Cable SUZUKI SWIFT 2008 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 38 of 1496

Downloaded from www.Manualslib.com manuals search engine 0B-8 Maintenance and Lubrication:

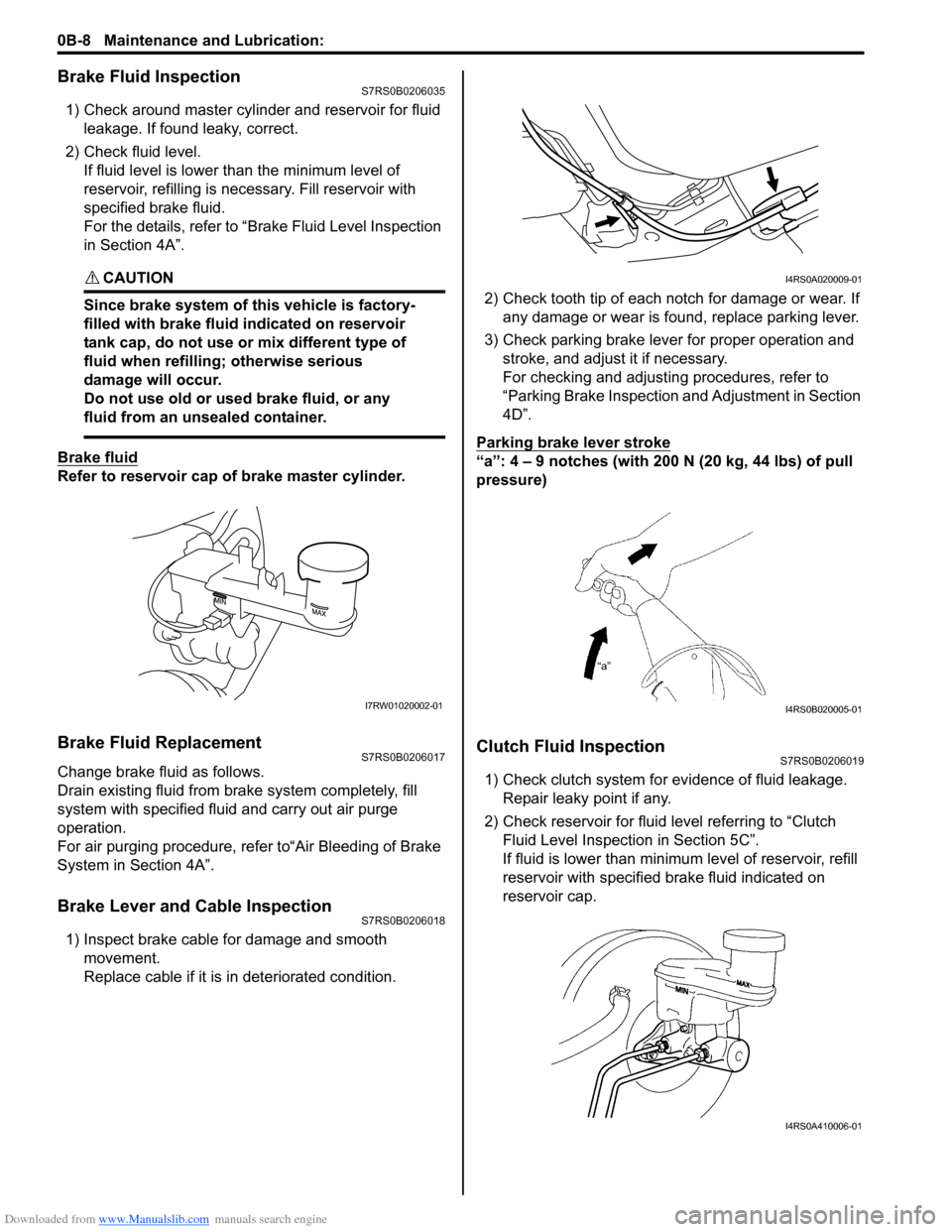

Brake Fluid InspectionS7RS0B0206035

1) Check around master cylinder and reservoir for fluid leakage. If found leaky, correct.

2) Check fluid level. If fluid level is lower than the minimum level of

reservoir, refilling is necessary. Fill reservoir with

specified brake fluid.

For the details, refer to “Brake Fluid Level Inspection

in Section 4A”.

CAUTION!

Since brake system of this vehicle is factory-

filled with brake fluid indicated on reservoir

tank cap, do not use or mix different type of

fluid when refilling; otherwise serious

damage will occur.

Do not use old or used brake fluid, or any

fluid from an unsealed container.

Brake fluid

Refer to reservoir cap of brake master cylinder.

Brake Fluid ReplacementS7RS0B0206017

Change brake fluid as follows.

Drain existing fluid from brake system completely, fill

system with specified fluid and carry out air purge

operation.

For air purging procedure, refer to“Air Bleeding of Brake

System in Section 4A”.

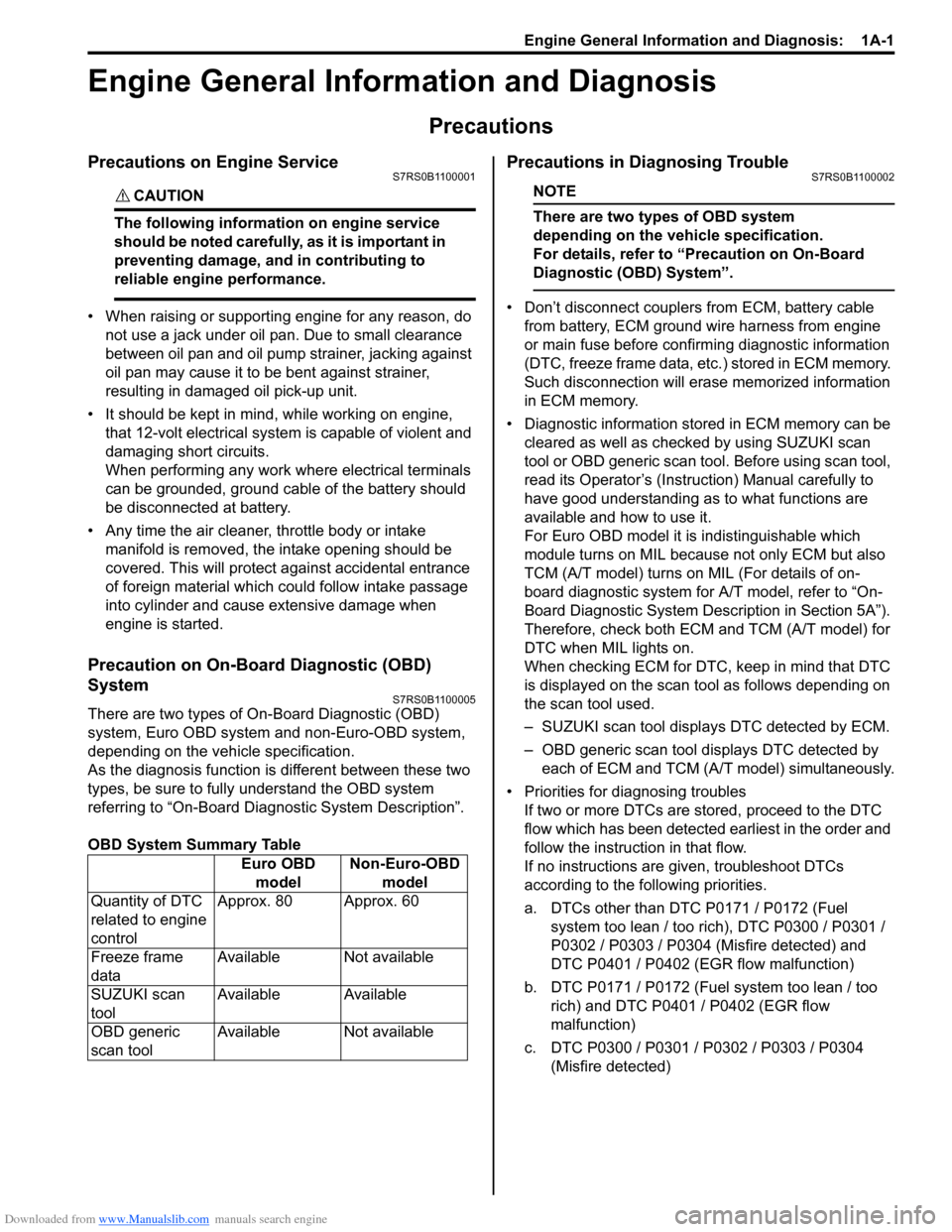

Brake Lever and Cable InspectionS7RS0B0206018

1) Inspect brake cable for damage and smooth movement.

Replace cable if it is in deteriorated condition. 2) Check tooth tip of each notch for damage or wear. If

any damage or wear is found, replace parking lever.

3) Check parking brake lever for proper operation and stroke, and adjust it if necessary.

For checking and adjusting procedures, refer to

“Parking Brake Inspection and Adjustment in Section

4D”.

Parking brake lever stroke

“a”: 4 – 9 notches (with 200 N (20 kg, 44 lbs) of pull

pressure)

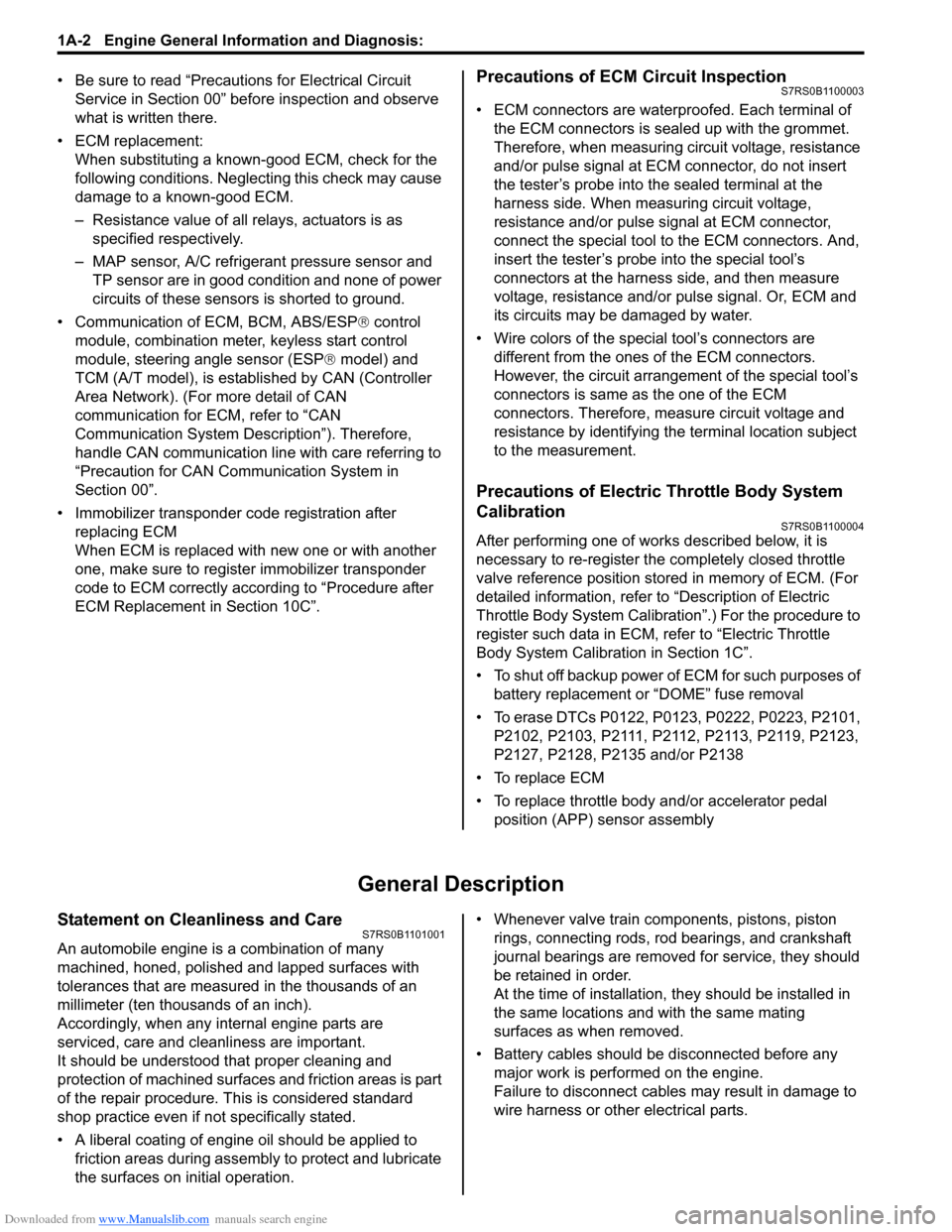

Clutch Fluid InspectionS7RS0B0206019

1) Check clutch system for evidence of fluid leakage. Repair leaky point if any.

2) Check reservoir for fluid level referring to “Clutch

Fluid Level Inspection in Section 5C”.

If fluid is lower than minimum level of reservoir, refill

reservoir with specified brake fluid indicated on

reservoir cap.

I7RW01020002-01

I4RS0A020009-01

I4RS0B020005-01

I4RS0A410006-01

Page 51 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-1

Engine

Engine General Information and Diagnosis

Precautions

Precautions on Engine ServiceS7RS0B1100001

CAUTION!

The following information on engine service

should be noted carefully, as it is important in

preventing damage, and in contributing to

reliable engine performance.

• When raising or supporting engine for any reason, do

not use a jack under oil pan. Due to small clearance

between oil pan and oil pump strainer, jacking against

oil pan may cause it to be bent against strainer,

resulting in damaged oil pick-up unit.

• It should be kept in mind , while working on engine,

that 12-volt electrical syste m is capable of violent and

damaging short circuits.

When performing any work where electrical terminals

can be grounded, ground cable of the battery should

be disconnected at battery.

• Any time the air cleaner, throttle body or intake manifold is removed, the intake opening should be

covered. This will protect against accidental entrance

of foreign material which could follow intake passage

into cylinder and cause extensive damage when

engine is started.

Precaution on On-Board Diagnostic (OBD)

System

S7RS0B1100005

There are two types of On -Board Diagnostic (OBD)

system, Euro OBD system and non-Euro-OBD system,

depending on the vehicle specification.

As the diagnosis function is different between these two

types, be sure to fully understand the OBD system

referring to “On-Board Diagnostic System Description”.

OBD System Summary Table

Precautions in Diagnosing TroubleS7RS0B1100002

NOTE

There are two types of OBD system

depending on the vehicle specification.

For details, refer to “Precaution on On-Board

Diagnostic (OBD) System”.

• Don’t disconnect couplers from ECM, battery cable

from battery, ECM ground wire harness from engine

or main fuse before confirming diagnostic information

(DTC, freeze frame data, etc.) stored in ECM memory.

Such disconnection will erase memorized information

in ECM memory.

• Diagnostic information stored in ECM memory can be cleared as well as checke d by using SUZUKI scan

tool or OBD generic scan tool. Before using scan tool,

read its Operator’s (Instruction) Manual carefully to

have good understanding as to what functions are

available and how to use it.

For Euro OBD model it is indistinguishable which

module turns on MIL because not only ECM but also

TCM (A/T model) turns on MIL (For details of on-

board diagnostic system for A/T model, refer to “On-

Board Diagnostic System Description in Section 5A”).

Therefore, check both ECM and TCM (A/T model) for

DTC when MIL lights on.

When checking ECM for DTC, keep in mind that DTC

is displayed on the scan tool as follows depending on

the scan tool used.

– SUZUKI scan tool displays DTC detected by ECM.

– OBD generic scan tool displays DTC detected by each of ECM and TCM (A/T model) simultaneously.

• Priorities for diagnosing troubles If two or more DTCs are stored, proceed to the DTC

flow which has been detected earliest in the order and

follow the instructi on in that flow.

If no instructions are given, troubleshoot DTCs

according to the following priorities.

a. DTCs other than DTC P0171 / P0172 (Fuel system too lean / too rich), DTC P0300 / P0301 /

P0302 / P0303 / P0304 (Misfire detected) and

DTC P0401 / P0402 (EGR flow malfunction)

b. DTC P0171 / P0172 (Fuel system too lean / too rich) and DTC P0401 / P0402 (EGR flow

malfunction)

c. DTC P0300 / P0301 / P0302 / P0303 / P0304 (Misfire detected)

Euro OBD

model Non-Euro-OBD

model

Quantity of DTC

related to engine

control Approx. 80 Approx. 60

Freeze frame

data Available Not available

SUZUKI scan

tool Available Available

OBD generic

scan tool Available Not available

Page 52 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-2 Engine General Information and Diagnosis:

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” befo re inspection and observe

what is written there.

• ECM replacement: When substituting a known-good ECM, check for the

following conditions. Neglec ting this check may cause

damage to a known-good ECM.

– Resistance value of all relays, actuators is as specified respectively.

– MAP sensor, A/C refrigerant pressure sensor and TP sensor are in good condition and none of power

circuits of these sensors is shorted to ground.

• Communication of ECM, BCM, ABS/ESP ® control

module, combination meter, keyless start control

module, steering angle sensor (ESP ® model) and

TCM (A/T model), is esta blished by CAN (Controller

Area Network). (For more detail of CAN

communication for ECM, refer to “CAN

Communication System Description”). Therefore,

handle CAN communication line with care referring to

“Precaution for CAN Communication System in

Section 00”.

• Immobilizer transponder code registration after

replacing ECM

When ECM is replaced with new one or with another

one, make sure to register immobilizer transponder

code to ECM correctly according to “Procedure after

ECM Replacement in Section 10C”.Precautions of ECM Circuit InspectionS7RS0B1100003

• ECM connectors are waterproofed. Each terminal of the ECM connectors is sealed up with the grommet.

Therefore, when measuring ci rcuit voltage, resistance

and/or pulse signal at ECM connector, do not insert

the tester’s probe into th e sealed terminal at the

harness side. When measuring circuit voltage,

resistance and/or pulse signal at ECM connector,

connect the special tool to the ECM connectors. And,

insert the tester’s probe into the special tool’s

connectors at the harness side, and then measure

voltage, resistance and/or pulse signal. Or, ECM and

its circuits may be damaged by water.

• Wire colors of the special tool’s connectors are different from the ones of the ECM connectors.

However, the circuit arrangement of the special tool’s

connectors is same as the one of the ECM

connectors. Therefore, measure circuit voltage and

resistance by identifying the terminal location subject

to the measurement.

Precautions of Electric Throttle Body System

Calibration

S7RS0B1100004

After performing one of works described below, it is

necessary to re-register the completely closed throttle

valve reference position stored in memory of ECM. (For

detailed information, refer to “Description of Electric

Throttle Body System Calibration”.) For the procedure to

register such data in ECM, refer to “Electric Throttle

Body System Calibration in Section 1C”.

• To shut off backup power of ECM for such purposes of battery replacement or “DOME” fuse removal

• To erase DTCs P0122, P01 23, P0222, P0223, P2101,

P2102, P2103, P2111, P2112, P2113, P2119, P2123,

P2127, P2128, P2135 and/or P2138

• To replace ECM

• To replace throttle body and/or accelerator pedal position (APP) sensor assembly

General Description

Statement on Cleanliness and CareS7RS0B1101001

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the thousands of an

millimeter (ten thous ands of an inch).

Accordingly, when any internal engine parts are

serviced, care and cleanliness are important.

It should be understood that proper cleaning and

protection of machined surfaces and friction areas is part

of the repair procedure. This is considered standard

shop practice even if not specifically stated.

• A liberal coating of engine oil should be applied to friction areas during assembly to protect and lubricate

the surfaces on initial operation. • Whenever valve train components, pistons, piston

rings, connecting rods, rod bearings, and crankshaft

journal bearings are removed for service, they should

be retained in order.

At the time of installation, they should be installed in

the same locations and with the same mating

surfaces as when removed.

• Battery cables should be disconnected before any major work is performed on the engine.

Failure to disconnect cables may result in damage to

wire harness or other electrical parts.

Page 72 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-22 Engine General Information and Diagnosis:

Diagnostic Information and Procedures

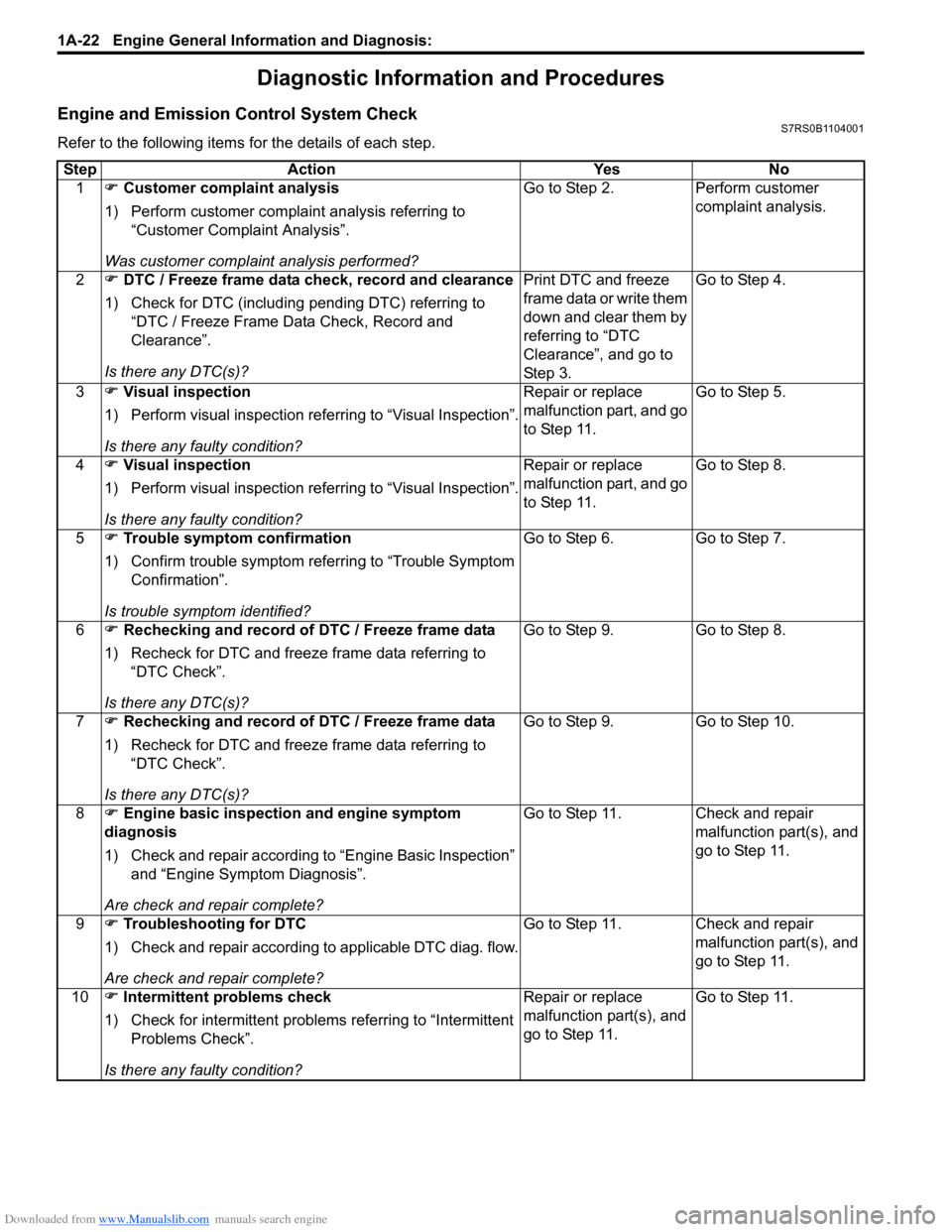

Engine and Emission Control System CheckS7RS0B1104001

Refer to the following items for the details of each step.Step Action Yes No 1 �) Customer complaint analysis

1) Perform customer complaint analysis referring to “Customer Complaint Analysis”.

Was customer complaint analysis performed? Go to Step 2. Perform customer

complaint analysis.

2 �) DTC / Freeze frame data check, record and clearance

1) Check for DTC (including pending DTC) referring to “DTC / Freeze Frame Data Check, Record and

Clearance”.

Is there any DTC(s)? Print DTC and freeze

frame data or write them

down and clear them by

referring to “DTC

Clearance”, and go to

St ep 3 .Go to Step 4.

3 �) Visual inspection

1) Perform visual inspection referring to “Visual Inspection”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 11.

Go to Step 5.

4 �) Visual inspection

1) Perform visual inspection referring to “Visual Inspection”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 11.

Go to Step 8.

5 �) Trouble symptom confirmation

1) Confirm trouble symptom referring to “Trouble Symptom Confirmation”.

Is trouble symptom identified? Go to Step 6.

Go to Step 7.

6 �) Rechecking and record of DTC / Freeze frame data

1) Recheck for DTC and freeze frame data referring to “DTC Check”.

Is there any DTC(s)? Go to Step 9.

Go to Step 8.

7 �) Rechecking and record of DTC / Freeze frame data

1) Recheck for DTC and freeze frame data referring to “DTC Check”.

Is there any DTC(s)? Go to Step 9.

Go to Step 10.

8 �) Engine basic inspection and engine symptom

diagnosis

1) Check and repair according to “Engine Basic Inspection”

and “Engine Symptom Diagnosis”.

Are check and repair complete? Go to Step 11. Check and repair

malfunction part(s), and

go to Step 11.

9 �) Troubleshooting for DTC

1) Check and repair according to applicable DTC diag. flow.

Are check and repair complete? Go to Step 11. Check and repair

malfunction part(s), and

go to Step 11.

10 �) Intermittent problems check

1) Check for intermittent problems referring to “Intermittent Problems Check”.

Is there any faulty condition? Repair or replace

malfunction part(s), and

go to Step 11.

Go to Step 11.

Page 75 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-25

Step 2: DTC / Freeze Frame Data Check, Record and

Clearance

First, check DTC (including pending DTC), referring to

“DTC Check”. If DTC is indicated, print it and freeze

frame data or write them down and then clear them by

referring to “DTC Clearance”. DTC indicates malfunction

that occurred in the system but does not indicate

whether it exists now or it occurred in the past and the

normal condition has been restored now. To check which

case applies, check the sy mptom in question according

to Step 5 and recheck DTC according to Step 6 and 7.

Attempt to diagnose a trouble based on DTC in this step

only or failure to clear the DTC in this step will lead to

incorrect diagnosis, trouble diagnosis of a normal circuit

or difficulty in troubleshooting.

Step 3 and 4: Visual Inspection

As a preliminary step, be sure to perform visual check of

the items that support proper function of the engine

referring to “Visual Inspection”.

Step 5: Trouble Symptom Confirmation

Based on information obtained in “Step 1: Customer

Complaint Analysis: ” and “Step 2: DTC / Freeze Frame

Data Check, Record and Clearance: ”, confirm trouble

symptoms. Also, reconfirm DTC according to “DTC

Confirmation Procedure” described in each DTC diag.

flow.

Step 6 and 7: Rechecking and Record of DTC /

Freeze Frame Data

Refer to “DTC Check” for checking procedure.

Step 8: Engine Basic Inspection and Engine

Symptom Diagnosis

Perform basic engine check according to “Engine Basic

Inspection” first. When the end of the flow has been

reached, check the parts of the system suspected as a

possible cause referring to “Engine Symptom Diagnosis”

and based on symptoms appearing on the vehicle

(symptoms obtained through steps of customer

complaint analysis, trouble symptom confirmation and/or

basic engine check) and repair or replace faulty parts, if

any.

Step 9: Troubleshooting for DTC (See each DTC

Diag. Flow)

Based on the DTC indicated in Step 6 or 7 and referring

to the applicable DTC diag. flow, locate the cause of the

trouble, namely in a sensor, switch, wire harness,

connector, actuator, ECM or other part and repair or

replace faulty parts. Step 10: Intermittent Problems Check

Check parts where an intermit

tent trouble is easy to

occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connec tion Inspection in Section

00” and related circuit of DTC recorded in Step 2.

Step 11: Final Confirmation Test

Confirm that the problem symptom has gone and the

engine is free from any abnormal conditions. If what has

been repaired is re lated to the DTC, clear the DTC once,

perform DTC confirmation procedure and confirm that no

DTC is indicated.

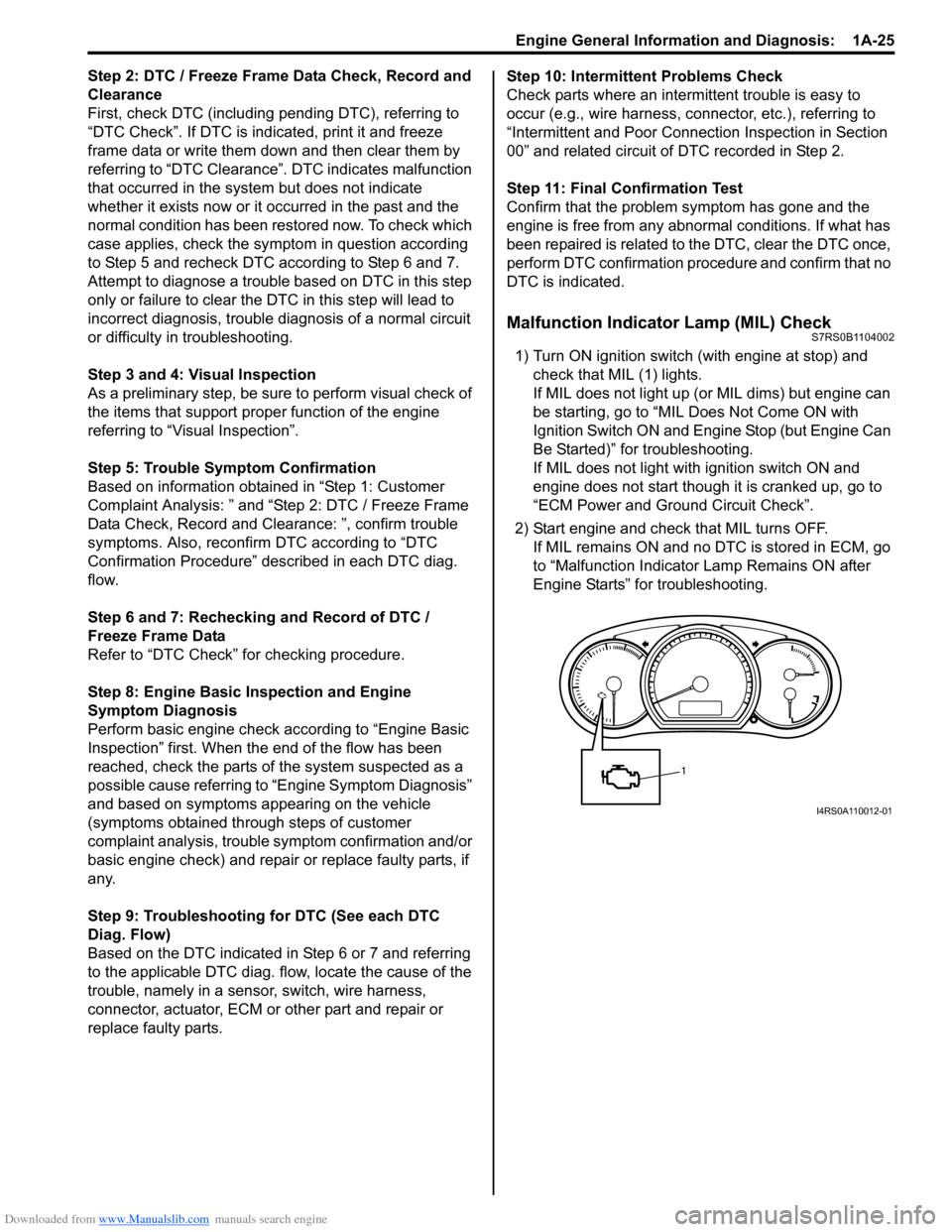

Malfunction Indicator Lamp (MIL) CheckS7RS0B1104002

1) Turn ON ignition switch (with engine at stop) and check that MIL (1) lights.

If MIL does not light up (or MIL dims) but engine can

be starting, go to “MIL Does Not Come ON with

Ignition Switch ON and Engine Stop (but Engine Can

Be Started)” for troubleshooting.

If MIL does not light with ignition switch ON and

engine does not start though it is cranked up, go to

“ECM Power and Ground Circuit Check”.

2) Start engine and check that MIL turns OFF. If MIL remains ON and no DTC is stored in ECM, go

to “Malfunction Indicator Lamp Remains ON after

Engine Starts” for troubleshooting.

1

I4RS0A110012-01

Page 76 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-26 Engine General Information and Diagnosis:

DTC CheckS7RS0B1104003

NOTE

• There are two types of OBD system depending on the vehicle specification.

For details, refer to “Precaution on On-

Board Diagnostic (OBD) System”.

• The MIL is turned on when the ECM and/or TCM detect malfunction(s). Each ECM and

TCM stores diagnostic information as the

diagnostic trouble code (DTC) in its

memory and outputs th e DTC to the scan

tool.

Therefore, check both of the ECM and TCM

for any DTC with the SUZUKI scan tool

because the DTC stored in ECM and TCM

is not read and displayed at a time.

However, each of the ECM and TCM needs

not to be checked with the generic scan

tool because the DTC stored in ECM and

TCM is read and displayed at a time.

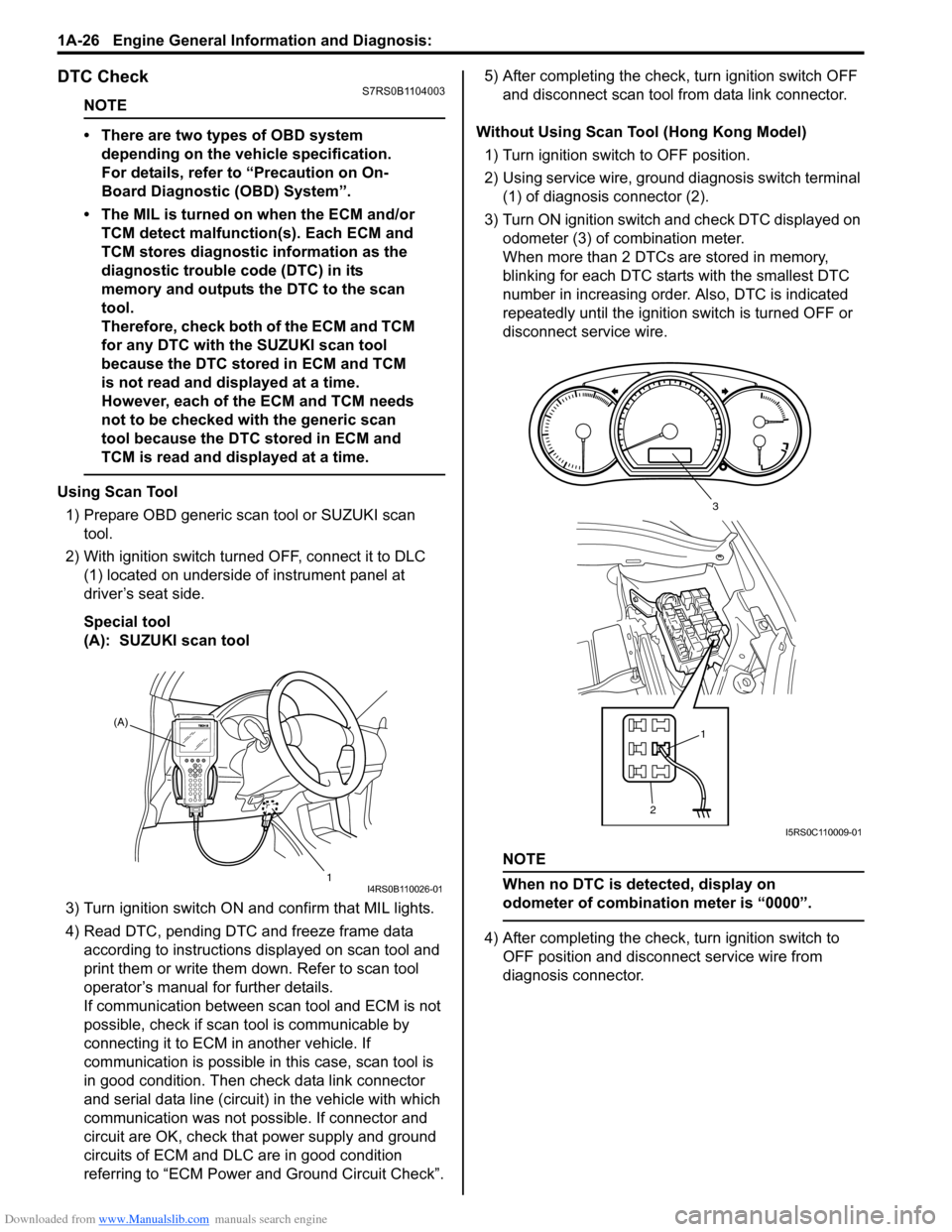

Using Scan Tool

1) Prepare OBD generic scan tool or SUZUKI scan tool.

2) With ignition switch turned OFF, connect it to DLC (1) located on underside of instrument panel at

driver’s seat side.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch ON and confirm that MIL lights.

4) Read DTC, pending DTC and freeze frame data according to instructions displayed on scan tool and

print them or write them down. Refer to scan tool

operator’s manual for further details.

If communication between scan tool and ECM is not

possible, check if scan tool is communicable by

connecting it to ECM in another vehicle. If

communication is possible in this case, scan tool is

in good condition. Then check data link connector

and serial data line (circuit) in the vehicle with which

communication was not possible. If connector and

circuit are OK, check that power supply and ground

circuits of ECM and DLC are in good condition

referring to “ECM Power and Ground Circuit Check”. 5) After completing the check,

turn ignition switch OFF

and disconnect scan tool from data link connector.

Without Using Scan Tool (Hong Kong Model) 1) Turn ignition switch to OFF position.

2) Using service wire, ground diagnosis switch terminal (1) of diagnosis connector (2).

3) Turn ON ignition switch and check DTC displayed on

odometer (3) of combination meter.

When more than 2 DTCs are stored in memory,

blinking for each DTC star ts with the smallest DTC

number in increasing order. Also, DTC is indicated

repeatedly until the ignition switch is turned OFF or

disconnect service wire.

NOTE

When no DTC is detected, display on

odometer of combinatio n meter is “0000”.

4) After completing the check, turn ignition switch to

OFF position and disconnect service wire from

diagnosis connector.

(A)

1

I4RS0B110026-01

21

3

I5RS0C110009-01

Page 77 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-27

DTC ClearanceS7RS0B1104004

NOTE

There are two types of OBD system

depending on the vehicle specification.

For details, refer to “Precaution on On-Board

Diagnostic (OBD) System”.

Using Scan Tool1) Connect OBD generic scan to ol or SUZUKI scan tool

to data link connector in the same manner as when

making this connection for DTC check.

2) Turn ignition switch OFF and then ON.

3) Erase DTC and pending DTC according to instructions displayed on scan tool. Refer to scan

tool operator’s manual for further details.

4) After completing the clear ance, turn ignition switch

OFF and disconnect scan tool from data link

connector.

NOTE

DTC and freeze frame data stored in ECM

memory are also cleared in the following

cases. Be careful not to clear them before

keeping their record.

• When power to ECM is cut off (by disconnecting battery cable, removing

fuse or disconnecting ECM connectors).

• When the same malfunction (DTC) is not detected again during 40 engine warm-up

cycles. (See “Warm-Up Cycle” of “On-

Board Diagnostic System Description”.)

Without Using Scan Tool (Hong Kong Model)

1) Turn ignition switch to OFF position.

2) Disconnect battery negative cable for specified time below to erase diagnostic trouble code stored in

ECM memory and reconnect it.

Time required to erase DTC

DTC TableS7RS0B1104005

NOTE

• There are two types of OBD system depending on the vehicle specification.

• For details, refer to “Precaution on On-Board Diagnostic (OBD) System”.

• For non-Euro-OBD model, some of DTC No. with delta ( �U) mark in the following table can not be

detected by ECM depending on vehicl e specification and local regulation.

• DTC with square ( �†) mark in the following table can be detected only for Hong Kong model.

• DTC with circle ( �{) mark in the following table can be detected only for Euro OBD model and Hong

Kong model.

• For Euro OBD model, with the generic scan tool, onl y star (*) marked DTC No. in the following table

can be read.

• 1 driving cycle: MIL lights up when DTC is detected during 1 driving cycle.

• 2 driving cycles: MIL lights up when the same DTC is detected also in the next driving cycle after DTC is detected and stored temporarily in the first driving cycle.

• *2 driving cycles: MIL blinks or lights up. Refer to “DTC P0300 / P0301 / P0302 / P0303 / P0304: Random / Multiple

Cylinder Misfire Detected / Cylinder 1 / Cylinder 2 / Cylinder 3 / Cylinder 4 Misfire Detected” for

details.

Ambient temperature Time to cut power to ECM

Over 0 °C (32 ° F) 30 sec. or longer

Under 0 °C (32 °F) Not specifiable.

Select a place with higher

than 0 °C (32 °F)

temperature.

DTC No. Detecting item Detecting condition

(DTC will set when detecting:) MIL

�) *P0010 “A” camshaft position actuator

circuit Oil control valve circuit open or short. 1 driving

cycle

�) *P0011 “A” camshaft position – timing

over-advanced or system

performance Actual value of advanced va

lve timing does not reach

target value, or valve timi ng is advanced although ECM

command is most retarding. 2 driving

cycles

�) *P0012 “A” camshaft position – timing

over-retarded 2 driving

cycles

Page 98 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-48 Engine General Information and Diagnosis:

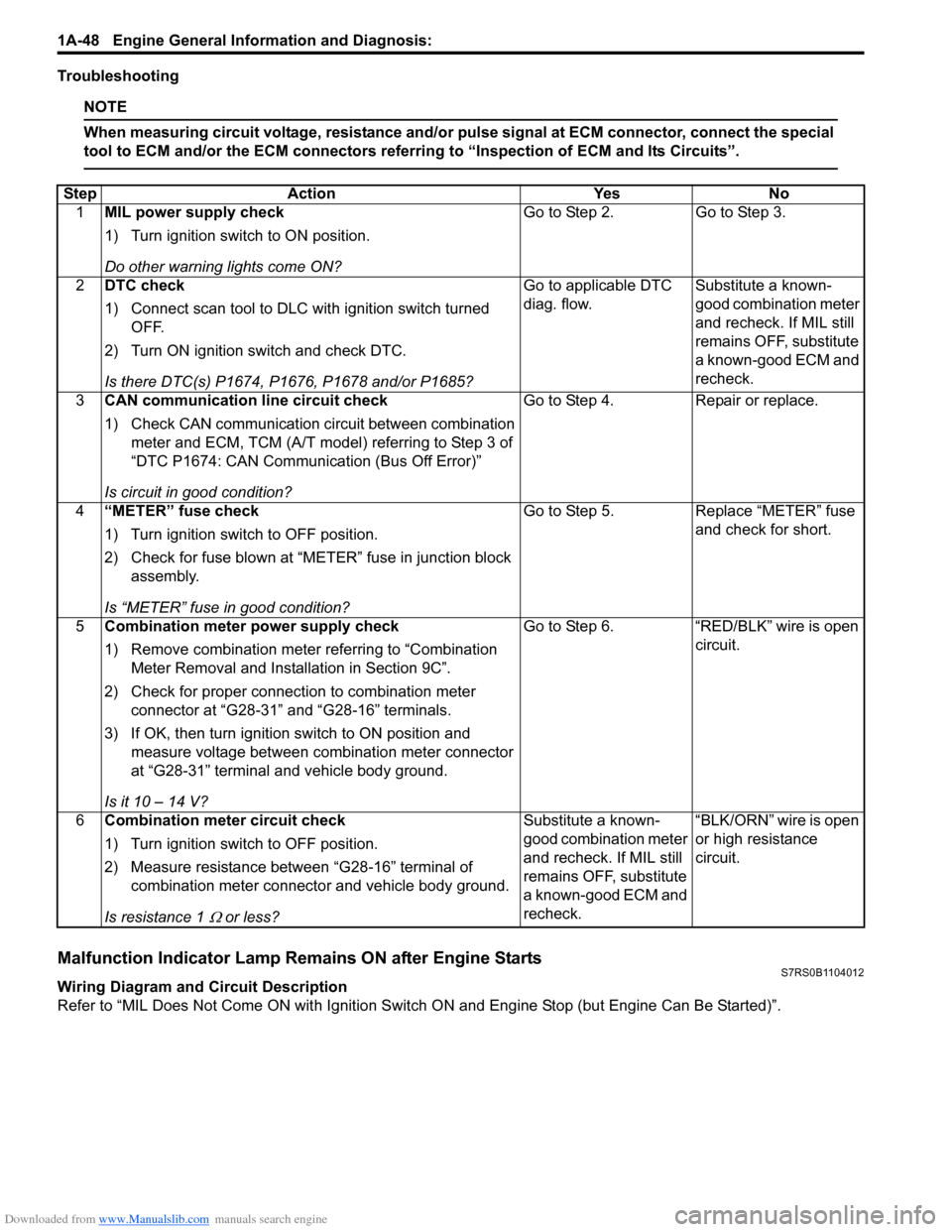

Troubleshooting

NOTE

When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the special

tool to ECM and/or the ECM connectors referri ng to “Inspection of ECM and Its Circuits”.

Malfunction Indicator Lamp Remains ON after Engine StartsS7RS0B1104012

Wiring Diagram and Circuit Description

Refer to “MIL Does Not Come ON wit h Ignition Switch ON and Engine Stop (but Engine Can Be Started)”.

Step

Action YesNo

1 MIL power supply check

1) Turn ignition switch to ON position.

Do other warning lights come ON? Go to Step 2.

Go to Step 3.

2 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch and check DTC.

Is there DTC(s) P1674, P1676, P1678 and/or P1685? Go to applicable DTC

diag. flow.

Substitute a known-

good combination meter

and recheck. If MIL still

remains OFF, substitute

a known-good ECM and

recheck.

3 CAN communication line circuit check

1) Check CAN communication circuit between combination

meter and ECM, TCM (A/T model) referring to Step 3 of

“DTC P1674: CAN Communication (Bus Off Error)”

Is circuit in good condition? Go to Step 4.

Repair or replace.

4 “METER” fuse check

1) Turn ignition switch to OFF position.

2) Check for fuse blown at “M ETER” fuse in junction block

assembly.

Is “METER” fuse in good condition? Go to Step 5.

Replace “METER” fuse

and check for short.

5 Combination meter power supply check

1) Remove combination meter referring to “Combination

Meter Removal and Installation in Section 9C”.

2) Check for proper connection to combination meter connector at “G28-31” and “G28-16” terminals.

3) If OK, then turn ignition switch to ON position and measure voltage between combination meter connector

at “G28-31” terminal and vehicle body ground.

Is it 10 – 14 V? Go to Step 6.

“RED/BLK” wire is open

circuit.

6 Combination meter circuit check

1) Turn ignition switch to OFF position.

2) Measure resistance between “G28-16” terminal of

combination meter connector and vehicle body ground.

Is resistance 1

Ω or less? Substitute a known-

good combination meter

and recheck. If MIL still

remains OFF, substitute

a known-good ECM and

recheck.

“BLK/ORN” wire is open

or high resistance

circuit.

Page 115 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-65

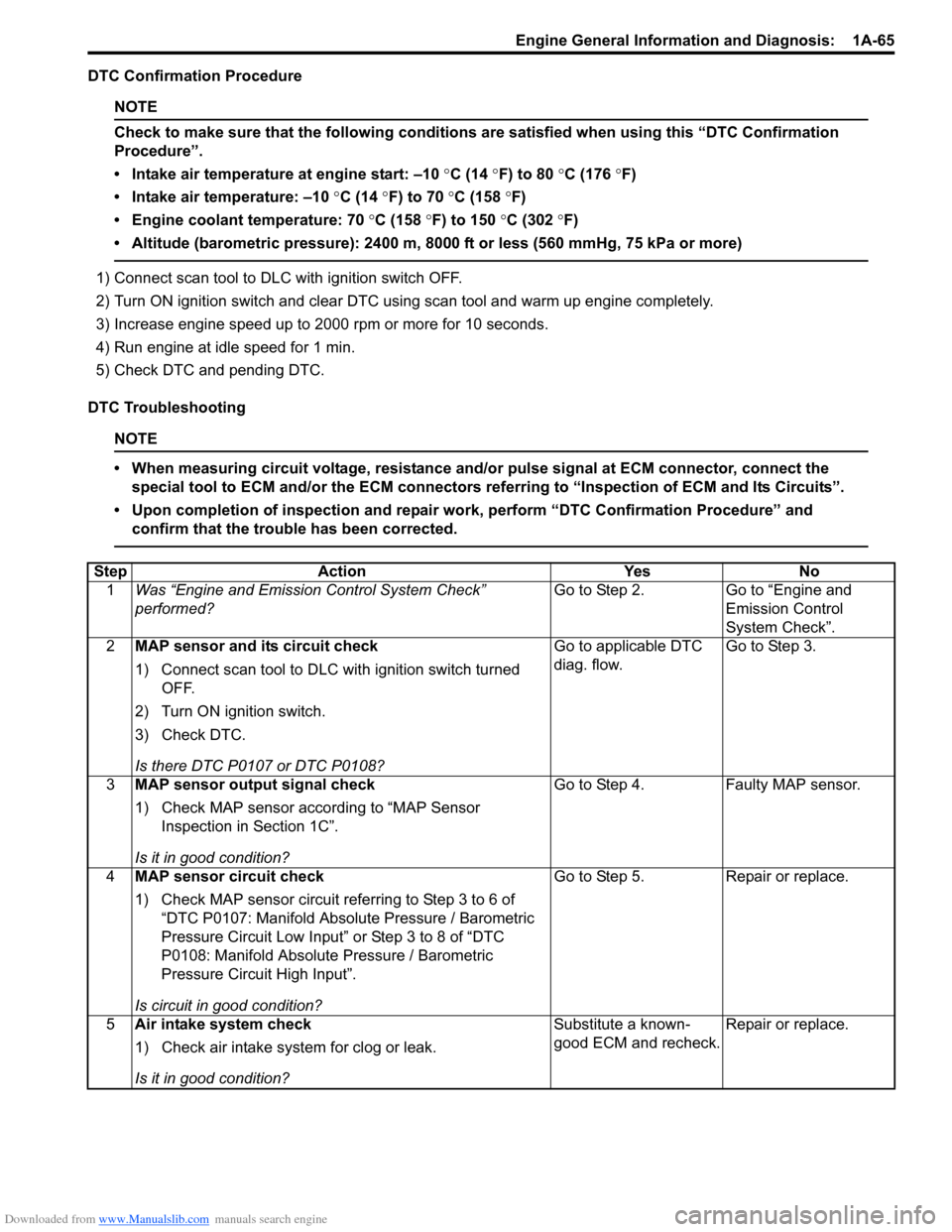

DTC Confirmation Procedure

NOTE

Check to make sure that the following conditions are satisfied when using this “DTC Confirmation

Procedure”.

• Intake air temperature at engine start: –10 °C (14 ° F) to 80 °C (176 °F)

• Intake air temperature: –10 °C (14 °F) to 70 °C (158 °F)

• Engine coolant temperature: 70 °C (158 °F) to 150 °C (302 °F)

• Altitude (barometric pressure): 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

1) Connect scan tool to DLC with ignition switch OFF.

2) Turn ON ignition switch and clear DTC using scan tool and warm up engine completely.

3) Increase engine speed up to 2000 rpm or more for 10 seconds.

4) Run engine at idle speed for 1 min.

5) Check DTC and pending DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 MAP sensor and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch.

3) Check DTC.

Is there DTC P0107 or DTC P0108? Go to applicable DTC

diag. flow.

Go to Step 3.

3 MAP sensor output signal check

1) Check MAP sensor acco rding to “MAP Sensor

Inspection in Section 1C”.

Is it in good condition? Go to Step 4.

Faulty MAP sensor.

4 MAP sensor circuit check

1) Check MAP sensor circuit referring to Step 3 to 6 of

“DTC P0107: Manifold Absolute Pressure / Barometric

Pressure Circuit Low Input” or Step 3 to 8 of “DTC

P0108: Manifold Absolute Pressure / Barometric

Pressure Circuit High Input”.

Is circuit in good condition? Go to Step 5.

Repair or replace.

5 Air intake system check

1) Check air intake system for clog or leak.

Is it in good condition? Substitute a known-

good ECM and recheck.

Repair or replace.

Page 139 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-89

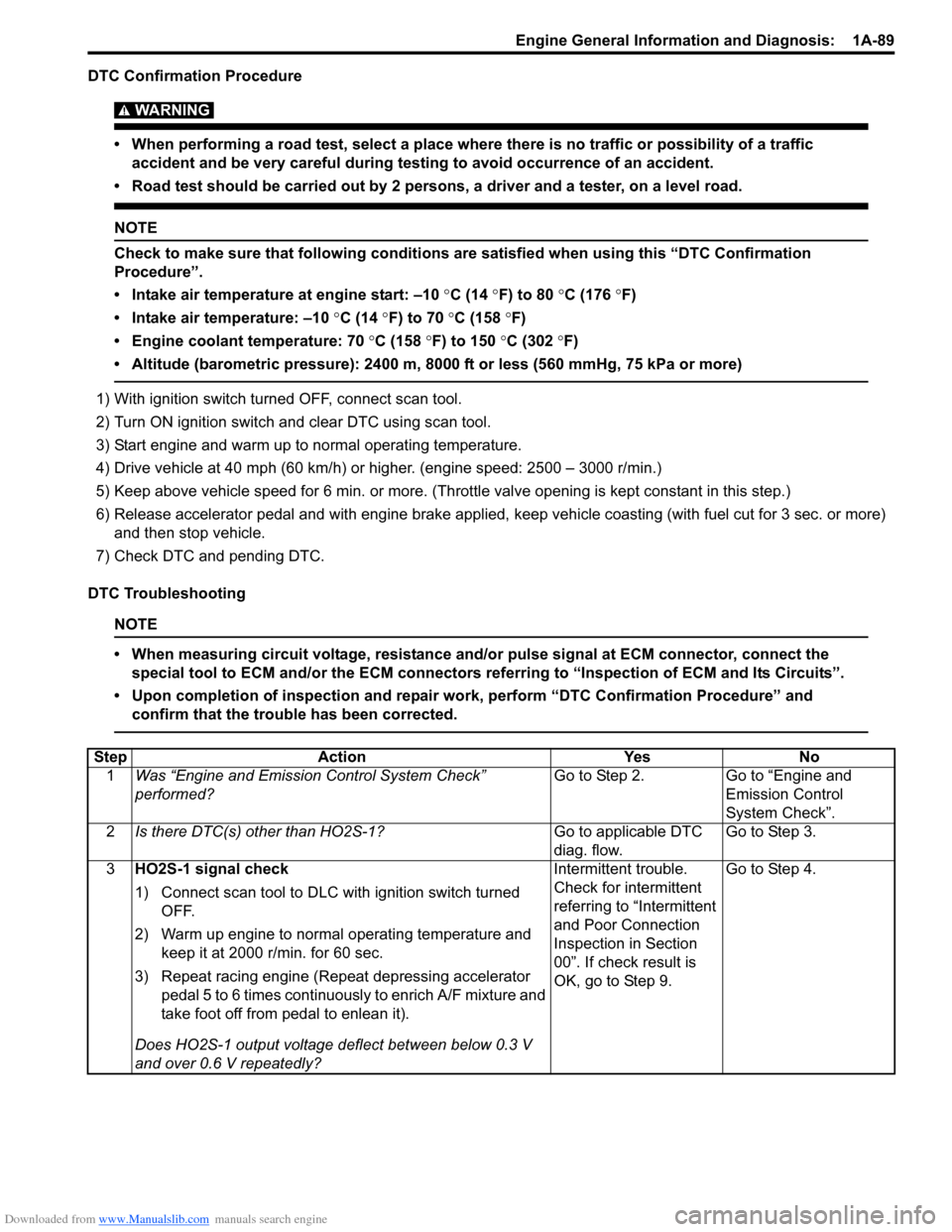

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

NOTE

Check to make sure that following conditions ar e satisfied when using this “DTC Confirmation

Procedure”.

• Intake air temperature at engine start: –10 °C (14 ° F) to 80 °C (176 °F)

• Intake air temperature: –10 °C (14 °F) to 70 °C (158 °F)

• Engine coolant temperature: 70 °C (158 °F) to 150 °C (302 °F)

• Altitude (barometric pressure): 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Start engine and warm up to normal operating temperature.

4) Drive vehicle at 40 mph (60 km/h) or higher. (engine speed: 2500 – 3000 r/min.)

5) Keep above vehicle speed for 6 min. or more. (Throt tle valve opening is kept constant in this step.)

6) Release accelerator pedal and with engine brake applied, keep vehicle coasting (with fuel cut for 3 sec. or more)

and then stop vehicle.

7) Check DTC and pending DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Is there DTC(s) other than HO2S-1? Go to applicable DTC

diag. flow.Go to Step 3.

3 HO2S-1 signal check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Warm up engine to normal operating temperature and keep it at 2000 r/min. for 60 sec.

3) Repeat racing engine (Repeat depressing accelerator pedal 5 to 6 times continuous ly to enrich A/F mixture and

take foot off from pedal to enlean it).

Does HO2S-1 output voltage deflect between below 0.3 V

and over 0.6 V repeatedly? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”. If check result is

OK, go to Step 9.

Go to Step 4.