bcm SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 1304 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-9 Instrumentation / Driver Info. / Horn:

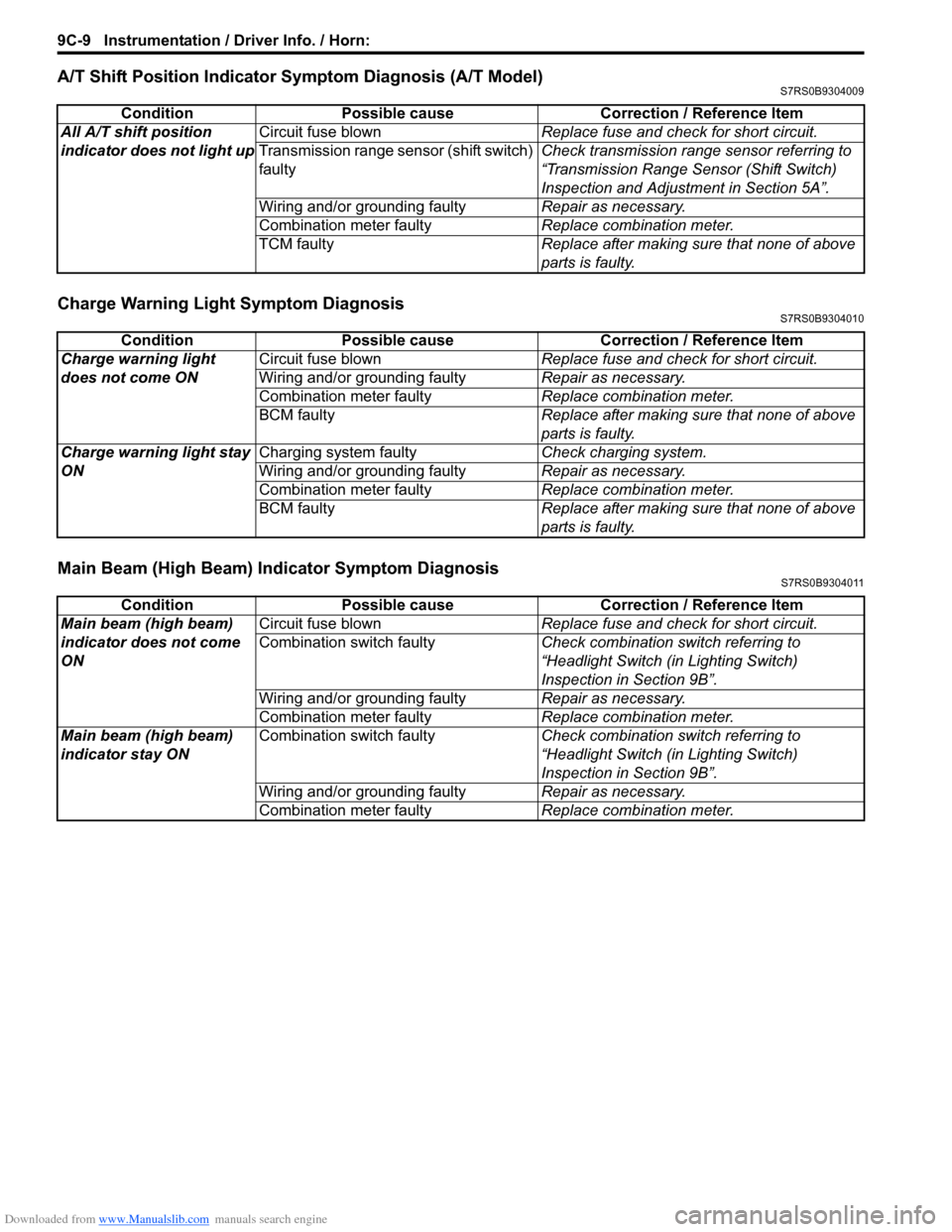

A/T Shift Position Indicator Symptom Diagnosis (A/T Model)S7RS0B9304009

Charge Warning Light Symptom DiagnosisS7RS0B9304010

Main Beam (High Beam) Indicator Symptom DiagnosisS7RS0B9304011

ConditionPossible cause Correction / Reference Item

All A/T shift position

indicator does not light up Circuit fuse blown

Replace fuse and check for short circuit.

Transmission range sens or (shift switch)

faulty Check transmission range sensor referring to

“Transmission Range Sensor (Shift Switch)

Inspection and Adjustment in Section 5A”.

Wiring and/or grounding faulty Repair as necessary.

Combination meter faulty Replace combination meter.

TCM faulty Replace after making sure that none of above

parts is faulty.

ConditionPossible cause Correction / Reference Item

Charge warning light

does not come ON Circuit fuse blown

Replace fuse and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Combination meter faulty Replace combination meter.

BCM faulty Replace after making sure that none of above

parts is faulty.

Charge warning light stay

ON Charging system faulty

Check charging system.

Wiring and/or grounding faulty Repair as necessary.

Combination meter faulty Replace combination meter.

BCM faulty Replace after making sure that none of above

parts is faulty.

ConditionPossible cause Correction / Reference Item

Main beam (high beam)

indicator does not come

ON Circuit fuse blown

Replace fuse and check for short circuit.

Combination switch faulty Check combination switch referring to

“Headlight Switch (in Lighting Switch)

Inspection in Section 9B”.

Wiring and/or grounding faulty Repair as necessary.

Combination meter faulty Replace combination meter.

Main beam (high beam)

indicator stay ON Combination switch faulty

Check combination switch referring to

“Headlight Switch (in Lighting Switch)

Inspection in Section 9B”.

Wiring and/or grounding faulty Repair as necessary.

Combination meter faulty Replace combination meter.

Page 1305 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-10

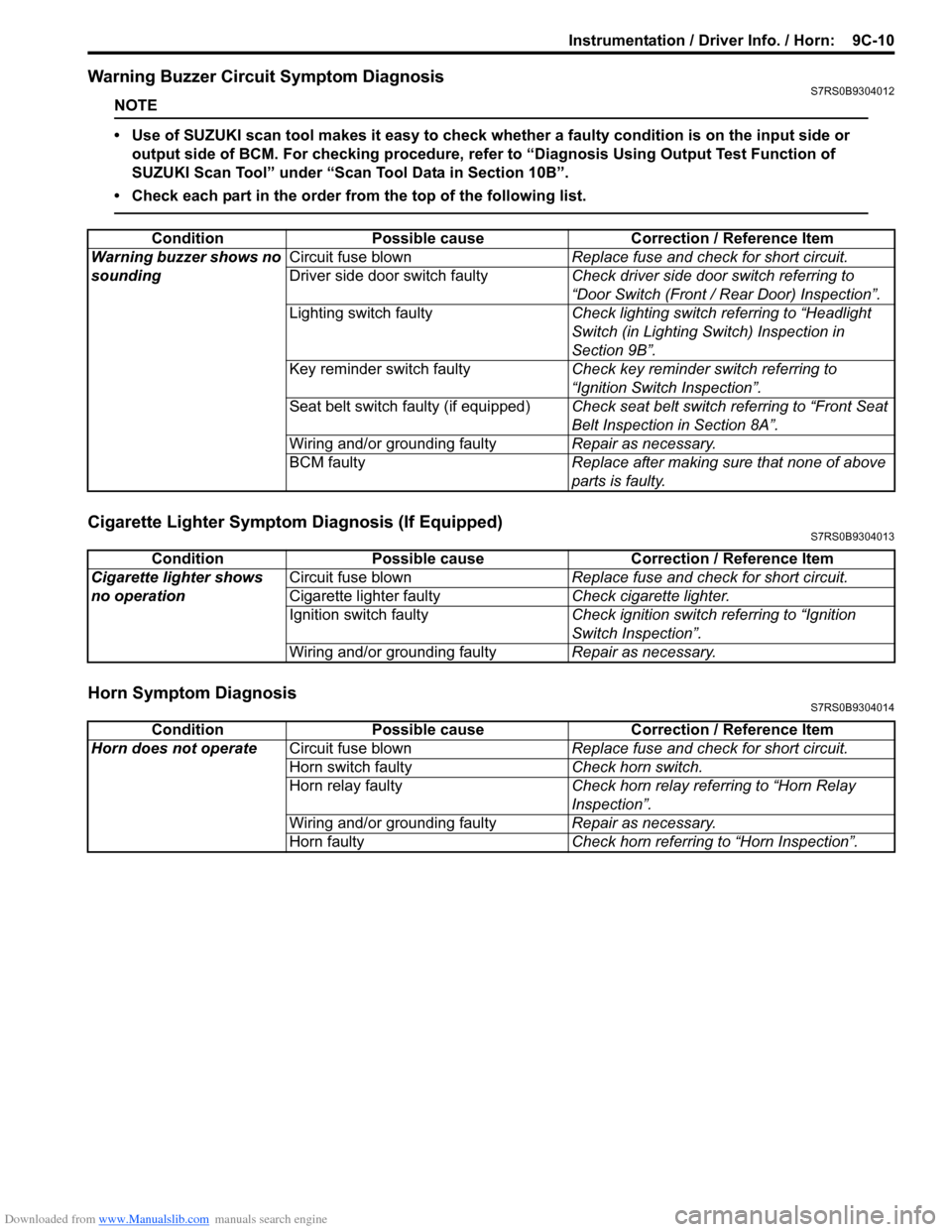

Warning Buzzer Circuit Symptom DiagnosisS7RS0B9304012

NOTE

• Use of SUZUKI scan tool makes it easy to check wh ether a faulty condition is on the input side or

output side of BCM. For checking procedure, re fer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Cigarette Lighter Symptom Diagnosis (If Equipped)S7RS0B9304013

Horn Symptom DiagnosisS7RS0B9304014

Condition Possible cause Correction / Reference Item

Warning buzzer shows no

sounding Circuit fuse blown

Replace fuse and check for short circuit.

Driver side door switch faulty Check driver side door switch referring to

“Door Switch (Front / Rear Door) Inspection”.

Lighting switch faulty Check lighting switch referring to “Headlight

Switch (in Lighting Switch) Inspection in

Section 9B”.

Key reminder switch faulty Check key reminder switch referring to

“Ignition Switch Inspection”.

Seat belt switch faulty (if equipped) Check seat belt switch referring to “Front Seat

Belt Inspection in Section 8A”.

Wiring and/or grounding faulty Repair as necessary.

BCM faulty Replace after making sure that none of above

parts is faulty.

ConditionPossible cause Correction / Reference Item

Cigarette lighter shows

no operation Circuit fuse blown

Replace fuse and check for short circuit.

Cigarette lighter faulty Check cigarette lighter.

Ignition switch faulty Check ignition switch referring to “Ignition

Switch Inspection”.

Wiring and/or grounding faulty Repair as necessary.

ConditionPossible cause Correction / Reference Item

Horn does not operate Circuit fuse blown Replace fuse and check for short circuit.

Horn switch faulty Check horn switch.

Horn relay faulty Check horn relay referring to “Horn Relay

Inspection”.

Wiring and/or grounding faulty Repair as necessary.

Horn faulty Check horn referring to “Horn Inspection”.

Page 1306 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-11 Instrumentation / Driver Info. / Horn:

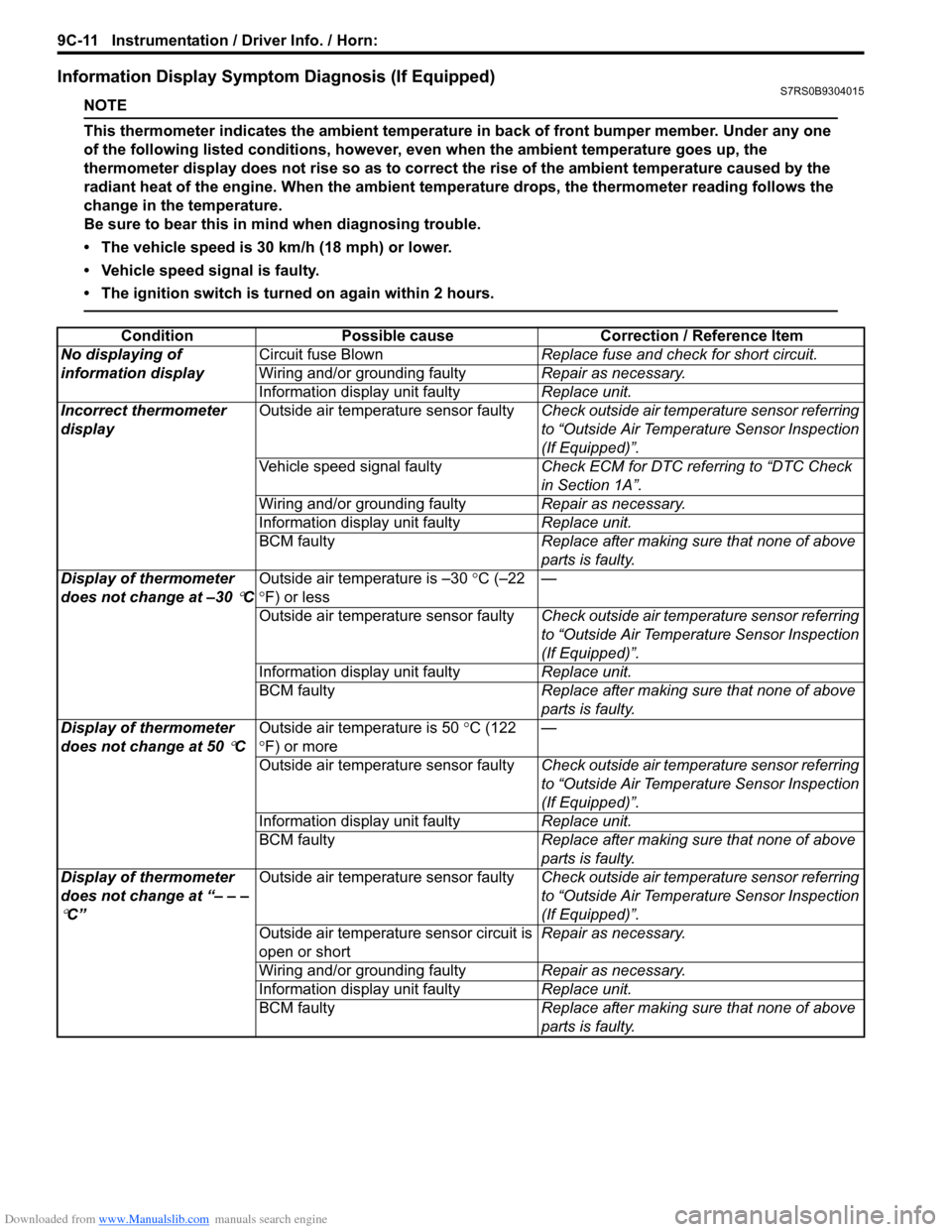

Information Display Symptom Diagnosis (If Equipped)S7RS0B9304015

NOTE

This thermometer indicates the ambient temperature in back of front bumper member. Under any one

of the following listed conditions, however, even when the ambient temperature goes up, the

thermometer display does not rise so as to correct the rise of the ambient temperature caused by the

radiant heat of the engine. When the ambient temperature drops, the thermometer reading follows the

change in the temperature.

Be sure to bear this in mind when diagnosing trouble.

• The vehicle speed is 30 km/h (18 mph) or lower.

• Vehicle speed signal is faulty.

• The ignition switch is turned on again within 2 hours.

ConditionPossible cause Correction / Reference Item

No displaying of

information display Circuit fuse Blown

Replace fuse and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Information display unit faulty Replace unit.

Incorrect thermometer

display Outside air temperature sensor faulty

Check outside air temperature sensor referring

to “Outside Air Temperature Sensor Inspection

(If Equipped)”.

Vehicle speed signal faulty Check ECM for DTC referring to “DTC Check

in Section 1A”.

Wiring and/or grounding faulty Repair as necessary.

Information display unit faulty Replace unit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Display of thermometer

does not change at –30

°C Outside air temperature is –30

°C (–22

° F) or less —

Outside air temperature sensor faulty Check outside air temperature sensor referring

to “Outside Air Temperature Sensor Inspection

(If Equipped)”.

Information display unit faulty Replace unit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Display of thermometer

does not change at 50

°C Outside air temperature is 50

°C (122

° F) or more —

Outside air temperature sensor faulty Check outside air temperature sensor referring

to “Outside Air Temperature Sensor Inspection

(If Equipped)”.

Information display unit faulty Replace unit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Display of thermometer

does not change at “– – –

°C” Outside air temperature sensor faulty

Check outside air temperature sensor referring

to “Outside Air Temperature Sensor Inspection

(If Equipped)”.

Outside air temperature sensor circuit is

open or short Repair as necessary.

Wiring and/or grounding faulty Repair as necessary.

Information display unit faulty Replace unit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Page 1307 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-12

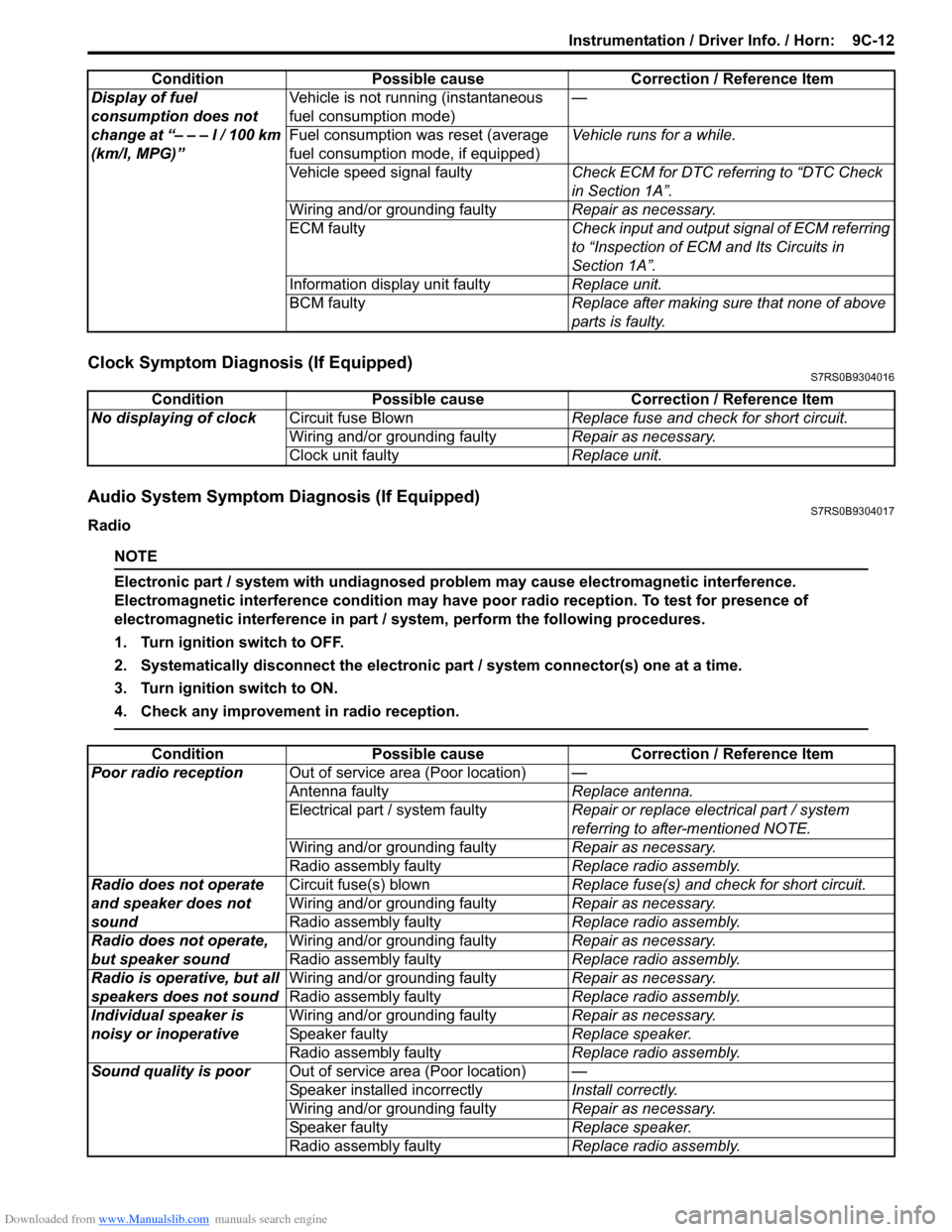

Clock Symptom Diagnosis (If Equipped)S7RS0B9304016

Audio System Symptom Diagnosis (If Equipped)S7RS0B9304017

Radio

NOTE

Electronic part / system with undiagnosed pr oblem may cause electromagnetic interference.

Electromagnetic interference condition may have poor radio reception. To test for presence of

electromagnetic interference in part / system, perform the following procedures.

1. Turn ignition switch to OFF.

2. Systematically disconnect the electronic part / system connector(s) one at a time.

3. Turn ignition switch to ON.

4. Check any improvement in radio reception.

Display of fuel

consumption does not

change at “– – – l / 100 km

(km/l, MPG)” Vehicle is not running (instantaneous

fuel consumption mode)

—

Fuel consumption was reset (average

fuel consumption mo de, if equipped)Vehicle runs for a while.

Vehicle speed signal faulty Check ECM for DTC referring to “DTC Check

in Section 1A”.

Wiring and/or grounding faulty Repair as necessary.

ECM faulty Check input and output signal of ECM referring

to “Inspection of ECM and Its Circuits in

Section 1A”.

Information display unit faulty Replace unit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Condition Possible cause Correction / Reference Item

Condition

Possible cause Correction / Reference Item

No displaying of clock Circuit fuse Blown Replace fuse and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Clock unit faulty Replace unit.

ConditionPossible cause Correction / Reference Item

Poor radio reception Out of service area (Poor location) —

Antenna faulty Replace antenna.

Electrical part / system faulty Repair or replace electrical part / system

referring to after-mentioned NOTE.

Wiring and/or grounding faulty Repair as necessary.

Radio assembly faulty Replace radio assembly.

Radio does not operate

and speaker does not

sound Circuit fuse(s) blown

Replace fuse(s) and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Radio assembly faulty Replace radio assembly.

Radio does not operate,

but speaker sound Wiring and/or grounding faulty

Repair as necessary.

Radio assembly faulty Replace radio assembly.

Radio is operative, but all

speakers does not sound Wiring and/or grounding faulty

Repair as necessary.

Radio assembly faulty Replace radio assembly.

Individual speaker is

noisy or inoperative Wiring and/or grounding faulty

Repair as necessary.

Speaker faulty Replace speaker.

Radio assembly faulty Replace radio assembly.

Sound quality is poor Out of service area (Poor location) —

Speaker installed incorrectly Install correctly.

Wiring and/or grounding faulty Repair as necessary.

Speaker faulty Replace speaker.

Radio assembly faulty Replace radio assembly.

Page 1315 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-20

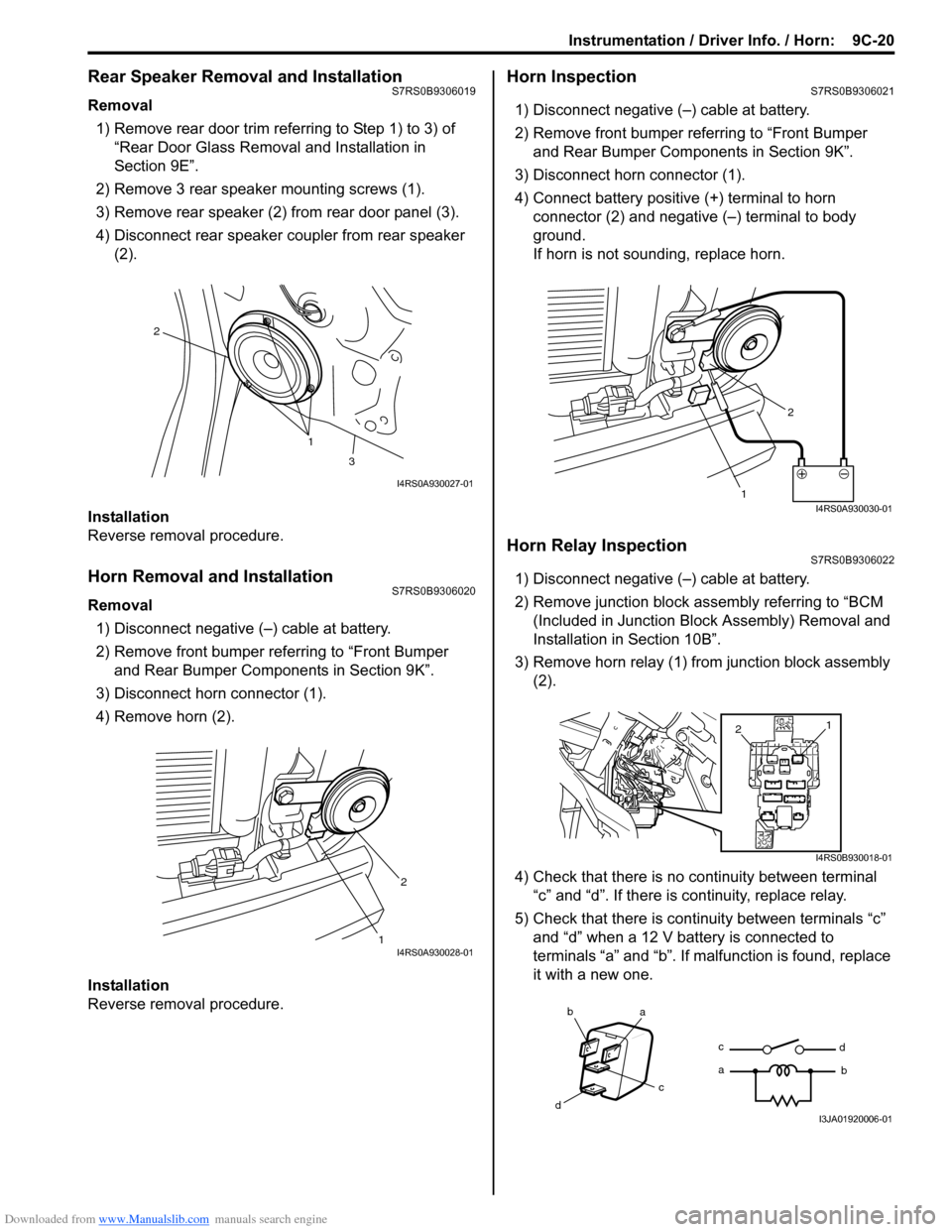

Rear Speaker Removal and InstallationS7RS0B9306019

Removal

1) Remove rear door trim referring to Step 1) to 3) of “Rear Door Glass Removal and Installation in

Section 9E”.

2) Remove 3 rear speaker mounting screws (1).

3) Remove rear speaker (2) from rear door panel (3).

4) Disconnect rear speaker coupler from rear speaker (2).

Installation

Reverse removal procedure.

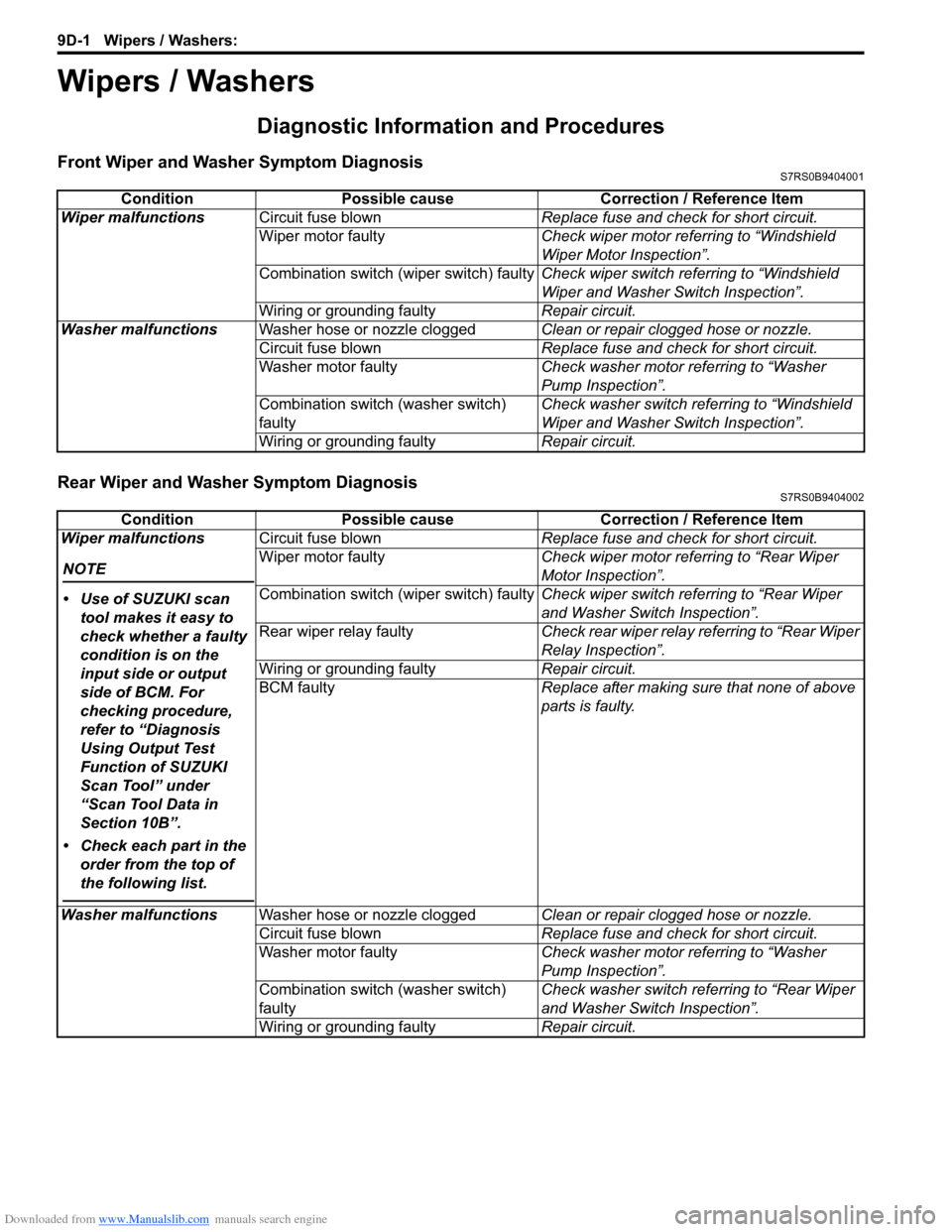

Horn Removal and InstallationS7RS0B9306020

Removal 1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Disconnect horn connector (1).

4) Remove horn (2).

Installation

Reverse removal procedure.

Horn InspectionS7RS0B9306021

1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Disconnect horn connector (1).

4) Connect battery positive (+) terminal to horn

connector (2) and negative (–) terminal to body

ground.

If horn is not sounding, replace horn.

Horn Relay InspectionS7RS0B9306022

1) Disconnect negative (–) cable at battery.

2) Remove junction block assembly referring to “BCM (Included in Junction Bl ock Assembly) Removal and

Installation in Section 10B”.

3) Remove horn relay (1) from junction block assembly (2).

4) Check that there is no continuity between terminal “c” and “d”. If there is continuity, replace relay.

5) Check that there is continuity between terminals “c” and “d” when a 12 V battery is connected to

terminals “a” and “b”. If malfunction is found, replace

it with a new one.

1

2

3

I4RS0A930027-01

12I4RS0A930028-01

1 2I4RS0A930030-01

1

2

I4RS0B930018-01

ba

c

d c

a

d

bI3JA01920006-01

Page 1318 of 1496

Downloaded from www.Manualslib.com manuals search engine 9D-1 Wipers / Washers:

Body, Cab and Accessories

Wipers / Washers

Diagnostic Information and Procedures

Front Wiper and Washer Symptom DiagnosisS7RS0B9404001

Rear Wiper and Washer Symptom DiagnosisS7RS0B9404002

ConditionPossible cause Correction / Reference Item

Wiper malfunctions Circuit fuse blown Replace fuse and check for short circuit.

Wiper motor faulty Check wiper motor referring to “Windshield

Wiper Motor Inspection”.

Combination switch (wiper switch) faulty Check wiper switch referring to “Windshield

Wiper and Washer Switch Inspection”.

Wiring or grounding faulty Repair circuit.

Washer malfunctions Washer hose or nozzle clogged Clean or repair clogged hose or nozzle.

Circuit fuse blown Replace fuse and check for short circuit.

Washer motor faulty Check washer motor referring to “Washer

Pump Inspection”.

Combination switch (washer switch)

faulty Check washer switch referring to “Windshield

Wiper and Washer Switch Inspection”.

Wiring or grounding faulty Repair circuit.

ConditionPossible cause Correction / Reference Item

Wiper malfunctions

NOTE

• Use of SUZUKI scan tool makes it easy to

check whether a faulty

condition is on the

input side or output

side of BCM. For

checking procedure,

refer to “Diagnosis

Using Output Test

Function of SUZUKI

Scan Tool” under

“Scan Tool Data in

Section 10B”.

• Check each part in the order from the top of

the following list.

Circuit fuse blown Replace fuse and check for short circuit.

Wiper motor faulty Check wiper motor referring to “Rear Wiper

Motor Inspection”.

Combination switch (wiper switch) faulty Check wiper switch referring to “Rear Wiper

and Washer Switch Inspection”.

Rear wiper relay faulty Check rear wiper relay referring to “Rear Wiper

Relay Inspection”.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Washer malfunctions Washer hose or nozzle clogged Clean or repair clogged hose or nozzle.

Circuit fuse blown Replace fuse and check for short circuit.

Washer motor faulty Check washer motor referring to “Washer

Pump Inspection”.

Combination switch (washer switch)

faulty Check washer switch referring to “Rear Wiper

and Washer Switch Inspection”.

Wiring or grounding faulty Repair circuit.

Page 1320 of 1496

Downloaded from www.Manualslib.com manuals search engine 9D-3 Wipers / Washers:

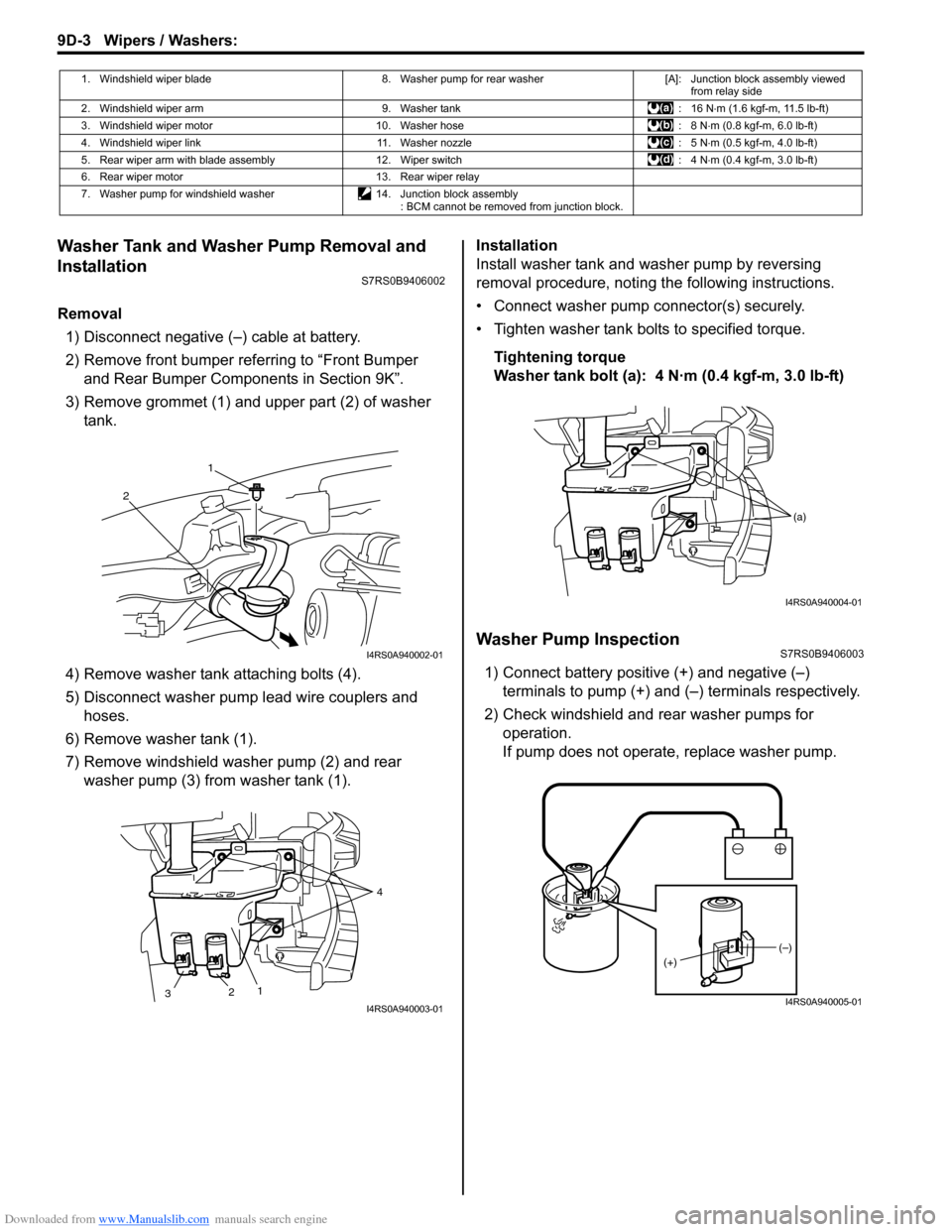

Washer Tank and Washer Pump Removal and

Installation

S7RS0B9406002

Removal1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Remove grommet (1) and upper part (2) of washer tank.

4) Remove washer tank attaching bolts (4).

5) Disconnect washer pump lead wire couplers and hoses.

6) Remove washer tank (1).

7) Remove windshield washer pump (2) and rear washer pump (3) from washer tank (1). Installation

Install washer tank and washer pump by reversing

removal procedure, noting the following instructions.

• Connect washer pump connector(s) securely.

• Tighten washer tank bolts to specified torque.

Tightening torque

Washer tank bolt (a): 4 N·m (0.4 kgf-m, 3.0 lb-ft)

Washer Pump InspectionS7RS0B9406003

1) Connect battery positive (+) and negative (–) terminals to pump (+) and (–) terminals respectively.

2) Check windshield and rear washer pumps for

operation.

If pump does not operate, replace washer pump.

1. Windshield wiper blade 8. Washer pump for rear washer[A]: Junction block assembly viewed

from relay side

2. Windshield wiper arm 9. Washer tank: 16 N⋅m (1.6 kgf-m, 11.5 lb-ft)

3. Windshield wiper motor 10. Washer hose : 8 N⋅m (0.8 kgf-m, 6.0 lb-ft)

4. Windshield wiper link 11. Washer nozzle : 5 N⋅m (0.5 kgf-m, 4.0 lb-ft)

5. Rear wiper arm with blade assembly 12. Wiper switch : 4 N⋅m (0.4 kgf-m, 3.0 lb-ft)

6. Rear wiper motor 13. Rear wiper relay

7. Washer pump for windshield washer 14. Junction block assembly

: BCM cannot be removed from junction block.

1

2

I4RS0A940002-01

2 1 4

3

I4RS0A940003-01

(a)

I4RS0A940004-01

(–)

(+)

I4RS0A940005-01

Page 1327 of 1496

Downloaded from www.Manualslib.com manuals search engine Wipers / Washers: 9D-10

Rear Wiper Relay Removal and InstallationS7RS0B9406012

Removal1) Disconnect negative (–) cable at battery.

2) Remove junction block assembly referring to “BCM (Included in Junction Block Assembly) Removal and

Installation in Section 10B”.

3) Remove rear wiper relay.

Installation

Reverse removal procedure for installation.

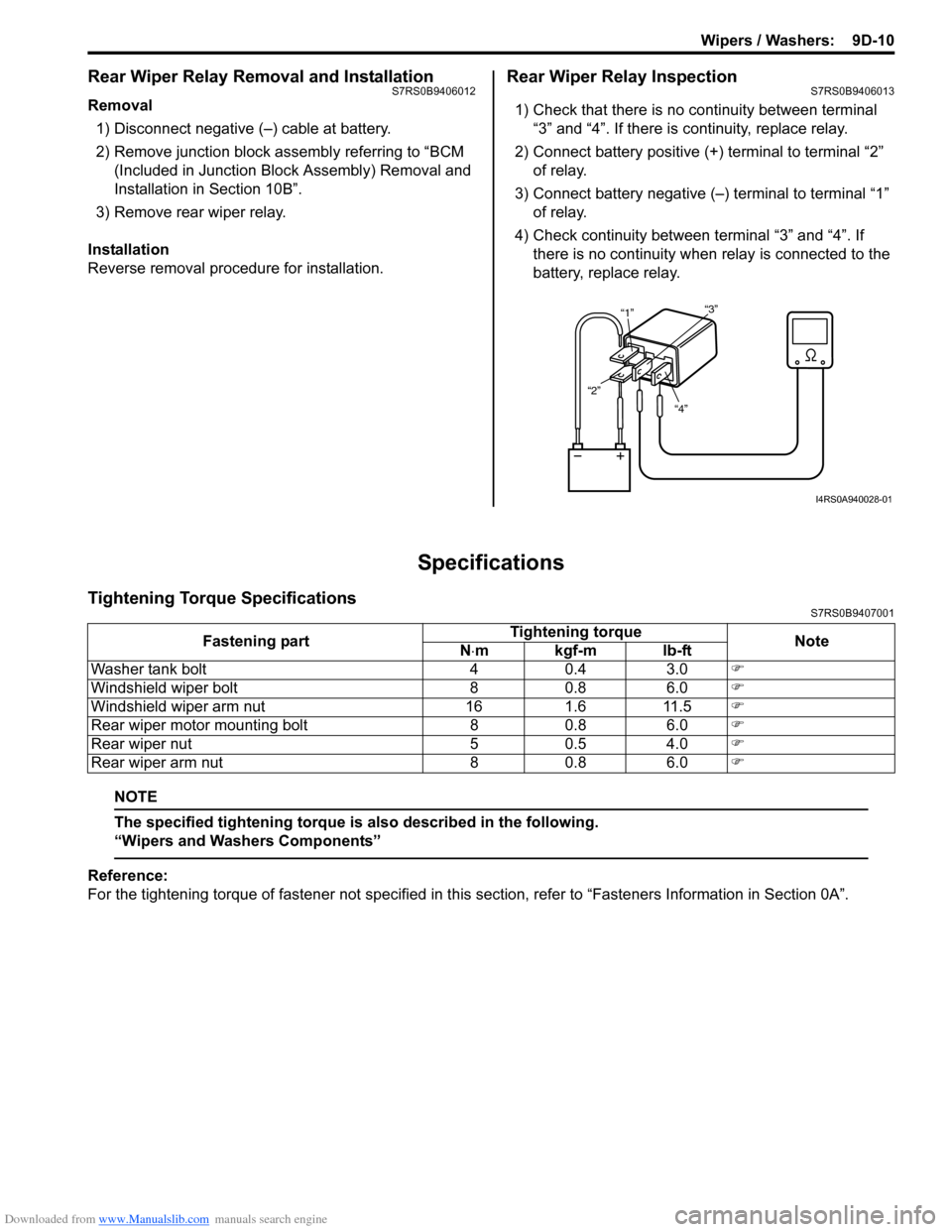

Rear Wiper Relay InspectionS7RS0B9406013

1) Check that there is no continuity between terminal “3” and “4”. If there is continuity, replace relay.

2) Connect battery positive (+ ) terminal to terminal “2”

of relay.

3) Connect battery negative (–) terminal to terminal “1” of relay.

4) Check continuity between terminal “3” and “4”. If

there is no continuity when relay is connected to the

battery, replace relay.

Specifications

Tightening Torque SpecificationsS7RS0B9407001

NOTE

The specified tightening torque is also described in the following.

“Wipers and Washers Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

“4”

“2” “1”

“3”

I4RS0A940028-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Washer tank bolt 4 0.4 3.0 �)

Windshield wiper bolt 8 0.8 6.0 �)

Windshield wiper arm nut 16 1.6 11.5 �)

Rear wiper motor mounting bolt 8 0.8 6.0 �)

Rear wiper nut 5 0.5 4.0 �)

Rear wiper arm nut 8 0.8 6.0 �)

Page 1328 of 1496

Downloaded from www.Manualslib.com manuals search engine 9E-1 Glass / Windows / Mirrors:

Body, Cab and Accessories

Glass / Windows / Mirrors

General Description

Rear End Door Window Defogger System DescriptionS7RS0B9501001

The rear end door window defogger is controlled by BCM. For the BCM description refer to “BCM General Description

in Section 10B”.

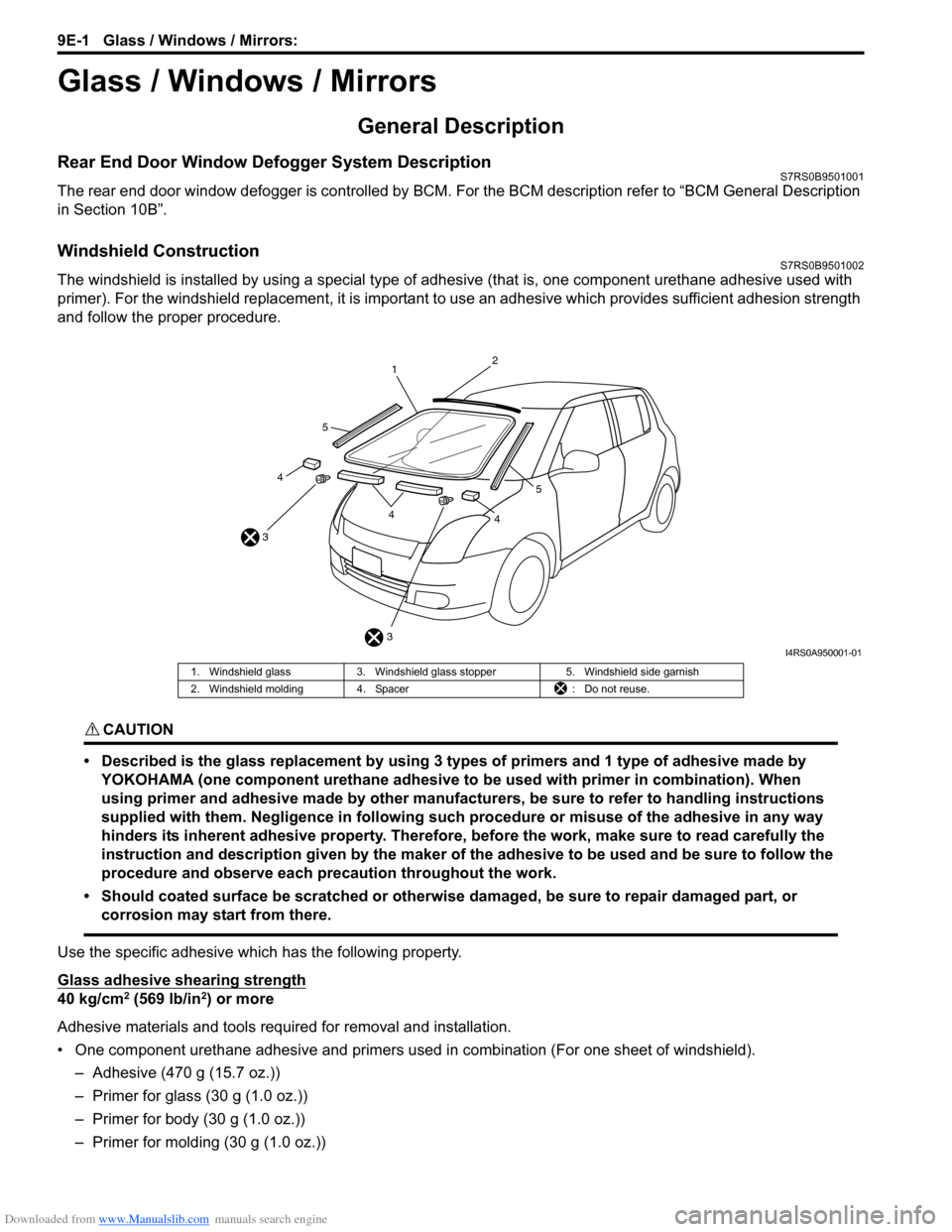

Windshield ConstructionS7RS0B9501002

The windshield is installed by using a special type of adhesive (that is, one component urethane adhesive used with

primer). For the windshield replacement, it is important to use an adhesive which provides sufficient adhesion strength

and follow the proper procedure.

CAUTION!

• Described is the glass replacement by using 3 types of primers and 1 type of adhesive made by YOKOHAMA (one component urethane adhesive to be used with primer in combination). When

using primer and adhesive made by other manufacturers, be sure to refer to handling instructions

supplied with them. Negligence in following such procedure or misuse of the adhesive in any way

hinders its inherent adhesive property. Therefore, before the work, make sure to read carefully the

instruction and description given by the maker of the adhesive to be used and be sure to follow the

procedure and observe each precaution throughout the work.

• Should coated surface be scratched or otherwise damaged, be sure to repair damaged part, or corrosion may start from there.

Use the specific adhesive which has the following property.

Glass adhesive shearing strength

40 kg/cm2 (569 lb/in2) or more

Adhesive materials and tools required for removal and installation.

• One component urethane adhesive and primers used in combination (For one sheet of windshield). – Adhesive (470 g (15.7 oz.))

– Primer for glass (30 g (1.0 oz.))

– Primer for body (30 g (1.0 oz.))

– Primer for molding (30 g (1.0 oz.))

3

3 1

2

44

4

5

5

I4RS0A950001-01

1. Windshield glass

3. Windshield glass stopper 5. Windshield side garnish

2. Windshield molding 4. Spacer : Do not reuse.

Page 1329 of 1496

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-2

• Eyeleteer

• Piano string

• Windshield knife

• Brush for primer application (2 pcs)

•Knife

• Rubber sucker grip

• Sealant gun (for filling adhesive)

• Putty spatula (for correcting adhered parts)

Diagnostic Information and Procedures

Rear End door Window Defogger Symptom DiagnosisS7RS0B9504001

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, re fer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Power Window Control System Symptom DiagnosisS7RS0B9504002

Condition Possible cause Correction / Reference Item

Rear end door window

defogger does not

operate Circuit fuse blown

Replace fuse and check for short circuit.

Rear end door window defogger switch

faulty Check rear end door window defogger switch

referring to “Rear End Door Window Defogger

Switch Inspection”.

Rear end door window defogger relay

faulty Check rear end door window defogger relay

referring to “Rear End Door Window Defogger

Relay Inspection”.

Defogger wire faulty Check defogger wire referring to “Rear End

Door Window Defogger Wire Inspection”.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

ConditionPossible cause Correction / Reference Item

All power windows do not

operate Circuit fuse blown

Replace fuse and check for short circuit.

Power window main switch faulty Check power window main switch referring to

“Power Window Main Switch Inspection”.

Ignition switch faulty Check ignition switch referring to “Ignition

Switch Inspection in Section 9C”.

Wiring or grounding faulty Repair circuit.

Only one power window

does not operate Power window main switch faulty

Check power window main switch referring to

“Power Window Main Switch Inspection”.

Power window sub switch faulty Check power window sub switch referring to

“Power Window Sub Switch Inspection”.

Wiring and/or coupler faulty Check wiring and/or coupler.

Power window regulator faulty Check window regulator.

Power window motor faulty Check power window motor.

Wiring or grounding faulty Repair circuit.