MOUNT SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 950 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-2 Air Conditioning System: Manual Type

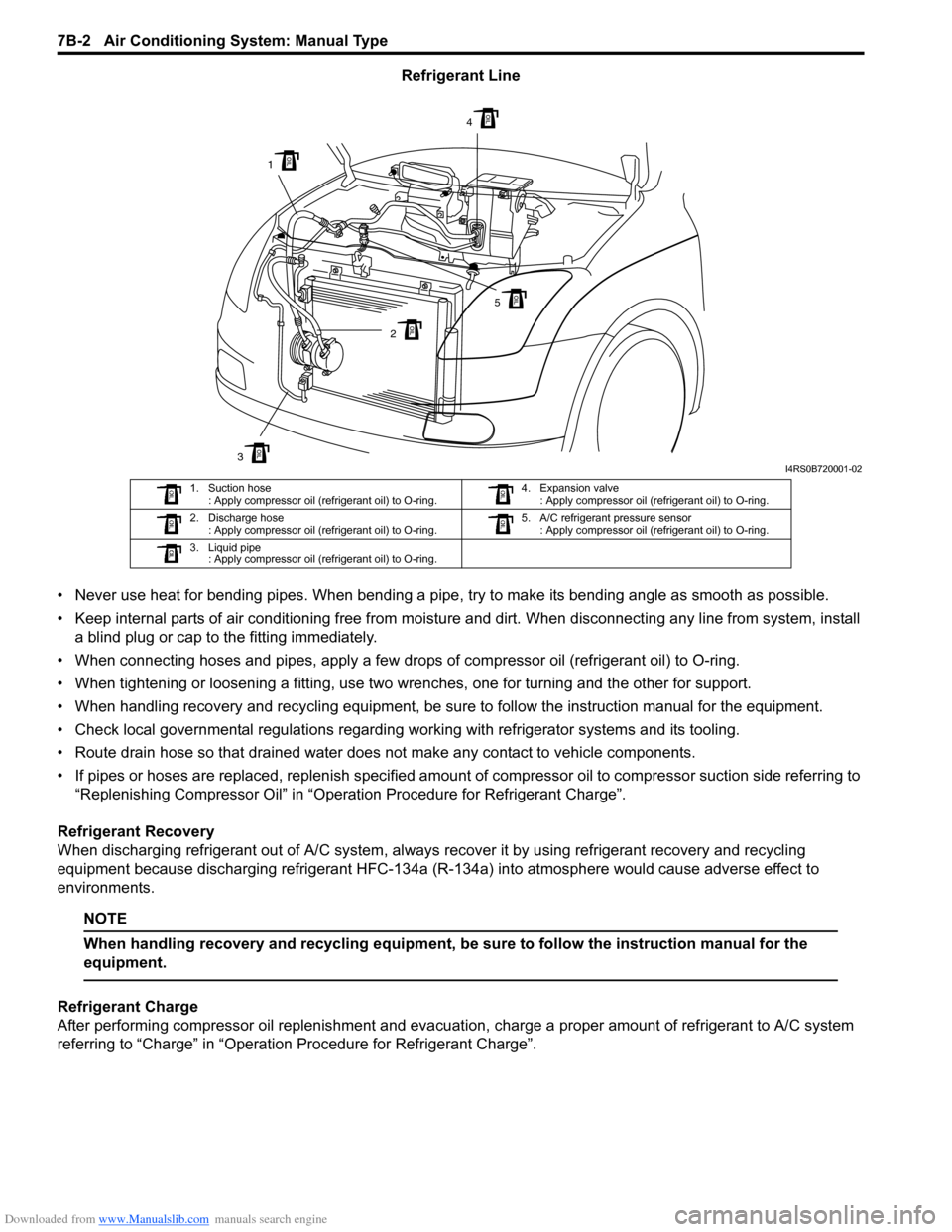

Refrigerant Line

• Never use heat for bending pipes. When bending a pipe , try to make its bending angle as smooth as possible.

• Keep internal parts of air conditioning free from moistu re and dirt. When disconnecting any line from system, install

a blind plug or cap to the fitting immediately.

• When connecting hoses and pipes, apply a few drops of compressor oil (refrigerant oil) to O-ring.

• When tightening or loosening a fitting, use two wrenches, one for turning and the other for support.

• When handling recovery and recycling equipment, be sure to follow the instruction manual for the equipment.

• Check local governmental regulations regarding working with refrigerator systems and its tooling.

• Route drain hose so that drained water does not make any contact to vehicle components.

• If pipes or hoses are replaced, replenish specified amount of compressor oil to compre ssor suction side referring to

“Replenishing Compressor Oil” in “Operation Procedure for Refrigerant Charge”.

Refrigerant Recovery

When discharging refrigerant out of A/C system, always recover it by using refrigerant recovery and recycling

equipment because discharging refrigerant HFC-134a (R-1 34a) into atmosphere would cause adverse effect to

environments.

NOTE

When handling recovery and recycling equipment, be sure to follow the instruction manual for the

equipment.

Refrigerant Charge

After performing compressor oil replenishment and evacuat ion, charge a proper amount of refrigerant to A/C system

referring to “Charge” in “Operation Procedure for Refrigerant Charge”.

3

1

2

4

5

I4RS0B720001-02

1. Suction hose : Apply compressor oil (refrigerant oil) to O-ring. 4. Expansion valve

: Apply compressor oil (refrigerant oil) to O-ring.

2. Discharge hose : Apply compressor oil (refrigerant oil) to O-ring. 5. A/C refrigerant pressure sensor

: Apply compressor oil (refrigerant oil) to O-ring.

3. Liquid pipe : Apply compressor oil (refrigerant oil) to O-ring.

Page 956 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-8 Air Conditioning System: Manual Type

Cool air does not come

out or insufficient cooling

(A/C system normal

operation)Insufficient or excessive charge of

refrigerant

Check the amount of refrigerant and system

for leaks.

Condenser clogged Check condenser referring to “Condenser

Assembly On-Vehicle Inspection”.

A/C evaporator clogged or frosted Check A/C evaporator and evaporator

thermistor (evaporator temperature sensor)

referring to “Evaporator Inspection” and

“Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Evaporator thermistor (Evaporator

temperature sensor) faulty Check evaporator thermistor (Evaporator

temperature sensor) referring to “Evaporator

Thermistor (Evaporator Temperature Sensor)

Inspection”.

Expansion valve faulty Check expansion valve referring to “Expansion

Valve Inspection”.

Desiccant clogged Replace receiver/dryer.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Magnet clutch faulty Check magnet clutch referring to “Magnet

Clutch Inspection”.

Compressor faulty Check compressor.

Air in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Air leaking from HVAC unit or air duct Repair as necessary.

Heater and ventilation system faulty Check HVAC unit.

Blower motor faulty Check blower motor referring to “Blower Motor

Inspection in Section 7A”.

Excessive compressor oil in A/C system Drain excessive compressor oil from A/C

system circuit and compressor.

Cool air does not come

out only intermittently Wiring connection faulty

Repair as necessary.

Expansion valve faulty Check expansion valve referring to “Expansion

Valve Inspection”.

Excessive moisture in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Magnet clutch faulty Check magnet clutch referring to “Magnet

Clutch Inspection”.

Excessive amount of refrigerant Check the amount of refrigerant.

Cool air comes out only

when driving vehicle at

high speed Condenser clogged

Check condenser referring to “Condenser

Assembly On-Vehicle Inspection”.

Insufficient charge of refrigerant Check the amount of refrigerant and system

for leaks.

Air in A/C system Replace receiver/dryer, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Compressor drive belt loosened or

broken Adjust or replace drive belt.

Compressor faulty Check compressor.

Cool air does not come

out only when driving

vehicle at high speed Excessive amount of refrigerant

Check the amount of refrigerant.

A/C evaporator frosted Check A/C evaporator and evaporator

thermistor (evaporator temperature sensor)

referring to “Evaporator Inspection” and

“Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Condition Possible cause Correction / Reference Item

Page 957 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-9

Abnormal Noise Symptom Diagnosis of A/C SystemS7RS0B7214002

Abnormal Noise from Compressor

Abnormal Noise from Magnetic Clutch

Abnormal Noise from Tubing

Abnormal Noise from Condenser Assembly

Abnormal Noise from Crankshaft PulleyInsufficient airflow of

cooled air

A/C evaporator clogged or frosted

Check A/C evaporator and evaporator

thermistor (evaporator temperature sensor)

referring to “Evaporator Inspection” and

“Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Air leaking from HVAC unit or air duct Repair as necessary.

Blower motor faulty Check blower motor referring to “Blower Motor

Inspection in Section 7A”.

Wiring or grounding faulty Repair as necessary.

Condition Possible cause Correction / Reference Item

Condition

Possible cause Correction / Reference Item

During compressor

operation, a rumbling

noise is heard

proportional to engine

revolutions Inadequate clearance in scroll area

Replace compressor.

A loud noise is heard at a

certain rpm,

disproportionately to

engine revolution Loose or faulty compressor drive belt

Adjust drive belt tension or replace drive belt.

Loose compressor mounting bolts Retighten mounting bolts.

A loud rattle is heard at

low engine rpm Loose compressor clutch plate bolt

Retighten clutch plate bolt.

Replace compressor if it was operated in this

condition for a long time.

Condition Possible cause Correction / Reference Item

A rumbling noise is heard

when compressor is not

in operation Worn or damaged bearings

Replace magnet clutch assembly.

A chattering noise is

heard when compressor

is in operation Faulty magnet clutch clearance

(excessive clearance)

Adjust magnet clutch clearance.

Worn magnet clutch friction surface Replace magnet clutch assembly.

Compressor oil leaked from shaft seal,

contaminating the friction surface Replace compressor body assembly.

Condition

Possible cause Correction / Reference Item

A droning noise is heard

from inside of the vehicle,

but not particularly

noticeable in engine

compartment Faulty tubing clamps

Reposition clamps or increase the number of

clamps.

Resonance caused by pulsation from

variations in re frigerant pressure Attach a silencer to tubing, or modify its

position and length.

Condition

Possible cause Correction / Reference Item

Considerable vibration in

condenser assembly Resonance from condenser assembly

bracket and body Firmly insert a silenc

er between condenser

assembly bracket and body.

Condition Possible cause Correction / Reference Item

A large rattling noise is

heard at idle or sudden

acceleration Loosen crankshaft pulley bolt

Retighten bolt.

Page 962 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-14 Air Conditioning System: Manual Type

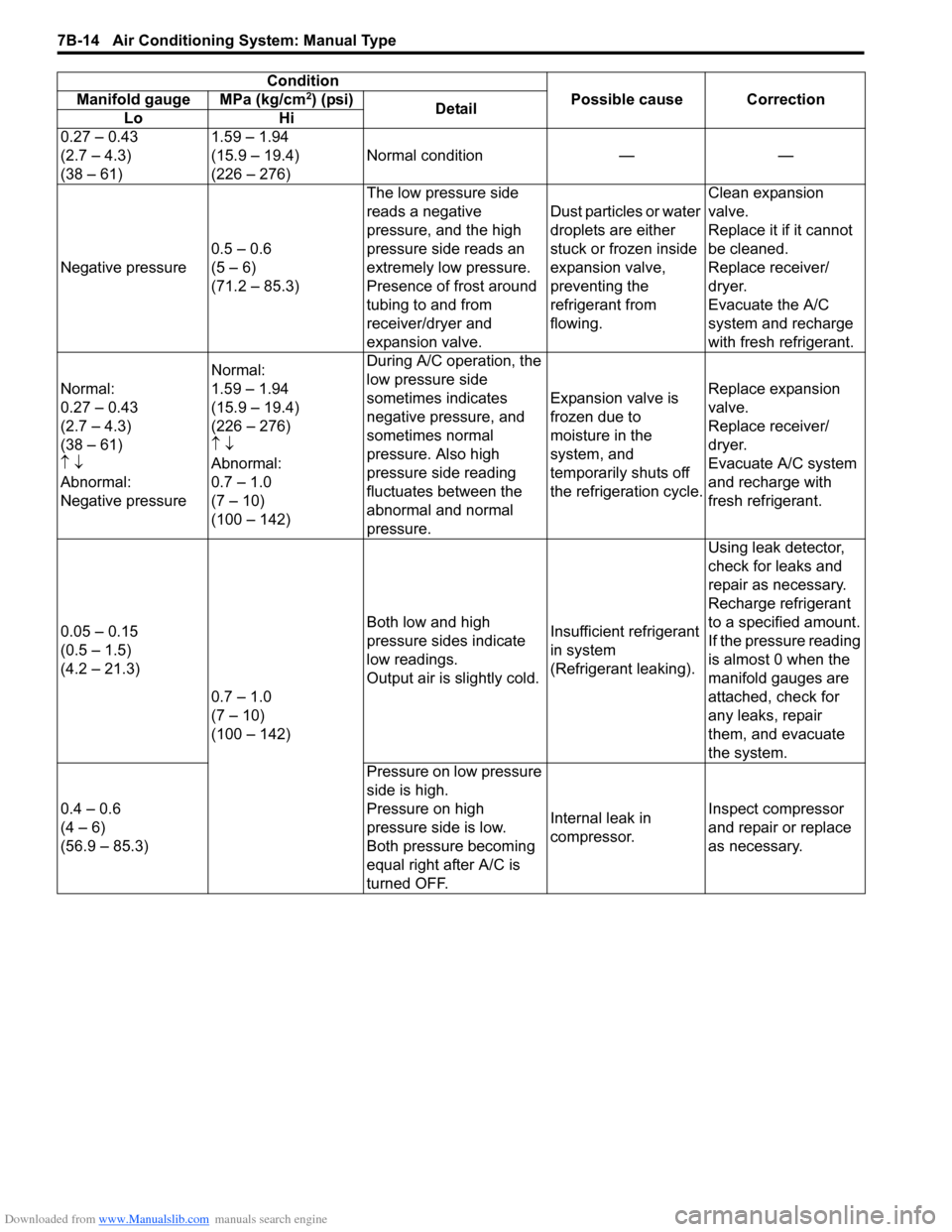

ConditionPossible cause Correction

Manifold gauge MPa (kg/cm2) (psi)

Detail

Lo Hi

0.27 – 0.43

(2.7 – 4.3)

(38 – 61) 1.59 – 1.94

(15.9 – 19.4)

(226 – 276)

Normal condition — —

Negative pressure 0.5 – 0.6

(5 – 6)

(71.2 – 85.3) The low pressure side

reads a negative

pressure, and the high

pressure side reads an

extremely low pressure.

Presence of frost around

tubing to and from

receiver/dryer and

expansion valve. Dust particles or water

droplets are either

stuck or frozen inside

expansion valve,

preventing the

refrigerant from

flowing.Clean expansion

valve.

Replace it if it cannot

be cleaned.

Replace receiver/

dryer.

Evacuate the A/C

system and recharge

with fresh refrigerant.

Normal:

0.27 – 0.43

(2.7 – 4.3)

(38 – 61)

↑ ↓

Abnormal:

Negative pressure Normal:

1.59 – 1.94

(15.9 – 19.4)

(226 – 276)

↑

↓

Abnormal:

0.7 – 1.0

(7 – 10)

(100 – 142) During A/C operation, the

low pressure side

sometimes indicates

negative pressure, and

sometimes normal

pressure. Also high

pressure side reading

fluctuates between the

abnormal and normal

pressure.

Expansion valve is

frozen due to

moisture in the

system, and

temporarily shuts off

the refrigeration cycle.

Replace expansion

valve.

Replace receiver/

dryer.

Evacuate A/C system

and recharge with

fresh refrigerant.

0.05 – 0.15

(0.5 – 1.5)

(4.2 – 21.3) 0.7 – 1.0

(7 – 10)

(100 – 142) Both low and high

pressure sides indicate

low readings.

Output air is slightly cold.

Insufficient refrigerant

in system

(Refrigerant leaking).Using leak detector,

check for leaks and

repair as necessary.

Recharge refrigerant

to a specified amount.

If the pressure reading

is almost 0 when the

manifold gauges are

attached, check for

any leaks, repair

them, and evacuate

the system.

0.4 – 0.6

(4 – 6)

(56.9 – 85.3) Pressure on low pressure

side is high.

Pressure on high

pressure side is low.

Both pressure becoming

equal right after A/C is

turned OFF.

Internal leak in

compressor.

Inspect compressor

and repair or replace

as necessary.

Page 963 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-15

A/C System Inspection at ECMS7RS0B7214004

Voltage Check

When checking voltage at ECM connector terminals related to A/C system, refer to “DTC P2101: Throttle Actuator

Control Motor Circuit Range / Performance in Section 1A”.

0.40 – 0.45

(4.0 – 4.5)

(57 – 64)

2.0 – 2.5

(20 – 25)

(285 – 355) High pressure reading on

both low and high

pressure sides.

Overcharged A/C

system.

Adjust refrigerant to

specified amount.

Faulty condenser

cooling operation. Clean condenser.

Faulty radiator cooling

fan operation. Inspect and repair

radiator cooling fan.

High pressure reading on

both low and high

pressure sides.

Low pressure side tubing

is not cold when touched. Presence of air in A/C

system

(Improperly

evacuated).Replace receiver/

dryer.

Inspect quantity of

compressor oil and

presence of

contaminants in oil.

Evacuate system and

recharge with fresh

refrigerant.

0.45 – 0.55

(4.5 – 5.5)

(64 – 78) High pressure reading on

both low and high

pressure sides.

Large amount of frost or

dew on the low pressure

side tubing.Faulty expansion

valve.

Refrigerant flow is not

regulated properly.

Replace expansion

valve.

Condition

Possible cause Correction

Manifold gauge MPa (kg/cm

2) (psi)

Detail

Lo Hi

Page 964 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-16 Air Conditioning System: Manual Type

Repair Instructions

Operation Procedure for Refrigerant ChargeS7RS0B7216001

WARNING!

• Your eyes should not be exposed to refrigerant (liquid).Any liquid HFC-134a (R-134a) escaping by accident shows a temperature as low as approximately –

6 °C (21.2 ° F) below freezing point. Should liquid HFC-134a (R-134a) is exposed to your eyes, it may

cause a serious injury. To protect your eyes from such accident, it is necessary to always wear

goggles. Should it occur that HFC-134a (R-134a) is exposed to your eyes, consult a doctor

immediately.

– Do not use your hand to rub the affected eye(s). Instead, use fresh cold water to splash it over the affected area to gradually raise temperature of such area above freezing point.

– Obtain proper treatment as soon as possible from a doctor or eye specialist.

• Should the liquid refrigerant HFC-134a (R-134a) is exposed to your skin, the affected area should be treated in the same manner as when skin is frostbitten or frozen.

• Do not handle refrigerant near any place where welding or steam cleaning is performed.

• Refrigerant should be kept in a cold and dark pl ace. It should never be stored in any place where

temperature is high, e.g. where exposed to direct su n light, close to fire or inside vehicle (including

trunk room).

• Avoid breathing fume produced when HFC-134a (R-134a) is burned. Such fume may be hazardous to your health.

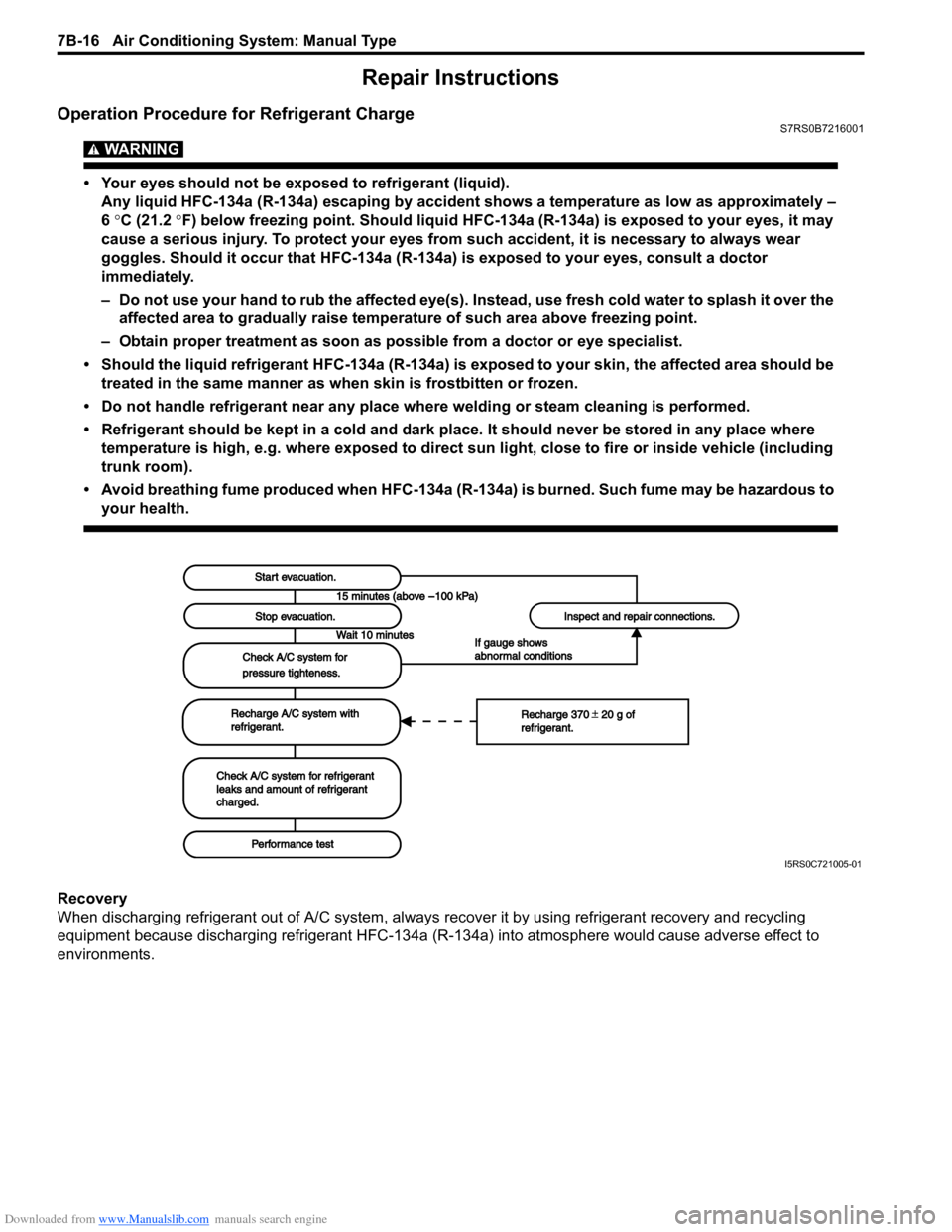

Recovery

When discharging refrigerant out of A/C system, always recover it by using refrigerant recovery and recycling

equipment because discharging refrigerant HFC-134a (R-1 34a) into atmosphere would cause adverse effect to

environments.

Start evacuation.Start evacuation.

Stop evacuation.Stop evacuation.

Wait 10 minutesWait 10 minutes

Check A/C system forCheck A/C system for

pressure tighteness.pressure tighteness.

Recharge A/C system withRecharge A/C system withrefrigerant.refrigerant.

Check A/C system for refrigerantCheck A/C system for refrigerantleaks and amount of refrigerantleaks and amount of refrigerantcharged.charged.

Performance testPerformance test

Inspect and repair connections.Inspect and repair connections.

If gauge showsIf gauge showsabnormal conditionsabnormal conditions

Recharge 370 20 g ofRecharge 370 20 g ofrefrigerant.refrigerant.

I5RS0C721005-01

Page 965 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-17

NOTE

• After recovering refrigerant from system, the amount of removed compressor oil must be measured

for replenishing compressor oil.

• When handling recovery and recycling equipment, be sure to follow the instruction manual for the equipment.

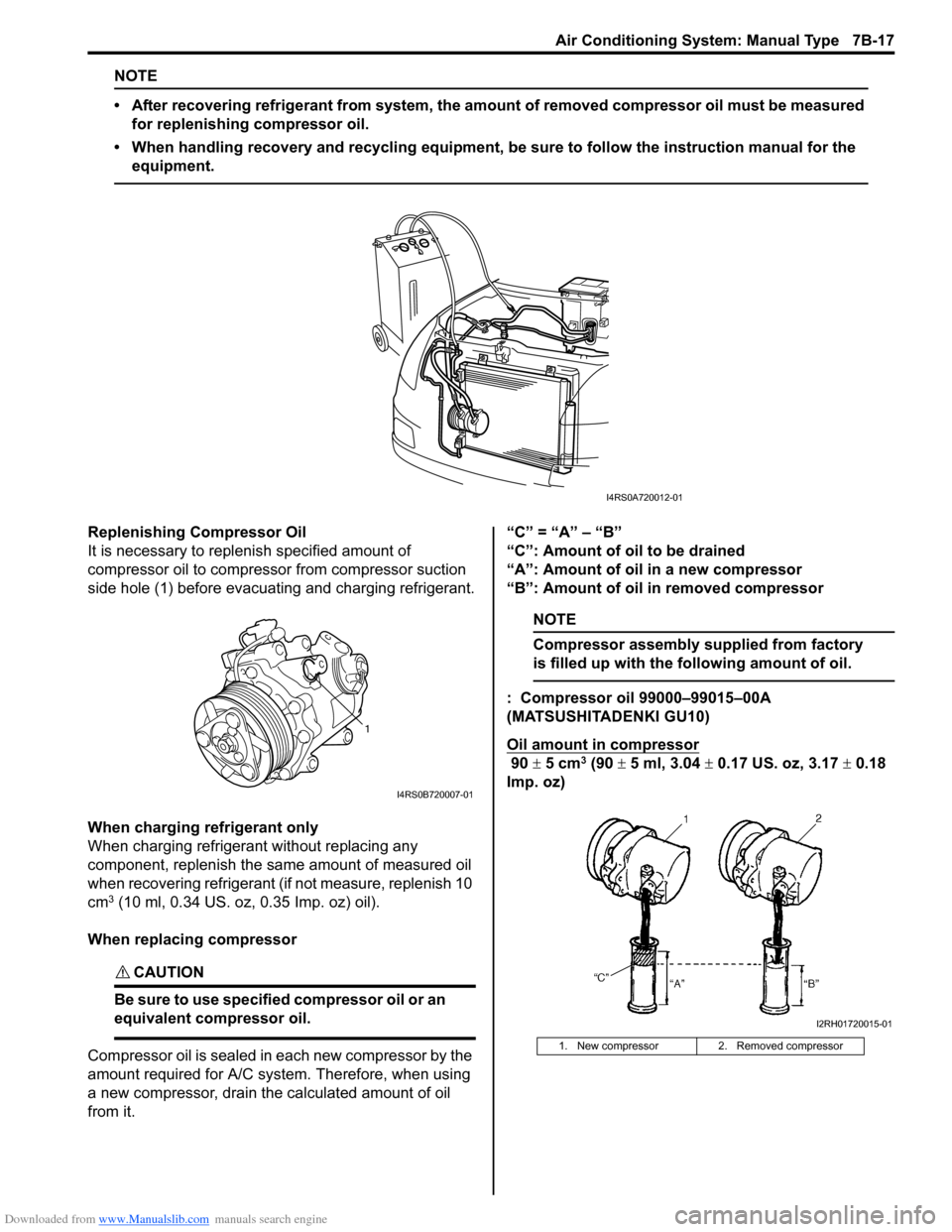

Replenishing Compressor Oil

It is necessary to replenish specified amount of

compressor oil to compressor from compressor suction

side hole (1) before evacuating and charging refrigerant.

When charging refrigerant only

When charging refrigerant without replacing any

component, replenish the same amount of measured oil

when recovering refrigerant (if not measure, replenish 10

cm

3 (10 ml, 0.34 US. oz, 0.35 Imp. oz) oil).

When replacing compressor

CAUTION!

Be sure to use specified compressor oil or an

equivalent compressor oil.

Compressor oil is sealed in each new compressor by the

amount required for A/C system. Therefore, when using

a new compressor, drain the calculated amount of oil

from it. “C” = “A” – “B”

“C”: Amount of oil to be drained

“A”: Amount of oil in a new compressor

“B”: Amount of oil in removed compressor

NOTE

Compressor assembly su

pplied from factory

is filled up with the following amount of oil.

: Compressor oil 99000–99015–00A

(MATSUSHITADENKI GU10)

Oil amount in compressor

90 ± 5 cm3 (90 ± 5 ml, 3.04 ± 0.17 US. oz, 3.17 ± 0.18

Imp. oz)

I4RS0A720012-01

1

I4RS0B720007-01

1. New compressor 2. Removed compressor

I2RH01720015-01

Page 966 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-18 Air Conditioning System: Manual Type

When replacing other parts

Replenish the following amount of oil to compressor.

Amount of compressor oil to be replenished

Evaporator: 25 cm3 (25 ml, 0.85 US. oz, 0.88 Imp. oz)

Condenser: 15 cm3 (15 ml, 0.51 US. oz, 0.53 Imp. oz)

Receiver/dryer: 10 cm3 (10 ml, 0.34 US. oz, 0.35 lmp.

oz)

Hoses: 10 cm

3 (10 ml, 0.34 US. oz, 0.35 Imp. oz) each

Pipes: 10 cm3 (10 ml, 0.34 US. oz, 0.35 Imp. oz) each

Evacuation

CAUTION!

Do not evacuate before recovering

refrigerant in A/C system.

NOTE

Once air conditioning system circuit is

opened (exposed) to atmospheric air, system

must be evacuated by using a vacuum pump.

The A/C system should be attached with a

manifold gauge set, and should be evacuated

for approximately 15 minutes.

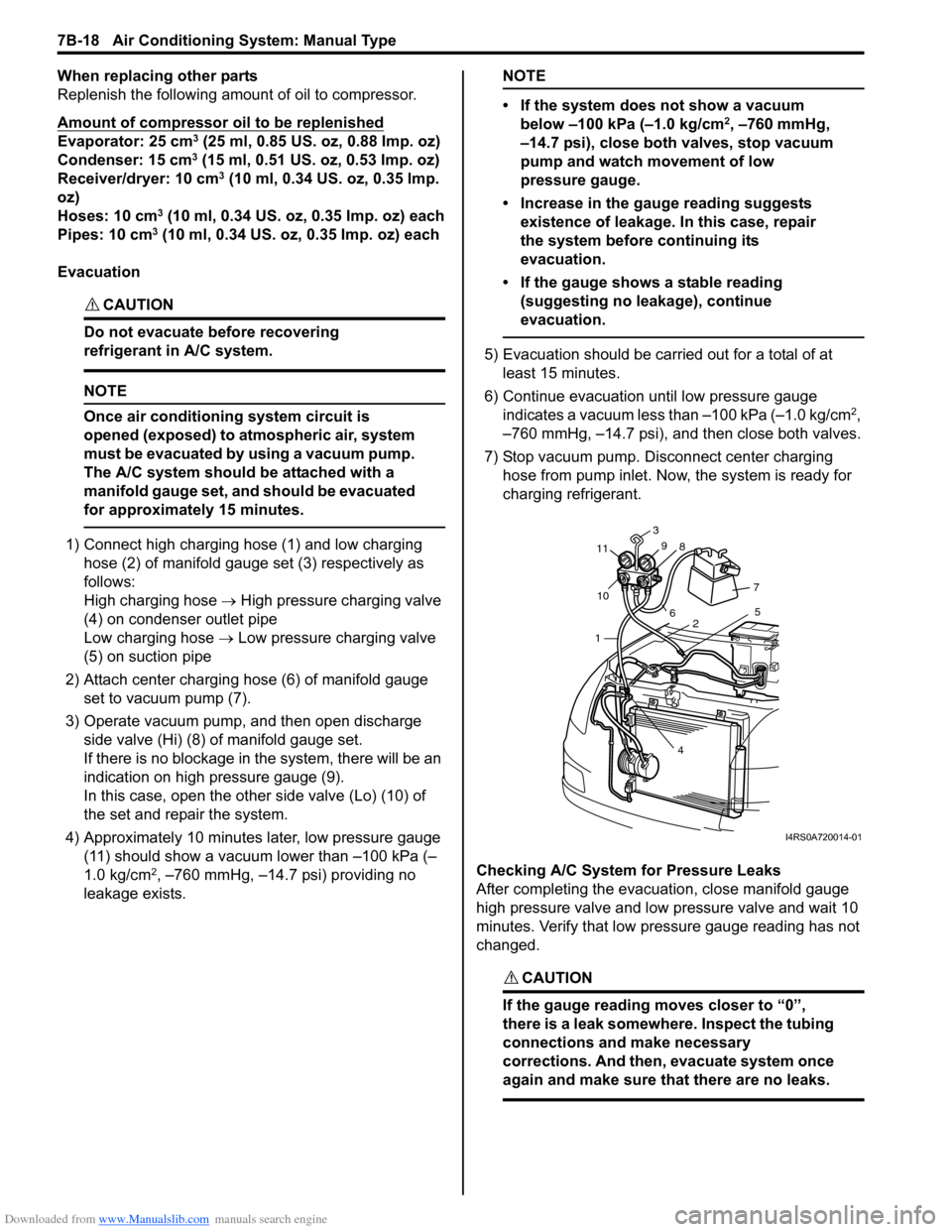

1) Connect high charging hose (1) and low charging hose (2) of manifold gauge set (3) respectively as

follows:

High charging hose → High pressure charging valve

(4) on condenser outlet pipe

Low charging hose → Low pressure charging valve

(5) on suction pipe

2) Attach center charging hose (6) of manifold gauge set to vacuum pump (7).

3) Operate vacuum pump, and then open discharge

side valve (Hi) (8) of manifold gauge set.

If there is no blockage in the system, there will be an

indication on high pressure gauge (9).

In this case, open the other side valve (Lo) (10) of

the set and repair the system.

4) Approximately 10 minutes later, low pressure gauge (11) should show a vacuum lower than –100 kPa (–

1.0 kg/cm

2, –760 mmHg, –14.7 psi) providing no

leakage exists.

NOTE

• If the system does not show a vacuum below –100 kPa (–1.0 kg/cm

2, –760 mmHg,

–14.7 psi), close both valves, stop vacuum

pump and watch movement of low

pressure gauge.

• Increase in the gauge reading suggests existence of leakage. In this case, repair

the system before continuing its

evacuation.

• If the gauge shows a stable reading (suggesting no leakage), continue

evacuation.

5) Evacuation should be carried out for a total of at least 15 minutes.

6) Continue evacuation until low pressure gauge indicates a vacuum less than –100 kPa (–1.0 kg/cm

2,

–760 mmHg, –14.7 psi), and then close both valves.

7) Stop vacuum pump. Disconnect center charging hose from pump inlet. No w, the system is ready for

charging refrigerant.

Checking A/C System for Pressure Leaks

After completing the evacuation, close manifold gauge

high pressure valve and low pressure valve and wait 10

minutes. Verify that low pressure gauge reading has not

changed.

CAUTION!

If the gauge reading moves closer to “0”,

there is a leak somewhere. Inspect the tubing

connections and make necessary

corrections. And then, evacuate system once

again and make sure that there are no leaks.

7 5

2

4

1

10

11

3

9 8

6

I4RS0A720014-01

Page 967 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-19

Charge

CAUTION!

• Because the sight glass is not used for this A/C system, do not perform an additional

charge to the A/C system. To charge the

proper amount of refrigerant, recover and

evacuate the A/C system first. And then,

charge the proper amount of refrigerant

into the A/C system.

• Always charge refrigerant through low pressure side of A/C system after the initial

charge is performed from the high

pressure side with the engine stopped.

• Never charge refrigerant through high pressure side of A/C system with engine

running.

• Do not charge refrigerant while compressor is hot.

• When installing tap valve to refrigerant container to make a hole there through,

carefully follow dire ctions given by

manufacturer.

• A pressure gauge should always be used before and during refrigerant charge.

• The refrigerant container should be emptied of refrigerant when discarding it.

• The refrigerant container should not be heated up to 40 °C (104 °F) or over.

• Refrigerant container should not be reversed in direction during refrigerant

charge. Reversing in direction causes

liquid refrigerant to enter compressor,

causing troubles, such as compression of

liquid refrigerant and the like.

NOTE

The air conditioning system contains HFC-

134a (R-134a).

Described here is a method to charge the air

conditioning system with refrigerant from the

refrigerant service container.

When charging refrigerant recovered by

using the refrigerant and recycling

equipment (when recycling refrigerant),

follow the procedure described in the

equipment manufacturer’s instruction

manual.

Charge proper amount of refrigerant accurately in

accordance with the following procedure.

Specified amount of refrigerant

370 ± 20 g (13.0 ± 0.7 oz)

The initial charge of the A/C system is performed

through the high pressure side with the engine stopped.

And next, this method must be followed by charging from

the low pressure side with the engine running.

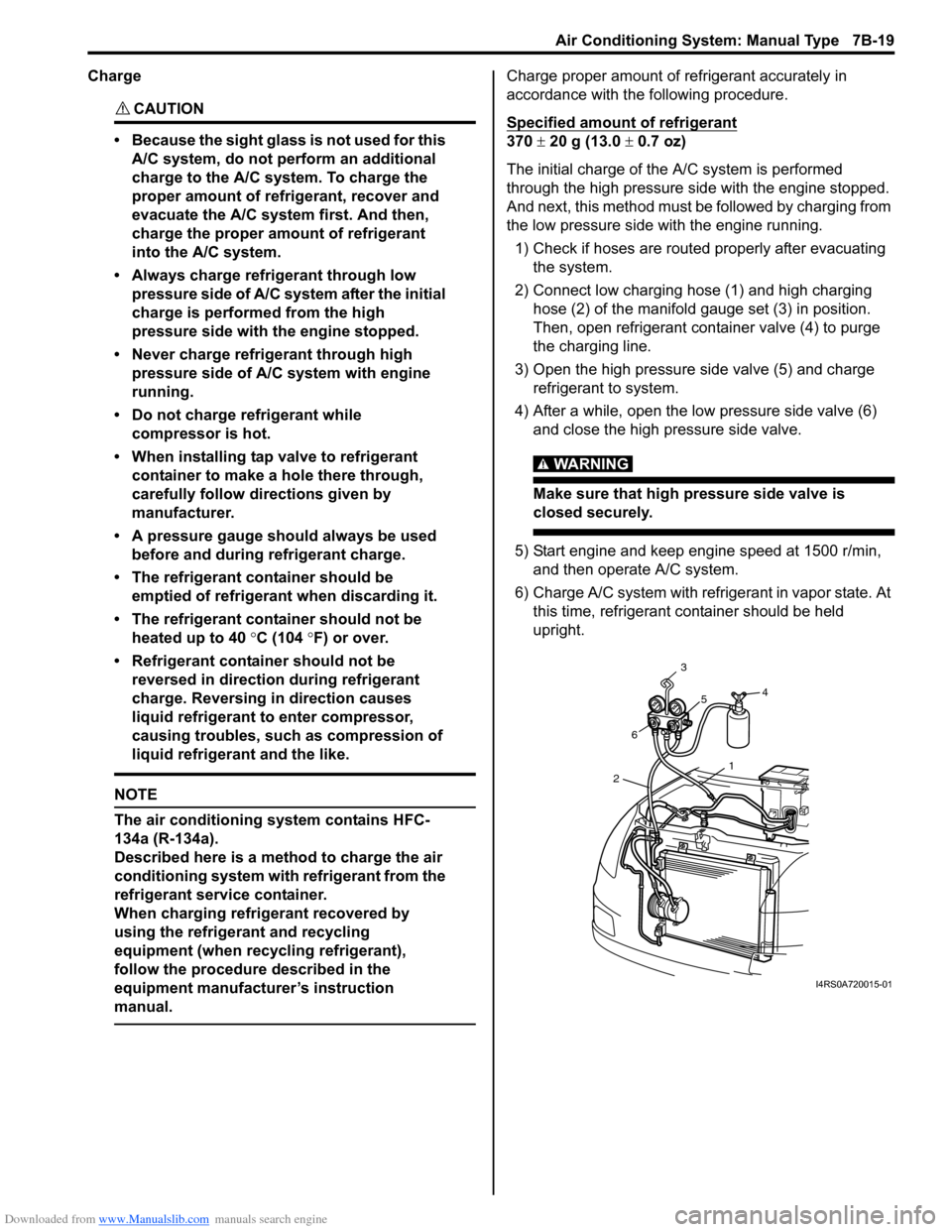

1) Check if hoses are routed properly after evacuating the system.

2) Connect low charging hose (1) and high charging hose (2) of the manifold gauge set (3) in position.

Then, open refrigerant container valve (4) to purge

the charging line.

3) Open the high pressure side valve (5) and charge refrigerant to system.

4) After a while, open the low pressure side valve (6) and close the high pressure side valve.

WARNING!

Make sure that high pressure side valve is

closed securely.

5) Start engine and keep engine speed at 1500 r/min, and then operate A/C system.

6) Charge A/C system with refrigerant in vapor state. At this time, refrigerant container should be held

upright.

1

2 6 3

5 4

I4RS0A720015-01

Page 968 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-20 Air Conditioning System: Manual Type

7) When refrigerant container (1) is emptied, use the following procedure to replace it with a new

refrigerant container.

a) Close low pressure valve.

b) Replace empty container with a refrigerant container which has been charged with

refrigerant. When using refrigerant container tap

valve (2), use the following procedure for

replacement.

i) Retract needle (3) and remove refrigerant container tap valve by loosening its plate nut

(4).

ii) Install the refrigerant container tap valve to a new refrigerant container.

c) Purge any air existing in center charging hose. When using refrigerant container tap valve, use

the following procedure to purge air.

i) Once fully tighten refrigerant container tap valve (1), and then loosen (open) plate nut

(2) slightly.

ii) Open low pressure side valve (3) of manifold

gauge set (4) a little.

iii) As soon as refrigerant comes out with a “hiss” through a clearance between

refrigerant container and tap valve, tighten

plate nut as well as low pressure side valve.

iv) Turn handle of tap valve clockwise so that its needle is screwed into the new container to

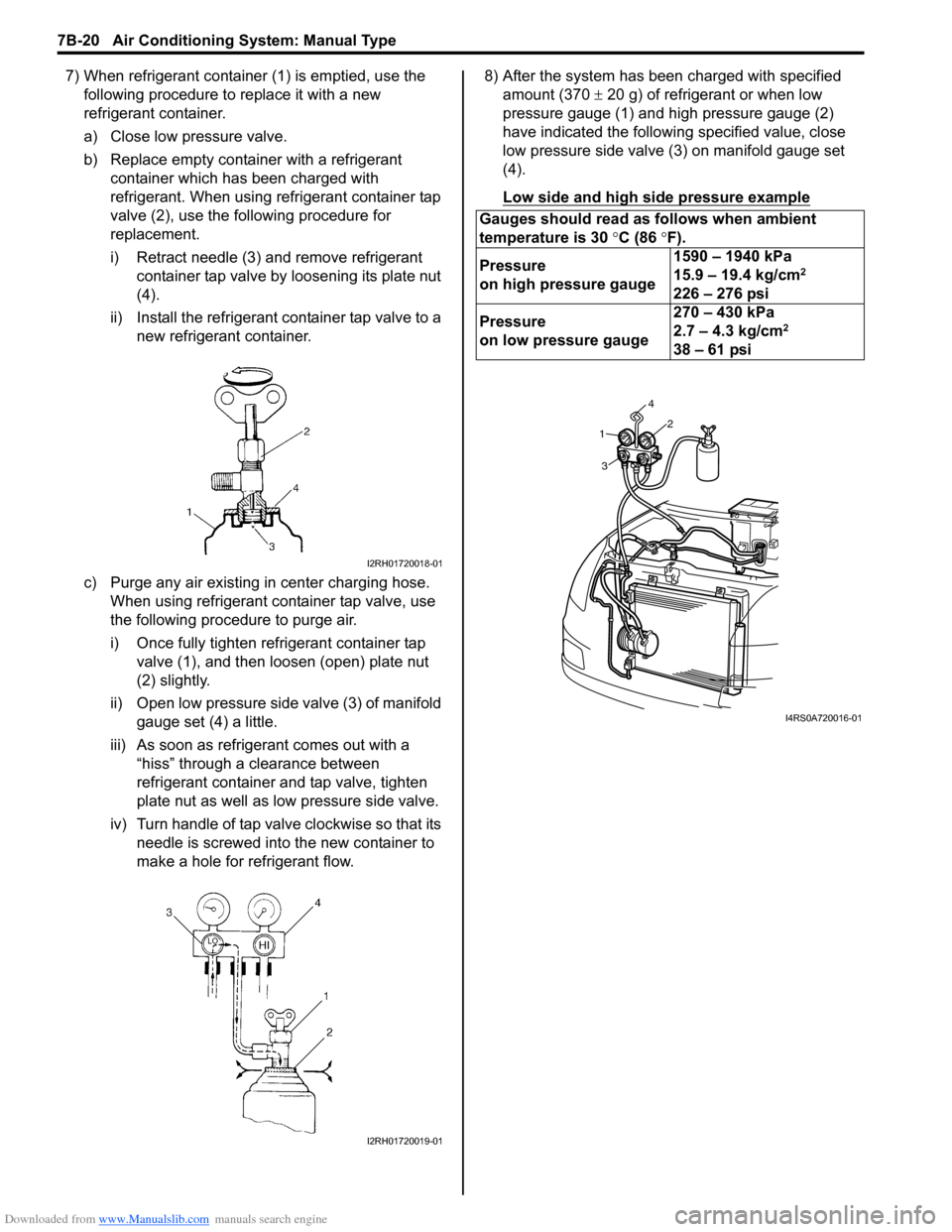

make a hole for refrigerant flow. 8) After the system has been charged with specified

amount (370 ± 20 g) of refrigerant or when low

pressure gauge (1) and high pressure gauge (2)

have indicated the following specified value, close

low pressure side valve (3) on manifold gauge set

(4).

Low side and high side pressure example

I2RH01720018-01

I2RH01720019-01

Gauges should read as follows when ambient

temperature is 30 °C (86 °F).

Pressure

on high pressure gauge 1590 – 1940 kPa

15.9 – 19.4 kg/cm

2

226 – 276 psi

Pressure

on low pressure gauge 270 – 430 kPa

2.7 – 4.3 kg/cm

2

38 – 61 psi

1

3 42

I4RS0A720016-01