R p m SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 181 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-131

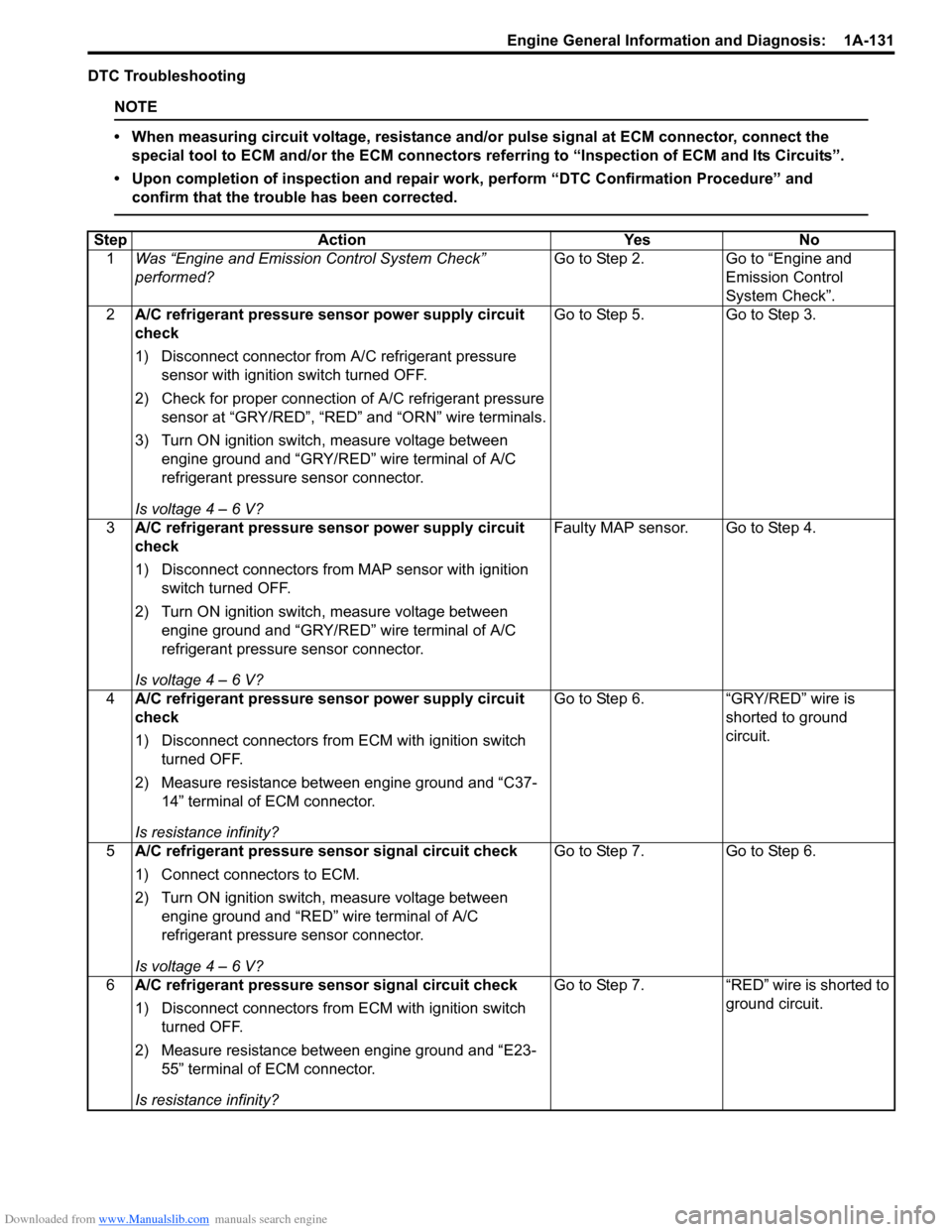

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 A/C refrigerant pressure sensor power supply circuit

check

1) Disconnect connector from A/C refrigerant pressure

sensor with ignition switch turned OFF.

2) Check for proper connection of A/C refrigerant pressure sensor at “GRY/RED”, “RED ” and “ORN” wire terminals.

3) Turn ON ignition switch, measure voltage between engine ground and “GRY/RED” wire terminal of A/C

refrigerant pressure sensor connector.

Is voltage 4 – 6 V? Go to Step 5.

Go to Step 3.

3 A/C refrigerant pressure sensor power supply circuit

check

1) Disconnect connectors from MAP sensor with ignition

switch turned OFF.

2) Turn ON ignition switch, measure voltage between engine ground and “GRY/RED” wire terminal of A/C

refrigerant pressure sensor connector.

Is voltage 4 – 6 V? Faulty MAP sensor. Go to Step 4.

4 A/C refrigerant pressure sensor power supply circuit

check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Measure resistance between engine ground and “C37- 14” terminal of ECM connector.

Is resistance infinity? Go to Step 6.

“GRY/RED” wire is

shorted to ground

circuit.

5 A/C refrigerant pressure sensor signal circuit check

1) Connect connectors to ECM.

2) Turn ON ignition switch, measure voltage between

engine ground and “RED” wire terminal of A/C

refrigerant pressure sensor connector.

Is voltage 4 – 6 V? Go to Step 7.

Go to Step 6.

6 A/C refrigerant pressure sensor signal circuit check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Measure resistance between engine ground and “E23- 55” terminal of ECM connector.

Is resistance infinity? Go to Step 7.

“RED” wire is shorted to

ground circuit.

Page 182 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-132 Engine General Information and Diagnosis:

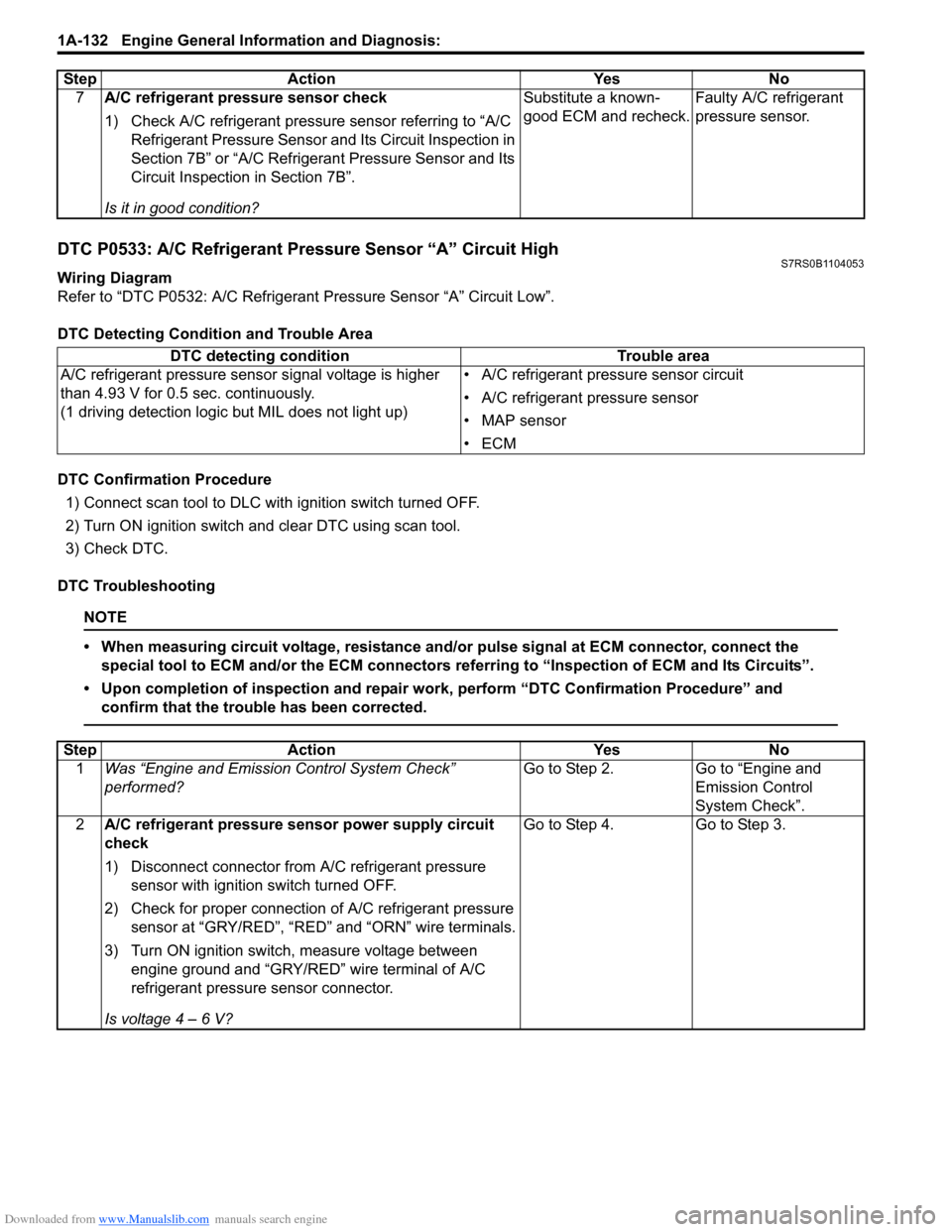

DTC P0533: A/C Refrigerant Pressure Sensor “A” Circuit HighS7RS0B1104053

Wiring Diagram

Refer to “DTC P0532: A/C Refrigerant Pressure Sensor “A” Circuit Low”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

7 A/C refrigerant pressure sensor check

1) Check A/C refrigerant pressure sensor referring to “A/C

Refrigerant Pressure Sensor and Its Circuit Inspection in

Section 7B” or “A/C Refrigerant Pressure Sensor and Its

Circuit Inspection in Section 7B”.

Is it in good condition? Substitute a known-

good ECM and recheck.

Faulty A/C refrigerant

pressure sensor.

Step Action Yes No

DTC detecting condition

Trouble area

A/C refrigerant pressure sensor signal voltage is higher

than 4.93 V for 0.5 sec. continuously.

(1 driving detection logic but MIL does not light up) • A/C refrigerant pressure sensor circuit

• A/C refrigerant pressure sensor

• MAP sensor

•ECM

Step

Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 A/C refrigerant pressure sensor power supply circuit

check

1) Disconnect connector from A/C refrigerant pressure

sensor with ignition switch turned OFF.

2) Check for proper connection of A/C refrigerant pressure sensor at “GRY/RED”, “RED ” and “ORN” wire terminals.

3) Turn ON ignition switch, measure voltage between engine ground and “GRY/RED” wire terminal of A/C

refrigerant pressure sensor connector.

Is voltage 4 – 6 V? Go to Step 4.

Go to Step 3.

Page 183 of 1496

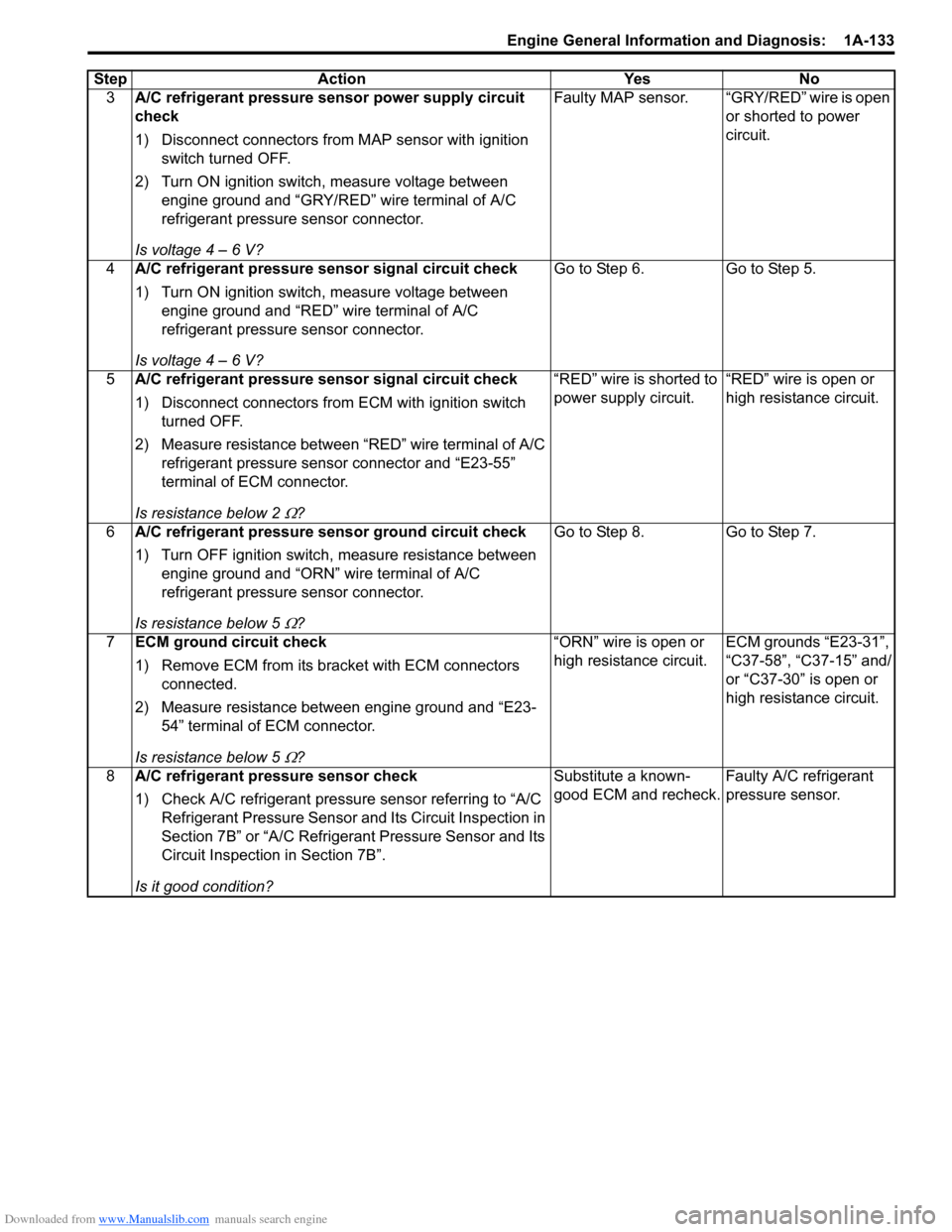

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-133

3A/C refrigerant pressure sensor power supply circuit

check

1) Disconnect connectors from MAP sensor with ignition

switch turned OFF.

2) Turn ON ignition switch, measure voltage between engine ground and “GRY/RED” wire terminal of A/C

refrigerant pressure sensor connector.

Is voltage 4 – 6 V? Faulty MAP sensor. “GRY/RED” wire is open

or shorted to power

circuit.

4 A/C refrigerant pressure sensor signal circuit check

1) Turn ON ignition switch, measure voltage between

engine ground and “RED” wire terminal of A/C

refrigerant pressure sensor connector.

Is voltage 4 – 6 V? Go to Step 6.

Go to Step 5.

5 A/C refrigerant pressure sensor signal circuit check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Measure resistance between “RED” wire terminal of A/C refrigerant pressure sensor connector and “E23-55”

terminal of ECM connector.

Is resistance below 2

Ω? “RED” wire is shorted to

power supply circuit.

“RED” wire is open or

high resistance circuit.

6 A/C refrigerant pressure sensor ground circuit check

1) Turn OFF ignition switch, measure resistance between

engine ground and “ORN” wire terminal of A/C

refrigerant pressure sensor connector.

Is resistance below 5

Ω? Go to Step 8.

Go to Step 7.

7 ECM ground circuit check

1) Remove ECM from its br acket with ECM connectors

connected.

2) Measure resistance between engine ground and “E23- 54” terminal of ECM connector.

Is resistance below 5

Ω? “ORN” wire is open or

high resistance circuit.

ECM grounds “E23-31”,

“C37-58”, “C37-15” and/

or “C37-30” is open or

high resistance circuit.

8 A/C refrigerant pressure sensor check

1) Check A/C refrigerant pressure sensor referring to “A/C

Refrigerant Pressure Sensor and Its Circuit Inspection in

Section 7B” or “A/C Refrigerant Pressure Sensor and Its

Circuit Inspection in Section 7B”.

Is it good condition? Substitute a known-

good ECM and recheck.

Faulty A/C refrigerant

pressure sensor.

Step Action Yes No

Page 184 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-134 Engine General Information and Diagnosis:

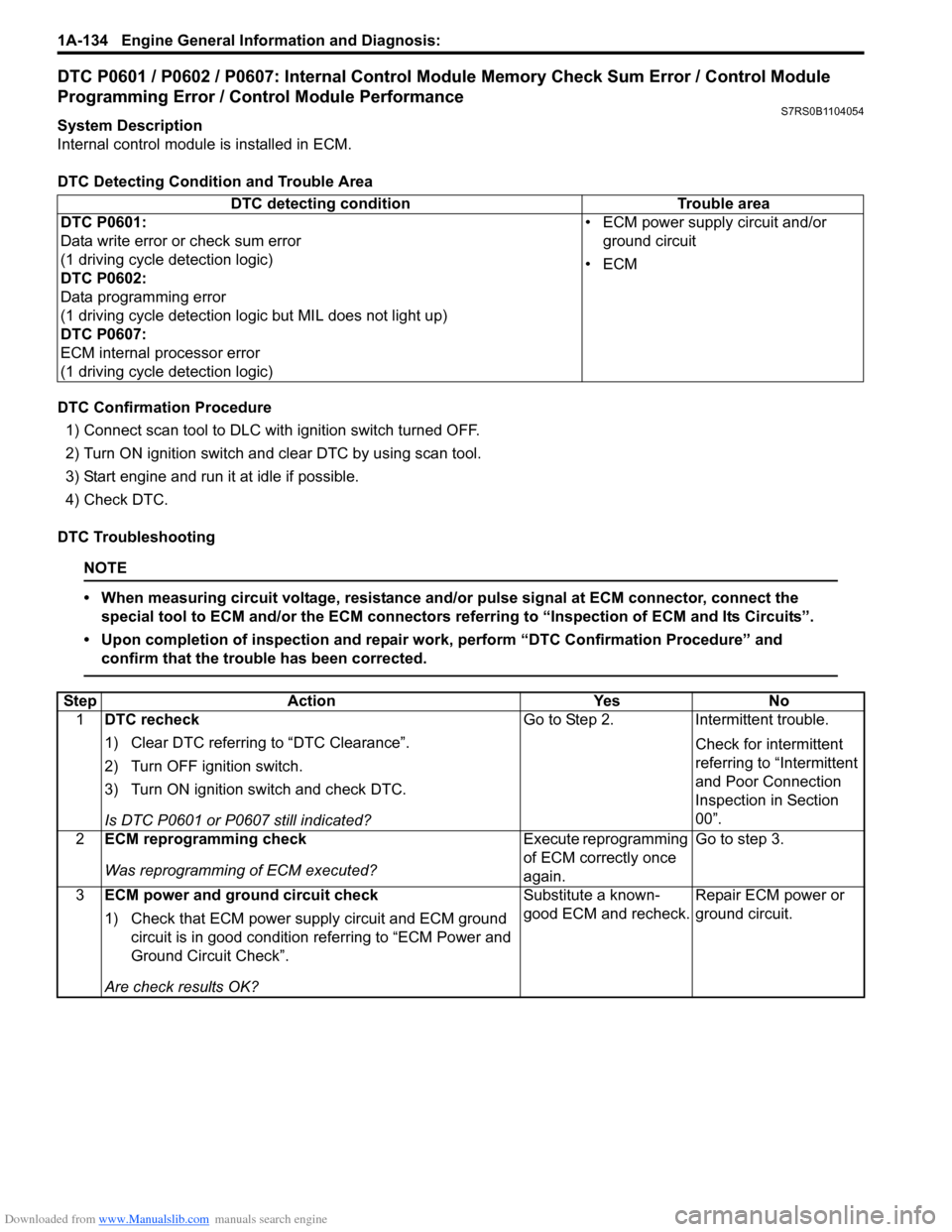

DTC P0601 / P0602 / P0607: Internal Control Module Memory Check Sum Error / Control Module

Programming Error / Control Module Performance

S7RS0B1104054

System Description

Internal control module is installed in ECM.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure 1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC by using scan tool.

3) Start engine and run it at idle if possible.

4) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC detecting condition Trouble area

DTC P0601:

Data write error or check sum error

(1 driving cycle detection logic)

DTC P0602:

Data programming error

(1 driving cycle detection logic but MIL does not light up)

DTC P0607:

ECM internal processor error

(1 driving cycle detection logic) • ECM power supply circuit and/or

ground circuit

•ECM

Step Action YesNo

1 DTC recheck

1) Clear DTC referring to “DTC Clearance”.

2) Turn OFF ignition switch.

3) Turn ON ignition switch and check DTC.

Is DTC P0601 or P0 607 still indicated? Go to Step 2.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

2 ECM reprogramming check

Was reprogramming of ECM executed? Execute reprogramming

of ECM correctly once

again.Go to step 3.

3 ECM power and ground circuit check

1) Check that ECM power supply circuit and ECM ground

circuit is in good condition referring to “ECM Power and

Ground Circuit Check”.

Are check results OK? Substitute a known-

good ECM and recheck.

Repair ECM power or

ground circuit.

Page 185 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-135

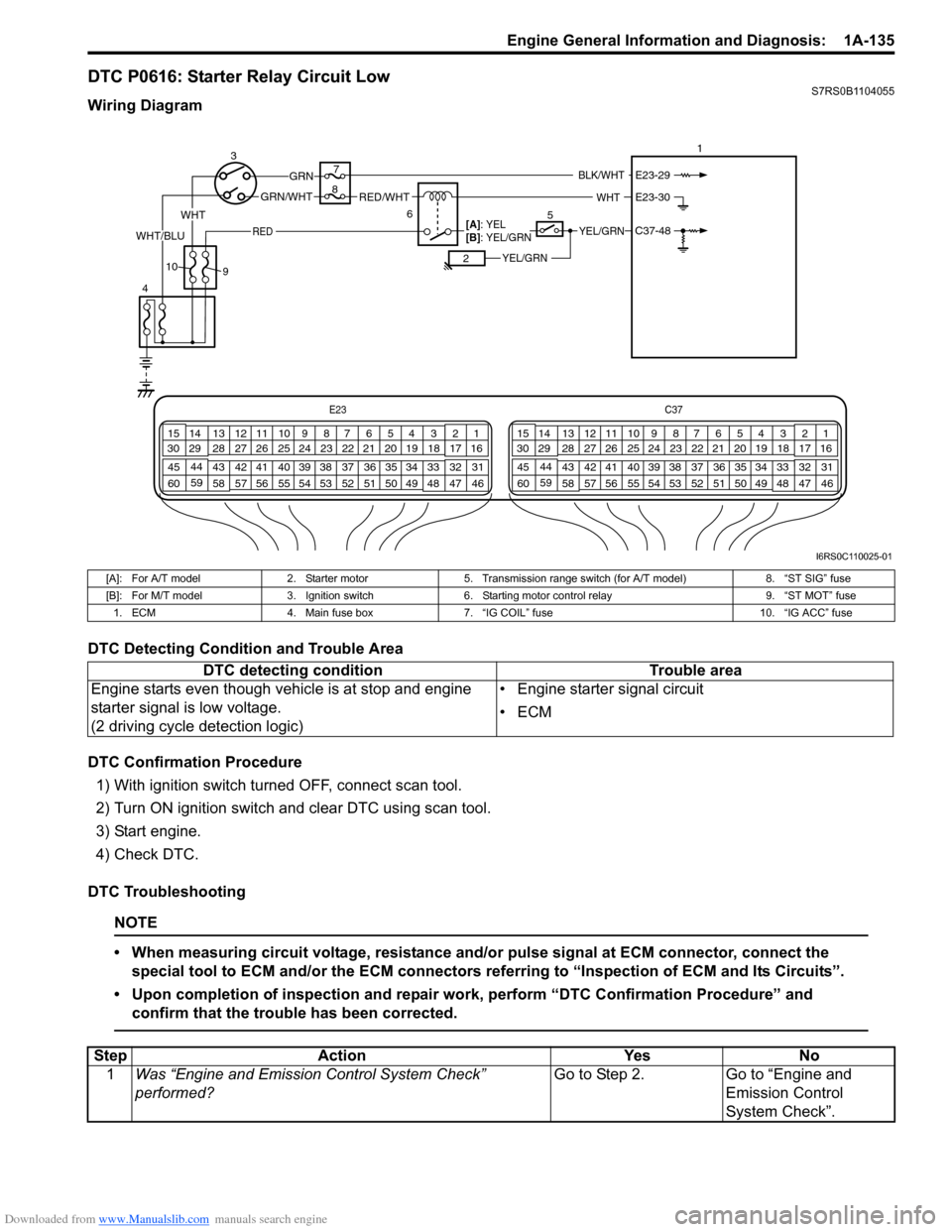

DTC P0616: Starter Relay Circuit LowS7RS0B1104055

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Start engine.

4) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

E23 C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

3

4 7

1

6

RED/WHTGRN/WHT

GRN

RED

BLK/WHT

YEL/GRN

YEL/GRN

WHT

[A]: YEL

[B]: YEL/GRN

25

8

9

10

WHT

WHT/BLUC37-48

E23-30

E23-29

I6RS0C110025-01

[A]: For A/T model

2. Starter motor5. Transmission range switch (for A/T model) 8. “ST SIG” fuse

[B]: For M/T model 3. Ignition switch6. Starting motor control relay 9. “ST MOT” fuse

1. ECM 4. Main fuse box 7. “IG COIL” fuse 10. “IG ACC” fuse

DTC detecting condition Trouble area

Engine starts even though vehicle is at stop and engine

starter signal is low voltage.

(2 driving cycle detection logic) • Engine starter signal circuit

•ECM

Step

Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

Page 186 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-136 Engine General Information and Diagnosis:

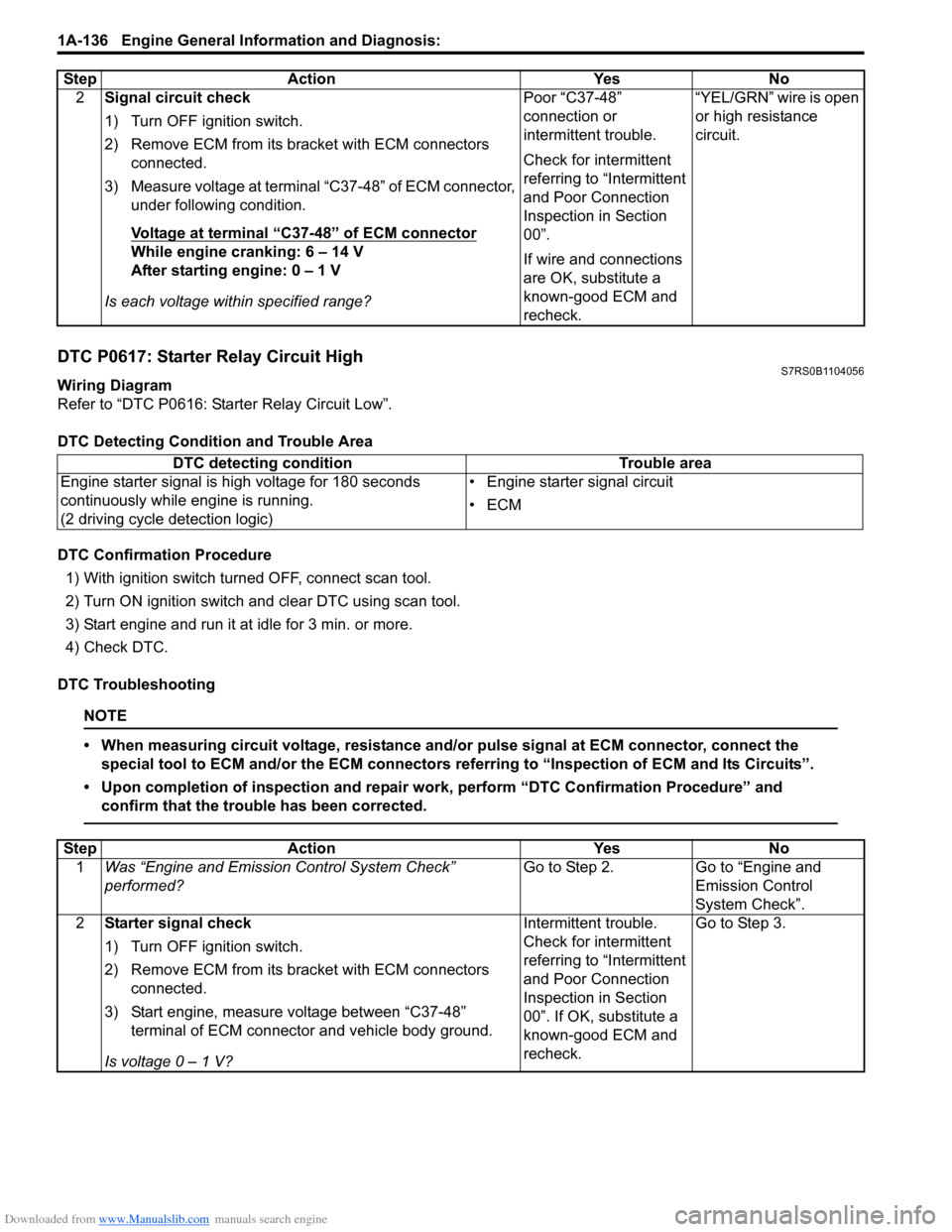

DTC P0617: Starter Relay Circuit HighS7RS0B1104056

Wiring Diagram

Refer to “DTC P0616: Starter Relay Circuit Low”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Start engine and run it at idle for 3 min. or more.

4) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

2 Signal circuit check

1) Turn OFF ignition switch.

2) Remove ECM from its br acket with ECM connectors

connected.

3) Measure voltage at terminal “C37-48” of ECM connector, under following condition.

Voltage at terminal “C37-48” of ECM connector

While engine cranking: 6 – 14 V

After starting engine: 0 – 1 V

Is each voltage within specified range? Poor “C37-48”

connection or

intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

If wire and connections

are OK, substitute a

known-good ECM and

recheck.“YEL/GRN” wire is open

or high resistance

circuit.

Step Action Yes No

DTC detecting condition

Trouble area

Engine starter signal is high voltage for 180 seconds

continuously while engine is running.

(2 driving cycle detection logic) • Engine starter signal circuit

•ECM

Step

Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Starter signal check

1) Turn OFF ignition switch.

2) Remove ECM from its br acket with ECM connectors

connected.

3) Start engine, measure voltage between “C37-48” terminal of ECM connector and vehicle body ground.

Is voltage 0 – 1 V? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”. If OK, substitute a

known-good ECM and

recheck.

Go to Step 3.

Page 187 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-137

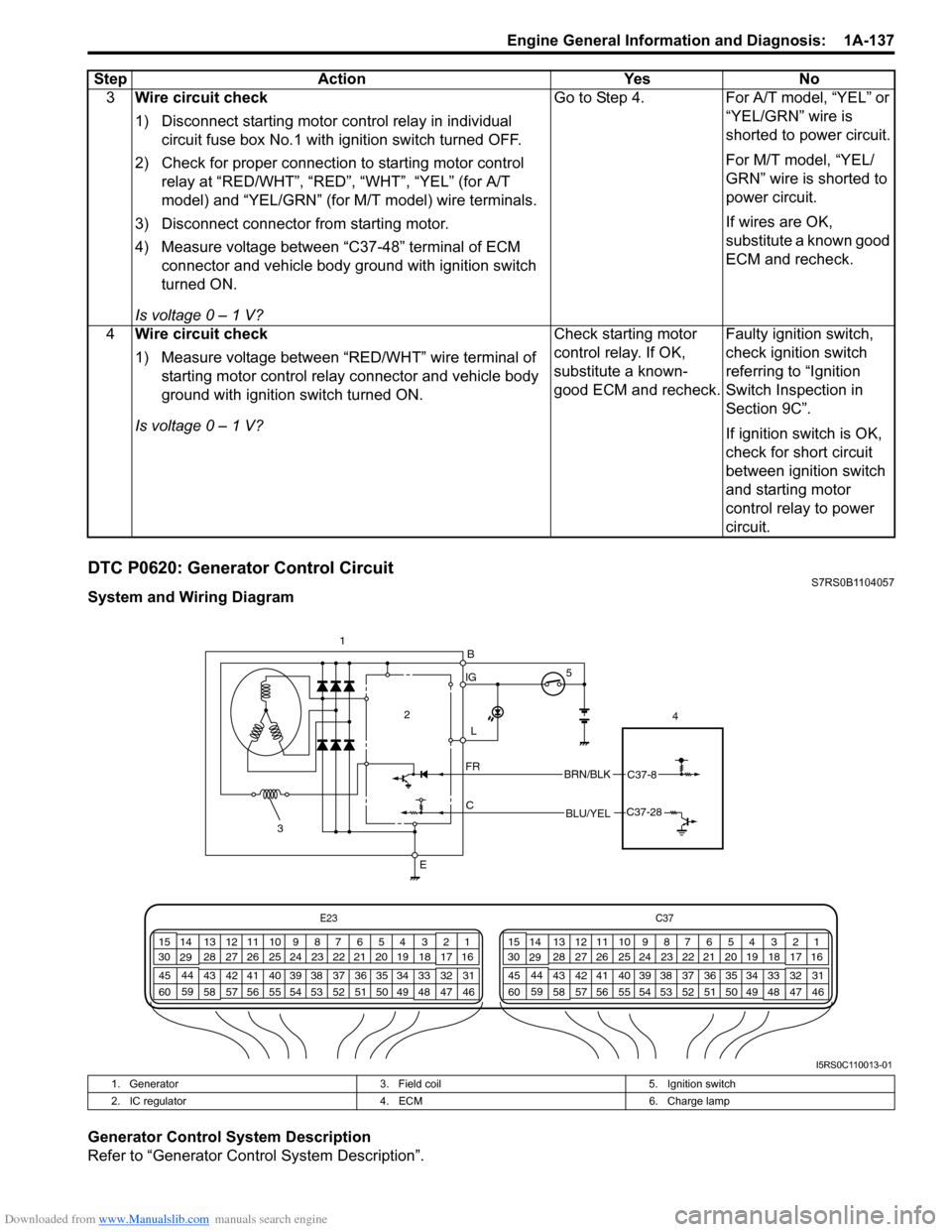

DTC P0620: Generator Control CircuitS7RS0B1104057

System and Wiring Diagram

Generator Control System Description

Refer to “Generator Control System Description”.3

Wire circuit check

1) Disconnect starting motor control relay in individual

circuit fuse box No.1 with ignition switch turned OFF.

2) Check for proper connection to starting motor control relay at “RED/WHT”, “RED”, “WHT”, “YEL” (for A/T

model) and “YEL/GRN” (for M/T model) wire terminals.

3) Disconnect connector from starting motor.

4) Measure voltage between “C37-48” terminal of ECM connector and vehicle body ground with ignition switch

turned ON.

Is voltage 0 – 1 V? Go to Step 4. For A/T model, “YEL” or

“YEL/GRN” wire is

shorted to power circuit.

For M/T model, “YEL/

GRN” wire is shorted to

power circuit.

If wires are OK,

substitute a known good

ECM and recheck.

4 Wire circuit check

1) Measure voltage between “RED/WHT” wire terminal of

starting motor control relay connector and vehicle body

ground with ignition switch turned ON.

Is voltage 0 – 1 V? Check starting motor

control relay. If OK,

substitute a known-

good ECM and recheck.

Faulty ignition switch,

check ignition switch

referring to “Ignition

Switch Inspection in

Section 9C”.

If ignition switch is OK,

check for short circuit

between ignition switch

and starting motor

control relay to power

circuit.

Step Action Yes No

IG

L

C

FR

E 4

2

BRN/BLKC37-8

BLU/YELC37-28

B

E23

C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238 1

3 5

I5RS0C110013-01

1. Generator

3. Field coil 5. Ignition switch

2. IC regulator 4. ECM 6. Charge lamp

Page 188 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-138 Engine General Information and Diagnosis:

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) With ignition switch turned OFF, connect scan tool to DLC

2) Turn ON ignition switch and clear DTC.

3) Make sure that all accessory switches are tuned OFF.

4) Start engine and warm it up to normal operating temperature (ECT approx. 90 – 95 °C, 193 – 203 °F).

5) Turn ON the followi ng accessory switches.

• Head light switch.

• Blower motor switch (max position).

• Rear defogger switch.

6) Increase engine speed to 4000 rpm and keep it for 10 sec or more.

7) Decrease engine speed to idle.

8) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC detecting condition Trouble area

• Battery voltage is higher than specification even through generator control is maximum regulation (duty 100%).

• Battery voltage is lower than specification even through generator control is minimum regulation (duty 0%) and electric

load is less than 15 A.

(1 driving cycle detection logic but MIL does not light up) • Generator and/or its circuit

• Electric load current sensor

•ECM

• Generator drive belt

Step

Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Generator drive belt check

1) Check generator drive belt tension referring to “Water

Pump / Generator Drive Belt Tension Inspection and

Adjustment in Section 1J”.

Is check result satisfactory? Go to Step 3.

Adjust or replace

generator drive belt.

Page 189 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-139

DTC P0625 / P0626: Generator Field Terminal Circuit Low / HighS7RS0B1104058

System and Wiring Diagram

Refer to “DTC P0620: Generator Control Circuit”.

Generator Control System Description

Refer to “Generator Control System Description”.

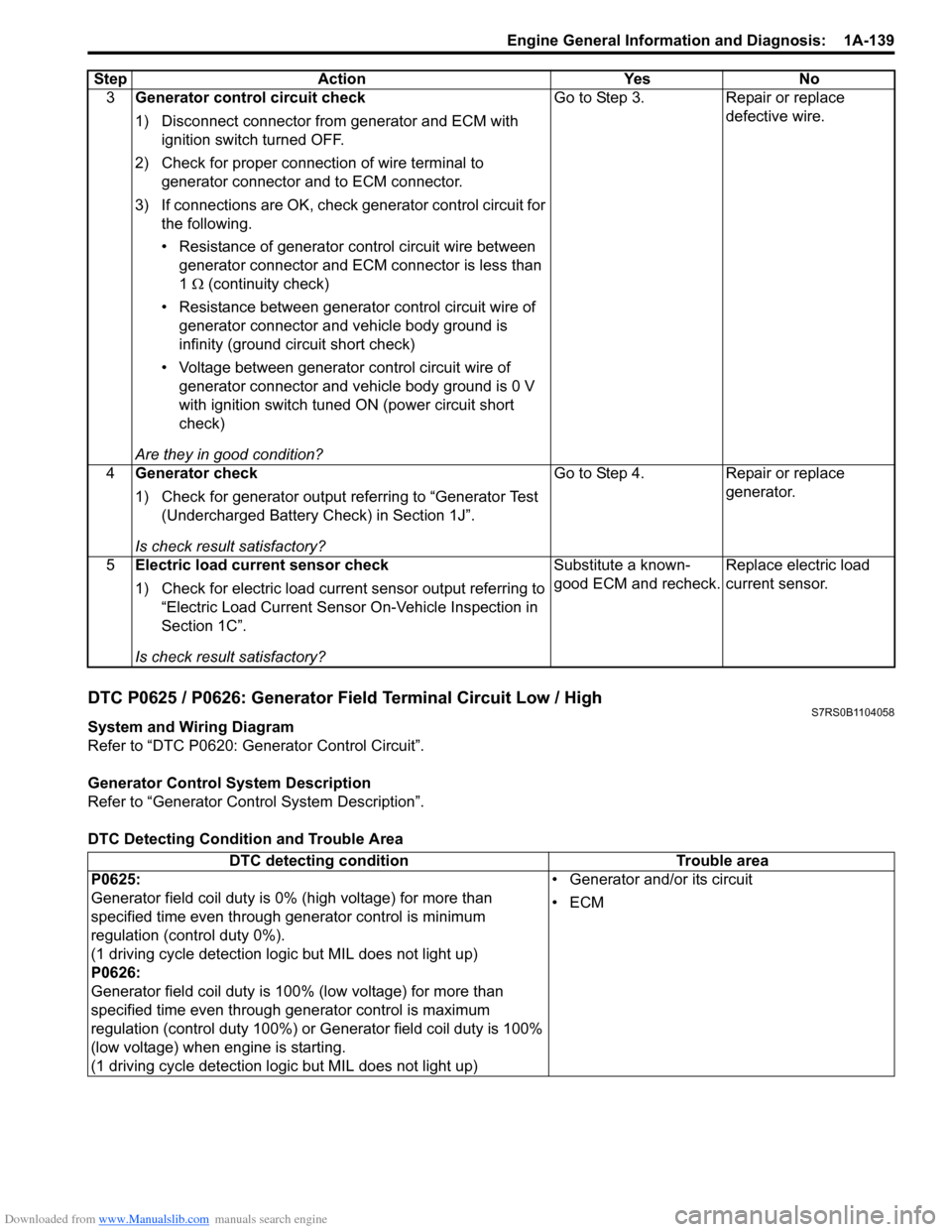

DTC Detecting Condition and Trouble Area 3

Generator control circuit check

1) Disconnect connector from generator and ECM with

ignition switch turned OFF.

2) Check for proper connection of wire terminal to generator connector and to ECM connector.

3) If connections are OK, check generator control circuit for

the following.

• Resistance of generator control circuit wire between generator connector and ECM connector is less than

1 Ω (continuity check)

• Resistance between generator control circuit wire of

generator connector and vehicle body ground is

infinity (ground circuit short check)

• Voltage between generator control circuit wire of generator connector and vehicle body ground is 0 V

with ignition switch tuned ON (power circuit short

check)

Are they in good condition? Go to Step 3. Repair or replace

defective wire.

4 Generator check

1) Check for generator output referring to “Generator Test

(Undercharged Battery Check) in Section 1J”.

Is check result satisfactory? Go to Step 4. Repair or replace

generator.

5 Electric load current sensor check

1) Check for electric load current sensor output referring to

“Electric Load Current Sensor On-Vehicle Inspection in

Section 1C”.

Is check result satisfactory? Substitute a known-

good ECM and recheck.

Replace electric load

current sensor.

Step Action Yes No

DTC detecting condition

Trouble area

P0625:

Generator field coil duty is 0% (high voltage) for more than

specified time even through generator control is minimum

regulation (control duty 0%).

(1 driving cycle detection logic but MIL does not light up)

P0626:

Generator field coil duty is 100% (low voltage) for more than

specified time even through ge nerator control is maximum

regulation (control duty 100%) or Generator field coil duty is 100%

(low voltage) when engine is starting.

(1 driving cycle detection logic but MIL does not light up) • Generator and/or its circuit

•ECM

Page 190 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-140 Engine General Information and Diagnosis:

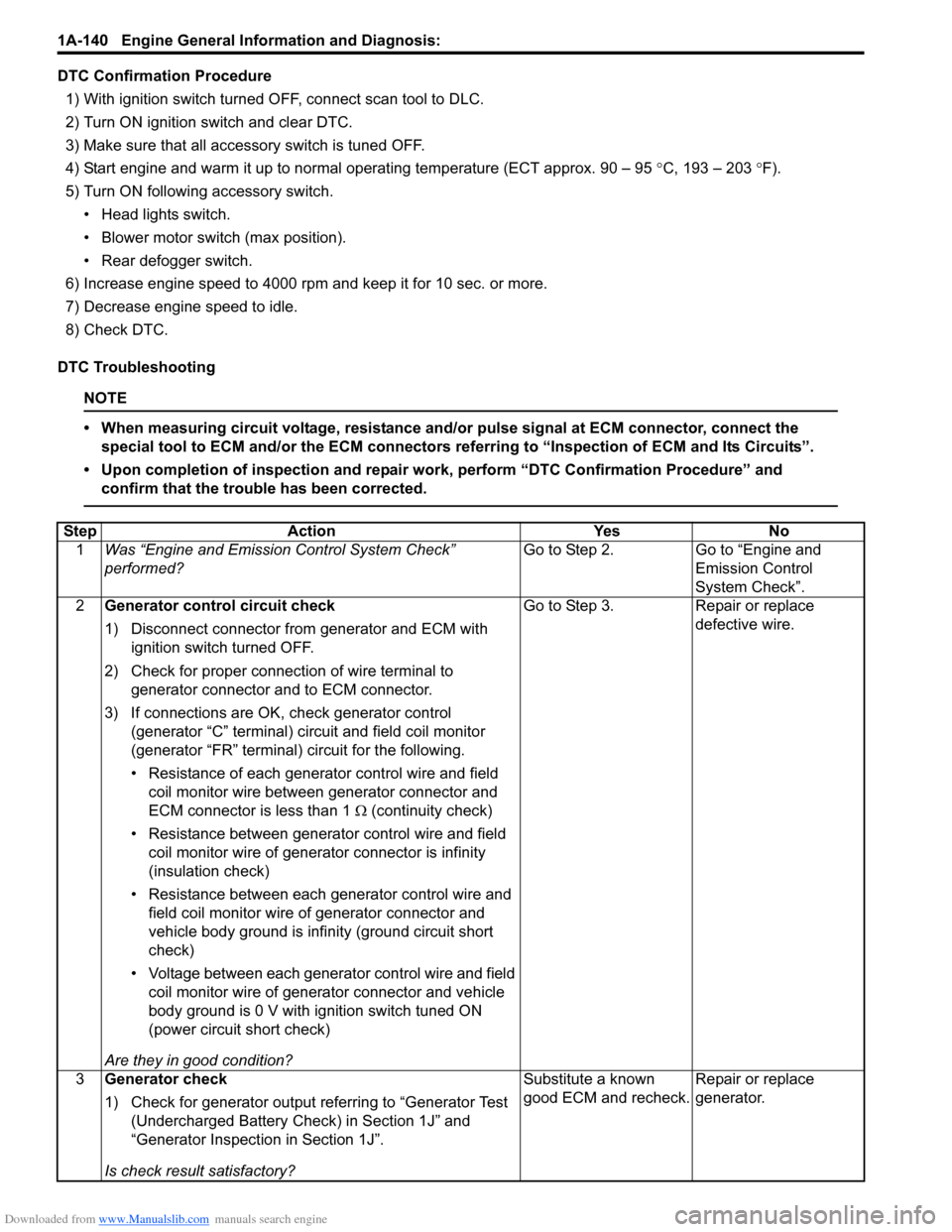

DTC Confirmation Procedure1) With ignition switch turned OFF, connect scan tool to DLC.

2) Turn ON ignition switch and clear DTC.

3) Make sure that all accessory switch is tuned OFF.

4) Start engine and warm it up to normal operating temperature (ECT approx. 90 – 95 °C, 193 – 203 °F).

5) Turn ON following accessory switch. • Head lights switch.

• Blower motor switch (max position).

• Rear defogger switch.

6) Increase engine speed to 4000 rpm and keep it for 10 sec. or more.

7) Decrease engine speed to idle.

8) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Generator control circuit check

1) Disconnect connector from generator and ECM with

ignition switch turned OFF.

2) Check for proper connection of wire terminal to generator connector and to ECM connector.

3) If connections are OK, check generator control (generator “C” terminal) circuit and field coil monitor

(generator “FR” terminal) circuit for the following.

• Resistance of each generato r control wire and field

coil monitor wire between generator connector and

ECM connector is less than 1 Ω (continuity check)

• Resistance between generator control wire and field coil monitor wire of generator connector is infinity

(insulation check)

• Resistance between each generator control wire and field coil monitor wire of generator connector and

vehicle body ground is infinity (ground circuit short

check)

• Voltage between each generator control wire and field

coil monitor wire of generator connector and vehicle

body ground is 0 V with ignition switch tuned ON

(power circuit short check)

Are they in good condition? Go to Step 3.

Repair or replace

defective wire.

3 Generator check

1) Check for generator output referring to “Generator Test

(Undercharged Battery Check) in Section 1J” and

“Generator Inspection in Section 1J”.

Is check result satisfactory? Substitute a known

good ECM and recheck.

Repair or replace

generator.