Cable SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 1349 of 1496

Downloaded from www.Manualslib.com manuals search engine Security and Locks: 9F-3

Diagnostic Information and Procedures

Power Door Lock System Symptom DiagnosisS7RS0B9604001

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, re fer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Power Door Lock System Operation InspectionS7RS0B9604002

1) Check the following operation:

a) Turn the driver side key cylinder is turned LOCK once, check all doors lock.

b) Turn the driver side door key cylinder is turned UNLOC K position with door key twice, check all doors unlock.

If malfunction is found, go to “Power Door Lock System Symptom Diagnosis”.

Condition Possible cause Correction / Reference Item

All door can not be locked

/ unlocked by all of

switches Circuit fuse blown

Replace fuse and check for short circuit.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

All door can not be locked

/ unlocked by only power

door lock switch Circuit fuse blown

Replace fuse and check for short circuit.

Power door lock switch faulty Check power door lock switch referring to

“Power Door Lock Switch Inspection”.

Wiring harness connected to power door

lock switch faulty Repair.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

All door can not be locked

/ unlocked by only key

cylinder switch Circuit fuse blown

Replace fuse and check for short circuit.

Key cylinder switch faulty Check key cylinder switch referring to “Door

Key Cylinder Switch Inspection”.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Only one door can not be

locked / unlocked Power door lock actuator faulty

Check actuator referring to “Power Door Lock

Actuator Inspection”.

Wiring harness connected to applicable

door lock actuator faulty Repair.

BCM faulty Replace after making sure that none of above

parts is faulty.

Page 1359 of 1496

Downloaded from www.Manualslib.com manuals search engine Security and Locks: 9F-13

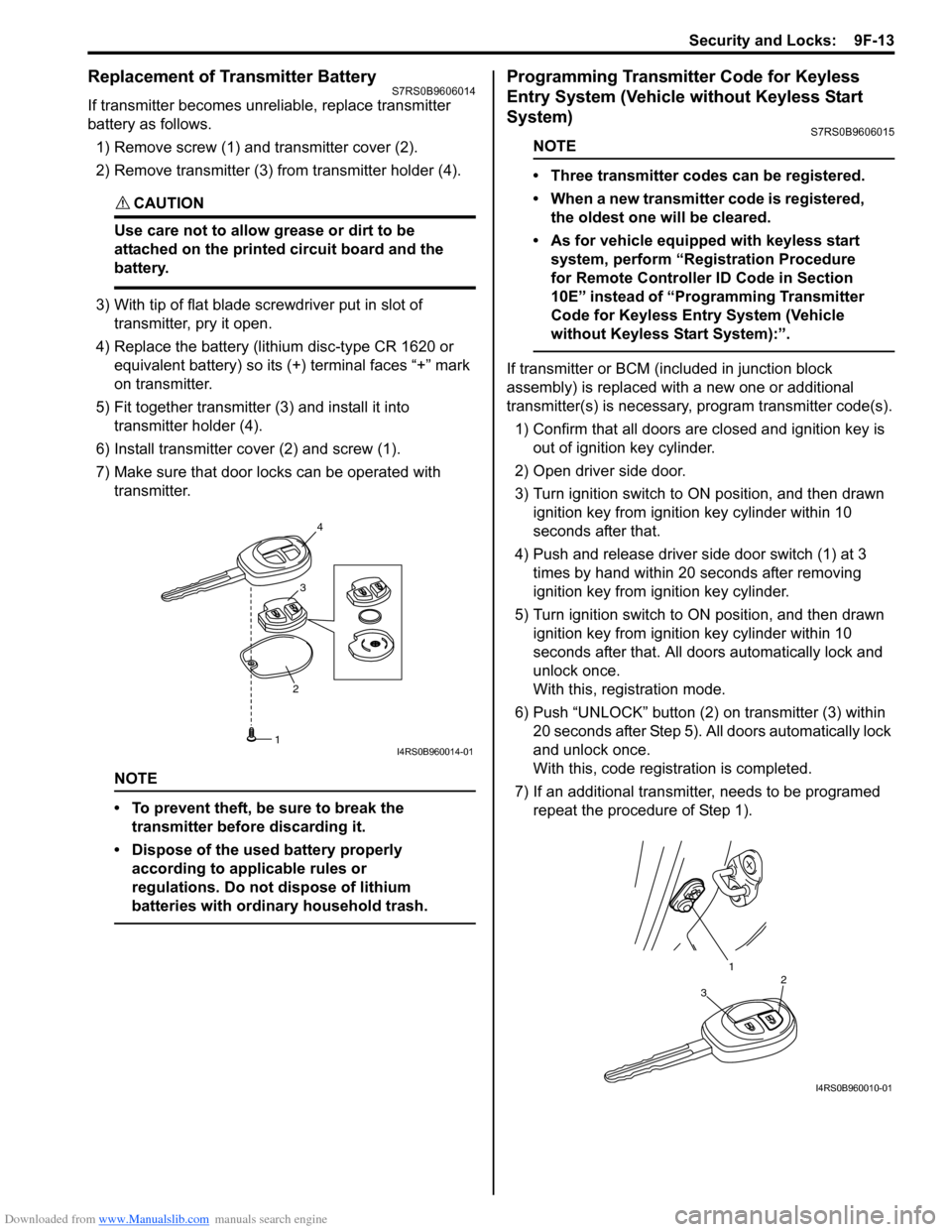

Replacement of Transmitter Battery S7RS0B9606014

If transmitter becomes unreliable, replace transmitter

battery as follows.

1) Remove screw (1) and transmitter cover (2).

2) Remove transmitter (3) from transmitter holder (4).

CAUTION!

Use care not to allow grease or dirt to be

attached on the printed circuit board and the

battery.

3) With tip of flat blade screwdriver put in slot of transmitter, pry it open.

4) Replace the battery (lithium disc-type CR 1620 or equivalent battery) so its (+) terminal faces “+” mark

on transmitter.

5) Fit together transmitter (3) and install it into

transmitter holder (4).

6) Install transmitter co ver (2) and screw (1).

7) Make sure that door locks can be operated with transmitter.

NOTE

• To prevent theft, be sure to break the transmitter before discarding it.

• Dispose of the used battery properly according to applicable rules or

regulations. Do not dispose of lithium

batteries with ordinary household trash.

Programming Transmitter Code for Keyless

Entry System (Vehicle without Keyless Start

System)

S7RS0B9606015

NOTE

• Three transmitter codes can be registered.

• When a new transmitter code is registered, the oldest one will be cleared.

• As for vehicle equipped with keyless start system, perform “Registration Procedure

for Remote Controller ID Code in Section

10E” instead of “Programming Transmitter

Code for Keyless Entry System (Vehicle

without Keyless Start System):”.

If transmitter or BCM (included in junction block

assembly) is replaced with a new one or additional

transmitter(s) is necessary, program transmitter code(s).

1) Confirm that all doors are closed and ignition key is

out of ignition key cylinder.

2) Open driver side door.

3) Turn ignition switch to ON position, and then drawn ignition key from igniti on key cylinder within 10

seconds after that.

4) Push and release driver side door switch (1) at 3 times by hand within 20 seconds after removing

ignition key from ig nition key cylinder.

5) Turn ignition switch to ON position, and then drawn ignition key from igniti on key cylinder within 10

seconds after that. All d oors automatically lock and

unlock once.

With this, registration mode.

6) Push “UNLOCK” button (2) on transmitter (3) within

20 seconds after Step 5). All doors automatically lock

and unlock once.

With this, code registration is completed.

7) If an additional transmitter, needs to be programed repeat the procedure of Step 1).

23

4

1I4RS0B960014-01

1

32

I4RS0B960010-01

Page 1360 of 1496

Downloaded from www.Manualslib.com manuals search engine 9F-14 Security and Locks:

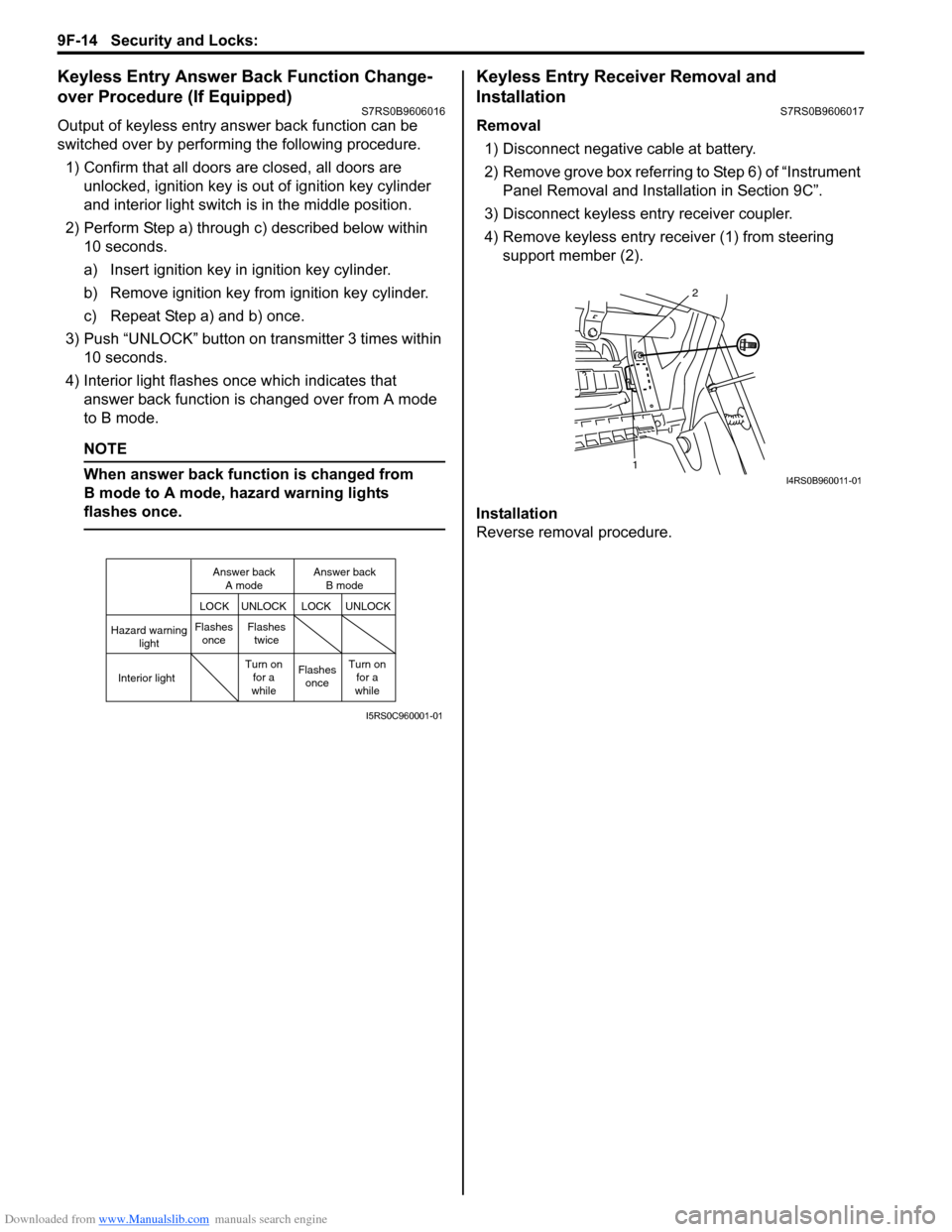

Keyless Entry Answer Back Function Change-

over Procedure (If Equipped)

S7RS0B9606016

Output of keyless entry answer back function can be

switched over by performing the following procedure.

1) Confirm that all doors are closed, all doors are unlocked, ignition key is out of ignition key cylinder

and interior light switch is in the middle position.

2) Perform Step a) through c) described below within 10 seconds.

a) Insert ignition key in ignition key cylinder.

b) Remove ignition key from ignition key cylinder.

c) Repeat Step a) and b) once.

3) Push “UNLOCK” button on transmitter 3 times within 10 seconds.

4) Interior light flashes once which indicates that answer back function is changed over from A mode

to B mode.

NOTE

When answer back function is changed from

B mode to A mode, hazard warning lights

flashes once.

Keyless Entry Receiver Removal and

Installation

S7RS0B9606017

Removal

1) Disconnect negative cable at battery.

2) Remove grove box referring to Step 6) of “Instrument Panel Removal and Installation in Section 9C”.

3) Disconnect keyless entry receiver coupler.

4) Remove keyless entry receiver (1) from steering support member (2).

Installation

Reverse removal procedure.

Hazard warning light

LOCK LOCK

UNLOCK UNLOCK

Interior lightFlashes

once Flashes

twice

Flashesonce

Turn on

for a

while Turn on

for a

while

Answer back

A mode Answer back

B mode

I5RS0C960001-01

1 2I4RS0B960011-01

Page 1361 of 1496

Downloaded from www.Manualslib.com manuals search engine Security and Locks: 9F-15

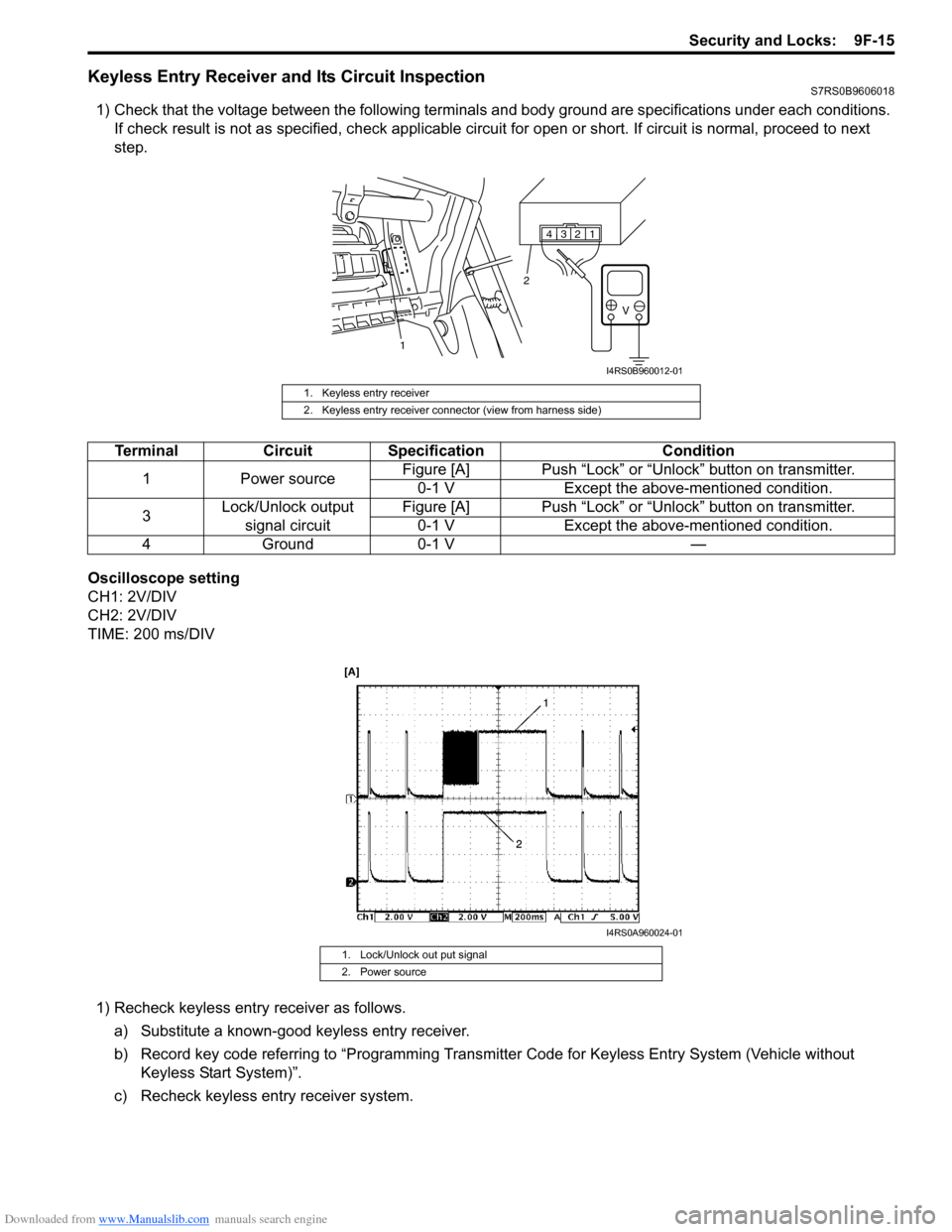

Keyless Entry Receiver and Its Circuit InspectionS7RS0B9606018

1) Check that the voltage between the following terminals and body ground are specifications under each conditions.

If check result is not as specified, ch eck applicable circuit for open or short. If circuit is normal, proceed to next

step.

Oscilloscope setting

CH1: 2V/DIV

CH2: 2V/DIV

TIME: 200 ms/DIV 1) Recheck keyless entry receiver as follows.

a) Substitute a known-good keyless entry receiver.

b) Record key code referring to “Programming Transmit ter Code for Keyless Entry System (Vehicle without

Keyless Start System)”.

c) Recheck keyless entry receiver system.

1. Keyless entry receiver

2. Keyless entry receiver connector (view from harness side)

1234

V

1 2

I4RS0B960012-01

Terminal

Circuit Specification Condition

1 Power source Figure [A] Push “Lock” or “Unlock” button on transmitter.

0-1 V Except the above-mentioned condition.

3 Lock/Unlock output

signal circuit Figure [A] Push “Lock” or “Unlock” button on transmitter.

0-1 V Except the above-mentioned condition.

4G ro un d0 -1 V —

1. Lock/Unlock out put signal

2. Power source

I4RS0A960024-01

Page 1383 of 1496

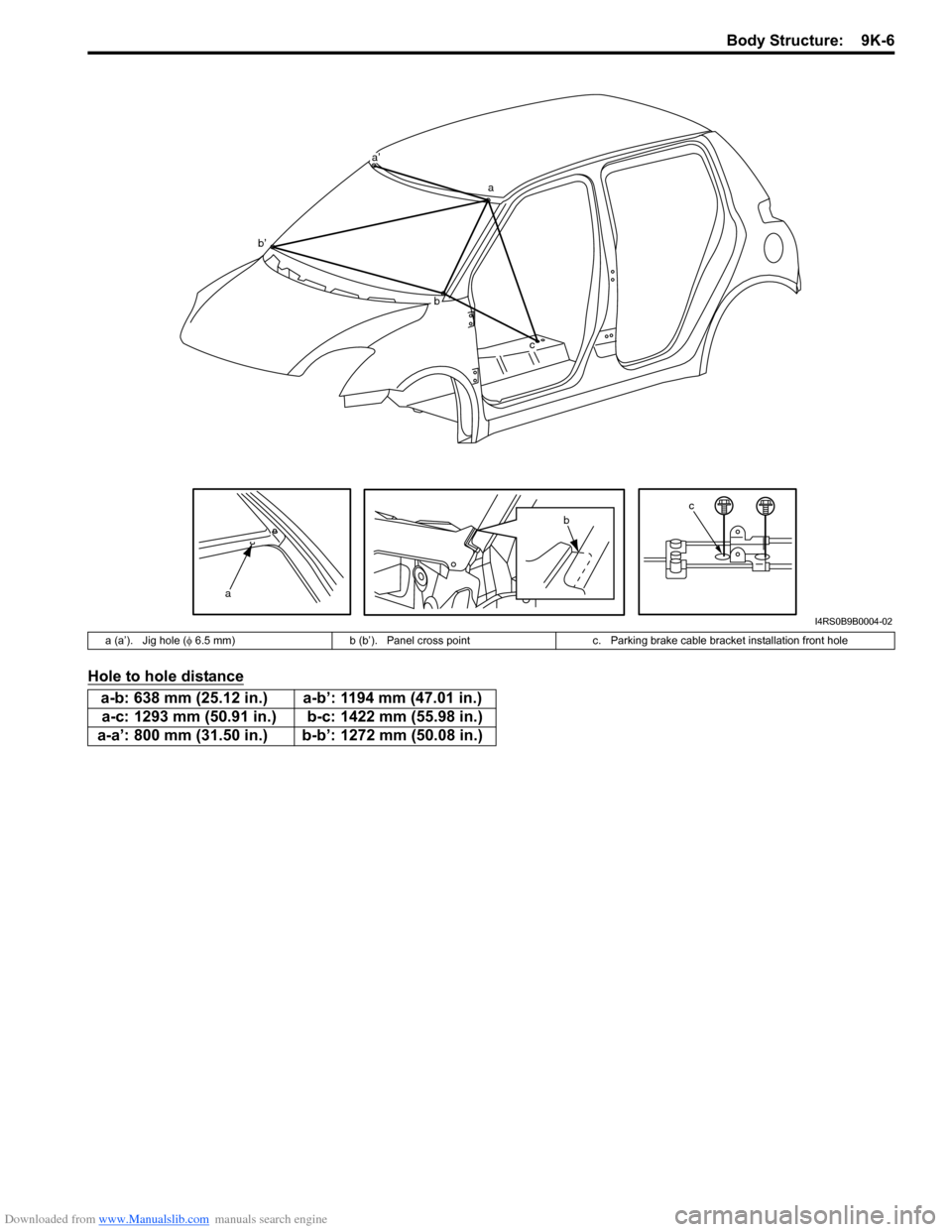

Downloaded from www.Manualslib.com manuals search engine Body Structure: 9K-6

Hole to hole distance

a

cb

a’

a

bc

b’

I4RS0B9B0004-02

a (a’). Jig hole (φ 6.5 mm) b (b’). Panel cross point c. Parking brake cable bracket installation front hole

a-b: 638 mm (25.12 in.) a-b’: 1194 mm (47.01 in.)

a-c: 1293 mm (50.91 in.) b-c: 1422 mm (55.98 in.)

a-a’: 800 mm (31.50 in.) b-b’: 1272 mm (50.08 in.)

Page 1414 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-11 Body Electrical Control System:

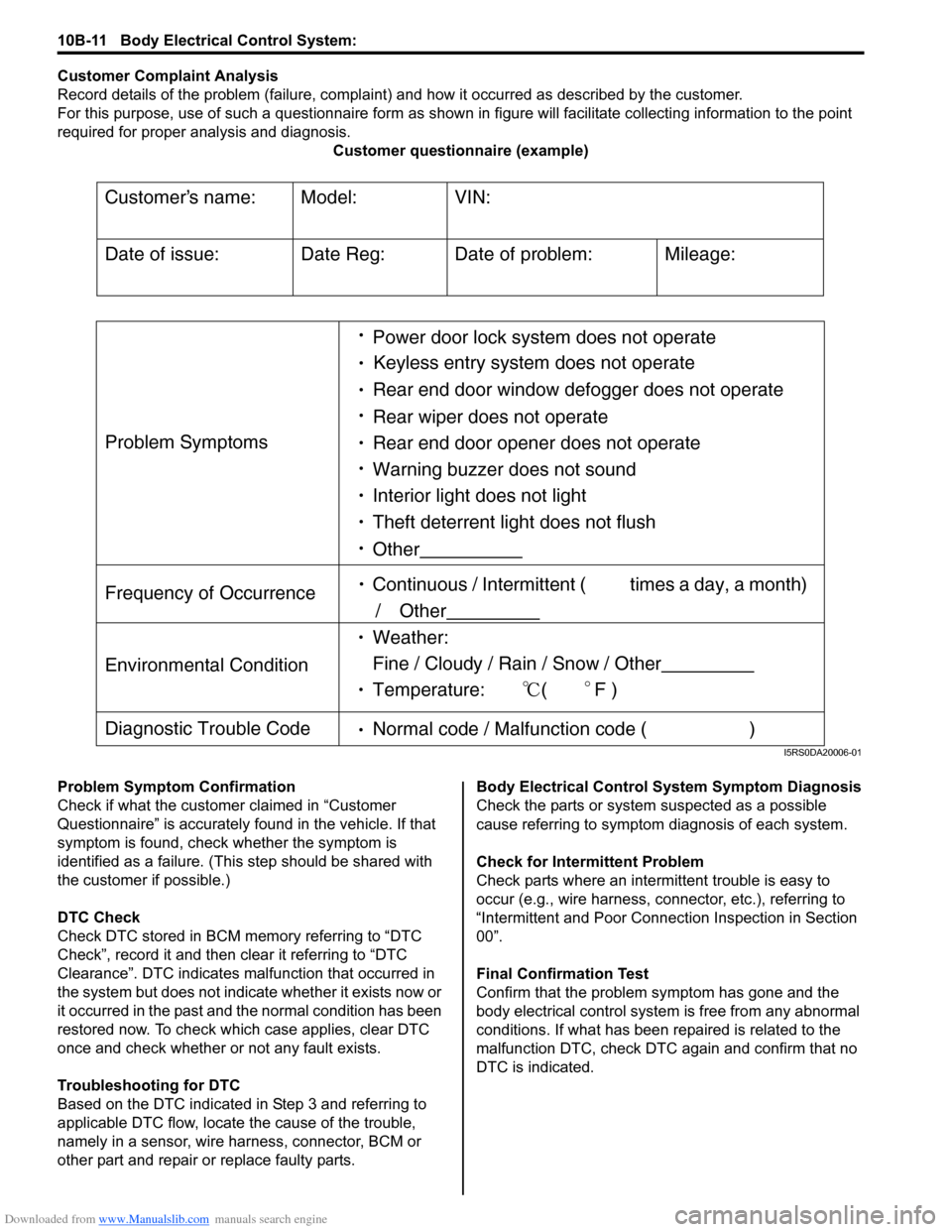

Customer Complaint Analysis

Record details of the problem (failure, complaint) and how it occurred as described by the customer.

For this purpose, use of such a questionnaire form as shown in figure will facilitate collectin g information to the point

required for proper analysis and diagnosis. Customer questionnaire (example)

Problem Symptom Confirmation

Check if what the custom er claimed in “Customer

Questionnaire” is accurately f ound in the vehicle. If that

symptom is found, check whether the symptom is

identified as a failure. (This step should be shared with

the customer if possible.)

DTC Check

Check DTC stored in BCM me mory referring to “DTC

Check”, record it and then clear it referring to “DTC

Clearance”. DTC indicates malfunction that occurred in

the system but does not indicate whether it exists now or

it occurred in the past and the normal condition has been

restored now. To check which case applies, clear DTC

once and check whether or not any fault exists.

Troubleshooting for DTC

Based on the DTC indicated in Step 3 and referring to

applicable DTC flow, locate the cause of the trouble,

namely in a sensor, wire harness, connector, BCM or

other part and repair or replace faulty parts. Body Electrical Control System Symptom Diagnosis

Check the parts or system

suspected as a possible

cause referring to symptom diagnosis of each system.

Check for Intermi ttent Problem

Check parts where an intermit tent trouble is easy to

occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connec tion Inspection in Section

00”.

Final Confirmation Test

Confirm that the problem symptom has gone and the

body electrical control system is free from any abnormal

conditions. If what has been repaired is related to the

malfunction DTC, check DTC again and confirm that no

DTC is indicated.

Customers name:

Model:

VIN:

Date of issue:

Date Reg:

Date of problem:

Mileage:

Problem Symptoms

Power door lock system does not operate

Keyless entry system does not operate

Rear end door window defogger does not operate

Rear wiper does not operate

Rear end door opener does not operate

Other

Frequency of Occurrence

Continuous / Intermittent ( times a day, a month)

/ Other

Environmental Condition

Weather:

Fine / Cloudy / Rain / Snow / Other

Temperature: (F )

Diagnostic Trouble Code Normal code / Malfunction code ( )

Warning buzzer does not sound

Interior light does not light

Theft deterrent light does not flush

I5RS0DA20006-01

Page 1417 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-14

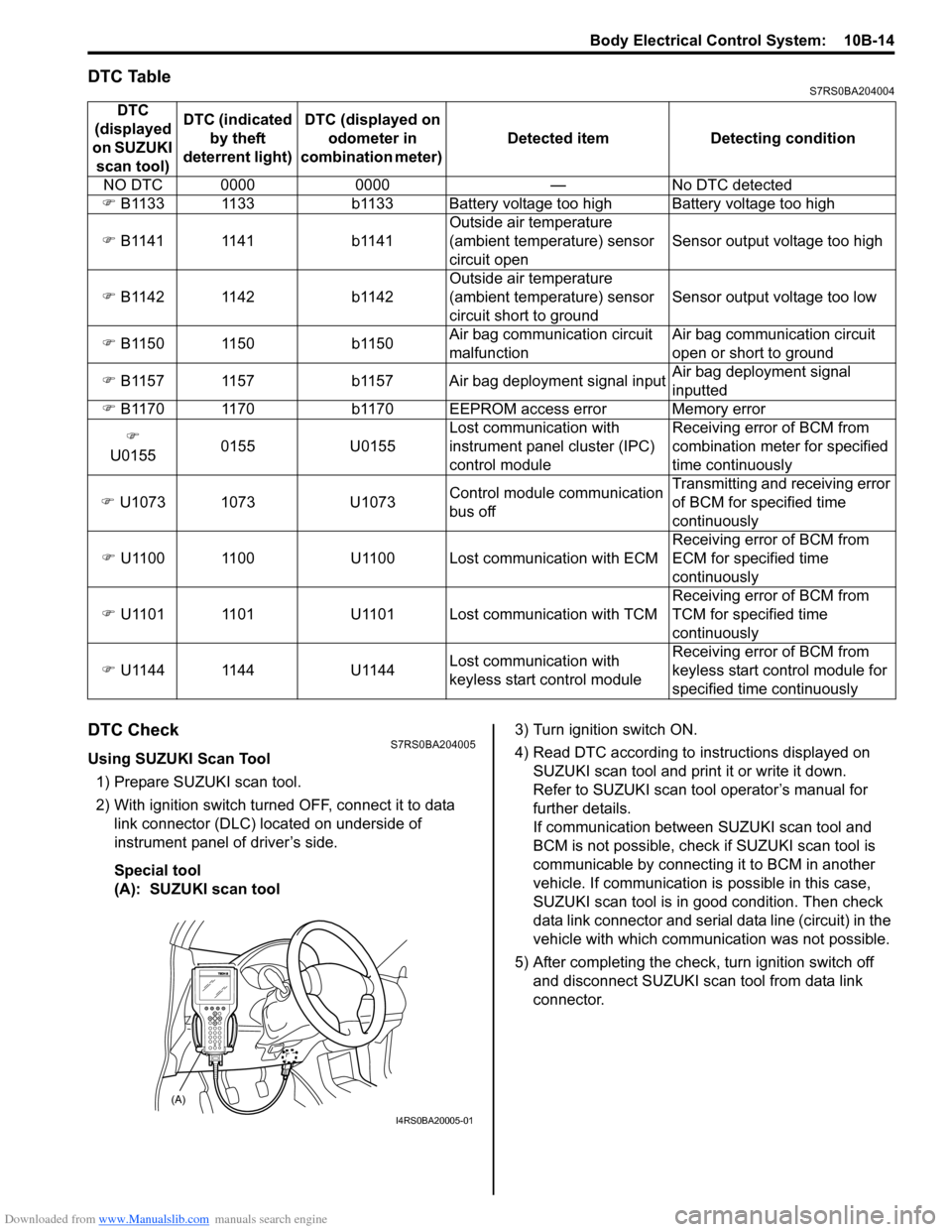

DTC TableS7RS0BA204004

DTC CheckS7RS0BA204005

Using SUZUKI Scan Tool1) Prepare SUZUKI scan tool.

2) With ignition switch turned OFF, connect it to data link connector (DLC) located on underside of

instrument panel of driver’s side.

Special tool

(A): SUZUKI scan tool 3) Turn ignition switch ON.

4) Read DTC according to

instructions displayed on

SUZUKI scan tool and print it or write it down.

Refer to SUZUKI scan tool operator’s manual for

further details.

If communication between SUZUKI scan tool and

BCM is not possible, check if SUZUKI scan tool is

communicable by connecting it to BCM in another

vehicle. If communication is possible in this case,

SUZUKI scan tool is in good condition. Then check

data link connector and serial data line (circuit) in the

vehicle with which communica tion was not possible.

5) After completing the check, turn ignition switch off and disconnect SUZUKI scan tool from data link

connector.

DTC

(displayed

on SUZUKI scan tool) DTC (indicated

by theft

deterrent light) DTC (displayed on

odometer in

combination meter) Detected item Detecting condition

NO DTC 0000 0000 — No DTC detected

�) B1133 1133 b1133 Battery voltage too high Battery voltage too high

�) B1141 1141 b1141 Outside air temperature

(ambient temperature) sensor

circuit openSensor output voltage too high

�) B1142 1142 b1142 Outside air temperature

(ambient temperature) sensor

circuit short to groundSensor output voltage too low

�) B1150 1150 b1150 Air bag communication circuit

malfunctionAir bag communication circuit

open or short to ground

�) B1157 1157 b1157 Air bag deployment signal input Air bag deployment signal

inputted

�) B1170 1170 b1170 EEPROM access error Memory error

�)

U0155 0155 U0155 Lost communication with

instrument panel cluster (IPC)

control moduleReceiving error of BCM from

combination mete

r for specified

time continuously

�) U1073 1073 U1073 Control module communication

bus offTransmitting and receiving error

of BCM for specified time

continuously

�) U1100 1100 U1100 Lost communication with ECM Receiving error of BCM from

ECM for specified time

continuously

�) U1101 1101 U1101 Lost communication with TCM Receiving error of BCM from

TCM for specified time

continuously

�) U1144 1144 U1144 Lost communication with

keyless start control moduleReceiving error of BCM from

keyless start control module for

specified time continuously

(A)

I4RS0BA20005-01

Page 1434 of 1496

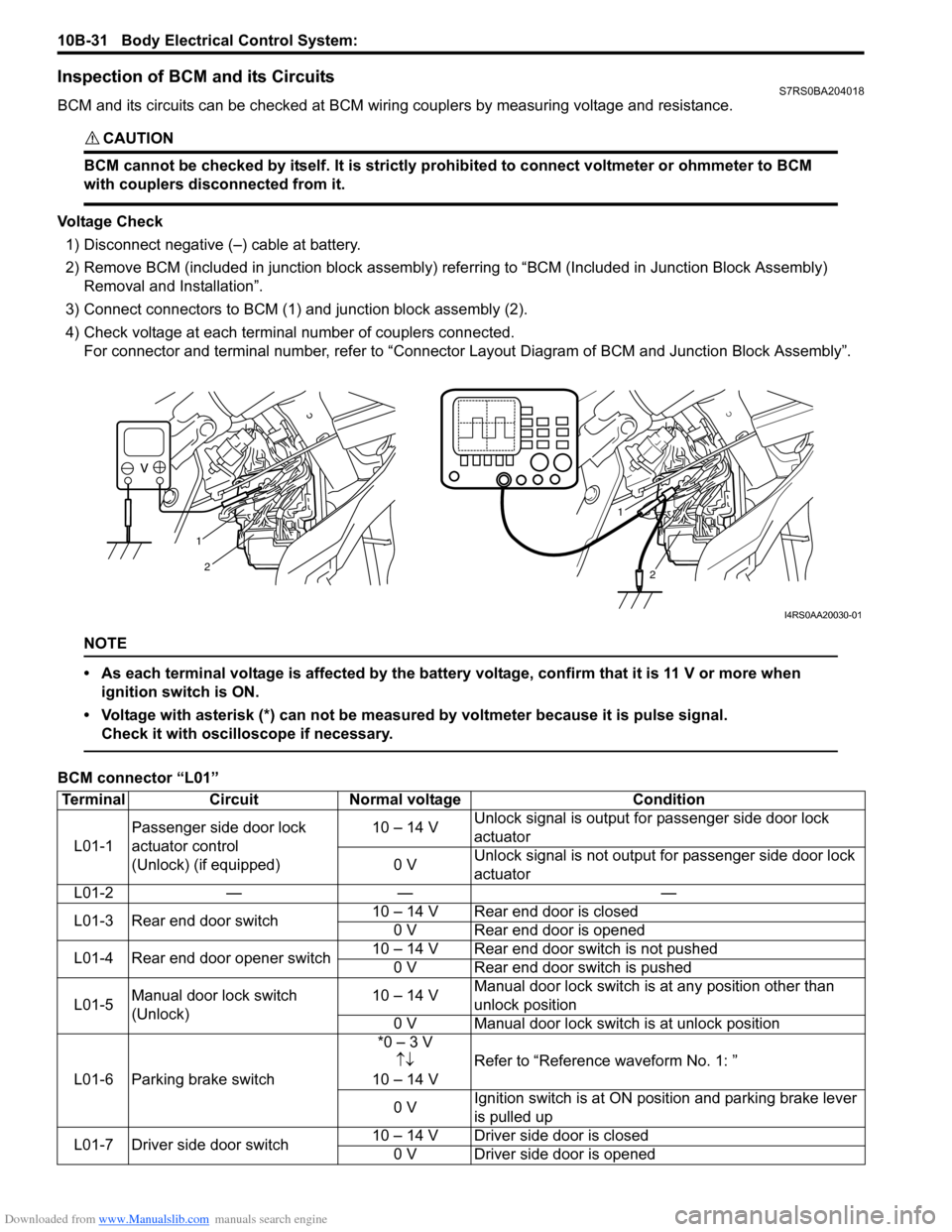

Downloaded from www.Manualslib.com manuals search engine 10B-31 Body Electrical Control System:

Inspection of BCM and its CircuitsS7RS0BA204018

BCM and its circuits can be checked at BCM wiring couplers by measuring voltage and resistance.

CAUTION!

BCM cannot be checked by itself. It is strictly prohibited to connect voltmeter or ohmmeter to BCM

with couplers disconnected from it.

Voltage Check1) Disconnect negative (–) cable at battery.

2) Remove BCM (included in junction block assembly) refe rring to “BCM (Included in Junction Block Assembly)

Removal and Installation”.

3) Connect connectors to BCM (1) and junction block assembly (2).

4) Check voltage at each terminal number of couplers connected. For connector and terminal number, refer to “Connector Layout Diagram of BCM and Junction Block Assembly”.

NOTE

• As each terminal voltage is affected by the battery voltage, confirm that it is 11 V or more when

ignition switch is ON.

• Voltage with asterisk (*) can not be measured by voltmeter because it is pulse signal. Check it with oscilloscope if necessary.

BCM connector “L01”

1

2

1

2

I4RS0AA20030-01

Terminal CircuitNormal voltage Condition

L01-1 Passenger side door lock

actuator control

(Unlock) (if equipped) 10 – 14 V

Unlock signal is output fo

r passenger side door lock

actuator

0 V Unlock signal is not output for passenger side door lock

actuator

L01-2 — — —

L01-3 Rear end door switch 10 – 14 V Rear end door is closed

0 V Rear end door is opened

L01-4 Rear end door opener switch 10 – 14 V Rear end door switch is not pushed

0 V Rear end door switch is pushed

L01-5 Manual door lock switch

(Unlock) 10 – 14 V

Manual door lock switch is at any position other than

unlock position

0 V Manual door lock switch is at unlock position

L01-6 Parking brake switch *0 – 3 V

↑↓

10 – 14 V Refer to “Reference waveform No. 1: ”

0 V Ignition switch is at ON po

sition and parking brake lever

is pulled up

L01-7 Driver side door switch 10 – 14 V Driver side door is closed

0 V Driver side door is opened

Page 1442 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-39 Body Electrical Control System:

Repair Instructions

BCM (Included in Junction Block Assembly)

Removal and Installation

S7RS0BA206001

CAUTION!

Do not attempt removal of BCM from junction

block assembly as it may cause contact

failure.

If there is faulty condition in BCM, replace

junction block assembly.

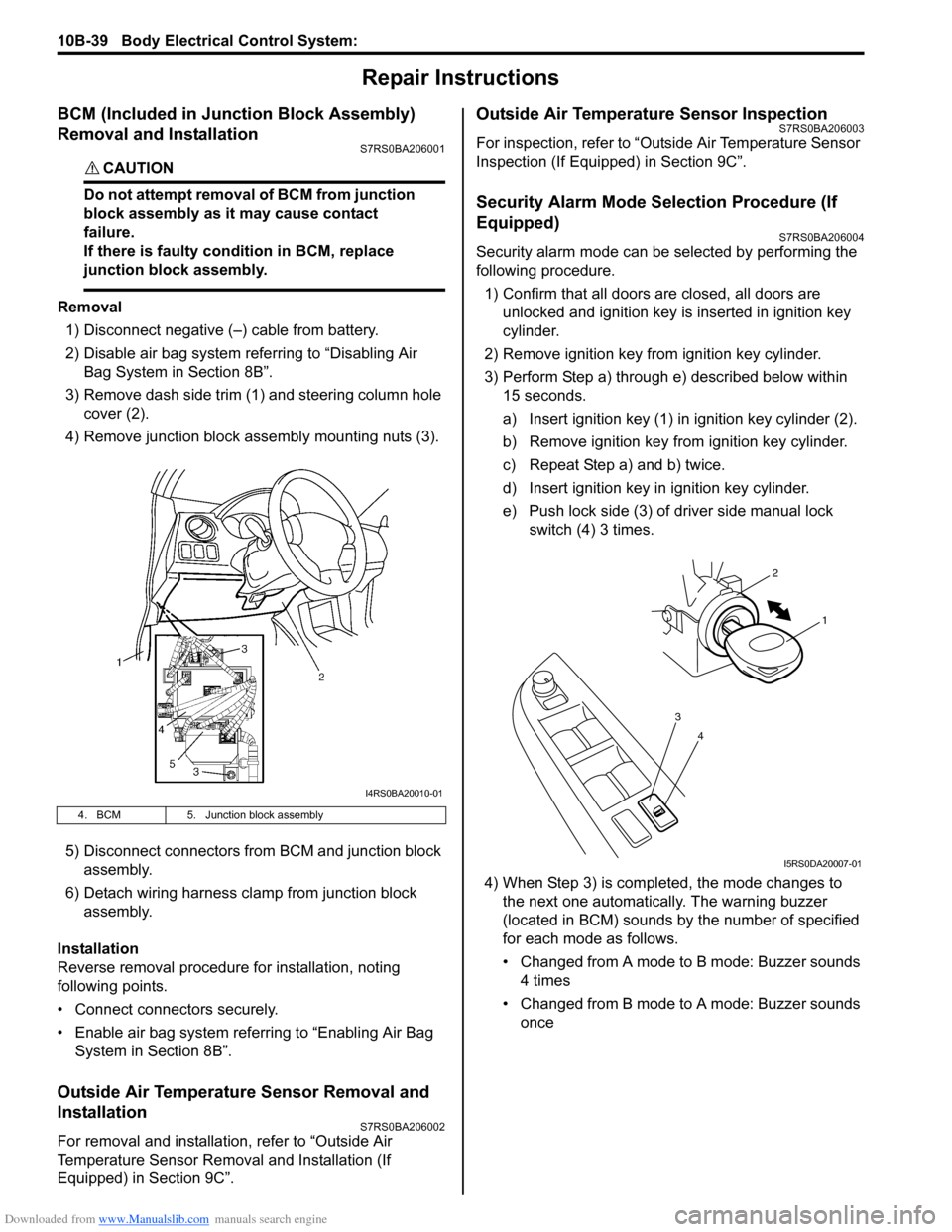

Removal

1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove dash side trim (1) and steering column hole cover (2).

4) Remove junction block assembly mounting nuts (3).

5) Disconnect connectors from BCM and junction block assembly.

6) Detach wiring harness clamp from junction block assembly.

Installation

Reverse removal procedure for installation, noting

following points.

• Connect connectors securely.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

Outside Air Temperature Sensor Removal and

Installation

S7RS0BA206002

For removal and installation, refer to “Outside Air

Temperature Sensor Removal and Installation (If

Equipped) in Section 9C”.

Outside Air Temperature Sensor InspectionS7RS0BA206003

For inspection, refer to “Outside Air Temperature Sensor

Inspection (If Equipped) in Section 9C”.

Security Alarm Mode Selection Procedure (If

Equipped)

S7RS0BA206004

Security alarm mode can be selected by performing the

following procedure.

1) Confirm that all doors are closed, all doors are unlocked and ignition key is inserted in ignition key

cylinder.

2) Remove ignition key from ignition key cylinder.

3) Perform Step a) through e) described below within 15 seconds.

a) Insert ignition key (1) in ignition key cylinder (2).

b) Remove ignition key from ignition key cylinder.

c) Repeat Step a) and b) twice.

d) Insert ignition key in ignition key cylinder.

e) Push lock side (3) of driver side manual lock switch (4) 3 times.

4) When Step 3) is completed, the mode changes to the next one automatically. The warning buzzer

(located in BCM) sounds by the number of specified

for each mode as follows.

• Changed from A mode to B mode: Buzzer sounds 4 times

• Changed from B mode to A mode: Buzzer sounds once

4. BCM 5. Junction block assembly

I4RS0BA20010-01

4

3

1

2

I5RS0DA20007-01

Page 1443 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-40

Special Tools and Equipment

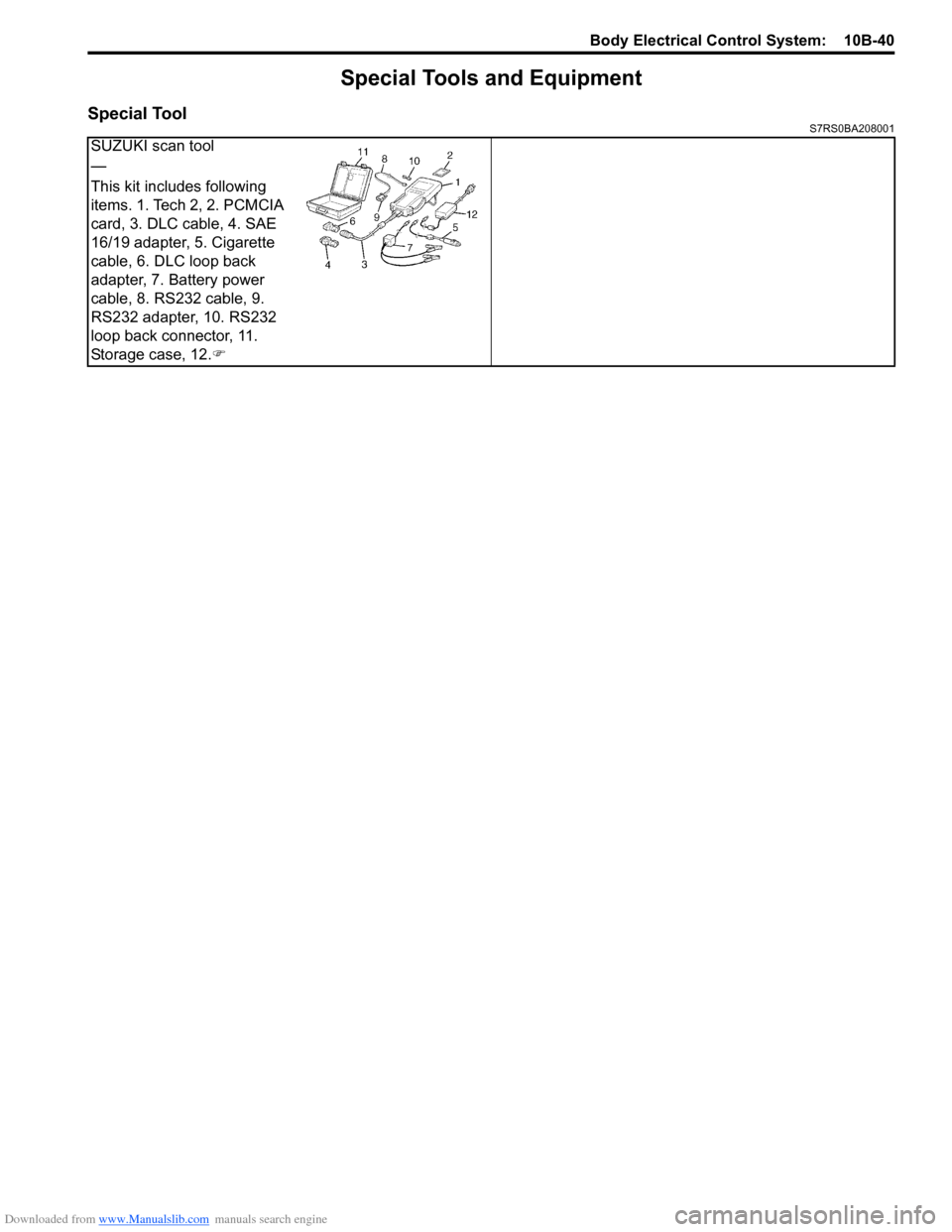

Special ToolS7RS0BA208001

SUZUKI scan tool

—

This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12.�)