Cable SUZUKI SWIFT 2008 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 373 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Cooling System: 1F-10

Radiator Cooling Fan Removal and InstallationS7RS0B1606011

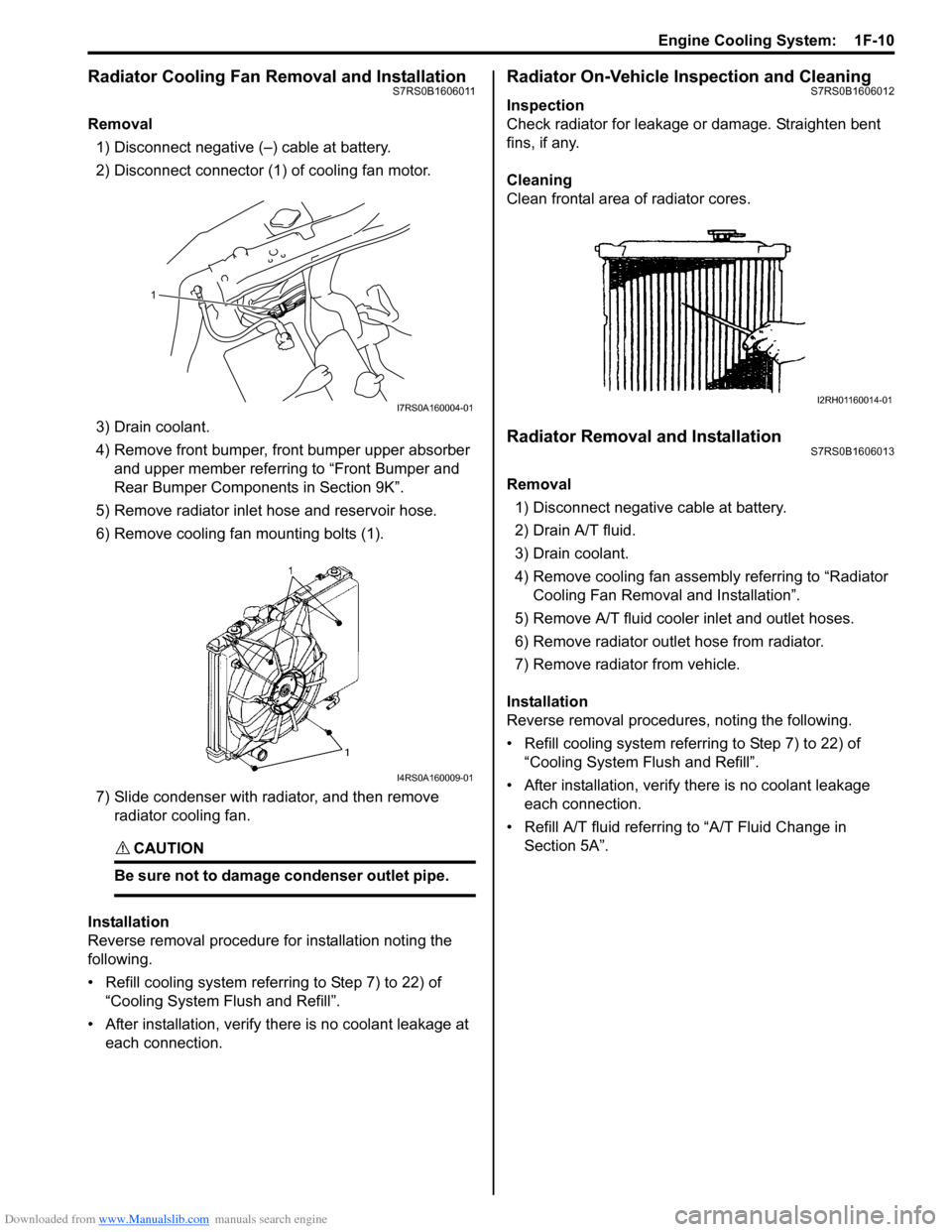

Removal1) Disconnect negative (–) cable at battery.

2) Disconnect connector (1) of cooling fan motor.

3) Drain coolant.

4) Remove front bumper, front bumper upper absorber and upper member referring to “Front Bumper and

Rear Bumper Componen ts in Section 9K”.

5) Remove radiator inlet hose and reservoir hose.

6) Remove cooling fan mounting bolts (1).

7) Slide condenser with radiator, and then remove radiator cooling fan.

CAUTION!

Be sure not to damage condenser outlet pipe.

Installation

Reverse removal procedure for installation noting the

following.

• Refill cooling system referring to Step 7) to 22) of “Cooling System Fl ush and Refill”.

• After installation, verify there is no coolant leakage at each connection.

Radiator On-Vehicle Inspection and CleaningS7RS0B1606012

Inspection

Check radiator for leakage or damage. Straighten bent

fins, if any.

Cleaning

Clean frontal area of radiator cores.

Radiator Removal and InstallationS7RS0B1606013

Removal

1) Disconnect negative cable at battery.

2) Drain A/T fluid.

3) Drain coolant.

4) Remove cooling fan assemb ly referring to “Radiator

Cooling Fan Removal and Installation”.

5) Remove A/T fluid cooler inlet and outlet hoses.

6) Remove radiator outlet hose from radiator.

7) Remove radiator from vehicle.

Installation

Reverse removal procedures, noting the following.

• Refill cooling system referrin g to Step 7) to 22) of

“Cooling System Flush and Refill”.

• After installation, verify there is no coolant leakage each connection.

• Refill A/T fluid referring to “A/T Fluid Change in

Section 5A”.

1

I7RS0A160004-01

I4RS0A160009-01

I2RH01160014-01

Page 374 of 1496

Downloaded from www.Manualslib.com manuals search engine 1F-11 Engine Cooling System:

Water Pump Removal and InstallationS7RS0B1606014

Removal1) Disconnect negative cable at battery.

2) Drain coolant.

3) Remove water pump / generator drive belt referring to “Water Pump / Generator Drive Belt Removal and

Installation in Section 1J”.

4) Remove water pump assembly (1).

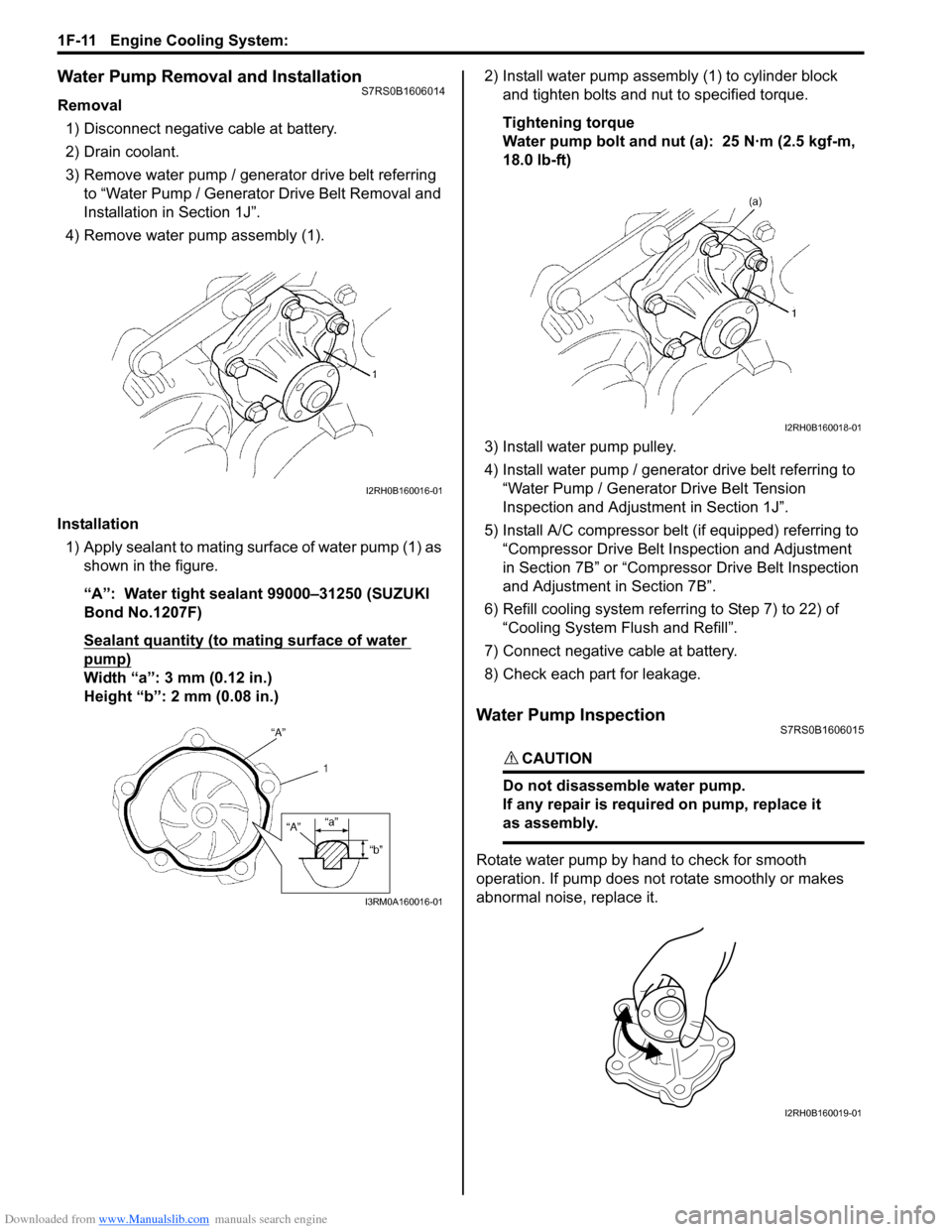

Installation 1) Apply sealant to mating surface of water pump (1) as shown in the figure.

“A”: Water tight sealant 99000–31250 (SUZUKI

Bond No.1207F)

Sealant quantity (to mating surface of water

pump)

Width “a”: 3 mm (0.12 in.)

Height “b”: 2 mm (0.08 in.) 2) Install water pump assemb

ly (1) to cylinder block

and tighten bolts and nut to specified torque.

Tightening torque

Water pump bolt and nut (a): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

3) Install water pump pulley.

4) Install water pump / generator drive belt referring to “Water Pump / Generator Drive Belt Tension

Inspection and Adjustment in Section 1J”.

5) Install A/C compressor belt (if equipped) referring to “Compressor Drive Belt Inspection and Adjustment

in Section 7B” or “Compressor Drive Belt Inspection

and Adjustment in Section 7B”.

6) Refill cooling system referri ng to Step 7) to 22) of

“Cooling System Flush and Refill”.

7) Connect negative cable at battery.

8) Check each part for leakage.

Water Pump InspectionS7RS0B1606015

CAUTION!

Do not disassemble water pump.

If any repair is requir ed on pump, replace it

as assembly.

Rotate water pump by hand to check for smooth

operation. If pump does not rotate smoothly or makes

abnormal noise, replace it.

I2RH0B160016-01

I3RM0A160016-01

I2RH0B160018-01

I2RH0B160019-01

Page 376 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-1 Fuel System:

Engine

Fuel System

Precautions

Precautions on Fuel System ServiceS7RS0B1700001

WARNING!

Before attempting service of any type on fuel system, the following should be always observed in

order to reduce the risk of fire and personal injury.

• Disconnect negative cable at battery.

• Do not smoke, and place no smoking signs near work area.

• Be sure to have CO

2 fire extinguisher handy.

• Be sure to perform work in a well-ventilated area and away from any open flames (such as gas hot heater).

• Wear safety glasses.

• To relieve fuel vapor pressure in fuel tank, remove fuel filler cap from fuel filler neck and then

reinstall it.

• As fuel feed line is still under high fuel pr essure even after stopping engine, loosening or

disconnecting fuel feed line directly may cause dangerous spout of fuel. Before loosening or

disconnecting fuel feed line, make sure to relieve fuel pressure referring to “Fuel Pressure Relief

Procedure”.

• A small amount of fuel may be released when the fuel line is disconnected. In order to reduce the risk of personal injury, cover a shop cloth to the fitting to be disconnected. Be sure to put that cloth

in an approved container after disconnecting.

• Never run engine with fuel pump relay disconnected when engine and exhaust system are hot.

• Note that fuel hose connection varies with each type of pipe. Be sure to connect and clamp each hose correctly referring to “Fuel Hose Disconnecting and Reconnecting”.

After connecting, make sure that it has no twist or kink.

• When installing inje ctor or fuel feed pipe, lubr icate its O-ring with gasoline.

General Description

Fuel System DescriptionS7RS0B1701001

CAUTION!

This engine requires the unleaded fuel only.

The leaded and/or low lead fuel can result in

engine damage and reduce the effectiveness

of the emission control system.

The main components of the fuel system are fuel tank,

fuel pump assembly (with fuel filter, fuel level gauge, fuel

pressure regulator, fuel feed line and fuel vapor line.

For the details of fuel flow, refer to “Fuel Delivery System

Diagram”.

Fuel Delivery System DescriptionS7RS0B1701002

The fuel delivery system consists of the fuel tank, fuel

pump assembly (with built-in f uel filter and fuel pressure

regulator), delivery pipe, injectors and fuel feed line.

The fuel in the fuel tank is pumped up by the fuel pump,

sent into delivery pipe and injected by the injectors.

As the fuel pump assembly is equipped with built-in fuel

filter and fuel pressure regulator, the fuel is filtered and

its pressure is regulated before being sent to the feed

pipe.

The excess fuel at fuel pressure regulation process is

returned back into the fuel tank.

Also, fuel vapor generated in fuel tank is led through the

fuel vapor line into the EVAP canister.

For system diagram, refer to “Fuel Delivery System

Diagram”.

Page 382 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-7 Fuel System:

Fuel Pressure Relief ProcedureS7RS0B1706003

CAUTION!

This work must not be done when engine is

hot. If done so, it may cause adverse effect to

catalyst.

NOTE

If ECM detects DTC(s) after servicing, clear

DTC(s) referring to “DTC Clearance in

Section 1A”.

1) Make sure that engine is cold.

2) Shift transaxle gear shift lever in “Neutral” (shift select lever in “P” range for A/T model), set parking

brake and block drive wheels.

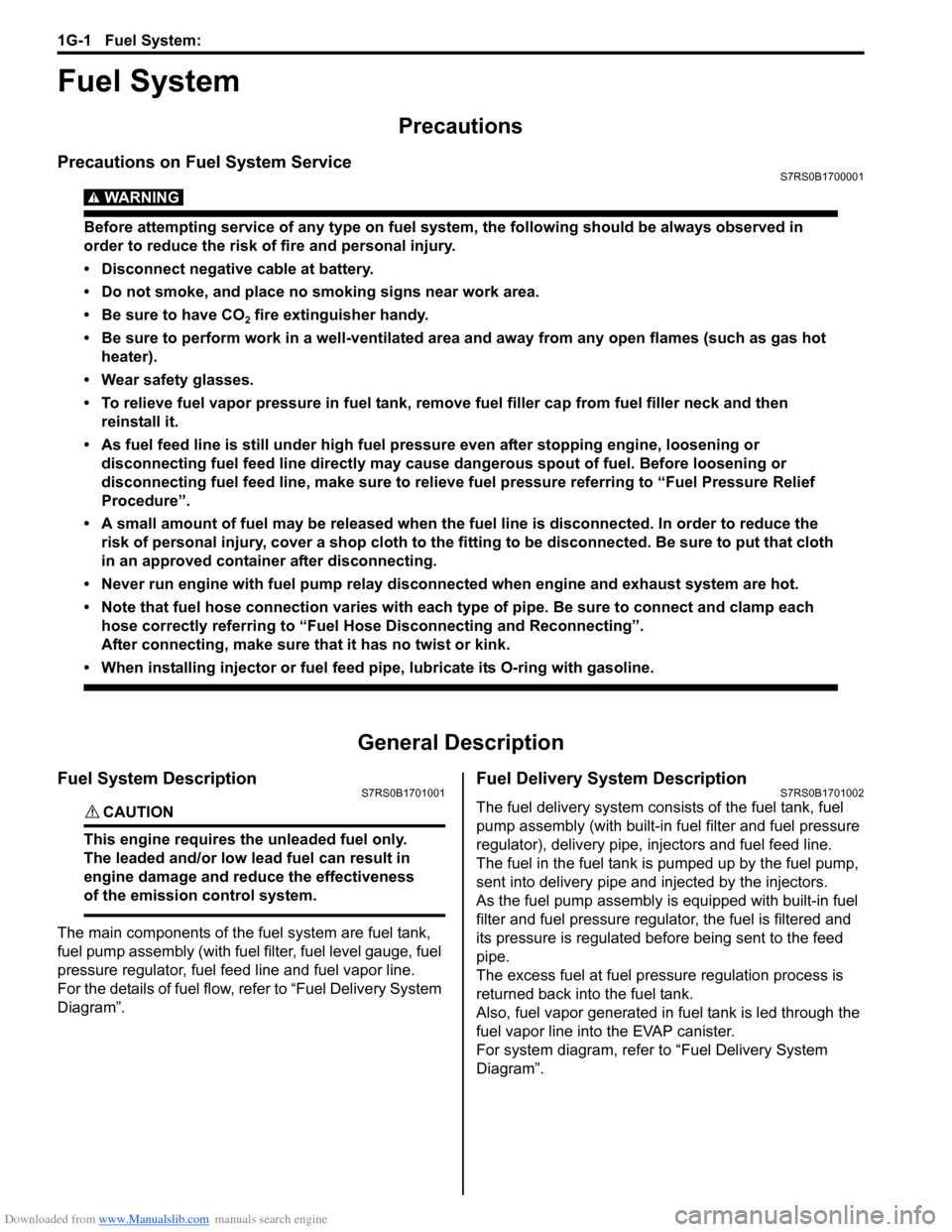

3) Remove relay / fuse box cover.

4) Disconnect fuel pump relay (1) from relay / fuse box (2).

5) Remove fuel filter cap in order to release fuel vapor pressure in fuel tank, and then reinstall it.

6) Start engine and run it until engine stops for lack of fuel. Repeat cranking engine 2 – 3 times for about 3

seconds each time in order to dissipate fuel pressure

in lines. Fuel connections are now safe for servicing.

7) After servicing, connect fuel pump relay (1) to relay / fuse box and install re lay / fuse box cover.

Fuel Leakage Check ProcedureS7RS0B1706004

After performing any service on fuel system, check to

make sure that there are no fuel leakages as follows.

1) Turn ON ignition switch for 3 seconds (to operate fuel pump) and then turn it OFF.

Repeat this (ON and OFF) 3 or 4 times and apply

fuel pressure to fuel line until fuel pressure is felt by

hand placed on fuel feed hose.

2) In this state, check to see that there are no fuel leakages from any part of fuel system.

Fuel Lines On-Vehicle InspectionS7RS0B1706005

CAUTION!

Due to the fact that fuel feed line (1) is under

high pressure, use special care when

servicing it.

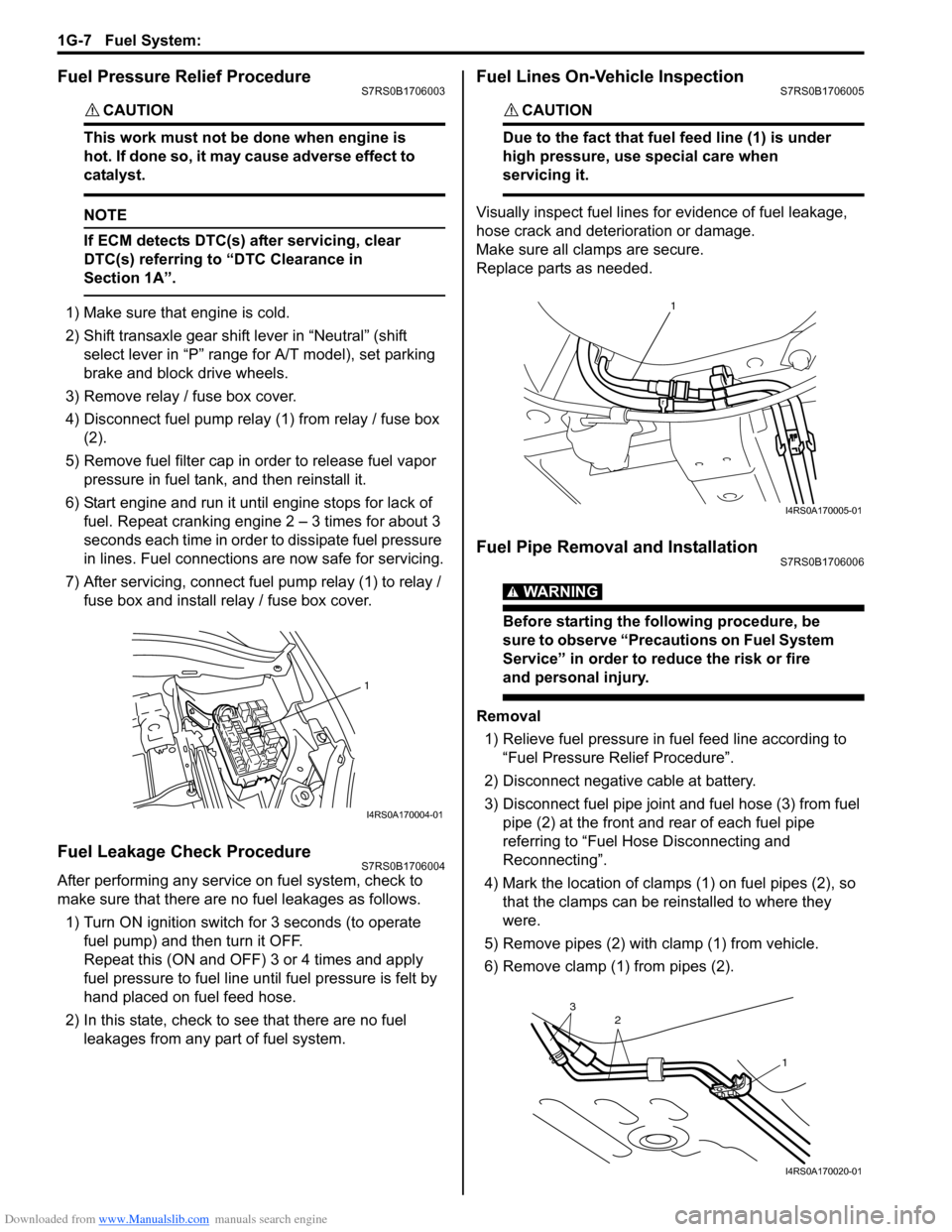

Visually inspect fuel lines for evidence of fuel leakage,

hose crack and deterioration or damage.

Make sure all cl amps are secure.

Replace parts as needed.

Fuel Pipe Removal and InstallationS7RS0B1706006

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

Removal

1) Relieve fuel pressure in fuel feed line according to “Fuel Pressure Relief Procedure”.

2) Disconnect negative cable at battery.

3) Disconnect fuel pipe joint and fuel hose (3) from fuel pipe (2) at the front and rear of each fuel pipe

referring to “Fuel Hose Disconnecting and

Reconnecting”.

4) Mark the location of clamps (1) on fuel pipes (2), so that the clamps can be reinstalled to where they

were.

5) Remove pipes (2) with clamp (1) from vehicle.

6) Remove clamp (1) from pipes (2).

1

I4RS0A170004-01

1

I4RS0A170005-01

2

13

I4RS0A170020-01

Page 383 of 1496

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-8

Installation1) Install clamps to marked location on pipes. If clamp is deformed, its claw is bent or broken, replace it with

new one.

2) Install pipes with pipe clamps to vehicle.

3) Connect fuel hoses and pipes to each pipe referring to “Fuel Hose Disconnecting and Reconnecting”.

4) Connect negative cable at battery.

5) With engine OFF, turn igniti on switch to ON position

and check for fuel leaks.

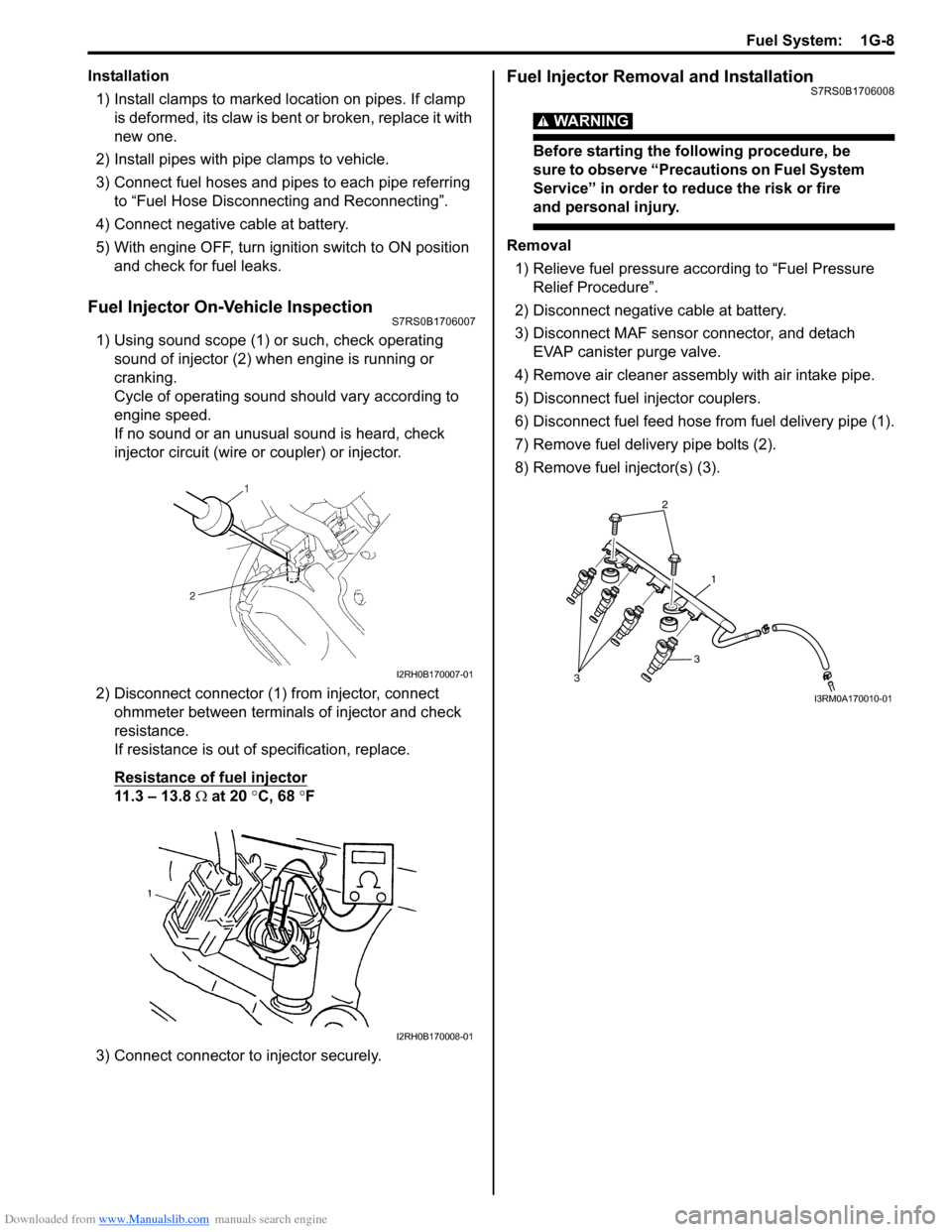

Fuel Injector On-Vehicle InspectionS7RS0B1706007

1) Using sound scope (1) or such, check operating sound of injector (2) when engine is running or

cranking.

Cycle of operating sound should vary according to

engine speed.

If no sound or an unusual sound is heard, check

injector circuit (wire or coupler) or injector.

2) Disconnect connector (1) from injector, connect ohmmeter between terminals of injector and check

resistance.

If resistance is out of specification, replace.

Resistance of fuel injector

11.3 – 13.8 Ω at 20 °C, 68 °F

3) Connect connector to injector securely.

Fuel Injector Removal and InstallationS7RS0B1706008

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

Removal 1) Relieve fuel pressure according to “Fuel Pressure Relief Procedure”.

2) Disconnect negative cable at battery.

3) Disconnect MAF sensor connector, and detach EVAP canister purge valve.

4) Remove air cleaner assembly with air intake pipe.

5) Disconnect fuel injector couplers.

6) Disconnect fuel feed hose from fuel delivery pipe (1).

7) Remove fuel delivery pipe bolts (2).

8) Remove fuel injector(s) (3).

I2RH0B170007-01

I2RH0B170008-01

2

1

3

3

I3RM0A170010-01

Page 387 of 1496

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-12

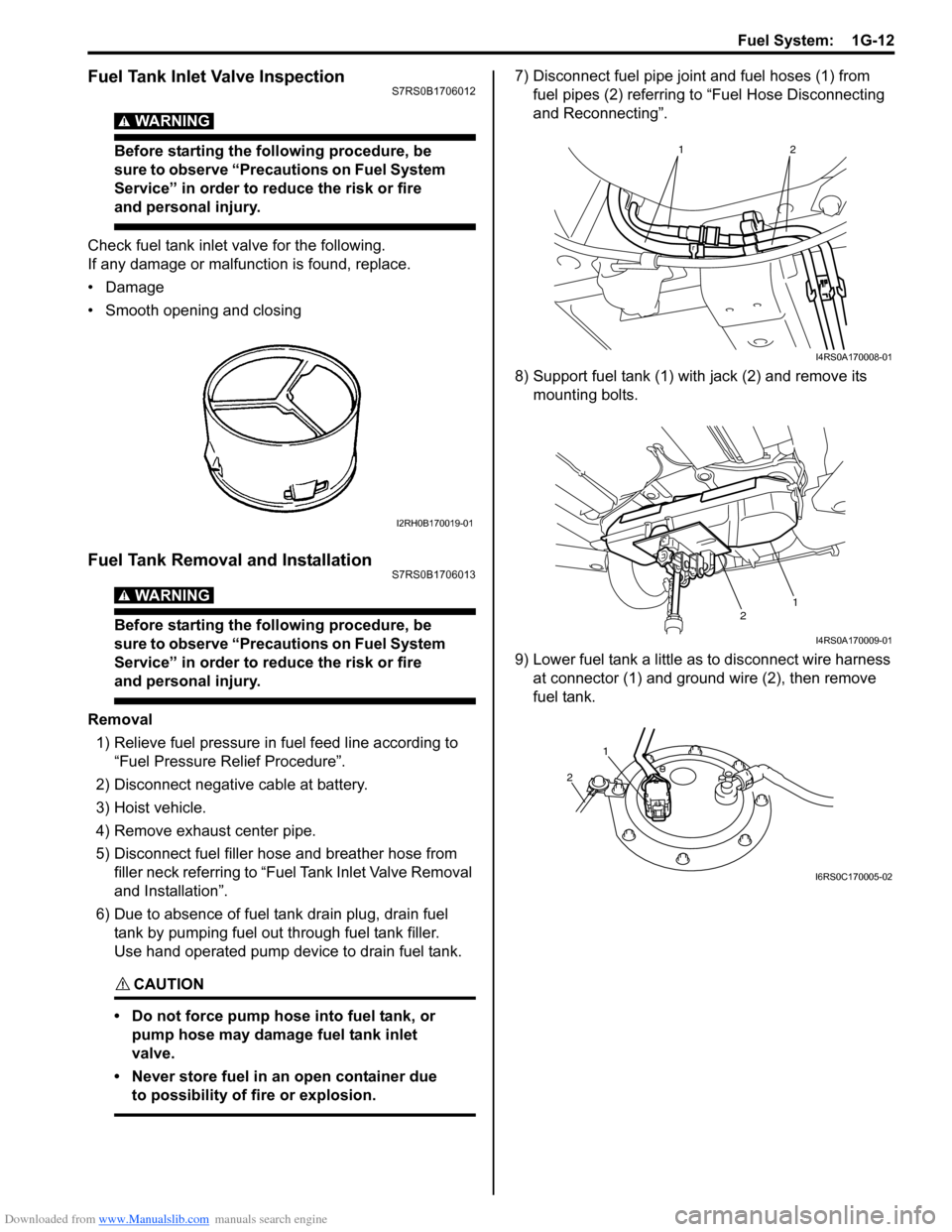

Fuel Tank Inlet Valve InspectionS7RS0B1706012

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

Check fuel tank inlet valve for the following.

If any damage or malfunction is found, replace.

•Damage

• Smooth opening and closing

Fuel Tank Removal and InstallationS7RS0B1706013

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

Removal1) Relieve fuel pressure in fuel feed line according to

“Fuel Pressure Relief Procedure”.

2) Disconnect negative cable at battery.

3) Hoist vehicle.

4) Remove exhaust center pipe.

5) Disconnect fuel filler hose and breather hose from

filler neck referring to “Fue l Tank Inlet Valve Removal

and Installation”.

6) Due to absence of fuel tank drain plug, drain fuel tank by pumping fuel out through fuel tank filler.

Use hand operated pump device to drain fuel tank.

CAUTION!

• Do not force pump hose into fuel tank, or pump hose may damage fuel tank inlet

valve.

• Never store fuel in an open container due to possibility of fire or explosion.

7) Disconnect fuel pipe joint and fuel hoses (1) from fuel pipes (2) referring to “Fuel Hose Disconnecting

and Reconnecting”.

8) Support fuel tank (1) with jack (2) and remove its mounting bolts.

9) Lower fuel tank a little as to disconnect wire harness at connector (1) and ground wire (2), then remove

fuel tank.

I2RH0B170019-01

12

I4RS0A170008-01

12

I4RS0A170009-01

1

2

I6RS0C170005-02

Page 388 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-13 Fuel System:

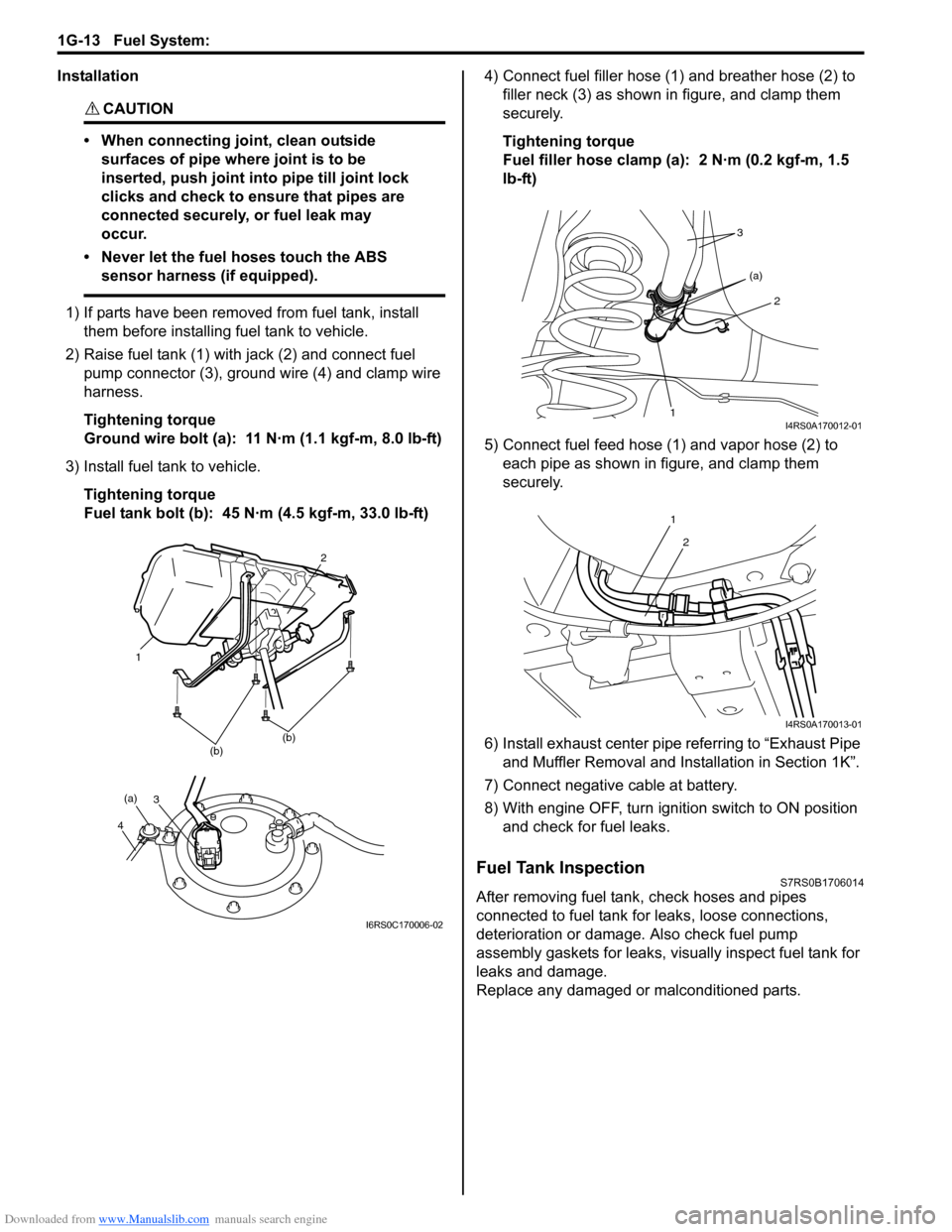

Installation

CAUTION!

• When connecting joint, clean outside surfaces of pipe where joint is to be

inserted, push joint into pipe till joint lock

clicks and check to ensure that pipes are

connected securely, or fuel leak may

occur.

• Never let the fuel hoses touch the ABS sensor harness (if equipped).

1) If parts have been removed from fuel tank, install them before installing fuel tank to vehicle.

2) Raise fuel tank (1) with jack (2) and connect fuel pump connector (3), ground wire (4) and clamp wire

harness.

Tightening torque

Ground wire bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

3) Install fuel tank to vehicle. Tightening torque

Fuel tank bolt (b): 45 N·m (4.5 kgf-m, 33.0 lb-ft) 4) Connect fuel filler hose (1

) and breather hose (2) to

filler neck (3) as shown in figure, and clamp them

securely.

Tightening torque

Fuel filler hose clamp (a): 2 N·m (0.2 kgf-m, 1.5

lb-ft)

5) Connect fuel feed hose (1) and vapor hose (2) to each pipe as shown in figure, and clamp them

securely.

6) Install exhaust center pipe referring to “Exhaust Pipe and Muffler Removal and Installation in Section 1K”.

7) Connect negative cable at battery.

8) With engine OFF, turn ignition switch to ON position and check for fuel leaks.

Fuel Tank InspectionS7RS0B1706014

After removing fuel tank, check hoses and pipes

connected to fuel tank for leaks, loose connections,

deterioration or damage. Also check fuel pump

assembly gaskets for leaks, visually inspect fuel tank for

leaks and damage.

Replace any damaged or malconditioned parts.

(b)(b)

1

2

3

4

(a)

I6RS0C170006-02

1

2

(a)

3

I4RS0A170012-01

1

2

I4RS0A170013-01

Page 392 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-17 Fuel System:

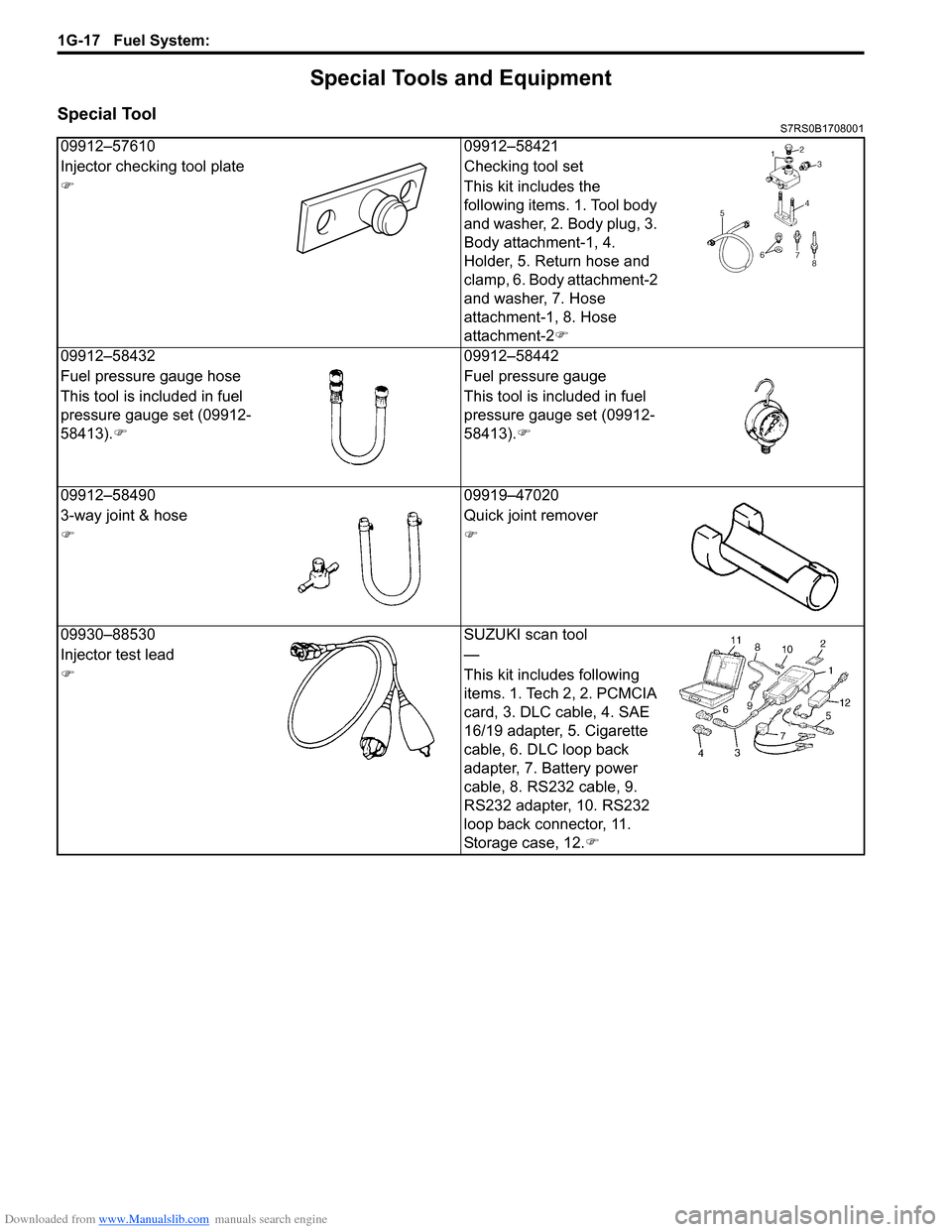

Special Tools and Equipment

Special ToolS7RS0B1708001

09912–5761009912–58421

Injector checking tool plate Checking tool set

�) This kit includes the

following items. 1. Tool body

and washer, 2. Body plug, 3.

Body attachment-1, 4.

Holder, 5. Return hose and

clamp, 6. Body attachment-2

and washer, 7. Hose

attachment-1, 8. Hose

attachment-2�)

09912–58432 09912–58442

Fuel pressure gauge hose Fuel pressure gauge

This tool is included in fuel

pressure gauge set (09912-

58413). �) This tool is included in fuel

pressure gauge set (09912-

58413).

�)

09912–58490 09919–47020

3-way joint & hose Quick joint remover

�)�)

09930–88530 SUZUKI scan tool

Injector test lead —

�) This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12.�)

Page 396 of 1496

Downloaded from www.Manualslib.com manuals search engine 1H-4 Ignition System:

Diagnostic Information and Procedures

Ignition System Symptom DiagnosisS7RS0B1804001

Reference Waveform of Ignition SystemS7RS0B1804002

Refer to “Reference waveform No.5”, “Reference waveform No.6” and “Reference waveform No.7” under “Inspection

of ECM and Its Circuits in Section 1A” for waveform of Ignition trigger signal.

Ignition System CheckS7RS0B1804003

Condition Possible cause Correction / Reference Item

Engine cranks, but will

not start or hard to start

(No spark) Blown fuse for ignition coil

Replace.

Loose connection or disconnection of

lead wire or high-tension cord(s) Connect securely.

Faulty high-tension cord(s) Replace.

Faulty spark plug(s) Replace.

Faulty ignition coil Replace ignition coil assembly.

Faulty CKP sensor or CKP sensor plate Clean, tighten or replace.

Faulty CMP sensor or sensor rotor tooth

of camshaft Clean, tighten or replace.

Faulty ECM Replace.

Poor fuel economy or

engine performance Incorrect ignition timing

Check related sensors and CKP sensor plate.

Faulty spark plug(s) or high-tension

cord(s) Adjust, clean or replace.

Faulty ignition coil assembly Replace.

Faulty CKP sensor or CKP sensor plate Clean, tighten or replace.

Faulty CMP sensor or sensor rotor tooth

of camshaft Clean, tighten or replace.

Faulty knock sensor Replace.

Faulty ECM Replace.

StepAction YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check in

Section 1A”.

2 Ignition spark test

1) Check all spark plugs for condition and type referring to

“Spark Plug Inspection”.

2) If OK, perform ignition spark test referring to “Ignition Spar k Tes t”.

Is spark emitted from all spark plugs? Go to Step 13. Go to Step 3.

3 DTC check

1) Perform DTC check referring to “DTC Check in Section

1A”.

Is DTC stored in ECM? Go to applicable DTC

diag. flow.

Go to Step 4.

4 Electrical connection check

1) Check ignition coil assemblies and high-tension cords

for electrical connection.

Are they connected securely? Go to Step 5.

Connect securely.

5 High-tension cords check

1) Check high-tension cord for resistance referring to

“High-Tension Cord Inspection”.

Is check result satisfactory? Go to Step 6.

Replace high-tension

cord(s).

Page 400 of 1496

Downloaded from www.Manualslib.com manuals search engine 1H-8 Ignition System:

Ignition Coil Assembly (Including ignitor)

Removal and Installation

S7RS0B1806005

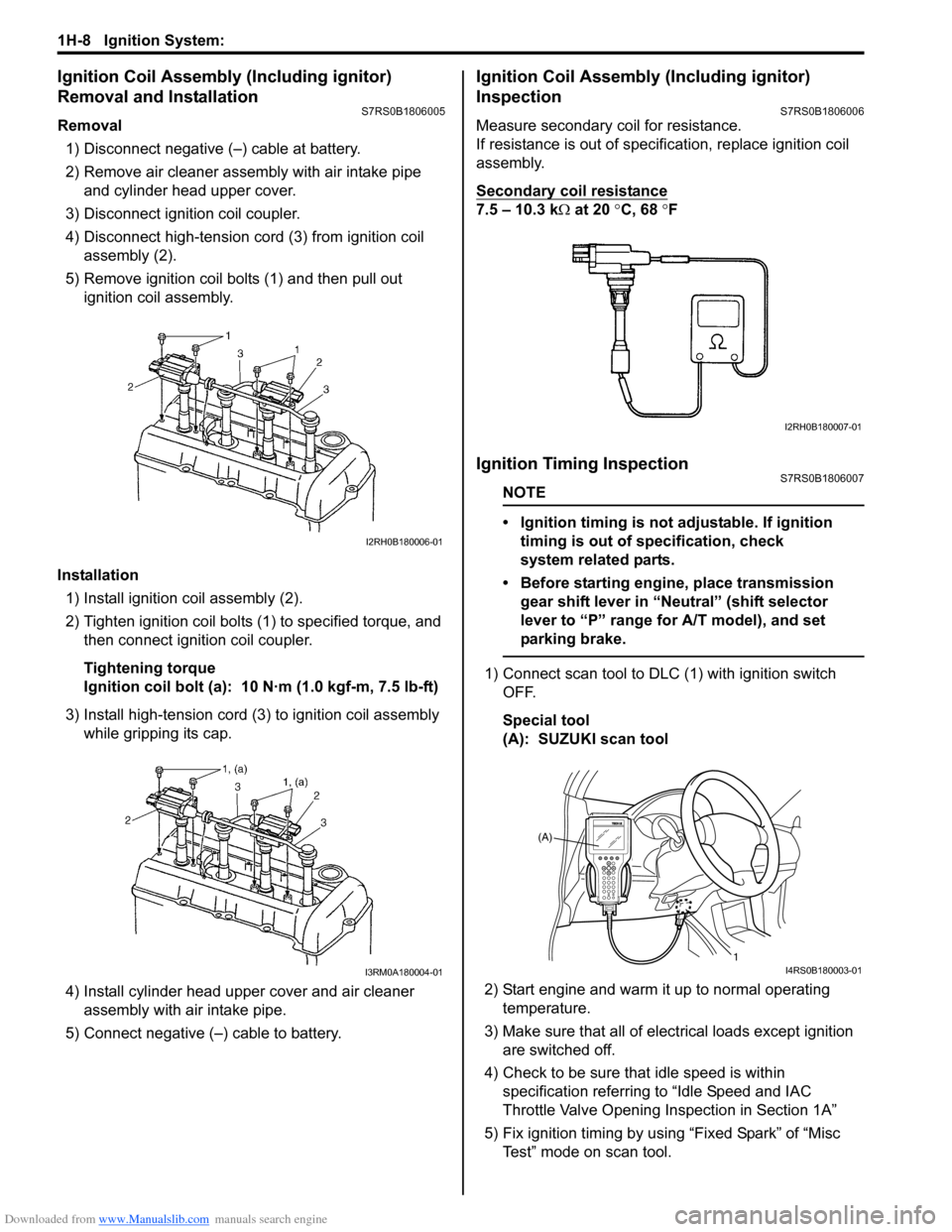

Removal1) Disconnect negative (–) cable at battery.

2) Remove air cleaner assembly with air intake pipe and cylinder head upper cover.

3) Disconnect ignition coil coupler.

4) Disconnect high-tension cord (3) from ignition coil assembly (2).

5) Remove ignition coil bolts (1) and then pull out ignition coil assembly.

Installation 1) Install ignition coil assembly (2).

2) Tighten ignition coil bolts (1) to specified torque, and then connect igni tion coil coupler.

Tightening torque

Ignition coil bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft)

3) Install high-tension cord (3) to ignition coil assembly while gripping its cap.

4) Install cylinder head upper cover and air cleaner assembly with air intake pipe.

5) Connect negative (–) cable to battery.

Ignition Coil Assembly (Including ignitor)

Inspection

S7RS0B1806006

Measure secondary coil for resistance.

If resistance is out of specification, replace ignition coil

assembly.

Secondary coil resistance

7.5 – 10.3 k Ω at 20 °C, 68 ° F

Ignition Timing InspectionS7RS0B1806007

NOTE

• Ignition timing is not adjustable. If ignition

timing is out of specification, check

system related parts.

• Before starting engine, place transmission gear shift lever in “Neutral” (shift selector

lever to “P” range for A/T model), and set

parking brake.

1) Connect scan tool to DLC (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

2) Start engine and warm it up to normal operating temperature.

3) Make sure that all of electrical loads except ignition are switched off.

4) Check to be sure that idle speed is within specification referring to “Idle Speed and IAC

Throttle Valve Opening Inspection in Section 1A”

5) Fix ignition timing by using “Fixed Spark” of “Misc Test” mode on scan tool.

I2RH0B180006-01

I3RM0A180004-01

I2RH0B180007-01

(A)

1

I4RS0B180003-01