Abs install SUZUKI SWIFT 2008 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 429 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 2- i

2

Section 2

CONTENTS

Suspension

Precautions ................................................. 2-1

Precautions............................................................. 2-1

Precautions on Suspension .................................. 2-1

Suspension General Dia gnosis.............. 2A-1

Diagnostic Information and Procedures ............ 2A-1

Suspension, Wheels and Tires Symptom Diagnosis .......................................................... 2A-1

Front Suspension ........... ......................... 2B-1

General Description ............................................. 2B-1

Front Suspension Construction ........................... 2B-1

Front Wheel Alignment Cons truction .................. 2B-2

Repair Instructions .............................................. 2B-2 Front Wheel Alignment Inspection and Adjustment ........................................................ 2B-2

Front Strut Assembly Comp onents ..................... 2B-4

Front Strut Assembly Removal and Installation ......................................................... 2B-4

Front Strut Assembly Disassembly and Assembly .......................................................... 2B-6

Front Strut Assembly Chec k ............................... 2B-7

Front Wheel Hub and Steering Knuckle Components...................................................... 2B-8

Front Wheel Hub, Steering Knuckle and Wheel Bearing Removal and Installation .......... 2B-8

Front Wheel Hub, Disc, Nut and Bearing Check .............................................................. 2B-12

Suspension Control Arm / Bushing Removal and Installation ................................................ 2B-12

Suspension Control Arm / Bushing Disassembly and Assembly ............................ 2B-13

Suspension Control Arm / Steering Knuckle Check .............................................................. 2B-14

Suspension Control Arm Bushing Check .......... 2B-14

Suspension Control Arm Joint Check ............... 2B-14

Front Suspension Fram e, Stabilizer Bar and/

or Bushings Components................................ 2B-15

Front Suspension Fram e, Stabilizer Bar and/

or Bushings Removal and Installation ............. 2B-15

Front Suspension Frame Ch eck ....................... 2B-19

Front Stabilizer Bar, Bushing and/or Joint Check .............................................................. 2B-19

Front Suspension Fastener s Check .................. 2B-19

Specifications ..................................................... 2B-20 Tightening Torque Specifications ...................... 2B-20

Special Tools and Equipmen t ...........................2B-21

Special Tool ...................................................... 2B-21

Rear Suspension ............ ......................... 2C-1

General Description .............................................2C-1

Rear Suspension Construction ...........................2C-1

Repair Instructions ........... ...................................2C-2

Rear Wheel Alignment Inspection .......................2C-2

Rear Shock Absorber Removal and Installation .........................................................2C-2

Rear Shock Absorber Ins pection ........................2C-3

Rear Shock Absorber Bush Removal and Installation .........................................................2C-4

Rear Shock Absorber Bush Inspection ...............2C-4

Rear Coil Spring Removal and Installation .........2C-4

Spring Upper Seat / Spring Lower Seat Inspection ..........................................................2C-5

Spring Upper Seat and Lower Seat Removal and Installation ..................................................2C-6

Rear Axle Removal and Inst allation ....................2C-6

Trailing Arm, Rear Axle and Coil Spring Inspection ..........................................................2C-9

Rear Axle Bush Inspection ..................................2C-9

Rear Wheel Hub Components ..........................2C-10

Rear Wheel Hub Removal an d Installation .......2C-10

Rear Wheel Disc, bolt and Bearing Inspection ..2C-11

Spindle Removal and Installation ......................2C-12

Spindle Inspection .............................................2C-13

Rear Suspension Fasteners Inspection ............2C-13

Specifications .................... .................................2C-13

Tightening Torque Specifications ......................2C-13

Special Tools and Equipmen t ...........................2C-13

Special Tool ......................................................2C-13

Wheels and Tires ............ ......................... 2D-1

Precautions...........................................................2D-1

Precaution for Emergency Flat Tire Repair Kit ....2D-1

General Description .............................................2D-1 Tires Description .................................................2D-1

Wheels Description .............................................2D-2

Irregular and/or Premature Wear Description .....2D-3

Wear Indicators Description ................................2D-3

Radial Tire Waddle Description...........................2D-4

Radial Tire Lead / Pull Description ......................2D-5

Page 456 of 1496

Downloaded from www.Manualslib.com manuals search engine 2C-2 Rear Suspension:

Repair Instructions

Rear Wheel Alignment InspectionS7RS0B2306017

Measure toe and camber referring to “Front Wheel

Alignment Inspection and Adjustment in Section 2B”.

NOTE

Rear suspension is not adjustable structure.

Rear toe (total)

: IN 3.8 ± 3.8 mm (IN 0.1969 ± 0.1969 in)

Rear camber

: –1 ° ± 1

If measured value is out of specified value, check

following items for damage, deformation and crack.

• Rear axle (torsion beam)

• Spindle, wheel hub or wheel bearing

• Vehicle body

Rear Shock Absorber Removal and InstallationS7RS0B2306001

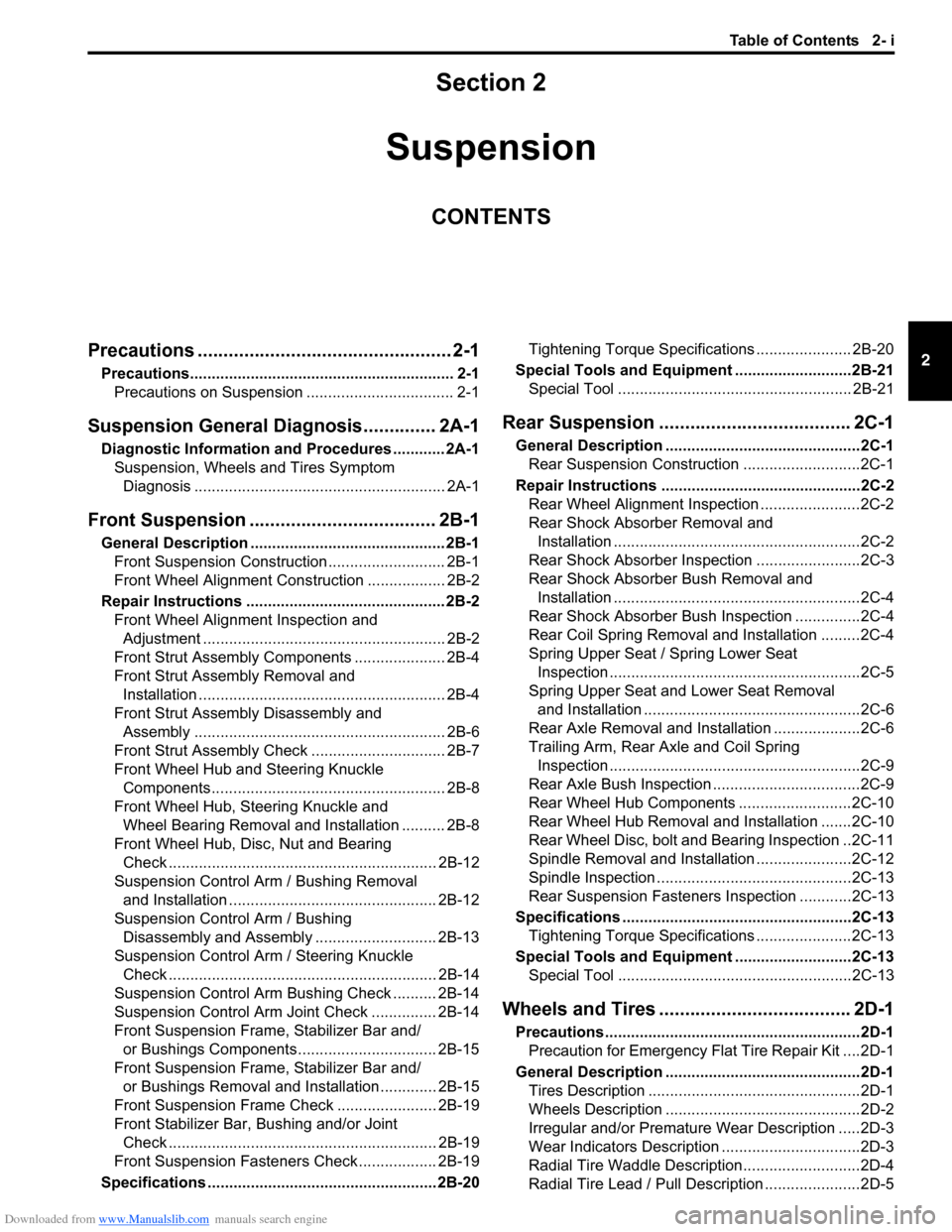

Removal 1) Hoist vehicle and remove rear wheels.

2) Remove tail end member trim (1) and quarter inner trim (2).

3) Support rear axle by using floor jack to prevent it from lowering.

4) Remove shock absorber lower nut.

5) Remove shock absorber upper nut. Then remove shock absorber, a pair of upper washers and lower

washer. Installation

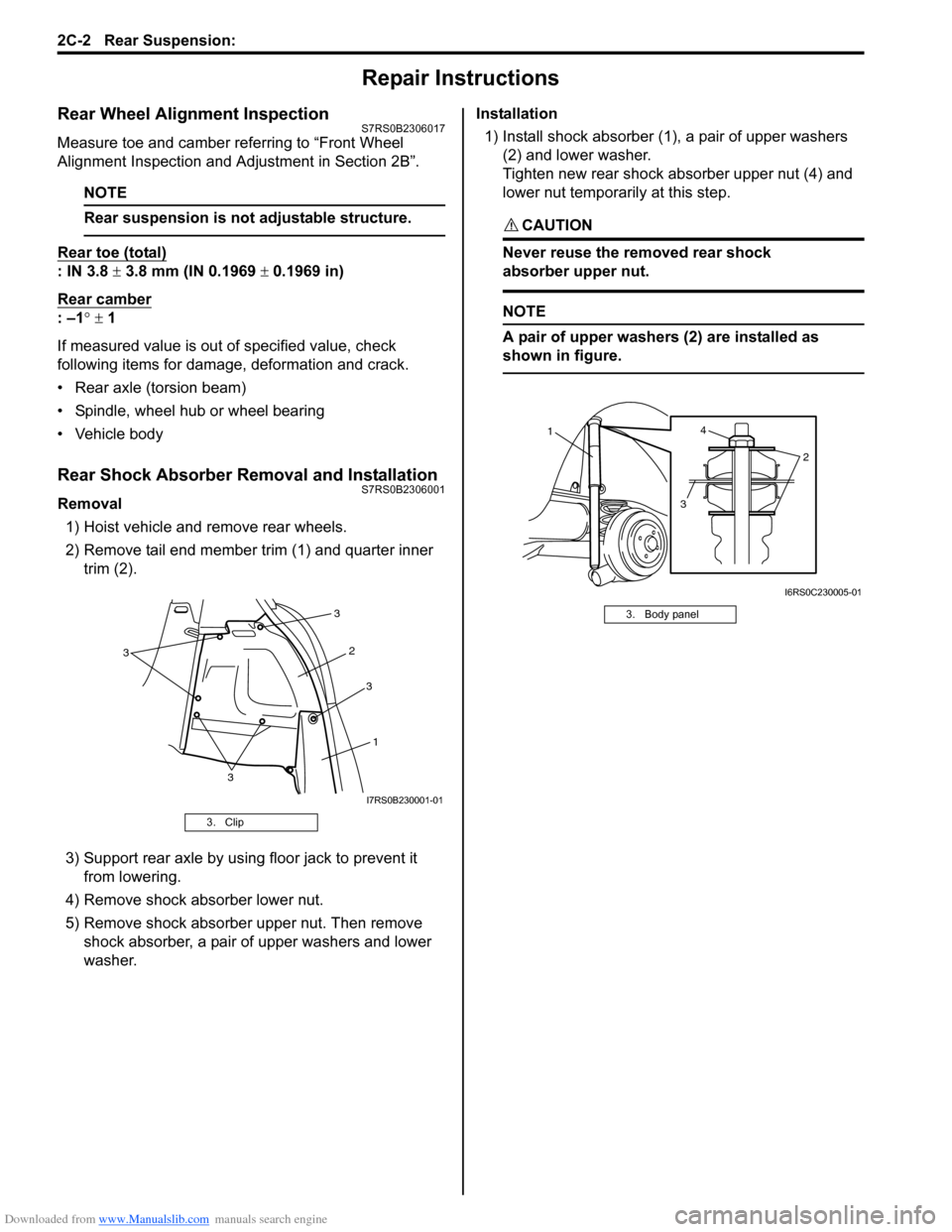

1) Install shock absorber (1), a pair of upper washers (2) and lower washer.

Tighten new rear shock absorber upper nut (4) and

lower nut temporarily at this step.

CAUTION!

Never reuse the removed rear shock

absorber upper nut.

NOTE

A pair of upper washers (2) are installed as

shown in figure.

3. Clip

3

3 2

3

1

3

I7RS0B230001-01

3. Body panel

14

3 2

I6RS0C230005-01

Page 457 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Suspension: 2C-3

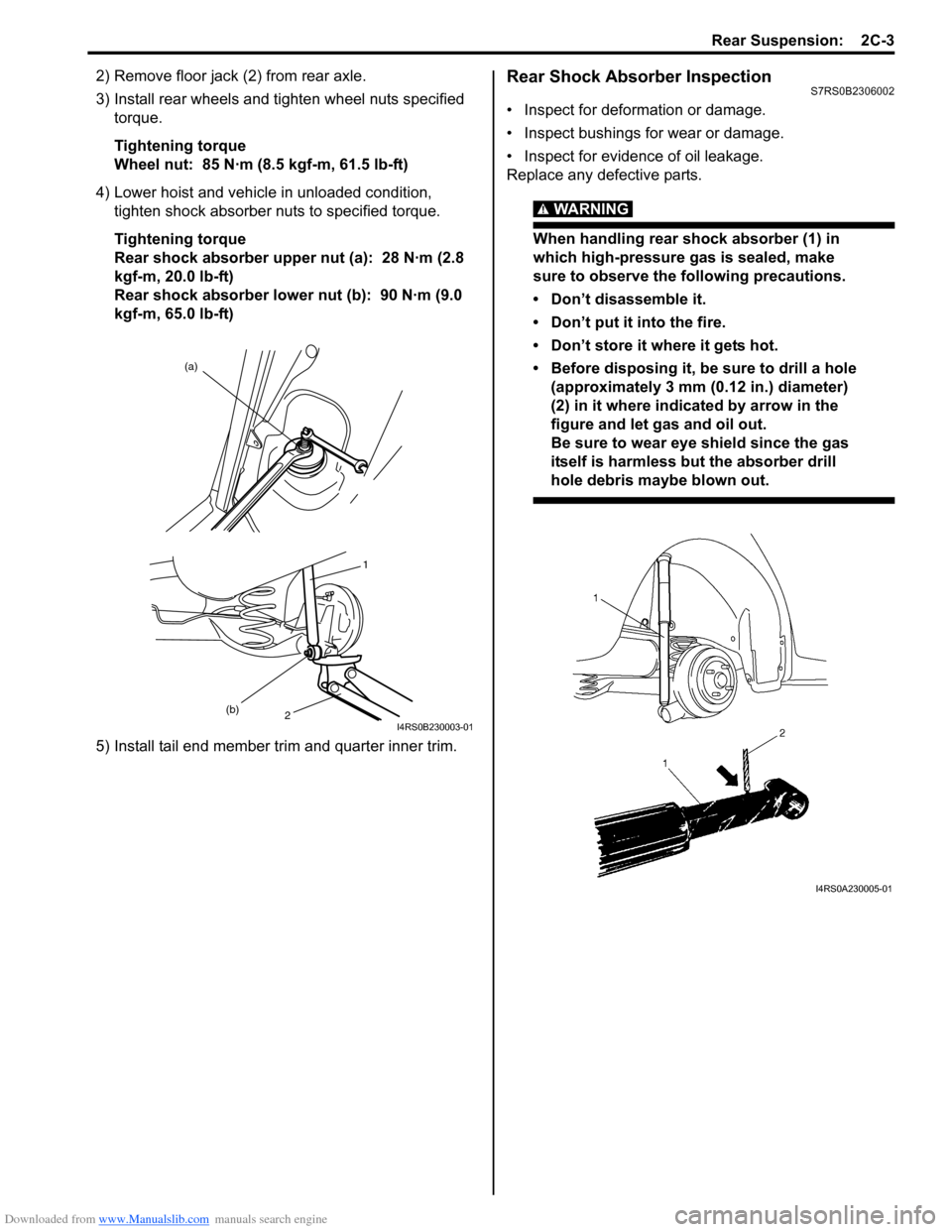

2) Remove floor jack (2) from rear axle.

3) Install rear wheels and tighten wheel nuts specified torque.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

4) Lower hoist and vehicle in unloaded condition, tighten shock absorber nuts to specified torque.

Tightening torque

Rear shock absorber upper nut (a): 28 N·m (2.8

kgf-m, 20.0 lb-ft)

Rear shock absorber lower nut (b): 90 N·m (9.0

kgf-m, 65.0 lb-ft)

5) Install tail end member trim and quarter inner trim.Rear Shock Absorber InspectionS7RS0B2306002

• Inspect for deformation or damage.

• Inspect bushings for wear or damage.

• Inspect for evidence of oil leakage.

Replace any defective parts.

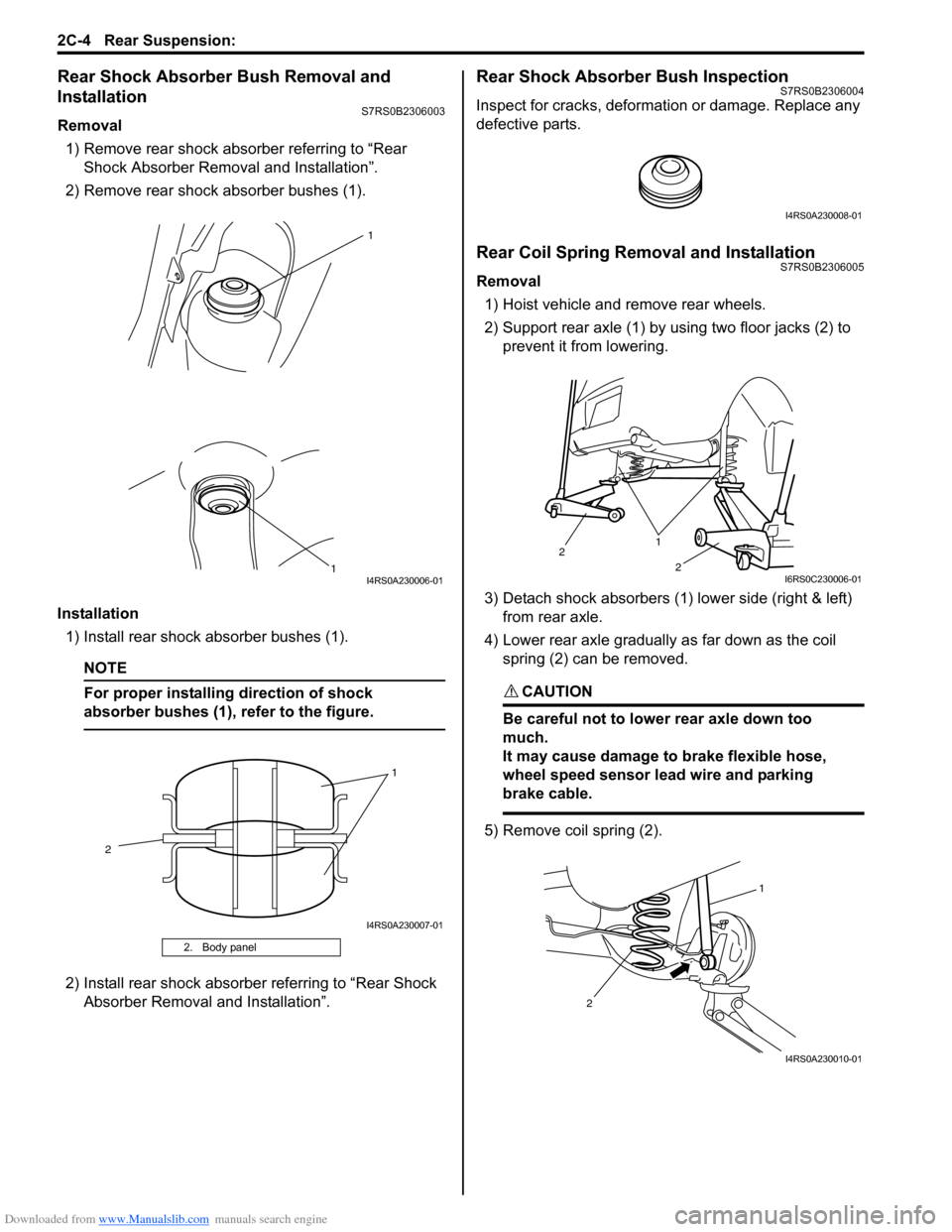

WARNING!

When handling rear shock absorber (1) in

which high-pressure gas is sealed, make

sure to observe the following precautions.

• Don’t disassemble it.

• Don’t put it into the fire.

• Don’t store it where it gets hot.

• Before disposing it, be sure to drill a hole (approximately 3 mm (0.12 in.) diameter)

(2) in it where indicated by arrow in the

figure and let gas and oil out.

Be sure to wear eye shield since the gas

itself is harmless but the absorber drill

hole debris maybe blown out.

(a)

1

(b) 2

I4RS0B230003-01

I4RS0A230005-01

Page 458 of 1496

Downloaded from www.Manualslib.com manuals search engine 2C-4 Rear Suspension:

Rear Shock Absorber Bush Removal and

Installation

S7RS0B2306003

Removal1) Remove rear shock absorber referring to “Rear Shock Absorber Remova l and Installation”.

2) Remove rear shock absorber bushes (1).

Installation 1) Install rear shock absorber bushes (1).

NOTE

For proper installing direction of shock

absorber bushes (1), refer to the figure.

2) Install rear shock absorber referring to “Rear Shock Absorber Removal and Installation”.

Rear Shock Absorber Bush InspectionS7RS0B2306004

Inspect for cracks, deformation or damage. Replace any

defective parts.

Rear Coil Spring Removal and InstallationS7RS0B2306005

Removal

1) Hoist vehicle and remove rear wheels.

2) Support rear axle (1) by using two floor jacks (2) to prevent it from lowering.

3) Detach shock absorbers (1) lower side (right & left) from rear axle.

4) Lower rear axle gradually as far down as the coil spring (2) can be removed.

CAUTION!

Be careful not to lowe r rear axle down too

much.

It may cause damage to brake flexible hose,

wheel speed sensor lead wire and parking

brake cable.

5) Remove coil spring (2).

2. Body panel

1

1

I4RS0A230006-01

1

2

I4RS0A230007-01

I4RS0A230008-01

1

2

2

I6RS0C230006-01

1

2

I4RS0A230010-01

Page 459 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Suspension: 2C-5

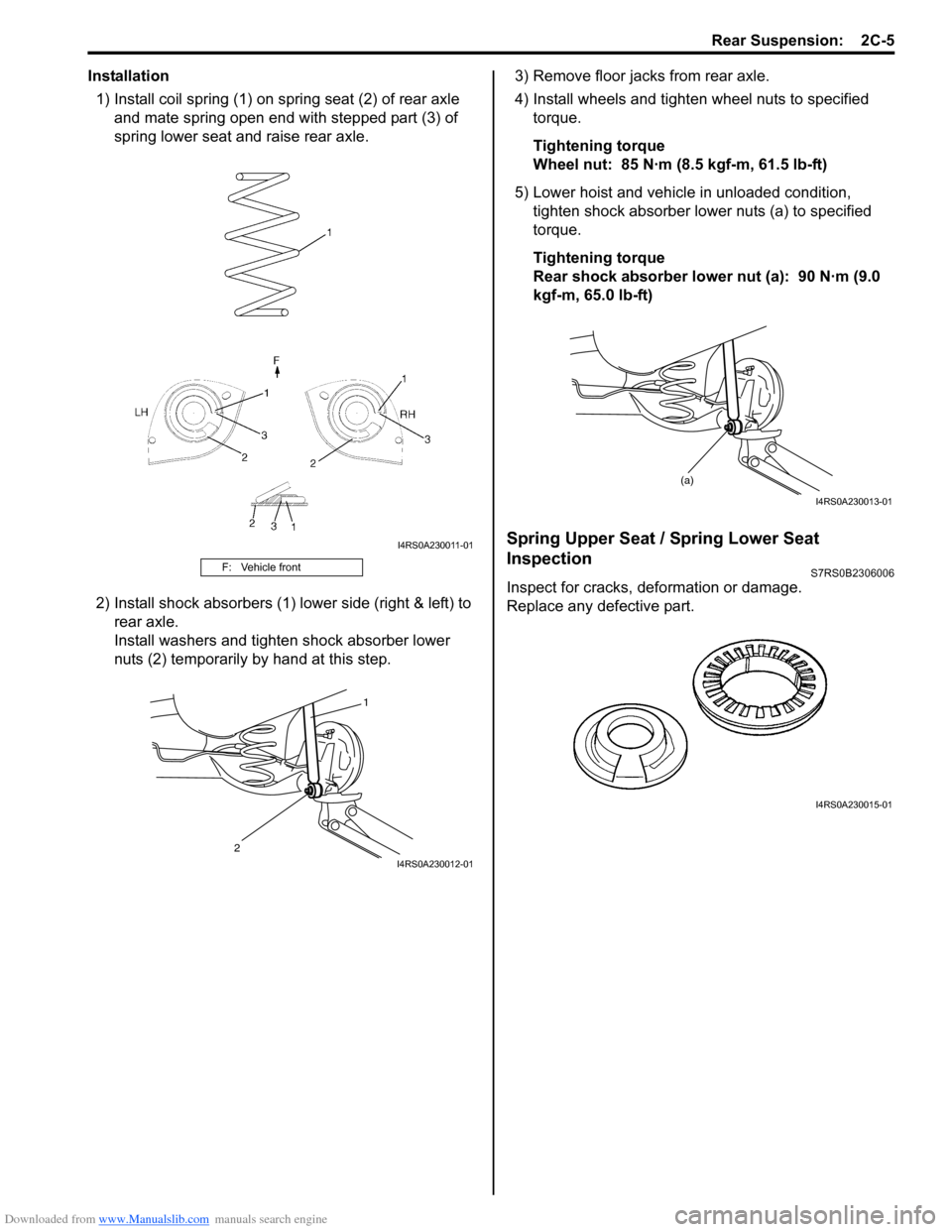

Installation1) Install coil spring (1) on spring seat (2) of rear axle and mate spring open end with stepped part (3) of

spring lower seat and raise rear axle.

2) Install shock absorbers (1) lower side (right & left) to rear axle.

Install washers and tighten shock absorber lower

nuts (2) temporarily by hand at this step. 3) Remove floor jacks from rear axle.

4) Install wheels and tighten wheel nuts to specified

torque.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

5) Lower hoist and vehicle in unloaded condition, tighten shock absorber lower nuts (a) to specified

torque.

Tightening torque

Rear shock absorber lower nut (a): 90 N·m (9.0

kgf-m, 65.0 lb-ft)

Spring Upper Seat / Spring Lower Seat

Inspection

S7RS0B2306006

Inspect for cracks, deformation or damage.

Replace any defective part.

F: Vehicle front

I4RS0A230011-01

1

2

I4RS0A230012-01

(a)

I4RS0A230013-01

I4RS0A230015-01

Page 462 of 1496

Downloaded from www.Manualslib.com manuals search engine 2C-8 Rear Suspension:

3) Install coil springs (right & left) on spring seats of rear

axle referring to “Spring Upper Seat and Lower Seat

Removal and Installation” and “Rear Coil Spring

Removal and Installation”.

4) Install shock absorbers lower side (right & left) and washers referring to “Rear Shock Absorber Removal

and Installation”.

5) Install brake dust covers, spindles and wheel speed sensors (right and left) referring to “Spindle Removal

and Installation”.

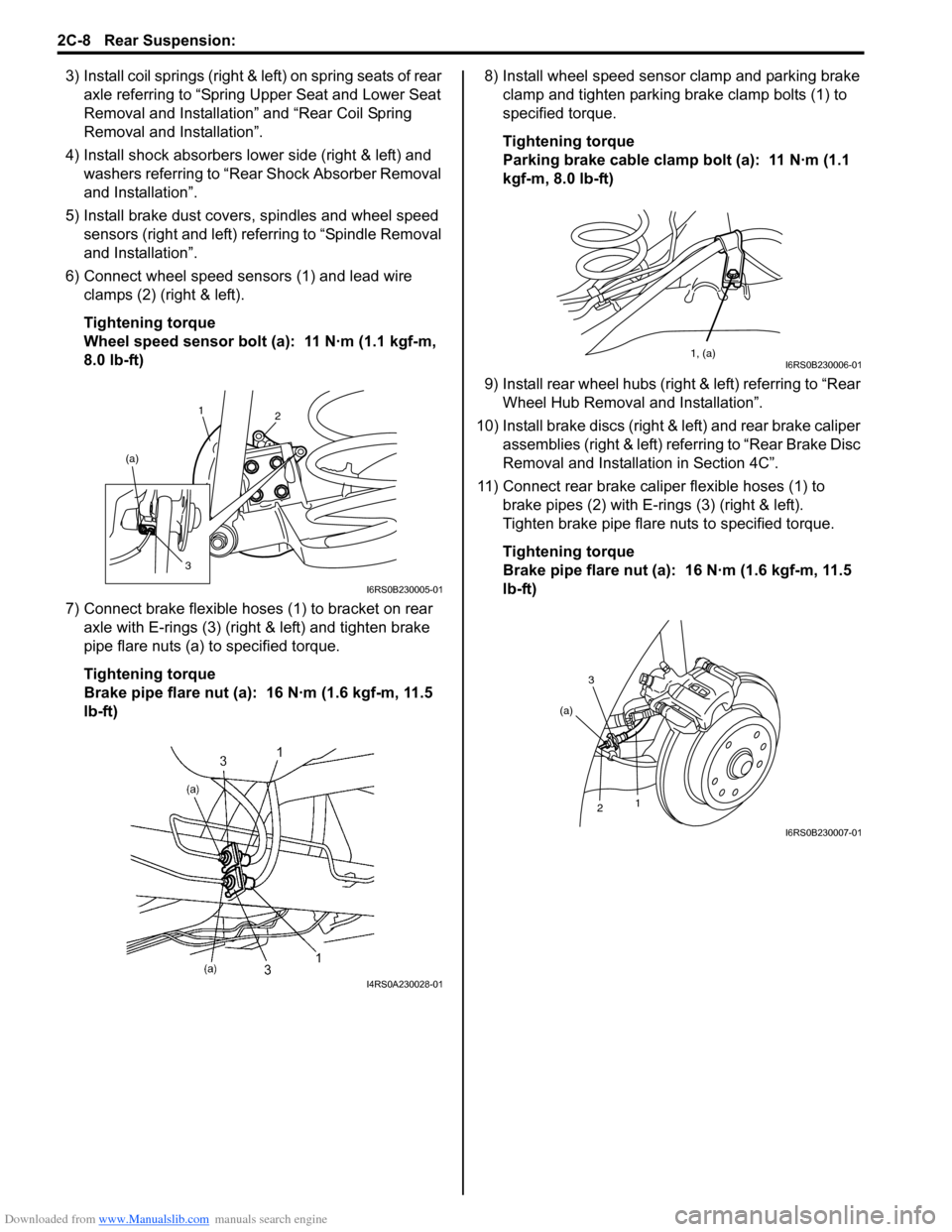

6) Connect wheel speed sensors (1) and lead wire clamps (2) (right & left).

Tightening torque

Wheel speed sensor bolt (a): 11 N·m (1.1 kgf-m,

8.0 lb-ft)

7) Connect brake flexible hoses (1) to bracket on rear axle with E-rings (3) (right & left) and tighten brake

pipe flare nuts (a) to specified torque.

Tightening torque

Brake pipe flare nut (a): 16 N·m (1.6 kgf-m, 11.5

lb-ft) 8) Install wheel speed sensor clamp and parking brake

clamp and tighten parking brake clamp bolts (1) to

specified torque.

Tightening torque

Parking brake cable clamp bolt (a): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

9) Install rear wheel hubs (right & left) referring to “Rear Wheel Hub Removal and Installation”.

10) Install brake discs (right & left) and rear brake caliper assemblies (right & left) referring to “Rear Brake Disc

Removal and Installati on in Section 4C”.

11) Connect rear brake caliper flexible hoses (1) to brake pipes (2) with E-rings (3) (right & left).

Tighten brake pipe flare nuts to specified torque.

Tightening torque

Brake pipe flare nut (a): 16 N·m (1.6 kgf-m, 11.5

lb-ft)

1 2

(a)

3

I6RS0B230005-01

I4RS0A230028-01

1, (a)I6RS0B230006-01

3

2 1

(a)

I6RS0B230007-01

Page 463 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Suspension: 2C-9

12) Fill reservoir with brake fluid and bleed brake system. For bleeding operation, see “Air Bleeding of

Brake System in Section 4A”.

13) Install wheel and tighten wheel nuts to specified torque.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

14) Adjust parking brake cable. For adjustment, refer to “Parking Brake Inspection and Adjustment in Section

4D”.

15) Lower hoist and bounce vehicle up and down several times to stabilize suspension.

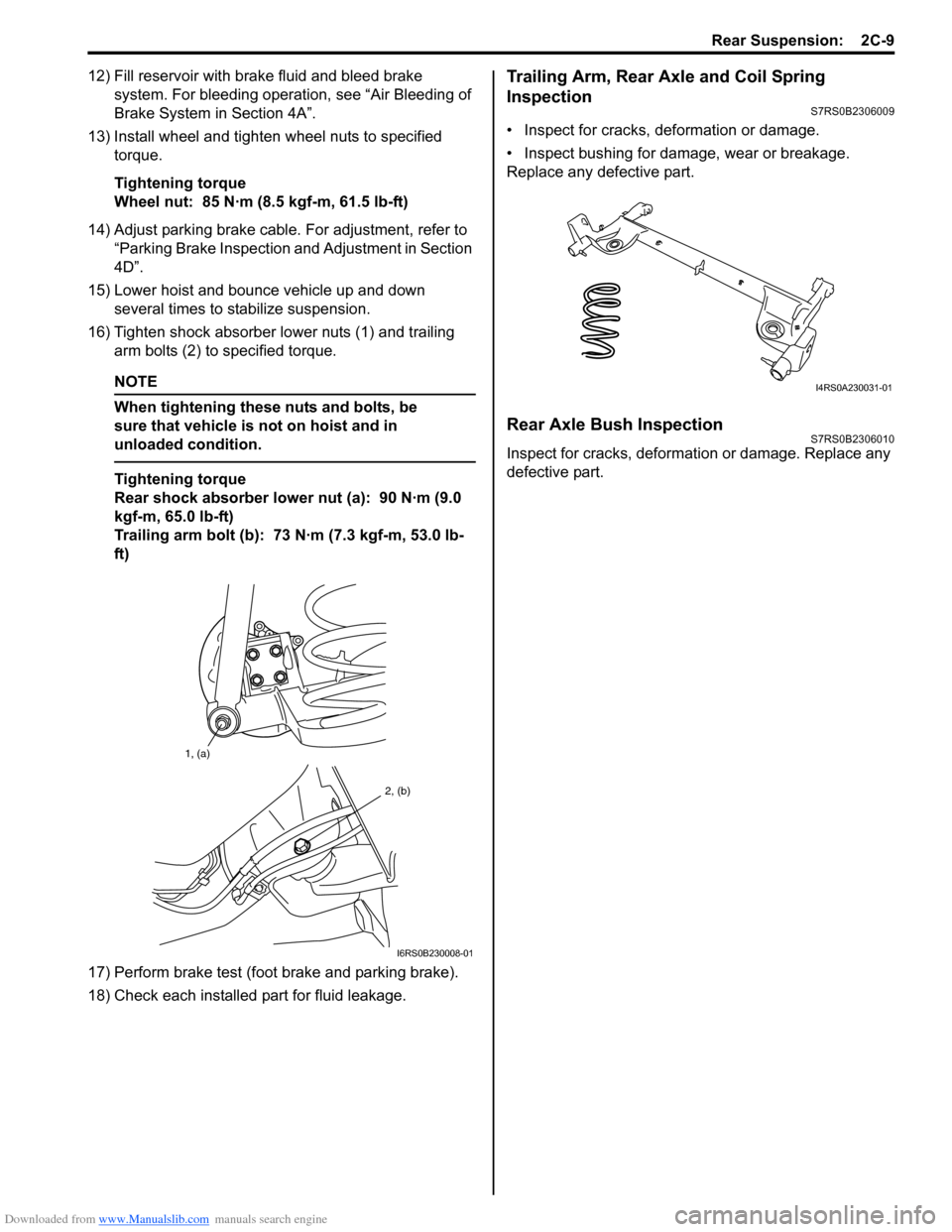

16) Tighten shock ab sorber lower nuts (1) and trailing

arm bolts (2) to specified torque.

NOTE

When tightening these nuts and bolts, be

sure that vehicle is not on hoist and in

unloaded condition.

Tightening torque

Rear shock absorber lower nut (a): 90 N·m (9.0

kgf-m, 65.0 lb-ft)

Trailing arm bolt (b): 73 N·m (7.3 kgf-m, 53.0 lb-

ft)

17) Perform brake test (foot brake and parking brake).

18) Check each installed part for fluid leakage.

Trailing Arm, Rear Axle and Coil Spring

Inspection

S7RS0B2306009

• Inspect for cracks, deformation or damage.

• Inspect bushing for damage, wear or breakage.

Replace any defective part.

Rear Axle Bush InspectionS7RS0B2306010

Inspect for cracks, deformation or damage. Replace any

defective part.

1, (a)

2, (b)

I6RS0B230008-01

I4RS0A230031-01

Page 496 of 1496

Downloaded from www.Manualslib.com manuals search engine 4-ii Table of Contents

Repair Instructions ..............................................4D-2Parking Brake Inspection and Adjustment ..........4D-2

Parking Brake Cable Removal and Installation ......................................................... 4D-3

Parking Brake Lever Removal and Installation ....4D-3

Specifications .... ...................................................4D-4

Tightening Torque Specifications ........................4D-4

ABS ........................................... .................4E-1

Precautions........................................................... 4E-1

Precautions in Diagnosing Troubles ................... 4E-1

Precautions in On-Vehicle Service...................... 4E-1

Precautions in Hydraulic Unit Operation Check ................................................................ 4E-1

General Description ............................................. 4E-2 ABS Description .................................................. 4E-2

ABS Hydraulic Unit / Control Module Assembly Description ....................................... 4E-2

CAN Communication System Description........... 4E-3

Schematic and Routing Diagram ........................ 4E-4 ABS Schematic ................................................... 4E-4

ABS Wiring Circuit Diagram ................................ 4E-5

Component Location ........... ................................ 4E-7

ABS Components Location ................................. 4E-7

Front Wheel Speed Sensor Components Location ............................................................ 4E-7

Rear Wheel Speed Sensor Components Location ............................................................ 4E-8

Diagnostic Information and Procedures ............ 4E-8 ABS Check .......................................................... 4E-8

ABS Warning Light Check................................. 4E-10

EBD Warning Light (Brake Warning Light) Check .............................................................. 4E-10

DTC Check........................................................ 4E-11

DTC Table ......................................................... 4E-11

DTC Clearance ................................................. 4E-12

Scan Tool Data ................................................. 4E-12

ABS Warning Light Does Not Come ON at Ignition Switch ON .......................................... 4E-13

ABS Warning Light Comes ON Steady ............. 4E-14

EBD Warning Light (Brake Warning Light) Comes ON Steady .......................................... 4E-15

Serial Data Link Circuit Check .......................... 4E-16

DTC C1021, C1022 / C1025, C1026 / C1031, C1032 / C1035, C1036: Right-Front / Left-

Front / Right-Rear / Left-Rear Wheel Speed

Sensor Circuit or Sensor Ring ........................ 4E-18

DTC C1041 / C1045 / C1051 / C1055, DTC C1042 / C1046 / C1052 / C1056: Right-Front

/ Left-Front / Right-Rear / Left-Rear Inlet

Solenoid Circuit, Right-Front / Left-Front /

Right-Rear / Left-Rear Outlet Solenoid

Circuit .............................................................. 4E-20

DTC C1057: Power Source Circuit ................... 4E-21

DTC C1061: ABS Pump Motor and/or Motor Driver Circuit ................................................... 4E-22

DTC C1063: Solenoid Valve Power Supply Driver Circuit ................................................... 4E-23

DTC C1071: ABS Control Module..................... 4E-24 DTC U1073: Control Module Communication

Bus Off ............................................................ 4E-25

DTC U1100: Lost Communication with ECM (Reception Error)............................................. 4E-27

Repair Instructions ............ ................................ 4E-28

ABS Hydraulic Unit Operati on Check................ 4E-28

ABS Hydraulic Unit / Control Module

Assembly Components ...... ............................. 4E-29

ABS Hydraulic Unit / Control Module

Assembly On-Vehicle Inspection .................... 4E-29

ABS Hydraulic Unit / Control Module

Assembly Removal and Inst allation ................ 4E-29

Front / Rear Wheel Speed Sensor On-Vehicle Inspection ........................................................ 4E-31

Front Wheel Speed Sensor Removal and Installation ....................................................... 4E-32

Front Wheel Speed Sensor Inspection ............. 4E-32

Rear Wheel Speed Sensor Removal and Installation ....................................................... 4E-33

Rear Wheel Speed Sensor Inspection .............. 4E-34

Front Wheel Encoder On-Veh icle Inspection .... 4E-34

Front wheel Enco der Removal and

Installation ....................................................... 4E-34

Rear Wheel Encoder On-Veh icle Inspection..... 4E-34

Rear Wheel Encoder Removal and Installation ....................................................... 4E-34

Specifications ..................... ................................ 4E-35

Tightening Torque Specifications ...................... 4E-35

Special Tools and Equipmen t ........................... 4E-35

Special Tool ...................................................... 4E-35

Electronic Stability Prog ram ...................4F-1

Precautions ........................................................... 4F-1

Precautions in Diagnosing Troubles ................... 4F-1

Precautions in On-Vehicle Service...................... 4F-1

Precautions in Hydraulic Unit Operation Check ................................................................ 4F-1

Precautions in Sensor Calibration ....................... 4F-1

Precautions in Speedometer Test or Other Tests ................................................................. 4F-2

General Description ............................................. 4F-2 Electronic Stability Program Description ............. 4F-2

Electronic Stability Program Construction ........... 4F-3

ESP® Hydraulic Unit / Control Module

Assembly Description........................................ 4F-5

Warning Lamp, Indicator Lamp Description ........ 4F-6

CAN Communication System Description........... 4F-6

CAN Communication System For Electronic Stability Program Description ............................ 4F-7

Schematic and Routing Diagram ........................ 4F-8 Electronic Stability Program Schematic .............. 4F-8

Electronic Stability Program Wiring Circuit Diagram............................................................. 4F-9

Component Location ............ ............................. 4F-11

Electronic Stability Program Component

Location........................................................... 4F-11

Diagnostic Information and Procedures .......... 4F-12 Electronic Stability Program System Check ...... 4F-12

ESP® Warning lamp Check .............................. 4F-14

Page 497 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 4-iii

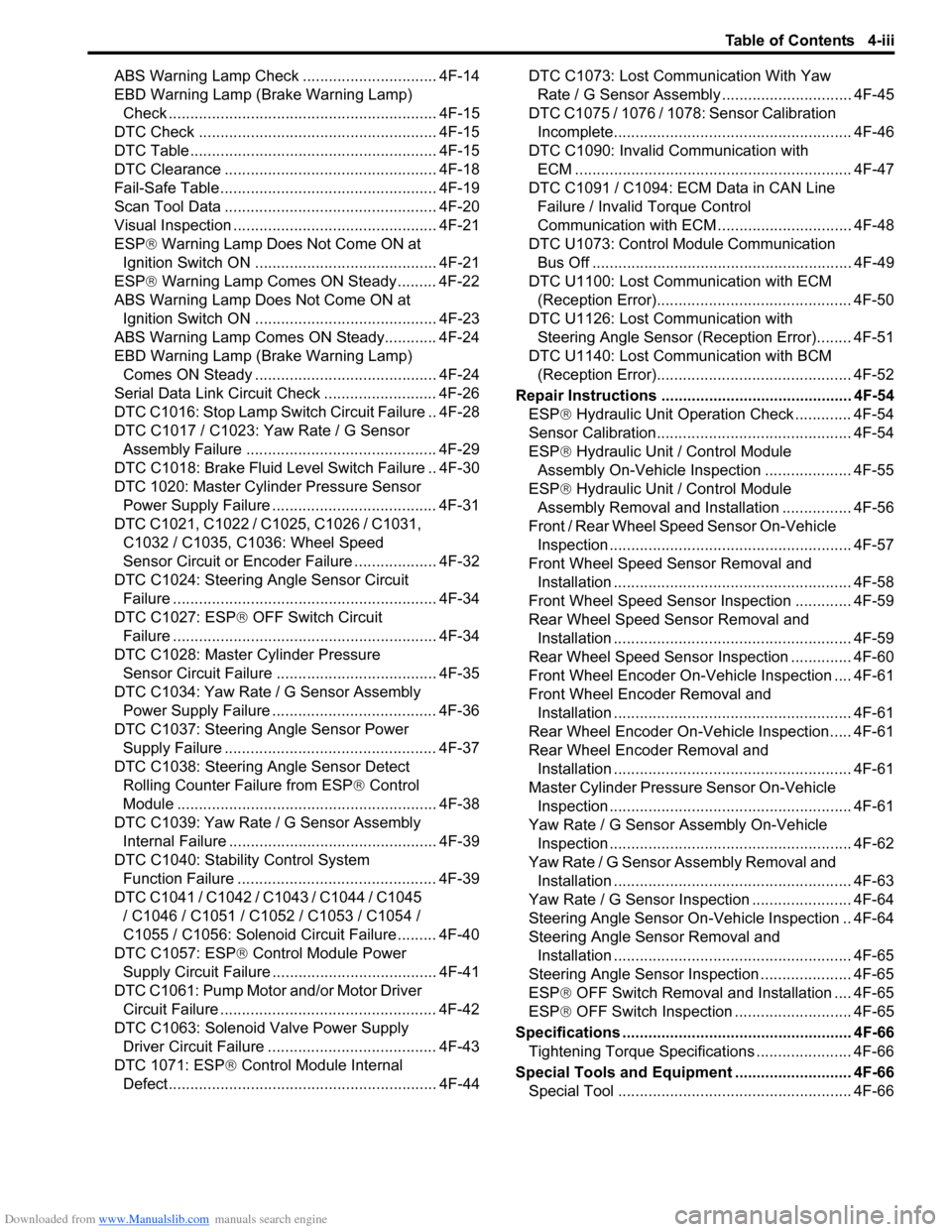

ABS Warning Lamp Check ............................... 4F-14

EBD Warning Lamp (Brake Warning Lamp) Check .............................................................. 4F-15

DTC Check ....................................................... 4F-15

DTC Table ......................................................... 4F-15

DTC Clearance ................................................. 4F-18

Fail-Safe Table ................ .................................. 4F-19

Scan Tool Data ................................................. 4F-20

Visual Inspection ............................................... 4F-21

ESP ® Warning Lamp Does Not Come ON at

Ignition Switch ON .......................................... 4F-21

ESP ® Warning Lamp Comes ON Steady......... 4F-22

ABS Warning Lamp Does Not Come ON at Ignition Switch ON .......................................... 4F-23

ABS Warning Lamp Comes ON Steady............ 4F-24

EBD Warning Lamp (Brake Warning Lamp) Comes ON Steady .......................................... 4F-24

Serial Data Link Circuit Check .......................... 4F-26

DTC C1016: Stop Lamp Swit ch Circuit Failure .. 4F-28

DTC C1017 / C1023: Yaw Rate / G Sensor Assembly Failure ............................................ 4F-29

DTC C1018: Brake Fluid Le vel Switch Failure .. 4F-30

DTC 1020: Master Cylinder Pressure Sensor Power Supply Failure ...................................... 4F-31

DTC C1021, C1022 / C1025, C1026 / C1031, C1032 / C1035, C1036: Wheel Speed

Sensor Circuit or Encode r Failure ................... 4F-32

DTC C1024: Steering Angle Sensor Circuit

Failure ............................................................. 4F-34

DTC C1027: ESP ® OFF Switch Circuit

Failure ............................................................. 4F-34

DTC C1028: Master Cylinder Pressure Sensor Circuit Failure ....... .............................. 4F-35

DTC C1034: Yaw Rate / G Sensor Assembly Power Supply Failure ...................................... 4F-36

DTC C1037: Steering Angle Sensor Power Supply Failure ................................................. 4F-37

DTC C1038: Steering Angle Sensor Detect Rolling Counter Fa ilure from ESP® Control

Module ............................................................ 4F-38

DTC C1039: Yaw Rate / G Sensor Assembly Internal Failure .............. .................................. 4F-39

DTC C1040: Stability Control System Function Failure .............................................. 4F-39

DTC C1041 / C1042 / C1043 / C1044 / C1045 / C1046 / C1051 / C1052 / C1053 / C1054 /

C1055 / C1056: Solenoid Circuit Failure ......... 4F-40

DTC C1057: ESP ® Control Module Power

Supply Circuit Failure .... .................................. 4F-41

DTC C1061: Pump Motor and/or Motor Driver Circuit Failure .................................................. 4F-42

DTC C1063: Solenoid Valve Power Supply Driver Circuit Failure ....................................... 4F-43

DTC 1071: ESP ® Control Module Internal

Defect.............................................................. 4F-44 DTC C1073: Lost Communication With Yaw

Rate / G Sensor Assembly .............................. 4F-45

DTC C1075 / 1076 / 1078: Sensor Calibration Incomplete.......................... ............................. 4F-46

DTC C1090: Invalid Communication with

ECM ................................................................ 4F-47

DTC C1091 / C1094: ECM Data in CAN Line Failure / Invalid Torque Control

Communication with ECM .. ............................. 4F-48

DTC U1073: Control Module Communication Bus Off ............................................................ 4F-49

DTC U1100: Lost Communication with ECM (Reception Error)............................................. 4F-50

DTC U1126: Lost Communication with Steering Angle Sensor (Reception Error)........ 4F-51

DTC U1140: Lost Communication with BCM (Reception Error)............................................. 4F-52

Repair Instructions ........... ................................. 4F-54

ESP® Hydraulic Unit Operation Check ............. 4F-54

Sensor Calibration............................................. 4F-54

ESP® Hydraulic Unit / Control Module

Assembly On-Vehicle Inspection .................... 4F-55

ESP ® Hydraulic

Unit / Control Module

Assembly Removal and Inst allation ................ 4F-56

Front / Rear Wheel Speed Sensor On-Vehicle Inspection ........................................................ 4F-57

Front Wheel Speed Sensor Removal and Installation ....................................................... 4F-58

Front Wheel Speed Sensor Inspection ............. 4F-59

Rear Wheel Speed Sensor Removal and Installation ....................................................... 4F-59

Rear Wheel Speed Sensor Inspection .............. 4F-60

Front Wheel Encode r On-Vehicle Inspection .... 4F-61

Front Wheel Encoder Removal and Installation ....................................................... 4F-61

Rear Wheel Encoder On-Veh icle Inspection..... 4F-61

Rear Wheel Encoder Removal and Installation ....................................................... 4F-61

Master Cylinder Pressure Sensor On-Vehicle

Inspection ........................................................ 4F-61

Yaw Rate / G Sensor Assembly On-Vehicle Inspection ........................................................ 4F-62

Yaw Rate / G Sensor Assembly Removal and Installation ....................................................... 4F-63

Yaw Rate / G Sensor Inspection ....................... 4F-64

Steering Angle Sensor On-Vehicle Inspection .. 4F-64

Steering Angle Sensor Removal and Installation ....................................................... 4F-65

Steering Angle Sensor Inspection ..................... 4F-65

ESP® OFF Switch Removal an d Installation .... 4F-65

ESP® OFF Switch Inspection ........................... 4F-65

Specifications .................... ................................. 4F-66

Tightening Torque Specifications ...................... 4F-66

Special Tools and Equipmen t ........................... 4F-66

Special Tool ...................................................... 4F-66

Page 504 of 1496

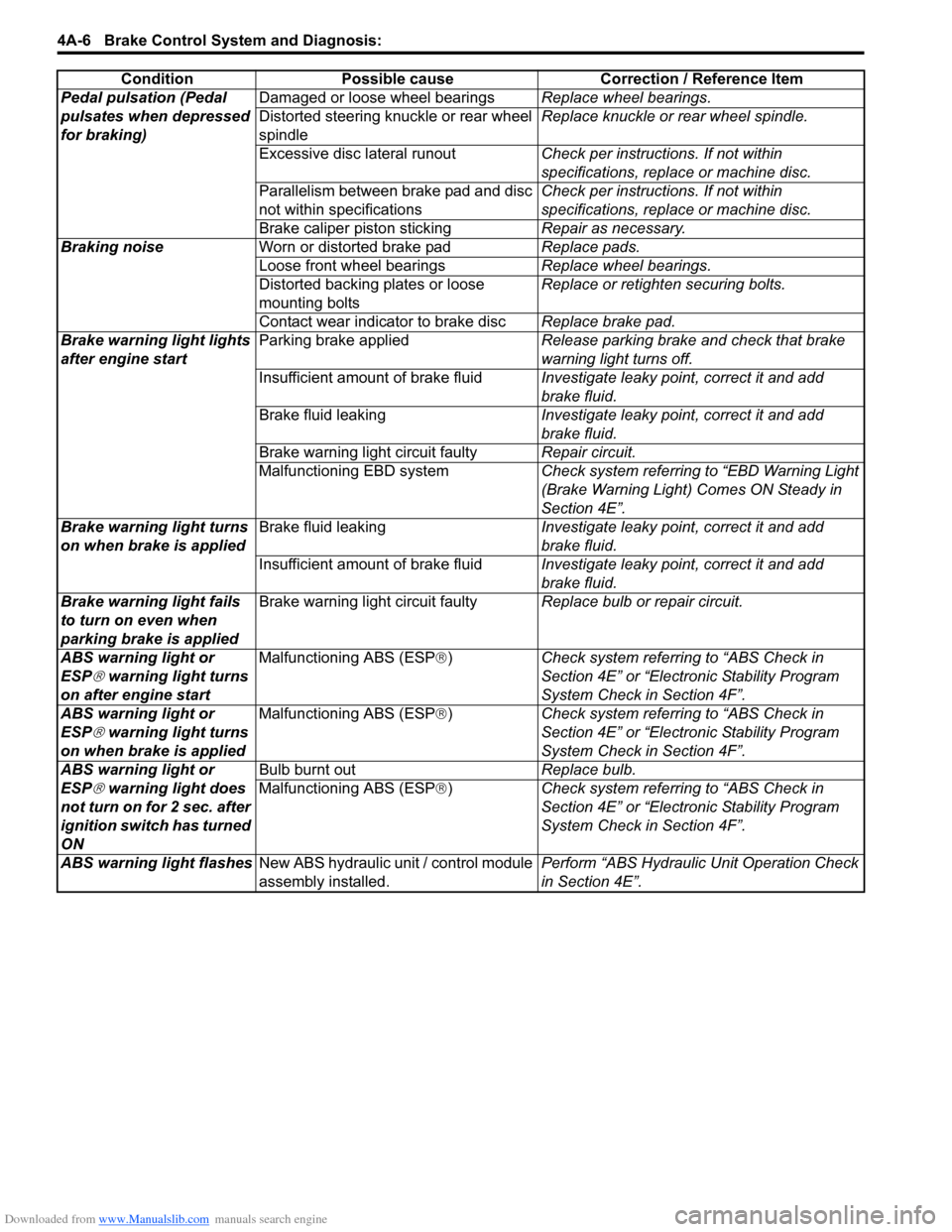

Downloaded from www.Manualslib.com manuals search engine 4A-6 Brake Control System and Diagnosis:

Pedal pulsation (Pedal

pulsates when depressed

for braking)Damaged or loose wheel bearings

Replace wheel bearings.

Distorted steering knuckle or rear wheel

spindle Replace knuckle or rear wheel spindle.

Excessive disc lateral runout Check per instructions. If not within

specifications, replace or machine disc.

Parallelism between brake pad and disc

not within specifications Check per instructions. If not within

specifications, replace or machine disc.

Brake caliper piston sticking Repair as necessary.

Braking noise Worn or distorted brake pad Replace pads.

Loose front wheel bearings Replace wheel bearings.

Distorted backing plates or loose

mounting bolts Replace or retighten securing bolts.

Contact wear indicator to brake disc Replace brake pad.

Brake warning light lights

after engine start Parking brake applied

Release parking brake and check that brake

warning light turns off.

Insufficient amount of brake fluid Investigate leaky point, correct it and add

brake fluid.

Brake fluid leaking Investigate leaky point, correct it and add

brake fluid.

Brake warning light circuit faulty Repair circuit.

Malfunctioning EBD system Check system referring to “EBD Warning Light

(Brake Warning Light) Comes ON Steady in

Section 4E”.

Brake warning light turns

on when brake is applied Brake fluid leaking

Investigate leaky point, correct it and add

brake fluid.

Insufficient amount of brake fluid Investigate leaky point, correct it and add

brake fluid.

Brake warning light fails

to turn on even when

parking brake is applied Brake warning light circuit faulty

Replace bulb or repair circuit.

ABS warning light or

ESP

® warning light turns

on after engine start Malfunctioning ABS (ESP

®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

ABS warning light or

ESP

® warning light turns

on when brake is applied Malfunctioning ABS (ESP

®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

ABS warning light or

ESP

® warning light does

not turn on for 2 sec. after

ignition switch has turned

ON Bulb burnt out

Replace bulb.

Malfunctioning ABS (ESP ®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

ABS warning light flashes New ABS hydraulic unit / control module

assembly installed. Perform “ABS Hydraulic

Unit Operation Check

in Section 4E”.

Condition Possible cause Correction / Reference Item