troubleshoot bcm SUZUKI SWIFT 2008 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 599 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-25

Circuit Description

EBD warning lamp (brake warning lamp) is controlled by ESP® control module and BCM through lamp driver module

in combination meter.

If EBD system is in good condition, ESP ® control module turns EBD warning lamp ON at the ignition switch ON,

keeps it ON for 2 seconds and then turns it OFF.

EBD warning lamp is turned ON cont inuously at the following conditions.

• EBD system is an abnormality

• Connector of ESP ® control module is disconnected

• Parking brake switch is ON

• Brake fluid level is lower than minimum level

The information of parking brake switch and brake fluid leve l are transmitted from BCM to lamp driver module in

combination meter through CAN communication line.

Troubleshooting

Step Action Yes No 1 Check parking brake and brake fluid level

1) Make sure that:

• Parking brake is completely released.

• Brake fluid level is upper than the minimum level.

Are the check results OK? Go to Step 2. Release parking brake

completely and/or

replenish brake fluid.

2 Check ABS warning lamp

1) Turn ignition switch to ON position.

Does ABS warning lamp come on steady? Perform “ABS Warning

Lamp Does Not Come

ON at Ignition Switch

ON” previously outlined.Go to Step 3.

3 Check parking brake switch circuit and brake fluid level

switch circuit

1) Release parking brake completely, and replenish brake

fluid.

2) Disconnect BCM connectors with ignition switch turned OFF.

3) Measure resistance between each terminal of “L01-6”, “E46-5” and vehicle body ground.

Are resistance

∞ Ω? Go to Step 4. Check each applicable

circuit for short to

vehicle body ground. If

OK, then check parking

brake switch and/or

brake fluid level switch.

4 CAN communication circuit check

1) CAN communication circuit between combination meter,

ABS (ESP® ) control module and BCM referring to “DTC

U1073: Control Module Communication Bus Off”.

Is CAN communication circuit in good condition? Substitute a known-

good combination meter

and recheck. If EBD

warning lamp remains

ON, substitute a known-

good ESP

® hydraulic

unit / control module

assembly and recheck. Repair or replace.

Page 604 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-30 Electronic Stability Program:

DTC Troubleshooting

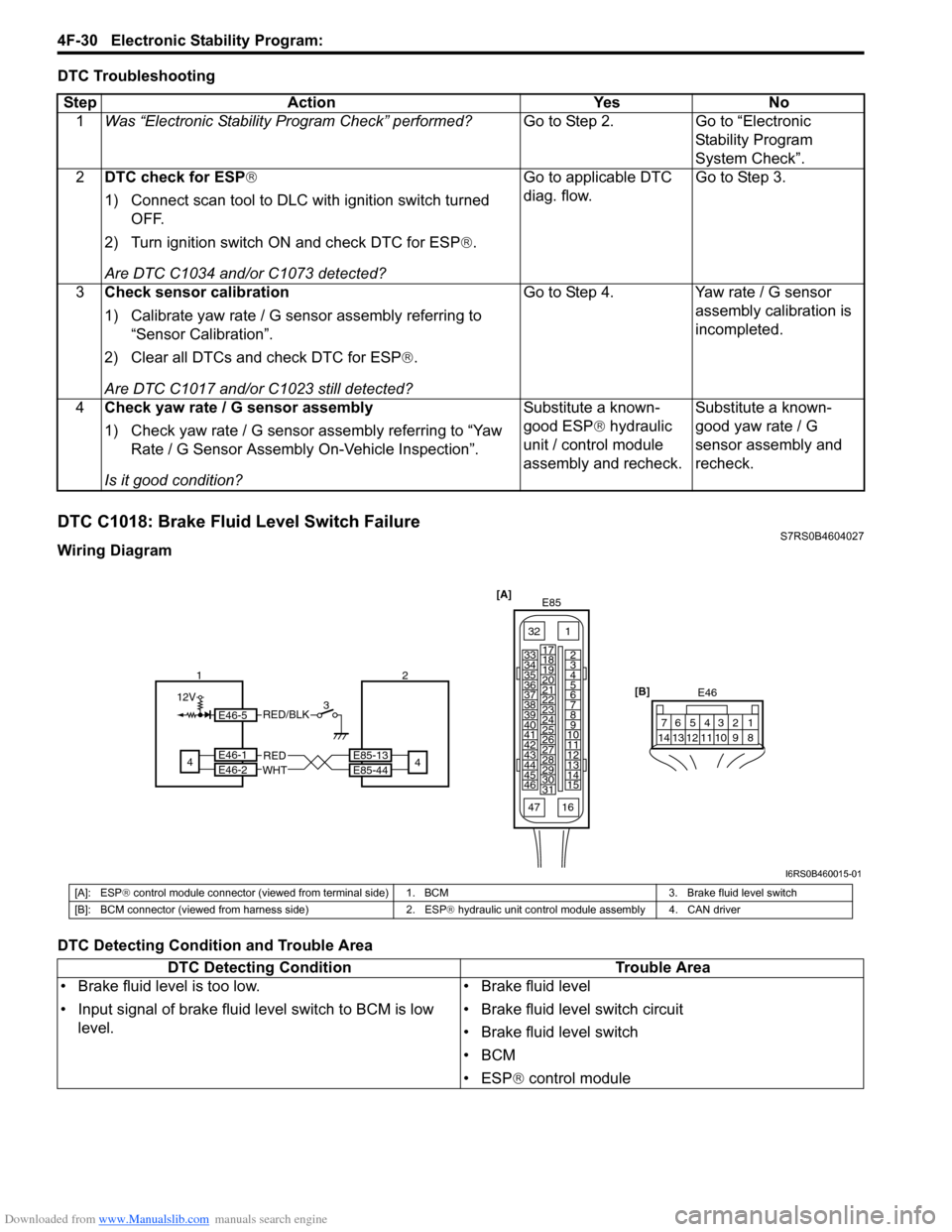

DTC C1018: Brake Fluid Level Switch FailureS7RS0B4604027

Wiring Diagram

DTC Detecting Condition and Trouble AreaStep Action Yes No

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2. Go to “Electronic

Stability Program

System Check”.

2 DTC check for ESP®

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ignition switch ON and check DTC for ESP ®.

Are DTC C1034 and/or C1073 detected? Go to applicable DTC

diag. flow.

Go to Step 3.

3 Check sensor calibration

1) Calibrate yaw rate / G sensor assembly referring to

“Sensor Calibration”.

2) Clear all DTCs and check DTC for ESP ®.

Are DTC C1017 and/or C1023 still detected? Go to Step 4. Yaw rate / G sensor

assembly calibration is

incompleted.

4 Check yaw rate / G sensor assembly

1) Check yaw rate / G sensor assembly referring to “Yaw

Rate / G Sensor Assembly On-Vehicle Inspection”.

Is it good condition? Substitute a known-

good ESP

® hydraulic

unit / control module

assembly and recheck. Substitute a known-

good yaw rate / G

sensor assembly and

recheck.

[A]

E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47 [B]

E46

124

53

67

891011121314

E85-13

E85-44REDWHT4E46-1E46-2

124

12V3E46-5RED/BLK

I6RS0B460015-01

[A]: ESP

® control module connector (viewed from terminal side) 1. BCM 3. Brake fluid level switch

[B]: BCM connector (viewed from harness side) 2. ESP ® hydraulic unit control module assembly 4. CAN driver

DTC Detecting Condition Trouble Area

• Brake fluid level is too low.

• Input signal of brake fluid level switch to BCM is low level. • Brake fluid level

• Brake fluid level switch circuit

• Brake fluid level switch

•BCM

• ESP

® control module

Page 605 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-31

DTC Troubleshooting

DTC 1020: Master Cylinder Pressure Sensor Power Supply FailureS7RS0B4604028

DTC Detecting Condition and Trouble Area

DTC Troubleshooting1) Turn ignition switch to OFF position.

2) Check for proper connection from harness to ESP ® control module.

3) If OK, substitute an ESP ® hydraulic unit / control module assembly with correct part number.

4) Recheck system.

Step Action Yes No

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2. Go to “Electronic

Stability Program

System Check”.

2 Check brake fluid level

1) Check brake fluid level in reservoir.

Is brake fluid level upper than the minimum level? Go to Step 3. Replenish brake fluid to

reservoir.

3 DTC check for ESP®

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ignition switch ON and check DTC for ESP ®.

Is DTC U1073 and/or U1140 detected? Go to applicable diag.

flow.

Go to Step 3.

4 Check brake fluid level switch

1) Turn ignition switch to OFF position.

2) Disconnect brake fluid level switch connector.

3) Check for proper connection at each terminal of brake

fluid level switch connector.

4) If OK, then check brake fluid level switch referring to “Brake Fluid Level Switch Inspection in Section 9C”.

Is check result OK? Go to Step 5. Replace brake fluid

level switch.

5 Check brake fluid level switch circuit

1) Disconnect BCM connector.

2) Check for proper connection to BCM connector at “E46-

5” terminal.

3) If OK, then check resistance between “E46-5” terminal and vehicle body ground.

Is resistance infinity? Go to Step 6. “BLKL/RED” wire circuit

is shorted to ground.

6 Check BCM

1) Connect brake fluid level switch connector and BCM

connector.

2) Check voltage at “E46-5” terminal of BCM referring to “Inspection of BCM and its Circuits in Section 10B”.

Is voltage in good condition? Substitute a known-

good ESP

® hydraulic

unit / control module

assembly and recheck. Check BCM power and

ground circuit. If circuit

is OK, substitute a

known-good BCM and

recheck.

DTC Detecting Condition

Trouble Area

Power supply voltage to master cylinder pressure sensor

in ESP® hydraulic unit / control mo dule assembly is out of

specification. • ESP

® control module

Page 624 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-50 Electronic Stability Program:

DTC Troubleshooting

DTC U1100: Lost Communication with ECM (Reception Error)S7RS0B4604058

Wiring Diagram

Refer to “Wiring Diagram” under “DTC U1073: Control Module Communication Bus Off”.

DTC Detecting Condition and Trouble Area

DTC TroubleshootingStep Action Yes No

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2. Go to “Electronic

Stability Program

System Check”.

2 DTC check for ESP®

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck DTC for ESP ®.

Is DTC U1073 indicated? Go to Step 3. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

3 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by means of CAN.

3) Check CAN communication circuit between control modules for open, short and high resistance.

Is each CAN communication circuit in good condition? Go to Step 4. Repair or replace the

CAN communication

line.

4 DTC check for ESP®

1) Connect connectors of disconnected control modules

communicating by means of CAN.

2) Disconnect each connector. •ECM

• Keyless start control module (if equipped)

• Combination meter

• Steering angle sensor

•BCM

3) Recheck DTC for ESP ®.

Is DTC U1073 detected? Check ESP

® control

module power and

ground circuit. If circuits

are OK, substitute a

known-good ESP ®

hydraulic unit / control

module assembly and

recheck. Check applicable

control module power

and ground circuit. If

circuit is OK, substitute

a known-good

applicable control

module and recheck.

DTC Detecting Condition

Trouble Area

ECM message data is missing from CAN communication. • CAN communication circuit

•ECM

• ESP® control module

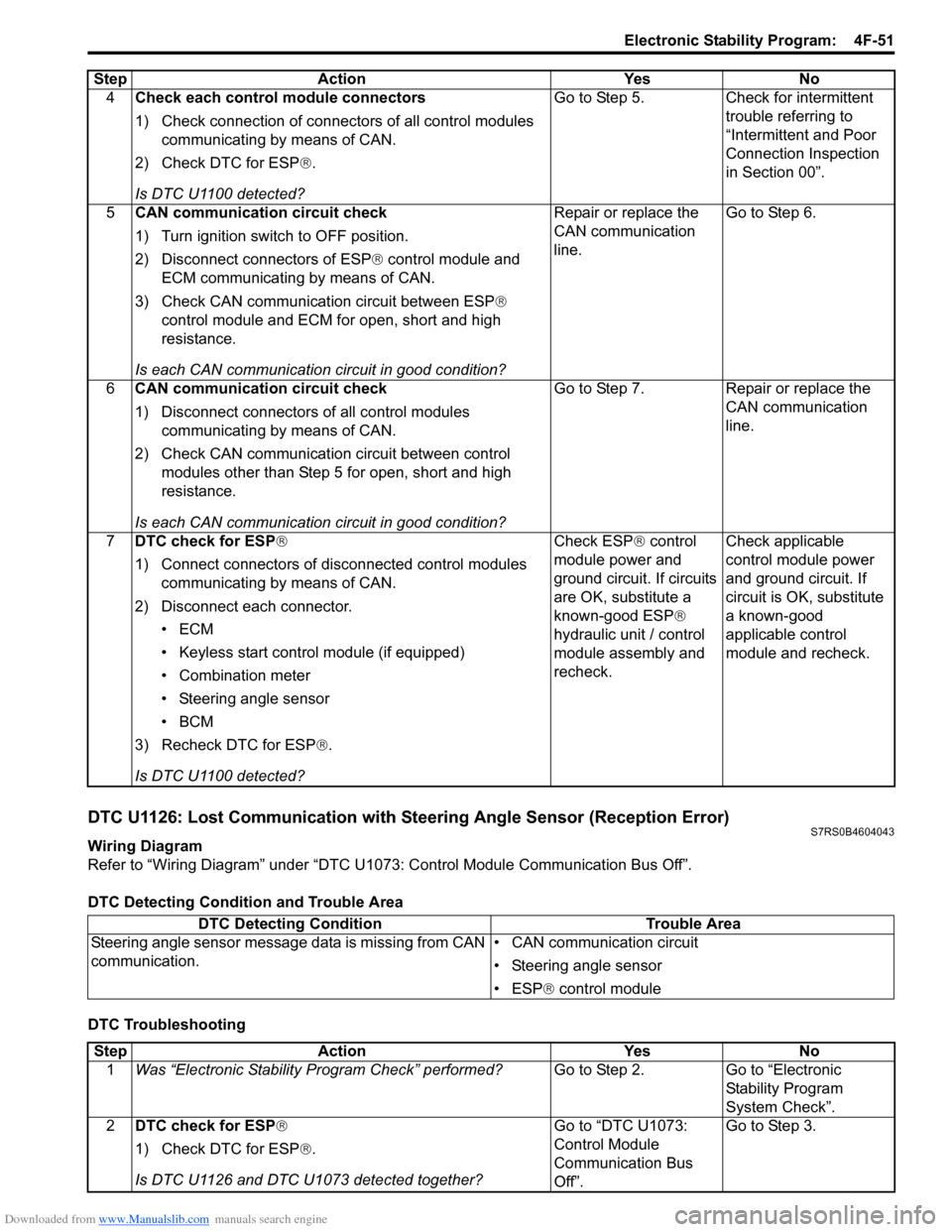

Step Action YesNo

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2.Go to “Electronic

Stability Program

System Check”.

2 DTC check for ESP®

1) Check DTC for ESP ®.

Is DTC U1100 and DTC U1073 detected together? Go to “DTC U1073:

Control Module

Communication Bus

Off”.Go to Step 3.

3 DTC check for ECM

1) Check DTC for ECM.

Is DTC P1674 detected? Go to “DTC P1674:

CAN Communication

(Bus Off Error) in

Section 1A”.Go to Step 4.

Page 625 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-51

DTC U1126: Lost Communication with Steering Angle Sensor (Reception Error)S7RS0B4604043

Wiring Diagram

Refer to “Wiring Diagram” under “DTC U1073: Control Module Communication Bus Off”.

DTC Detecting Condition and Trouble Area

DTC Troubleshooting4

Check each control module connectors

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Check DTC for ESP ®.

Is DTC U1100 detected? Go to Step 5. Check for intermittent

trouble referring to

“Intermittent and Poor

Connection Inspection

in Section 00”.

5 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of ESP ® control module and

ECM communicating by means of CAN.

3) Check CAN communication circuit between ESP®

control module and ECM for open, short and high

resistance.

Is each CAN communication circuit in good condition? Repair or replace the

CAN communication

line.

Go to Step 6.

6 CAN communication circuit check

1) Disconnect connectors of all control modules

communicating by means of CAN.

2) Check CAN communication circuit between control modules other than Step 5 for open, short and high

resistance.

Is each CAN communication circuit in good condition? Go to Step 7. Repair or replace the

CAN communication

line.

7 DTC check for ESP®

1) Connect connectors of disconnected control modules

communicating by means of CAN.

2) Disconnect each connector. •ECM

• Keyless start control module (if equipped)

• Combination meter

• Steering angle sensor

•BCM

3) Recheck DTC for ESP ®.

Is DTC U1100 detected? Check ESP

® control

module power and

ground circuit. If circuits

are OK, substitute a

known-good ESP ®

hydraulic unit / control

module assembly and

recheck. Check applicable

control module power

and ground circuit. If

circuit is OK, substitute

a known-good

applicable control

module and recheck.

Step Action Yes No

DTC Detecting Condition

Trouble Area

Steering angle sensor message data is missing from CAN

communication. • CAN communication circuit

• Steering angle sensor

• ESP

® control module

Step Action YesNo

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2.Go to “Electronic

Stability Program

System Check”.

2 DTC check for ESP®

1) Check DTC for ESP ®.

Is DTC U1126 and DTC U1073 detected together? Go to “DTC U1073:

Control Module

Communication Bus

Off”.Go to Step 3.

Page 627 of 1496

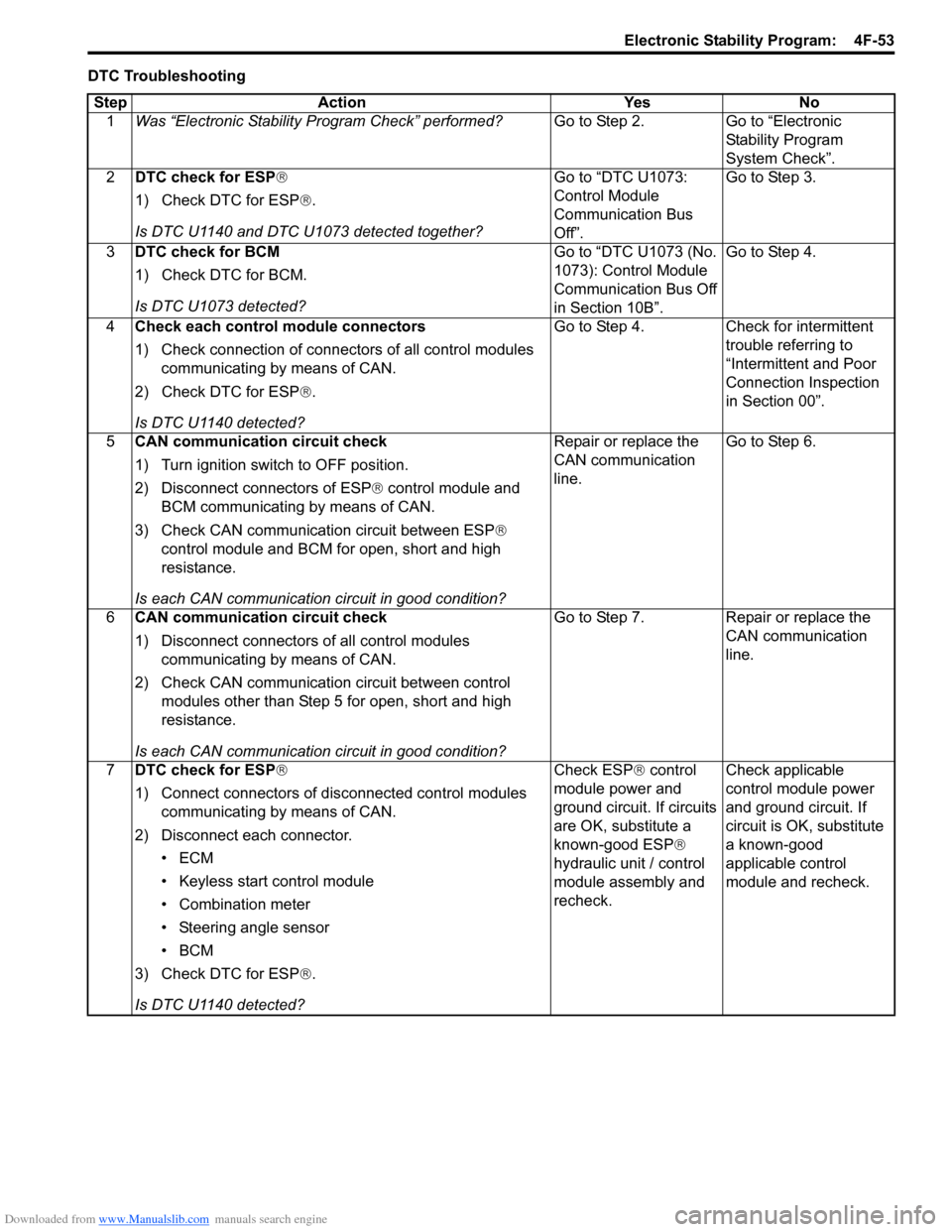

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-53

DTC TroubleshootingStep Action Yes No 1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2. Go to “Electronic

Stability Program

System Check”.

2 DTC check for ESP®

1) Check DTC for ESP ®.

Is DTC U1140 and DTC U1073 detected together? Go to “DTC U1073:

Control Module

Communication Bus

Off”.Go to Step 3.

3 DTC check for BCM

1) Check DTC for BCM.

Is DTC U1073 detected? Go to “DTC U1073 (No.

1073): Control Module

Communication Bus Off

in Section 10B”.Go to Step 4.

4 Check each control module connectors

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Check DTC for ESP ®.

Is DTC U1140 detected? Go to Step 4. Check for intermittent

trouble referring to

“Intermittent and Poor

Connection Inspection

in Section 00”.

5 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of ESP ® control module and

BCM communicating by means of CAN.

3) Check CAN communication circuit between ESP®

control module and BCM for open, short and high

resistance.

Is each CAN communication circuit in good condition? Repair or replace the

CAN communication

line.

Go to Step 6.

6 CAN communication circuit check

1) Disconnect connectors of all control modules

communicating by means of CAN.

2) Check CAN communication circuit between control modules other than Step 5 for open, short and high

resistance.

Is each CAN communication circuit in good condition? Go to Step 7. Repair or replace the

CAN communication

line.

7 DTC check for ESP®

1) Connect connectors of disconnected control modules

communicating by means of CAN.

2) Disconnect each connector. •ECM

• Keyless start control module

• Combination meter

• Steering angle sensor

•BCM

3) Check DTC for ESP ®.

Is DTC U1140 detected? Check ESP

® control

module power and

ground circuit. If circuits

are OK, substitute a

known-good ESP ®

hydraulic unit / control

module assembly and

recheck. Check applicable

control module power

and ground circuit. If

circuit is OK, substitute

a known-good

applicable control

module and recheck.

Page 686 of 1496

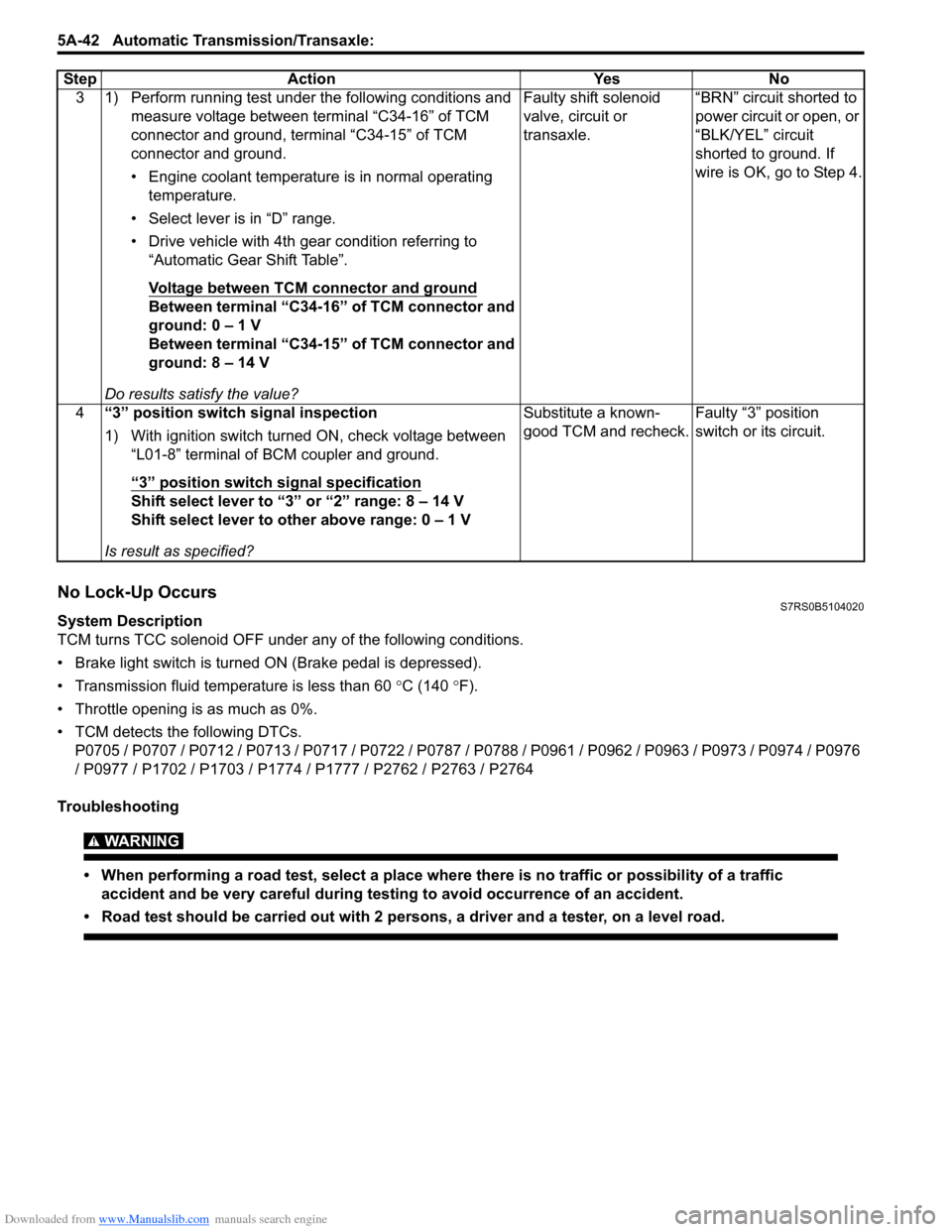

Downloaded from www.Manualslib.com manuals search engine 5A-42 Automatic Transmission/Transaxle:

No Lock-Up OccursS7RS0B5104020

System Description

TCM turns TCC solenoid OFF under any of the following conditions.

• Brake light switch is turned ON (Brake pedal is depressed).

• Transmission fluid temperat ure is less than 60 °C (140 °F).

• Throttle opening is as much as 0%.

• TCM detects the following DTCs. P0705 / P0707 / P0712 / P0713 / P0717 / P0722 / P0787 / P0788 / P0961 / P0962 / P0963 / P0973 / P0974 / P0976

/ P0977 / P1702 / P1703 / P1774 / P1777 / P2762 / P2763 / P2764

Troubleshooting

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

3 1) Perform running test under the following conditions and measure voltage between terminal “C34-16” of TCM

connector and ground, terminal “C34-15” of TCM

connector and ground.

• Engine coolant temperature is in normal operating temperature.

• Select lever is in “D” range.

• Drive vehicle with 4th gear condition referring to “Automatic Gear Shift Table”.

Voltage between TCM connector and ground

Between terminal “C34-16” of TCM connector and

ground: 0 – 1 V

Between terminal “C34-15” of TCM connector and

ground: 8 – 14 V

Do results satisfy the value? Faulty shift solenoid

valve, circuit or

transaxle.

“BRN” circuit shorted to

power circuit or open, or

“BLK/YEL” circuit

shorted to ground. If

wire is OK, go to Step 4.

4 “3” position switch signal inspection

1) With ignition switch turned ON, check voltage between

“L01-8” terminal of BCM coupler and ground.

“3” position switch signal specification

Shift select lever to “3” or “2” range: 8 – 14 V

Shift select lever to other above range: 0 – 1 V

Is result as specified? Substitute a known-

good TCM and recheck.

Faulty “3” position

switch or its circuit.

Step Action Yes No

Page 714 of 1496

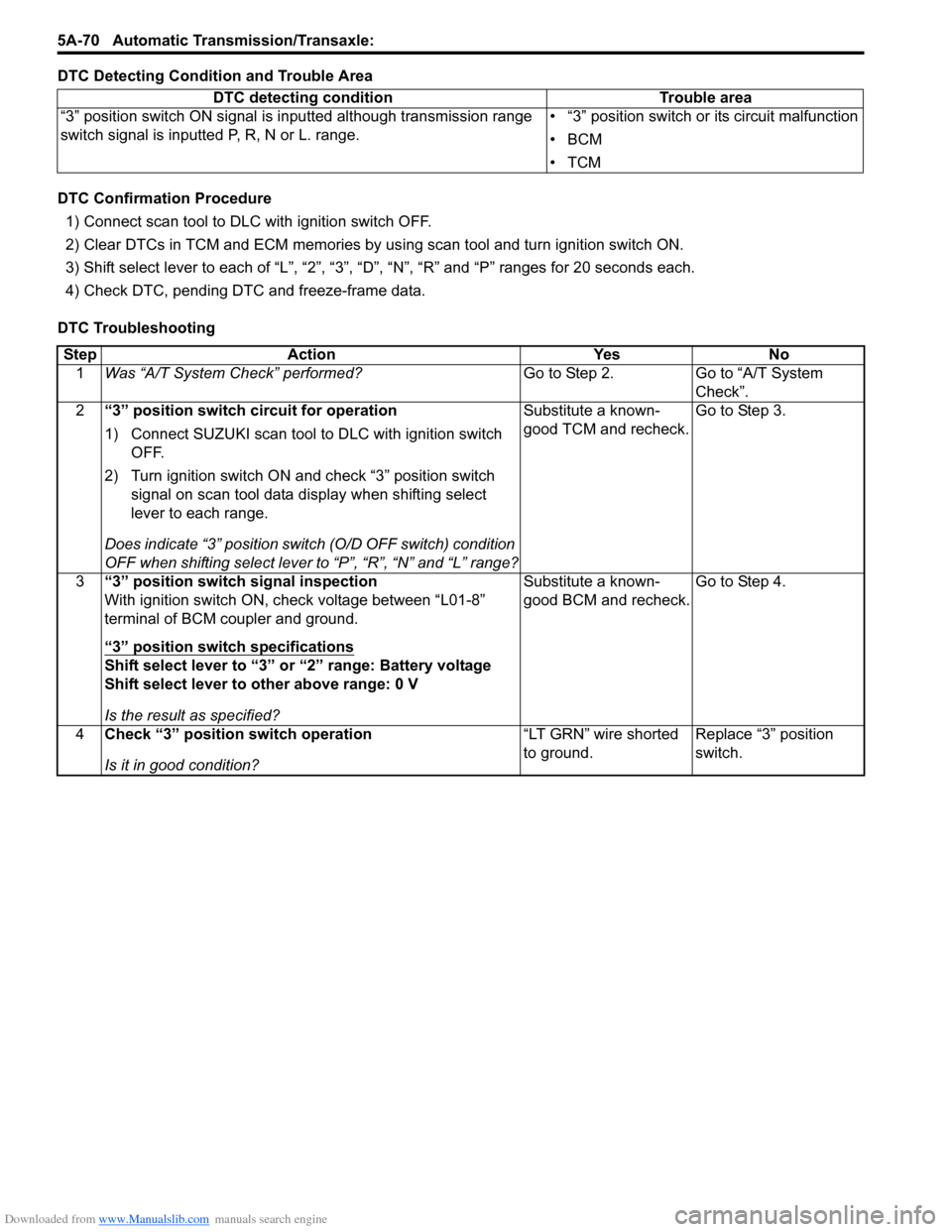

Downloaded from www.Manualslib.com manuals search engine 5A-70 Automatic Transmission/Transaxle:

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Connect scan tool to DLC with ignition switch OFF.

2) Clear DTCs in TCM and ECM memories by us ing scan tool and turn ignition switch ON.

3) Shift select lever to each of “L”, “2”, “3”, “D”, “N”, “R” and “P” ranges for 20 seconds each.

4) Check DTC, pending DTC and freeze-frame data.

DTC Troubleshooting DTC detecting condition Trouble area

“3” position switch ON signal is inputted although transmission range

switch signal is inputted P, R, N or L. range. • “3” position switch or its circuit malfunction

•BCM

•TCM

Step

Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

2 “3” position switch circuit for operation

1) Connect SUZUKI scan tool to DLC with ignition switch

OFF.

2) Turn ignition switch ON and check “3” position switch signal on scan tool data display when shifting select

lever to each range.

Does indicate “3” position swit ch (O/D OFF switch) condition

OFF when shifting select lever to “P”, “R”, “N” and “L” range? Substitute a known-

good TCM and recheck.

Go to Step 3.

3 “3” position switch signal inspection

With ignition switch ON, check voltage between “L01-8”

terminal of BCM coupler and ground.

“3” position switch specifications

Shift select lever to “3” or “2” range: Battery voltage

Shift select lever to other above range: 0 V

Is the result as specified? Substitute a known-

good BCM and recheck.

Go to Step 4.

4 Check “3” position switch operation

Is it in good condition? “LT GRN” wire shorted

to ground.

Replace “3” position

switch.

Page 716 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-72 Automatic Transmission/Transaxle:

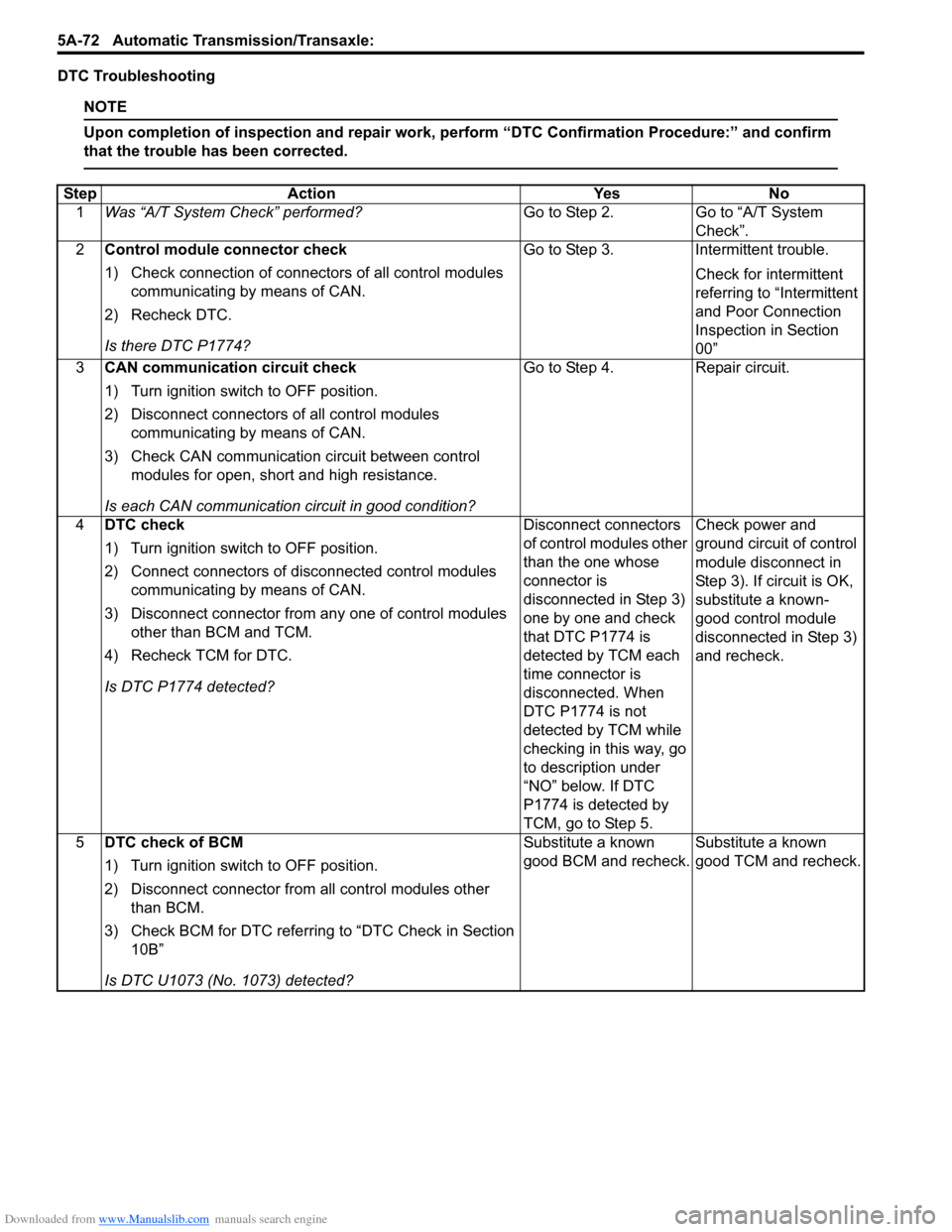

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform “DTC Confirmation Procedure:” and confirm

that the trouble has been corrected.

Step Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

2 Control module connector check

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck DTC.

Is there DTC P1774? Go to Step 3.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”

3 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by means of CAN.

3) Check CAN communication circuit between control modules for open, short and high resistance.

Is each CAN communication circuit in good condition? Go to Step 4.

Repair circuit.

4 DTC check

1) Turn ignition switch to OFF position.

2) Connect connectors of disconnected control modules

communicating by means of CAN.

3) Disconnect connector from any one of control modules other than BCM and TCM.

4) Recheck TCM for DTC.

Is DTC P1774 detected? Disconnect connectors

of control modules other

than the one whose

connector is

disconnected in Step 3)

one by one and check

that DTC P1774 is

detected by TCM each

time connector is

disconnected. When

DTC P1774 is not

detected by TCM while

checking in this way, go

to description under

“NO” below. If DTC

P1774 is detected by

TCM, go to Step 5.Check power and

ground circuit of control

module disconnect in

Step 3). If circuit is OK,

substitute a known-

good control module

disconnected in Step 3)

and recheck.

5 DTC check of BCM

1) Turn ignition switch to OFF position.

2) Disconnect connector from all control modules other

than BCM.

3) Check BCM for DTC referring to “DTC Check in Section 10B”

Is DTC U1073 (No. 1073) detected? Substitute a known

good BCM and recheck.

Substitute a known

good TCM and recheck.

Page 718 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-74 Automatic Transmission/Transaxle:

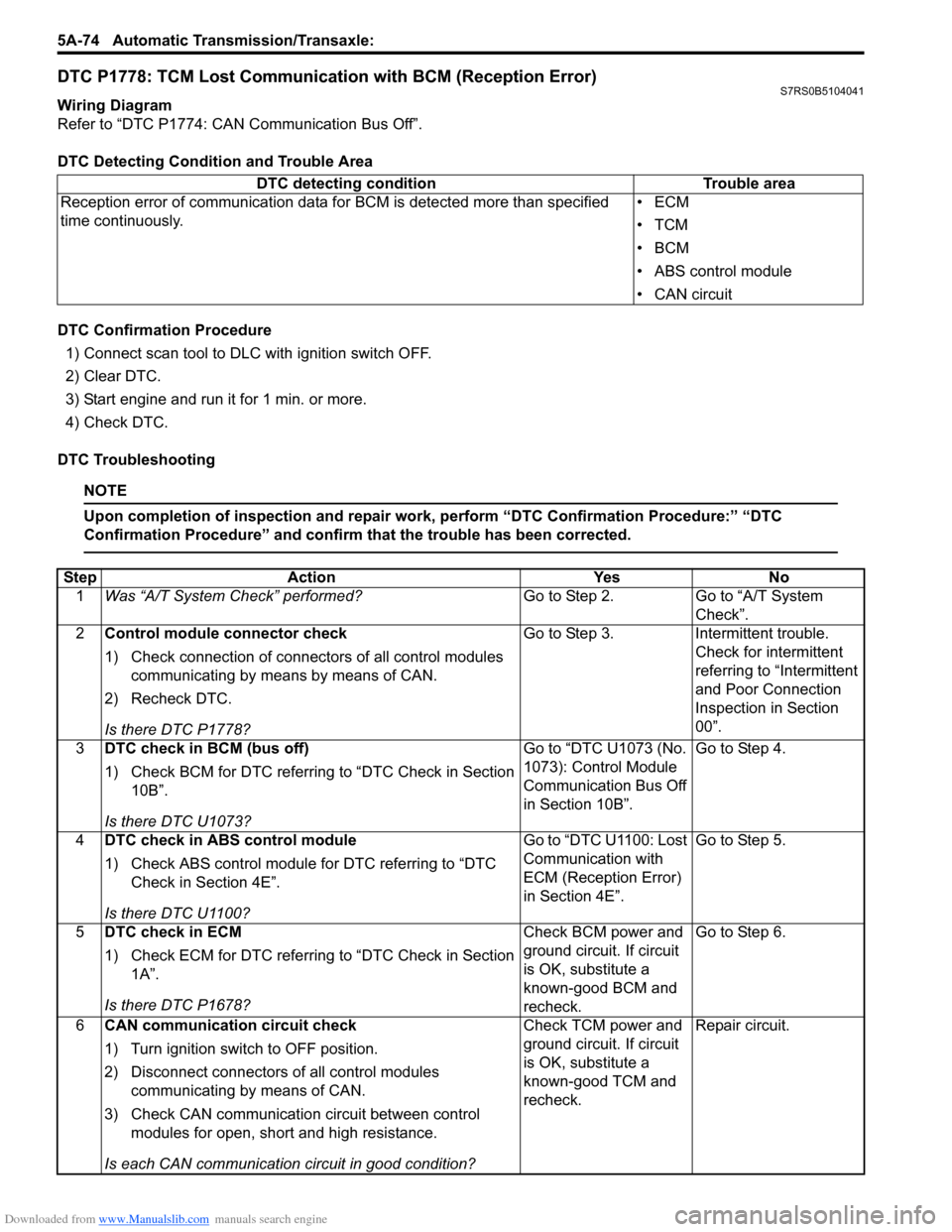

DTC P1778: TCM Lost Communication with BCM (Reception Error)S7RS0B5104041

Wiring Diagram

Refer to “DTC P1774: CAN Communication Bus Off”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Connect scan tool to DLC with ignition switch OFF.

2) Clear DTC.

3) Start engine and run it for 1 min. or more.

4) Check DTC.

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform “DTC Confirmation Procedure:” “DTC

Confirmation Procedure” and confirm that the trouble has been corrected.

DTC detecting condition Trouble area

Reception error of communication data fo r BCM is detected more than specified

time continuously. •ECM

•TCM

•BCM

• ABS control module

• CAN circuit

Step

Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

2 Control module connector check

1) Check connection of connectors of all control modules

communicating by means by means of CAN.

2) Recheck DTC.

Is there DTC P1778? Go to Step 3.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

3 DTC check in BCM (bus off)

1) Check BCM for DTC referring to “DTC Check in Section

10B”.

Is there DTC U1073? Go to “DTC U1073 (No.

1073): Control Module

Communication Bus Off

in Section 10B”.

Go to Step 4.

4 DTC check in ABS control module

1) Check ABS control module for DTC referring to “DTC

Check in Section 4E”.

Is there DTC U1100? Go to “DTC U1100: Lost

Communication with

ECM (Reception Error)

in Section 4E”.

Go to Step 5.

5 DTC check in ECM

1) Check ECM for DTC referring to “DTC Check in Section

1A”.

Is there DTC P1678? Check BCM power and

ground circuit. If circuit

is OK, substitute a

known-good BCM and

recheck.Go to Step 6.

6 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by means of CAN.

3) Check CAN communication circuit between control modules for open, short and high resistance.

Is each CAN communication circuit in good condition? Check TCM power and

ground circuit. If circuit

is OK, substitute a

known-good TCM and

recheck.

Repair circuit.