Check valve SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 742 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-98 Automatic Transmission/Transaxle:

Transmission Fluid Temperature Sensor

Inspection

S7RS0B5106021

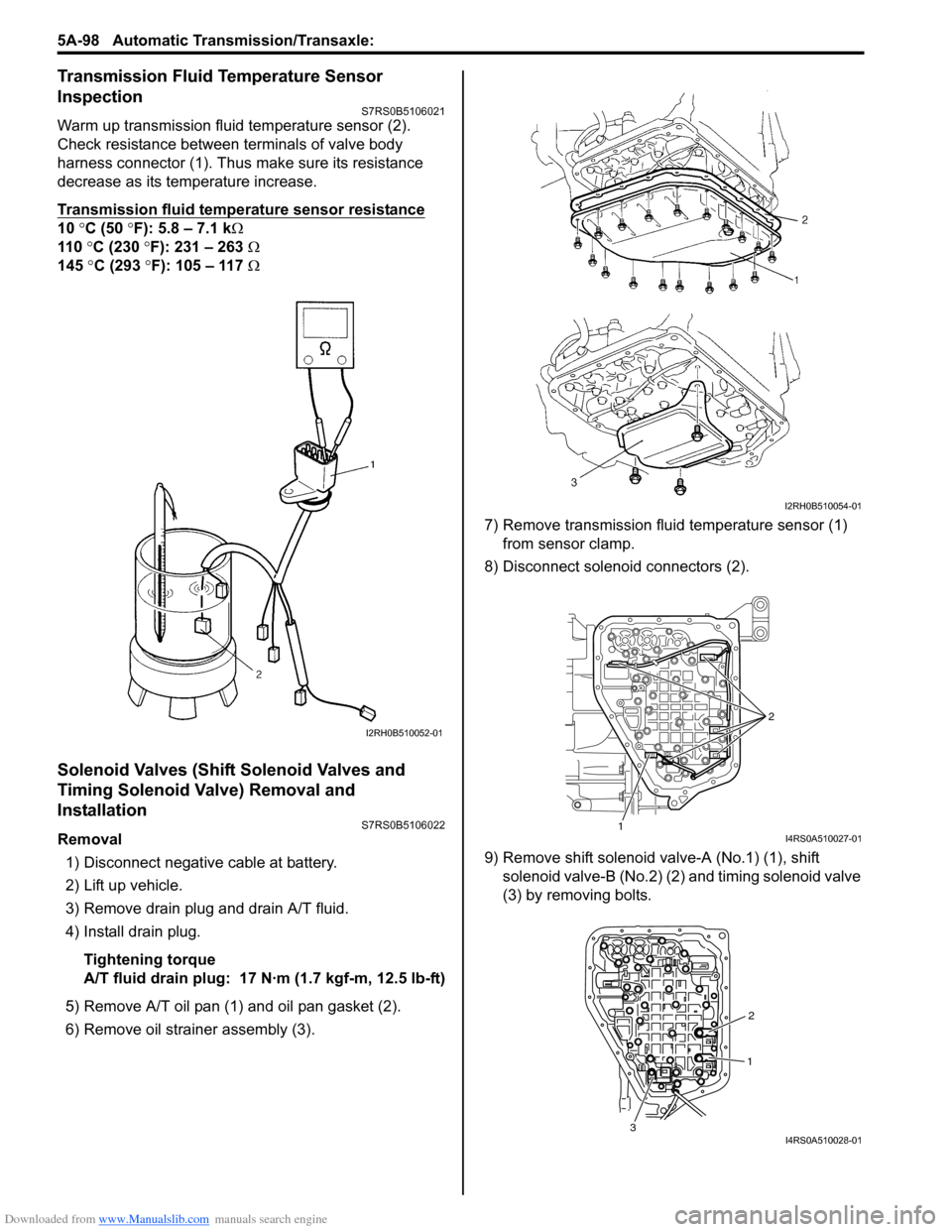

Warm up transmission fluid temperature sensor (2).

Check resistance between terminals of valve body

harness connector (1). Thus make sure its resistance

decrease as its temperature increase.

Transmission fluid temperature sensor resistance

10 °C (50 °F): 5.8 – 7.1 k Ω

110 °C (230 °F): 231 – 263 Ω

145 °C (293 °F): 105 – 117 Ω

Solenoid Valves (Shift Solenoid Valves and

Timing Solenoid Valve) Removal and

Installation

S7RS0B5106022

Removal

1) Disconnect negative cable at battery.

2) Lift up vehicle.

3) Remove drain plug and drain A/T fluid.

4) Install drain plug.

Tightening torque

A/T fluid drain plug: 17 N· m (1.7 kgf-m, 12.5 lb-ft)

5) Remove A/T oil pan (1) and oil pan gasket (2).

6) Remove oil strain er assembly (3). 7) Remove transmission fluid temperature sensor (1)

from sensor clamp.

8) Disconnect solenoid connectors (2).

9) Remove shift solenoid va lve-A (No.1) (1), shift

solenoid valve-B (No.2) (2) and timing solenoid valve

(3) by removing bolts.

I2RH0B510052-01

I2RH0B510054-01

1 2I4RS0A510027-01

1

2

3

I4RS0A510028-01

Page 743 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-99

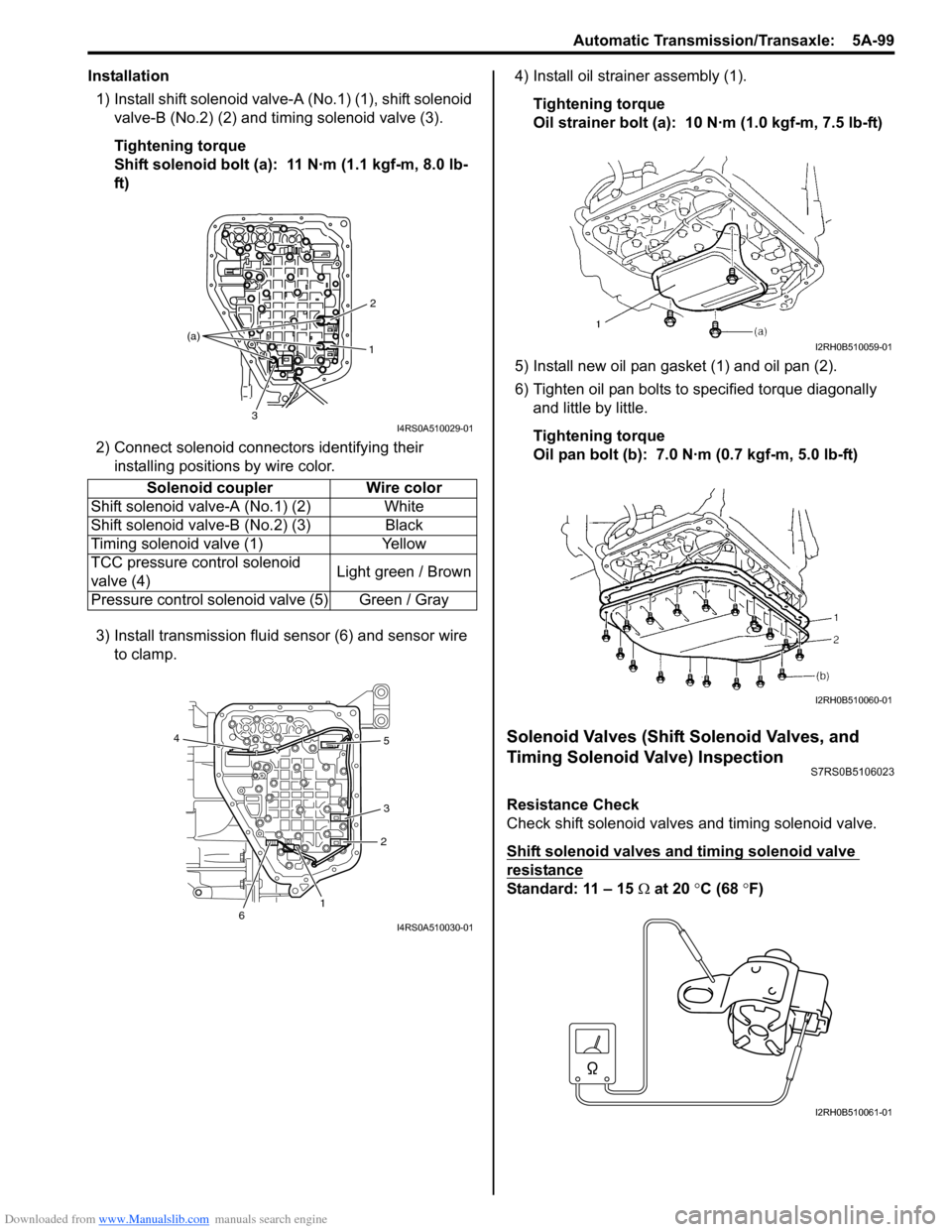

Installation1) Install shift solenoid valve- A (No.1) (1), shift solenoid

valve-B (No.2) (2) and timing solenoid valve (3).

Tightening torque

Shift solenoid bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-

ft)

2) Connect solenoid connectors identifying their installing positions by wire color.

3) Install transmission fluid sensor (6) and sensor wire to clamp. 4) Install oil strain

er assembly (1).

Tightening torque

Oil strainer bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft)

5) Install new oil pan gasket (1) and oil pan (2).

6) Tighten oil pan bolts to specified torque diagonally and little by little.

Tightening torque

Oil pan bolt (b): 7.0 N·m (0.7 kgf-m, 5.0 lb-ft)

Solenoid Valves (Shift Solenoid Valves, and

Timing Solenoid Valve) Inspection

S7RS0B5106023

Resistance Check

Check shift solenoid valves and timing solenoid valve.

Shift solenoid valves and timing solenoid valve

resistance

Standard: 11 – 15 Ω at 20 °C (68 ° F)

Solenoid coupler Wire color

Shift solenoid valv e-A (No.1) (2) White

Shift solenoid valv e-B (No.2) (3) Black

Timing solenoid valve (1) Yellow

TCC pressure control solenoid

valve (4) Light green / Brown

Pressure control solenoid valve (5) Green / Gray

1 2

3

(a)

I4RS0A510029-01

1

2

3 5

4

6

I4RS0A510030-01

I2RH0B510059-01

I2RH0B510060-01

I2RH0B510061-01

Page 744 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-100 Automatic Transmission/Transaxle:

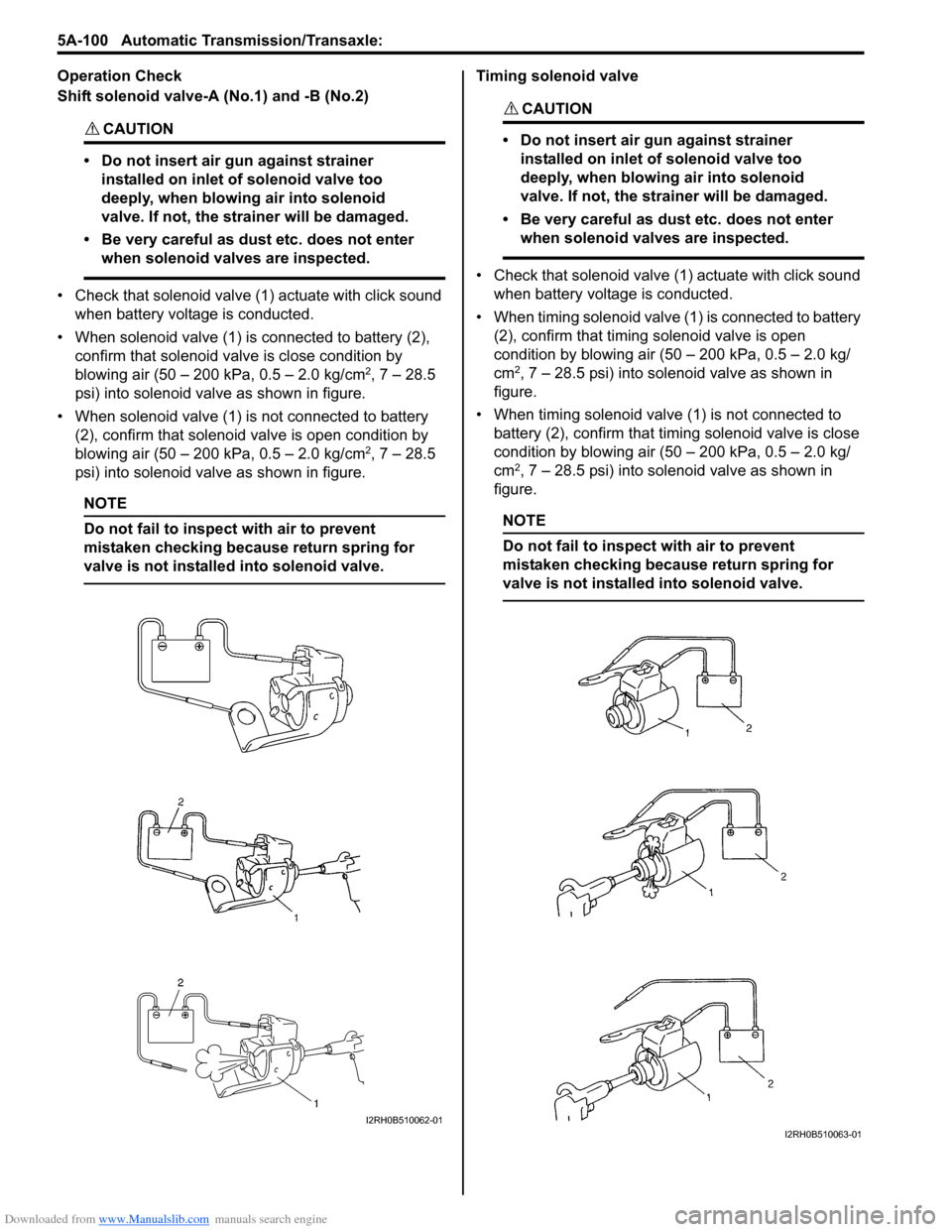

Operation Check

Shift solenoid valve-A (No.1) and -B (No.2)

CAUTION!

• Do not insert air gun against strainer installed on inlet of solenoid valve too

deeply, when blowing air into solenoid

valve. If not, the strainer will be damaged.

• Be very careful as dust etc. does not enter when solenoid valves are inspected.

• Check that solenoid valve (1) actuate with click sound when battery voltage is conducted.

• When solenoid valve (1) is connected to battery (2), confirm that solenoid valve is close condition by

blowing air (50 – 200 kPa, 0.5 – 2.0 kg/cm

2, 7 – 28.5

psi) into solenoid valve as shown in figure.

• When solenoid valve (1) is not connected to battery (2), confirm that solenoid valve is open condition by

blowing air (50 – 200 kPa, 0.5 – 2.0 kg/cm

2, 7 – 28.5

psi) into solenoid valve as shown in figure.

NOTE

Do not fail to inspect with air to prevent

mistaken checking because return spring for

valve is not installe d into solenoid valve.

Timing solenoid valve

CAUTION!

• Do not insert air gun against strainer

installed on inlet of solenoid valve too

deeply, when blowing air into solenoid

valve. If not, the strainer will be damaged.

• Be very careful as dust etc. does not enter when solenoid valves are inspected.

• Check that solenoid valve (1) actuate with click sound

when battery voltage is conducted.

• When timing solenoid valve (1 ) is connected to battery

(2), confirm that timing solenoid valve is open

condition by blowing air (50 – 200 kPa, 0.5 – 2.0 kg/

cm

2, 7 – 28.5 psi) into solenoid valve as shown in

figure.

• When timing solenoid valve (1) is not connected to battery (2), confirm that timi ng solenoid valve is close

condition by blowing air (50 – 200 kPa, 0.5 – 2.0 kg/

cm

2, 7 – 28.5 psi) into solenoid valve as shown in

figure.

NOTE

Do not fail to inspect with air to prevent

mistaken checking because return spring for

valve is not installed into solenoid valve.

I2RH0B510062-01I2RH0B510063-01

Page 745 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-101

Pressure Control Solenoid Valves (Pressure

Control Solenoid and TCC Pressure Control

Solenoid) Removal and Installation

S7RS0B5106024

Removal1) Disconnect negative cable at battery.

2) Lift up vehicle.

3) Remove drain plug and drain A/T fluid.

4) Install drain plug.

Tightening torque

A/T fluid drain plug: 17 N·m (1.7 kgf-m, 12.5 lb-ft)

5) Remove A/T oil pan (1) and oil pan gasket (2).

6) Remove oil strain er assembly (3).

7) Remove transmission fluid temperature sensor (1) from sensor clamp.

8) Disconnect solenoid connectors (2). 9) Remove valve body assembly referring to

“Automatic Transaxl e Unit Disassembly”.

10) Remove pressure control solenoid valve and TCC pressure control solenoid valve referring to “Valve

Body Assembly Disassembly and Reassembly”.

Installation

Reverse removal procedure to install pressure control

solenoid valve and valve body assembly noting the

following points.

• For detail of pressure control solenoid valve and TCC pressure control solenoid va lve installation, refer to

“Valve Body Assembly Disassembly and

Reassembly”.

• For detail of valve body asse mbly installation, refer to

“Automatic Transaxle Unit Assembly”.

• For detail of installing wire harness for solenoid valves and sensor, refer to “Automatic Transaxle Unit

Assembly”. Use new O-rings.

• For detail of A/T oil pan and oil strainer assembly

installation, refer to “A utomatic Transaxle Unit

Assembly”. Use new oil pan gasket.

• Pour A/T fluid and check fluid level according to procedure described in “A/T Fluid Change”.

• Check for fluid leakage after warming up A/T.

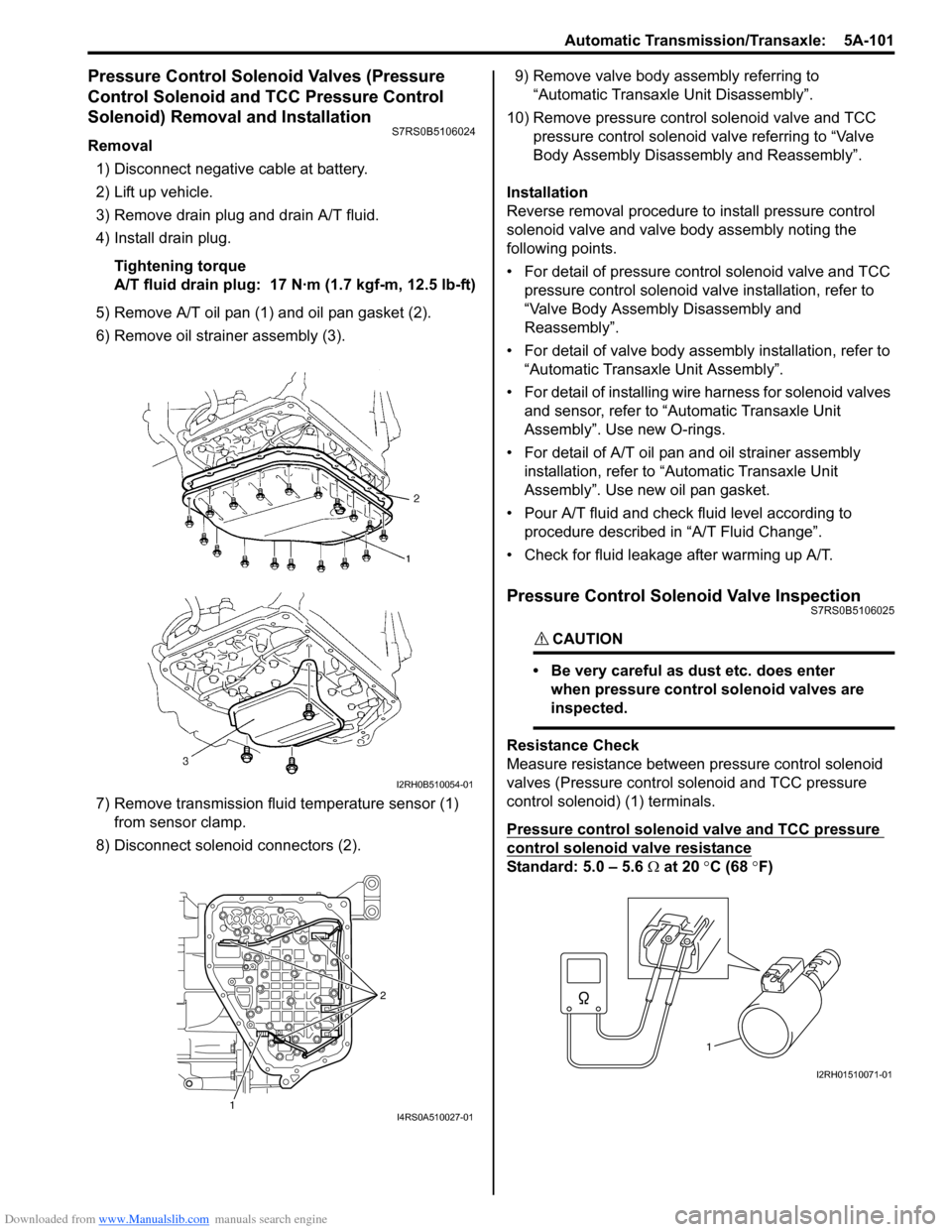

Pressure Control Solenoid Valve InspectionS7RS0B5106025

CAUTION!

• Be very careful as dust etc. does enter when pressure control solenoid valves are

inspected.

Resistance Check

Measure resistance between pressure control solenoid

valves (Pressure control solenoid and TCC pressure

control solenoid) (1) terminals.

Pressure control solenoid valve and TCC pressure

control solenoid valve resistance

Standard: 5.0 – 5.6 Ω at 20 °C (68 °F)

I2RH0B510054-01

1 2I4RS0A510027-01

1

I2RH01510071-01

Page 746 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-102 Automatic Transmission/Transaxle:

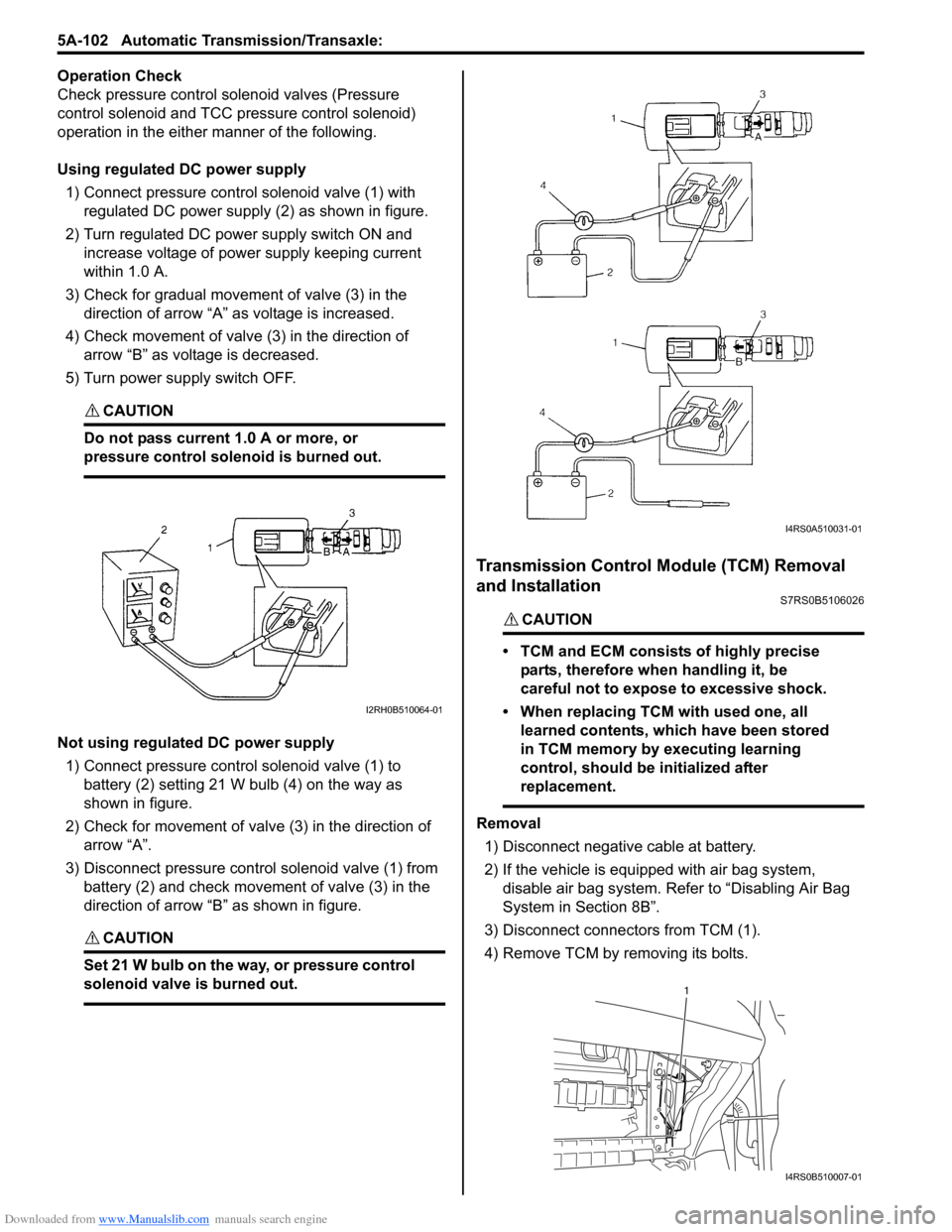

Operation Check

Check pressure control solenoid valves (Pressure

control solenoid and TCC pressure control solenoid)

operation in the either manner of the following.

Using regulated DC power supply

1) Connect pressure contro l solenoid valve (1) with

regulated DC power supply (2) as shown in figure.

2) Turn regulated DC power supply switch ON and increase voltage of power supply keeping current

within 1.0 A.

3) Check for gradual movement of valve (3) in the direction of arrow “A” as voltage is increased.

4) Check movement of valve (3) in the direction of arrow “B” as voltage is decreased.

5) Turn power supply switch OFF.

CAUTION!

Do not pass current 1.0 A or more, or

pressure control solenoid is burned out.

Not using regulated DC power supply 1) Connect pressure control solenoid valve (1) to battery (2) setting 21 W bulb (4) on the way as

shown in figure.

2) Check for movement of valve (3) in the direction of arrow “A”.

3) Disconnect pressure control solenoid valve (1) from battery (2) and check movement of valve (3) in the

direction of arrow “B” as shown in figure.

CAUTION!

Set 21 W bulb on the way, or pressure control

solenoid valve is burned out.

Transmission Control Module (TCM) Removal

and Installation

S7RS0B5106026

CAUTION!

• TCM and ECM consists of highly precise

parts, therefore when handling it, be

careful not to expose to excessive shock.

• When replacing TCM with used one, all learned contents, which have been stored

in TCM memory by executing learning

control, should be initialized after

replacement.

Removal

1) Disconnect negative cable at battery.

2) If the vehicle is equipped with air bag system, disable air bag system. Refer to “Disabling Air Bag

System in Section 8B”.

3) Disconnect connectors from TCM (1).

4) Remove TCM by removing its bolts.

I2RH0B510064-01

I4RS0A510031-01

1

I4RS0B510007-01

Page 753 of 1496

Downloaded from www.Manualslib.com manuals search engine A u to m a tic Tra n s m is s io n /Tra n s a x le : 5 A -1 0 9

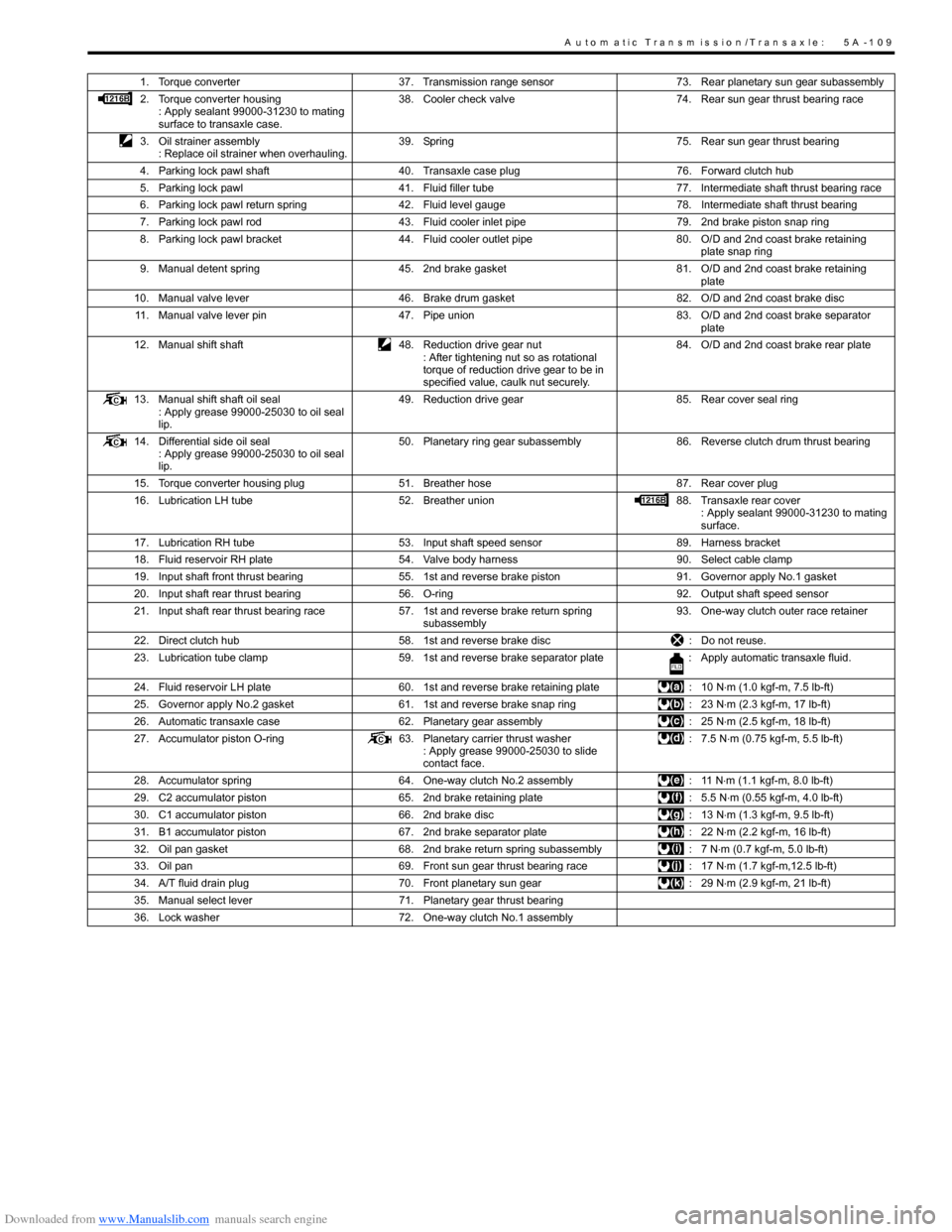

1. Torque converter37. Transmission range sensor 73. Rear planetary sun gear subassembly

2. Torque converter housing : Apply sealant 99000-31230 to mating

surface to transaxle case. 38. Cooler check valve

74. Rear sun gear thrust bearing race

3. Oil strainer assembly : Replace oil strainer when overhauling. 39. Spring

75. Rear sun gear thrust bearing

4. Parking lock pawl shaft 40. Transaxle case plug 76. Forward clutch hub

5. Parking lock pawl 41. Fluid filler tube 77. Intermediate shaft thrust bearing race

6. Parking lock pawl return spring 42. Fluid level gauge 78. Intermediate shaft thrust bearing

7. Parking lock pawl rod 43. Fluid cooler inlet pipe 79. 2nd brake piston snap ring

8. Parking lock pawl bracket 44. Fluid cooler outlet pipe 80. O/D and 2nd coast brake retaining

plate snap ring

9. Manual detent spring 45. 2nd brake gasket 81. O/D and 2nd coast brake retaining

plate

10. Manual valve lever 46. Brake drum gasket 82. O/D and 2nd coast brake disc

11. Manual valve lever pin 47. Pipe union 83. O/D and 2nd coast brake separator

plate

12. Manual shift shaft 48. Reduction drive gear nut

: After tightening nut so as rotational

torque of reduction drive gear to be in

specified value, caulk nut securely. 84. O/D and 2nd coast brake rear plate

13. Manual shift shaft oil seal : Apply grease 99000-25030 to oil seal

lip. 49. Reduction drive gear

85. Rear cover seal ring

14. Differential side oil seal : Apply grease 99000-25030 to oil seal

lip. 50. Planetary ring gear subassembly

86. Reverse clutch drum thrust bearing

15. Torque converter housing plug 51. Breather hose 87. Rear cover plug

16. Lubrication LH tube 52. Breather union 88. Transaxle rear cover

: Apply sealant 99000-31230 to mating

surface.

17. Lubrication RH tube 53. Input shaft speed sensor 89. Harness bracket

18. Fluid reservoir RH plate 54. Valve body harness 90. Select cable clamp

19. Input shaft front thrust bearing 55. 1st and reverse brake piston 91. Governor apply No.1 gasket

20. Input shaft rear thrust bearing 56. O-ring 92. Output shaft speed sensor

21. Input shaft rear thrust bearing race 57. 1st and reverse brake return spring

subassembly 93. One-way clutch outer race retainer

22. Direct clutch hub 58. 1st and reverse brake disc : Do not reuse.

23. Lubrication tube clamp 59. 1st and reverse brake separator plate : Apply automatic transaxle fluid.

24. Fluid reservoir LH plate 60. 1st and reverse brake retaining plate : 10 N⋅m (1.0 kgf-m, 7.5 lb-ft)

25. Governor apply No.2 gasket 61. 1st and reverse brake snap ring : 23 N⋅m (2.3 kgf-m, 17 lb-ft)

26. Automatic transaxle case 62. Planetary gear assembly : 25 N⋅m (2.5 kgf-m, 18 lb-ft)

27. Accumulator piston O-ring 63. Planetary carrier thrust washer

: Apply grease 99000-25030 to slide

contact face. : 7.5 N

⋅m (0.75 kgf-m, 5.5 lb-ft)

28. Accumulator spring 64. One-way clutch No.2 assembly : 11 N⋅m (1.1 kgf-m, 8.0 lb-ft)

29. C2 accumulator piston 65. 2nd brake retaining plate : 5.5 N⋅m (0.55 kgf-m, 4.0 lb-ft)

30. C1 accumulator piston 66. 2nd brake disc : 13 N⋅m (1.3 kgf-m, 9.5 lb-ft)

31. B1 accumulator piston 67. 2nd brake separator plate : 22 N⋅m (2.2 kgf-m, 16 lb-ft)

32. Oil pan gasket 68. 2nd brake return spring subassembly : 7 N⋅m (0.7 kgf-m, 5.0 lb-ft)

33. Oil pan 69. Front sun gear thrust bearing race : 17 N⋅m (1.7 kgf-m,12.5 lb-ft)

34. A/T fluid drain plug 70. Front planetary sun gear : 29 N⋅m (2.9 kgf-m, 21 lb-ft)

35. Manual select lever 71. Planetary gear thrust bearing

36. Lock washer 72. One-way clutch No.1 assembly

Page 756 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-112 Automatic Transmission/Transaxle:

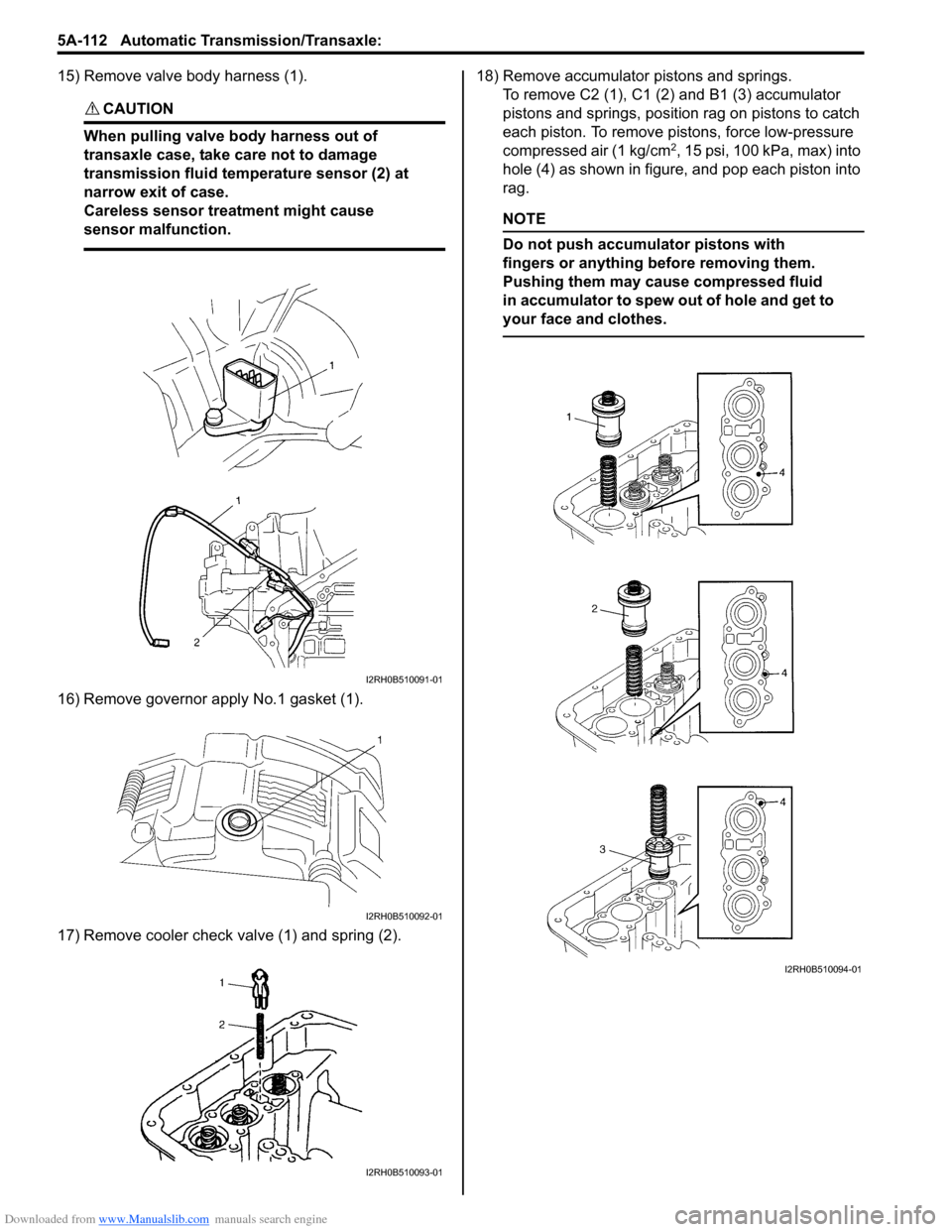

15) Remove valve body harness (1).

CAUTION!

When pulling valve body harness out of

transaxle case, take care not to damage

transmission fluid temperature sensor (2) at

narrow exit of case.

Careless sensor treatment might cause

sensor malfunction.

16) Remove governor apply No.1 gasket (1).

17) Remove cooler check valve (1) and spring (2).18) Remove accumulator pistons and springs.

To remove C2 (1), C1 (2) and B1 (3) accumulator

pistons and springs, position rag on pistons to catch

each piston. To remove pistons, force low-pressure

compressed air (1 kg/cm

2, 15 psi, 100 kPa, max) into

hole (4) as shown in figure, and pop each piston into

rag.

NOTE

Do not push accumulator pistons with

fingers or anything before removing them.

Pushing them may cause compressed fluid

in accumulator to spew out of hole and get to

your face and clothes.

I2RH0B510091-01

I2RH0B510092-01

I2RH0B510093-01

I2RH0B510094-01

Page 794 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-150 Automatic Transmission/Transaxle:

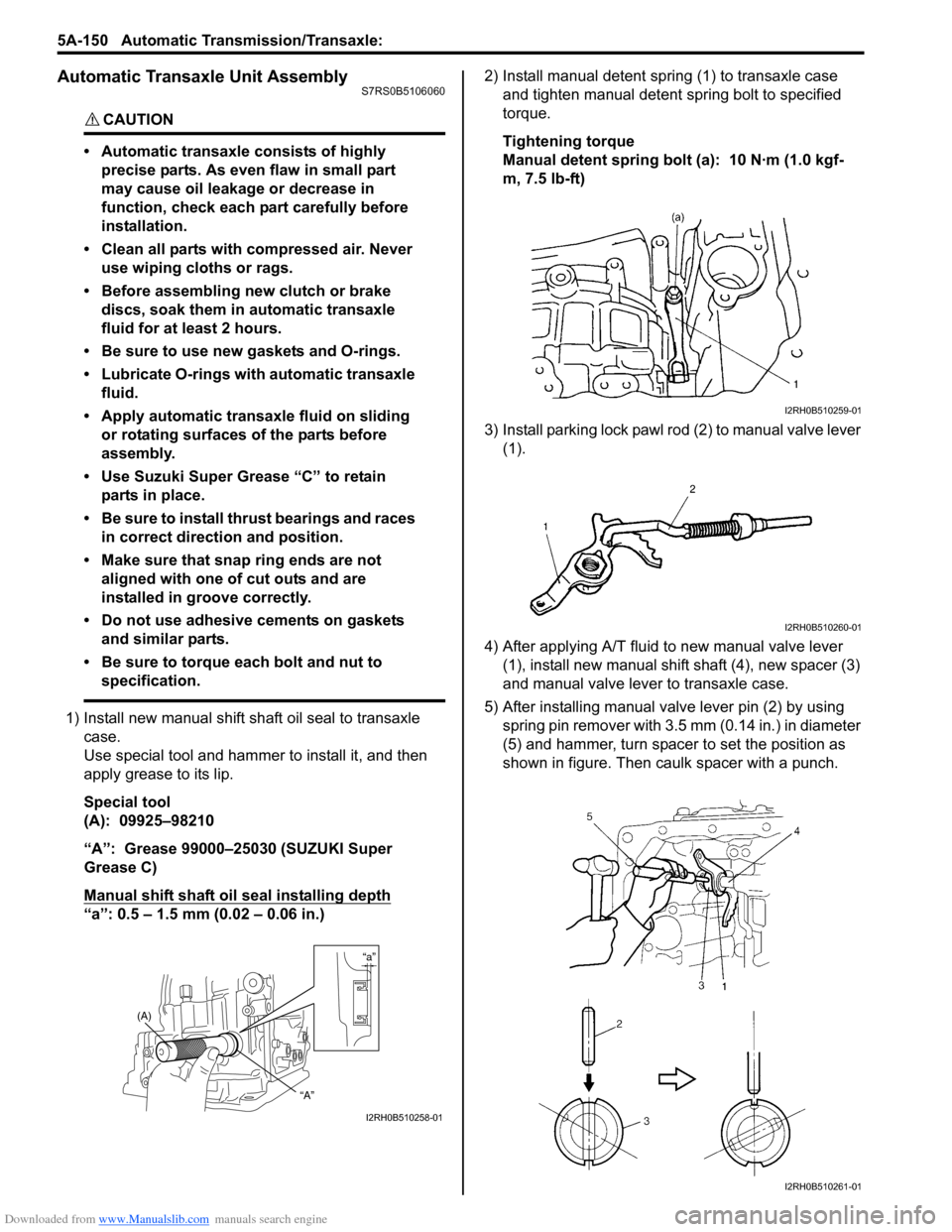

Automatic Transaxle Unit AssemblyS7RS0B5106060

CAUTION!

• Automatic transaxle consists of highly precise parts. As even flaw in small part

may cause oil leakage or decrease in

function, check each part carefully before

installation.

• Clean all parts with compressed air. Never use wiping cloths or rags.

• Before assembling new clutch or brake discs, soak them in automatic transaxle

fluid for at least 2 hours.

• Be sure to use new gaskets and O-rings.

• Lubricate O-rings with automatic transaxle

fluid.

• Apply automatic transaxle fluid on sliding or rotating surfaces of the parts before

assembly.

• Use Suzuki Super Grease “C” to retain parts in place.

• Be sure to install thrust bearings and races in correct direction and position.

• Make sure that snap ring ends are not aligned with one of cut outs and are

installed in groove correctly.

• Do not use adhesive cements on gaskets and similar parts.

• Be sure to torque each bolt and nut to specification.

1) Install new manual shift sh aft oil seal to transaxle

case.

Use special tool and hammer to install it, and then

apply grease to its lip.

Special tool

(A): 09925–98210

“A”: Grease 99000–25030 (SUZUKI Super

Grease C)

Manual shift shaft oil seal installing depth

“a”: 0.5 – 1.5 mm (0.02 – 0.06 in.) 2) Install manual detent spring (1) to transaxle case

and tighten manual detent spring bolt to specified

torque.

Tightening torque

Manual detent spring bolt (a): 10 N·m (1.0 kgf-

m, 7.5 lb-ft)

3) Install parking lock pawl ro d (2) to manual valve lever

(1).

4) After applying A/T fluid to new manual valve lever (1), install new manual shift shaft (4), new spacer (3)

and manual valve lever to transaxle case.

5) After installing manual valve lever pin (2) by using spring pin remover with 3.5 mm (0.14 in.) in diameter

(5) and hammer, turn spacer to set the position as

shown in figure. Then caulk spacer with a punch.

“a”

(A)

“A”

I2RH0B510258-01

I2RH0B510259-01

I2RH0B510260-01

I2RH0B510261-01

Page 806 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-162 Automatic Transmission/Transaxle:

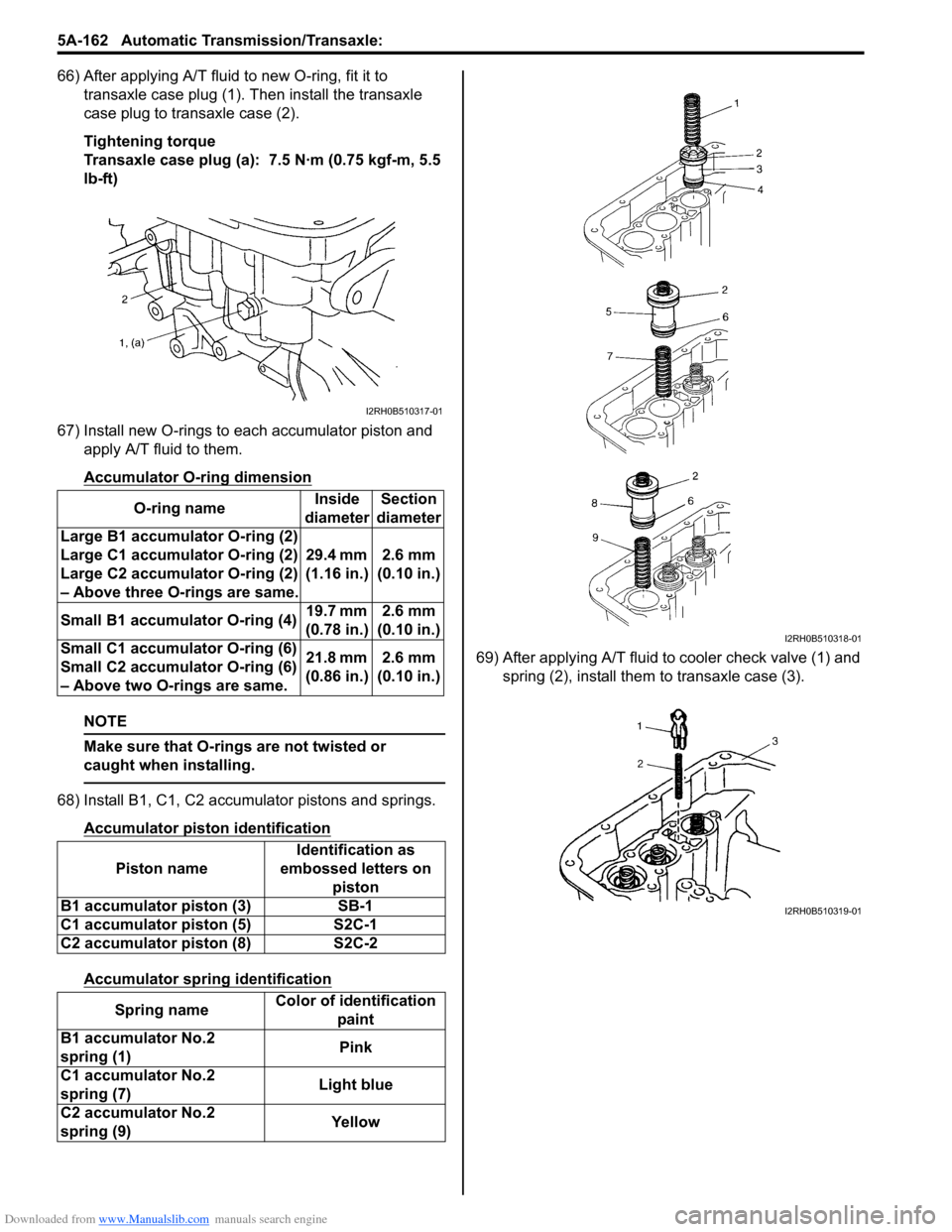

66) After applying A/T fluid to new O-ring, fit it to transaxle case plug (1). Then install the transaxle

case plug to transaxle case (2).

Tightening torque

Transaxle case plug (a): 7.5 N·m (0.75 kgf-m, 5.5

lb-ft)

67) Install new O-rings to each accumulator piston and apply A/T fluid to them.

Accumulator O-ri ng dimension

NOTE

Make sure that O-rings are not twisted or

caught when installing.

68) Install B1, C1, C2 accumulator pistons and springs.

Accumulator piston identification

Accumulator spring identification

69) After applying A/T fluid to cooler check valve (1) and

spring (2), install them to transaxle case (3).

O-ring name

Inside

diameter Section

diameter

Large B1 accumula tor O-ring (2)

Large C1 accumula tor O-ring (2)

Large C2 accumula tor O-ring (2)

– Above three O-rings are same. 29.4 mm

(1.16 in.) 2.6 mm

(0.10 in.)

Small B1 accumulator O-ring (4) 19.7 mm

(0.78 in.) 2.6 mm

(0.10 in.)

Small C1 accumulator O-ring (6)

Small C2 accumulator O-ring (6)

– Above two O-rings are same. 21.8 mm

(0.86 in.) 2.6 mm

(0.10 in.)

Piston name Identification as

embossed letters on piston

B1 accumulator piston (3) SB-1

C1 accumulator piston (5) S2C-1

C2 accumulator piston (8) S2C-2

Spring name Color of identification

paint

B1 accumulator No.2

spring (1) Pink

C1 accumulator No.2

spring (7) Light blue

C2 accumulator No.2

spring (9) Yellow

I2RH0B510317-01

I2RH0B510318-01

I2RH0B510319-01

Page 934 of 1496

Downloaded from www.Manualslib.com manuals search engine 7-ii Table of Contents

Recommended Service Material ....................... 7B-33

Special Tool ...................................................... 7B-33

Automatic Type .................... .................................7B-34

Precautions.........................................................7B-34 A/C System Caution .......................................... 7B-34

Precautions in Diagnosing Trouble ................... 7B-34

Precautions on Servicing A/C System .............. 7B-34

General Description .......... .................................7B-34

Auto A/C System Descript ion ............................ 7B-34

HVAC Control Module Operation Description ... 7B-36

Refrigerant Type Identifica tion .......................... 7B-36

Sub-Cool A/C System Description .................... 7B-36

A/C Operation Description ................................ 7B-36

On-Board Diagnostic System Description ......... 7B-37

Schematic and Routing Diagram ......................7B-37 Major Components of A/C System .................... 7B-37

A/C System Wiring Diagra m ............................. 7B-38

Diagnostic Information and Procedures ..........7B-39 A/C System Symptom Diagnosis ...................... 7B-39

Abnormal Noise Sympto m Diagnosis of A/C

System ............................................................ 7B-42

DTC Check........................................................ 7B-42

DTC Clearance ................................................. 7B-43

DTC Table ......................................................... 7B-44

Fail-Safe Table ................. ................................. 7B-45

Scan Tool Data ................................................. 7B-46

Air Conditioning System Check......................... 7B-47

Visual Inspection ............................................... 7B-49

DTC B1502: Inside Air Temperature Sensor and/or Its Circuit Malfunction .......................... 7B-49

DTC B1503: A/C Evaporator Air Temperature Sensor and/or Its Circuit Malfunction .............. 7B-50

DTC B1504: Sunload Sensor and/or Its Circuit Malfunction ......... ................................. 7B-52

DTC B1511: Temperature Control Actuator (Position Sensor) and/or Its Circuit

Malfunction ...................................................... 7B-53

DTC B1512: Air flow Control Actuator (Position Sensor) and/or Its Circuit

Malfunction ...................................................... 7B-55

DTC B1513: Temperature Control Actuator and/or Its Circuit Malfunction .......................... 7B-57

DTC B1514: Air Flow Co ntrol Actuator and/or

Its Circuit Malfunction ...................................... 7B-60

DTC B1541: HVAC Control Module Back-Up Power Supply Malfunction .............................. 7B-62

DTC B1546: A/C Refrigerant Pressure Malfunction ...................................................... 7B-63

DTC B1551: Serial Communication Circuit Malfunction ...................................................... 7B-63

DTC B1552: Serial Communication Signal Malfunction ...................................................... 7B-64

DTC B1553: CAN Communication Signal Malfunction ...................................................... 7B-65

DTC B1557: Vehicle Speed Sensor Signal Malfunction ...................................................... 7B-65

DTC B1561: Engine Coolant Temperature Sensor Signal Malfunctio n .............................. 7B-66 DTC B1562: Outside Air Temperature Sensor

Signal Malfunction ........................................... 7B-66

DTC B1563: A/C Refr igerant Pressure

Sensor Signal Malfunction .............................. 7B-66

Inspection of HVAC Control Module and Its Circuit .............................................................. 7B-67

A/C System Performance Inspection ................ 7B-70

A/C System Inspection at ECM ......................... 7B-70

Repair Instructions ............ ................................7B-71

Operation Procedure for Refrigerant Charge .... 7B-71

HVAC Unit Components ................................... 7B-72

HVAC Unit Removal and In stallation ................ 7B-73

Temperature Control Actuator Removal and Installation ....................................................... 7B-73

Temperature Control Actuat or Inspection ......... 7B-73

Air Flow Control Actuator Removal and Installation ....................................................... 7B-74

Air Flow Control Actuator Inspection ................. 7B-74

Air Intake Control Actuator Removal and Installation ....................................................... 7B-75

Air Intake Control Actuator Inspection............... 7B-75

Actuator Linkage Inspection .............................. 7B-76

Blower Motor Controller Removal and Installation ....................................................... 7B-76

Blower Motor Controller Inspection ................... 7B-76

HVAC Control Module Removal and Installation ....................................................... 7B-77

Sunload Sensor Removal and Installation ........ 7B-77

Sunload Sensor Inspection ............................... 7B-77

Outside Air Temperature Sensor Removal and Installation ................................................ 7B-77

Outside Air Temperature Sensor Inspection ..... 7B-77

Inside Air Temperature Sensor Removal and Installation ....................................................... 7B-78

Inside Air Temperature Sens or Inspection ........ 7B-78

Condenser Assembly On-Vehicle Inspection .... 7B-78

Condenser Assembly Removal and Installation ....................................................... 7B-78

Receiver/Dryer Removal and Installation .......... 7B-78

Evaporator Inspection ....................................... 7B-78

Evaporator Temperature Sensor Removal and Installation ................................................ 7B-78

Evaporator Temperature Se nsor Inspection ..... 7B-78

Expansion Valve Removal an d Installation ....... 7B-78

Expansion Valve Inspection .............................. 7B-78

A/C Refrigerant Pressure Sensor and Its Circuit Inspection............................................. 7B-78

A/C Refrigerant Pressu re Sensor Removal

and Installation ................................................ 7B-78

Compressor Relay Inspection .

.......................... 7B-78

Compressor Drive Belt Inspection and Adjustment ...................................................... 7B-78

Compressor Drive Belt Removal and Installation ....................................................... 7B-79

Compressor Assembly Removal and Installation ....................................................... 7B-79

Compressor Assembly Components................. 7B-79

Magnet Clutch Removal and Installation........... 7B-79

Magnet Clutch Inspection.................................. 7B-79

Relief Valve Inspection...................................... 7B-79