jump start terminals SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 12 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-7 Precautions:

Warning for Wheel (with tire) RemovalS7RS0B0000003

WARNING!

When removing any of these wheels installed

with wheel bolts, never remove all wheel

bolts at the same time. Leave at least 1 bolt

for each wheel as it is to prevent wheel from

dropping. When removing this remaining 1

bolt, hold wheel and tire so as not to allow

them to come off.

Warning for Handling Emergency Flat Tire

Repair Kit

S7RS0B0000004

WARNING!

If vehicle is equipped with Emergency Flat

Tire Repair Kit instead of spare tire, be sure

to observe “Precaution for Emergency Flat

Tire Repair Kit in Section 2D” when handling

Emergency Flat Tire Repair Kit and repairing

flat tire.

Otherwise, your health may be ruined or it

will be impossible to repair flat tire.

Precautions for Catalytic ConverterS7RS0B0000005

For vehicles equipped with a catalytic converter, use

only unleaded gasoline and be careful not to let a large

amount of unburned gasoline enter the converter or it

can be damaged.

• Conduct a spark jump test only when necessary, make it as short as possible, and do not open the

throttle.

• Conduct engine compression checks within the shortest possible time.

• Avoid situations which can result in engine misfire (e.g. starting the engine when the fuel tank is nearly

empty.)

Precautions for Installing Mobile

Communication Equipment

S7RS0B0000006

When installing mobile communication equipment such

as CB (Citizens-Band)-radi o or cellular-telephone, be

sure to observe the following precautions.

Failure to follow cautions may adversely affect electronic

control system.

• Keep the antenna as far away as possible from the vehicle’s electronic control unit.

• Keep the antenna feeder more than 20 cm (7.9 in.) away from electronic control unit and its wire

harnesses.

• Do not run the antenna feeder parallel with other wire harnesses.

• Confirm that the antenna and feeder are correctly adjusted.

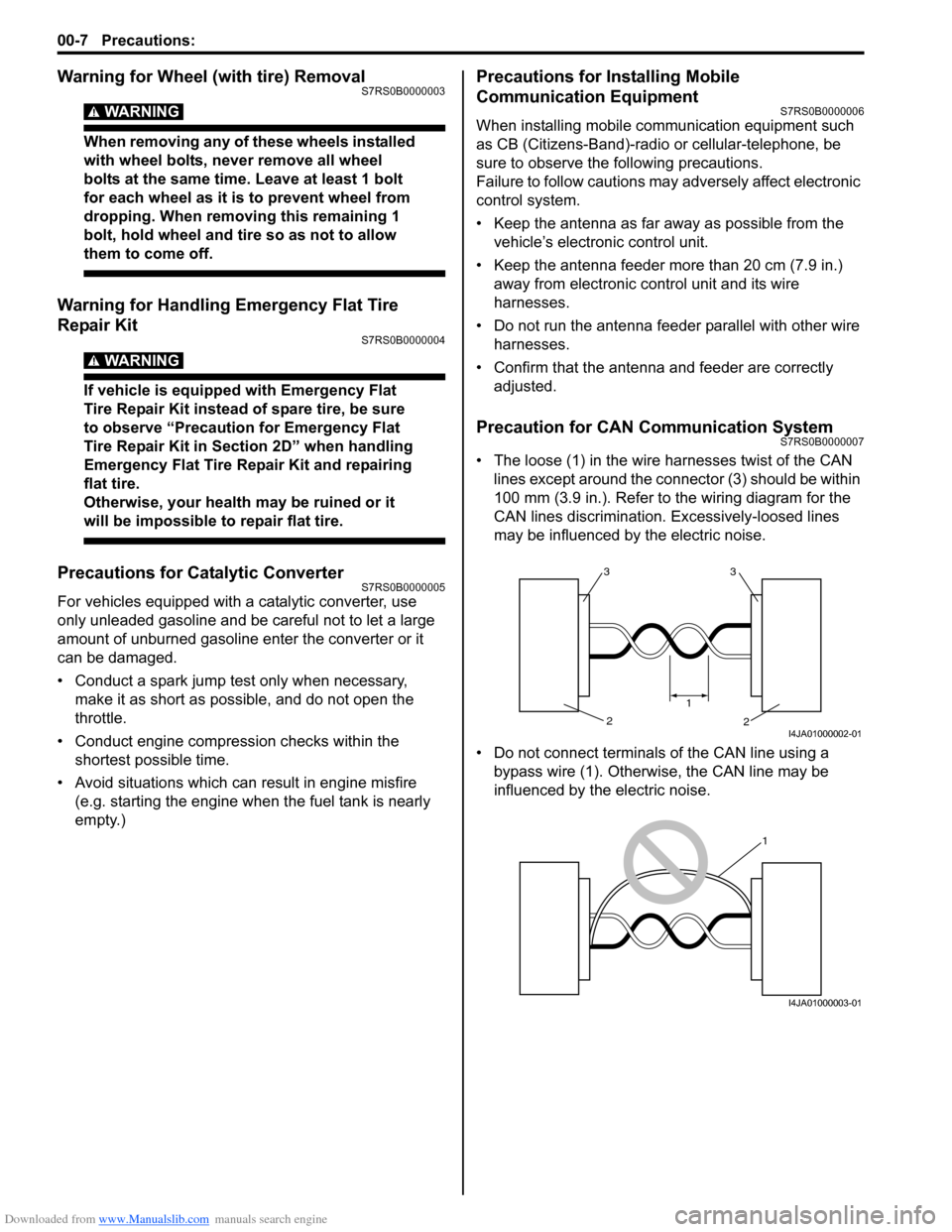

Precaution for CAN Communication SystemS7RS0B0000007

• The loose (1) in the wire harnesses twist of the CAN lines except around the connector (3) should be within

100 mm (3.9 in.). Refer to the wiring diagram for the

CAN lines discrimination. Excessively-loosed lines

may be influenced by the electric noise.

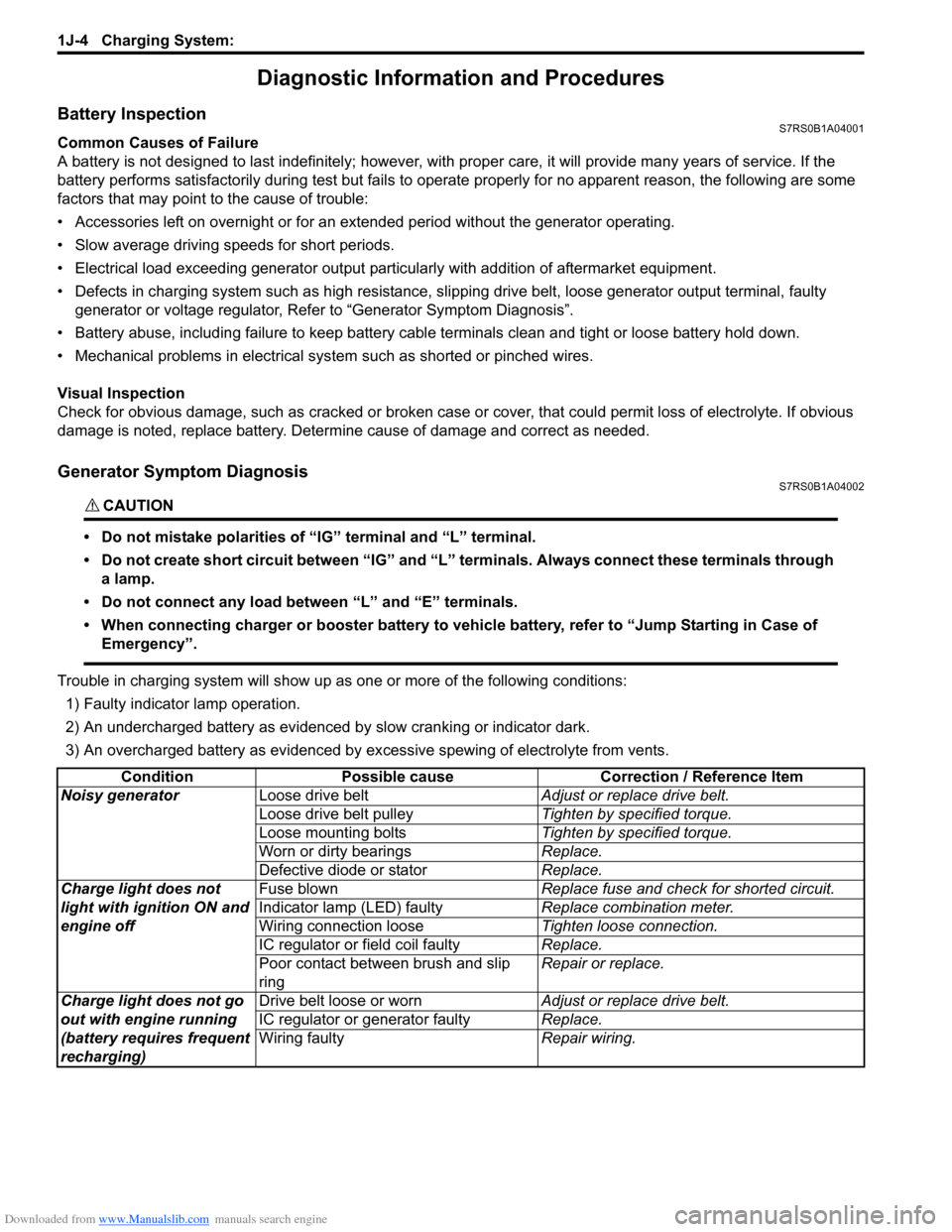

• Do not connect terminals of the CAN line using a bypass wire (1). Otherwise, the CAN line may be

influenced by the electric noise.

33

2

2

1

I4JA01000002-01

1

I4JA01000003-01

Page 414 of 1496

Downloaded from www.Manualslib.com manuals search engine 1J-4 Charging System:

Diagnostic Information and Procedures

Battery InspectionS7RS0B1A04001

Common Causes of Failure

A battery is not designed to last indefinitely; however, with proper care, it will provide many years of service. If the

battery performs satisfactorily during te st but fails to operate properly for no apparent reason, the following are some

factors that may point to the cause of trouble:

• Accessories left on overnight or for an extended period without the generator operating.

• Slow average driving speeds for short periods.

• Electrical load exceeding generator output partic ularly with addition of aftermarket equipment.

• Defects in charging system such as high resistance, s lipping drive belt, loose generator output terminal, faulty

generator or voltage regulator, Refer to “Generator Symptom Diagnosis”.

• Battery abuse, including failure to keep battery cable terminals clean and tight or loose battery hold down.

• Mechanical problems in electrical sys tem such as shorted or pinched wires.

Visual Inspection

Check for obvious damage, such as cracked or broken case or cover, that could permit loss of electrolyte. If obvious

damage is noted, replace battery. Determine cause of damage and correct as needed.

Generator Symptom DiagnosisS7RS0B1A04002

CAUTION!

• Do not mistake polarities of “IG” terminal and “L” terminal.

• Do not create short circuit between “IG” and “L” terminals. Always connect these terminals through a lamp.

• Do not connect any load between “L” and “E” terminals.

• When connecting charger or booster battery to vehicle battery, refer to “Jump Starting in Case of Emergency”.

Trouble in charging system will show up as one or more of the following conditions:

1) Faulty indicator lamp operation.

2) An undercharged battery as evidenced by slow cranking or indicator dark.

3) An overcharged battery as evidenced by ex cessive spewing of electrolyte from vents.

Condition Possible cause Correction / Reference Item

Noisy generator Loose drive belt Adjust or replace drive belt.

Loose drive belt pulley Tighten by specified torque.

Loose mounting bolts Tighten by specified torque.

Worn or dirty bearings Replace.

Defective diode or stator Replace.

Charge light does not

light with ignition ON and

engine off Fuse blown

Replace fuse and check for shorted circuit.

Indicator lamp (LED) faulty Replace combination meter.

Wiring connection loose Tighten loose connection.

IC regulator or field coil faulty Replace.

Poor contact between brush and slip

ring Repair or replace.

Charge light does not go

out with engine running

(battery requires frequent

recharging) Drive belt loose or worn

Adjust or replace drive belt.

IC regulator or generator faulty Replace.

Wiring faulty Repair wiring.