main SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 376 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-1 Fuel System:

Engine

Fuel System

Precautions

Precautions on Fuel System ServiceS7RS0B1700001

WARNING!

Before attempting service of any type on fuel system, the following should be always observed in

order to reduce the risk of fire and personal injury.

• Disconnect negative cable at battery.

• Do not smoke, and place no smoking signs near work area.

• Be sure to have CO

2 fire extinguisher handy.

• Be sure to perform work in a well-ventilated area and away from any open flames (such as gas hot heater).

• Wear safety glasses.

• To relieve fuel vapor pressure in fuel tank, remove fuel filler cap from fuel filler neck and then

reinstall it.

• As fuel feed line is still under high fuel pr essure even after stopping engine, loosening or

disconnecting fuel feed line directly may cause dangerous spout of fuel. Before loosening or

disconnecting fuel feed line, make sure to relieve fuel pressure referring to “Fuel Pressure Relief

Procedure”.

• A small amount of fuel may be released when the fuel line is disconnected. In order to reduce the risk of personal injury, cover a shop cloth to the fitting to be disconnected. Be sure to put that cloth

in an approved container after disconnecting.

• Never run engine with fuel pump relay disconnected when engine and exhaust system are hot.

• Note that fuel hose connection varies with each type of pipe. Be sure to connect and clamp each hose correctly referring to “Fuel Hose Disconnecting and Reconnecting”.

After connecting, make sure that it has no twist or kink.

• When installing inje ctor or fuel feed pipe, lubr icate its O-ring with gasoline.

General Description

Fuel System DescriptionS7RS0B1701001

CAUTION!

This engine requires the unleaded fuel only.

The leaded and/or low lead fuel can result in

engine damage and reduce the effectiveness

of the emission control system.

The main components of the fuel system are fuel tank,

fuel pump assembly (with fuel filter, fuel level gauge, fuel

pressure regulator, fuel feed line and fuel vapor line.

For the details of fuel flow, refer to “Fuel Delivery System

Diagram”.

Fuel Delivery System DescriptionS7RS0B1701002

The fuel delivery system consists of the fuel tank, fuel

pump assembly (with built-in f uel filter and fuel pressure

regulator), delivery pipe, injectors and fuel feed line.

The fuel in the fuel tank is pumped up by the fuel pump,

sent into delivery pipe and injected by the injectors.

As the fuel pump assembly is equipped with built-in fuel

filter and fuel pressure regulator, the fuel is filtered and

its pressure is regulated before being sent to the feed

pipe.

The excess fuel at fuel pressure regulation process is

returned back into the fuel tank.

Also, fuel vapor generated in fuel tank is led through the

fuel vapor line into the EVAP canister.

For system diagram, refer to “Fuel Delivery System

Diagram”.

Page 377 of 1496

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-2

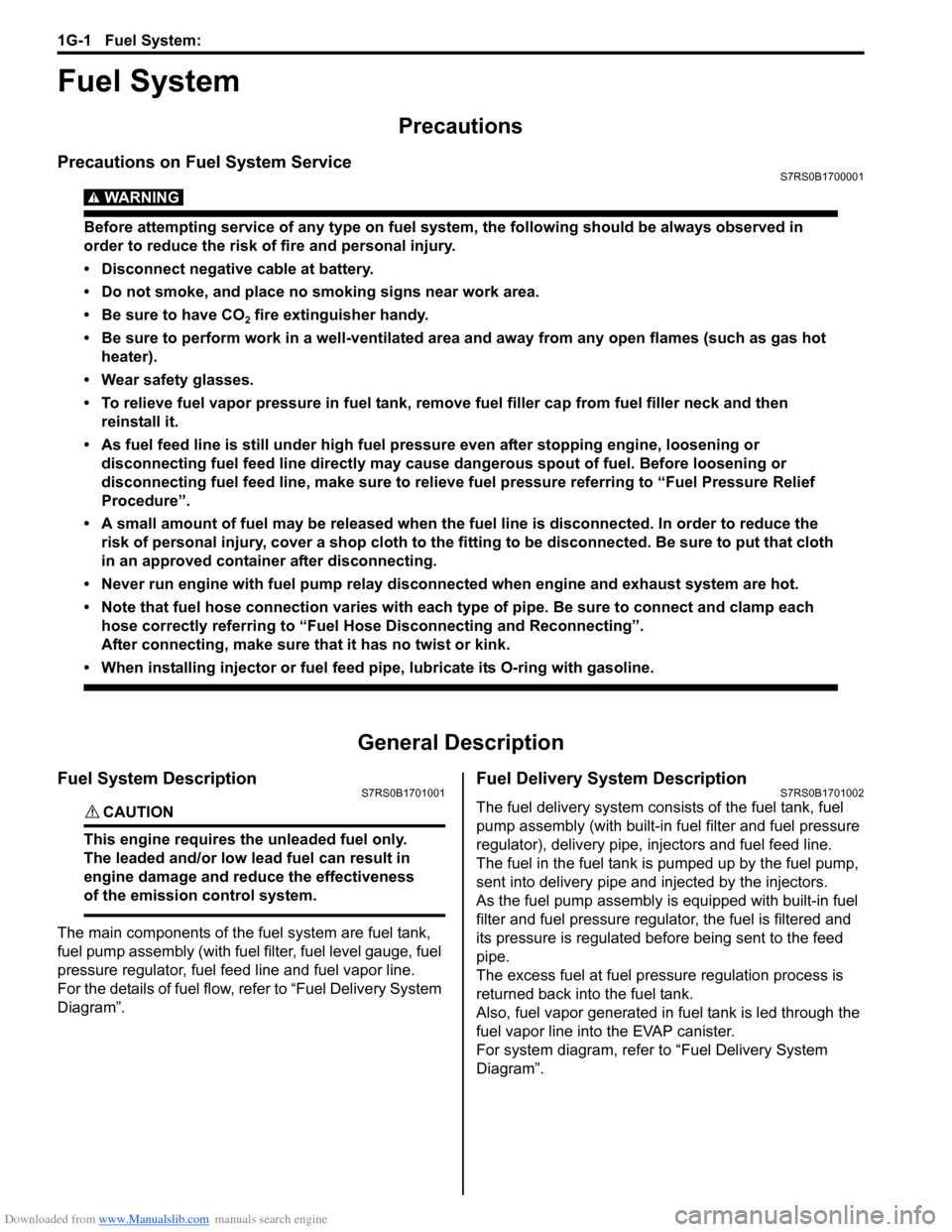

Fuel Pump DescriptionS7RS0B1701003

The fuel pump (1) is an in-tank type electric pump.

Incorporated in the pump assembly are;

a fuel filter (2) and a fuel pressure regulator (3) are

included and a fuel level gauge (4) is attached.

Addition of the fuel pressure regulator to the fuel pump

makes it possible to mainta in the fuel pressure at

constant level and ECM controls compensation for

variation in the intake manifold pressure.

Schematic and Routing Diagram

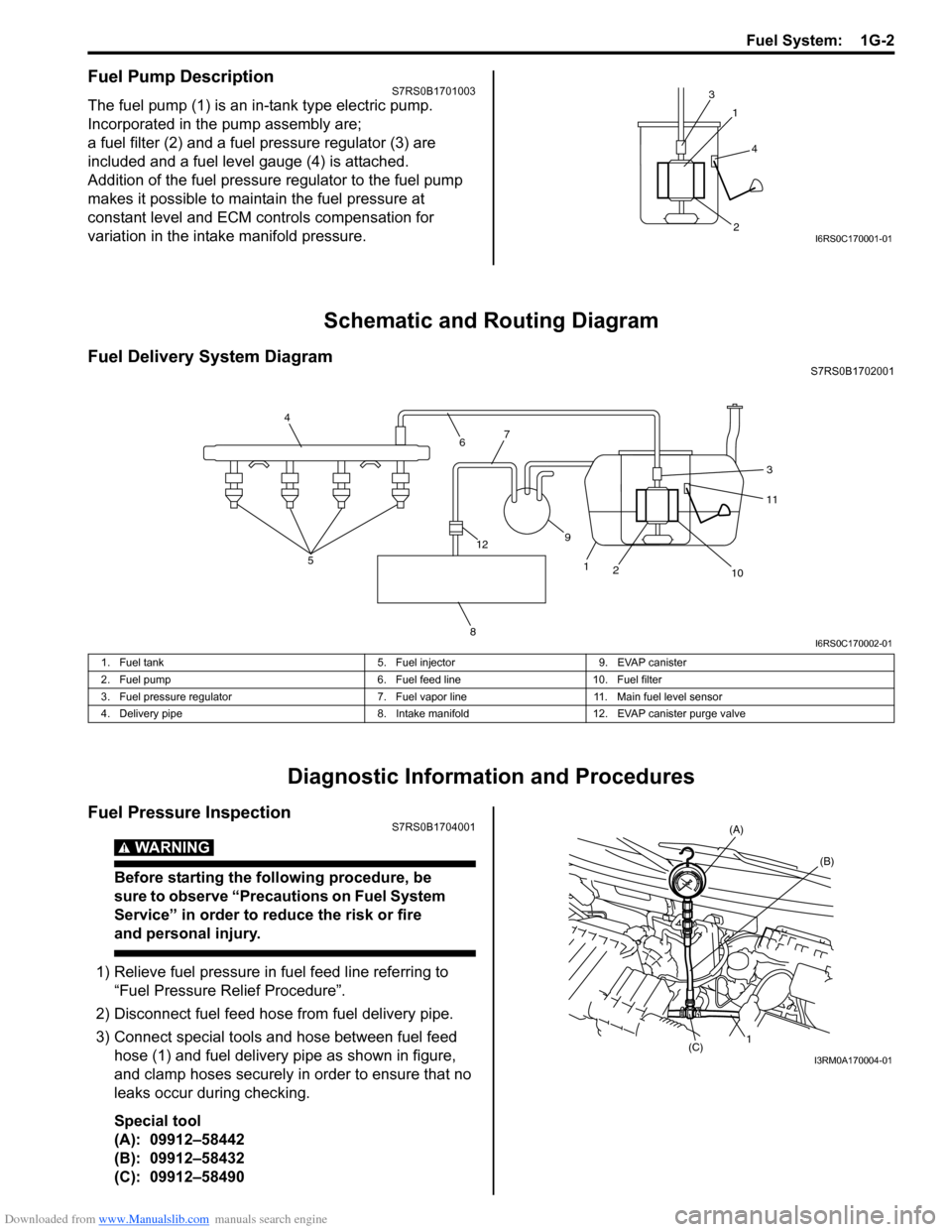

Fuel Delivery System DiagramS7RS0B1702001

Diagnostic Information and Procedures

Fuel Pressure InspectionS7RS0B1704001

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

1) Relieve fuel pressure in fuel feed line referring to

“Fuel Pressure Relief Procedure”.

2) Disconnect fuel feed hose from fuel delivery pipe.

3) Connect special tools and hose between fuel feed hose (1) and fuel delivery pipe as shown in figure,

and clamp hoses securely in order to ensure that no

leaks occur during checking.

Special tool

(A): 09912–58442

(B): 09912–58432

(C): 09912–58490

1

3

2

4

I6RS0C170001-01

4

6 7

8

12

2 3

11

10

5

1

9

I6RS0C170002-01

1. Fuel tank

5. Fuel injector9. EVAP canister

2. Fuel pump 6. Fuel feed line10. Fuel filter

3. Fuel pressure regulator 7. Fuel vapor line 11. Main fuel level sensor

4. Delivery pipe 8. Intake manifold12. EVAP canister purge valve

1

(C) (B)

(A)

I3RM0A170004-01

Page 379 of 1496

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-4

Repair Instructions

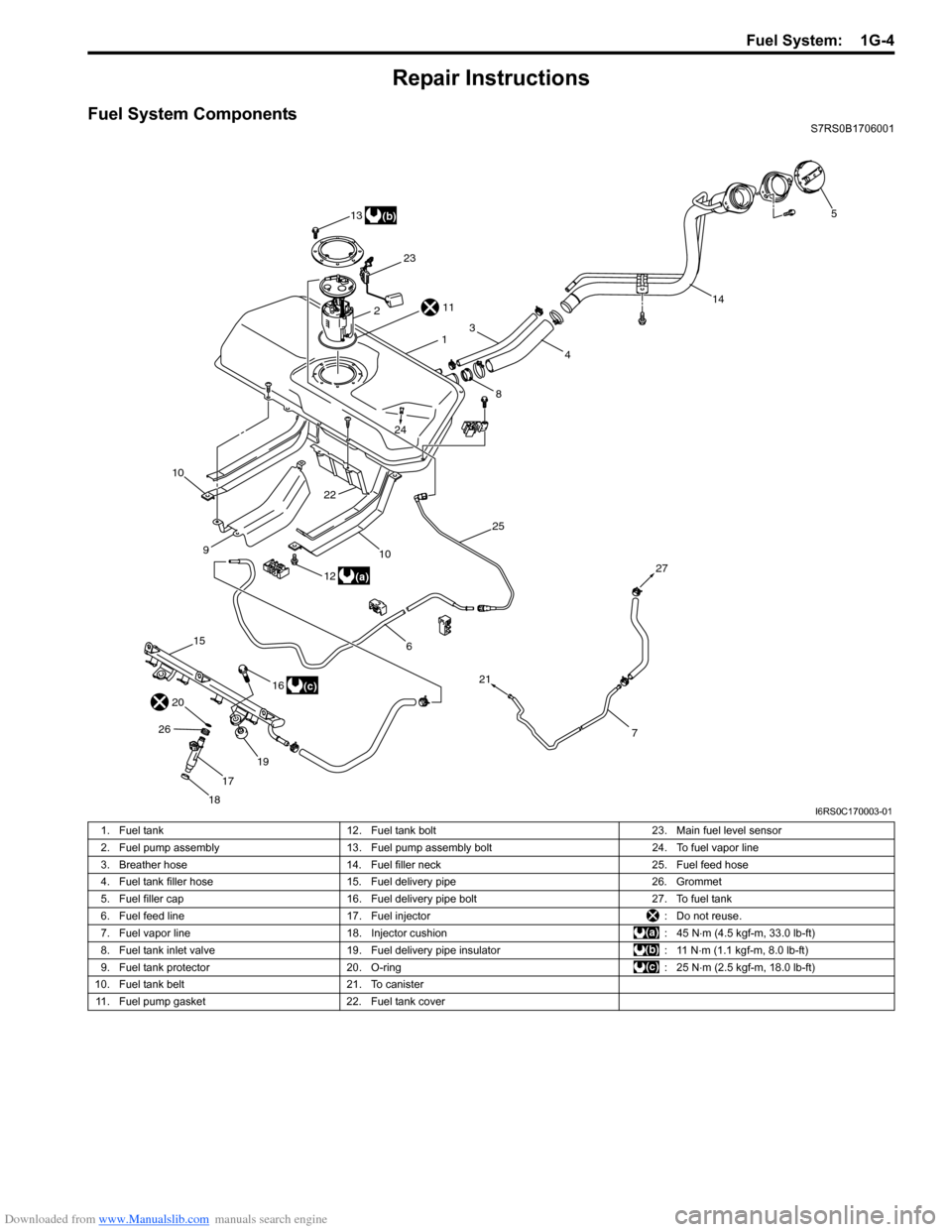

Fuel System ComponentsS7RS0B1706001

5

14

4

24

8

3

13

23

1

25

21

112

22 10

6

16

26

18

17

19

10

12

9

(b)

(a)

15

(c)

20 27

7

I6RS0C170003-01

1. Fuel tank 12. Fuel tank bolt 23. Main fuel level sensor

2. Fuel pump assembly 13. Fuel pump assembly bolt 24. To fuel vapor line

3. Breather hose 14. Fuel filler neck 25. Fuel feed hose

4. Fuel tank filler hose 15. Fuel delivery pipe 26. Grommet

5. Fuel filler cap 16. Fuel delivery pipe bolt 27. To fuel tank

6. Fuel feed line 17. Fuel injector : Do not reuse.

7. Fuel vapor line 18. Injector cushion : 45 N⋅m (4.5 kgf-m, 33.0 lb-ft)

8. Fuel tank inlet valve 19. Fuel delivery pipe insulator : 11 N⋅m (1.1 kgf-m, 8.0 lb-ft)

9. Fuel tank protector 20. O-ring : 25 N⋅m (2.5 kgf-m, 18.0 lb-ft)

10. Fuel tank belt 21. To canister

11. Fuel pump gasket 22. Fuel tank cover

Page 389 of 1496

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-14

Fuel Tank Purging ProcedureS7RS0B1706015

WARNING!

• Before starting the following procedure, be sure to observe “Precautions on Fuel

System Service” in order to reduce the risk

or fire and personal injury.

• This purging procedure will not remove all fuel vapor.

Do not attempt any repair on tank using

heat of flame as an explosion resulting in

personal injury could occur.

CAUTION!

Never remain water in fu el tank after washing,

or fuel tank inside will get corrosion.

The following procedure are used for purging fuel tank.

1) After removing fuel tank, remove all hoses, pipes and fuel pump assembly from fuel tank.

2) Drain all remaining fuel from tank.

3) Place fuel tank to flushing area.

4) Fill tank with warm water or tap water, and agitate

vigorously and drain. Repeat this washing until

inside of tank is clean. Replace tank if its inside is

rusty.

5) Completely flush out rema ining water after washing.

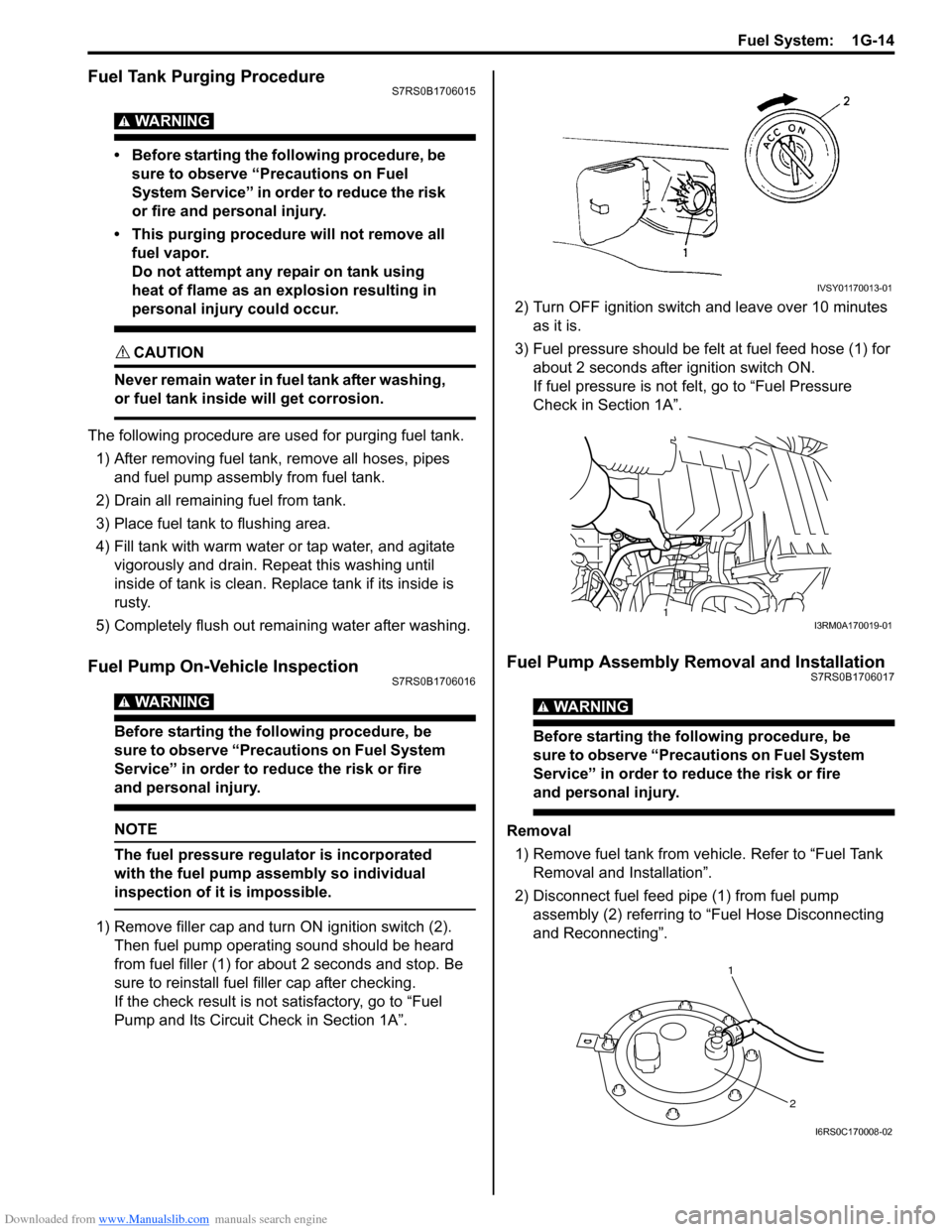

Fuel Pump On-Vehicle InspectionS7RS0B1706016

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

NOTE

The fuel pressure regulator is incorporated

with the fuel pump assembly so individual

inspection of it is impossible.

1) Remove filler cap and turn ON ignition switch (2).

Then fuel pump operating sound should be heard

from fuel filler (1) for about 2 seconds and stop. Be

sure to reinstall fuel filler cap after checking.

If the check result is not satisfactory, go to “Fuel

Pump and Its Circuit Check in Section 1A”. 2) Turn OFF ignition switch and leave over 10 minutes

as it is.

3) Fuel pressure should be felt at fuel feed hose (1) for about 2 seconds after ignition switch ON.

If fuel pressure is not felt, go to “Fuel Pressure

Check in Section 1A”.

Fuel Pump Assembly Removal and InstallationS7RS0B1706017

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

Removal

1) Remove fuel tank from vehicle. Refer to “Fuel Tank Removal and Installation”.

2) Disconnect fuel feed pipe (1) from fuel pump assembly (2) referring to “Fuel Hose Disconnecting

and Reconnecting”.

IVSY01170013-01

1I3RM0A170019-01

1

2

I6RS0C170008-02

Page 390 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-15 Fuel System:

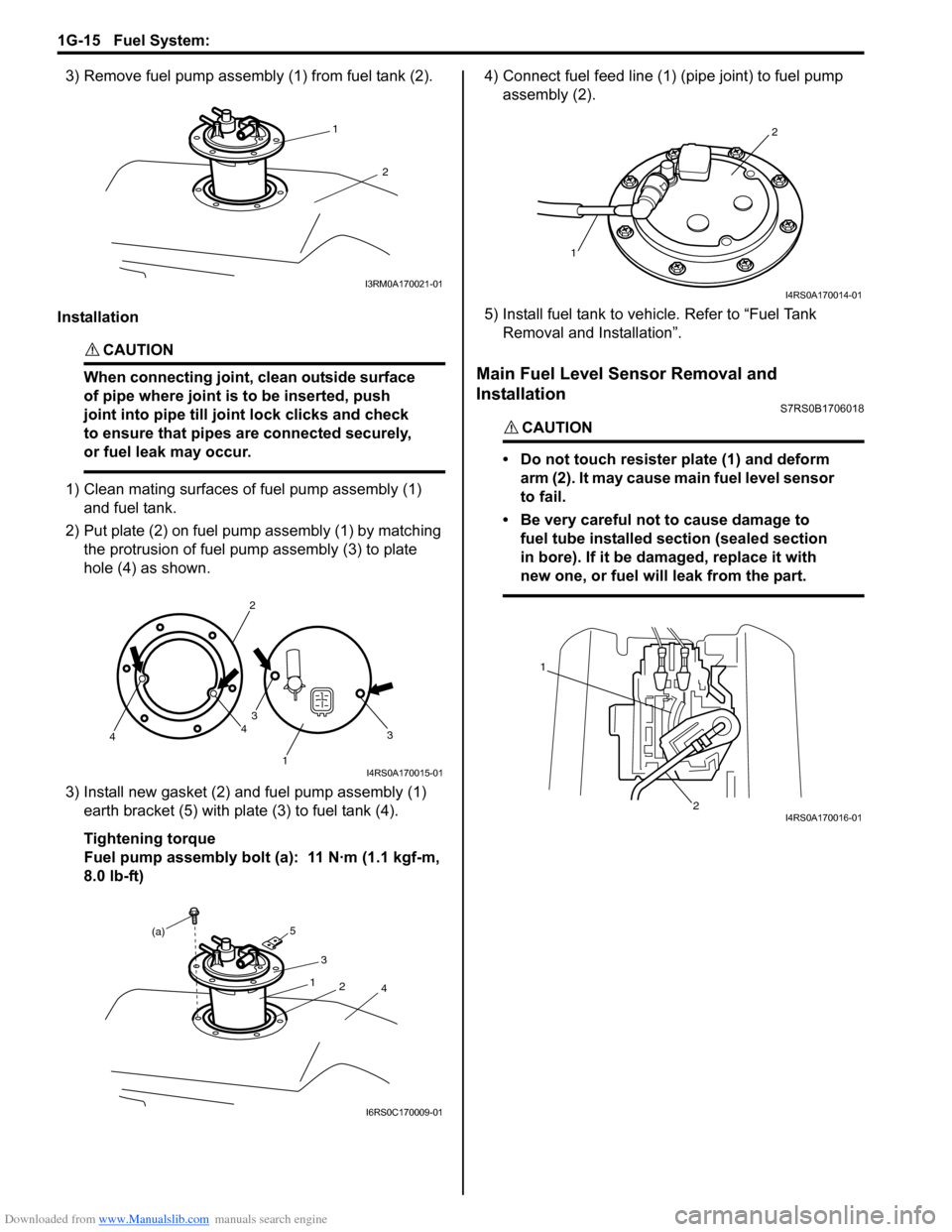

3) Remove fuel pump assembly (1) from fuel tank (2).

Installation

CAUTION!

When connecting joint, clean outside surface

of pipe where joint is to be inserted, push

joint into pipe till jo int lock clicks and check

to ensure that pipes are connected securely,

or fuel leak may occur.

1) Clean mating surfaces of fuel pump assembly (1) and fuel tank.

2) Put plate (2) on fuel pump assembly (1) by matching the protrusion of fuel pump assembly (3) to plate

hole (4) as shown.

3) Install new gasket (2) and fuel pump assembly (1) earth bracket (5) with plate (3) to fuel tank (4).

Tightening torque

Fuel pump assembly bolt (a): 11 N·m (1.1 kgf-m,

8.0 lb-ft) 4) Connect fuel feed line (1) (pipe joint) to fuel pump

assembly (2).

5) Install fuel tank to vehi cle. Refer to “Fuel Tank

Removal and Installation”.

Main Fuel Level Sensor Removal and

Installation

S7RS0B1706018

CAUTION!

• Do not touch resister plate (1) and deform arm (2). It may cause main fuel level sensor

to fail.

• Be very careful not to cause damage to fuel tube installed section (sealed section

in bore). If it be damaged, replace it with

new one, or fuel will leak from the part.

1

2

I3RM0A170021-01

3

1

3

2

44

I4RS0A170015-01

3

1 2

(a)

4

5

I6RS0C170009-01

2

1

I4RS0A170014-01

1

2I4RS0A170016-01

Page 391 of 1496

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-16

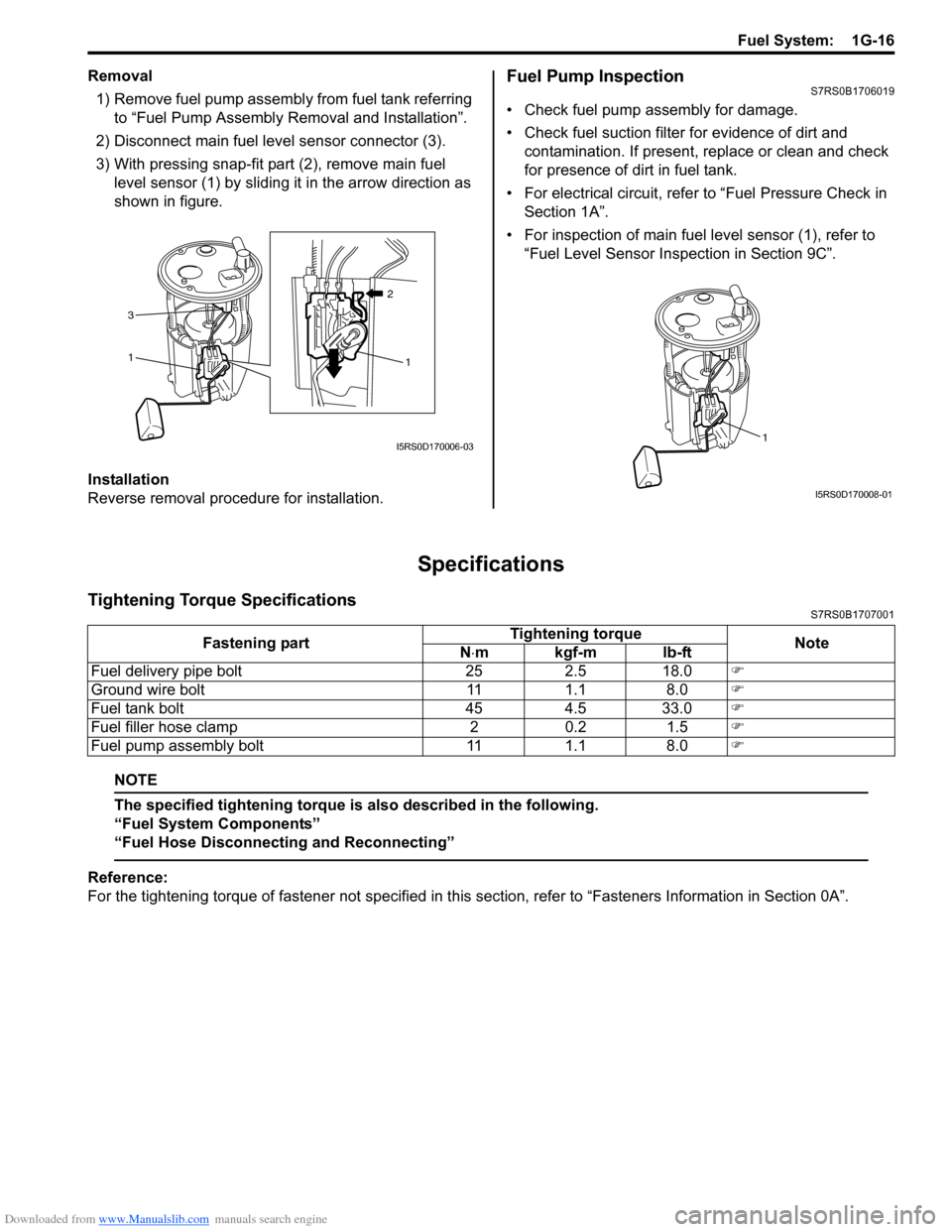

Removal1) Remove fuel pump assembly from fuel tank referring to “Fuel Pump Assembly Removal and Installation”.

2) Disconnect main fuel level sensor connector (3).

3) With pressing snap-fit part (2), remove main fuel level sensor (1) by sliding it in the arrow direction as

shown in figure.

Installation

Reverse removal procedure for installation.Fuel Pump InspectionS7RS0B1706019

• Check fuel pump assembly for damage.

• Check fuel suction filter for evidence of dirt and contamination. If present, replace or clean and check

for presence of dirt in fuel tank.

• For electrical circuit, refer to “Fuel Pressure Check in Section 1A”.

• For inspection of main fuel level sensor (1), refer to “Fuel Level Sensor Inspection in Section 9C”.

Specifications

Tightening Torque SpecificationsS7RS0B1707001

NOTE

The specified tightening torque is also described in the following.

“Fuel System Components”

“Fuel Hose Disconnecting and Reconnecting”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

1

21

3

I5RS0D170006-031

I5RS0D170008-01

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Fuel delivery pipe bolt 25 2.5 18.0 �)

Ground wire bolt 11 1.1 8.0 �)

Fuel tank bolt 45 4.5 33.0 �)

Fuel filler hose clamp 2 0.2 1.5 �)

Fuel pump assembly bolt 11 1.1 8.0 �)

Page 394 of 1496

Downloaded from www.Manualslib.com manuals search engine 1H-2 Ignition System:

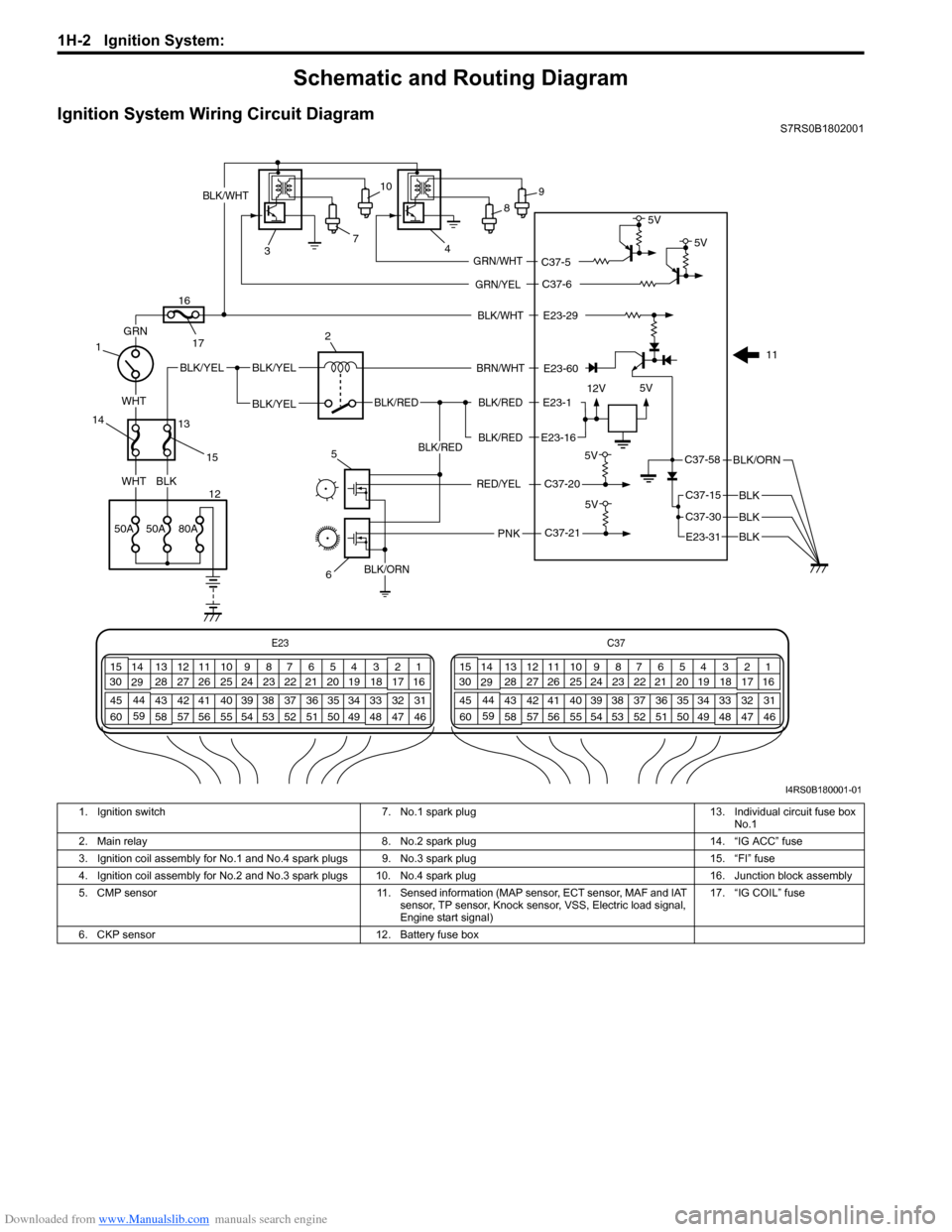

Schematic and Routing Diagram

Ignition System Wiring Circuit DiagramS7RS0B1802001

E23-60

E23-29 12V 5V

5V

E23-1

E23-16

BLK/WHT

BLK/RED

BLK/RED BLK/RED

BLK/YELBLK/YEL

BLK/YEL

GRN

BLKWHT

WHT

BRN/WHT

BLK/ORN

BLK

BLK

C37-20

BLK/RED

PNK

5V

C37-21

BLK/WHT

7

3 4

1

12 5

6

2

11

8

9

10

GRN/YEL

GRN/WHT

C37-6

C37-5 5V

5V

RED/YEL

C37-58

C37-15

C37-30

E23

C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

13

14

15

16

17

50A50A80A

BLK/ORN

E23-31 BLK

I4RS0B180001-01

1. Ignition switch 7. No.1 spark plug 13. Individual circuit fuse box

No.1

2. Main relay 8. No.2 spark plug 14. “IG ACC” fuse

3. Ignition coil assembly for No.1 and No.4 spark plugs 9. No.3 spark plug 15. “FI” fuse

4. Ignition coil assembly for No.2 and No.3 spark plugs 10. No.4 spark plug 16. Junction block assembly

5. CMP sensor 11. Sensed information (MAP sensor, ECT sensor, MAF and IAT

sensor, TP sensor, Knock sensor, VSS, Electric load signal,

Engine start signal) 17. “IG COIL” fuse

6. CKP sensor 12. Battery fuse box

Page 403 of 1496

Downloaded from www.Manualslib.com manuals search engine Starting System: 1I-2

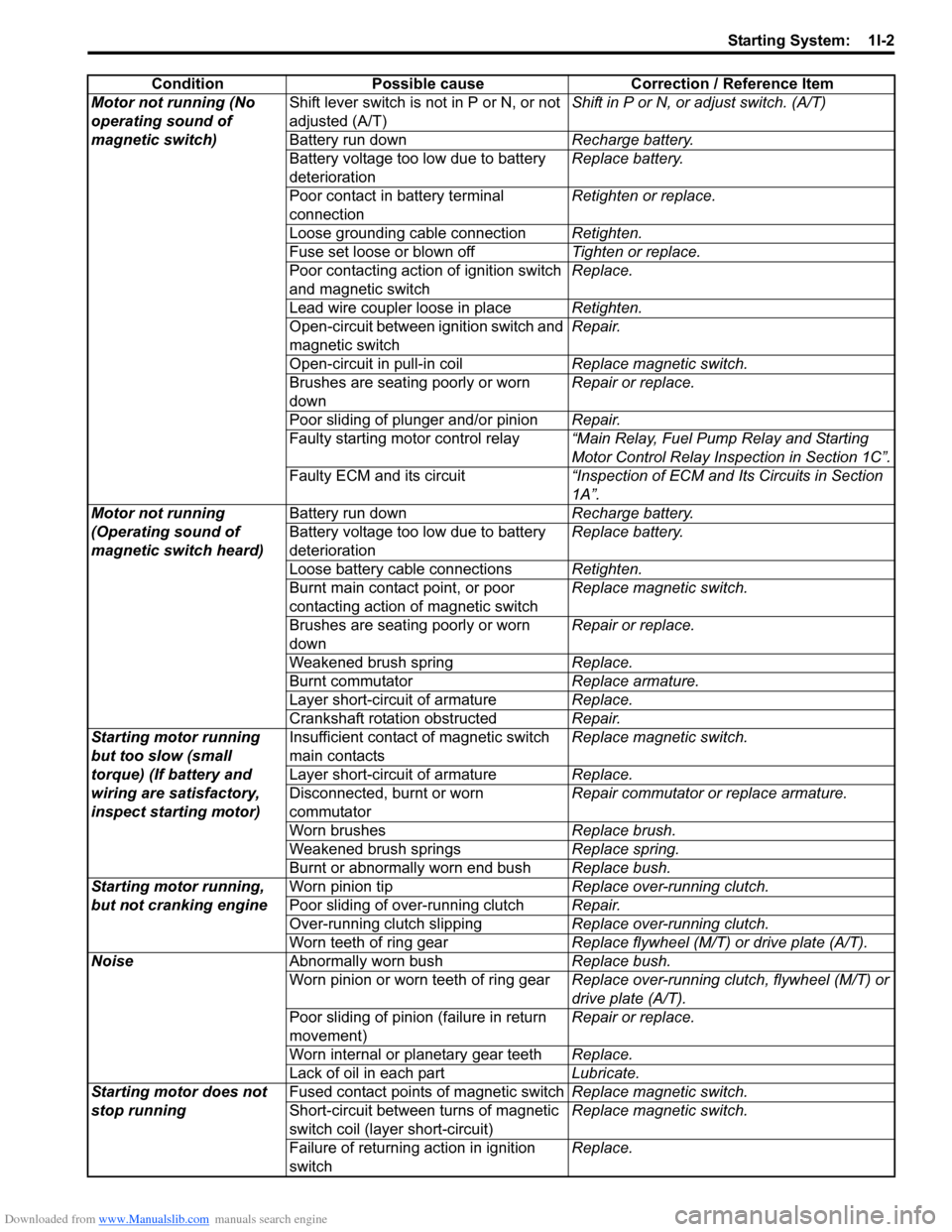

ConditionPossible cause Correction / Reference Item

Motor not running (No

operating sound of

magnetic switch) Shift lever switch is not in P or N, or not

adjusted (A/T)

Shift in P or N, or

adjust switch. (A/T)

Battery run down Recharge battery.

Battery voltage too low due to battery

deterioration Replace battery.

Poor contact in battery terminal

connection Retighten or replace.

Loose grounding cable connection Retighten.

Fuse set loose or blown off Tighten or replace.

Poor contacting action of ignition switch

and magnetic switch Replace.

Lead wire coupler loose in place Retighten.

Open-circuit between ignition switch and

magnetic switch Repair.

Open-circuit in pull-in coil Replace magnetic switch.

Brushes are seating poorly or worn

down Repair or replace.

Poor sliding of plunger and/or pinion Repair.

Faulty starting motor control relay “Main Relay, Fuel Pump Relay and Starting

Motor Control Relay Inspection in Section 1C”.

Faulty ECM and its circuit “Inspection of ECM and Its Circuits in Section

1A”.

Motor not running

(Operating sound of

magnetic switch heard) Battery run down

Recharge battery.

Battery voltage too low due to battery

deterioration Replace battery.

Loose battery cable connections Retighten.

Burnt main contact point, or poor

contacting action of magnetic switch Replace magnetic switch.

Brushes are seating poorly or worn

down Repair or replace.

Weakened brush spring Replace.

Burnt commutator Replace armature.

Layer short-circuit of armature Replace.

Crankshaft rotation obstructed Repair.

Starting motor running

but too slow (small

torque) (If battery and

wiring are satisfactory,

inspect starting motor) Insufficient contact

of magnetic switch

main contacts Replace magnetic switch.

Layer short-circuit of armature Replace.

Disconnected, burnt or worn

commutator Repair commutator or replace armature.

Worn brushes Replace brush.

Weakened brush springs Replace spring.

Burnt or abnormally worn end bush Replace bush.

Starting motor running,

but not cranking engine Worn pinion tip

Replace over-running clutch.

Poor sliding of over-running clutch Repair.

Over-running clutch slipping Replace over-running clutch.

Worn teeth of ring gear Replace flywheel (M/T) or drive plate (A/T).

Noise Abnormally worn bush Replace bush.

Worn pinion or worn teeth of ring gear Replace over-running clutch, flywheel (M/T) or

drive plate (A/T).

Poor sliding of pinion (failure in return

movement) Repair or replace.

Worn internal or planetary gear teeth Replace.

Lack of oil in each part Lubricate.

Starting motor does not

stop running Fused contact points of magnetic switch

Replace magnetic switch.

Short-circuit between turns of magnetic

switch coil (layer short-circuit) Replace magnetic switch.

Failure of returning action in ignition

switch Replace.

Page 404 of 1496

Downloaded from www.Manualslib.com manuals search engine 1I-3 Starting System:

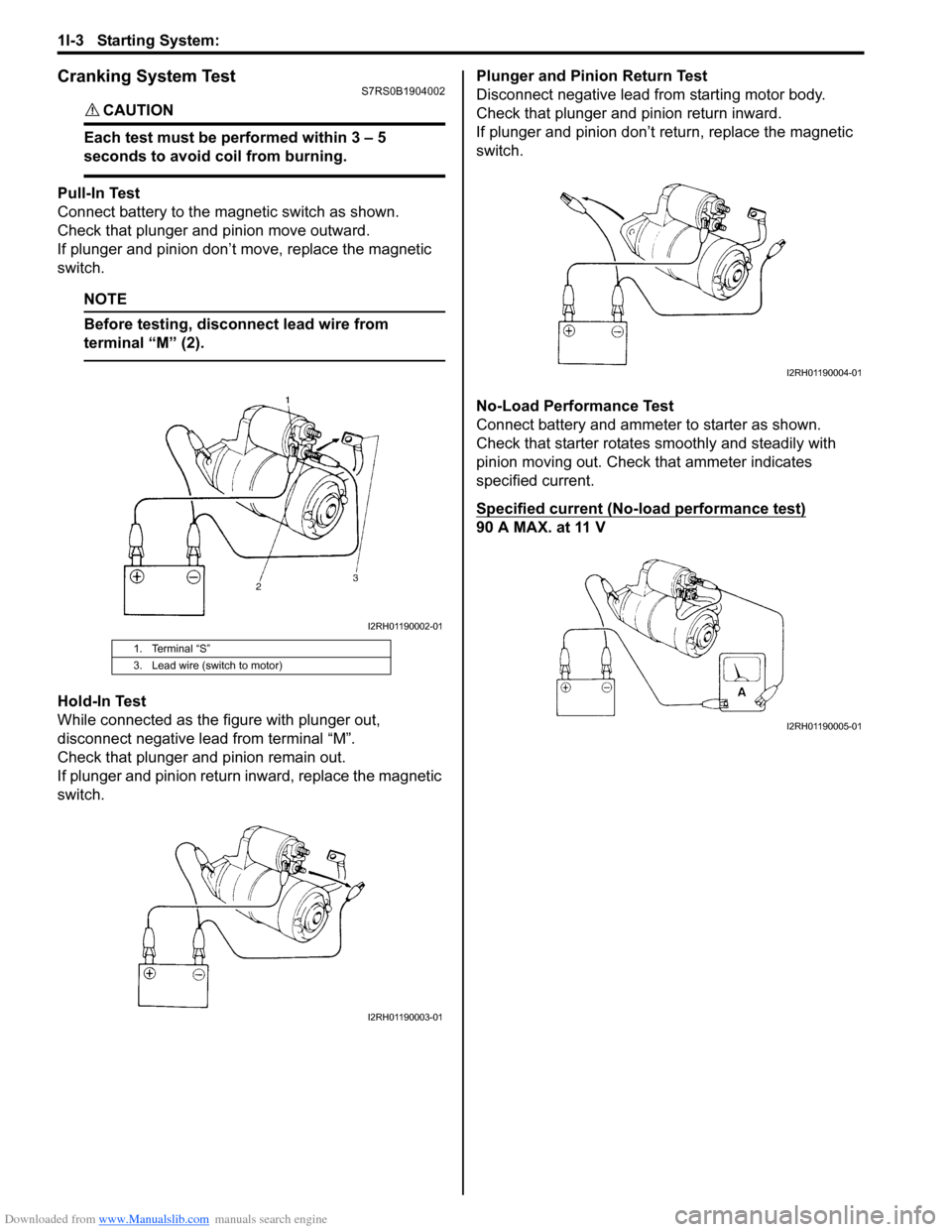

Cranking System TestS7RS0B1904002

CAUTION!

Each test must be performed within 3 – 5

seconds to avoid coil from burning.

Pull-In Test

Connect battery to the magnetic switch as shown.

Check that plunger and pinion move outward.

If plunger and pinion don’t move, replace the magnetic

switch.

NOTE

Before testing, disconnect lead wire from

terminal “M” (2).

Hold-In Test

While connected as the figure with plunger out,

disconnect negative lead from terminal “M”.

Check that plunger and pinion remain out.

If plunger and pinion return inward, replace the magnetic

switch. Plunger and Pinion Return Test

Disconnect negative lead from starting motor body.

Check that plunger and pinion return inward.

If plunger and pinion don’t return, replace the magnetic

switch.

No-Load Performance Test

Connect battery and ammeter to starter as shown.

Check that starter rotates

smoothly and steadily with

pinion moving out. Check that ammeter indicates

specified current.

Specified current (No-load performance test)

90 A MAX. at 11 V

1. Terminal “S”

3. Lead wire (switch to motor)

I2RH01190002-01

I2RH01190003-01

I2RH01190004-01

I2RH01190005-01

Page 413 of 1496

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-3

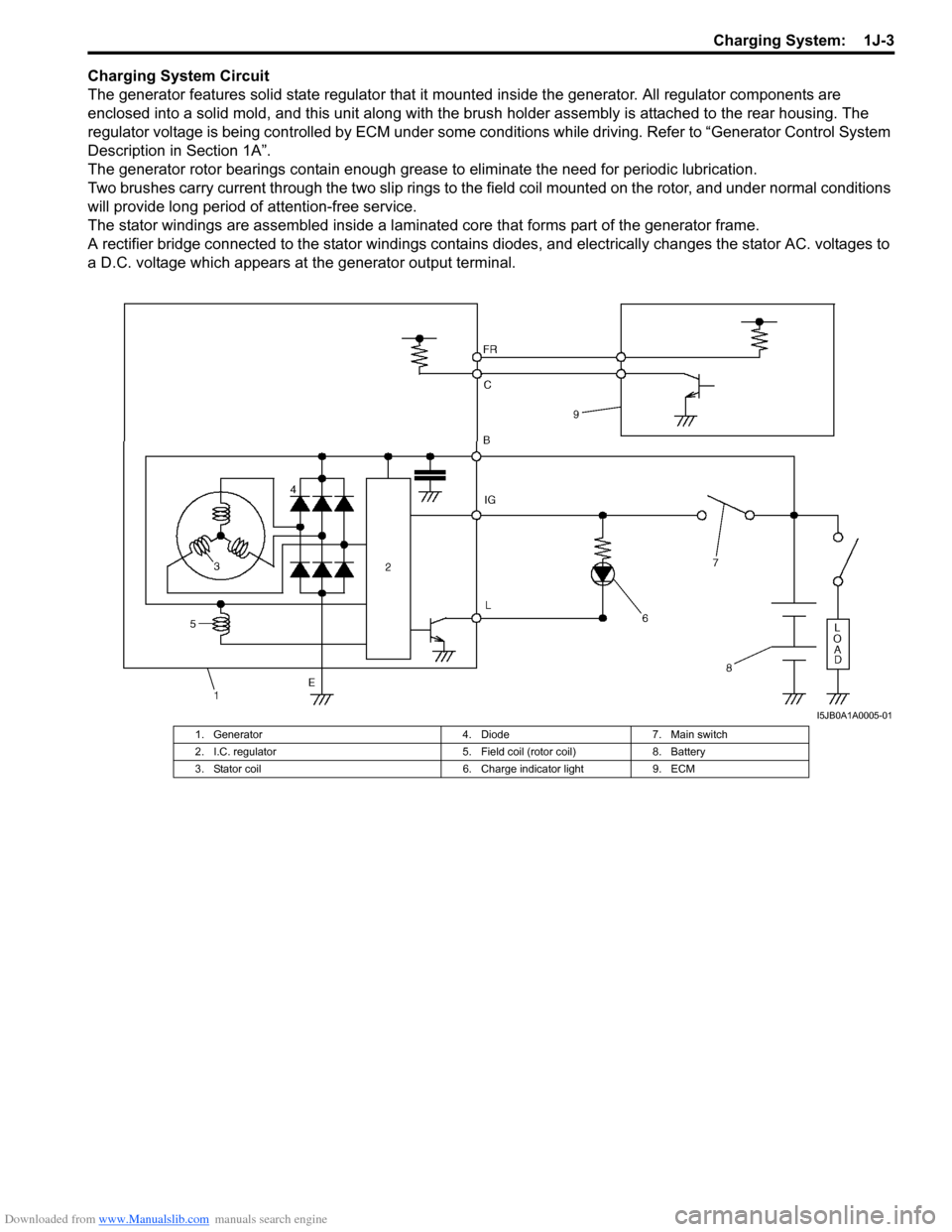

Charging System Circuit

The generator features solid state regulator that it mounted inside the generator. All regulator components are

enclosed into a solid mold, and this unit along with the brus h holder assembly is attached to the rear housing. The

regulator voltage is being controlled by ECM under some cond itions while driving. Refer to “Generator Control System

Description in Section 1A”.

The generator rotor bearings contain enough grease to eliminate the need for periodic lubrication.

Two brushes carry current through the two slip rings to the field coil mounted on the rotor, and under normal conditions

will provide long period of attention-free service.

The stator windings are assembled inside a laminate d core that forms part of the generator frame.

A rectifier bridge connected to the stator windings contains diodes, and electrically changes the stator AC. voltages to

a D.C. voltage which appears at the generator output terminal.

I5JB0A1A0005-01

1. Generator 4. Diode7. Main switch

2. I.C. regulator 5. Field coil (rotor coil)8. Battery

3. Stator coil 6. Charge indicator light9. ECM