low pressure SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 992 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-44 Air Conditioning System: Automatic Type

3) Light over sunload sensor vertically with an incandescent lamp approximately 100 W apart from

about 100 mm (3.94 in.).

NOTE

If sunload sensor is not lighted over with an

incandescent lamp, DTC B1504 is detected

as current DTC even though there is not any

malfunction.

4) Turn ignition switch to ON position.

5) Erase DTC according to instructions displayed on SUZUKI scan tool.

NOTE

To know how to use SUZUKI scan tool, refer

to operator’s manual for SUZUKI scan tool.

6) After completing the clearance, turn ignition switch to OFF position, and then di sconnect SUZUKI scan

tool from DLC.

Not Using SUZUKI Scan Tool 1) Turn ignition switch to ON position.

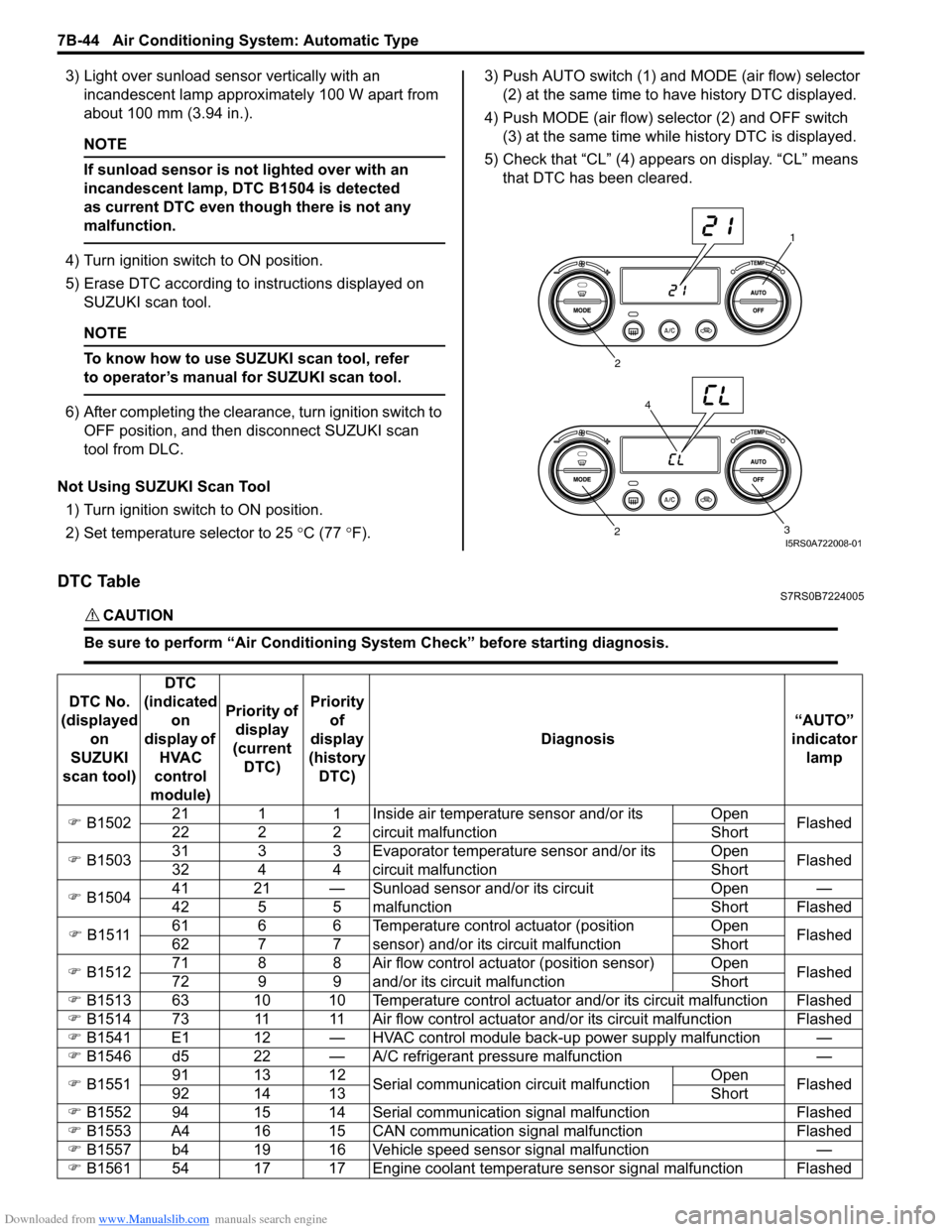

2) Set temperature selector to 25 °C (77 °F). 3) Push AUTO switch (1) and

MODE (air flow) selector

(2) at the same time to have history DTC displayed.

4) Push MODE (air flow) selector (2) and OFF switch (3) at the same time while history DTC is displayed.

5) Check that “CL” (4) appears on display. “CL” means that DTC has been cleared.

DTC TableS7RS0B7224005

CAUTION!

Be sure to perform “Air Conditioning Sy stem Check” before starting diagnosis.

1

2

3

2

4

I5RS0A722008-01

DTC No.

(displayed on

SUZUKI

scan tool) DTC

(indicated on

display of HVAC

control

module) Priority of

display

(current DTC) Priority

of

display

(history DTC) Diagnosis

“AUTO”

indicator lamp

�) B1502 21 1 1 Inside air temperature sensor and/or its

circuit malfunction Open

Flashed

22 2 2 Short

�) B1503 31 3 3 Evaporator temperature sensor and/or its

circuit malfunction Open

Flashed

32 4 4 Short

�) B1504 41 21 — Sunload sensor and/or its circuit

malfunction Open —

42 5 5 Short Flashed

�) B1511 61 6 6 Temperature control actuator (position

sensor) and/or its circuit malfunction Open

Flashed

62 7 7 Short

�) B1512 71 8 8 Air flow control actuator (position sensor)

and/or its circuit malfunction Open

Flashed

72 9 9 Short

�) B1513 63 10 10 Temperature control actuator and/or its circuit malfunction Flashed

�) B1514 73 11 11 Air flow control actuator and/or its circuit malfunction Flashed

�) B1541 E1 12 — HVAC control module back-up power supply malfunction —

�) B1546 d5 22 — A/C refrigerant pressure malfunction —

�) B1551 91 13 12

Serial communication circuit malfunction Open

Flashed

92 14 13 Short

�) B1552 94 15 14 Serial communication signal malfunction Flashed

�) B1553 A4 16 15 CAN communication signal malfunction Flashed

�) B1557 b4 19 16 Vehicle speed sensor signal malfunction —

�) B1561 54 17 17 Engine coolant temperature sensor signal malfunction Flashed

Page 993 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-45

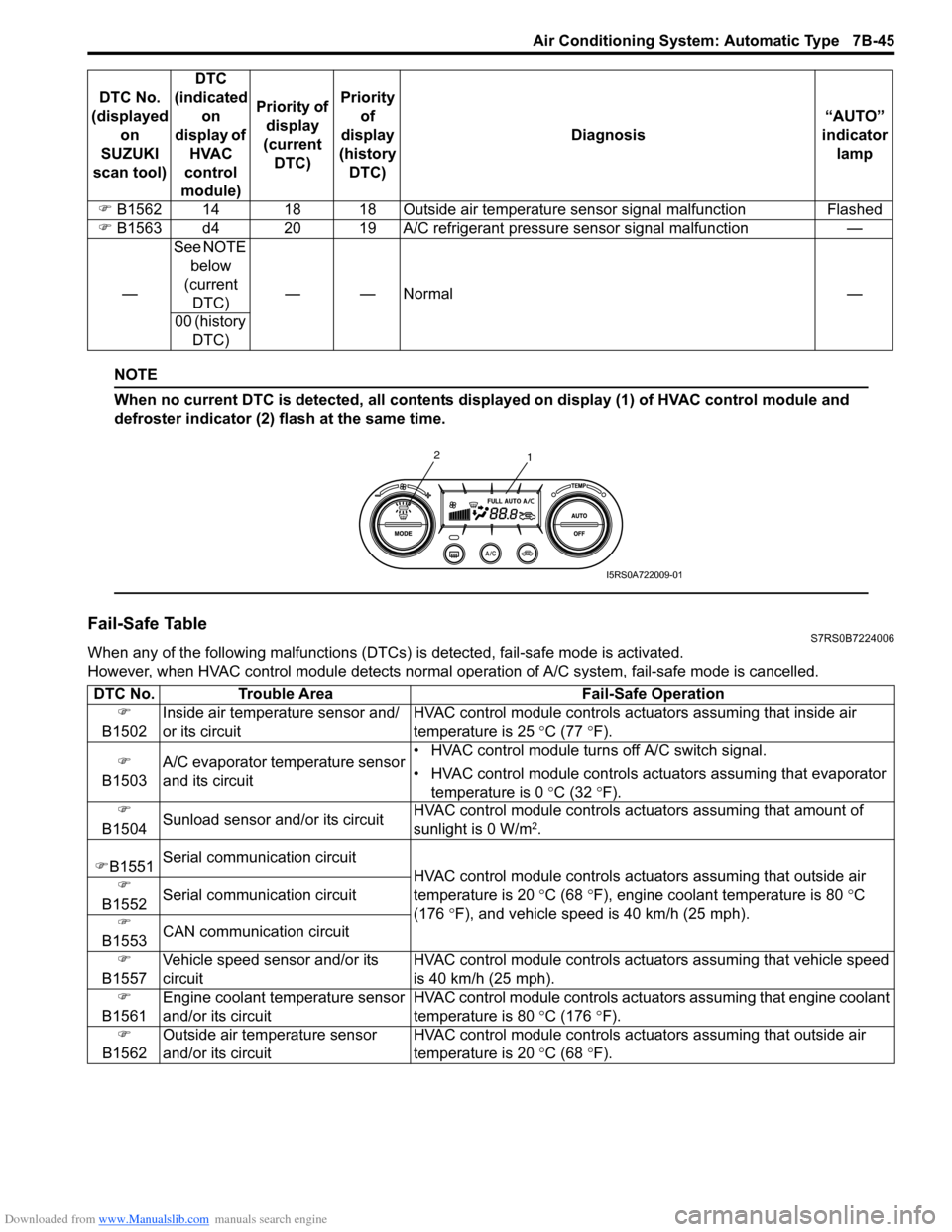

NOTE

When no current DTC is detected, all contents displayed on display (1) of HVAC control module and

defroster indicator (2) flash at the same time.

Fail-Safe TableS7RS0B7224006

When any of the following malfunctions (DTCs) is detected, fail-safe mode is activated.

However, when HVAC control module detects normal ope ration of A/C system, fail-safe mode is cancelled.

�)

B1562 14 18 18 Outside air temperatur e sensor signal malfunction Flashed

�) B1563 d4 20 19 A/C refrigerant pressure sensor signal malfunction —

— See NOTE

below

(current DTC) ——Normal —

00 (history DTC)

DTC No.

(displayed on

SUZUKI

scan tool) DTC

(indicated on

display of HVAC

control

module) Priority of

display

(current DTC) Priority

of

display

(history DTC) Diagnosis

“AUTO”

indicator lamp

1

2

I5RS0A722009-01

DTC No.

Trouble Area Fail-Safe Operation

�)

B1502 Inside air temperature sensor and/

or its circuit HVAC control module controls actu

ators assuming that inside air

temperature is 25 ° C (77 °F).

�)

B1503 A/C evaporator temperature sensor

and its circuit • HVAC control module turn

s off A/C switch signal.

• HVAC control module controls actu ators assuming that evaporator

temperature is 0 ° C (32 °F).

�)

B1504 Sunload sensor and/or its circuit HVAC control module controls actu

ators assuming that amount of

sunlight is 0 W/m

2.

�) B1551 Serial communication circuit

HVAC control module controls actuators assuming that outside air

temperature is 20 ° C (68 °F), engine coolant temperature is 80 °C

(176 °F), and vehicle speed is 40 km/h (25 mph).

�)

B1552 Serial communication circuit

�)

B1553 CAN communication circuit

�)

B1557 Vehicle speed sensor and/or its

circuit HVAC control module controls act

uators assuming that vehicle speed

is 40 km/h (25 mph).

�)

B1561 Engine coolant temperature sensor

and/or its circuit HVAC control module controls act

uators assuming that engine coolant

temperature is 80 ° C (176 °F).

�)

B1562 Outside air temperature sensor

and/or its circuit HVAC control module controls actu

ators assuming that outside air

temperature is 20 ° C (68 °F).

Page 994 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-46 Air Conditioning System: Automatic Type

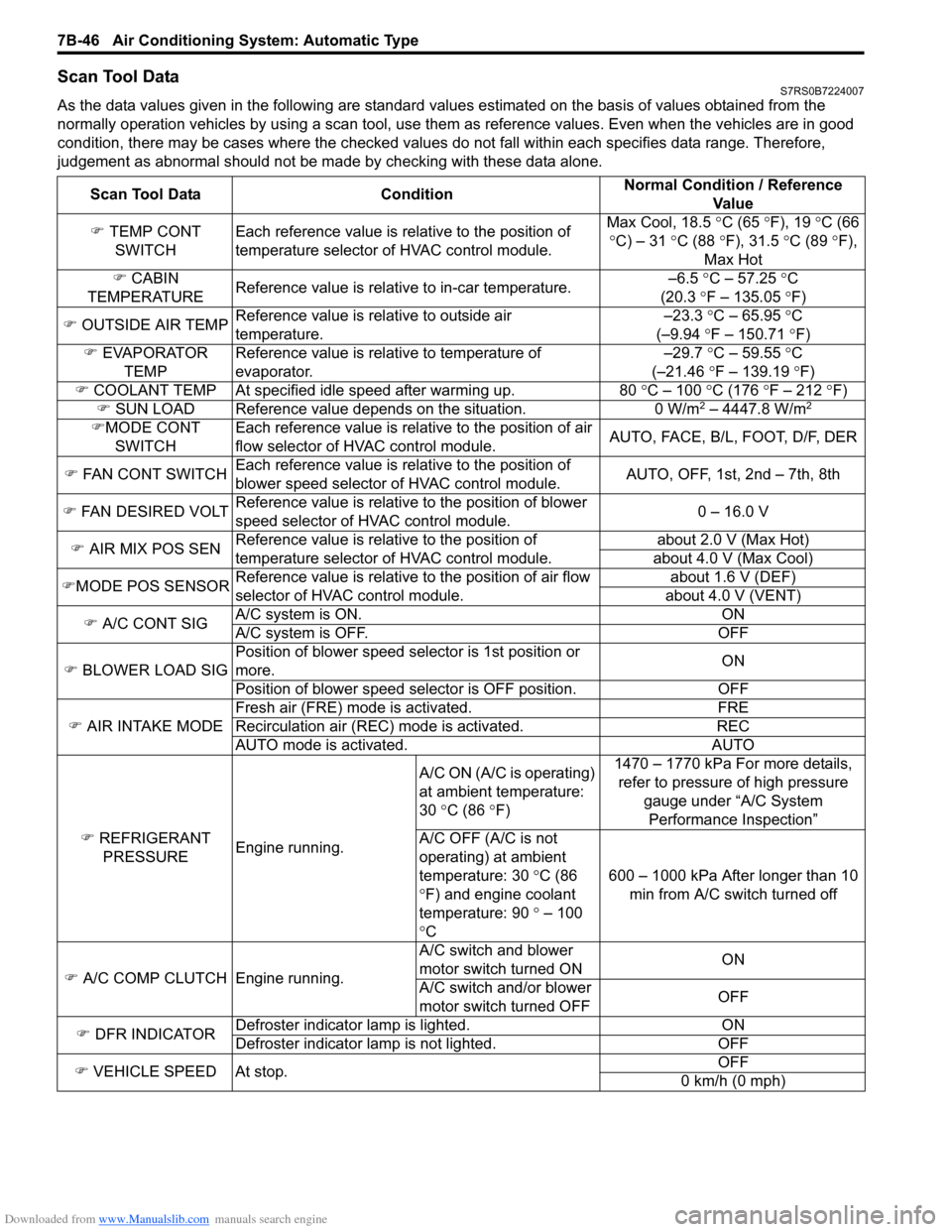

Scan Tool DataS7RS0B7224007

As the data values given in the following are standard values estimated on the basis of values obtained from the

normally operation vehicles by using a scan tool, use them as reference values. Even when the vehicles are in good

condition, there may be cases where the checked values do not fall within each specifies data range. Therefore,

judgement as abnormal should not be ma de by checking with these data alone.

Scan Tool Data Condition Normal Condition / Reference

Va l u e

�) TEMP CONT

SWITCH Each reference value is relative to the position of

temperature selector of HVAC control module. Max Cool, 18.5

°C (65 ° F), 19 °C (66

° C) – 31 °C (88 °F), 31.5 °C (89 °F),

Max Hot

�) CABIN

TEMPERATURE Reference value is relative to in-car temperature. –6.5

°C – 57.25 ° C

(20.3 °F – 135.05 °F)

�) OUTSIDE AIR TEMP Reference value is relative to outside air

temperature. –23.3

°C – 65.95 °C

(–9.94 °F – 150.71 °F)

�) EVAPORATOR

TEMP Reference value is relative to temperature of

evaporator. –29.7

°C – 59.55 °C

(–21.46 °F – 139.19 °F)

�) COOLANT TEMP At specified id le speed after warming up. 80 °C – 100 °C (176 ° F – 212 ° F)

�) SUN LOAD Reference value depends on the situation. 0 W/m

2 – 4447.8 W/m2

�)MODE CONT

SWITCH Each reference value is relative to the position of air

flow selector of HVAC control module.

AUTO, FACE, B/L, FOOT, D/F, DER

�) FAN CONT SWITCH Each reference value is relative to the position of

blower speed selector of HVAC control module. AUTO, OFF, 1st, 2nd – 7th, 8th

�) FAN DESIRED VOLT Reference value is relative to the position of blower

speed selector of HVAC control module. 0 – 16.0 V

�) AIR MIX POS SEN Reference value is relative to the position of

temperature selector of HVAC control module. about 2.0 V (Max Hot)

about 4.0 V (Max Cool)

�) MODE POS SENSOR Reference value is relative to the position of air flow

selector of HVAC control module. about 1.6 V (DEF)

about 4.0 V (VENT)

�) A/C CONT SIG A/C system is ON. ON

A/C system is OFF. OFF

�) BLOWER LOAD SIG Position of blower speed selector is 1st position or

more.

ON

Position of blower speed selector is OFF position. OFF

�) AIR INTAKE MODE Fresh air (FRE) mode is activated. FRE

Recirculation air (REC) mode is activated. REC

AUTO mode is activated. AUTO

�) REFRIGERANT

PRESSURE Engine running. A/C ON (A/C is operating)

at ambient temperature:

30

°C (86 °F) 1470 – 1770 kPa For more details,

refer to pressure of high pressure

gauge under “A/C System Performance Inspection”

A/C OFF (A/C is not

operating) at ambient

temperature: 30 °C (86

° F) and engine coolant

temperature: 90 ° – 100

° C 600 – 1000 kPa After longer than 10

min from A/C switch turned off

�) A/C COMP CLUTCH Engine running. A/C switch and blower

motor switch turned ON

ON

A/C switch and/or blower

motor switch turned OFF OFF

�) DFR INDICATOR Defroster indicator

lamp is lighted. ON

Defroster indicator la mp is not lighted. OFF

�) VEHICLE SPEED At stop. OFF

0 km/h (0 mph)

Page 995 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-47

Scan Tool Data Definitions

TEMP CONT SWITCH (TEMPERATURE SELECTOR): Position of temperature control

selector of HVAC control module

CABIN TEMPERATURE: In-car temperature detected

by inside air temperature sensor installed in HVAC

control module

OUTSIDE AIR TEMP (OUTSIDE AIR TEMPERATURE): Outside air temperature

detected by outside air temperature sensor installed

in front bumper member

EVAPORATOR TEMP (EVAPORATOR TEMPERATURE): Temperature of air passed

through evaporator

COOLANT TEMP (ENGINE COOLANT TEMPERATURE): Engine coolant temperature

detected by engine coolant temperature sensor

SUN LOAD: Amount of sunlight detected by sunload

sensor installed on the driver side on the dashboard

MODE CONT SWITCH (MODE (AIR FLOW) SELECTOR): Position of air flow selector of HVAC

control module

FAN CONT SWITCH (BLOWER SPEED SELECTOR): Position of blower speed selector of HVAC control

module

FAN DESIRED VOLT: Voltage for blower motor AIR MIX POS SEN (TEMPERATURE CONTROL

ACTUATOR POSITI ON SENSOR): Input signal

from position sensor in temperature control actuator

MODE POS SENSOR (AIR FLOW CONTROL ACTUATOR POSITI ON SENSOR): Input signal

from position sensor in air flow control actuator

A/C CONT SIG (A/C SWITCH SIGNAL, ON or OFF): State of A/C switch

BLOWER LOAD SIG (BLO WER FAN LOAD SIGNAL,

ON or OFF): ON: Position of blower speed selector

is 1st position or more / OFF: Position of blower

speed selector is OFF position.

AIR INTAKE MODE (AUTO, FRE or REC): State of air

intake mode

REFRIGERANT PRESSURE (A/C REFRIGERANT ABSOLUTE PRESSURE): This parameter

indicates A/C refrigerant absolute pressure

calculated by ECM

A/C COMP CLUTCH (A/C COMPRESSOR MAGNET CLUTCH, ON or OFF): This parameter indicates

the state of the A/C switch

DFR INDICATOR (DEFROSTER INDICATOR LAMP, ON or OFF): State of defroster indicator lamp

VEHICLE SPEED: It is computed based on pulse

signals from vehicle speed sensor

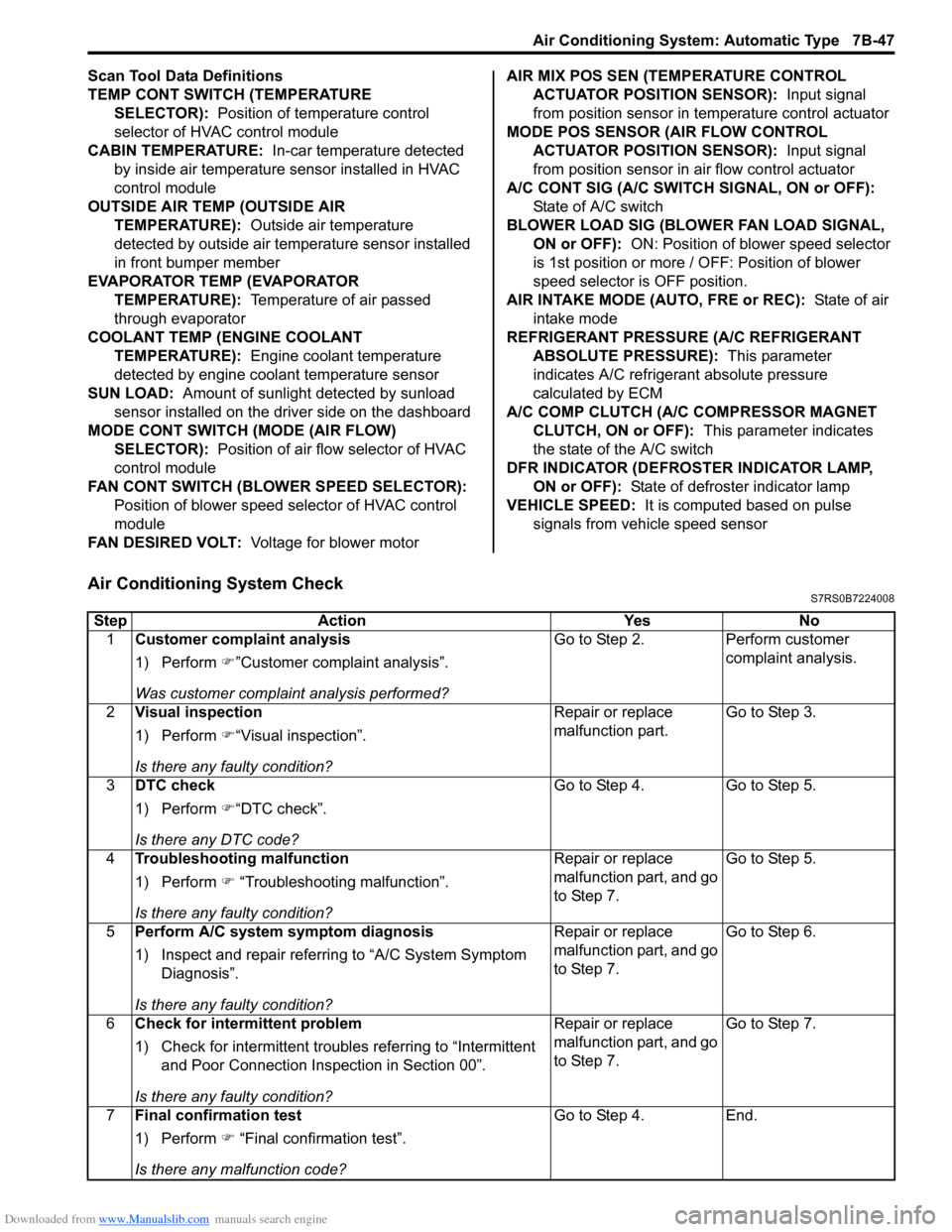

Air Conditioning System CheckS7RS0B7224008

Step Action YesNo

1 Customer complaint analysis

1) Perform �)”Customer complaint analysis”.

Was customer complaint analysis performed? Go to Step 2.

Perform customer

complaint analysis.

2 Visual inspection

1) Perform �)“Visual inspection”.

Is there any faulty condition? Repair or replace

malfunction part.

Go to Step 3.

3 DTC check

1) Perform �)“DTC check”.

Is there any DTC code? Go to Step 4.

Go to Step 5.

4 Troubleshooting malfunction

1) Perform �) “Troubleshooting malfunction”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 7.

Go to Step 5.

5 Perform A/C system symptom diagnosis

1) Inspect and repair referri ng to “A/C System Symptom

Diagnosis”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 7.

Go to Step 6.

6 Check for intermittent problem

1) Check for intermittent troubles referring to “Intermittent

and Poor Connection Inspection in Section 00”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 7.

Go to Step 7.

7 Final confirmation test

1) Perform �) “Final confirmation test”.

Is there any malfunction code? Go to Step 4.

End.

Page 1011 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-63

DTC B1546: A/C Refrigerant Pressure MalfunctionS7RS0B7224018

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

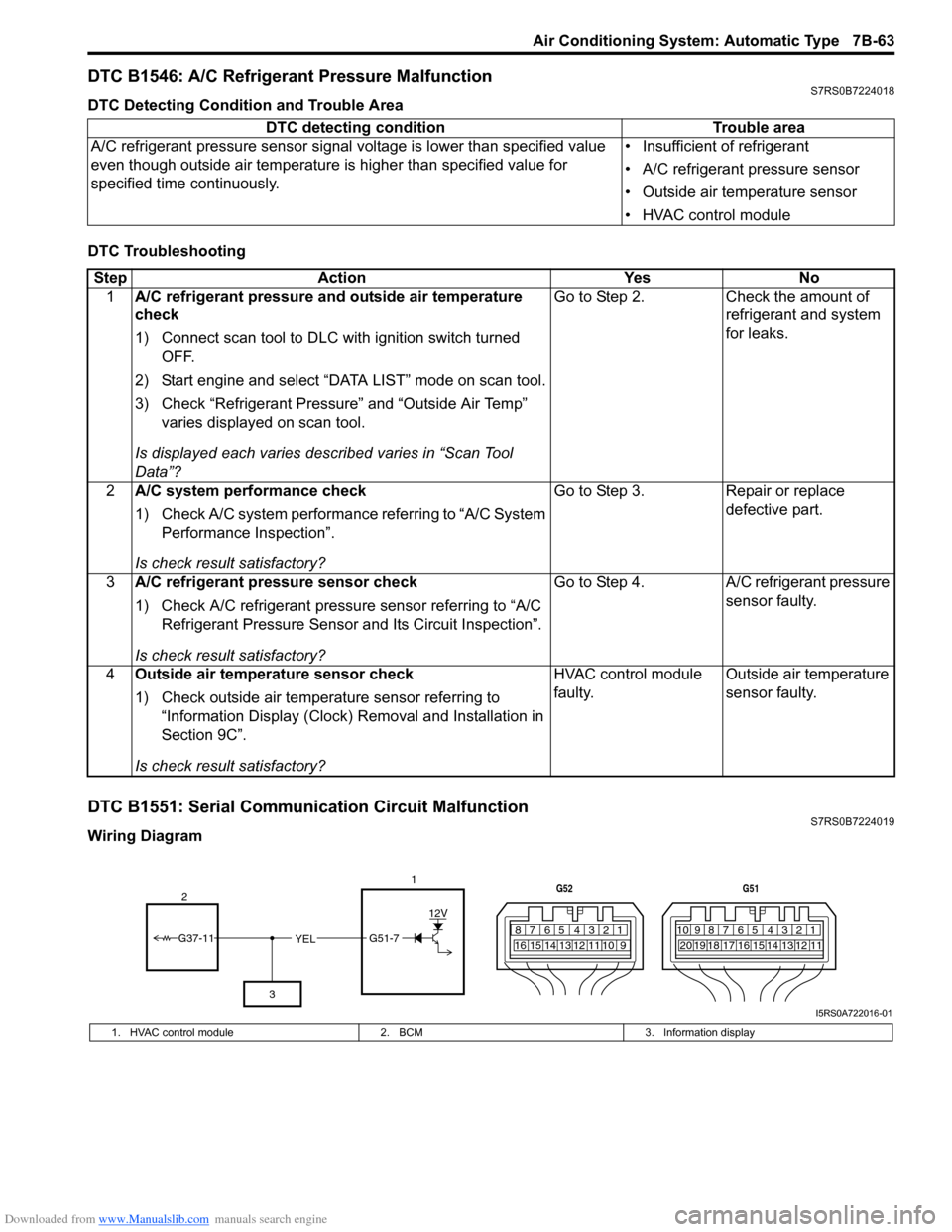

DTC B1551: Serial Communication Circuit MalfunctionS7RS0B7224019

Wiring DiagramDTC detecting condition Trouble area

A/C refrigerant pressure sensor signal voltage is lower t han specified value

even though outside air temperature is higher than specified value for

specified time continuously. • Insufficient of refrigerant

• A/C refrigerant pressure sensor

• Outside air temperature sensor

• HVAC control module

Step

Action YesNo

1 A/C refrigerant pressure and outside air temperature

check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Start engine and select “DATA LIST” mode on scan tool.

3) Check “Refrigerant Pressure” and “Outside Air Temp” varies displayed on scan tool.

Is displayed each va ries described varies in “Scan Tool

Data”? Go to Step 2.

Check the amount of

refrigerant and system

for leaks.

2 A/C system performance check

1) Check A/C system performance referring to “A/C System

Performance Inspection”.

Is check result satisfactory? Go to Step 3.

Repair or replace

defective part.

3 A/C refrigerant pressure sensor check

1) Check A/C refrigerant pressure sensor referring to “A/C

Refrigerant Pressure Sensor and Its Circuit Inspection”.

Is check result satisfactory? Go to Step 4.

A/C refrigerant pressure

sensor faulty.

4 Outside air temperature sensor check

1) Check outside air temperature sensor referring to

“Information Display (Clock) Removal and Installation in

Section 9C”.

Is check result satisfactory? HVAC control module

faulty.

Outside air temperature

sensor faulty.

YEL17812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

G51-7

12V

2

3

G37-11

I5RS0A722016-01

1. HVAC control module 2. BCM3. Information display

Page 1013 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-65

DTC Troubleshooting

DTC B1553: CAN Communication Signal MalfunctionS7RS0B7224021

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC B1557: Vehicle Speed Sensor Signal MalfunctionS7RS0B7224022

DTC Detecting Condition and Trouble Area

DTC TroubleshootingStep Action Yes No

1 Serial communication signal data check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Start engine and select “DATA LIST” mode on scan tool.

3) Check “Refrigerant Pressure”, “Vehicle Speed”, “Coolant Temp” and “Outside Air Temp” varies displayed on scan

tool.

Is displayed each va ries described varies in “Scan Tool

Data”? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 2.

2 Serial communication signal check

1) Connect connectors to BCM and HVAC control module.

2) Using oscilloscope, check that serial communication

signal is outputted referring to “Reference waveform

No.8” of “Inspection of BCM and its Circuits in Section

10B”.

Is serial communication signal outputted at “G37-11”

terminal of BCM connector? HVAC control module

faulty.

BCM (included in

junction block

assembly) faulty.

DTC detecting condition

Trouble area

HVAC control module receives error code fr om BCM continuously.• CAN communication circuit

• BCM (included in junction block assembly)

•ECM

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check ECM and BCM for DTC.

Is there DTC(s)? Go to applicable DTC

diag. flow.

Substitute a known-

good HVAC control

module and recheck.

DTC detecting condition

Trouble area

HVAC control module receives error code from BCM continuously. • VSS circuit

• VSS

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check ECM for DTC.

Is there DTC P0500? Go to “DTC P0480: Fan

1 (Radiator Cooling

Fan) Control Circuit in

Section 1A”.

Substitute a known-

good HVAC control

module and recheck.

Page 1014 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-66 Air Conditioning System: Automatic Type

DTC B1561: Engine Coolant Temperature Sensor Signal MalfunctionS7RS0B7224023

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC B1562: Outside Air Temperature Sensor Signal MalfunctionS7RS0B7224024

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC B1563: A/C Refrigerant Pressure Sensor Signal MalfunctionS7RS0B7224025

DTC Detecting Condition and Trouble Area

DTC TroubleshootingDTC detecting condition Trouble area

HVAC control module receives error code from BCM continuously. • ECT sensor circuit

• ECT sensor

• HVAC control module

StepAction YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check ECM for DTC.

Are there DTC P0116, P0117 or P0118? Go to applicable DTC

diag. flow.

Substitute a known-

good HVAC control

module and recheck.

DTC detecting condition

Trouble area

HVAC control module receives er ror code from BCM continuously. • Outside air temperature sensor

circuit

• Outside air temperature sensor

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check BCM for DTC.

Are there DTC B1141, B1142 or B1143? Go to applicable DTC

diag. flow.

Substitute a known-

good HVAC control

module and recheck.

DTC detecting condition

Trouble area

HVAC control module receives er ror code from BCM continuously. • A/C refrigerant pressure sensor

circuit

• A/C refrigerant pressure sensor

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check ECM for DTC.

Are there DTC P0532 or P0533? Go to applicable DTC

diag. flow.

Substitute a known-

good HVAC control

module and recheck.

Page 1019 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-71

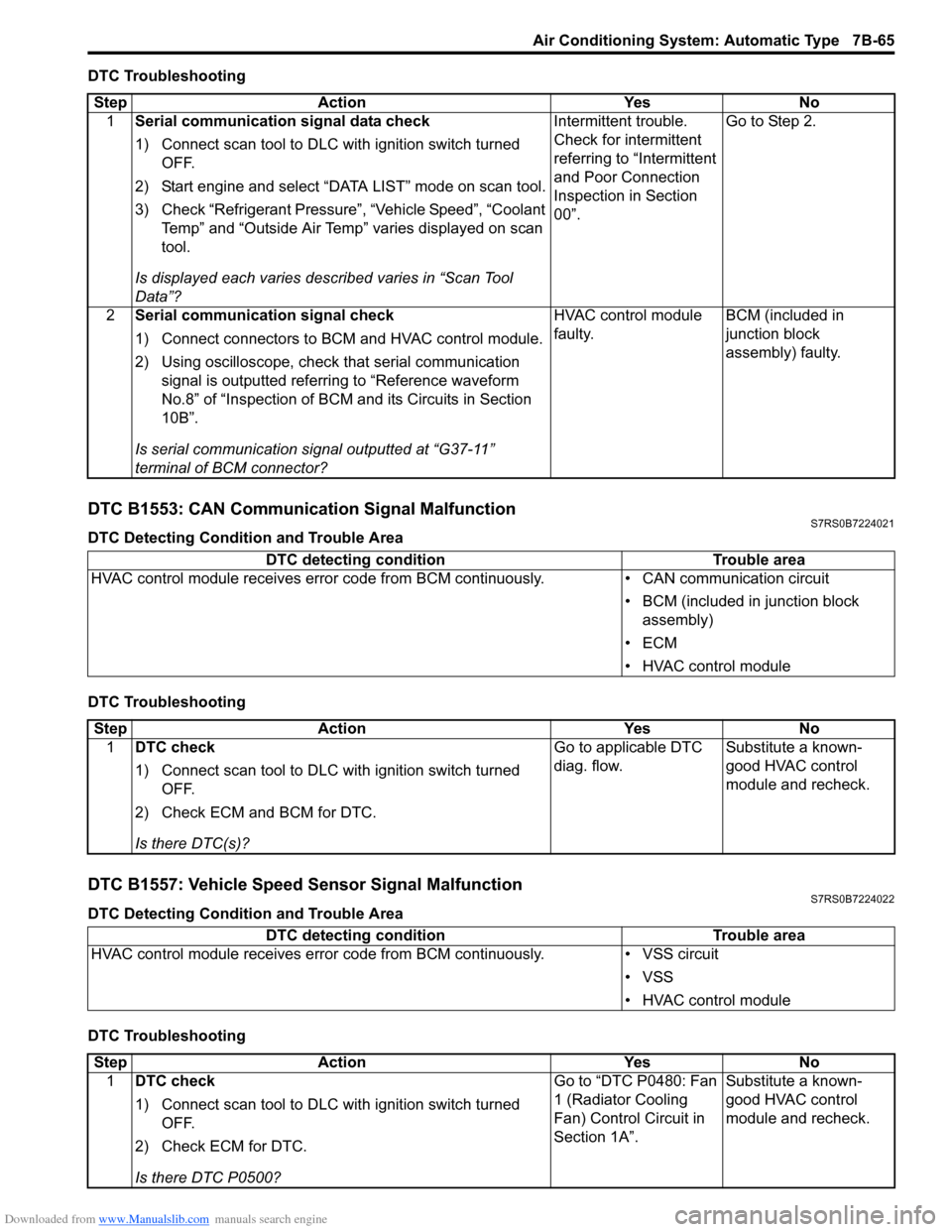

ECM Voltage Values Table for Relation of A/C Control

Repair Instructions

Operation Procedure for Refrigerant ChargeS7RS0B7226001

Refer to “Operation Procedure for Refrigerant Charge”.Terminal Wire Color Circuit Normal Value Condition

C37-14 GRY/RED Output of 5 V power

source 4.5 – 5.5 V Ignition switch turned ON

C37-15 BLK Ground for ECM Below 0.3 V Ignition switch turned ON

C37-24 LT GRN Engine coolant temp.

(ETC) sensor signal 3.3 – 3.8 V Ignition switch turned ON, ECT at 0

°C (32 ° F)

1.38 – 1.72 V Ignition switch turned ON, ECT at 50 °C (122 °F)

C37-30 BLK Ground for ECM Below 0.3 V Ignition switch turned ON

C37-55 ORN Ground for sensors Below 0.3 V Ignition switch turned ON

C37-58 BLK/ORN Ground for ECM Below 0.3 V Ignition switch turned ON E23-1 BLK/RED Main power supply 10 – 14 V Ignition switch turned ON

E23-3 RED CAN (high)

communication line

(active high signal)

for BCM and

combination meterRefer to “DTC P2101: Throttle Actu

ator Control Motor Circuit Range /

Performance in Section 1A”

E23-16 BLK/RED Main power supply 10 – 14 V Ignition switch turned ON

E23-18 WHT CAN (low)

communication line

(active low signal) for

BCM and

combination meterRefer to “DTC P2101: Throttle Actu

ator Control Motor Circuit Range /

Performance in Section 1A”

E23-19 BLU/WHT Electric load signal

for blower motor 10 – 14 V

Ignition switch turned ON, blower speed selector

OFF or between 1st and 5th position

0 – 1 V Ignition switch turned ON, blower speed selector

between 6th and HIGH position

E23-46 LT GRN Radiator fan relay

No.1 output 10 – 14 V

Ignition switch turned ON, engine coolant temp.:

below 95

°C (203 ° F), or A/C refrigerant pressure:

below 600 kPa (87 psi).

0 – 2 V Ignition switch turned ON, engine coolant temp.:

97.5

°C (207.5 °F) or higher, or A/C refrigerant

pressure: 1100 kPa (159.5 psi) or higher.

E23-47 GRY A/C compressor relay

output 10 – 14 V Engine running, A/C request signal high input

0 – 1 V Engine running, A/C request signal low input

E23-48 GRN Radiator fan relay

No.2 and No.3 output 10 – 14 V

Ignition switch turned ON, engine coolant temp.:

below 100

°C (212 °F), or A/C refrigerant

pressure: below 1200 kPa (174 psi).

0 – 2 V Ignition switch turned ON, engine coolant temp.:

102.5

°C (216.5 ° F) or higher, or A/C refrigerant

pressure: 1500 kPa (217.5 psi) or higher.

E23-55 RED A/C refrigerant

pressure sensor

signal 1.46 – 1.71 V

Engine running, A/C refrigerant pressure at 0.8

MPa (8.0 kg/cm

2) (A/C refrigerant pressure

measured by manifold gauge)

2.55 – 2.80 V Engine running, A/C refrigerant pressure at 1.6

MPa (16.0 kg/cm

2) (A/C refrigerant pressure

measured by manifold gauge)

E23-60 BRN/WHT Main power supply

relay output 10 – 14 V Ignition switch turned OFF

0 – 2 V Ignition switch turned ON

Page 1168 of 1496

Downloaded from www.Manualslib.com manuals search engine 9-ii Table of Contents

List of Connectors ........................................... 9A-103

C Connector .................................................... 9A-103

D Connector (M16A engine) ........................... 9A-104

E Connector .................................................... 9A-104

G Connector .................................................... 9A-106

J Connector ..................................................... 9A-108

K Connector .................................................... 9A-109

L Connector..................................................... 9A-109

M Connector (SPORT model) ......................... 9A-111

O Connector .................................................... 9A-111

R Connector .................................................... 9A-111

Lighting Systems .................................... 9B-1

Component Location ........... ................................9B-1

Lighting System Component s Location............... 9B-1

Interior Light System Location............................. 9B-2

Diagnostic Information and Procedures ............ 9B-2 Headlight Symptom Diagnosis ............................ 9B-2

Headlight Leveling System Symptom Diagnosis (If Equipped) ..................................... 9B-2

Turn Signal and Hazard Warning Light Symptom Diagnosis .......................................... 9B-3

Clearance, Tail and License Plate Light Symptom Diagnosis .......................................... 9B-3

Back-Up Light Symptom Diagnosis..................... 9B-4

Brake Light Symptom Diagnosis ......................... 9B-4

Front Fog Light Symptom Diagnosis (If Equipped) .......................................................... 9B-4

Interior Light Symptom Diagnosis ....................... 9B-5

Repair Instructions ..............................................9B-5 Headlight Housing Removal and Installation ...... 9B-5

Headlight Bulb Replacemen t............................... 9B-6

Headlight Aiming Adjustment with Screen .......... 9B-6

Headlight Switch (in Lighting Switch) Removal and Installation ................................... 9B-8

Headlight Switch (in Lighting Switch) Inspection .......................................................... 9B-8

Hazard Warning Switch Removal and Installation ......................................................... 9B-8

Hazard Warning Switch Inspection ..................... 9B-9

Brake Light Switch Inspection ............................. 9B-9

Turn Signal Light Switch (in Lighting Switch) Removal and Installation ................................... 9B-9

Turn Signal Light Switch (in Lighting Switch) Inspection .......................................................... 9B-9

Turn Signal and Hazard Warning Relay Removal and Installation ................................... 9B-9

Turn Signal and Hazard Warning Relay Inspection ........................................................ 9B-10

License Light Removal and Installation............. 9B-10

Front Fog Light Removal and Installation (If Equipped) ........................................................ 9B-11

Front Fog Light Bulb Replacement (If Equipped) ........................................................ 9B-11

Front Fog Light Switch Inspection (If Equipped) ........................................................ 9B-11

Front Fog Light Relay Inspection (If Equipped) ........................................................ 9B-11

Front Fog Light Aiming Adjustment with Screen (If Equipped) ....................................... 9B-12 Headlight Leveling Switch Inspection (If

Equipped) ........................................................ 9B-13

Headlight Leveling Actuator Inspection (If Equipped) ........................................................ 9B-13

Instrumentation / Driver Info. / Horn ...... 9C-1

Precautions ...........................................................9C-1 Precautions in Diagnosing Troubles for Combination Meter ............................................9C-1

General Description .............................................9C-1 CAN Communication System Description...........9C-1

Auto Volume Co ntrol System Description (If

Equipped) ..........................................................9C-3

Schematic and Routing Diagram ........................9C-4 Combination Meter Circuit Diagram ....................9C-4

Component Location ............ ...............................9C-6

Audio System Component Location ....................9C-6

Diagnostic Information and Procedures ............9C-6 Speedometer and VSS Symp tom Diagnosis ......9C-6

Tachometer Symptom Diagnosis ........................9C-6

Engine Coolant Temperature (ECT) Meter Symptom Diagnosis ..........................................9C-7

Fuel Meter Symptom Diagnosis ..........................9C-7

Low Fuel Warning Light Symptom Diagnosis .....9C-7

Oil Pressure Warning Light Symptom Diagnosis ..........................................................9C-8

Brake and Parking Brake Warning Light Symptom Diagnosis ..........................................9C-8

Seat Belt Reminder Light Symptom Diagnosis (If Equipped)......................................................9C-8

A/T Shift Position Indicator Symptom Diagnosis (A/T Model).......................................9C-9

Charge Warning Light Sy mptom Diagnosis ........9C-9

Main Beam (High Beam) Indicator Symptom Diagnosis ..........................................................9C-9

Warning Buzzer Circuit Sy mptom Diagnosis ....9C-10

Cigarette Lighter Symptom Diagnosis (If Equipped) ........................................................9C-10

Horn Symptom Diagnosis .................................9C-10

Information Display Symptom Diagnosis (If Equipped) ........................................................9C-11

Clock Symptom Diagnosis (If Equipped)...........9C-12

Audio System Symptom Diagnosis (If Equipped) ........................................................9C-12

Remote Audio Control Switch Symptom Diagnosis (If Equipped) ...................................9C-13

Navigation Symptom Diagnosis (If Equipped)...9C-14

Repair Instructions ............ ................................9C-14

Ignition Switch Removal and Installation...........9C-14

Ignition Switch Inspection..................................9C-14

Combination Meter Removal and Installation ...9C-15

Fuel Level Sensor Removal and Installation .....9C-15

Fuel Level Sensor Inspection ............................9C-15

Oil Pressure Switch Remova l and Installation ..9C-15

Oil Pressure Switch Inspec tion .........................9C-16

Engine Coolant Temperature (ECT) Sensor Inspection ........................................................9C-16

Brake Fluid Level Switch Inspection .................9C-16

Parking Brake Switch Inspec tion.......................9C-16

Page 1172 of 1496

Downloaded from www.Manualslib.com manuals search engine 9A-1 Wiring Systems:

Body, Cab and Accessories

Wiring Systems

Precautions

Cautions in Body Electrical System ServicingS7RS0B9100001

When servicing the electric systems, observe the cautions described in “Precautions for Electrical Circuit Service in

Section 00” to protect electrical parts and to prevent a fire.

General Description

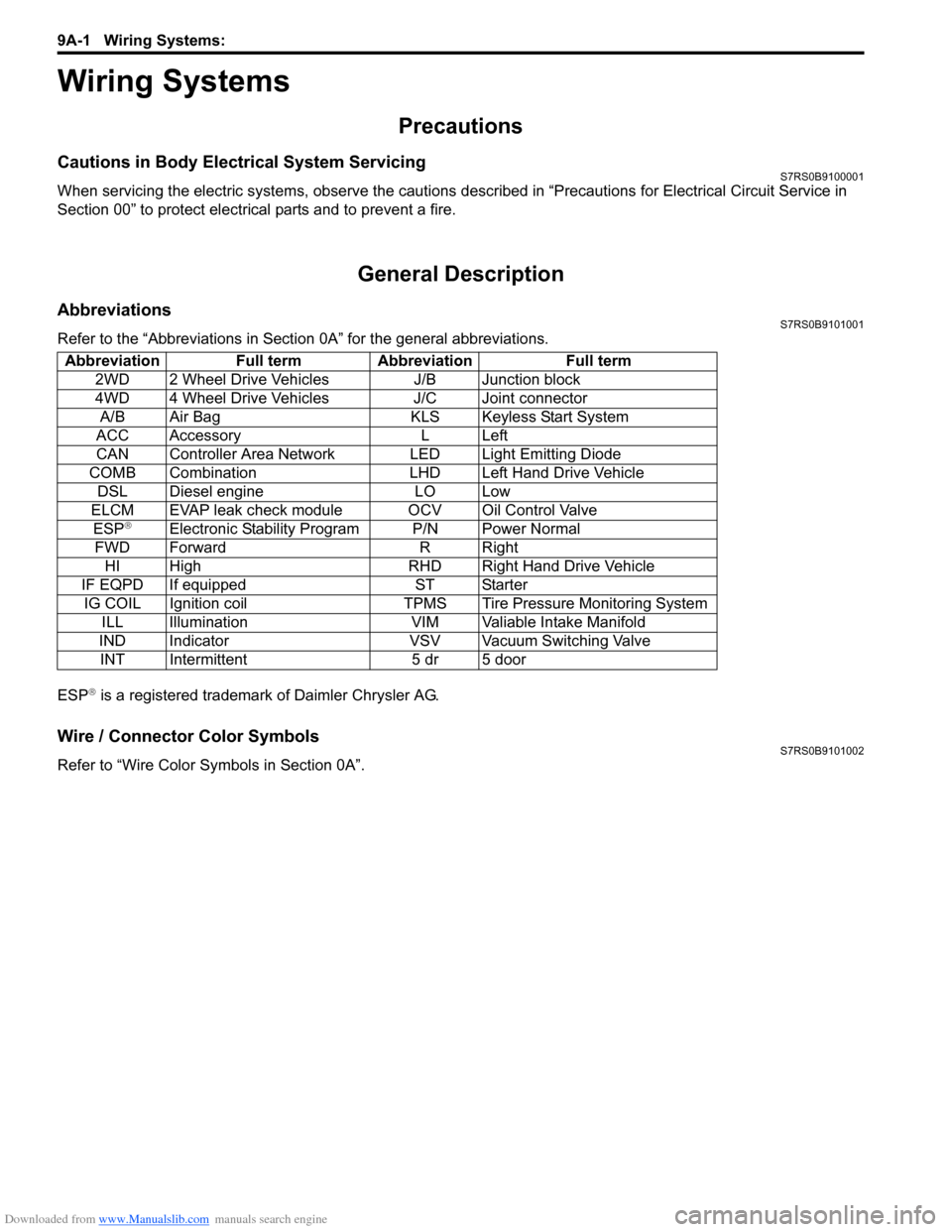

AbbreviationsS7RS0B9101001

Refer to the “Abbreviations in Sect ion 0A” for the general abbreviations.

ESP

® is a registered trademark of Daimler Chrysler AG.

Wire / Connector Color SymbolsS7RS0B9101002

Refer to “Wire Color Sy mbols in Section 0A”.

Abbreviation Full term Abbreviation Full term

2WD 2 Wheel Drive Vehicles J/B Junction block

4WD 4 Wheel Drive Vehicles J/C Joint connectorA/B Air Bag KLS Keyless Start System

ACC Accessory L Left

CAN Controller Area Network LED Light Emitting Diode

COMB Combination LHD Left Hand Drive Vehicle DSL Diesel engine LO Low

ELCM EVAP leak check module OCV Oil Control Valve ESP

®Electronic Stability Program P/N Power Normal

FWD Forward R Right HI High RHD Right Hand Drive Vehicle

IF EQPD If equipped ST Starter IG COIL Ignition coil TPMS Tire Pressure Monitoring System ILL Illumination VIM Valiable Intake Manifold

IND Indicator VSV Vacuum Switching Valve INT Intermittent 5 dr 5 door