dtc check SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 1007 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-59

7Wire harness check

1) Connect connector to HVAC control module with ignition

switch turned OFF.

2) Measure voltage between “GRY/RED” wire terminal of temperature control actuator connector and vehicle body

ground with ignition switch turned ON when temperature

selector is operation to HOT direction.

Is voltage 10 – 14 V? Go to Step 11. Go to Step 8.

8 Wire harness check

1) Disconnect connector from HVAC control module with

ignition switch turned OFF.

2) Check for proper connection to HVAC control module connector at “G51-3” and “G51-4” terminals.

3) If OK, measure resistance between “GRY/RED” wire terminal of temperature control actuator connector and

“G51-4” terminal of HVAC control module connector.

Is resistance below 5

Ω? Go to Step 9. “GRY/RED” wire open

or high resistance

circuit.

9 Wire harness check

1) Measure resistance between “GRY/RED” wire terminal

of temperature control actuator connector and vehicle

body ground.

Is resistance infinity? Go to Step 10. “GRY/RED” wire

shorted to ground

circuit.

10 Wire harness check

1) Measure voltage between “GRY/RED” wire terminal of

temperature control actuator connector and vehicle body

ground with ignition switch turned ON.

Is voltage 0 V? Go to Step 11. “GRY/RED” wire

shorted to other circuit.

11 Position sensor circuit check

1) Check temperature control actuator position sensor

circuit referring to Step 1 to Step 5 and Step 10 to Step

11 of “DTC B1511: Temperature Control Actuator

(Position Sensor) and/or Its Circuit Malfunction”.

Is it in good condition? Go to Step 12. Repair circuit.

12 Temperature control actuator check

1) Check temperature control actuator referring to

“Temperature Control Actuator Inspection”.

Is it in good condition? HVAC control module

faulty.

Temperature control

actuator faulty.

Step Action Yes No

Page 1008 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-60 Air Conditioning System: Automatic Type

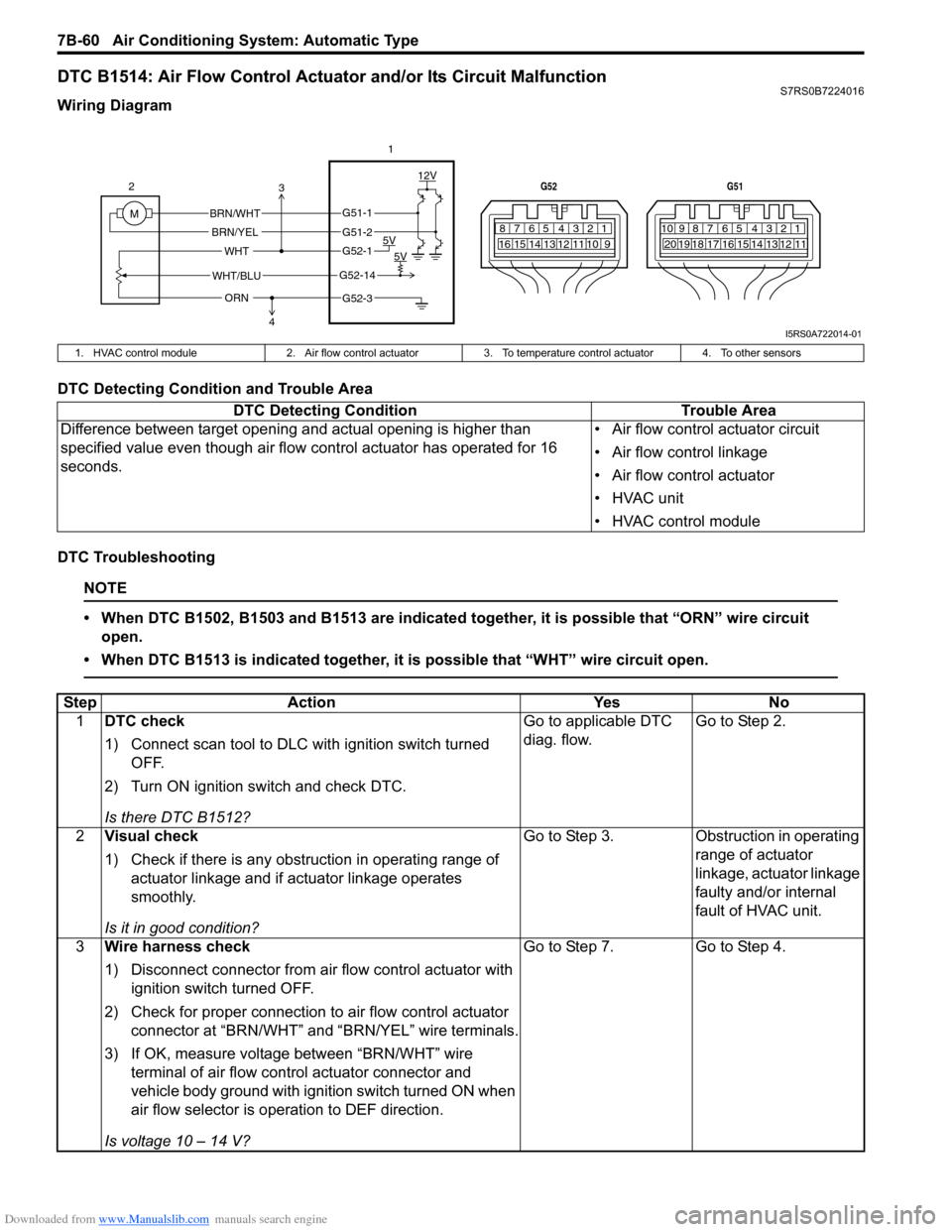

DTC B1514: Air Flow Control Actuator and/or Its Circuit MalfunctionS7RS0B7224016

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

NOTE

• When DTC B1502, B1503 and B1513 are indicated together, it is possible that “ORN” wire circuit open.

• When DTC B1513 is indicated together, it is possible that “WHT” wire circuit open.

7812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

M 12V

5V 5V

WHT/BLU

WHT

BRN/WHT

BRN/YEL

2

1

ORN

G51-1

G51-2

G52-1

G52-14

G52-3

3

4

I5RS0A722014-01

1. HVAC control module 2. Air flow control actuator3. To temperature control actuator 4. To other sensors

DTC Detecting Condition Trouble Area

Difference between target opening and actual opening is higher than

specified value even though air flow control actuator has operated for 16

seconds. • Air flow control actuator circuit

• Air flow control linkage

• Air flow control actuator

• HVAC unit

• HVAC control module

Step

Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch and check DTC.

Is there DTC B1512? Go to applicable DTC

diag. flow.

Go to Step 2.

2 Visual check

1) Check if there is any obstruction in operating range of

actuator linkage and if actuator linkage operates

smoothly.

Is it in good condition? Go to Step 3.

Obstruction in operating

range of actuator

linkage, actuator linkage

faulty and/or internal

fault of HVAC unit.

3 Wire harness check

1) Disconnect connector from air flow control actuator with

ignition switch turned OFF.

2) Check for proper connection to air flow control actuator

connector at “BRN/WHT” and “BRN/YEL” wire terminals.

3) If OK, measure voltage between “BRN/WHT” wire terminal of air flow control actuator connector and

vehicle body ground with ignition switch turned ON when

air flow selector is operation to DEF direction.

Is voltage 10 – 14 V? Go to Step 7.

Go to Step 4.

Page 1010 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-62 Air Conditioning System: Automatic Type

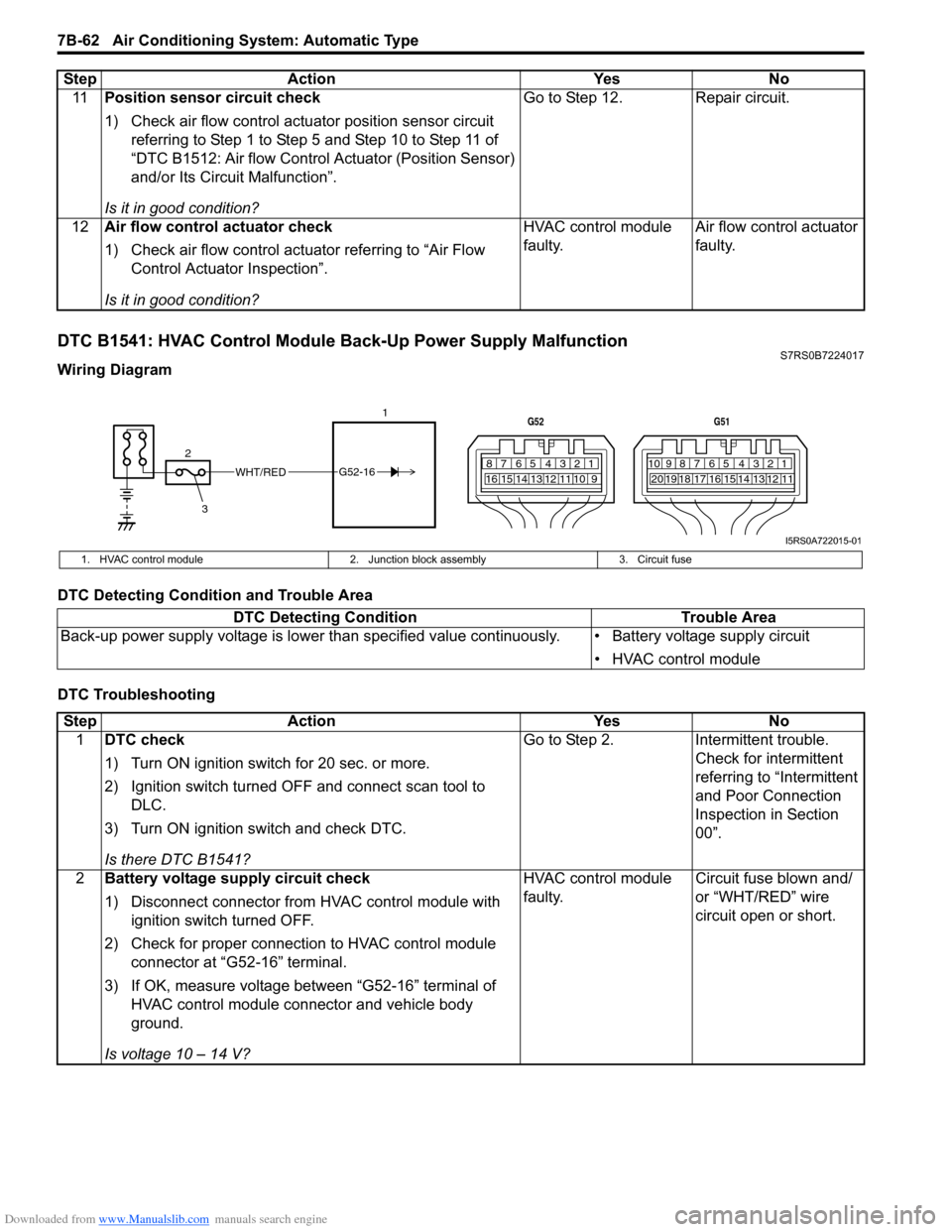

DTC B1541: HVAC Control Module Back-Up Power Supply MalfunctionS7RS0B7224017

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting11

Position sensor circuit check

1) Check air flow control actuator position sensor circuit

referring to Step 1 to Step 5 and Step 10 to Step 11 of

“DTC B1512: Air flow Control Actuator (Position Sensor)

and/or Its Circuit Malfunction”.

Is it in good condition? Go to Step 12. Repair circuit.

12 Air flow control actuator check

1) Check air flow control actuator referring to “Air Flow

Control Actuator Inspection”.

Is it in good condition? HVAC control module

faulty.

Air flow control actuator

faulty.

Step Action Yes No

WHT/RED

2 17812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

3

G52-16

I5RS0A722015-01

1. HVAC control module

2. Junction block assembly 3. Circuit fuse

DTC Detecting Condition Trouble Area

Back-up power supply voltage is lo wer than specified value continuously. • Battery voltage supply circuit

• HVAC control module

StepAction YesNo

1 DTC check

1) Turn ON ignition switch for 20 sec. or more.

2) Ignition switch turned OF F and connect scan tool to

DLC.

3) Turn ON ignition switch and check DTC.

Is there DTC B1541? Go to Step 2.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

2 Battery voltage supply circuit check

1) Disconnect connector from HVAC control module with

ignition switch turned OFF.

2) Check for proper connection to HVAC control module connector at “G52-16” terminal.

3) If OK, measure voltage between “G52-16” terminal of HVAC control module connector and vehicle body

ground.

Is voltage 10 – 14 V? HVAC control module

faulty.

Circuit fuse blown and/

or “WHT/RED” wire

circuit open or short.

Page 1011 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-63

DTC B1546: A/C Refrigerant Pressure MalfunctionS7RS0B7224018

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

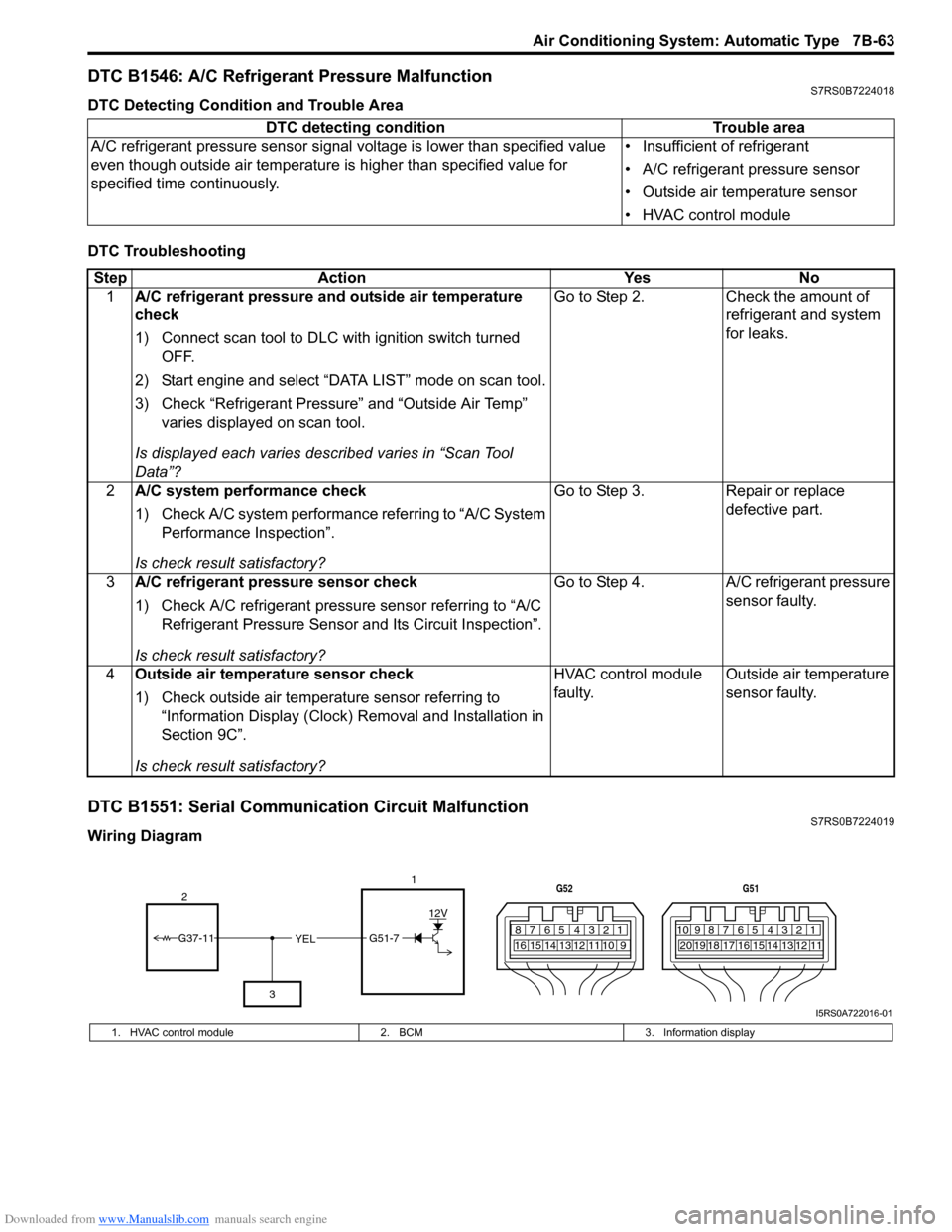

DTC B1551: Serial Communication Circuit MalfunctionS7RS0B7224019

Wiring DiagramDTC detecting condition Trouble area

A/C refrigerant pressure sensor signal voltage is lower t han specified value

even though outside air temperature is higher than specified value for

specified time continuously. • Insufficient of refrigerant

• A/C refrigerant pressure sensor

• Outside air temperature sensor

• HVAC control module

Step

Action YesNo

1 A/C refrigerant pressure and outside air temperature

check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Start engine and select “DATA LIST” mode on scan tool.

3) Check “Refrigerant Pressure” and “Outside Air Temp” varies displayed on scan tool.

Is displayed each va ries described varies in “Scan Tool

Data”? Go to Step 2.

Check the amount of

refrigerant and system

for leaks.

2 A/C system performance check

1) Check A/C system performance referring to “A/C System

Performance Inspection”.

Is check result satisfactory? Go to Step 3.

Repair or replace

defective part.

3 A/C refrigerant pressure sensor check

1) Check A/C refrigerant pressure sensor referring to “A/C

Refrigerant Pressure Sensor and Its Circuit Inspection”.

Is check result satisfactory? Go to Step 4.

A/C refrigerant pressure

sensor faulty.

4 Outside air temperature sensor check

1) Check outside air temperature sensor referring to

“Information Display (Clock) Removal and Installation in

Section 9C”.

Is check result satisfactory? HVAC control module

faulty.

Outside air temperature

sensor faulty.

YEL17812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

G51-7

12V

2

3

G37-11

I5RS0A722016-01

1. HVAC control module 2. BCM3. Information display

Page 1012 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-64 Air Conditioning System: Automatic Type

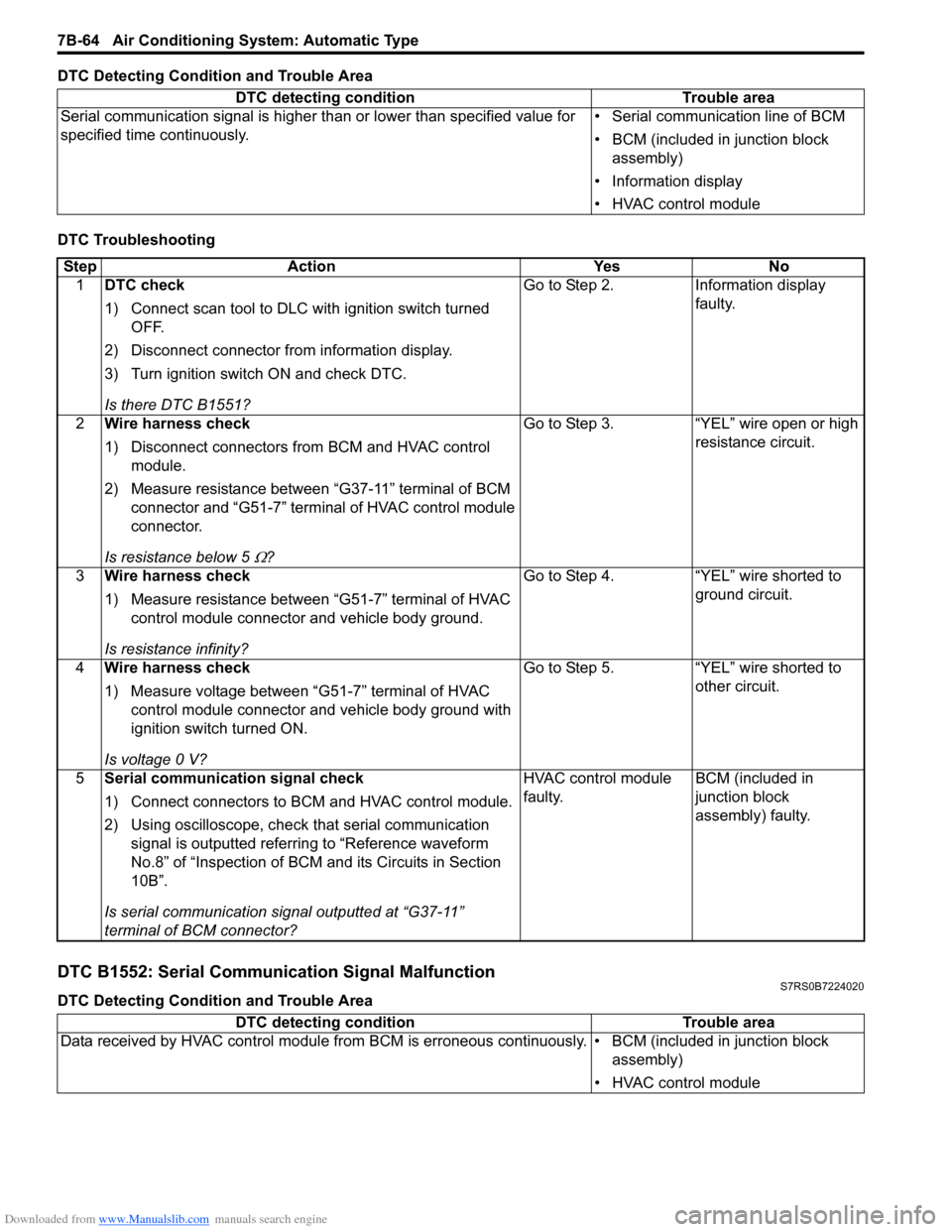

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC B1552: Serial Communication Signal MalfunctionS7RS0B7224020

DTC Detecting Condition and Trouble AreaDTC detecting condition Trouble area

Serial communication signal is higher than or lower than specified value for

specified time continuously. • Serial communication line of BCM

• BCM (included in junction block

assembly)

• Information display

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Disconnect connector from information display.

3) Turn ignition switch ON and check DTC.

Is there DTC B1551? Go to Step 2.

Information display

faulty.

2 Wire harness check

1) Disconnect connectors from BCM and HVAC control

module.

2) Measure resistance between “G37-11” terminal of BCM connector and “G51-7” terminal of HVAC control module

connector.

Is resistance below 5

Ω? Go to Step 3. “YEL” wire open or high

resistance circuit.

3 Wire harness check

1) Measure resistance between “G51-7” terminal of HVAC

control module connector and vehicle body ground.

Is resistance infinity? Go to Step 4. “YEL” wire shorted to

ground circuit.

4 Wire harness check

1) Measure voltage between “G51-7” terminal of HVAC

control module connector and vehicle body ground with

ignition switch turned ON.

Is voltage 0 V? Go to Step 5. “YEL” wire shorted to

other circuit.

5 Serial communication signal check

1) Connect connectors to BCM and HVAC control module.

2) Using oscilloscope, check that serial communication

signal is outputted referring to “Reference waveform

No.8” of “Inspection of BCM and its Circuits in Section

10B”.

Is serial communication signal outputted at “G37-11”

terminal of BCM connector? HVAC control module

faulty.

BCM (included in

junction block

assembly) faulty.

DTC detecting condition

Trouble area

Data received by HVAC control module from BCM is erroneous continuously. • BCM (included in junction block assembly)

• HVAC control module

Page 1013 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-65

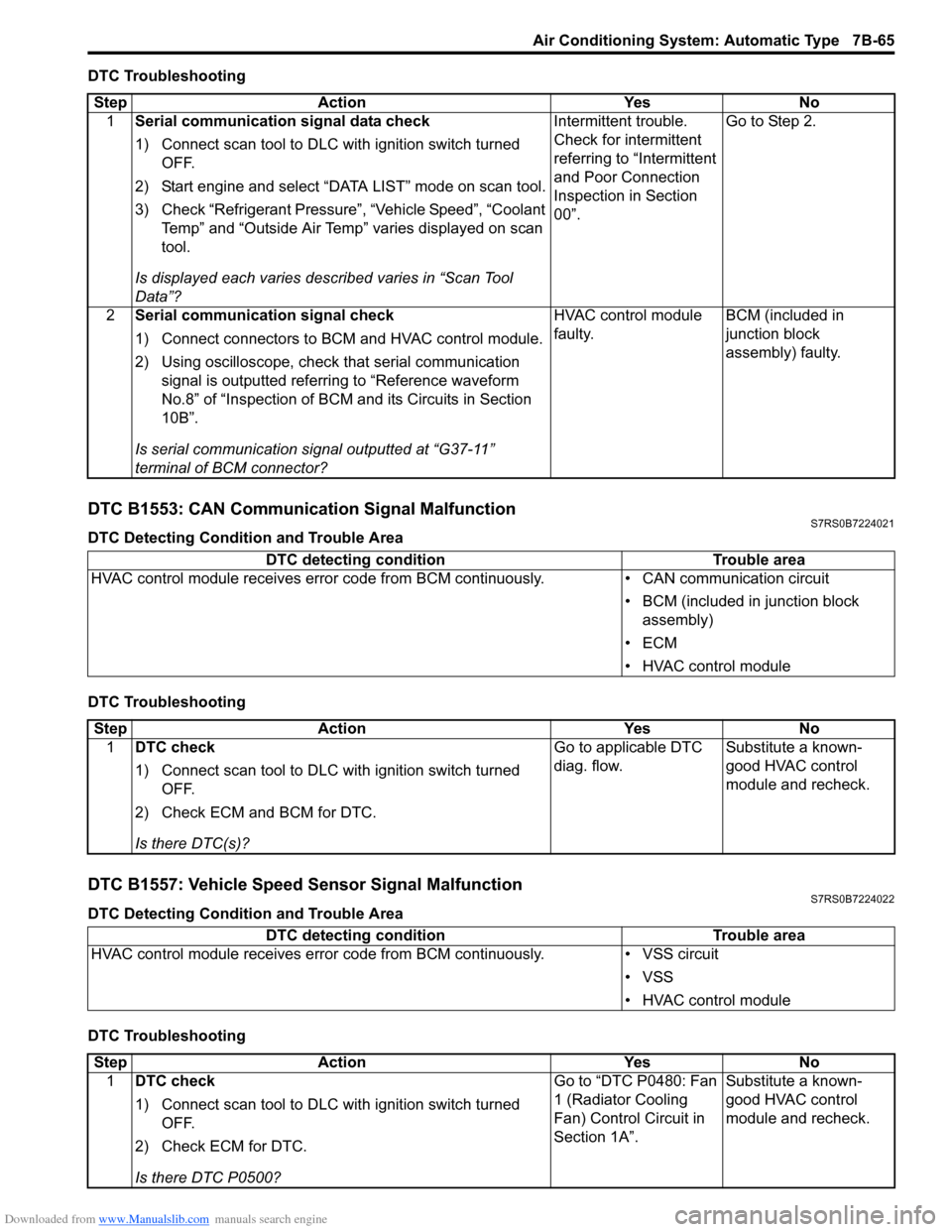

DTC Troubleshooting

DTC B1553: CAN Communication Signal MalfunctionS7RS0B7224021

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC B1557: Vehicle Speed Sensor Signal MalfunctionS7RS0B7224022

DTC Detecting Condition and Trouble Area

DTC TroubleshootingStep Action Yes No

1 Serial communication signal data check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Start engine and select “DATA LIST” mode on scan tool.

3) Check “Refrigerant Pressure”, “Vehicle Speed”, “Coolant Temp” and “Outside Air Temp” varies displayed on scan

tool.

Is displayed each va ries described varies in “Scan Tool

Data”? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 2.

2 Serial communication signal check

1) Connect connectors to BCM and HVAC control module.

2) Using oscilloscope, check that serial communication

signal is outputted referring to “Reference waveform

No.8” of “Inspection of BCM and its Circuits in Section

10B”.

Is serial communication signal outputted at “G37-11”

terminal of BCM connector? HVAC control module

faulty.

BCM (included in

junction block

assembly) faulty.

DTC detecting condition

Trouble area

HVAC control module receives error code fr om BCM continuously.• CAN communication circuit

• BCM (included in junction block assembly)

•ECM

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check ECM and BCM for DTC.

Is there DTC(s)? Go to applicable DTC

diag. flow.

Substitute a known-

good HVAC control

module and recheck.

DTC detecting condition

Trouble area

HVAC control module receives error code from BCM continuously. • VSS circuit

• VSS

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check ECM for DTC.

Is there DTC P0500? Go to “DTC P0480: Fan

1 (Radiator Cooling

Fan) Control Circuit in

Section 1A”.

Substitute a known-

good HVAC control

module and recheck.

Page 1014 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-66 Air Conditioning System: Automatic Type

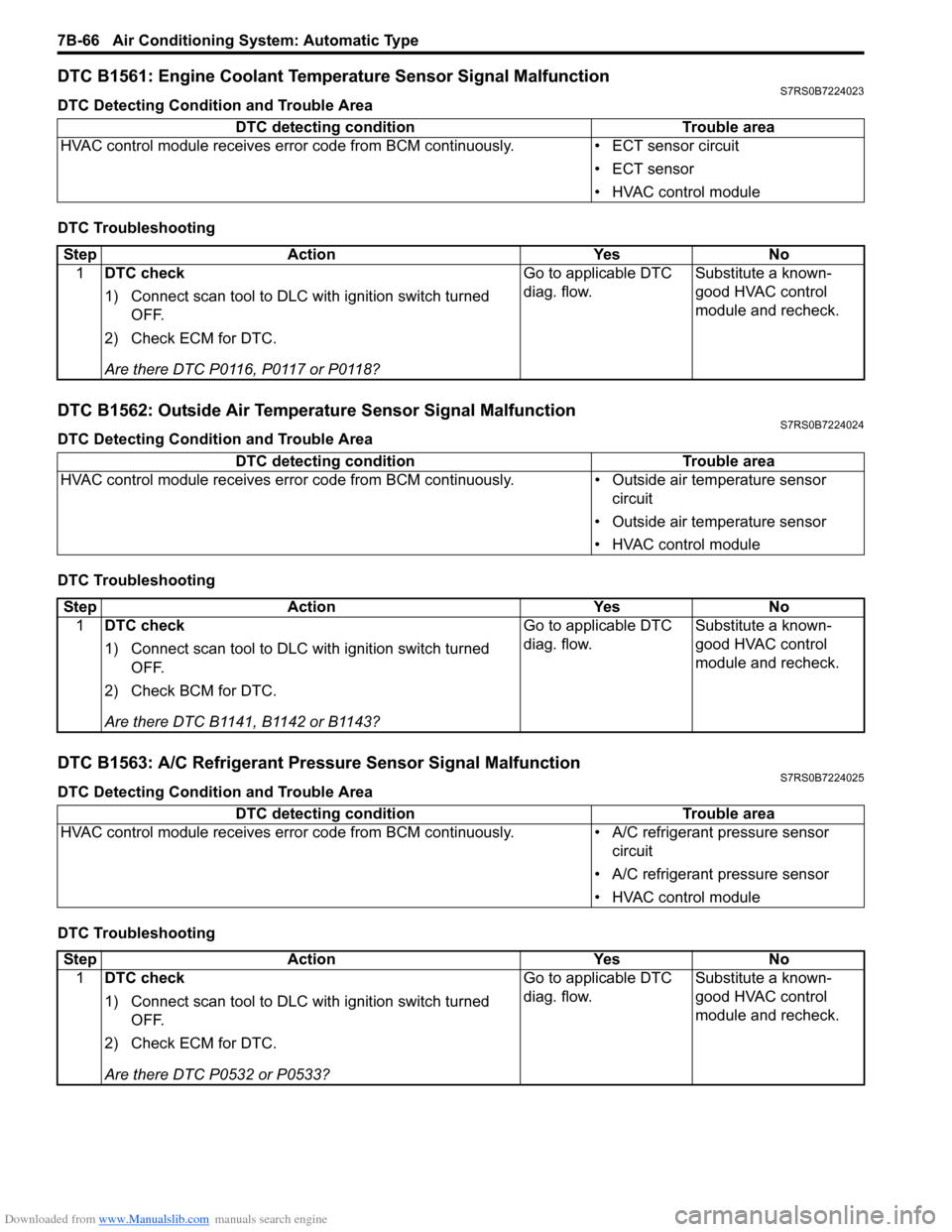

DTC B1561: Engine Coolant Temperature Sensor Signal MalfunctionS7RS0B7224023

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC B1562: Outside Air Temperature Sensor Signal MalfunctionS7RS0B7224024

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC B1563: A/C Refrigerant Pressure Sensor Signal MalfunctionS7RS0B7224025

DTC Detecting Condition and Trouble Area

DTC TroubleshootingDTC detecting condition Trouble area

HVAC control module receives error code from BCM continuously. • ECT sensor circuit

• ECT sensor

• HVAC control module

StepAction YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check ECM for DTC.

Are there DTC P0116, P0117 or P0118? Go to applicable DTC

diag. flow.

Substitute a known-

good HVAC control

module and recheck.

DTC detecting condition

Trouble area

HVAC control module receives er ror code from BCM continuously. • Outside air temperature sensor

circuit

• Outside air temperature sensor

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check BCM for DTC.

Are there DTC B1141, B1142 or B1143? Go to applicable DTC

diag. flow.

Substitute a known-

good HVAC control

module and recheck.

DTC detecting condition

Trouble area

HVAC control module receives er ror code from BCM continuously. • A/C refrigerant pressure sensor

circuit

• A/C refrigerant pressure sensor

• HVAC control module

Step Action YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check ECM for DTC.

Are there DTC P0532 or P0533? Go to applicable DTC

diag. flow.

Substitute a known-

good HVAC control

module and recheck.

Page 1029 of 1496

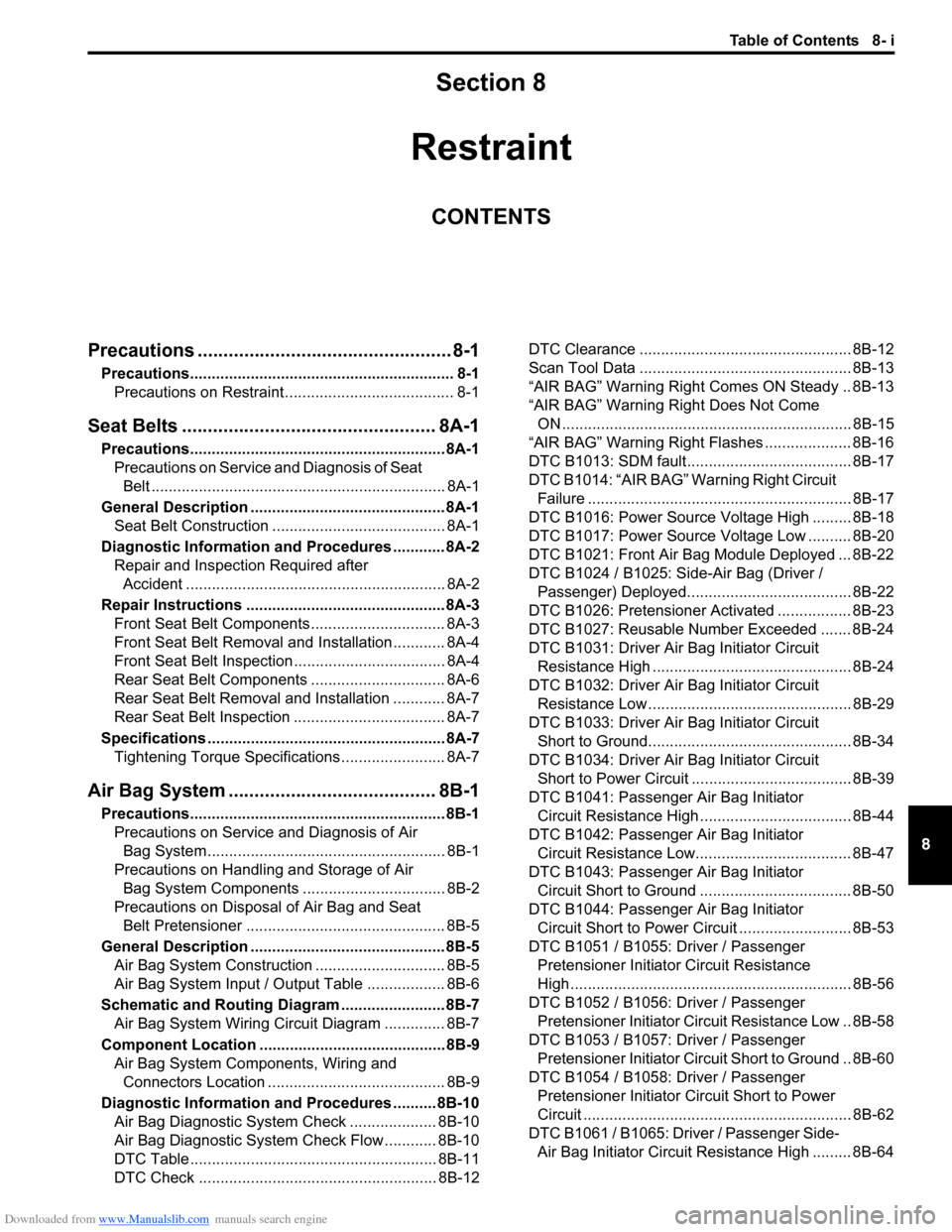

Downloaded from www.Manualslib.com manuals search engine Table of Contents 8- i

8

Section 8

CONTENTS

Restraint

Precautions ................................................. 8-1

Precautions............................................................. 8-1

Precautions on Restraint ....................................... 8-1

Seat Belts .......... ............................... ........ 8A-1

Precautions........................................................... 8A-1

Precautions on Service a nd Diagnosis of Seat

Belt .................................................................... 8A-1

General Description ............................................. 8A-1 Seat Belt Construction ........................................ 8A-1

Diagnostic Information and Procedures ............ 8A-2 Repair and Inspection Required after Accident ............................................................ 8A-2

Repair Instructions .............................................. 8A-3 Front Seat Belt Components ............................... 8A-3

Front Seat Belt Removal and Installation ............ 8A-4

Front Seat Belt Inspection ................................... 8A-4

Rear Seat Belt Components ............................... 8A-6

Rear Seat Belt Removal and Installation ............ 8A-7

Rear Seat Belt Inspection ................................... 8A-7

Specifications ....................................................... 8A-7

Tightening Torque Specifications ........................ 8A-7

Air Bag System ............... ......................... 8B-1

Precautions........................................................... 8B-1

Precautions on Service and Diagnosis of Air Bag System....................................................... 8B-1

Precautions on Handling and Storage of Air Bag System Components . ................................ 8B-2

Precautions on Disposal of Air Bag and Seat

Belt Pretensioner .............................................. 8B-5

General Description ............................................. 8B-5 Air Bag System Construction .............................. 8B-5

Air Bag System Input / Output Table .................. 8B-6

Schematic and Routing Diagram ........................ 8B-7 Air Bag System Wiring Circuit Diagram .............. 8B-7

Component Locatio n ........................................... 8B-9

Air Bag System Components, Wiring and Connectors Location ......................................... 8B-9

Diagnostic Information and Procedures .......... 8B-10 Air Bag Diagnostic System Check .................... 8B-10

Air Bag Diagnostic System Check Flow ............ 8B-10

DTC Table ......................................................... 8B-11

DTC Check ....................................................... 8B-12 DTC Clearance ................................................. 8B-12

Scan Tool Data ................................................. 8B-13

“AIR BAG” Warning Right Comes ON Steady .. 8B-13

“AIR BAG” Warning Right Does Not Come

ON ................................................................... 8B-15

“AIR BAG” Warning Right Flashes .................... 8B-16

DTC B1013: SDM fault...................................... 8B-17

DTC B1014: “AIR BAG” Warning Right Circuit Failure ............................................................. 8B-17

DTC B1016: Power Source Voltage High ......... 8B-18

DTC B1017: Power Source Voltage Low .......... 8B-20

DTC B1021: Front Air Bag Module Deployed ... 8B-22

DTC B1024 / B1025: Side-Air Bag (Driver / Passenger) Deployed...................................... 8B-22

DTC B1026: Pretensioner Activated ................. 8B-23

DTC B1027: Reusable Number Exceeded ....... 8B-24

DTC B1031: Driver Air Bag Initiator Circuit

Resistance High .............................................. 8B-24

DTC B1032: Driver Air Bag Initiator Circuit

Resistance Low ............................................... 8B-29

DTC B1033: Driver Air Bag Initiator Circuit

Short to Ground............................................... 8B-34

DTC B1034: Driver Air Bag Initiator Circuit

Short to Power Circuit .... ................................. 8B-39

DTC B1041: Passenger Air Bag Initiator Circuit Resistance High ................................... 8B-44

DTC B1042: Passenger Air Bag Initiator Circuit Resistance Low.................................... 8B-47

DTC B1043: Passenger Air Bag Initiator Circuit Short to Ground ................................... 8B-50

DTC B1044: Passenger Air Bag Initiator Circuit Short to Power Circ uit .......................... 8B-53

DTC B1051 / B1055: Driver / Passenger Pretensioner Initiator Circuit Resistance

High ................................................................. 8B-56

DTC B1052 / B1056: Driver / Passenger Pretensioner Initiator Circu it Resistance Low .. 8B-58

DTC B1053 / B1057: Driver / Passenger Pretensioner Initiator Circuit Short to Ground .. 8B-60

DTC B1054 / B1058: Driver / Passenger Pretensioner Initiator Circuit Short to Power

Circuit .............................................................. 8B-62

DTC B1061 / B1065: Driver / Passenger Side- Air Bag Initiator Circuit Resistance High ......... 8B-64

Page 1030 of 1496

Downloaded from www.Manualslib.com manuals search engine 8-ii Table of Contents

DTC B1062 / B1066: Driver / Passenger Side-Air Bag Initiator Circuit Resistance Low .......... 8B-67

DTC B1063 / B1067: Driver / Passenger Side- Air Bag Initiator Circuit S hort to Ground .......... 8B-70

DTC B1064 / B1068: Driver / Passenger Side- Air Bag Initiator Circu it Short to Power

Circuit .............................................................. 8B-73

DTC B1071: Forward-Sensor Performance Problem ........................................................... 8B-76

DTC B1072: Forward-Sensor Communication Error ................................................................ 8B-76

DTC B1073: Forward-Sensor Circuit Short to Ground ............................................................ 8B-76

DTC B1074: Forward-Sensor Circuit Short to Power Circuit or Open ..................................... 8B-78

DTC B1081 / B1091: Driver / Passenger Side- Sensor Performance Probl em ......................... 8B-80

DTC B1082 / B1092: Driver / Passenger Side- Sensor Communication Erro r .......................... 8B-80

DTC B1083 / B1093: Driver / Passenger Side- Sensor Circuit Short to Ground ....................... 8B-80

DTC B1084 / B1094: Driver / Passenger Side- Sensor Circuit Short to Power Circuit or

Open ............................................................... 8B-81

DTC B1085 / B1095: Wrong Side-Sensor (Driver Side / Passenger) ID ........................... 8B-83

DTC B1361 / B1365: Driver / Passenger Side Curtain-Air Bag Initiator Circuit Resistance

High ................................................................. 8B-84

DTC B1362 / B1366: Driver / Passenger Side Curtain-Air Bag Initiator Circuit Resistance

Low ................................................................. 8B-86

DTC B1363 / B1367: Driver / Passenger Side Curtain-Air Bag Initiator Circuit Short to

Ground ............................................................ 8B-88

DTC B1364 / B1368: Driver / Passenger Side Curtain-Air Bag Initiator Circuit Short to

Power Circuit ................................................... 8B-90

Contact Coil Cable and Its Circuit Check .......... 8B-93 Inspection of Intermittent and Poor

Connections .................................................... 8B-95

Repair and Inspection Required after Accident .......................................................... 8B-96

Repair Instructions ............ ................................8B-98

Disabling Air Bag System.................................. 8B-98

Enabling Air Bag System .................................. 8B-99

SDM Removal and Installation ........................ 8B-100

SDM Inspection ............................................... 8B-101

Driver Air Bag (Inflato r) Module Removal and

Installation ..................................................... 8B-101

Driver Air Bag (Inflator) Module Inspection ..... 8B-103

Passenger Air Bag (Inflator) Module Removal and Installation .............................................. 8B-103

Passenger Air Bag (I nflator) Module

Inspection ...................................................... 8B-105

Side-Air Bag (Inflator) Module Removal and

Installation ..................................................... 8B-105

Side-Air Bag (Inflator) Inspection .................... 8B-107

Side Curtain-Air Bag (Inflator) Module Removal and Installation ............................... 8B-107

Side Curtain-Air Bag (Inflator) Module Inspection ...................................................... 8B-109

Forward-Sensor Removal and Installation ...... 8B-109

Forward-Sensor In spection ............................. 8B-110

Side-Sensor Removal and Installation ............ 8B-110

Side-Sensor Inspection ................................... 8B-111

Passenger Air Bag (Inflator) Module Repair

Harness Installation....................................... 8B-112

Air Bag (Inflator) Module and Seat Belt Pretensioner Disposal ................................... 8B-113

Deployed Air Bag (Inflator) Module and Activated Seat Belt Pretensioner Disposal.... 8B-124

Specifications .................. .................................8B-125

Tightening Torque Specifications .................... 8B-125

Special Tools and Equipmen t .........................8B-125

Use of Special Tools ....................................... 8B-125

Recommended Service Material ..................... 8B-127

Special Tool .................................................... 8B-127

Page 1039 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-1

Restraint

Air Bag System

Precautions

Precautions on Service and Diagnosis of Air

Bag System

S7RS0B8200001

WARNING!

• If the air bag system and another vehicle system both need repair, SUZUKI

recommends that the air bag system be

repaired first, to help avoid unintended air

bag system activation.

• Do not modify the steering wheel, dashboard, both front seat or any other on

or around air bag system components.

Modifications can adversely affect air bag

system performance and lead to injury.

• Be sure to follow the procedures described in this section. Failure to follow

procedures could result in possible air bag

system activation, personal injury or

unneeded air bag system repairs.

• WARNING / CAUTION labels are attached on each

part of air bag system components (SDM, air bag

(inflator) modules and seat belt pretensioners). Be

sure to follow the instructions.

• Many of service procedures require disconnection of

“A/BAG” fuse and air bag (inflator) module(s) (driver,

passenger, side of both si des and curtain of both

sides) from initiator circuit to avoid an accidental

deployment.

• Do not apply power to the air bag system unless all components are connected or a diagnostic flow

requests it, as this will set a DTC.

• The “Air Bag Diagnostic S ystem Check” must be the

starting point of any air bag diagnostics. The “Air Bag

Diagnostic System Check” will verify proper “AIR

BAG” warning right operatio n and will lead you to the

correct flow to diagnose any air bag malfunctions.

Bypassing these procedures may result in extended

diagnostic time, incorrect diagnosis, and incorrect

parts replacements. • Never use air bag component parts from another

vehicle.

• If the vehicle will be exposed to temperatures over 93

° C (200 °F) (for example, during a paint baking

process), remove the air bag system components

beforehand to avoid component damage or

unintended system activation.

• When handling the air bag (inflator) modules (driver, passenger, side of both si des and curtain of both

sides), seat belt pretensio ners (driver and passenger),

SDM, forward-sensor or side-sensor, be careful not to

drop it or apply an impact to it. If an excessive impact

was applied (e.g., SDM, forward-sensor and side-

sensor are dropped, air bag (inflator) module is

dropped from a height of 90 cm (3 ft) or more, seat

belt pretensioner (retractor assembly) is dropped from

a height of 30 cm (1 ft) or more), never attempt

disassembly or repair but replace it with a new one.

• When using electric welding, be sure to disconnect air bag (inflator) module connectors (driver, passenger,

side of both sides and curtain of both sides) and seat

belt pretensioner connectors (driver and passenger)

respectively.

• When applying paint around the air bag system related parts, use care so that the harness or

connector will not be expo sed to the paint mist.

• Never expose air bag system component parts directly to hot air (drying or baking the vehicle after

painting) or flames.

WARNING!

When performing service on or around air

bag system components or air bag wiring,

follow the procedures listed in “Disabling Air

Bag System” to temporarily disable the air

bag system.

Failure to follow procedures could result in

possible air bag system activation, personal

injury or unneeded air bag system repairs.