Turn SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 233 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-183

E23-45BLU/

ORNThrottle actuator

control relay output

0 β 1 V Ignition switch turned ON. β

E23-46 LT GRN Radiator cooling

fan relay No.1

output 10 β 14 V

Ignition switch turned ON,

engine coolant temp.:

below 95

Β°C (203 Β° F), or

A/C refrigerant pressure (if

equipped with A/C): below

600 kPa (87 psi) with A/C

switch turned ON while

engine is running. β

0 β 2 V Ignition switch turned ON,

engine coolant temp.: 97.5

Β°

C (207.5 Β° F) or higher, or

A/C refrigerant pressure (if

equipped with A/C): 1100

kPa (159.5 psi) or higher

with A/C switch turned ON

while engine is running.

E23-47 GRY A/C compressor

relay output 10 β 14 V

Engine running, A/C

switch OFF and blower

selector at OFF position.

β

0 β 1 V Engine running, A/C

switch ON and blower

selector at 1st position or

more.

E23-48 GRN Radiator cooling

fan relay No.2 and

No.3 output 10 β 14 V

Ignition switch turned ON,

engine coolant temp.:

below 100

Β°C (212 Β°F), or

A/C refrigerant pressure (if

equipped with A/C): below

1200 kPa (174 psi) with A/

C switch turned ON while

engine is running. β

0 β 2 V Ignition switch turned ON,

engine coolant temp.:

102.5

Β°C (216.5 Β°F) or

higher, or A/C refrigerant

pressure (if equipped with

A/C): 1500 kPa (217.5 psi)

or higher with A/C switch

turned ON while engine is

running.

E23-49 β β β β β

E23-50 β Ground for shield

wire of APP sensor Below 0.3 V Ignition switch turned ON. β

E23-51 WHT Ground for APP

sensor (sub) Below 0.3 V Ignition switch turned ON. β

E23-52 BLU Ground for APP

sensor (main) Below 0.3 V Ignition switch turned ON. β

E23-53 β β β β β

E23-54 ORN Ground for sensors Below 0.3 V Ignition switch turned ON. β

Terminal

No. Wire

color Circuit Normal voltage Condition Remarks

Page 234 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-184 Engine General Information and Diagnosis:

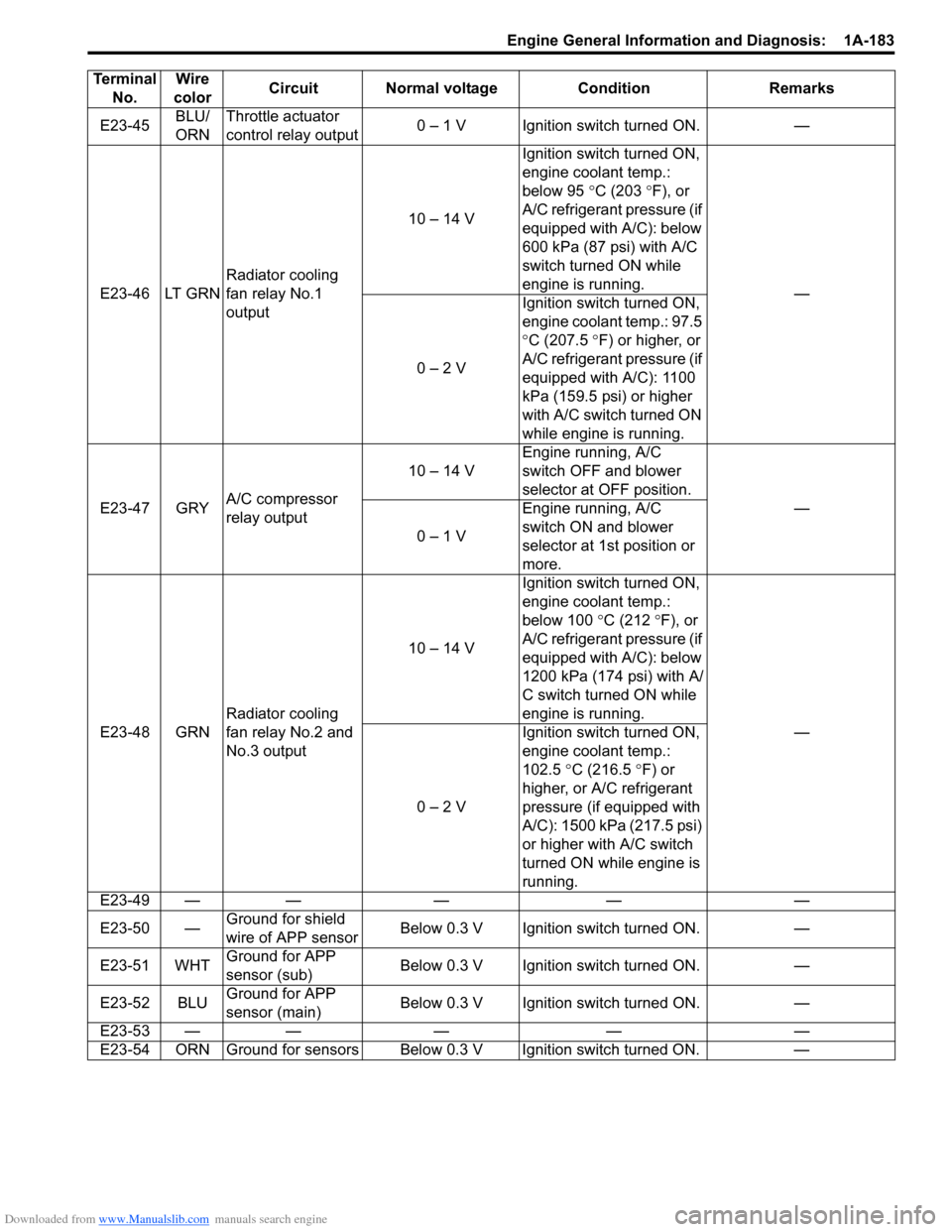

Reference waveform No.1

Fuel injector signal (1) with engine idling

E23-55 RED

A/C refrigerant

pressure sensor

signal 1.38 β 1.52 V

Engine running, A/C

switch OFF and blower

selector at OFF position,

A/C refrigerant pressure:

800 kPa (116 psi)

β

2.15 β 2.38 V Engine running, A/C

switch ON and blower

selector at 1st position or

more, A/C refrigerant

pressure: 1400 kPa (203

psi)

2.67 β 2.95 V Engine running, A/C

switch ON and blower

selector at 1st position or

more, A/C refrigerant

pressure: 1800 kPa (261

psi)

E23-56 β β β β β

E23-57 WHT/

BLK A/C evaporator

outlet air temp.

sensor signal

(manual A/C

model) 3.4 β 3.7 V

Ignition switch turned ON

at A/C evaporator outlet

temperature 0

Β°C (32 Β°F).

β

2.5 β 2.8 V Ignition switch turned ON

at A/C evaporator outlet

temperature 15

Β°C (59 Β°F).

1.7 β 2.0 V Ignition switch turned ON

at A/C evaporator outlet

temperature 30

Β°C (86 Β°F).

E23-58 β β β β β

E23-59 β β β β β

E23-60 BRN/

WHT Main power supply

relay output 10 β 14 V Ignition switch turned OFF.

β

0 β 2 V Ignition switch turned ON.

Terminal

No. Wire

color Circuit Normal voltage Condition Remarks

Measurement

terminal CH1: βC37-2β to βC37-58β

Oscilloscope

setting CH1: 20 V/DIV

TIME: 1 ms/DIV

Measurement

condition β’ After warmed up to normal

operating temperature

β’ Engine at specified idle speed

2. Fuel injection pulse width: 2 β 4 msec.

3. 10 β 14 V

I4RS0B110050-01

Page 236 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-186 Engine General Information and Diagnosis:

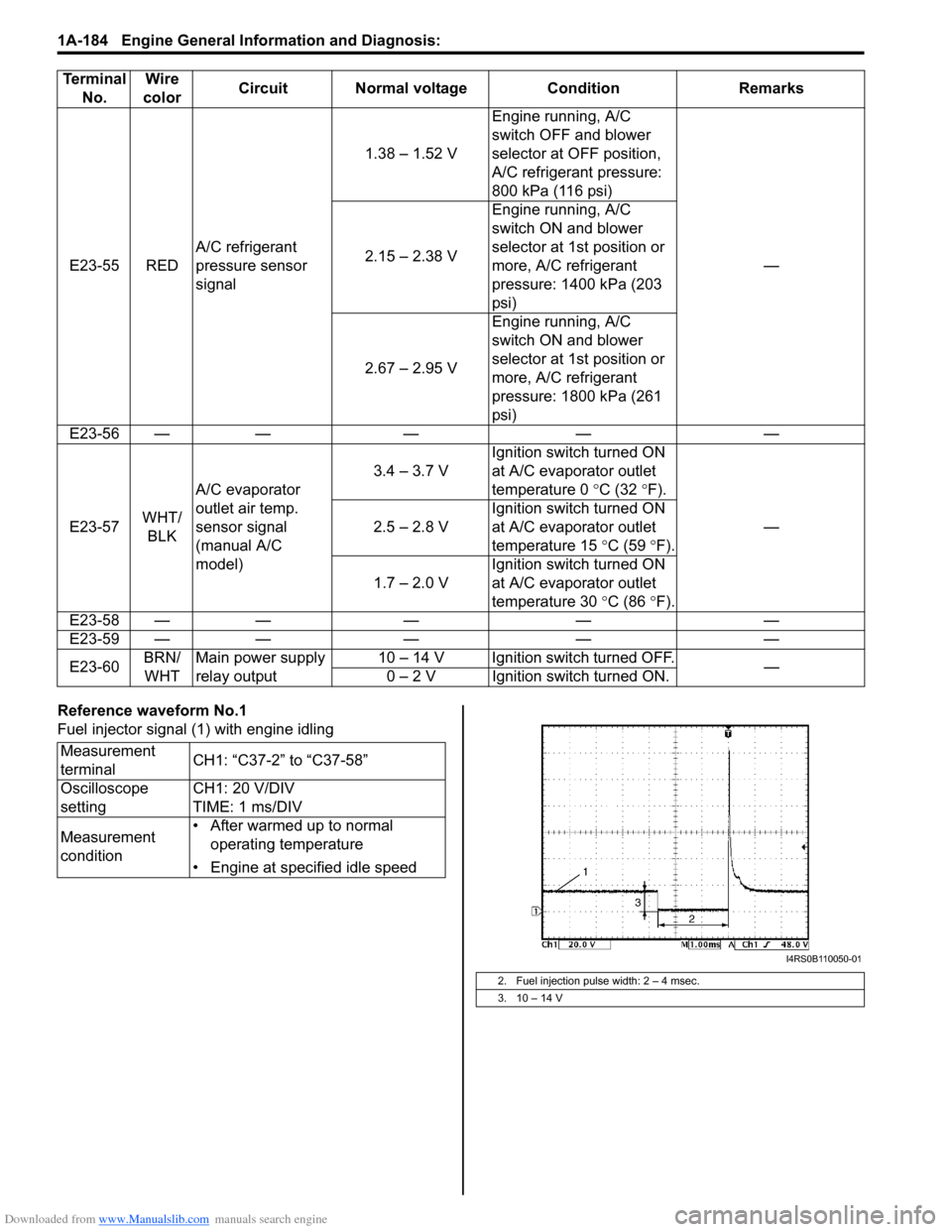

Reference waveform No.6

Ignition coil signal (1) with engine idling

Reference waveform No.7

Ignition coil No.1 and No.4 signal (2) with engine idlingReference waveform No.8

Generator field coil monitor signal (1) at engine idling

Reference waveform No.9

Throttle actuator output signal with ignition switch turned

ON

Measurement

terminal

CH1: βC37-6β to βC37-58β

Oscilloscope

setting CH1: 2 V/DIV

TIME: 4 ms/DIV

Measurement

condition β’ After warmed up to normal

operating temperature

β’ Engine at specified idle speed

2. 4 β 6 V

3. Ignition coil pulse width: 4 β 5 msec.

Measurement

terminal CH1: βC37-20β to βC37-58β

CH2: βC37-6β to βC37-58β

Oscilloscope

setting CH1: 2 V/DIV, CH2: 2 V/DIV

TIME: 40 ms/DIV

Measurement

condition β’ After warmed up to normal

operating temperature

β’ Engine at specified idle speed

1. Cylinder reference signal (CMP reference signal)

3. 720 Β° crank angle

I4RS0B110055-02

I6RS0C110031-01

Measurement

terminal CH1: βC37-8β to βC37-58β

Oscilloscope

setting CH1: 5 V/DIV

TIME: 10 ms/DIV

Measurement

condition β’ After warmed up to normal

operating temperature

β’ Engine at specified idle speed

β’ Lighting switch at CLEARANCE position

Measurement

terminal CH1: βC37-45β to βC37-58β

CH2: βC37-44β to βC37-58β

Oscilloscope

setting CH1: 5 V/DIV, CH2: 5 V/DIV

TIME: 2 ms/DIV

Measurement

condition β’ After warmed up to normal

operating temperature

β’ Ignition switch turned ON and accelerator pedal at idle position

1. Throttle actuator drive signal (βC37-45β terminal)

2. Throttle actuator drive signal (βC37-44β terminal)

3. ON signal

4. OFF signal

5. One duty cycle

I5RS0C110016-01

I4RS0B110081-02

Page 237 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-187

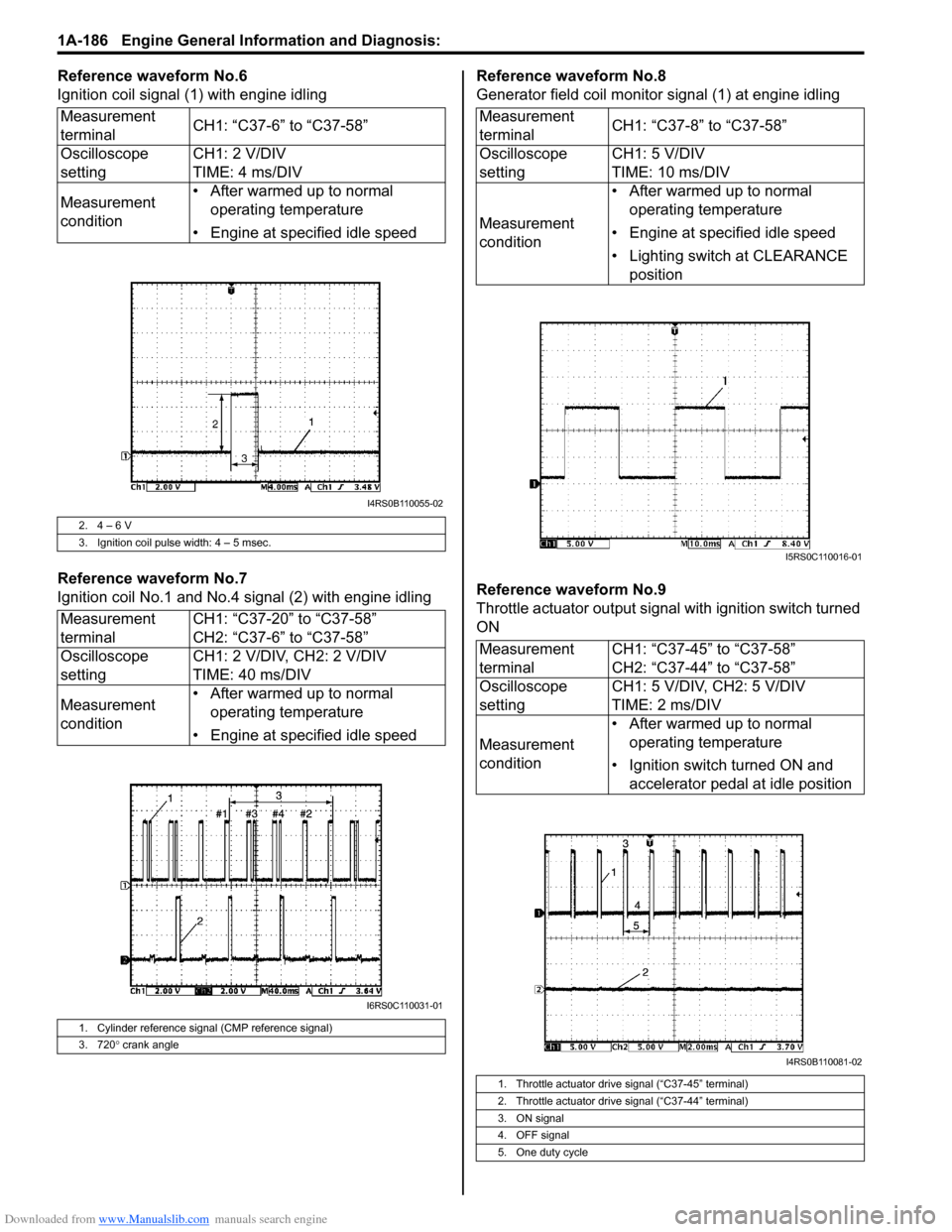

Reference waveform No.10

HOS2-1 signal (1) with engine idling

Reference waveform No.11

HO2S-1 heater signal (2) with engine idlingReference waveform No.12

HO2S-2 heater signal (4) with engine idling

Reference waveform No.13

CAN communication line signal from TCM with ignition

switch turned ON

Measurement

terminal

CH1: βC37-10β to βC37-57β

CH2: βC37-46β to βC37-58β

Oscilloscope

setting CH1: 500 mV/DIV, CH2: 20 V/DIV

TIME: 1 s/DIV

Measurement

condition β’ After warmed up to normal

operating temperature

β’ Engine at specified idle speed

2. HO2S-1 heater signal

Measurement

terminal CH1: βC37-10β to βC37-57β

CH2: βC37-46β to βC37-58β

Oscilloscope

setting CH1: 500 mV/DIV, CH2: 10 V/DIV

TIME: 200 ms/DIV

Measurement

condition β’ After warmed up to normal

operating temperature

β’ Engine at specified idle speed

1. HO2S-1 signal

3. OFF signal

4. ON signal

5. One duty cycle

I4RS0B110058-01

I4RS0B110059-01

Measurement

terminal CH1: βC37-11β to βC37-57β

CH2: βC37-47β to βC37-58β

Oscilloscope

setting CH1: 500 mV/DIV, CH2: 10 V/DIV

TIME: 2 s/DIV

Measurement

condition β’ After warmed up to normal

operating temperature

β’ Vehicle driving at 60 km/h (37 mph) for 10 min.

β’ Engine at specified idle speed

1. HO2S-2 signal upper limit

2. HO2S-2 signal lower limit

3. Normal waveform range

Measurement

terminal CH1: βC37-13β to βC37-58β

CH2: βC37-12β to βC37-58β

Oscilloscope

setting CH1: 1 V/DIV, CH2: 1 V/DIV

TIME: 40

Β΅s/DIV

Measurement

condition Ignition switch turned ON

(Signal pattern is depending on

engine condition)

1. CAN communication line signal (High)

2. CAN communication line signal (Low)

I4RS0B110060-01

I4RS0B110061-01

Page 239 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-189

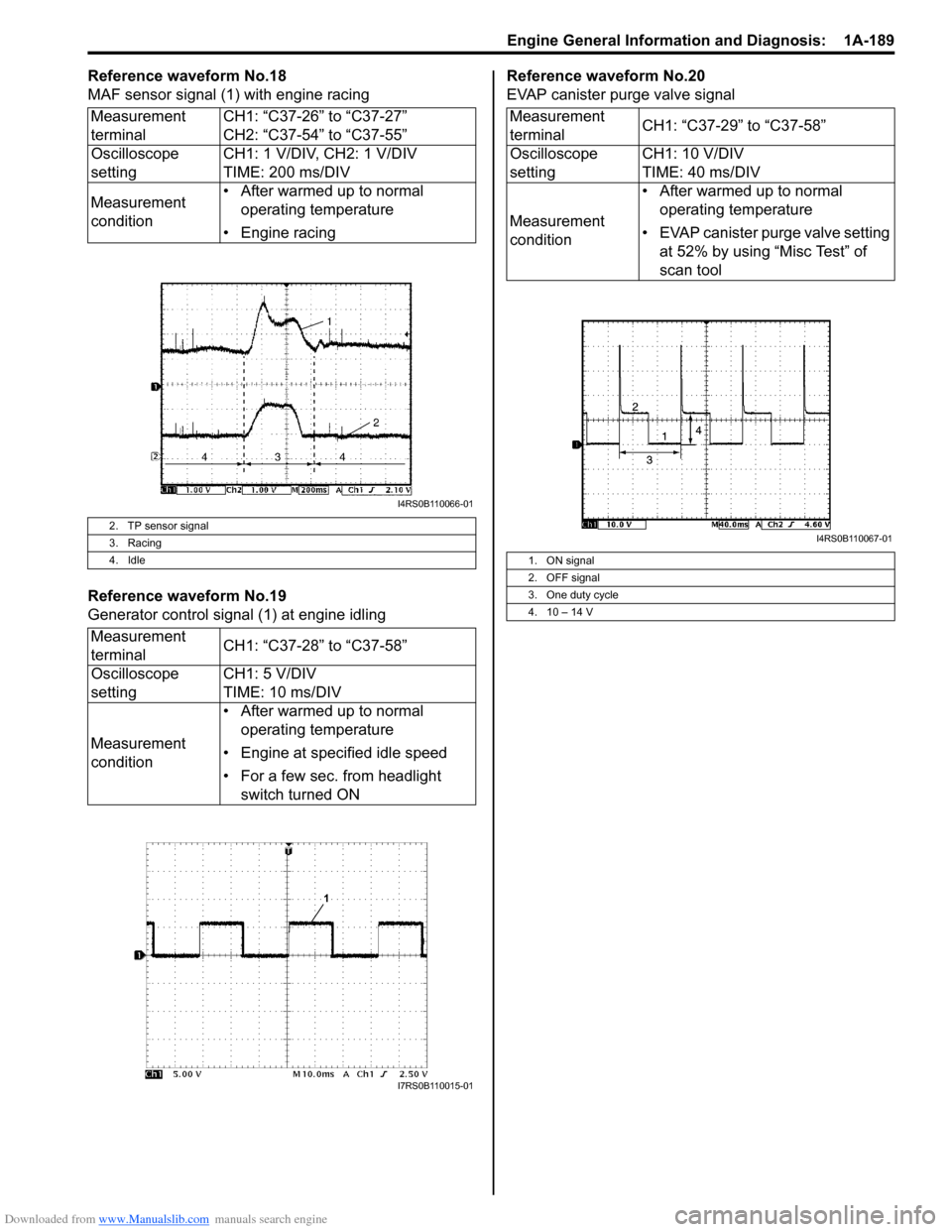

Reference waveform No.18

MAF sensor signal (1) with engine racing

Reference waveform No.19

Generator control signal (1) at engine idlingReference waveform No.20

EVAP canister purge valve signal

Measurement

terminal CH1: βC37-26β to βC37-27β

CH2: βC37-54β to βC37-55β

Oscilloscope

setting CH1: 1 V/DIV, CH2: 1 V/DIV

TIME: 200 ms/DIV

Measurement

condition β’ After warmed up to normal

operating temperature

β’ Engine racing

2. TP sensor signal

3. Racing

4. Idle

Measurement

terminal CH1: βC37-28β to βC37-58β

Oscilloscope

setting CH1: 5 V/DIV

TIME: 10 ms/DIV

Measurement

condition β’ After warmed up to normal

operating temperature

β’ Engine at specified idle speed

β’ For a few sec. from headlight switch turned ON

I4RS0B110066-01

I7RS0B110015-01

Measurement

terminal CH1: βC37-29β to βC37-58β

Oscilloscope

setting CH1: 10 V/DIV

TIME: 40 ms/DIV

Measurement

condition β’ After warmed up to normal

operating temperature

β’ EVAP canister purge valve setting at 52% by using βMisc Testβ of

scan tool

1. ON signal

2. OFF signal

3. One duty cycle

4. 10 β 14 V

I4RS0B110067-01

Page 240 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-190 Engine General Information and Diagnosis:

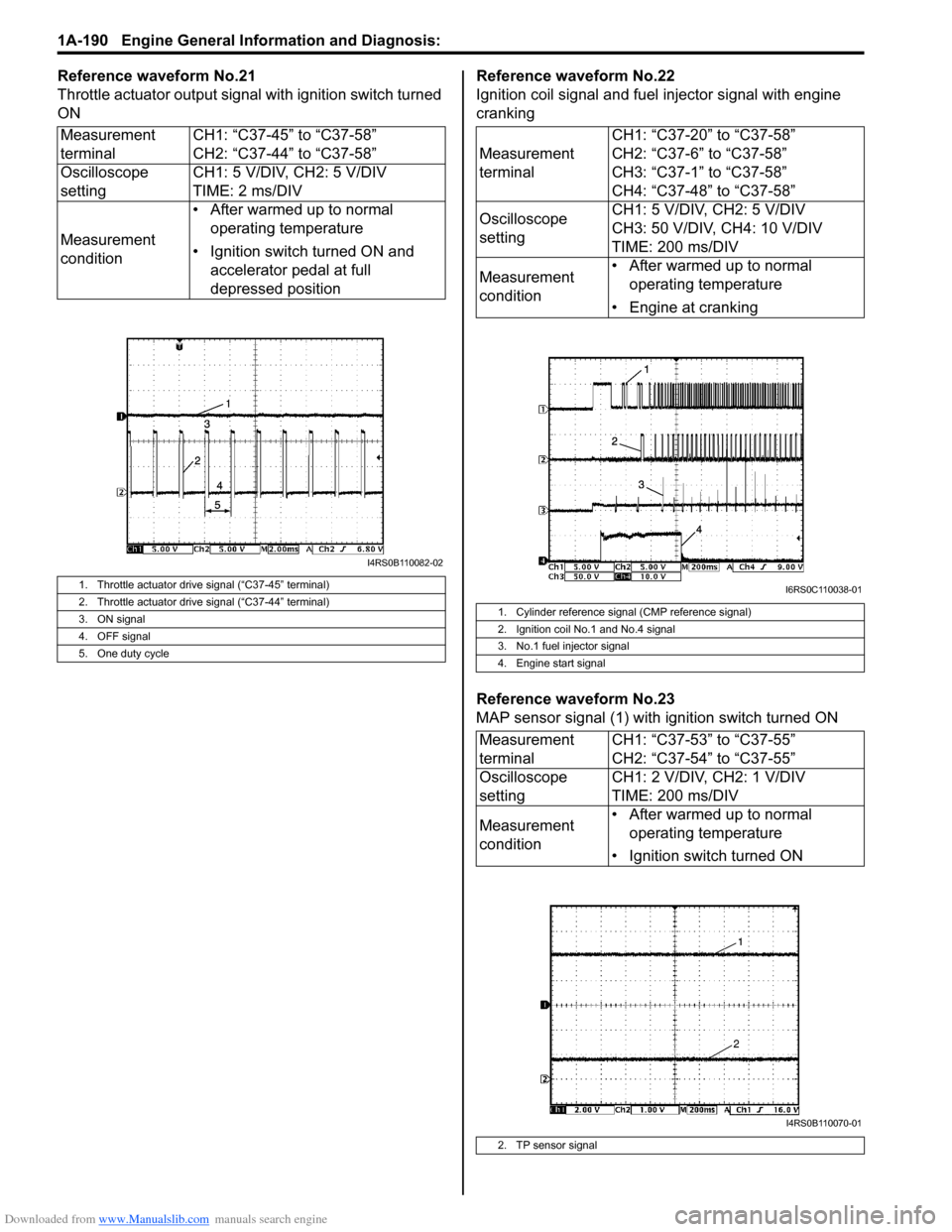

Reference waveform No.21

Throttle actuator output signal with ignition switch turned

ONReference waveform No.22

Ignition coil signal and fuel injector signal with engine

cranking

Reference waveform No.23

MAP sensor signal (1) with ignition switch turned ON

Measurement

terminal

CH1: βC37-45β to βC37-58β

CH2: βC37-44β to βC37-58β

Oscilloscope

setting CH1: 5 V/DIV, CH2: 5 V/DIV

TIME: 2 ms/DIV

Measurement

condition β’ After warmed up to normal

operating temperature

β’ Ignition switch turned ON and accelerator pedal at full

depressed position

1. Throttle actuator drive signal (βC37-45β terminal)

2. Throttle actuator drive signal (βC37-44β terminal)

3. ON signal

4. OFF signal

5. One duty cycle

I4RS0B110082-02

Measurement

terminal CH1: βC37-20β to βC37-58β

CH2: βC37-6β to βC37-58β

CH3: βC37-1β to βC37-58β

CH4: βC37-48β to βC37-58β

Oscilloscope

setting CH1: 5 V/DIV, CH2: 5 V/DIV

CH3: 50 V/DIV, CH4: 10 V/DIV

TIME: 200 ms/DIV

Measurement

condition β’ After warmed up to normal

operating temperature

β’ Engine at cranking

1. Cylinder reference signal (CMP reference signal)

2. Ignition coil No.1 and No.4 signal

3. No.1 fuel injector signal

4. Engine start signal

Measurement

terminal CH1: βC37-53β to βC37-55β

CH2: βC37-54β to βC37-55β

Oscilloscope

setting CH1: 2 V/DIV, CH2: 1 V/DIV

TIME: 200 ms/DIV

Measurement

condition β’ After warmed up to normal

operating temperature

β’ Ignition switch turned ON

2. TP sensor signal

I6RS0C110038-01

I4RS0B110070-01

Page 241 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-191

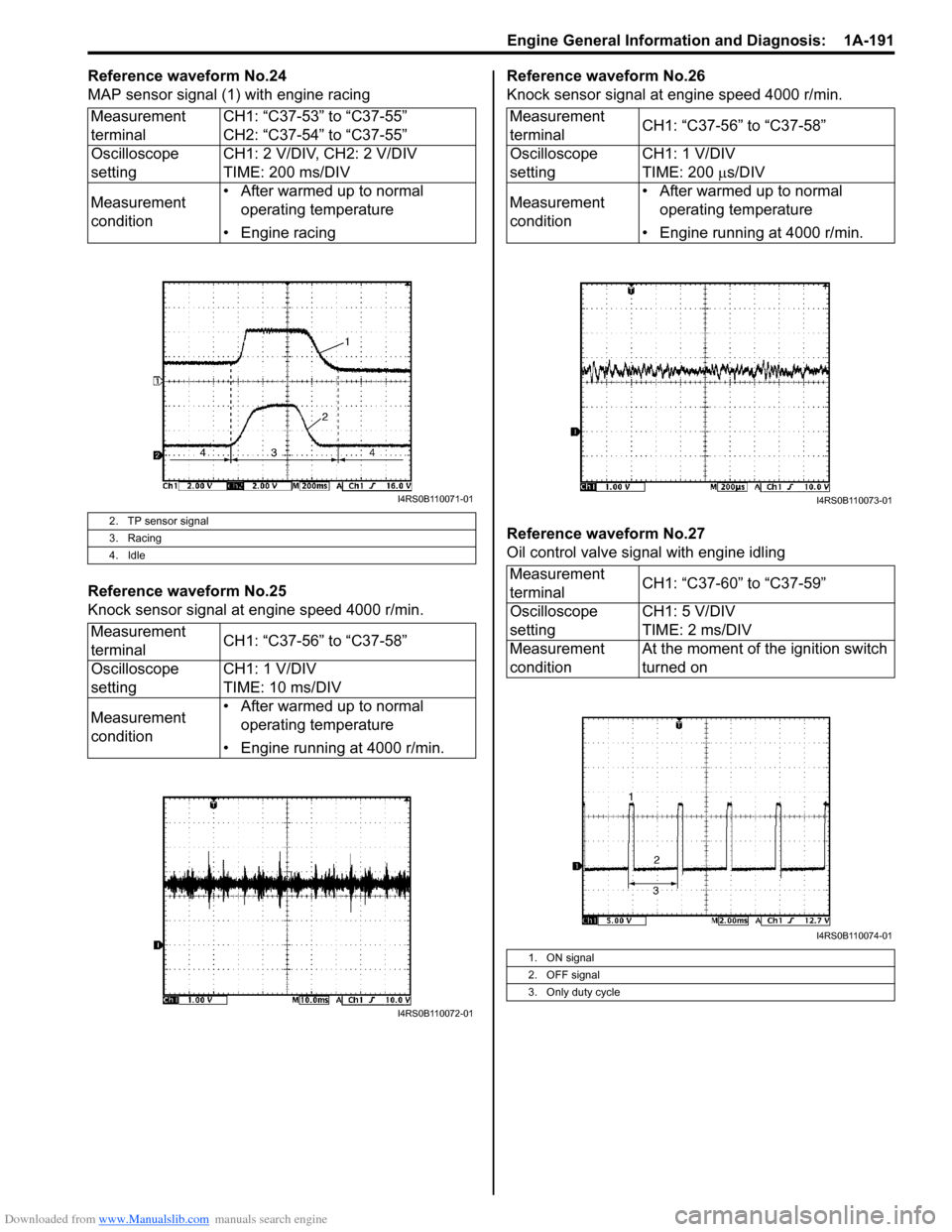

Reference waveform No.24

MAP sensor signal (1) with engine racing

Reference waveform No.25

Knock sensor signal at engine speed 4000 r/min.Reference waveform No.26

Knock sensor signal at engine speed 4000 r/min.

Reference waveform No.27

Oil control valve signal with engine idling

Measurement

terminal

CH1: βC37-53β to βC37-55β

CH2: βC37-54β to βC37-55β

Oscilloscope

setting CH1: 2 V/DIV, CH2: 2 V/DIV

TIME: 200 ms/DIV

Measurement

condition β’ After warmed up to normal

operating temperature

β’ Engine racing

2. TP sensor signal

3. Racing

4. Idle

Measurement

terminal CH1: βC37-56β to βC37-58β

Oscilloscope

setting CH1: 1 V/DIV

TIME: 10 ms/DIV

Measurement

condition β’ After warmed up to normal

operating temperature

β’ Engine running at 4000 r/min.

I4RS0B110071-01

I4RS0B110072-01

Measurement

terminal CH1: βC37-56β to βC37-58β

Oscilloscope

setting CH1: 1 V/DIV

TIME: 200

Β΅s/DIV

Measurement

condition β’ After warmed up to normal

operating temperature

β’ Engine running at 4000 r/min.

Measurement

terminal CH1: βC37-60β to βC37-59β

Oscilloscope

setting CH1: 5 V/DIV

TIME: 2 ms/DIV

Measurement

condition At the moment of the ignition switch

turned on

1. ON signal

2. OFF signal

3. Only duty cycle

I4RS0B110073-01

I4RS0B110074-01

Page 242 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-192 Engine General Information and Diagnosis:

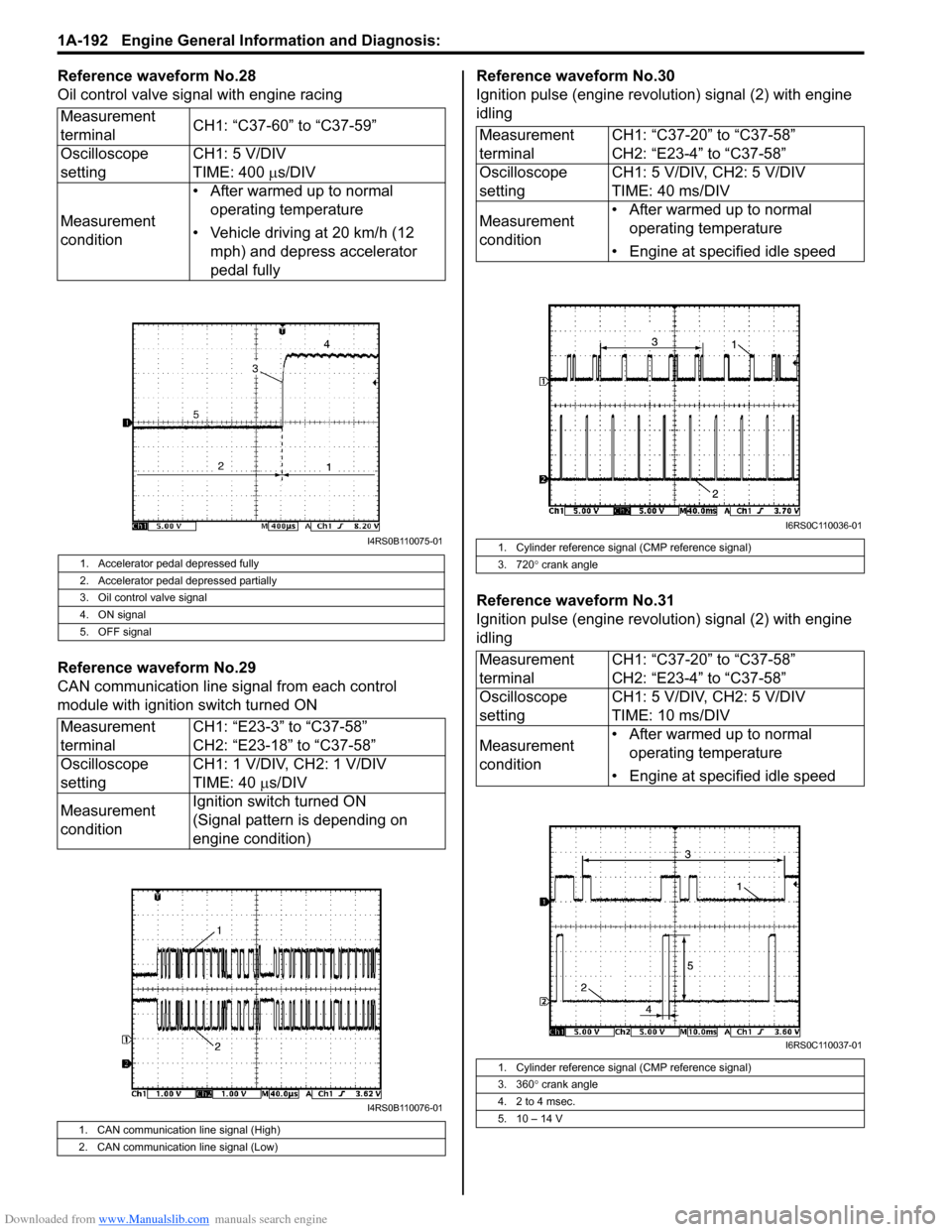

Reference waveform No.28

Oil control valve signal with engine racing

Reference waveform No.29

CAN communication line signal from each control

module with ignition switch turned ONReference waveform No.30

Ignition pulse (engine revolution) signal (2) with engine

idling

Reference waveform No.31

Ignition pulse (engine revolution) signal (2) with engine

idling

Measurement

terminal

CH1: βC37-60β to βC37-59β

Oscilloscope

setting CH1: 5 V/DIV

TIME: 400

Β΅s/DIV

Measurement

condition β’ After warmed up to normal

operating temperature

β’ Vehicle driving at 20 km/h (12 mph) and depress accelerator

pedal fully

1. Accelerator pedal depressed fully

2. Accelerator pedal depressed partially

3. Oil control valve signal

4. ON signal

5. OFF signal

Measurement

terminal CH1: βE23-3β to βC37-58β

CH2: βE23-18β to βC37-58β

Oscilloscope

setting CH1: 1 V/DIV, CH2: 1 V/DIV

TIME: 40

Β΅s/DIV

Measurement

condition Ignition switch turned ON

(Signal pattern is depending on

engine condition)

1. CAN communication line signal (High)

2. CAN communication line signal (Low)

I4RS0B110075-01

I4RS0B110076-01

Measurement

terminal

CH1: βC37-20β to βC37-58β

CH2: βE23-4β to βC37-58β

Oscilloscope

setting CH1: 5 V/DIV, CH2: 5 V/DIV

TIME: 40 ms/DIV

Measurement

condition β’ After warmed up to normal

operating temperature

β’ Engine at specified idle speed

1. Cylinder reference signal (CMP reference signal)

3. 720 Β° crank angle

Measurement

terminal CH1: βC37-20β to βC37-58β

CH2: βE23-4β to βC37-58β

Oscilloscope

setting CH1: 5 V/DIV, CH2: 5 V/DIV

TIME: 10 ms/DIV

Measurement

condition β’ After warmed up to normal

operating temperature

β’ Engine at specified idle speed

1. Cylinder reference signal (CMP reference signal)

3. 360 Β° crank angle

4. 2 to 4 msec.

5. 10 β 14 V

I6RS0C110036-01

I6RS0C110037-01

Page 243 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-193

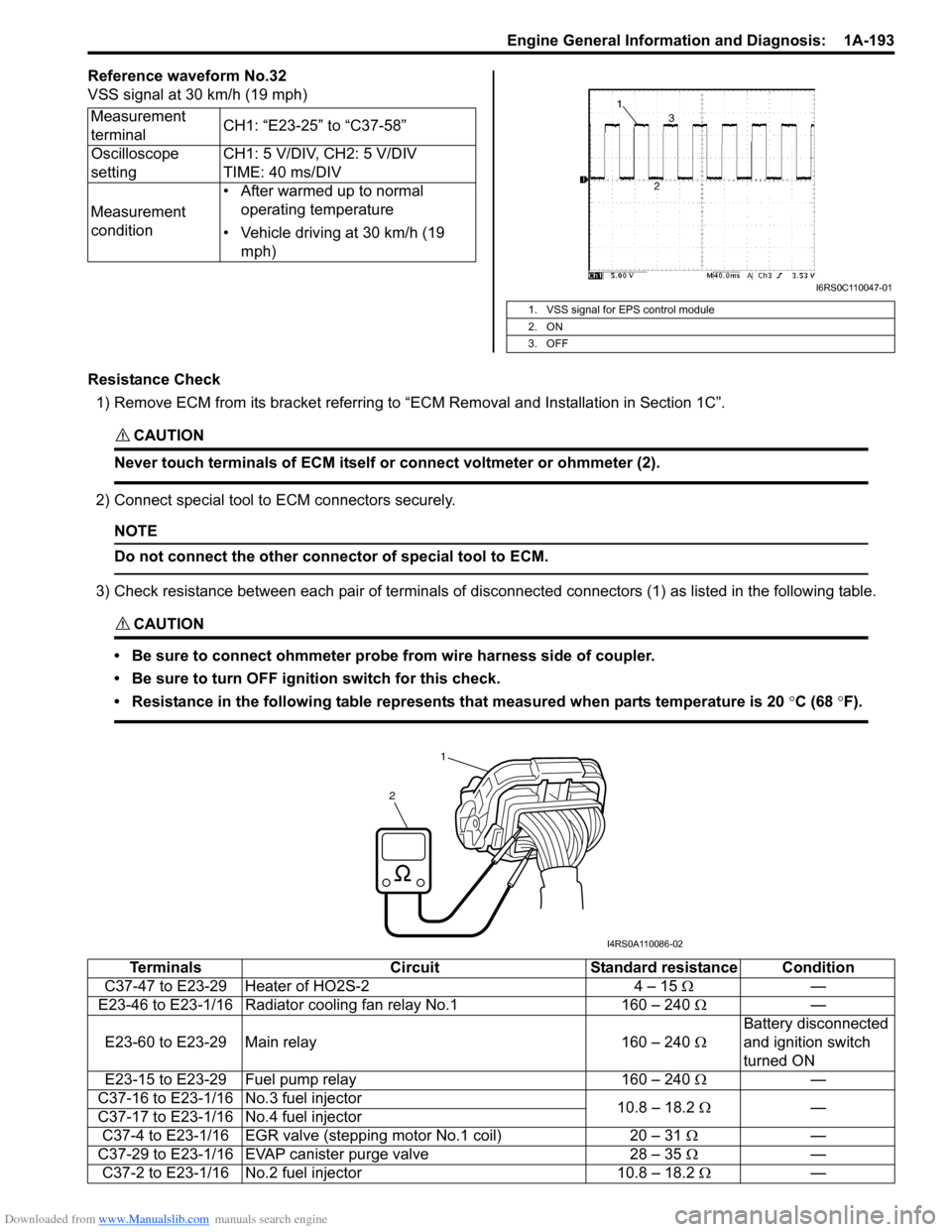

Reference waveform No.32

VSS signal at 30 km/h (19 mph)

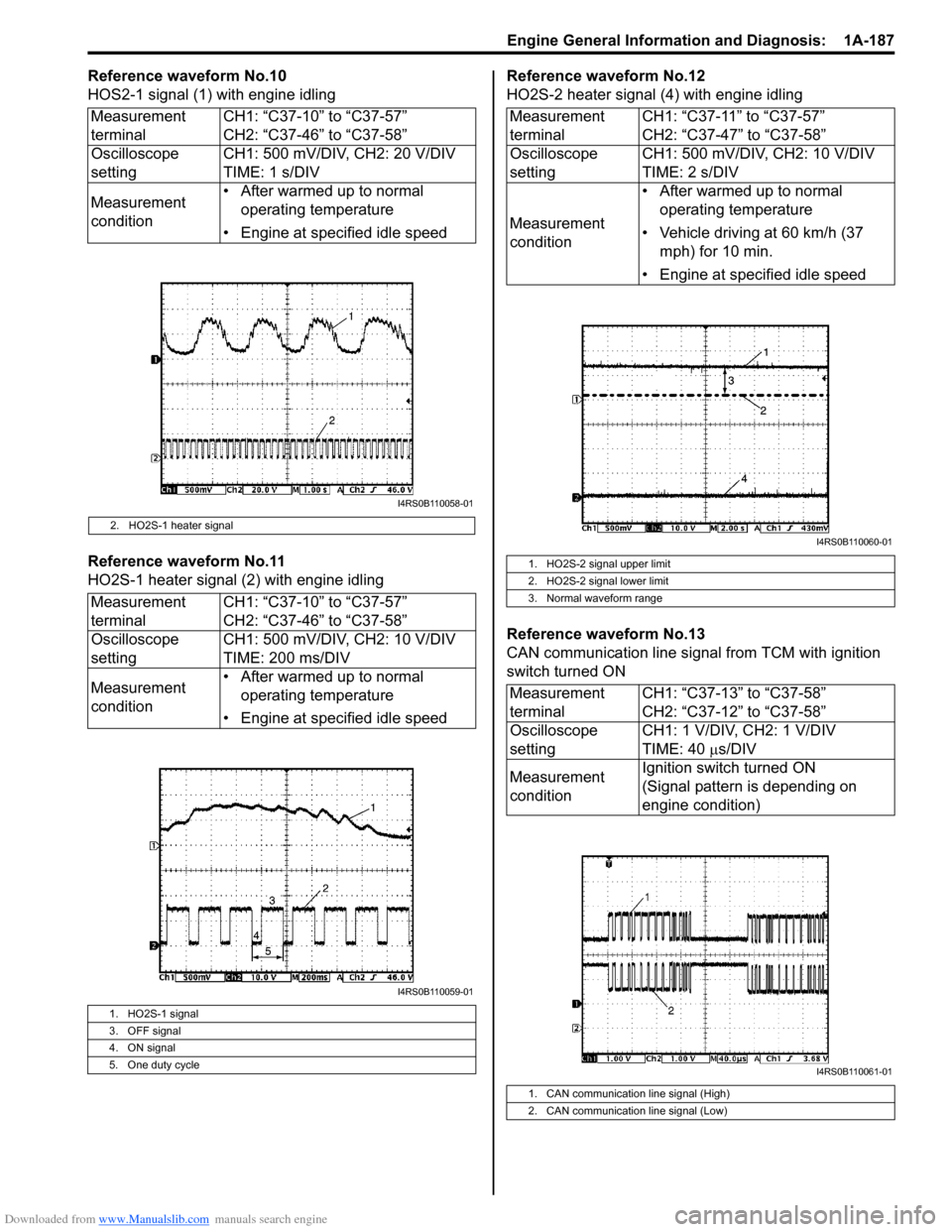

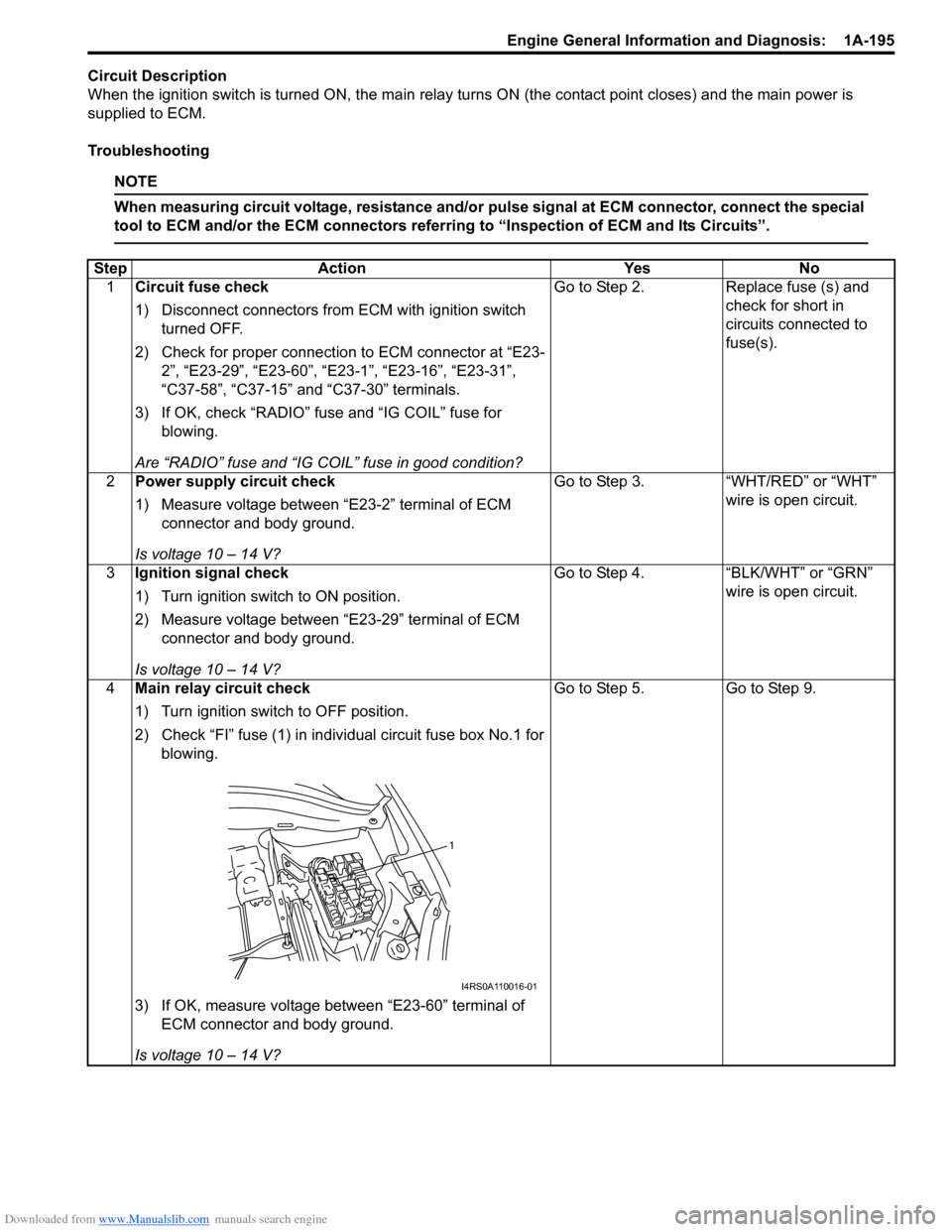

Resistance Check1) Remove ECM from its bracket referring to βECM Removal and Installation in Section 1Cβ.

CAUTION!

Never touch terminals of ECM itself or connect voltmeter or ohmmeter (2).

2) Connect special tool to ECM connectors securely.

NOTE

Do not connect the other connector of special tool to ECM.

3) Check resistance between each pair of terminals of disconnected connectors (1) as listed in the following table.

CAUTION!

β’ Be sure to connect ohmmeter probe from wire harness side of coupler.

β’ Be sure to turn OFF ignition switch for this check.

β’ Resistance in the following table represents that measured when parts temperature is 20 Β°C (68 Β°F).

Measurement

terminal CH1: βE23-25β to βC37-58β

Oscilloscope

setting CH1: 5 V/DIV, CH2: 5 V/DIV

TIME: 40 ms/DIV

Measurement

condition β’ After warmed up to normal

operating temperature

β’ Vehicle driving at 30 km/h (19 mph)

1. VSS signal for EPS control module

2. ON

3. OFF

I6RS0C110047-01

1

2

I4RS0A110086-02

Terminals CircuitStandard resistance Condition

C37-47 to E23-29 Heater of HO2S-2 4 β 15 β¦β

E23-46 to E23-1/16 Radiator cooling fan relay No.1 160 β 240 β¦ β

E23-60 to E23-29 Main relay 160 β 240 β¦Battery disconnected

and ignition switch

turned ON

E23-15 to E23-29 Fuel pump relay 160 β 240 β¦ β

C37-16 to E23-1/16 No.3 fuel injector 10.8 β 18.2 β¦ β

C37-17 to E23-1/16 No.4 fuel injector

C37-4 to E23-1/16 EGR valve (st epping motor No.1 coil) 20 β 31 β¦ β

C37-29 to E23-1/16 EVAP canister purge valve 28 β 35 β¦ β

C37-2 to E23-1/16 No.2 fuel injector 10.8 β 18.2 β¦β

Page 245 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-195

Circuit Description

When the ignition switch is turned ON, the main relay turns ON (the contact point closes) and the main power is

supplied to ECM.

Troubleshooting

NOTE

When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the special

tool to ECM and/or the ECM connectors referri ng to βInspection of ECM and Its Circuitsβ.

StepAction YesNo

1 Circuit fuse check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection to ECM connector at βE23- 2β, βE23-29β, βE23-60β, βE23-1β, βE23-16β, βE23-31β,

βC37-58β, βC37-15β and βC37-30β terminals.

3) If OK, check βRADIOβ fuse and βIG COILβ fuse for blowing.

Are βRADIOβ fuse and βIG COILβ fuse in good condition? Go to Step 2.

Replace fuse (s) and

check for short in

circuits connected to

fuse(s).

2 Power supply circuit check

1) Measure voltage between βE23-2β terminal of ECM

connector and body ground.

Is voltage 10 β 14 V? Go to Step 3.

βWHT/REDβ or βWHTβ

wire is open circuit.

3 Ignition signal check

1) Turn ignition switch to ON position.

2) Measure voltage between βE23-29β terminal of ECM

connector and body ground.

Is voltage 10 β 14 V? Go to Step 4.

βBLK/WHTβ or βGRNβ

wire is open circuit.

4 Main relay circuit check

1) Turn ignition switch to OFF position.

2) Check βFIβ fuse (1) in indivi dual circuit fuse box No.1 for

blowing.

3) If OK, measure voltage between βE23-60β terminal of ECM connector and body ground.

Is voltage 10 β 14 V? Go to Step 5.

Go to Step 9.

1

I4RS0A110016-01