine speed

signal circuit.

6 ECM voltage check

1) Connect P/S control mo dule and ECM connectors.

2) Check ECM for engine speed signal and vehicle speed signal output voltage to P/S control module referring to

“Inspection of ECM and Its Circuits in Section 1A”.

Is check result in good condition? Substitute a known-

good P/S control

module and recheck.

Substitute a known-

good ECM and recheck.

Page 995 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-47

Scan Tool Data Definitions

TEMP CONT SWITCH (TEMPERATURE SELECTOR): Position of temperature control

selector of HVAC control module

CABIN TEMPERATURE: In-car temperature detected

by inside air temperature sensor installed in HVAC

control module

OUTSIDE AIR TEMP (OUTSIDE AIR TEMPERATURE): Outside air temperature

detected by outside air temperature sensor installed

in front bumper member

EVAPORATOR TEMP (EVAPORATOR TEMPERATURE): Temperature of air passed

through evaporator

COOLANT TEMP (ENGINE COOLANT TEMPERATURE): Engine coolant temperature

detected by engine coolant temperature sensor

SUN LOAD: Amount of sunlight detected by sunload

sensor installed on the driver side on the dashboard

MODE CONT SWITCH (MODE (AIR FLOW) SELECTOR): Position of air flow selector of HVAC

control module

FAN CONT SWITCH (BLOWER SPEED SELECTOR): Position of blower speed selector of HVAC control

module

FAN DESIRED VOLT: Voltage for blower motor AIR MIX POS SEN (TEMPERATURE CONTROL

ACTUATOR POSITI ON SENSOR): Input signal

from position sensor in temperature control actuator

MODE POS SENSOR (AIR FLOW CONTROL ACTUATOR POSITI ON SENSOR): Input signal

from position sensor in air flow control actuator

A/C CONT SIG (A/C SWITCH SIGNAL, ON or OFF): State of A/C switch

BLOWER LOAD SIG (BLO WER FAN LOAD SIGNAL,

ON or OFF): ON: Position of blower speed selector

is 1st position or more / OFF: Position of blower

speed selector is OFF position.

AIR INTAKE MODE (AUTO, FRE or REC): State of air

intake mode

REFRIGERANT PRESSURE (A/C REFRIGERANT ABSOLUTE PRESSURE): This parameter

indicates A/C refrigerant absolute pressure

calculated by ECM

A/C COMP CLUTCH (A/C COMPRESSOR MAGNET CLUTCH, ON or OFF): This parameter indicates

the state of the A/C switch

DFR INDICATOR (DEFROSTER INDICATOR LAMP, ON or OFF): State of defroster indicator lamp

VEHICLE SPEED: It is computed based on pulse

signals from vehicle speed sensor

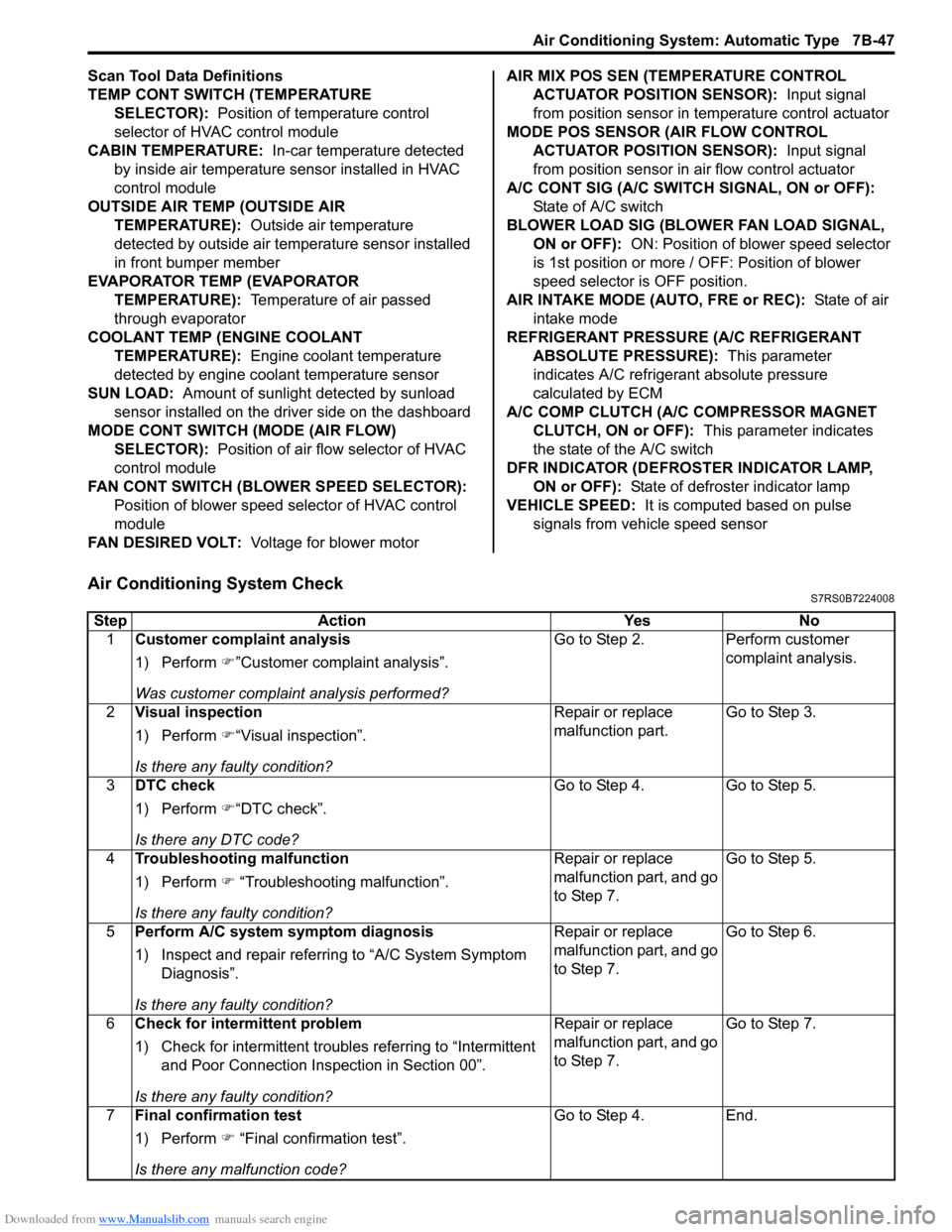

Air Conditioning System CheckS7RS0B7224008

Step Action YesNo

1 Customer complaint analysis

1) Perform �)”Customer complaint analysis”.

Was customer complaint analysis performed? Go to Step 2.

Perform customer

complaint analysis.

2 Visual inspection

1) Perform �)“Visual inspection”.

Is there any faulty condition? Repair or replace

malfunction part.

Go to Step 3.

3 DTC check

1) Perform �)“DTC check”.

Is there any DTC code? Go to Step 4.

Go to Step 5.

4 Troubleshooting malfunction

1) Perform �) “Troubleshooting malfunction”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 7.

Go to Step 5.

5 Perform A/C system symptom diagnosis

1) Inspect and repair referri ng to “A/C System Symptom

Diagnosis”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 7.

Go to Step 6.

6 Check for intermittent problem

1) Check for intermittent troubles referring to “Intermittent

and Poor Connection Inspection in Section 00”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 7.

Go to Step 7.

7 Final confirmation test

1) Perform �) “Final confirmation test”.

Is there any malfunction code? Go to Step 4.

End.

Page 996 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-48 Air Conditioning System: Automatic Type

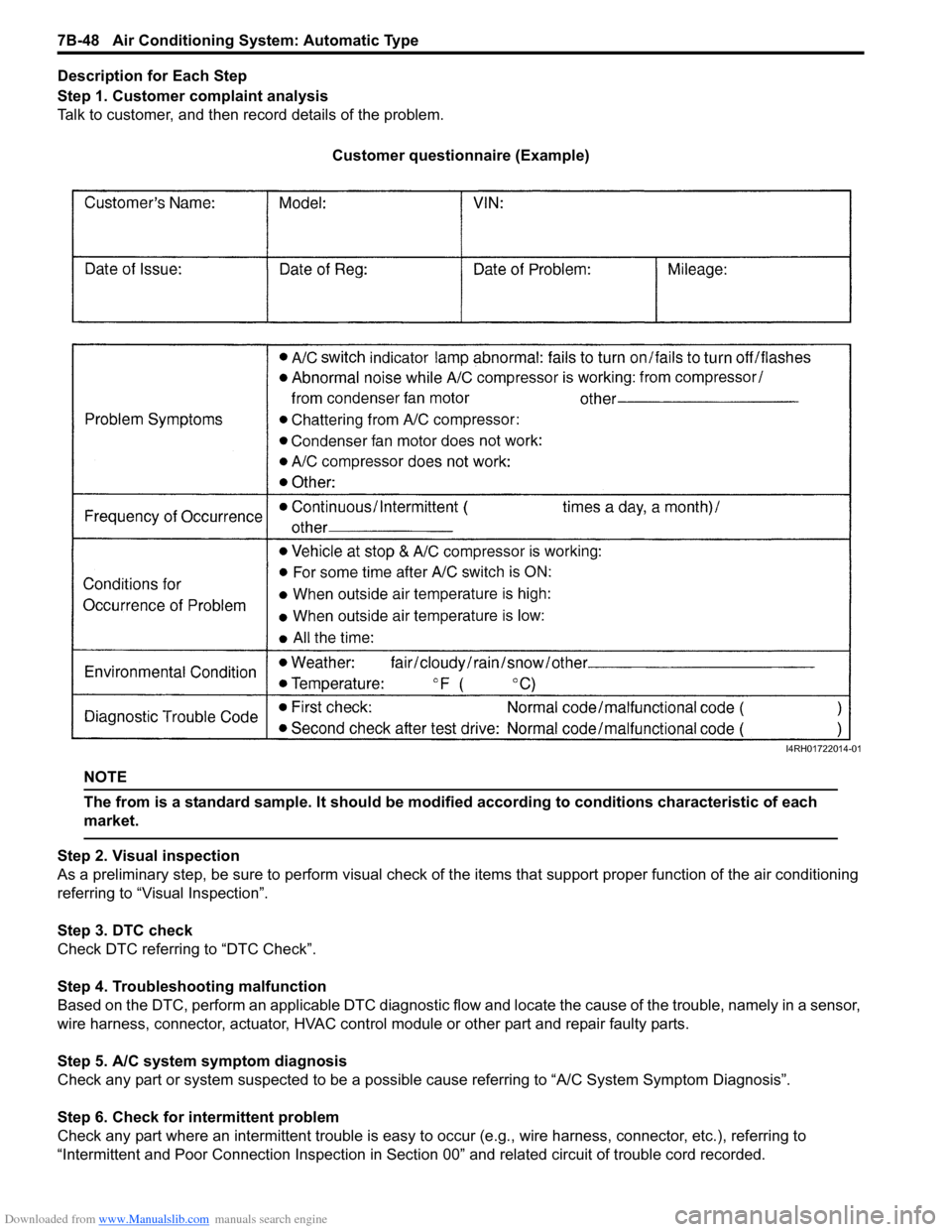

Description for Each Step

Step 1. Customer complaint analysis

Talk to customer, and then record details of the problem.

Customer questionnaire (Example)

NOTE

The from is a standard sample. It should be modified according to conditions characteristic of each

market.

Step 2. Visual inspection

As a preliminary step, be sure to perform visual check of th e items that support proper function of the air conditioning

referring to “Visual Inspection”.

Step 3. DTC check

Check DTC referring to “DTC Check”.

Step 4. Troubleshooting malfunction

Based on the DTC, perform an applicable DTC diagnostic flow and locate the cause of the trouble, namely in a sensor,

wire harness, connector, actuat or, HVAC control module or other part and repair faulty parts.

Step 5. A/C system symptom diagnosis

Check any part or system suspected to be a possible cause referring to “A/C System Symptom Diagnosis”.

Step 6. Check for intermittent problem

Check any part where an intermittent trouble is easy to oc cur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connection Inspection in Sect ion 00” and related circuit of trouble cord recorded.

I4RH01722014-01

Page 1010 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-62 Air Conditioning System: Automatic Type

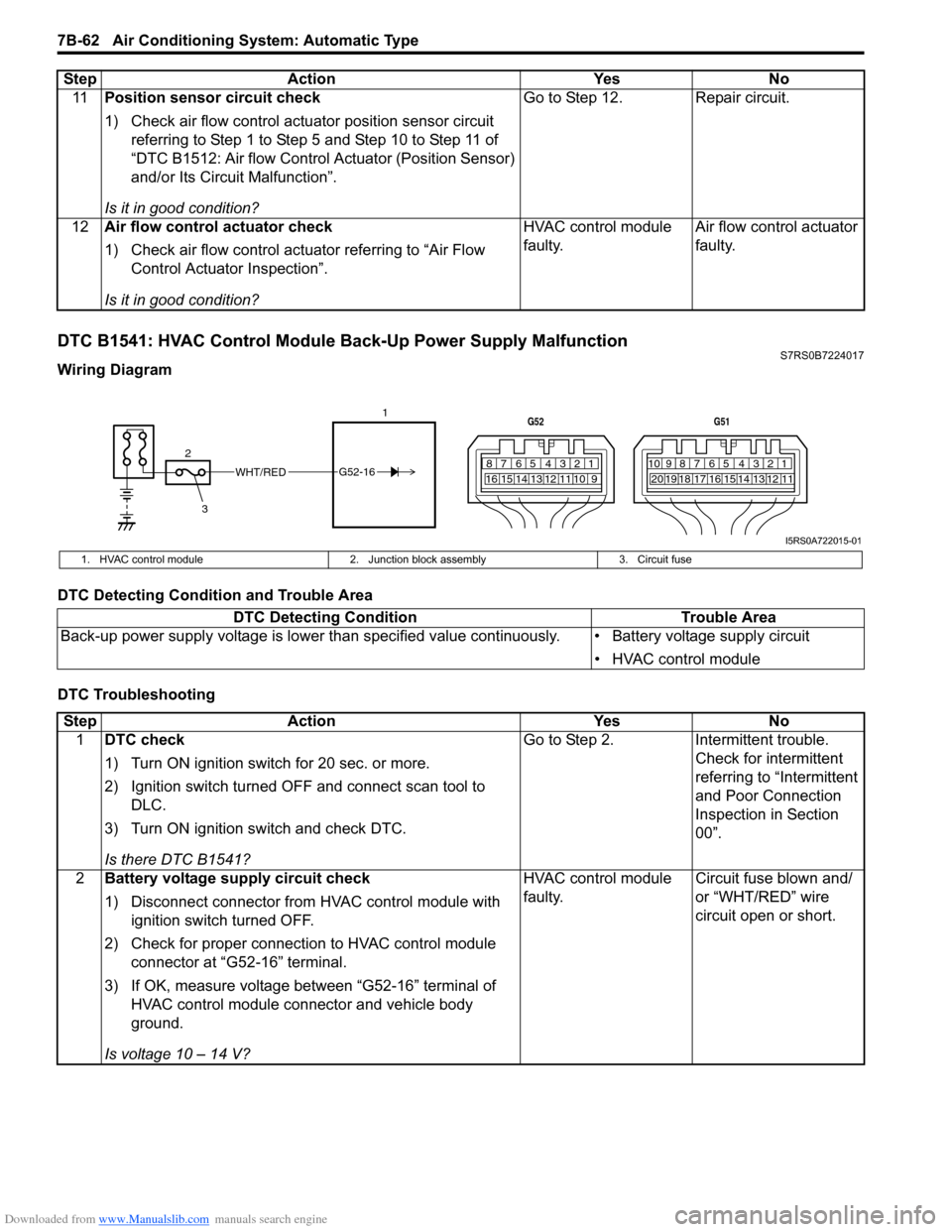

DTC B1541: HVAC Control Module Back-Up Power Supply MalfunctionS7RS0B7224017

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting11

Position sensor circuit check

1) Check air flow control actuator position sensor circuit

referring to Step 1 to Step 5 and Step 10 to Step 11 of

“DTC B1512: Air flow Control Actuator (Position Sensor)

and/or Its Circuit Malfunction”.

Is it in good condition? Go to Step 12. Repair circuit.

12 Air flow control actuator check

1) Check air flow control actuator referring to “Air Flow

Control Actuator Inspection”.

Is it in good condition? HVAC control module

faulty.

Air flow control actuator

faulty.

Step Action Yes No

WHT/RED

2 17812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

3

G52-16

I5RS0A722015-01

1. HVAC control module

2. Junction block assembly 3. Circuit fuse

DTC Detecting Condition Trouble Area

Back-up power supply voltage is lo wer than specified value continuously. • Battery voltage supply circuit

• HVAC control module

StepAction YesNo

1 DTC check

1) Turn ON ignition switch for 20 sec. or more.

2) Ignition switch turned OF F and connect scan tool to

DLC.

3) Turn ON ignition switch and check DTC.

Is there DTC B1541? Go to Step 2.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

2 Battery voltage supply circuit check

1) Disconnect connector from HVAC control module with

ignition switch turned OFF.

2) Check for proper connection to HVAC control module connector at “G52-16” terminal.

3) If OK, measure voltage between “G52-16” terminal of HVAC control module connector and vehicle body

ground.

Is voltage 10 – 14 V? HVAC control module

faulty.

Circuit fuse blown and/

or “WHT/RED” wire

circuit open or short.

Page 1013 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-65

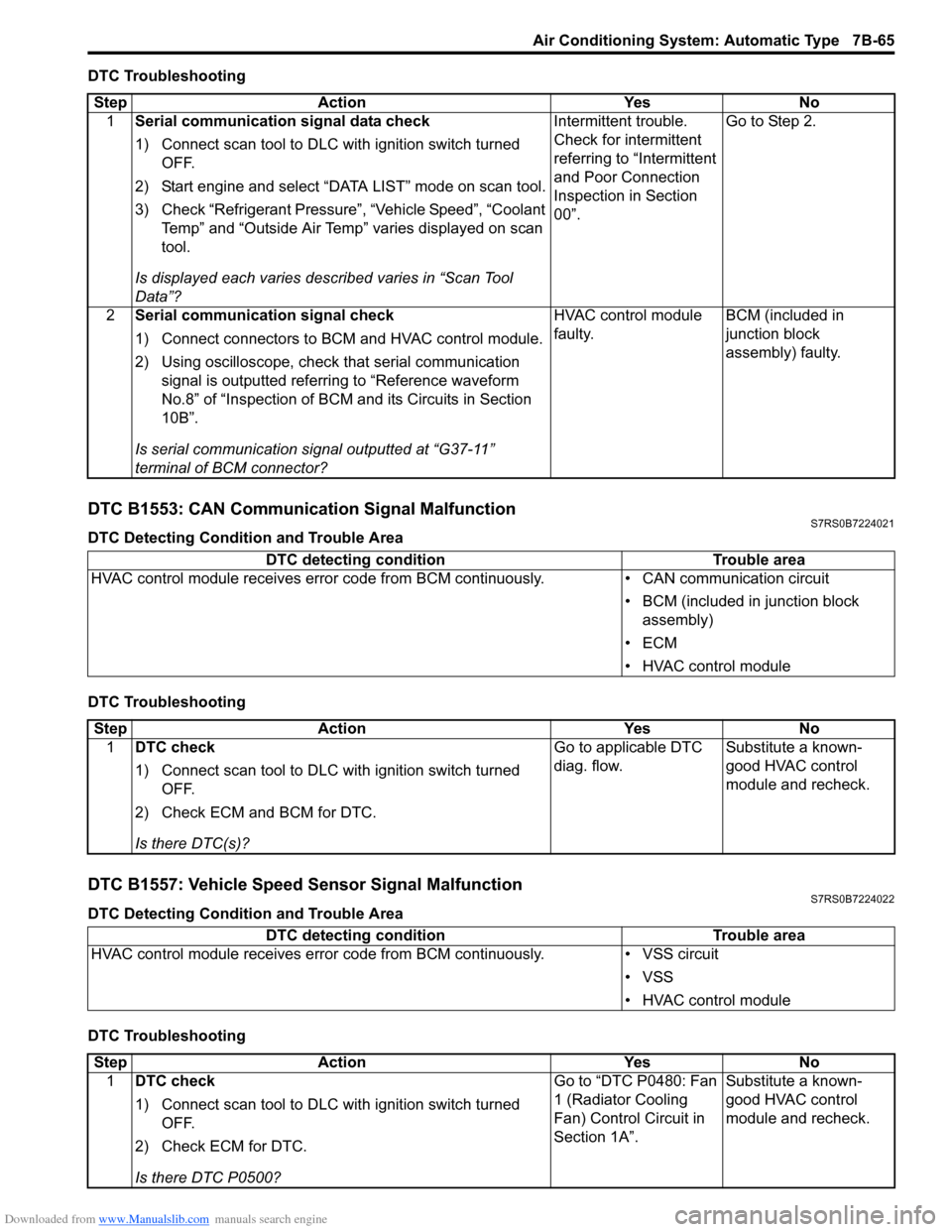

DTC Troubleshooting

DTC B1553: CAN Communication Signal MalfunctionS7RS0B7224021

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC B1557: Vehicle Speed Sensor Signal MalfunctionS7RS0B7224022

DTC Detecting Condition and Trouble Area

DTC TroubleshootingStep Action Yes No

1 Serial communication signal data check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Start engine and select “DATA LIST” mode on scan tool.

3) Check “Refrigerant Pressure”, “Vehicle Speed”, “Coolant Temp” and “Outside Air Temp” varies displayed on scan

tool.

Is displayed each va ries described varies in “Scan Tool

Data”? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 2.

2 Serial communication signal check

1) Connect connectors to BCM and HVAC control module.

2) Using oscilloscope, check that serial communication

signal is outputted referring to “Reference waveform

No.8” of “Inspection of BCM and its Circuits in Section

10B”.

Is serial communication signal outputted at “G37-11”

terminal of BCM connector? HVAC control module

faulty.

BCM (included in

junction block

assembly) faulty.

DTC detecting condition

Trouble area

HVAC control module receives error code fr om BCM continuously.• CAN communication circuit

• BCM (included in junction block assembly)

•ECM

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check ECM and BCM for DTC.

Is there DTC(s)? Go to applicable DTC

diag. flow.

Substitute a known-

good HVAC control

module and recheck.

DTC detecting condition

Trouble area

HVAC control module receives error code from BCM continuously. • VSS circuit

• VSS

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check ECM for DTC.

Is there DTC P0500? Go to “DTC P0480: Fan

1 (Radiator Cooling

Fan) Control Circuit in

Section 1A”.

Substitute a known-

good HVAC control

module and recheck.

Page 1030 of 1496

Downloaded from www.Manualslib.com manuals search engine 8-ii Table of Contents

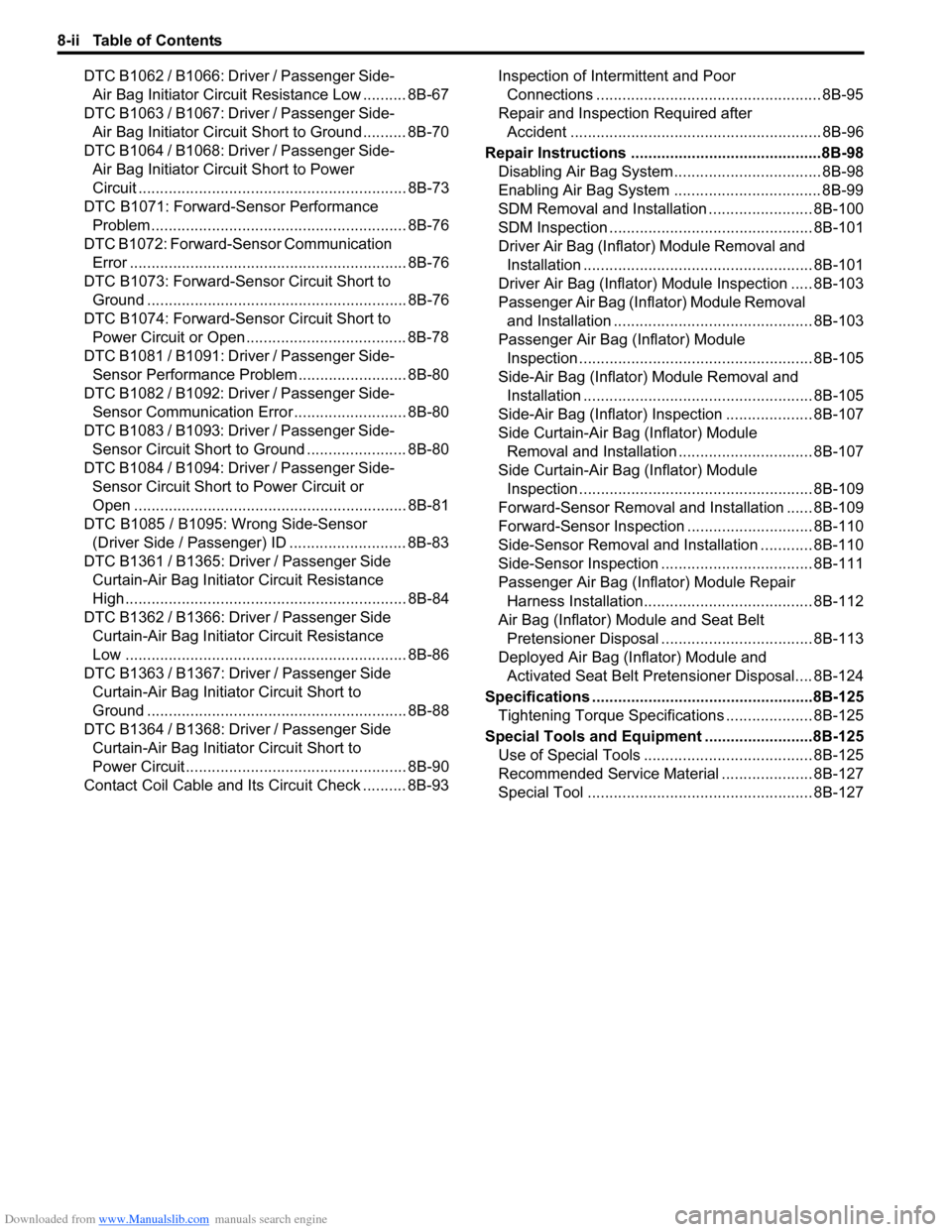

DTC B1062 / B1066: Driver / Passenger Side-Air Bag Initiator Circuit Resistance Low .......... 8B-67

DTC B1063 / B1067: Driver / Passenger Side- Air Bag Initiator Circuit S hort to Ground .......... 8B-70

DTC B1064 / B1068: Driver / Passenger Side- Air Bag Initiator Circu it Short to Power

Circuit .............................................................. 8B-73

DTC B1071: Forward-Sensor Performance Problem ........................................................... 8B-76

DTC B1072: Forward-Sensor Communication Error ................................................................ 8B-76

DTC B1073: Forward-Sensor Circuit Short to Ground ............................................................ 8B-76

DTC B1074: Forward-Sensor Circuit Short to Power Circuit or Open ..................................... 8B-78

DTC B1081 / B1091: Driver / Passenger Side- Sensor Performance Probl em ......................... 8B-80

DTC B1082 / B1092: Driver / Passenger Side- Sensor Communication Erro r .......................... 8B-80

DTC B1083 / B1093: Driver / Passenger Side- Sensor Circuit Short to Ground ....................... 8B-80

DTC B1084 / B1094: Driver / Passenger Side- Sensor Circuit Short to Power Circuit or

Open ............................................................... 8B-81

DTC B1085 / B1095: Wrong Side-Sensor (Driver Side / Passenger) ID ........................... 8B-83

DTC B1361 / B1365: Driver / Passenger Side Curtain-Air Bag Initiator Circuit Resistance

High ................................................................. 8B-84

DTC B1362 / B1366: Driver / Passenger Side Curtain-Air Bag Initiator Circuit Resistance

Low ................................................................. 8B-86

DTC B1363 / B1367: Driver / Passenger Side Curtain-Air Bag Initiator Circuit Short to

Ground ............................................................ 8B-88

DTC B1364 / B1368: Driver / Passenger Side Curtain-Air Bag Initiator Circuit Short to

Power Circuit ................................................... 8B-90

Contact Coil Cable and Its Circuit Check .......... 8B-93 Inspection of Intermittent and Poor

Connections .................................................... 8B-95

Repair and Inspection Required after Accident .......................................................... 8B-96

Repair Instructions ............ ................................8B-98

Disabling Air Bag System.................................. 8B-98

Enabling Air Bag System .................................. 8B-99

SDM Removal and Installation ........................ 8B-100

SDM Inspection ............................................... 8B-101

Driver Air Bag (Inflato r) Module Removal and

Installation ..................................................... 8B-101

Driver Air Bag (Inflator) Module Inspection ..... 8B-103

Passenger Air Bag (Inflator) Module Removal and Installation .............................................. 8B-103

Passenger Air Bag (I nflator) Module

Inspection ...................................................... 8B-105

Side-Air Bag (Inflator) Module Removal and

Installation ..................................................... 8B-105

Side-Air Bag (Inflator) Inspection .................... 8B-107

Side Curtain-Air Bag (Inflator) Module Removal and Installation ............................... 8B-107

Side Curtain-Air Bag (Inflator) Module Inspection ...................................................... 8B-109

Forward-Sensor Removal and Installation ...... 8B-109

Forward-Sensor In spection ............................. 8B-110

Side-Sensor Removal and Installation ............ 8B-110

Side-Sensor Inspection ................................... 8B-111

Passenger Air Bag (Inflator) Module Repair

Harness Installation....................................... 8B-112

Air Bag (Inflator) Module and Seat Belt Pretensioner Disposal ................................... 8B-113

Deployed Air Bag (Inflator) Module and Activated Seat Belt Pretensioner Disposal.... 8B-124

Specifications .................. .................................8B-125

Tightening Torque Specifications .................... 8B-125

Special Tools and Equipmen t .........................8B-125

Use of Special Tools ....................................... 8B-125

Recommended Service Material ..................... 8B-127

Special Tool .................................................... 8B-127