wire color SUZUKI SWIFT 2008 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 230 of 1496

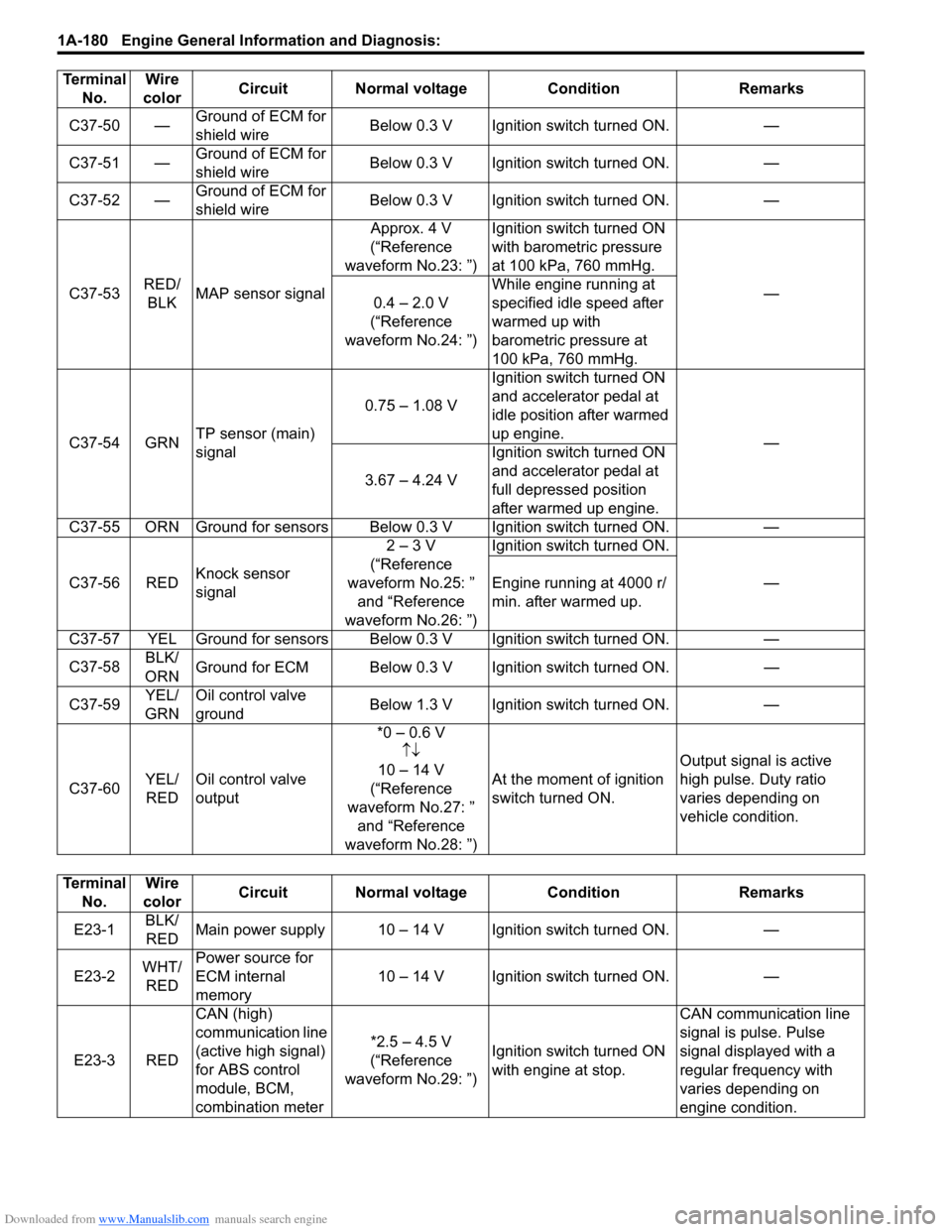

Downloaded from www.Manualslib.com manuals search engine 1A-180 Engine General Information and Diagnosis:

C37-50 βGround of ECM for

shield wire Below 0.3 V Ignition switch turned ON. β

C37-51 β Ground of ECM for

shield wire Below 0.3 V Ignition switch turned ON. β

C37-52 β Ground of ECM for

shield wire Below 0.3 V Ignition switch turned ON. β

C37-53 RED/

BLK MAP sensor signal Approx. 4 V

(βReference

waveform No.23: β) Ignition switch turned ON

with barometric pressure

at 100 kPa, 760 mmHg.

β

0.4 β 2.0 V

(βReference

waveform No.24: β) While engine running at

specified idle speed after

warmed up with

barometric pressure at

100 kPa, 760 mmHg.

C37-54 GRN TP sensor (main)

signal 0.75 β 1.08 V

Ignition switch turned ON

and accelerator pedal at

idle position after warmed

up engine.

β

3.67 β 4.24 V Ignition switch turned ON

and accelerator pedal at

full depressed position

after warmed up engine.

C37-55 ORN Ground for sensors Below 0.3 V Ignition switch turned ON. β

C37-56 RED Knock sensor

signal 2 β 3 V

(βReference

waveform No.25: β and βReference

waveform No.26: β) Ignition switch turned ON.

β

Engine running at 4000 r/

min. after warmed up.

C37-57 YEL Ground for sensors Below 0.3 V Ignition switch turned ON. β

C37-58 BLK/

ORN Ground for ECM Below 0.3 V Ignition switch turned ON.

β

C37-59 YEL/

GRN Oil control valve

ground

Below 1.3 V Ignition switch turned ON.

β

C37-60 YEL/

RED Oil control valve

output *0 β 0.6 V

ββ

10 β 14 V

(βReference

waveform No.27: β and βReference

waveform No.28: β) At the moment of ignition

switch turned ON.

Output signal is active

high pulse. Duty ratio

varies depending on

vehicle condition.

Terminal

No. Wire

color Circuit Normal voltage

ConditionRemarks

Terminal

No. Wire

color Circuit Normal voltage Condition Remarks

E23-1 BLK/

RED Main power supply 10 β 14 V Ignition switch turned ON. β

E23-2 WHT/

RED Power source for

ECM internal

memory

10 β 14 V Ignition switch turned ON. β

E23-3 RED CAN (high)

communication line

(active high signal)

for ABS control

module, BCM,

combination meter *2.5 β 4.5 V

(βReference

waveform No.29: β) Ignition switch turned ON

with engine at stop. CAN communication line

signal is pulse. Pulse

signal displayed with a

regular frequency with

varies depending on

engine condition.

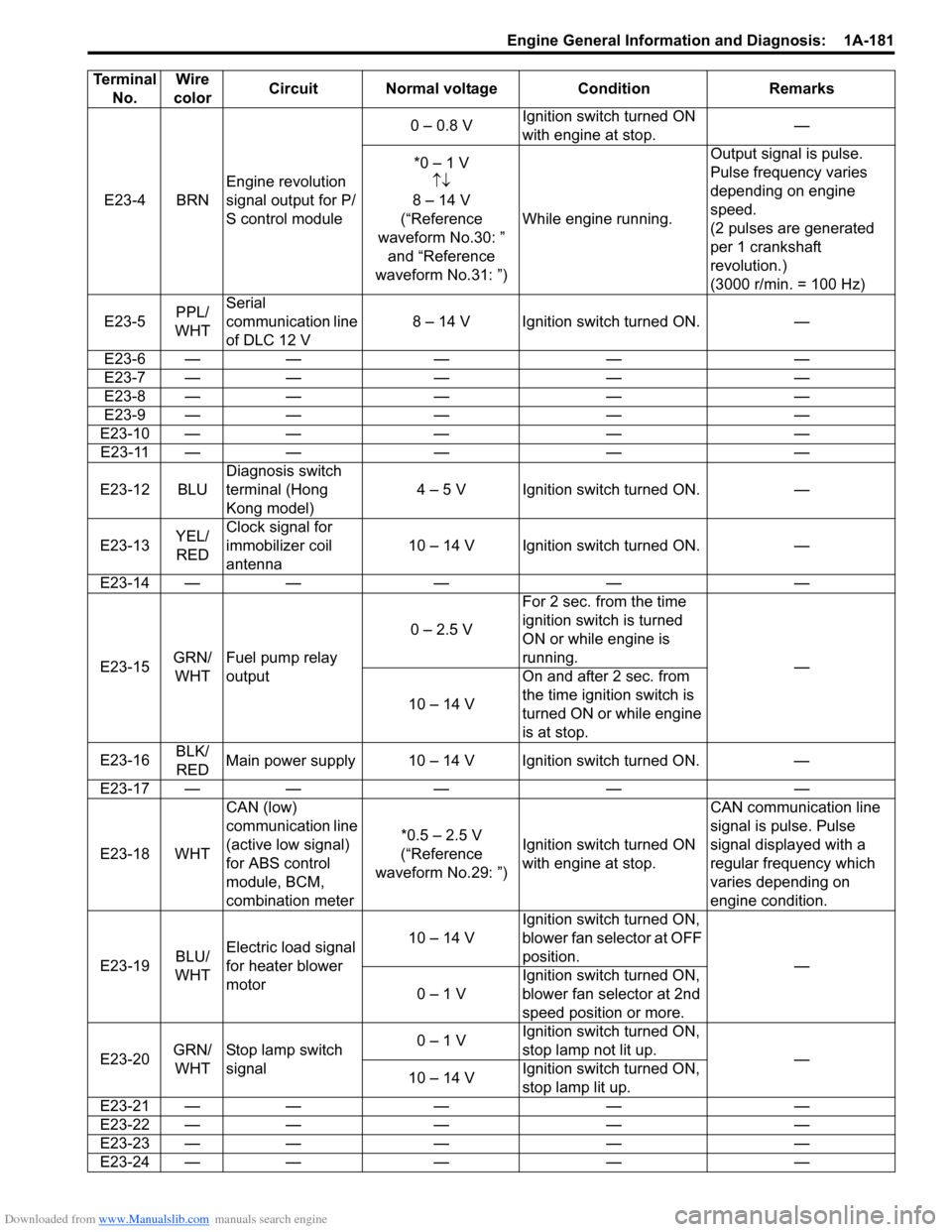

Page 231 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-181

E23-4 BRNEngine revolution

signal output for P/

S control module 0 β 0.8 V

Ignition switch turned ON

with engine at stop. β

*0 β 1 V ββ

8 β 14 V

(βReference

waveform No.30: β and βReference

waveform No.31: β) While engine running. Output signal is pulse.

Pulse frequency varies

depending on engine

speed.

(2 pulses are generated

per 1 crankshaft

revolution.)

(3000 r/min. = 100 Hz)

E23-5 PPL/

WHT Serial

communication line

of DLC 12 V

8 β 14 V Ignition switch turned ON. β

E23-6 β β β β β

E23-7 β β β β β

E23-8 β β β β β

E23-9 β β β β β

E23-10 β β β β β E23-11 β β β β β

E23-12 BLU Diagnosis switch

terminal (Hong

Kong model) 4 β 5 V Ignition switch turned ON. β

E23-13 YEL/

RED Clock signal for

immobilizer coil

antenna

10 β 14 V Ignition switch turned ON. β

E23-14 β β β β β

E23-15 GRN/

WHT Fuel pump relay

output 0 β 2.5 V

For 2 sec. from the time

ignition switch is turned

ON or while engine is

running.

β

10 β 14 V On and after 2 sec. from

the time ignition switch is

turned ON or while engine

is at stop.

E23-16 BLK/

RED Main power supply 10 β 14 V Ignition switch turned ON. β

E23-17 β β β β β

E23-18 WHT CAN (low)

communication line

(active low signal)

for ABS control

module, BCM,

combination meter *0.5 β 2.5 V

(βReference

waveform No.29: β) Ignition switch turned ON

with engine at stop. CAN communication line

signal is pulse. Pulse

signal displayed with a

regular frequency which

varies depending on

engine condition.

E23-19 BLU/

WHT Electric load signal

for heater blower

motor 10 β 14 V

Ignition switch turned ON,

blower fan selector at OFF

position.

β

0 β 1 V Ignition switch turned ON,

blower fan selector at 2nd

speed position or more.

E23-20 GRN/

WHT Stop lamp switch

signal 0 β 1 V

Ignition switch turned ON,

stop lamp not lit up.

β

10 β 14 V Ignition switch turned ON,

stop lamp lit up.

E23-21 β β β β β

E23-22 β β β β β

E23-23 β β β β β

E23-24 β β β β β

Terminal

No. Wire

color Circuit Normal voltage Condition Remarks

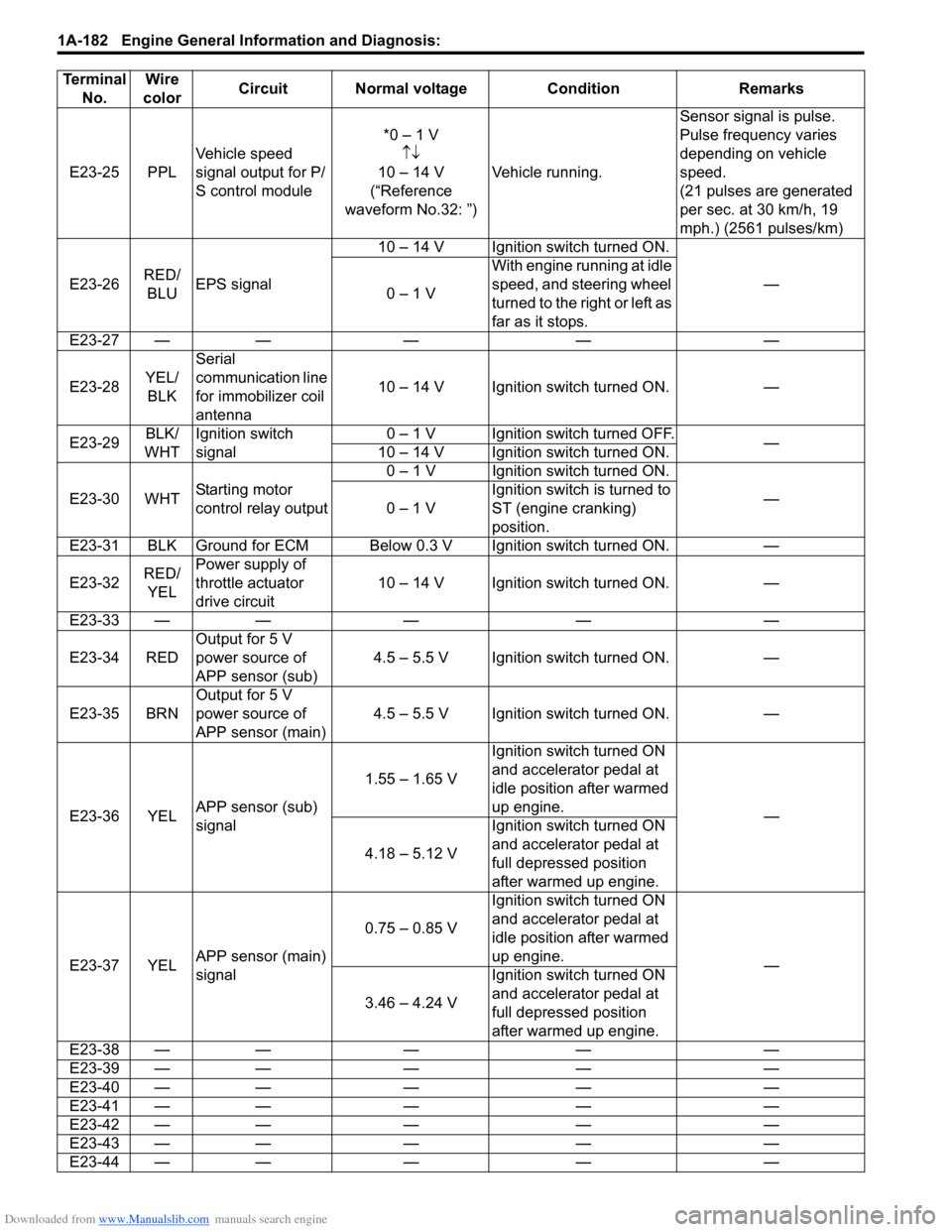

Page 232 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-182 Engine General Information and Diagnosis:

E23-25 PPLVehicle speed

signal output for P/

S control module *0 β 1 V

ββ

10 β 14 V

(βReference

waveform No.32: β) Vehicle running. Sensor signal is pulse.

Pulse frequency varies

depending on vehicle

speed.

(21 pulses are generated

per sec. at 30 km/h, 19

mph.) (2561 pulses/km)

E23-26 RED/

BLU EPS signal 10 β 14 V Ignition switch turned ON.

β

0 β 1 V With engine running at idle

speed, and steering wheel

turned to the right or left as

far as it stops.

E23-27 β β β β β

E23-28 YEL/

BLK Serial

communication line

for immobilizer coil

antenna

10 β 14 V Ignition switch turned ON. β

E23-29 BLK/

WHT Ignition switch

signal 0 β 1 V Ignition switch turned OFF.

β

10 β 14 V Ignition switch turned ON.

E23-30 WHT Starting motor

control relay output 0 β 1 V Ignition switch turned ON.

β

0 β 1 V Ignition switch is turned to

ST (engine cranking)

position.

E23-31 BLK Ground for ECM Below 0.3 V Ignition switch turned ON. β

E23-32 RED/

YEL Power supply of

throttle actuator

drive circuit

10 β 14 V Ignition switch turned ON. β

E23-33 β β β β β

E23-34 RED Output for 5 V

power source of

APP sensor (sub) 4.5 β 5.5 V Ignition switch turned ON. β

E23-35 BRN Output for 5 V

power source of

APP sensor (main) 4.5 β 5.5 V Ignition switch turned ON. β

E23-36 YEL APP sensor (sub)

signal 1.55 β 1.65 V

Ignition switch turned ON

and accelerator pedal at

idle position after warmed

up engine.

β

4.18 β 5.12 V Ignition switch turned ON

and accelerator pedal at

full depressed position

after warmed up engine.

E23-37 YEL APP sensor (main)

signal 0.75 β 0.85 V

Ignition switch turned ON

and accelerator pedal at

idle position after warmed

up engine.

β

3.46 β 4.24 V Ignition switch turned ON

and accelerator pedal at

full depressed position

after warmed up engine.

E23-38 β β β β β

E23-39 β β β β β

E23-40 β β β β β

E23-41 β β β β β

E23-42 β β β β β

E23-43 β β β β β

E23-44 β β β β β

Terminal

No. Wire

color Circuit Normal voltage Condition Remarks

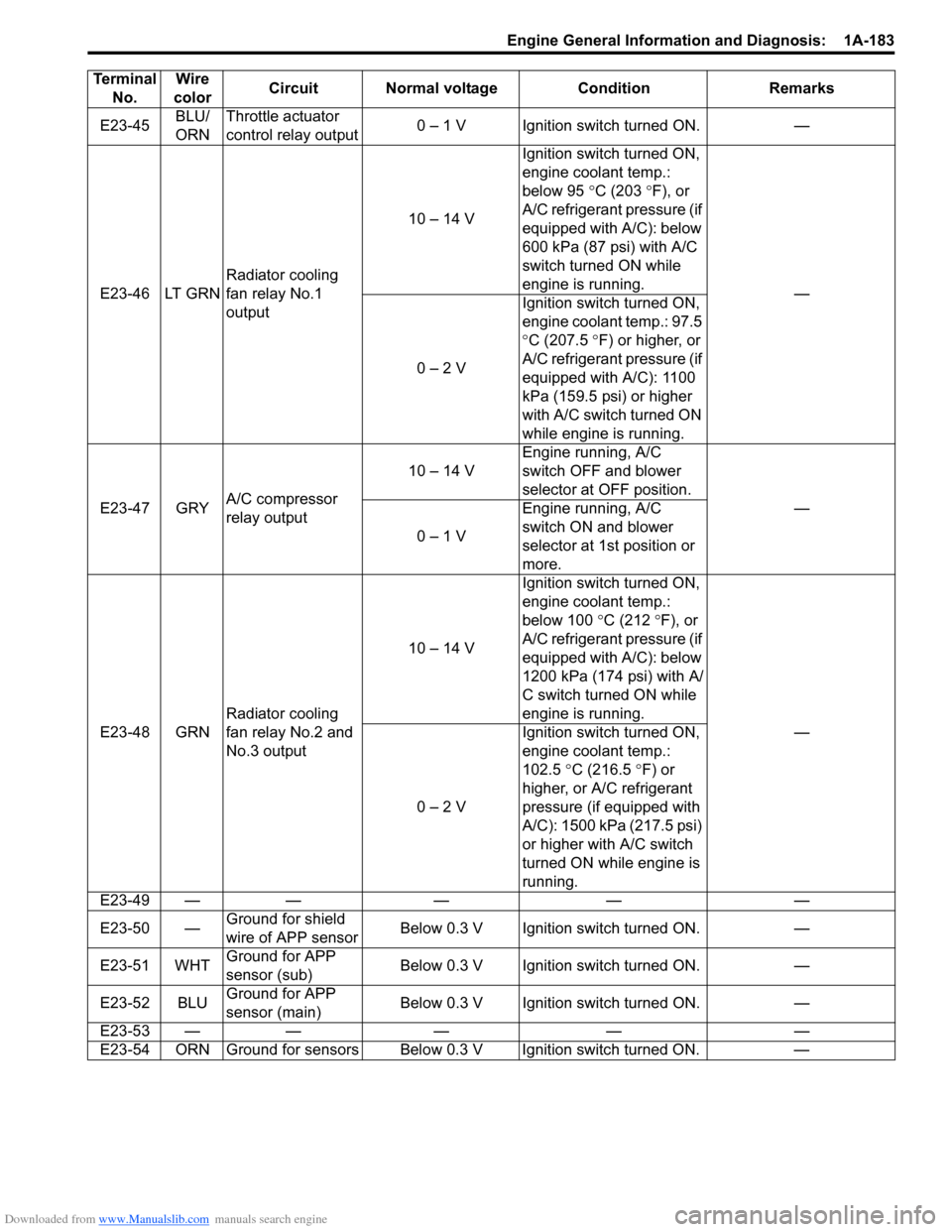

Page 233 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-183

E23-45BLU/

ORNThrottle actuator

control relay output

0 β 1 V Ignition switch turned ON. β

E23-46 LT GRN Radiator cooling

fan relay No.1

output 10 β 14 V

Ignition switch turned ON,

engine coolant temp.:

below 95

Β°C (203 Β° F), or

A/C refrigerant pressure (if

equipped with A/C): below

600 kPa (87 psi) with A/C

switch turned ON while

engine is running. β

0 β 2 V Ignition switch turned ON,

engine coolant temp.: 97.5

Β°

C (207.5 Β° F) or higher, or

A/C refrigerant pressure (if

equipped with A/C): 1100

kPa (159.5 psi) or higher

with A/C switch turned ON

while engine is running.

E23-47 GRY A/C compressor

relay output 10 β 14 V

Engine running, A/C

switch OFF and blower

selector at OFF position.

β

0 β 1 V Engine running, A/C

switch ON and blower

selector at 1st position or

more.

E23-48 GRN Radiator cooling

fan relay No.2 and

No.3 output 10 β 14 V

Ignition switch turned ON,

engine coolant temp.:

below 100

Β°C (212 Β°F), or

A/C refrigerant pressure (if

equipped with A/C): below

1200 kPa (174 psi) with A/

C switch turned ON while

engine is running. β

0 β 2 V Ignition switch turned ON,

engine coolant temp.:

102.5

Β°C (216.5 Β°F) or

higher, or A/C refrigerant

pressure (if equipped with

A/C): 1500 kPa (217.5 psi)

or higher with A/C switch

turned ON while engine is

running.

E23-49 β β β β β

E23-50 β Ground for shield

wire of APP sensor Below 0.3 V Ignition switch turned ON. β

E23-51 WHT Ground for APP

sensor (sub) Below 0.3 V Ignition switch turned ON. β

E23-52 BLU Ground for APP

sensor (main) Below 0.3 V Ignition switch turned ON. β

E23-53 β β β β β

E23-54 ORN Ground for sensors Below 0.3 V Ignition switch turned ON. β

Terminal

No. Wire

color Circuit Normal voltage Condition Remarks

Page 234 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-184 Engine General Information and Diagnosis:

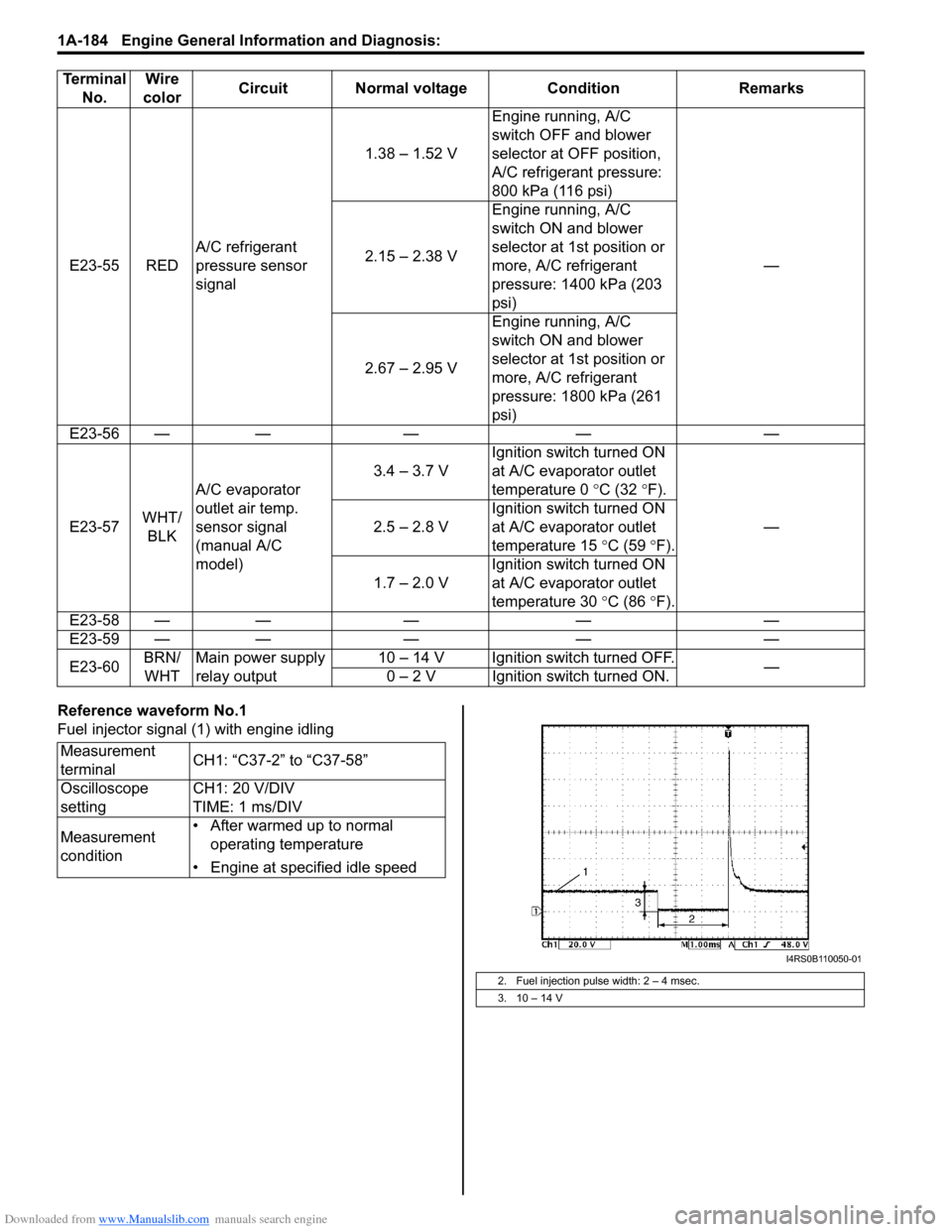

Reference waveform No.1

Fuel injector signal (1) with engine idling

E23-55 RED

A/C refrigerant

pressure sensor

signal 1.38 β 1.52 V

Engine running, A/C

switch OFF and blower

selector at OFF position,

A/C refrigerant pressure:

800 kPa (116 psi)

β

2.15 β 2.38 V Engine running, A/C

switch ON and blower

selector at 1st position or

more, A/C refrigerant

pressure: 1400 kPa (203

psi)

2.67 β 2.95 V Engine running, A/C

switch ON and blower

selector at 1st position or

more, A/C refrigerant

pressure: 1800 kPa (261

psi)

E23-56 β β β β β

E23-57 WHT/

BLK A/C evaporator

outlet air temp.

sensor signal

(manual A/C

model) 3.4 β 3.7 V

Ignition switch turned ON

at A/C evaporator outlet

temperature 0

Β°C (32 Β°F).

β

2.5 β 2.8 V Ignition switch turned ON

at A/C evaporator outlet

temperature 15

Β°C (59 Β°F).

1.7 β 2.0 V Ignition switch turned ON

at A/C evaporator outlet

temperature 30

Β°C (86 Β°F).

E23-58 β β β β β

E23-59 β β β β β

E23-60 BRN/

WHT Main power supply

relay output 10 β 14 V Ignition switch turned OFF.

β

0 β 2 V Ignition switch turned ON.

Terminal

No. Wire

color Circuit Normal voltage Condition Remarks

Measurement

terminal CH1: βC37-2β to βC37-58β

Oscilloscope

setting CH1: 20 V/DIV

TIME: 1 ms/DIV

Measurement

condition β’ After warmed up to normal

operating temperature

β’ Engine at specified idle speed

2. Fuel injection pulse width: 2 β 4 msec.

3. 10 β 14 V

I4RS0B110050-01

Page 545 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-6

1. Battery12. Pump motor23. Internal memory

2. Main fuse box 13. Solenoid valves24. Solenoid valve driver (transistor)

3. Ignition switch 14. Right-rear wheel speed sensor25. ECM

4. Circuit fuse box 15. Left-rear wheel speed sensor26. BCM

5. Combination meter 16. Right-front wheel speed sensor27. Brake fluid level switch

6. ABS warning light 17. Left-front wheel speed sensor28. Parking brake switch

7. EBD warning light (Brake warning light) 18. Data link connector29. CAN driver

8. Lamp driver module 19. To ECM, SDM and BCM

9. ABS hydraulic unit / control module assembly 20. Stop lamp

Terminal Wire color Circuit

E03 1

WHT/RED ABS pump motor driver (Transistor)

2β β

3β β

4β β

5 PPL/WHT Data link connector

6 WHT CAN communication line (low) for BCM

7 GRN/ORN Ignition switch

8 WHT CAN communication line (low) for ECM

9β β

10 RED CAN communication line (high) for ECM

11 β β

12 RED CAN communication line (high) for BCM

13 BLK Ground

14 WHT/BLU Solenoid valve power supply driver (Transistor)

15 LT GRN/BLK Leftβrear wheel speed sensor (β)

16 LT GRN Leftβrear wheel speed sensor (+)

17 β β

18 WHT Rightβfront wheel speed sensor (+)

19 WHT/BLK Rightβfront wheel speed sensor (β)

20 β β

21 RED/BLK Leftβfront wheel speed sensor (β)

22 RED Leftβfront wheel speed sensor (+)

23 β β

24 YEL Rightβrear wheel speed sensor (+)

25 BRN Rightβrear wheel speed sensor (β)

26 BLK Ground

Page 662 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-18 Automatic Transmission/Transaxle:

Visual InspectionS7RS0B5104002

Visually check the following parts and systems.

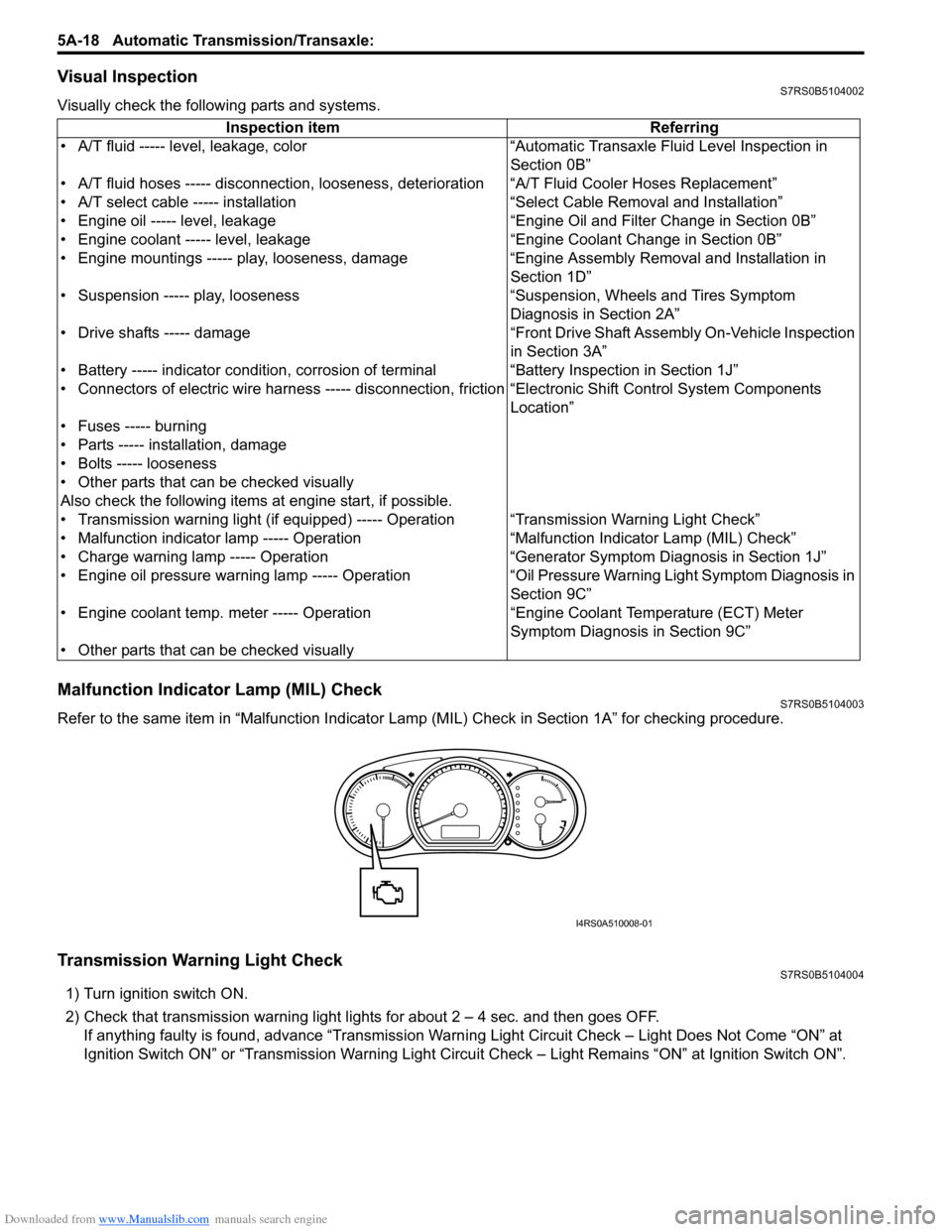

Malfunction Indicator Lamp (MIL) CheckS7RS0B5104003

Refer to the same item in βMalfunction Indicator Lam p (MIL) Check in Section 1Aβ for checking procedure.

Transmission Warning Light CheckS7RS0B5104004

1) Turn ignition switch ON.

2) Check that transmission warning light lights for about 2 β 4 sec. and then goes OFF.

If anything faulty is found, advance βTransmission Warn ing Light Circuit Check β Light Does Not Come βONβ at

Ignition Switch ONβ or βTransmission Warning Light Circu it Check β Light Remains βONβ at Ignition Switch ONβ.

Inspection item Referring

β’ A/T fluid ----- level, leakage, color βAutomatic Transaxle Fluid Level Inspection in Section 0Bβ

β’ A/T fluid hoses ----- disconnection, looseness, deterioration βA/T Fluid Cooler Hoses Replacementβ

β’ A/T select cable ----- installation βS elect Cable Removal and Installationβ

β’ Engine oil ----- level, leakage βEngine Oil and Filter Change in Section 0Bβ

β’ Engine coolant ----- level, leakage βEngine Coolant Change in Section 0Bβ

β’ Engine mountings ----- play, looseness, damage βEngine Assembly Removal and Installation in Section 1Dβ

β’ Suspension ----- play, looseness βSuspension, Wheels and Tires Symptom Diagnosis in Section 2Aβ

β’ Drive shafts ----- damage βFront Drive Shaft Assembly On-Vehicle Inspection in Section 3Aβ

β’ Battery ----- indicator condition, corrosion of terminal βBattery Inspection in Section 1Jβ

β’ Connectors of electric wire harness ----- disconnection, friction βElectronic Shift Control System Components

Locationβ

β’ Fuses ----- burning

β’ Parts ----- installation, damage

β’ Bolts ----- looseness

β’ Other parts that can be checked visually

Also check the following items at engine start, if possible.

β’ Transmission warning light (if equipped) ----- Operation βTransmission Warning Light Checkβ

β’ Malfunction indicator lamp ----- Operation βMalfunction Indicator Lamp (MIL) Checkβ

β’ Charge warning lamp ----- Operation βGenerator Symptom Diagnosis in Section 1Jβ

β’ Engine oil pressure warning lamp ----- Operation βOil Pressure Warning Ligh t Symptom Diagnosis in

Section 9Cβ

β’ Engine coolant temp. meter ----- Operation βEngine Coolant Temperature (ECT) Meter

Symptom Diagnosis in Section 9Cβ

β’ Other parts that can be checked visually

I4RS0A510008-01

Page 727 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-83

Connector βC34βTerminal Wire color Circuit Standard

voltage Condition

1 BLK Ground 0 β 1 V Ignition switch ON

2 LT GRN/

BLK Pressure control

solenoid valve (β)

0.6 β 1.0 V Ignition switch ON

3WHT/BLK TCC pressure control

solenoid valve (β) 0.6 β 1.0 V Ignition switch ON

4GRY Pressure control

solenoid valve (+) *0 β 0.6 V

ββ

10 β 14 V

(βReference waveform No. 1: β) Engine running at idling.

(Output signal is duty pulse. Duty ratio varies

depending on throttle valve opening.)

5WHT/BLU TCC pressure control

solenoid valve (+) *0 β 0.6 V

ββ

10 β 14 V

(βReference waveform No. 2: β) Engine running at idling.

(Output signal is duty pulse. Duty ratio varies

depending on torque converter clutch operating

condition.)

6 YEL/BLK Power source 10 β 14 V Ignition switch ON

7WHT CAN communication

line (Low) *2.5 β 3.6 V

ββ

1.6 β 2.5 V

(βReference waveform No. 3: β) Engine running at idling with after warming up.

(CAN communication signal is pulse. Pulse signal

frequency varies depending on engine condition.))

8β β β β

9β β β β

10 β ββ β

11 LT G R N Transmission fluid

temperature sensor (+) 2.9 β 3.1 V Ignition switch ON, fluid temperature is 20

Β°C (68 Β°F)

0.3 β 0.5 V Ignition switch ON, fluid temperature is 100 Β°C (212 Β°F)

12 ORN Transmission fluid

temperature sensor (β) 0 β 1 V Ignition switch ON

13 β ββ β

14 BLU/BLK Timing solenoid valv e 0 β 1 V Ignition switch ON

15 BLK/YEL Shift solenoid valve-B

(No.2) 9 β 14 V Ignition switch ON, select lever in βPβ range

16 BRN Shift solenoid valve-A

(No.1) 9 β 14 V Ignition switch ON, select lever in βPβ range

17 RED CAN communication

line (High) *2.5 β 3.6 V

ββ

1.6 β 2.5 V

(βReference waveform No. 3: β) Engine running at idling with after warming up.

(CAN communication signal is pulse. Pulse signal

frequency varies depending on engine condition.)

18 β ββ β

19 β ββ β

20 β ββ β

21 β ββ β

22 β ββ β

23 BLK Ground 0 β 1 V Ignition switch ON

24 WHT/RED Power source

for back-

up 10 β 14 V Constantly

Page 728 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-84 Automatic Transmission/Transaxle:

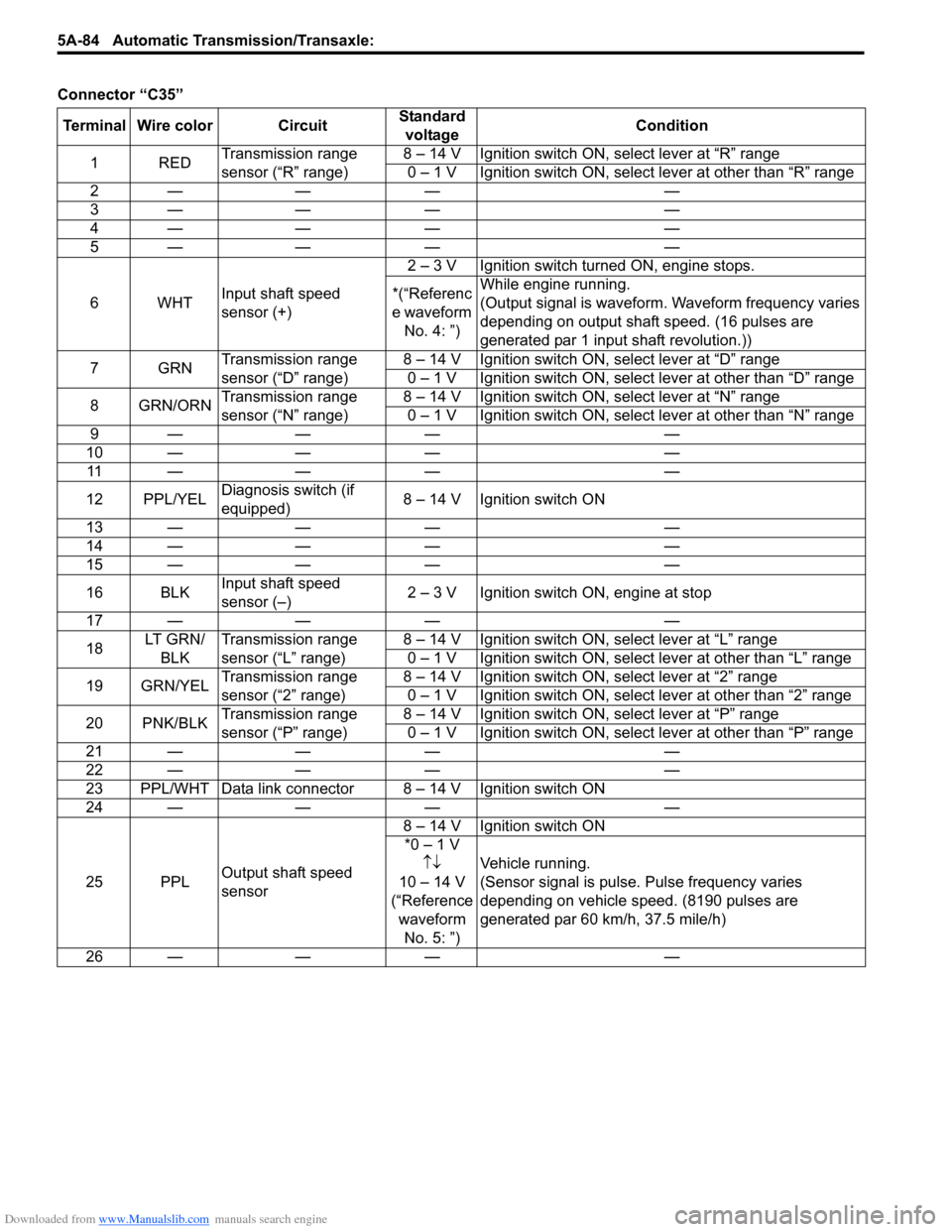

Connector βC35β

Terminal Wire color Circuit Standard

voltage Condition

1RED Transmission range

sensor (βRβ range) 8 β 14 V Ignition switch ON, select lever at βRβ range

0 β 1 V Ignition switch ON, select lever at other than βRβ range

2β β β β

3β β β β

4β β β β

5β β β β

6WHT Input shaft speed

sensor (+) 2 β 3 V Ignition switch turned ON, engine stops.

*(βReferenc

e waveform No. 4: β) While engine running.

(Output signal is waveform. Waveform frequency varies

depending on output shaft speed. (16 pulses are

generated par 1 input shaft revolution.))

7GRN Transmission range

sensor (βDβ range) 8 β 14 V Ignition switch ON, select lever at βDβ range

0 β 1 V Ignition switch ON, select lever at other than βDβ range

8 GRN/ORN Transmission range

sensor (βNβ range) 8 β 14 V Ignition switch ON, select lever at βNβ range

0 β 1 V Ignition switch ON, select lever at other than βNβ range

9β β β β

10 β β β β 11 β β β β

12 PPL/YEL Diagnosis switch (if

equipped) 8 β 14 V Ignition switch ON

13 β β β β

14 β β β β

15 β β β β

16 BLK Input shaft speed

sensor (β) 2 β 3 V Ignition switch ON, engine at stop

17 β β β β

18 LT G R N /

BLK Transmission range

sensor (βLβ range) 8 β 14 V Ignition switch ON, select lever at βLβ range

0 β 1 V Ignition switch ON, select lever at other than βLβ range

19 GRN/YEL Transmission range

sensor (β2β range) 8 β 14 V Ignition switch ON, select lever at β2β range

0 β 1 V Ignition switch ON, select lever at other than β2β range

20 PNK/BLK Transmission range

sensor (βPβ range) 8 β 14 V Ignition switch ON, select lever at βPβ range

0 β 1 V Ignition switch ON, select lever at other than βPβ range

21 β β β β

22 β β β β

23 PPL/WHT Data link connector 8 β 14 V Ignition switch ON

24 β β β β

25 PPL Output shaft speed

sensor 8 β 14 V Ignition switch ON

*0 β 1 V ββ

10 β 14 V

(βReference waveform No. 5: β) Vehicle running.

(Sensor signal is pulse. Pulse frequency varies

depending on vehicle speed. (8190 pulses are

generated par 60 km/h, 37.5 mile/h)

26 β β β β

Page 743 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-99

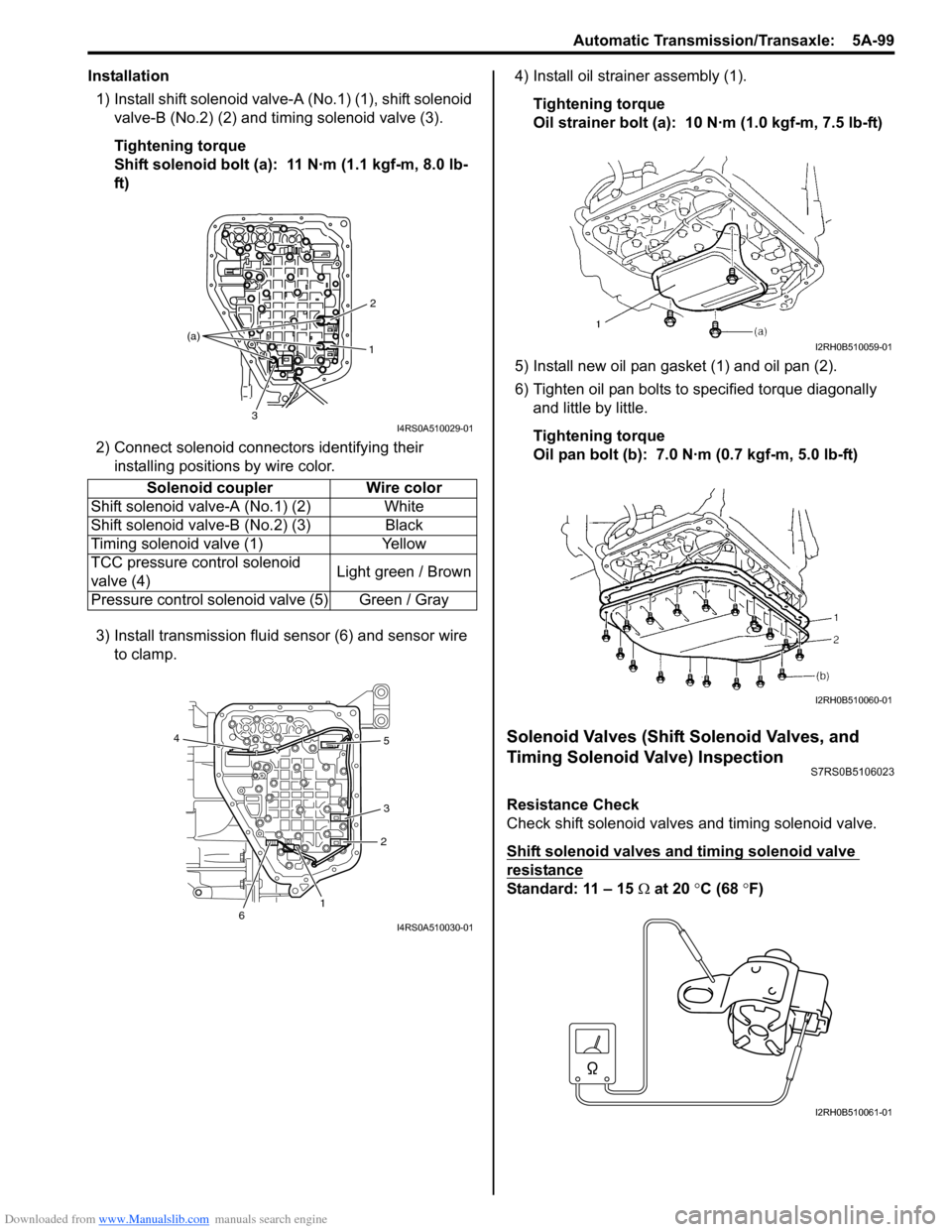

Installation1) Install shift solenoid valve- A (No.1) (1), shift solenoid

valve-B (No.2) (2) and timing solenoid valve (3).

Tightening torque

Shift solenoid bolt (a): 11 NΒ·m (1.1 kgf-m, 8.0 lb-

ft)

2) Connect solenoid connectors identifying their installing positions by wire color.

3) Install transmission fluid sensor (6) and sensor wire to clamp. 4) Install oil strain

er assembly (1).

Tightening torque

Oil strainer bolt (a): 10 NΒ·m (1.0 kgf-m, 7.5 lb-ft)

5) Install new oil pan gasket (1) and oil pan (2).

6) Tighten oil pan bolts to specified torque diagonally and little by little.

Tightening torque

Oil pan bolt (b): 7.0 NΒ·m (0.7 kgf-m, 5.0 lb-ft)

Solenoid Valves (Shift Solenoid Valves, and

Timing Solenoid Valve) Inspection

S7RS0B5106023

Resistance Check

Check shift solenoid valves and timing solenoid valve.

Shift solenoid valves and timing solenoid valve

resistance

Standard: 11 β 15 β¦ at 20 Β°C (68 Β° F)

Solenoid coupler Wire color

Shift solenoid valv e-A (No.1) (2) White

Shift solenoid valv e-B (No.2) (3) Black

Timing solenoid valve (1) Yellow

TCC pressure control solenoid

valve (4) Light green / Brown

Pressure control solenoid valve (5) Green / Gray

1 2

3

(a)

I4RS0A510029-01

1

2

3 5

4

6

I4RS0A510030-01

I2RH0B510059-01

I2RH0B510060-01

I2RH0B510061-01