low pressure SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 703 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-59

DTC TroubleshootingStep Action Yes No 1 Was “A/T System Check” performed? Go to Step 2. Go to “A/T System

Check”.

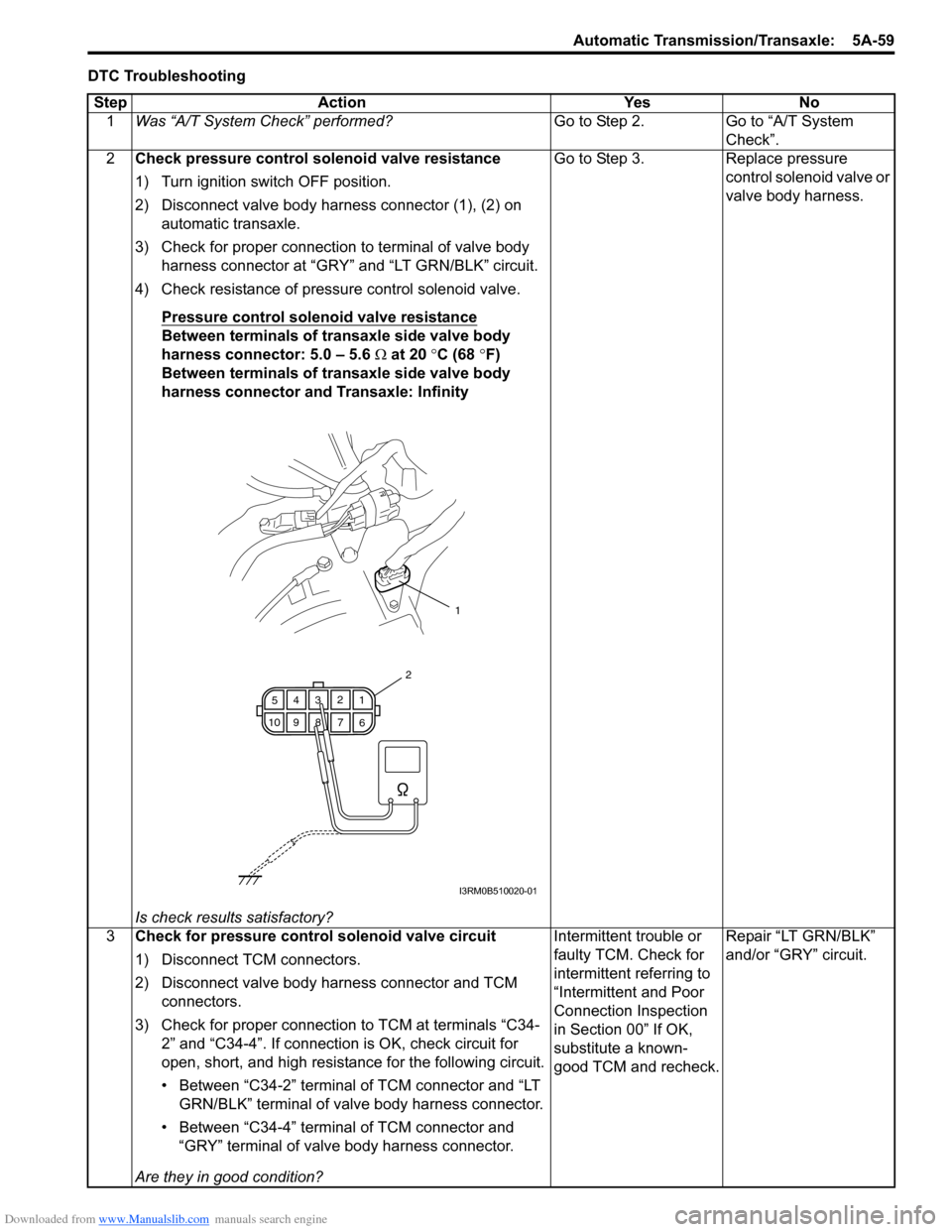

2 Check pressure control solenoid valve resistance

1) Turn ignition switch OFF position.

2) Disconnect valve body harness connector (1), (2) on

automatic transaxle.

3) Check for proper connection to terminal of valve body harness connector at “GRY” and “LT GRN/BLK” circuit.

4) Check resistance of pressure control solenoid valve.

Pressure control solenoid valve resistance

Between terminals of transaxle side valve body

harness connector: 5.0 – 5.6 Ω at 20 °C (68 °F)

Between terminals of transaxle side valve body

harness connector and Transaxle: Infinity

Is check results satisfactory? Go to Step 3. Replace pressure

control solenoid valve or

valve body harness.

3 Check for pressure control solenoid valve circuit

1) Disconnect TCM connectors.

2) Disconnect valve body harness connector and TCM

connectors.

3) Check for proper connection to TCM at terminals “C34- 2” and “C34-4”. If connection is OK, check circuit for

open, short, and high resistance for the following circuit.

• Between “C34-2” terminal of TCM connector and “LT GRN/BLK” terminal of valve body harness connector.

• Between “C34-4” terminal of TCM connector and “GRY” terminal of valve body harness connector.

Are they in good condition? Intermittent trouble or

faulty TCM. Check for

intermittent referring to

“Intermittent and Poor

Connection Inspection

in Section 00” If OK,

substitute a known-

good TCM and recheck.

Repair “LT GRN/BLK”

and/or “GRY” circuit.

1

6

7

89

10 5

43 2

1

2

I3RM0B510020-01

Page 704 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-60 Automatic Transmission/Transaxle:

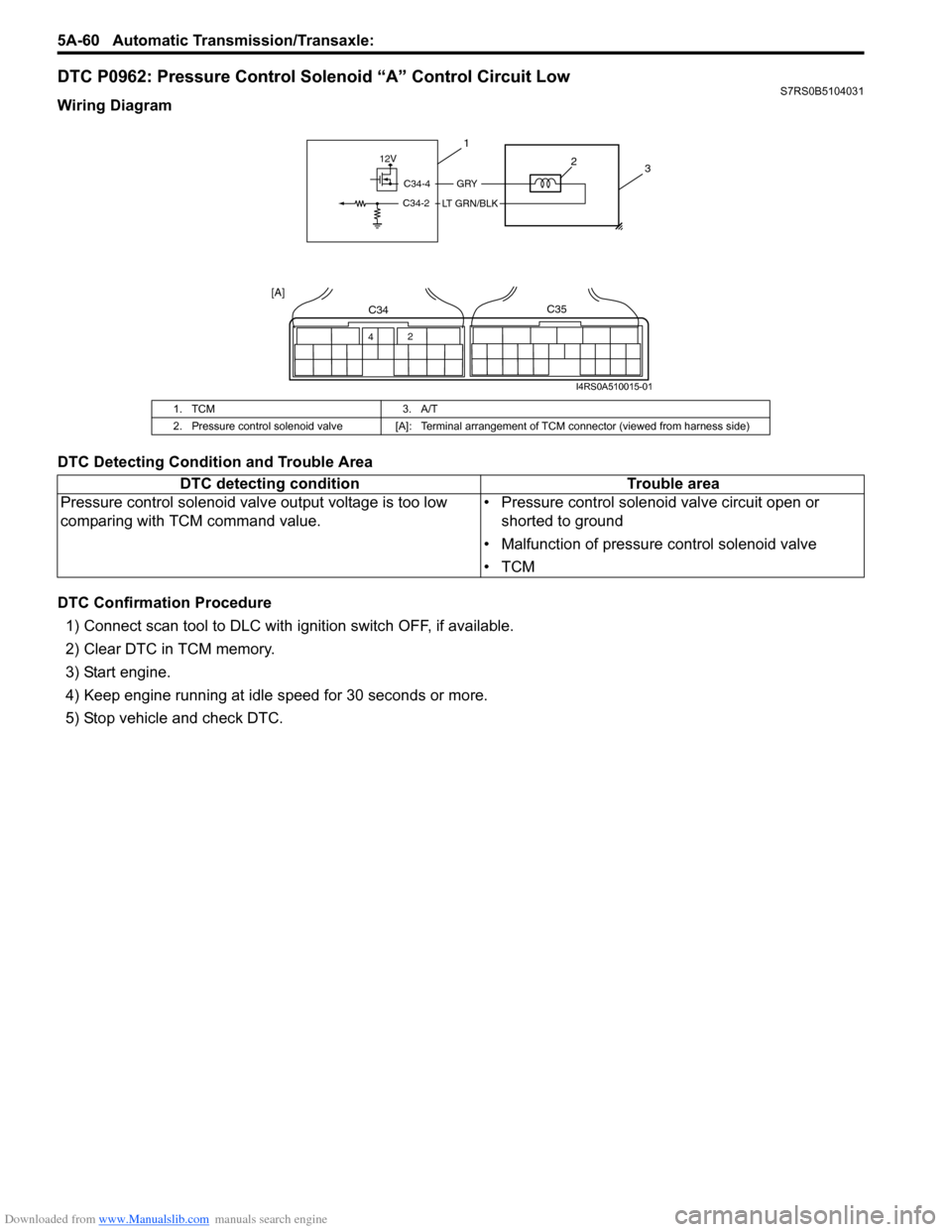

DTC P0962: Pressure Control Solenoid “A” Control Circuit LowS7RS0B5104031

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Connect scan tool to DLC with ig nition switch OFF, if available.

2) Clear DTC in TCM memory.

3) Start engine.

4) Keep engine running at idle speed for 30 seconds or more.

5) Stop vehicle and check DTC.

1. TCM 3. A/T

2. Pressure control solenoid valve [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Pressure control solenoid valv e output voltage is too low

comparing with TCM command value. • Pressure control solenoid valve circuit open or

shorted to ground

• Malfunction of pressure control solenoid valve

•TCM

12V

C34-4

C34-2

GRY

LT GRN/BLK

3

1

2

42

C34C35

[A]

I4RS0A510015-01

Page 721 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-77

DTC TroubleshootingStep Action Yes No 1 Was “A/T System Check” performed? Go to Step 2. Go to “A/T System

Check”.

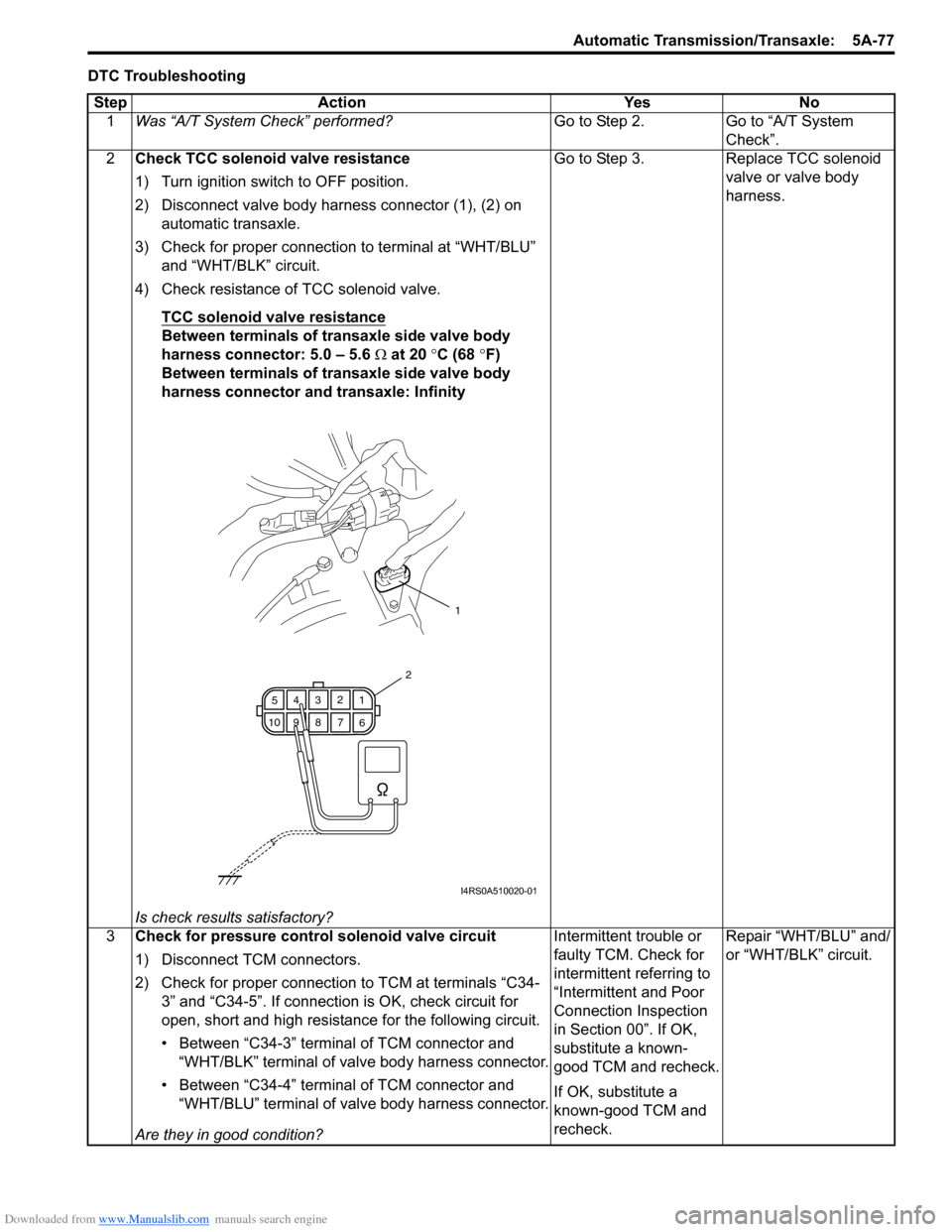

2 Check TCC solenoid valve resistance

1) Turn ignition switch to OFF position.

2) Disconnect valve body harness connector (1), (2) on

automatic transaxle.

3) Check for proper connection to terminal at “WHT/BLU” and “WHT/BLK” circuit.

4) Check resistance of TCC solenoid valve.

TCC solenoid valve resistance

Between terminals of transaxle side valve body

harness connector: 5.0 – 5.6 Ω at 20 °C (68 °F)

Between terminals of transaxle side valve body

harness connector and transaxle: Infinity

Is check results satisfactory? Go to Step 3. Replace TCC solenoid

valve or valve body

harness.

3 Check for pressure control solenoid valve circuit

1) Disconnect TCM connectors.

2) Check for proper connection to TCM at terminals “C34-

3” and “C34-5”. If connection is OK, check circuit for

open, short and high resistance for the following circuit.

• Between “C34-3” terminal of TCM connector and “WHT/BLK” terminal of valve body harness connector.

• Between “C34-4” terminal of TCM connector and “WHT/BLU” terminal of valve body harness connector.

Are they in good condition? Intermittent trouble or

faulty TCM. Check for

intermittent referring to

“Intermittent and Poor

Connection Inspection

in Section 00”. If OK,

substitute a known-

good TCM and recheck.

If OK, substitute a

known-good TCM and

recheck.

Repair “WHT/BLU” and/

or “WHT/BLK” circuit.

1

6

7

89

10 5

43 2

1

2

I4RS0A510020-01

Page 724 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-80 Automatic Transmission/Transaxle:

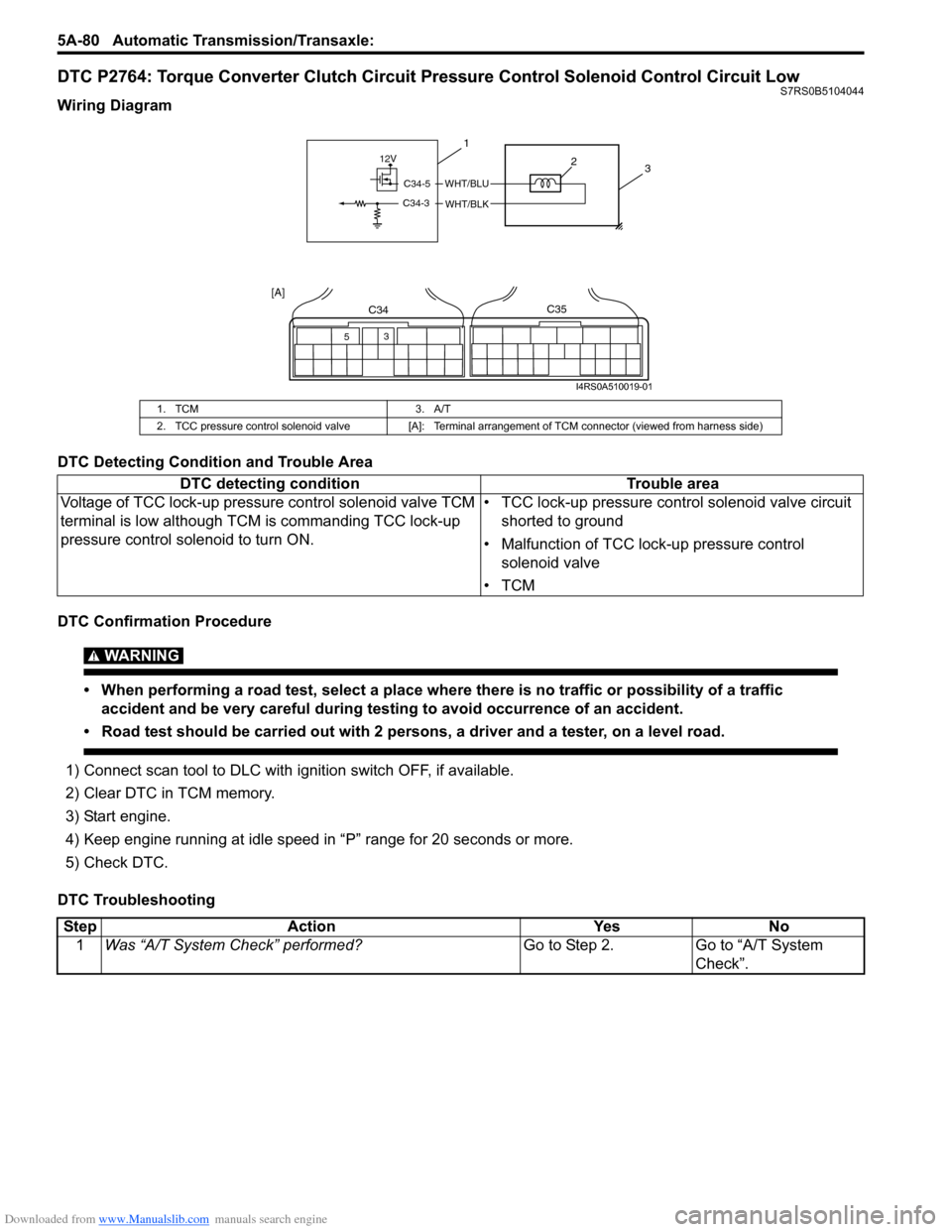

DTC P2764: Torque Converter Clutch Circuit Pressure Control Solenoid Control Circuit LowS7RS0B5104044

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ig nition switch OFF, if available.

2) Clear DTC in TCM memory.

3) Start engine.

4) Keep engine running at idle speed in “P” range for 20 seconds or more.

5) Check DTC.

DTC Troubleshooting

1. TCM 3. A/T

2. TCC pressure control solenoid valve [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Voltage of TCC lock-up pressure control solenoid valve TCM

terminal is low although TCM is commanding TCC lock-up

pressure control sole noid to turn ON. • TCC lock-up pressure contro

l solenoid valve circuit

shorted to ground

• Malfunction of TCC lock-up pressure control solenoid valve

•TCM

12V

C34-5

C34-3

WHT/BLU

WHT/BLK

3

1

2

53

C34C35

[A]

I4RS0A510019-01

Step

Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

Page 727 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-83

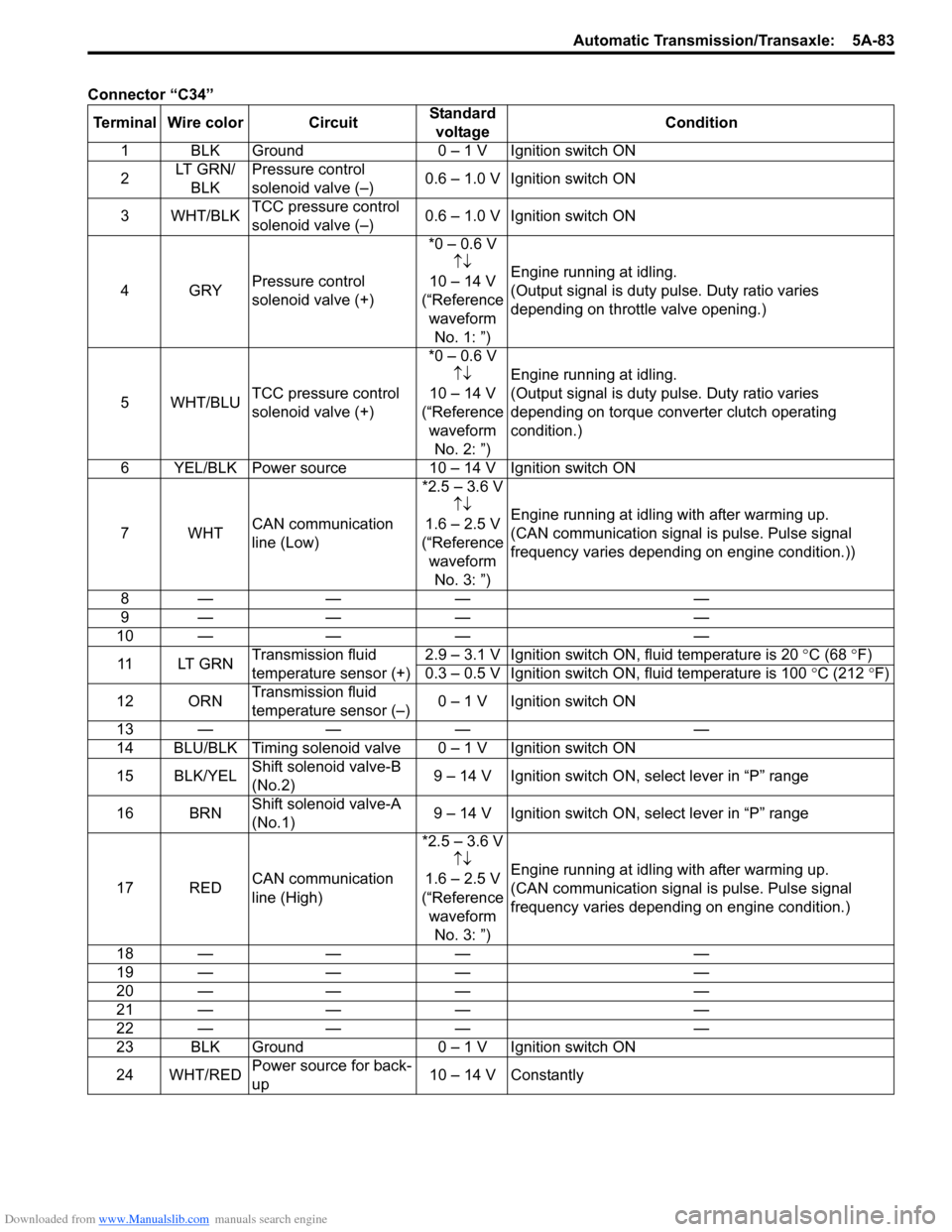

Connector “C34”Terminal Wire color Circuit Standard

voltage Condition

1 BLK Ground 0 – 1 V Ignition switch ON

2 LT GRN/

BLK Pressure control

solenoid valve (–)

0.6 – 1.0 V Ignition switch ON

3WHT/BLK TCC pressure control

solenoid valve (–) 0.6 – 1.0 V Ignition switch ON

4GRY Pressure control

solenoid valve (+) *0 – 0.6 V

↑↓

10 – 14 V

(“Reference waveform No. 1: ”) Engine running at idling.

(Output signal is duty pulse. Duty ratio varies

depending on throttle valve opening.)

5WHT/BLU TCC pressure control

solenoid valve (+) *0 – 0.6 V

↑↓

10 – 14 V

(“Reference waveform No. 2: ”) Engine running at idling.

(Output signal is duty pulse. Duty ratio varies

depending on torque converter clutch operating

condition.)

6 YEL/BLK Power source 10 – 14 V Ignition switch ON

7WHT CAN communication

line (Low) *2.5 – 3.6 V

↑↓

1.6 – 2.5 V

(“Reference waveform No. 3: ”) Engine running at idling with after warming up.

(CAN communication signal is pulse. Pulse signal

frequency varies depending on engine condition.))

8— — — —

9— — — —

10 — —— —

11 LT G R N Transmission fluid

temperature sensor (+) 2.9 – 3.1 V Ignition switch ON, fluid temperature is 20

°C (68 °F)

0.3 – 0.5 V Ignition switch ON, fluid temperature is 100 °C (212 °F)

12 ORN Transmission fluid

temperature sensor (–) 0 – 1 V Ignition switch ON

13 — —— —

14 BLU/BLK Timing solenoid valv e 0 – 1 V Ignition switch ON

15 BLK/YEL Shift solenoid valve-B

(No.2) 9 – 14 V Ignition switch ON, select lever in “P” range

16 BRN Shift solenoid valve-A

(No.1) 9 – 14 V Ignition switch ON, select lever in “P” range

17 RED CAN communication

line (High) *2.5 – 3.6 V

↑↓

1.6 – 2.5 V

(“Reference waveform No. 3: ”) Engine running at idling with after warming up.

(CAN communication signal is pulse. Pulse signal

frequency varies depending on engine condition.)

18 — —— —

19 — —— —

20 — —— —

21 — —— —

22 — —— —

23 BLK Ground 0 – 1 V Ignition switch ON

24 WHT/RED Power source

for back-

up 10 – 14 V Constantly

Page 729 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-85

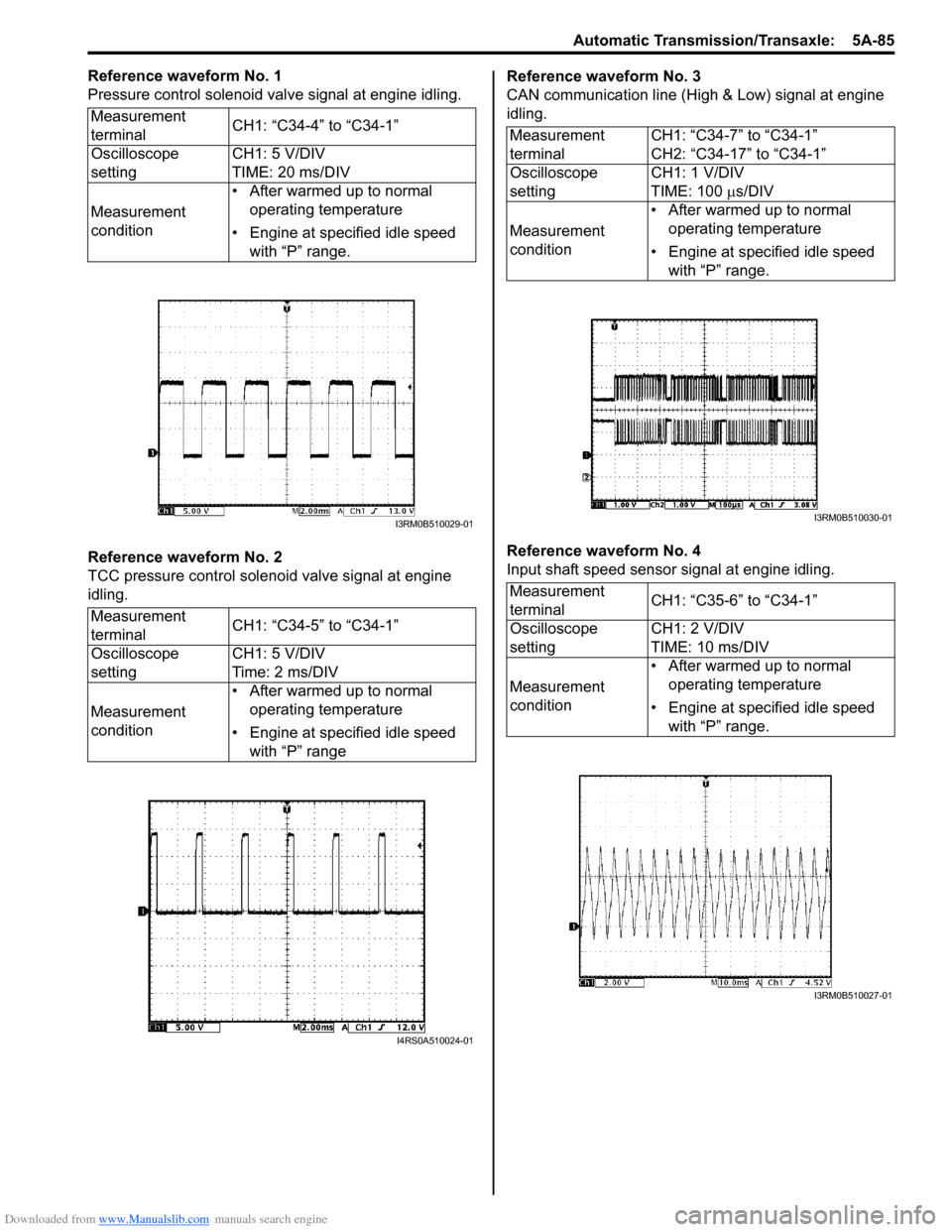

Reference waveform No. 1

Pressure control solenoid valve signal at engine idling.

Reference waveform No. 2

TCC pressure control solenoid valve signal at engine

idling.Reference waveform No. 3

CAN communication line (High & Low) signal at engine

idling.

Reference waveform No. 4

Input shaft speed sensor signal at engine idling.

Measurement

terminal

CH1: “C34-4” to “C34-1”

Oscilloscope

setting CH1: 5 V/DIV

TIME: 20 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at specified idle speed with “P” range.

Measurement

terminal CH1: “C34-5” to “C34-1”

Oscilloscope

setting CH1: 5 V/DIV

Time: 2 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at specified idle speed with “P” range

I3RM0B510029-01

I4RS0A510024-01

Measurement

terminal CH1: “C34-7” to “C34-1”

CH2: “C34-17” to “C34-1”

Oscilloscope

setting CH1: 1 V/DIV

TIME: 100

µs/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at specified idle speed with “P” range.

Measurement

terminal CH1: “C35-6” to “C34-1”

Oscilloscope

setting CH1: 2 V/DIV

TIME: 10 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at specified idle speed with “P” range.

I3RM0B510030-01

I3RM0B510027-01

Page 743 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-99

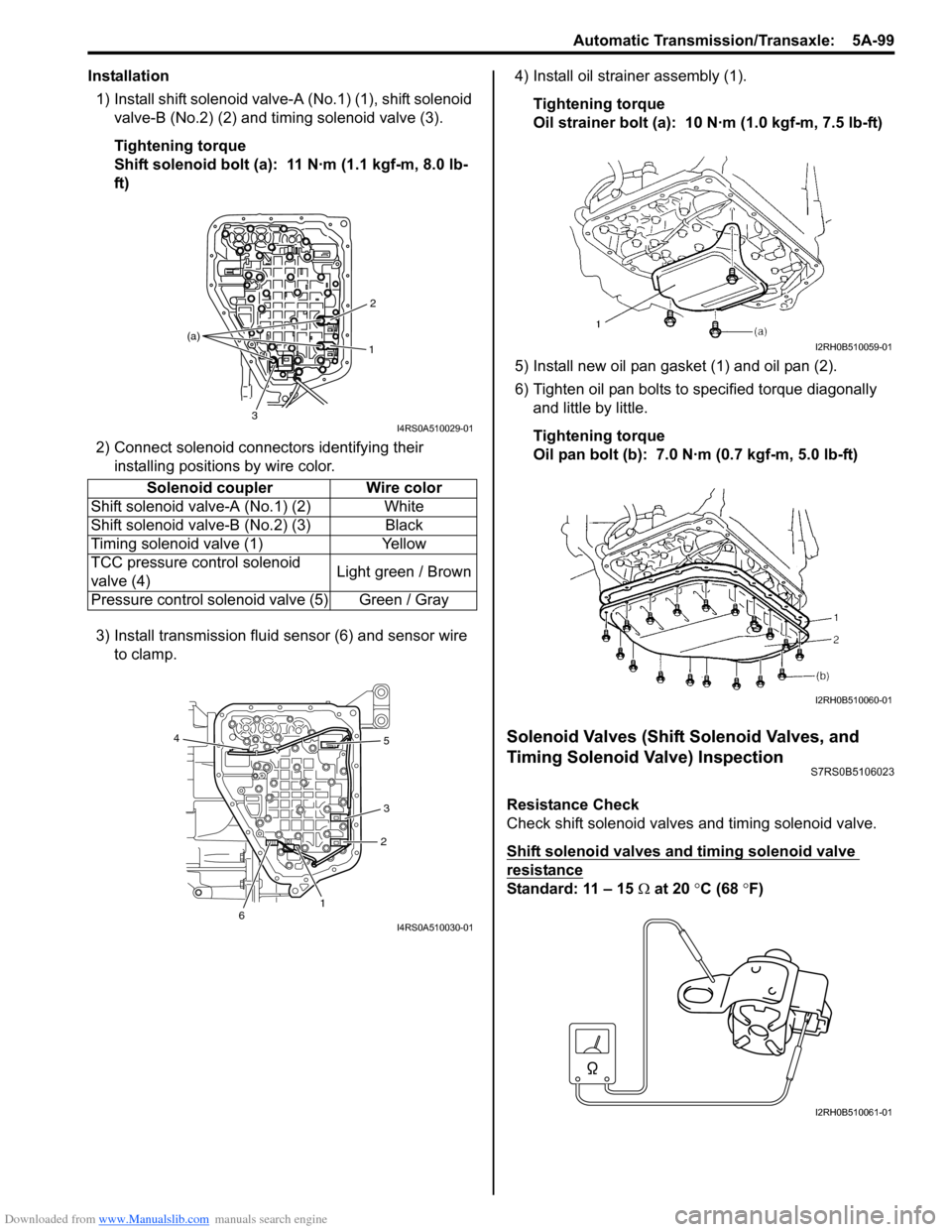

Installation1) Install shift solenoid valve- A (No.1) (1), shift solenoid

valve-B (No.2) (2) and timing solenoid valve (3).

Tightening torque

Shift solenoid bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-

ft)

2) Connect solenoid connectors identifying their installing positions by wire color.

3) Install transmission fluid sensor (6) and sensor wire to clamp. 4) Install oil strain

er assembly (1).

Tightening torque

Oil strainer bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft)

5) Install new oil pan gasket (1) and oil pan (2).

6) Tighten oil pan bolts to specified torque diagonally and little by little.

Tightening torque

Oil pan bolt (b): 7.0 N·m (0.7 kgf-m, 5.0 lb-ft)

Solenoid Valves (Shift Solenoid Valves, and

Timing Solenoid Valve) Inspection

S7RS0B5106023

Resistance Check

Check shift solenoid valves and timing solenoid valve.

Shift solenoid valves and timing solenoid valve

resistance

Standard: 11 – 15 Ω at 20 °C (68 ° F)

Solenoid coupler Wire color

Shift solenoid valv e-A (No.1) (2) White

Shift solenoid valv e-B (No.2) (3) Black

Timing solenoid valve (1) Yellow

TCC pressure control solenoid

valve (4) Light green / Brown

Pressure control solenoid valve (5) Green / Gray

1 2

3

(a)

I4RS0A510029-01

1

2

3 5

4

6

I4RS0A510030-01

I2RH0B510059-01

I2RH0B510060-01

I2RH0B510061-01

Page 745 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-101

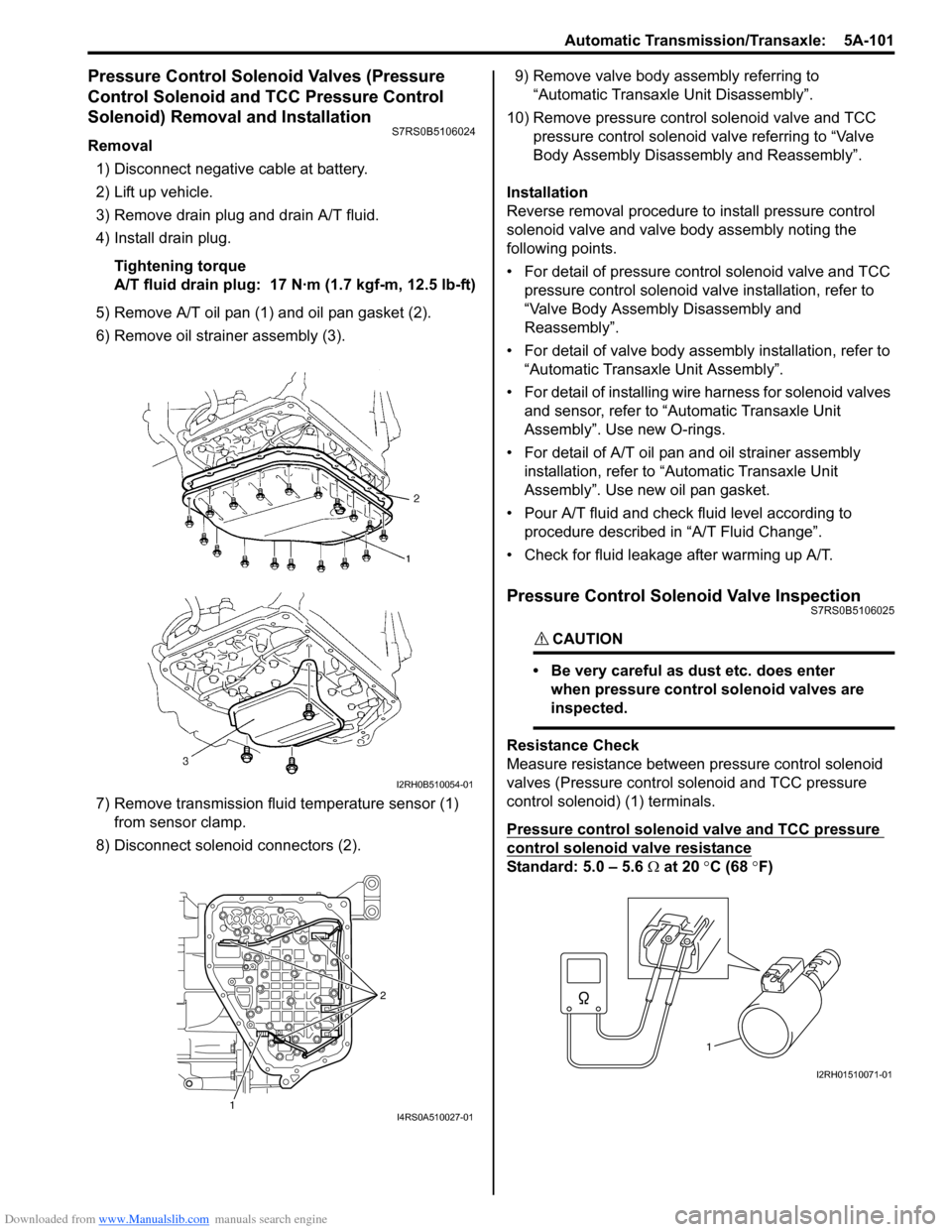

Pressure Control Solenoid Valves (Pressure

Control Solenoid and TCC Pressure Control

Solenoid) Removal and Installation

S7RS0B5106024

Removal1) Disconnect negative cable at battery.

2) Lift up vehicle.

3) Remove drain plug and drain A/T fluid.

4) Install drain plug.

Tightening torque

A/T fluid drain plug: 17 N·m (1.7 kgf-m, 12.5 lb-ft)

5) Remove A/T oil pan (1) and oil pan gasket (2).

6) Remove oil strain er assembly (3).

7) Remove transmission fluid temperature sensor (1) from sensor clamp.

8) Disconnect solenoid connectors (2). 9) Remove valve body assembly referring to

“Automatic Transaxl e Unit Disassembly”.

10) Remove pressure control solenoid valve and TCC pressure control solenoid valve referring to “Valve

Body Assembly Disassembly and Reassembly”.

Installation

Reverse removal procedure to install pressure control

solenoid valve and valve body assembly noting the

following points.

• For detail of pressure control solenoid valve and TCC pressure control solenoid va lve installation, refer to

“Valve Body Assembly Disassembly and

Reassembly”.

• For detail of valve body asse mbly installation, refer to

“Automatic Transaxle Unit Assembly”.

• For detail of installing wire harness for solenoid valves and sensor, refer to “Automatic Transaxle Unit

Assembly”. Use new O-rings.

• For detail of A/T oil pan and oil strainer assembly

installation, refer to “A utomatic Transaxle Unit

Assembly”. Use new oil pan gasket.

• Pour A/T fluid and check fluid level according to procedure described in “A/T Fluid Change”.

• Check for fluid leakage after warming up A/T.

Pressure Control Solenoid Valve InspectionS7RS0B5106025

CAUTION!

• Be very careful as dust etc. does enter when pressure control solenoid valves are

inspected.

Resistance Check

Measure resistance between pressure control solenoid

valves (Pressure control solenoid and TCC pressure

control solenoid) (1) terminals.

Pressure control solenoid valve and TCC pressure

control solenoid valve resistance

Standard: 5.0 – 5.6 Ω at 20 °C (68 °F)

I2RH0B510054-01

1 2I4RS0A510027-01

1

I2RH01510071-01

Page 746 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-102 Automatic Transmission/Transaxle:

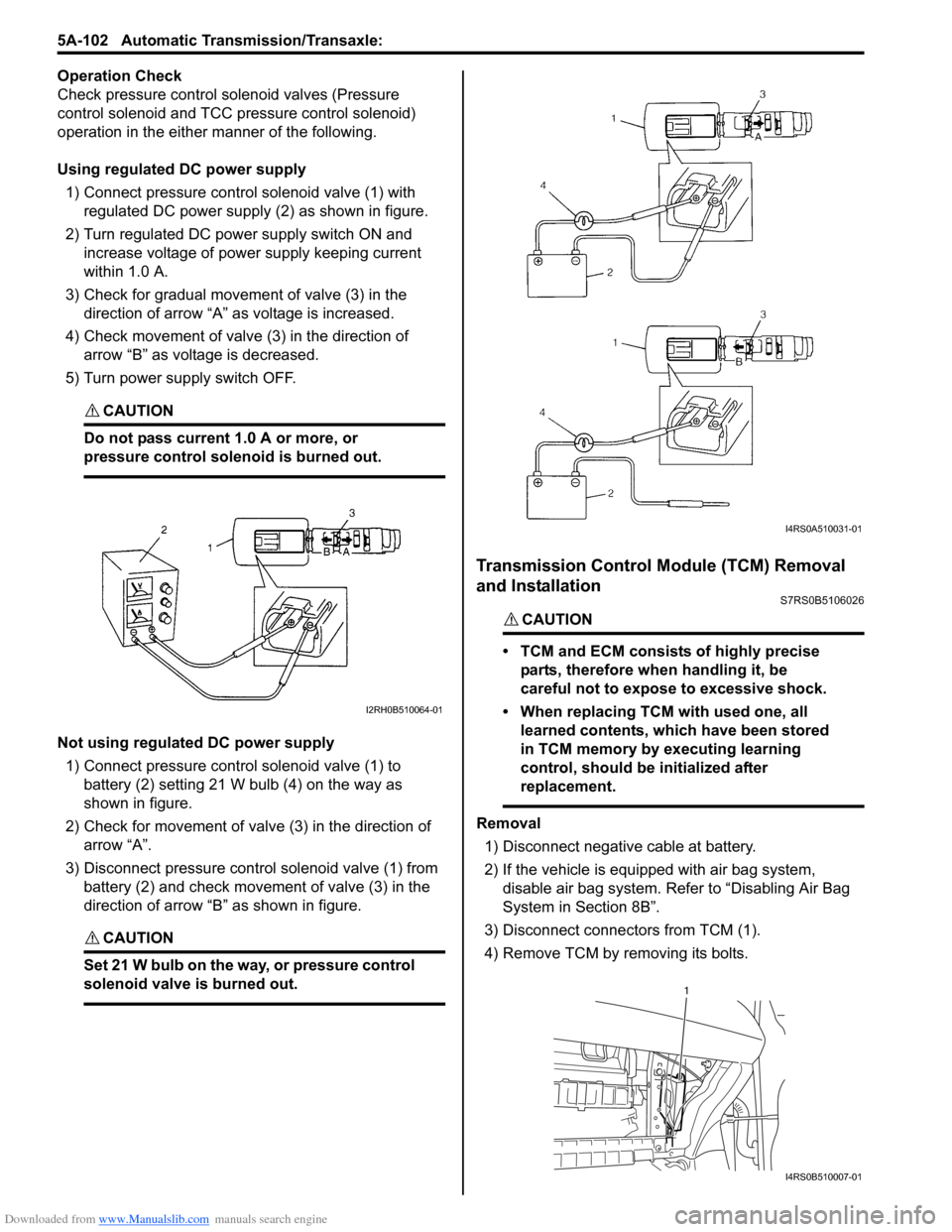

Operation Check

Check pressure control solenoid valves (Pressure

control solenoid and TCC pressure control solenoid)

operation in the either manner of the following.

Using regulated DC power supply

1) Connect pressure contro l solenoid valve (1) with

regulated DC power supply (2) as shown in figure.

2) Turn regulated DC power supply switch ON and increase voltage of power supply keeping current

within 1.0 A.

3) Check for gradual movement of valve (3) in the direction of arrow “A” as voltage is increased.

4) Check movement of valve (3) in the direction of arrow “B” as voltage is decreased.

5) Turn power supply switch OFF.

CAUTION!

Do not pass current 1.0 A or more, or

pressure control solenoid is burned out.

Not using regulated DC power supply 1) Connect pressure control solenoid valve (1) to battery (2) setting 21 W bulb (4) on the way as

shown in figure.

2) Check for movement of valve (3) in the direction of arrow “A”.

3) Disconnect pressure control solenoid valve (1) from battery (2) and check movement of valve (3) in the

direction of arrow “B” as shown in figure.

CAUTION!

Set 21 W bulb on the way, or pressure control

solenoid valve is burned out.

Transmission Control Module (TCM) Removal

and Installation

S7RS0B5106026

CAUTION!

• TCM and ECM consists of highly precise

parts, therefore when handling it, be

careful not to expose to excessive shock.

• When replacing TCM with used one, all learned contents, which have been stored

in TCM memory by executing learning

control, should be initialized after

replacement.

Removal

1) Disconnect negative cable at battery.

2) If the vehicle is equipped with air bag system, disable air bag system. Refer to “Disabling Air Bag

System in Section 8B”.

3) Disconnect connectors from TCM (1).

4) Remove TCM by removing its bolts.

I2RH0B510064-01

I4RS0A510031-01

1

I4RS0B510007-01

Page 756 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-112 Automatic Transmission/Transaxle:

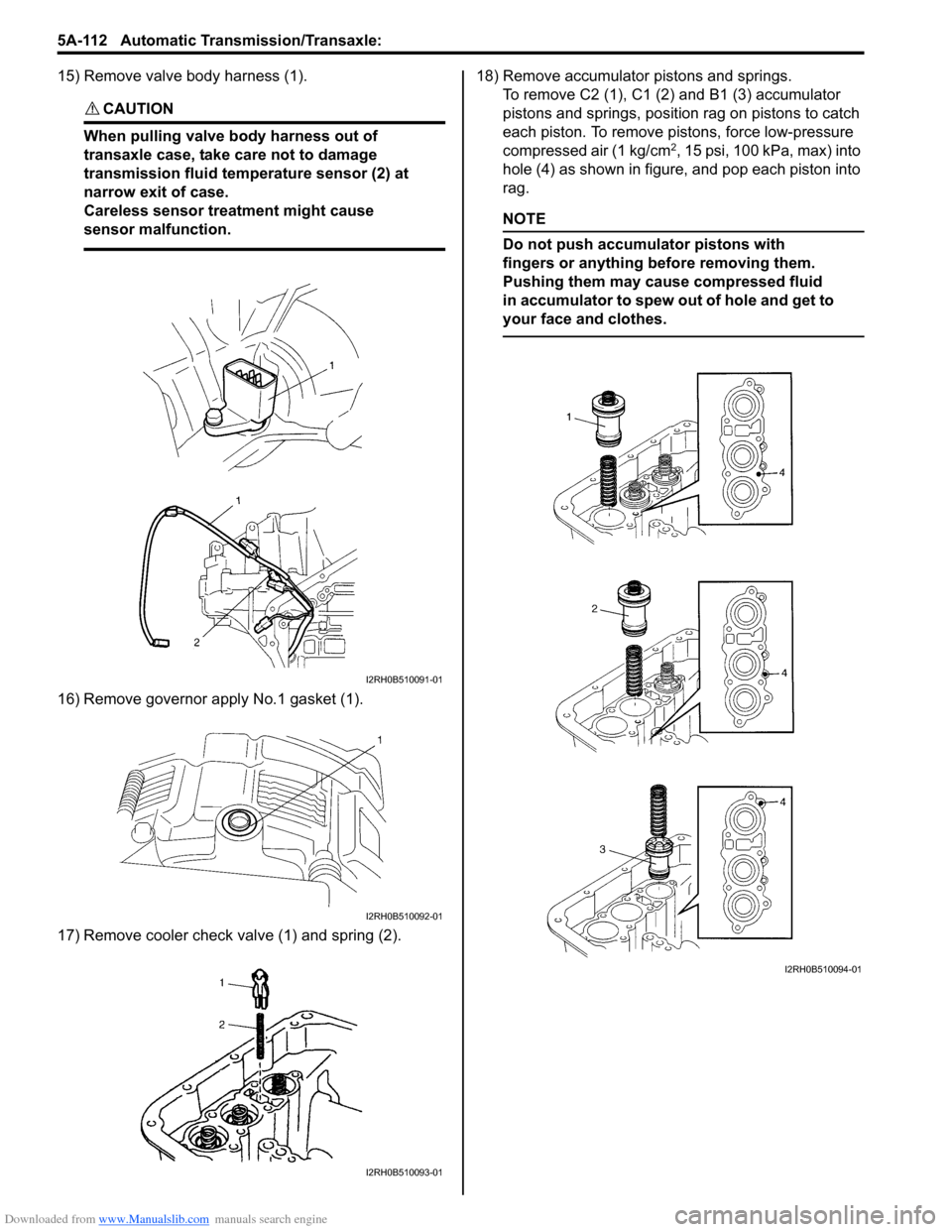

15) Remove valve body harness (1).

CAUTION!

When pulling valve body harness out of

transaxle case, take care not to damage

transmission fluid temperature sensor (2) at

narrow exit of case.

Careless sensor treatment might cause

sensor malfunction.

16) Remove governor apply No.1 gasket (1).

17) Remove cooler check valve (1) and spring (2).18) Remove accumulator pistons and springs.

To remove C2 (1), C1 (2) and B1 (3) accumulator

pistons and springs, position rag on pistons to catch

each piston. To remove pistons, force low-pressure

compressed air (1 kg/cm

2, 15 psi, 100 kPa, max) into

hole (4) as shown in figure, and pop each piston into

rag.

NOTE

Do not push accumulator pistons with

fingers or anything before removing them.

Pushing them may cause compressed fluid

in accumulator to spew out of hole and get to

your face and clothes.

I2RH0B510091-01

I2RH0B510092-01

I2RH0B510093-01

I2RH0B510094-01