Fluid SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 795 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-151

6) Install parking lock pawl bracket (1) to transaxle

case.

Tightening torque

Parking lock pawl bracket bolt (a): 7.5 N·m (0.75

kgf-m, 5.5 lb-ft)

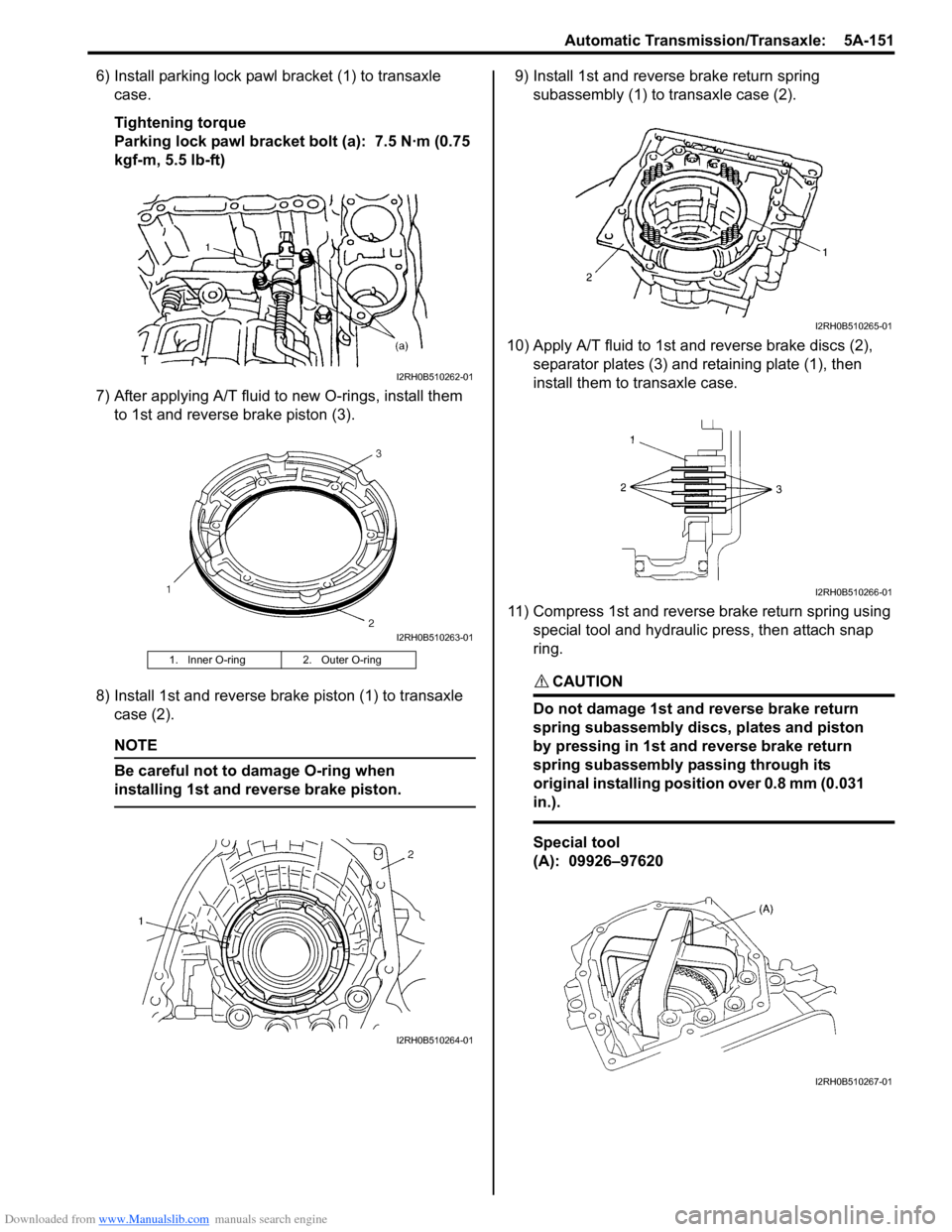

7) After applying A/T fluid to new O-rings, install them to 1st and reverse brake piston (3).

8) Install 1st and reverse brake piston (1) to transaxle case (2).

NOTE

Be careful not to damage O-ring when

installing 1st and reverse brake piston.

9) Install 1st and reverse brake return spring subassembly (1) to transaxle case (2).

10) Apply A/T fluid to 1st and reverse brake discs (2), separator plates (3) and retaining plate (1), then

install them to transaxle case.

11) Compress 1st and reverse brake return spring using special tool and hydraulic press, then attach snap

ring.

CAUTION!

Do not damage 1st and reverse brake return

spring subassembly discs, plates and piston

by pressing in 1st and reverse brake return

spring subassembly passing through its

original installing position over 0.8 mm (0.031

in.).

Special tool

(A): 09926–97620

1. Inner O-ring 2. Outer O-ring

I2RH0B510262-01

I2RH0B510263-01

I2RH0B510264-01

I2RH0B510265-01

I2RH0B510266-01

I2RH0B510267-01

Page 796 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-152 Automatic Transmission/Transaxle:

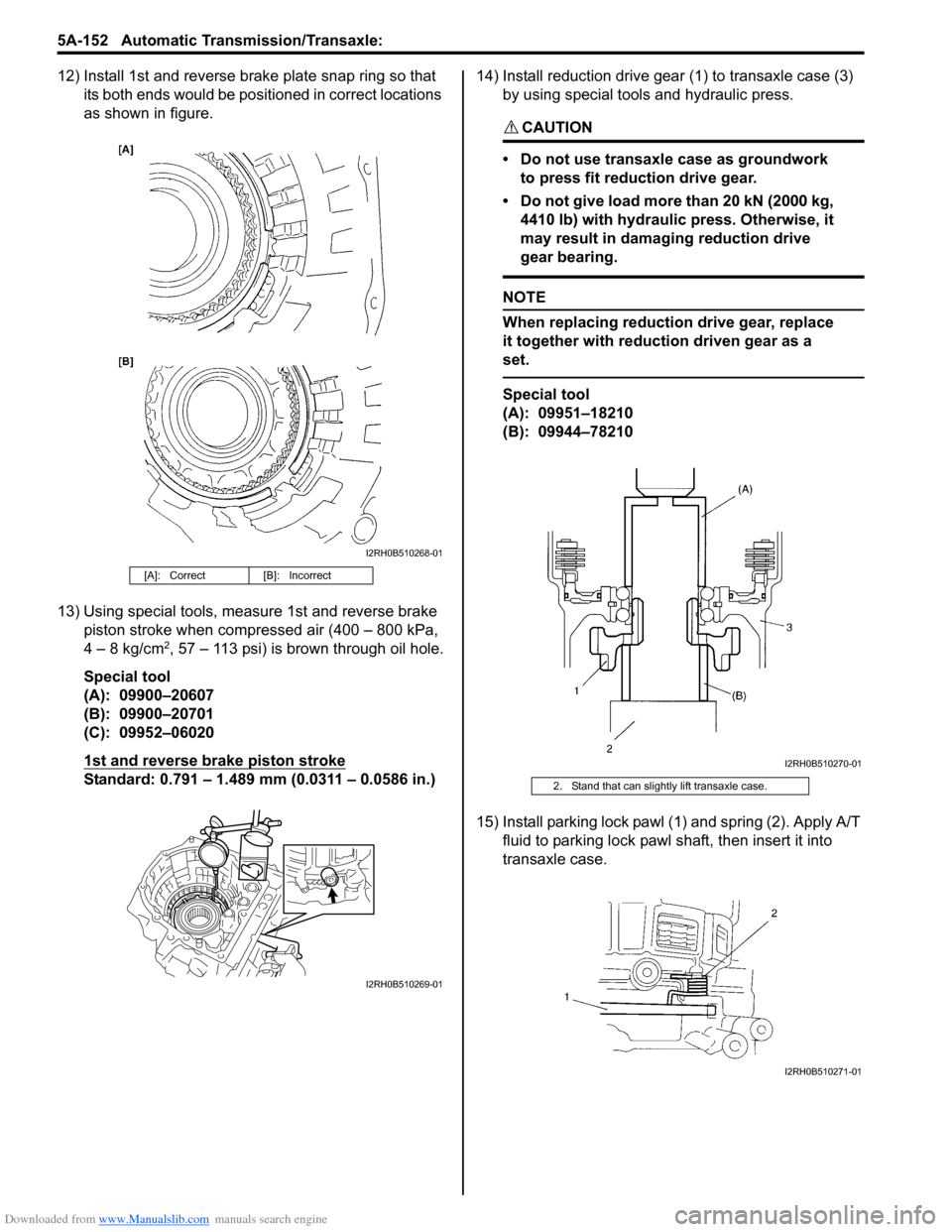

12) Install 1st and reverse brake plate snap ring so that its both ends would be positioned in correct locations

as shown in figure.

13) Using special tools, meas ure 1st and reverse brake

piston stroke when compressed air (400 – 800 kPa,

4 – 8 kg/cm

2, 57 – 113 psi) is brown through oil hole.

Special tool

(A): 09900–20607

(B): 09900–20701

(C): 09952–06020

1st and reverse brake piston stroke

Standard: 0.791 – 1.489 mm (0.0311 – 0.0586 in.) 14) Install reduction drive gear (1) to transaxle case (3)

by using special tools and hydraulic press.

CAUTION!

• Do not use transaxle case as groundwork to press fit reduction drive gear.

• Do not give load more than 20 kN (2000 kg, 4410 lb) with hydraulic press. Otherwise, it

may result in damaging reduction drive

gear bearing.

NOTE

When replacing reduction drive gear, replace

it together with reduction driven gear as a

set.

Special tool

(A): 09951–18210

(B): 09944–78210

15) Install parking lock pawl (1) and spring (2). Apply A/T fluid to parking lock pawl sh aft, then insert it into

transaxle case.

[A]: Correct [B]: Incorrect

I2RH0B510268-01

I2RH0B510269-01

2. Stand that can slightly lift transaxle case.

I2RH0B510270-01

I2RH0B510271-01

Page 797 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-153

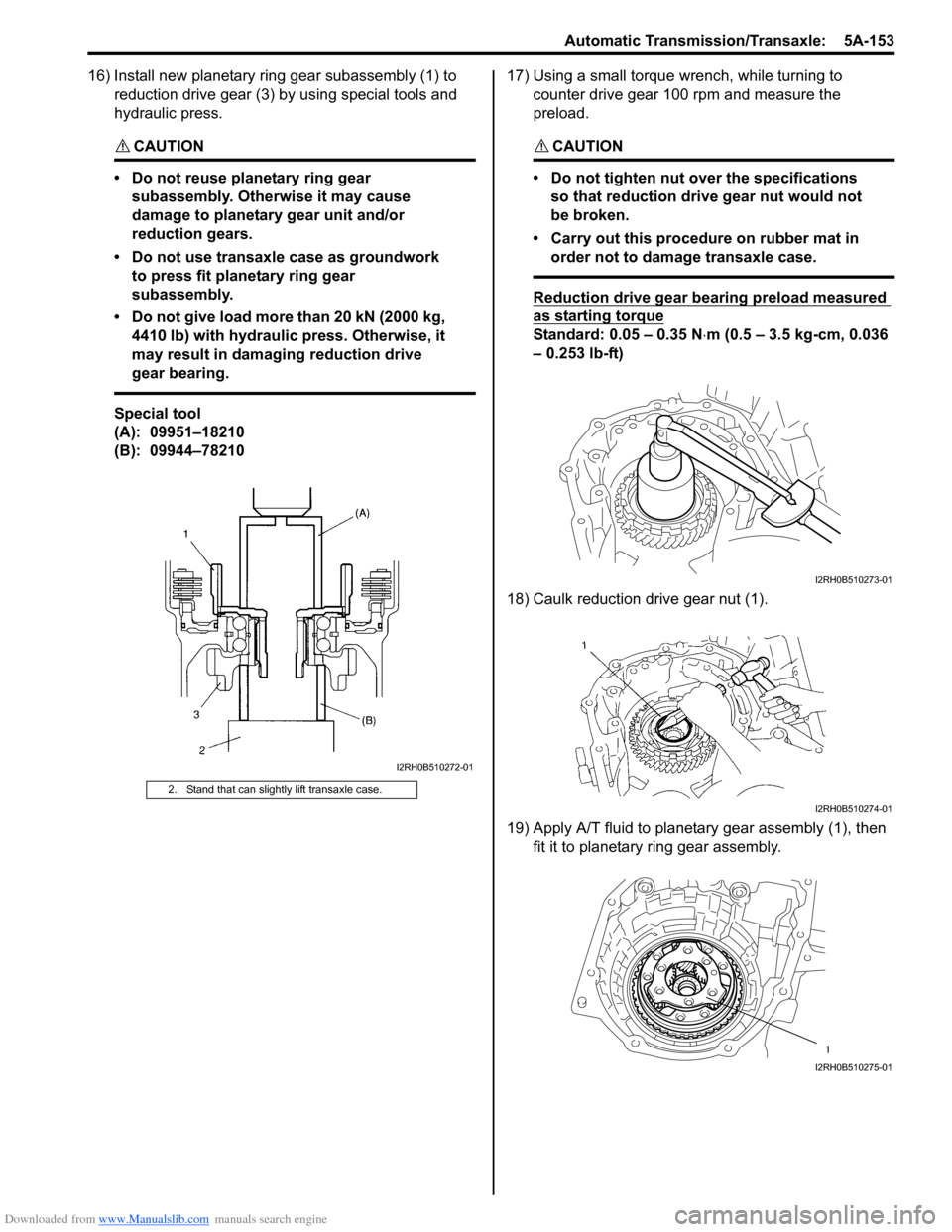

16) Install new planetary ring gear subassembly (1) to reduction drive gear (3) by using special tools and

hydraulic press.

CAUTION!

• Do not reuse planetary ring gear subassembly. Otherwise it may cause

damage to planetary gear unit and/or

reduction gears.

• Do not use transaxle case as groundwork to press fit planetary ring gear

subassembly.

• Do not give load more than 20 kN (2000 kg, 4410 lb) with hydraulic press. Otherwise, it

may result in damaging reduction drive

gear bearing.

Special tool

(A): 09951–18210

(B): 09944–78210 17) Using a small torque

wrench, while turning to

counter drive gear 100 rpm and measure the

preload.

CAUTION!

• Do not tighten nut over the specifications so that reduction drive gear nut would not

be broken.

• Carry out this procedure on rubber mat in order not to damage transaxle case.

Reduction drive gear bearing preload measured

as starting torque

Standard: 0.05 – 0.35 N ⋅m (0.5 – 3.5 kg-cm, 0.036

– 0.253 lb-ft)

18) Caulk reduction drive gear nut (1).

19) Apply A/T fluid to planetary gear assembly (1), then fit it to planetary ring gear assembly.

2. Stand that can slightly lift transaxle case.

I2RH0B510272-01

I2RH0B510273-01

I2RH0B510274-01

1

I2RH0B510275-01

Page 798 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-154 Automatic Transmission/Transaxle:

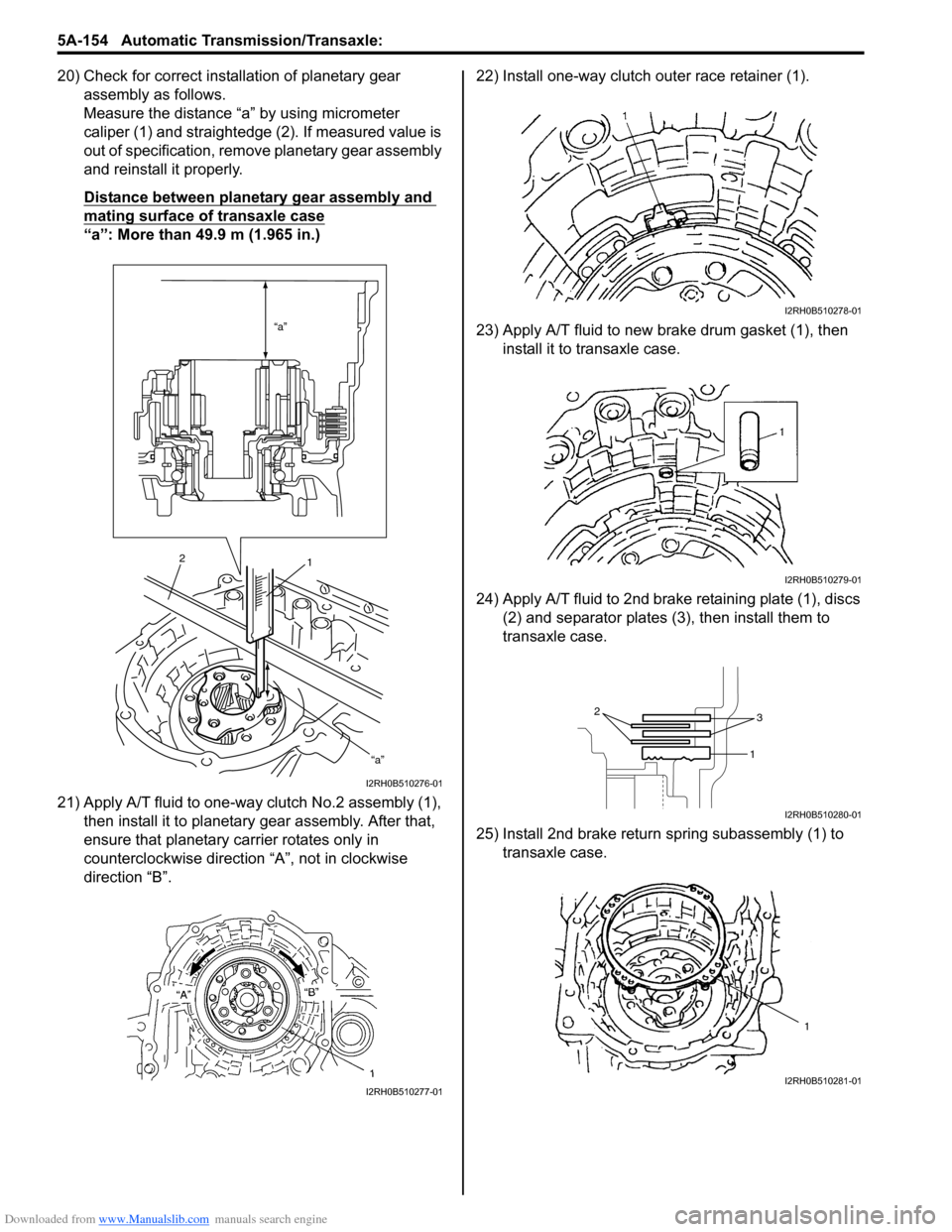

20) Check for correct installation of planetary gear assembly as follows.

Measure the distance “a” by using micrometer

caliper (1) and straightedge (2). If measured value is

out of specification, remove planetary gear assembly

and reinstall it properly.

Distance between planetary gear assembly and

mating surface of transaxle case

“a”: More than 49.9 m (1.965 in.)

21) Apply A/T fluid to one-way clutch No.2 assembly (1), then install it to planetar y gear assembly. After that,

ensure that planetary carrier rotates only in

counterclockwise direction “A”, not in clockwise

direction “B”. 22) Install one-way clutch outer race retainer (1).

23) Apply A/T fluid to new brake drum gasket (1), then

install it to transaxle case.

24) Apply A/T fluid to 2nd brak e retaining plate (1), discs

(2) and separator plates (3), then install them to

transaxle case.

25) Install 2nd brake return spring subassembly (1) to transaxle case.

“a”

“a”

2 1

I2RH0B510276-01

I2RH0B510277-01

I2RH0B510278-01

I2RH0B510279-01

2

3

1

I2RH0B510280-01

1

I2RH0B510281-01

Page 799 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-155

26) Apply A/T fluid to 2nd brake piston assembly (1), and align the projection of 2nd brake piston assembly

with the groove of transaxle case, then put together.

27) Install 2nd brake piston snap ring (1) by using special tool and hydraulic press.

CAUTION!

Do not damage 2nd brake piston assembly,

return spring subassembly, plates and discs

by pressing in 2nd brake assembly passing

through its original installing position over

0.4 mm (0.016 in.).

Special tool

(A): 09926–96050

28) After applying A/T fluid to front sun gear thrust bearing race (2), install it to front planetary sun gear

(1). 29) Apply A/T fluid to front planetary sun gear (1) and

install it to planetary gear assembly (2).

30) Install O/D and 2nd coast brake retaining plate snap ring (1).

CAUTION!

Be sure to install O/D and 2nd coast brake

retaining plate snap ring correctly in groove

of transaxle case.

31) After applying grease to slide contact face of planetary carrier thrust washer (1), install it to

planetary gear assembly.

“A”: Grease 99000–25030 (SUZUKI Super

Grease C)

I2RH0B510282-01

I2RH0B510283-01

I2RH0B510285-01

I2RH0B510286-01

I2RH0B510287-01

I2RH0B510288-01

Page 800 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-156 Automatic Transmission/Transaxle:

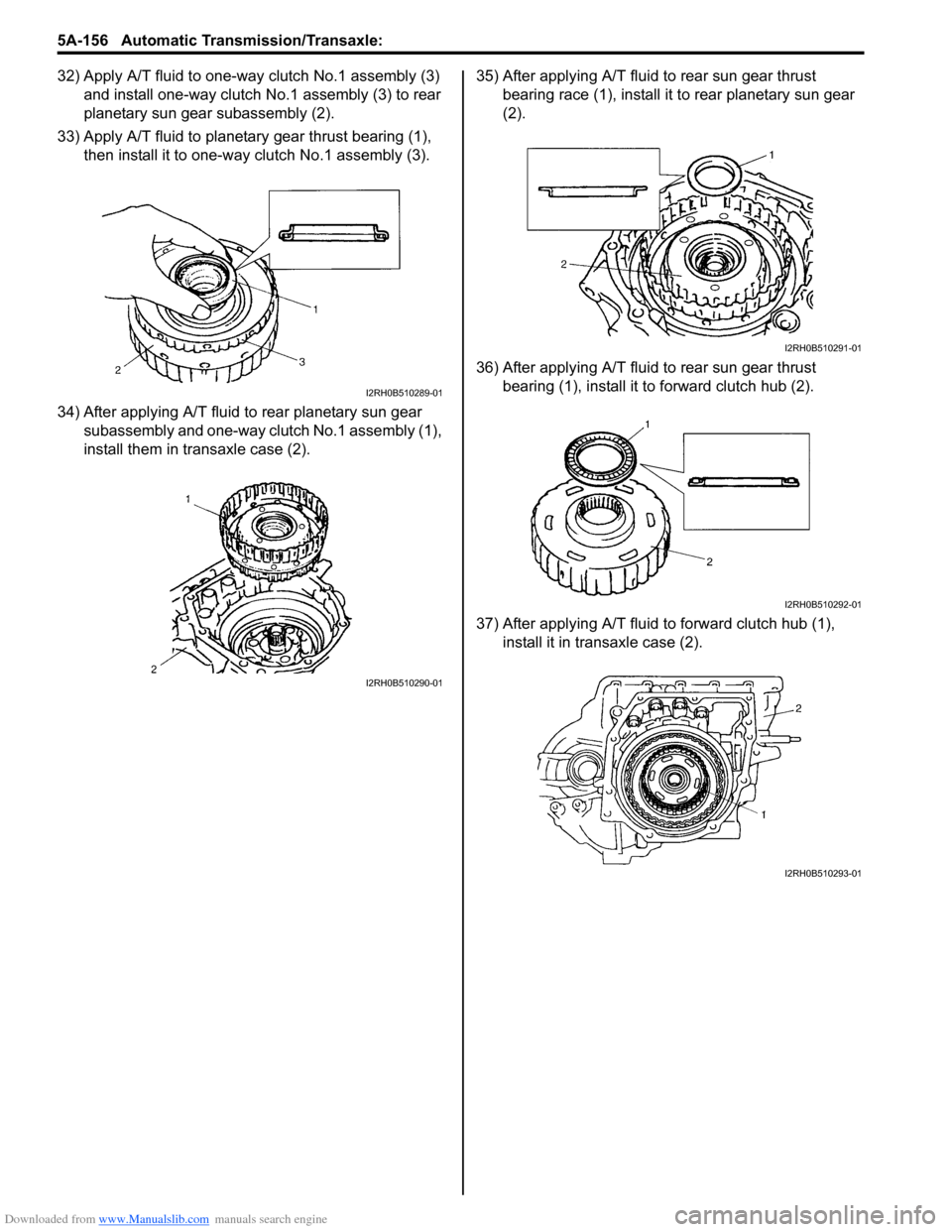

32) Apply A/T fluid to one-way clutch No.1 assembly (3) and install one-way clutch No .1 assembly (3) to rear

planetary sun gear subassembly (2).

33) Apply A/T fluid to planetary gear thrust bearing (1), then install it to one-way clutch No.1 assembly (3).

34) After applying A/T fluid to rear planetary sun gear subassembly and one-way clutch No.1 assembly (1),

install them in transaxle case (2). 35) After applying A/T fluid to rear sun gear thrust

bearing race (1), install it to rear planetary sun gear

(2).

36) After applying A/T fluid to rear sun gear thrust bearing (1), install it to forward clutch hub (2).

37) After applying A/T fluid to forward clutch hub (1), install it in transaxle case (2).

I2RH0B510289-01

I2RH0B510290-01

I2RH0B510291-01

I2RH0B510292-01

I2RH0B510293-01

Page 801 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-157

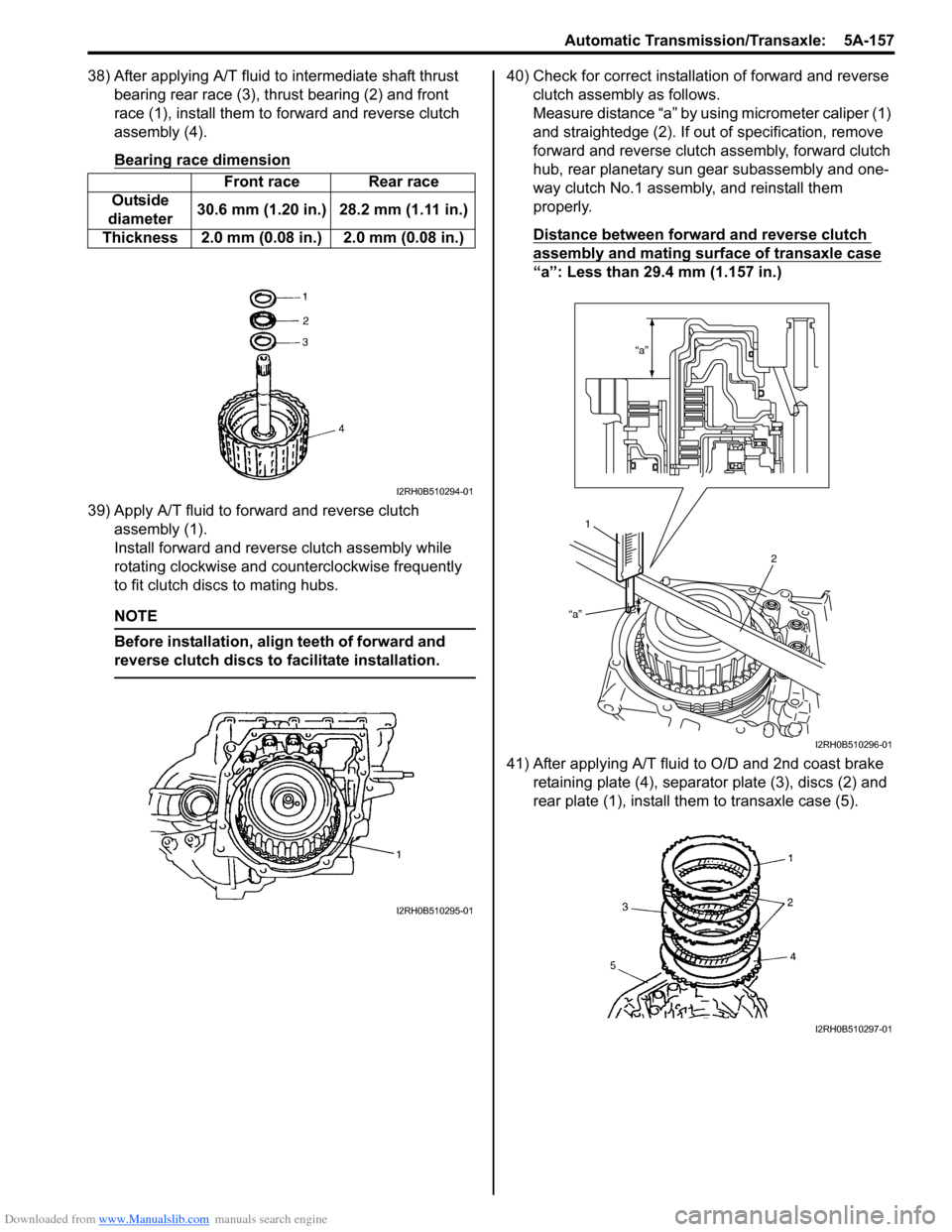

38) After applying A/T fluid to intermediate shaft thrust bearing rear race (3), thrust bearing (2) and front

race (1), install them to forward and reverse clutch

assembly (4).

Bearing race dimension

39) Apply A/T fluid to forward and reverse clutch assembly (1).

Install forward and revers e clutch assembly while

rotating clockwise and co unterclockwise frequently

to fit clutch discs to mating hubs.

NOTE

Before installation, align teeth of forward and

reverse clutch discs to facilitate installation.

40) Check for correct installation of forward and reverse clutch assembly as follows.

Measure distance “a” by using micrometer caliper (1)

and straightedge (2). If out of specification, remove

forward and reverse clutch assembly, forward clutch

hub, rear planetary sun gear subassembly and one-

way clutch No.1 assemb ly, and reinstall them

properly.

Distance between forward and reverse clutch

assembly and mating surface of transaxle case

“a”: Less than 29.4 mm (1.157 in.)

41) After applying A/T fluid to O/D and 2nd coast brake retaining plate (4), separator plate (3), discs (2) and

rear plate (1), install th em to transaxle case (5).

Front race Rear race

Outside

diameter 30.6 mm (1.20 in.) 28.2 mm (1.11 in.)

Thickness 2.0 mm (0.08 in.) 2.0 mm (0.08 in.)

I2RH0B510294-01

I2RH0B510295-01

“a”

“a”

1 2

I2RH0B510296-01

I2RH0B510297-01

Page 802 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-158 Automatic Transmission/Transaxle:

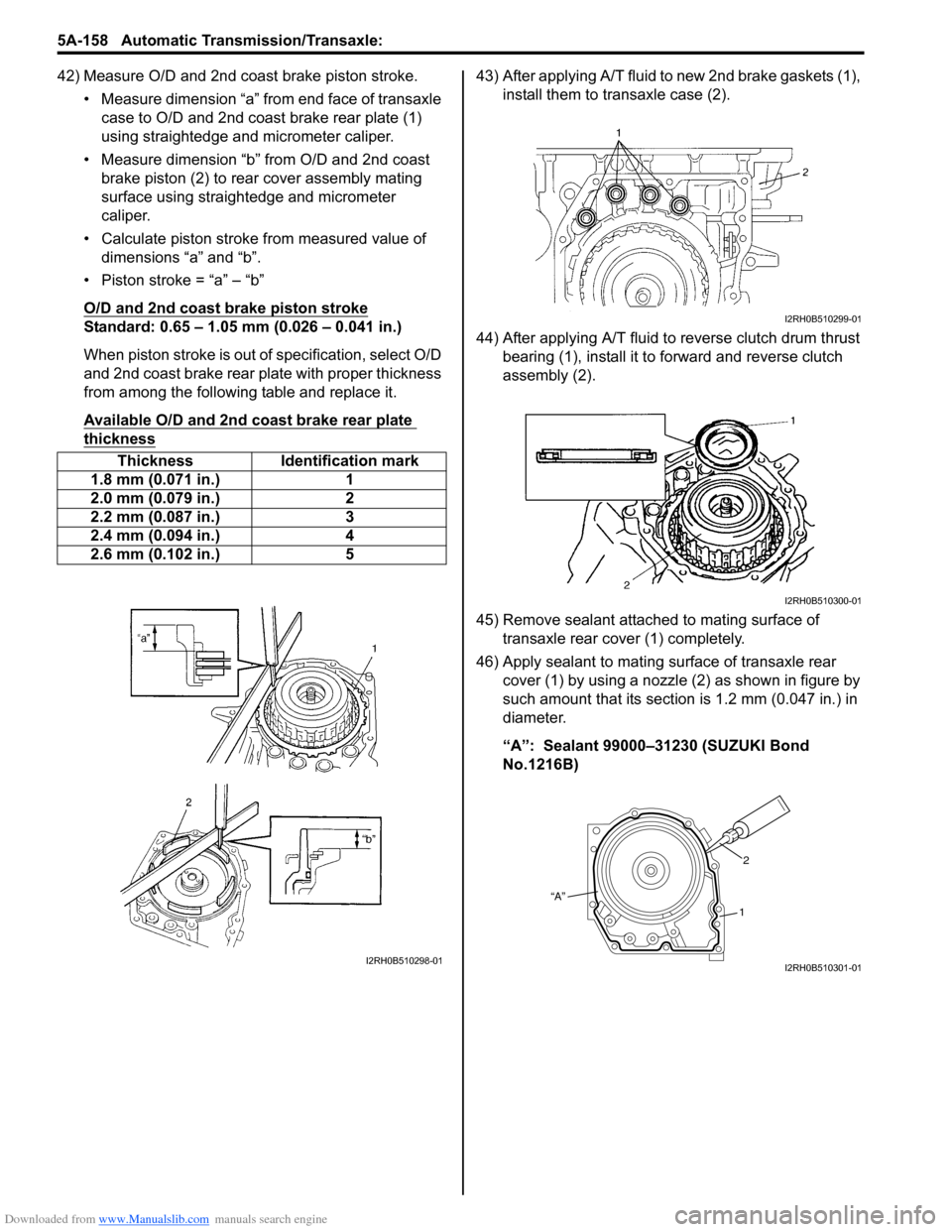

42) Measure O/D and 2nd coast brake piston stroke.• Measure dimension “a” from end face of transaxle case to O/D and 2nd coast brake rear plate (1)

using straightedge and micrometer caliper.

• Measure dimension “b” from O/D and 2nd coast brake piston (2) to rear cover assembly mating

surface using straightedge and micrometer

caliper.

• Calculate piston stroke from measured value of dimensions “a” and “b”.

• Piston stroke = “a” – “b”

O/D and 2nd coast brake piston stroke

Standard: 0.65 – 1.05 mm (0.026 – 0.041 in.)

When piston stroke is out of specification, select O/D

and 2nd coast brake rear plate with proper thickness

from among the following table and replace it.

Available O/D and 2nd coast brake rear plate

thickness

43) After applying A/T fluid to new 2nd brake gaskets (1), install them to transaxle case (2).

44) After applying A/T fluid to reverse clutch drum thrust bearing (1), install it to forward and reverse clutch

assembly (2).

45) Remove sealant attached to mating surface of transaxle rear cover (1) completely.

46) Apply sealant to mating surface of transaxle rear cover (1) by using a nozzle (2) as shown in figure by

such amount that its section is 1.2 mm (0.047 in.) in

diameter.

“A”: Sealant 99000–31230 (SUZUKI Bond

No.1216B)

Thickness Identification mark

1.8 mm (0.071 in.) 1

2.0 mm (0.079 in.) 2

2.2 mm (0.087 in.) 3

2.4 mm (0.094 in.) 4

2.6 mm (0.102 in.) 5

I2RH0B510298-01

I2RH0B510299-01

I2RH0B510300-01

“A” 2

1

I2RH0B510301-01

Page 803 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-159

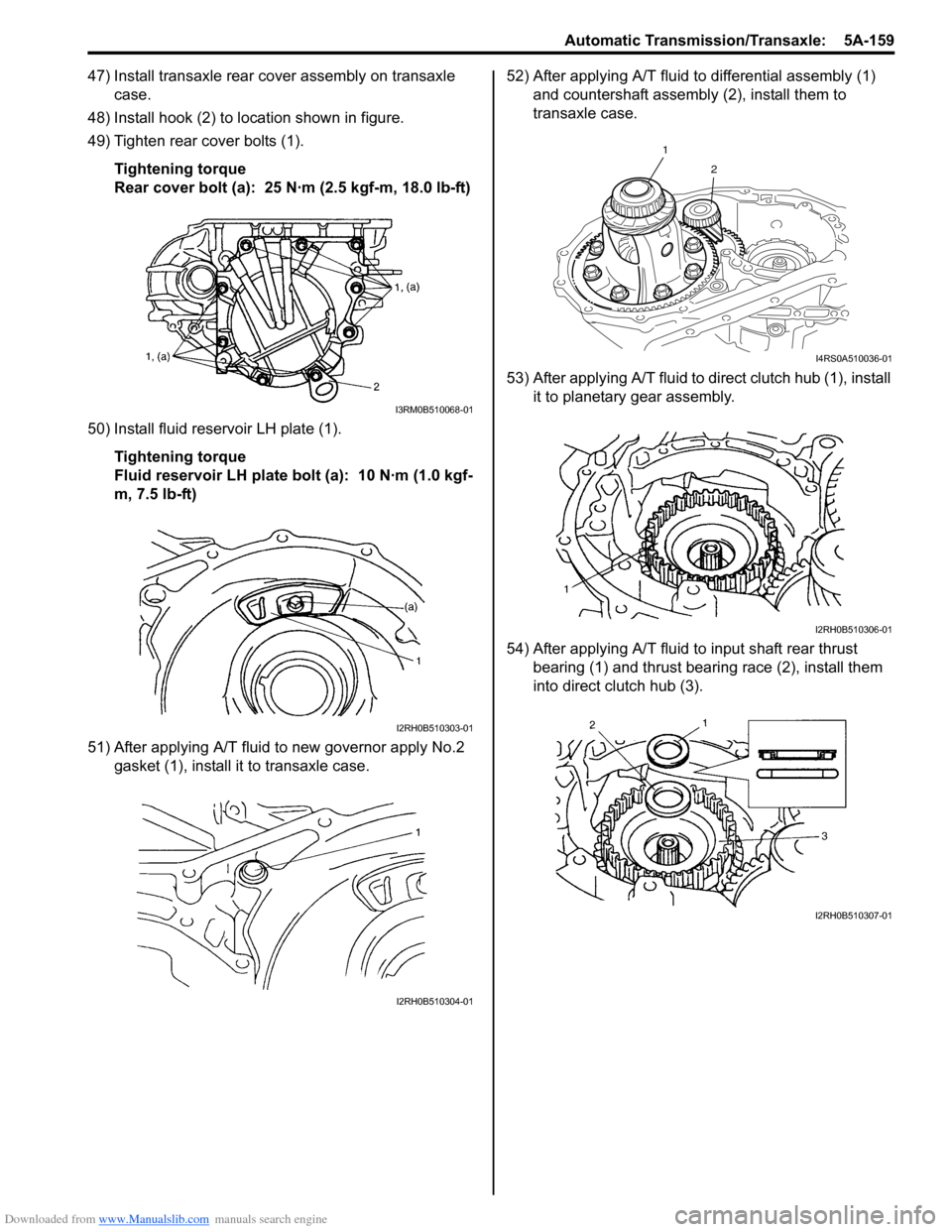

47) Install transaxle rear cover assembly on transaxle case.

48) Install hook (2) to location shown in figure.

49) Tighten rear cover bolts (1).

Tightening torque

Rear cover bolt (a): 25 N·m (2.5 kgf-m, 18.0 lb-ft)

50) Install fluid reservoir LH plate (1). Tightening torque

Fluid reservoir LH plate bolt (a): 10 N·m (1.0 kgf-

m, 7.5 lb-ft)

51) After applying A/T fluid to new governor apply No.2 gasket (1), install it to transaxle case. 52) After applying A/T fluid to differential assembly (1)

and countershaft assembly (2), install them to

transaxle case.

53) After applying A/T fluid to di rect clutch hub (1), install

it to planetary gear assembly.

54) After applying A/T fluid to input shaft rear thrust

bearing (1) and thrust bearing race (2), install them

into direct clutch hub (3).

I3RM0B510068-01

I2RH0B510303-01

I2RH0B510304-01

1

2

I4RS0A510036-01

I2RH0B510306-01

I2RH0B510307-01

Page 804 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-160 Automatic Transmission/Transaxle:

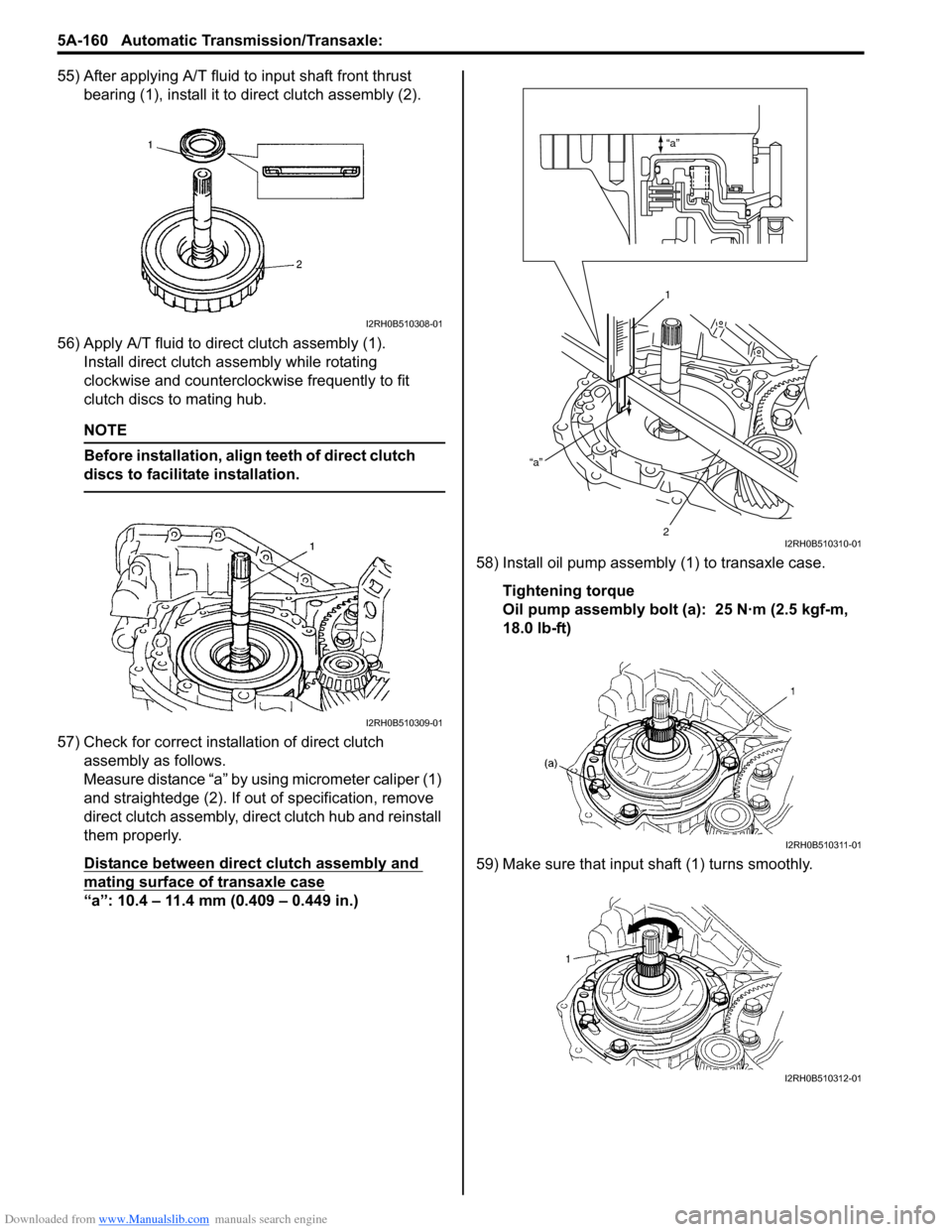

55) After applying A/T fluid to input shaft front thrust bearing (1), install it to direct clutch assembly (2).

56) Apply A/T fluid to direct clutch assembly (1). Install direct clutch a ssembly while rotating

clockwise and counterclockwise frequently to fit

clutch discs to mating hub.

NOTE

Before installation, align teeth of direct clutch

discs to facilitate installation.

57) Check for correct installation of direct clutch assembly as follows.

Measure distance “a” by using micrometer caliper (1)

and straightedge (2). If out of specification, remove

direct clutch assembly, direct clutch hub and reinstall

them properly.

Distance between direct clutch assembly and

mating surface of transaxle case

“a”: 10.4 – 11.4 mm (0.409 – 0.449 in.) 58) Install oil pump assembly

(1) to transaxle case.

Tightening torque

Oil pump assembly bolt (a): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

59) Make sure that input shaft (1) turns smoothly.

I2RH0B510308-01

I2RH0B510309-01

“a”

“a”

1

2

I2RH0B510310-01

I2RH0B510311-01

I2RH0B510312-01