Engine cover SUZUKI SWIFT 2008 2.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 304 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-19 Engine Mechanical:

24) Before removing engine with transaxle from engine compartment, recheck to make sure all hoses,

electric wires and cables are disconnected from

engine and transaxle.

25) Lower engine with transaxle from engine compartment.

CAUTION!

Before lowering engine, to avoid damage to

A/C compressor and clutch operating

cylinder, make clearance by rising them. Be

sure not to damage suspended A/C

compressor and clutch operating cylinder.

26) Disconnect transaxle from engine, referring to “Manual Transaxle Unit Dismounting and

Remounting in Section 5B” or “Automatic Transaxle

Unit Dismounting and Re mounting in Section 5A”.

27) For M/T model, remove clutch cover and clutch disk referring to “Clutch Cover, Clutch Disc and Flywheel

Removal and Installa tion in Section 5C”.

Installation 1) For M/T model, install clutch cover and clutch disk referring to “Clutch Cover, Clutch Disc and Flywheel

Removal and Installa tion in Section 5C”.

2) Connect transaxle to engine referring to “Manual Transaxle Unit Dismounting and Remounting in

Section 5B” or “Automatic Transaxle Unit

Dismounting and Remounting in Section 5A”.

3) Lift engine and transaxle into engine compartment with jack.

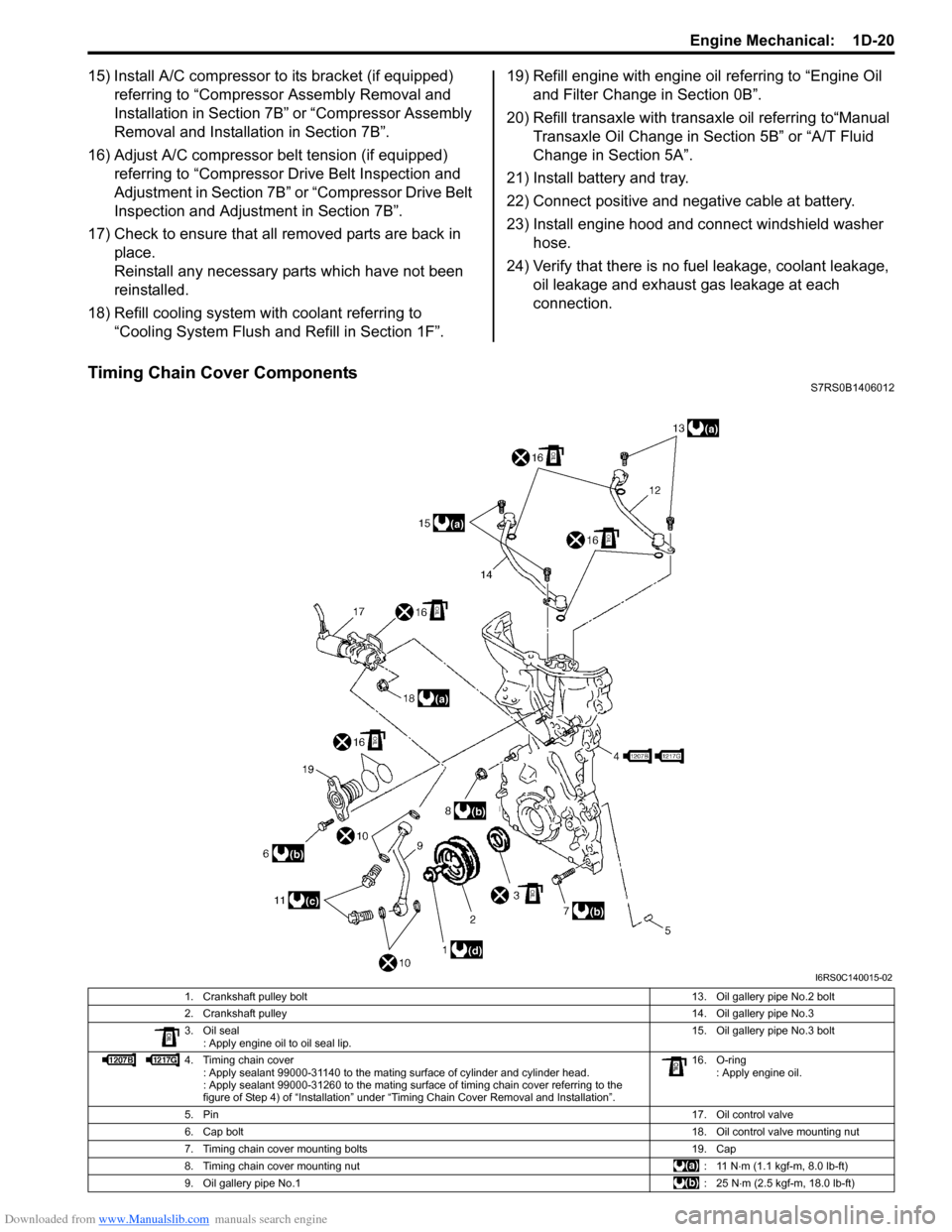

4) Install engine left mounting bracket nuts (1) and engine right mounting nuts (2).Tighten these nuts to

specified torque.

Tightening torque

Engine left mounting bracket nut (a): 55 N·m (5.5

kgf-m, 40.0 lb-ft)

Engine right mounting nut (b): 65 N·m (6.5 kgf-

m, 47.0 lb-ft) 5) Support engine assemble by using chain hoist.

6) Install engine rear mounting to engine rear

mountingNo.1 bracket.

Tightening torque

Engine rear mounting bush bolt: 55 N·m (5.5

kgf-m, 40.0 lb-ft)

7) Install suspension frame referring to “Front Suspension Frame, Stabiliz er Bar and/or Bushings

Removal and Installati on in Section 2B”.

8) Remove chain hoist.

9) Install exhaust No.1, No.2 and center pipes referring to “Exhaust Pipe and Muffler Removal and

Installation in Section 1K”.

10) Connect drive shaft joints referring to “Front Drive Shaft Assembly Removal and Installation in Section

3A”.

11) Reverse disconnected hoses, cables and electric wires for connection noting the followings.

• Tighten nuts to specified torque.

Tightening torque

Starting motor terminal nut: 11 N·m (1.1 kgf-m,

8.0 lb-ft)

Generator terminal nut: 6 N·m (0.6 kgf-m, 4.5 lb-

ft)

Intake manifold ground terminal bolt: 11 N·m (

1.1 kgf-m, 18.0 lb-ft)

12) Install intake manifold rear stiffener to intake

manifold and cylinder block.

13) Install air cleaner assembly referring to “Air Cleaner Components”.

14) Install cowl top referring to “Cowl Top Components in

Section 9K”.

I4RS0A140009-01

1, (a)

2, (b)

I4RS0A140010-01

Page 305 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-20

15) Install A/C compressor to its bracket (if equipped) referring to “Compressor Assembly Removal and

Installation in Section 7B” or “Compressor Assembly

Removal and Installa tion in Section 7B”.

16) Adjust A/C compressor belt tension (if equipped) referring to “Compressor Drive Belt Inspection and

Adjustment in Section 7B” or “Compressor Drive Belt

Inspection and Adjustment in Section 7B”.

17) Check to ensure that a ll removed parts are back in

place.

Reinstall any necessary parts which have not been

reinstalled.

18) Refill cooling system with coolant referring to “Cooling System Flush and Refill in Section 1F”. 19) Refill engine with engine oil

referring to “Engine Oil

and Filter Change in Section 0B”.

20) Refill transaxle with transa xle oil referring to“Manual

Transaxle Oil Change in Section 5B” or “A/T Fluid

Change in Section 5A”.

21) Install battery and tray.

22) Connect positive and negative cable at battery.

23) Install engine hood and connect windshield washer hose.

24) Verify that there is no fu el leakage, coolant leakage,

oil leakage and exhaust gas leakage at each

connection.

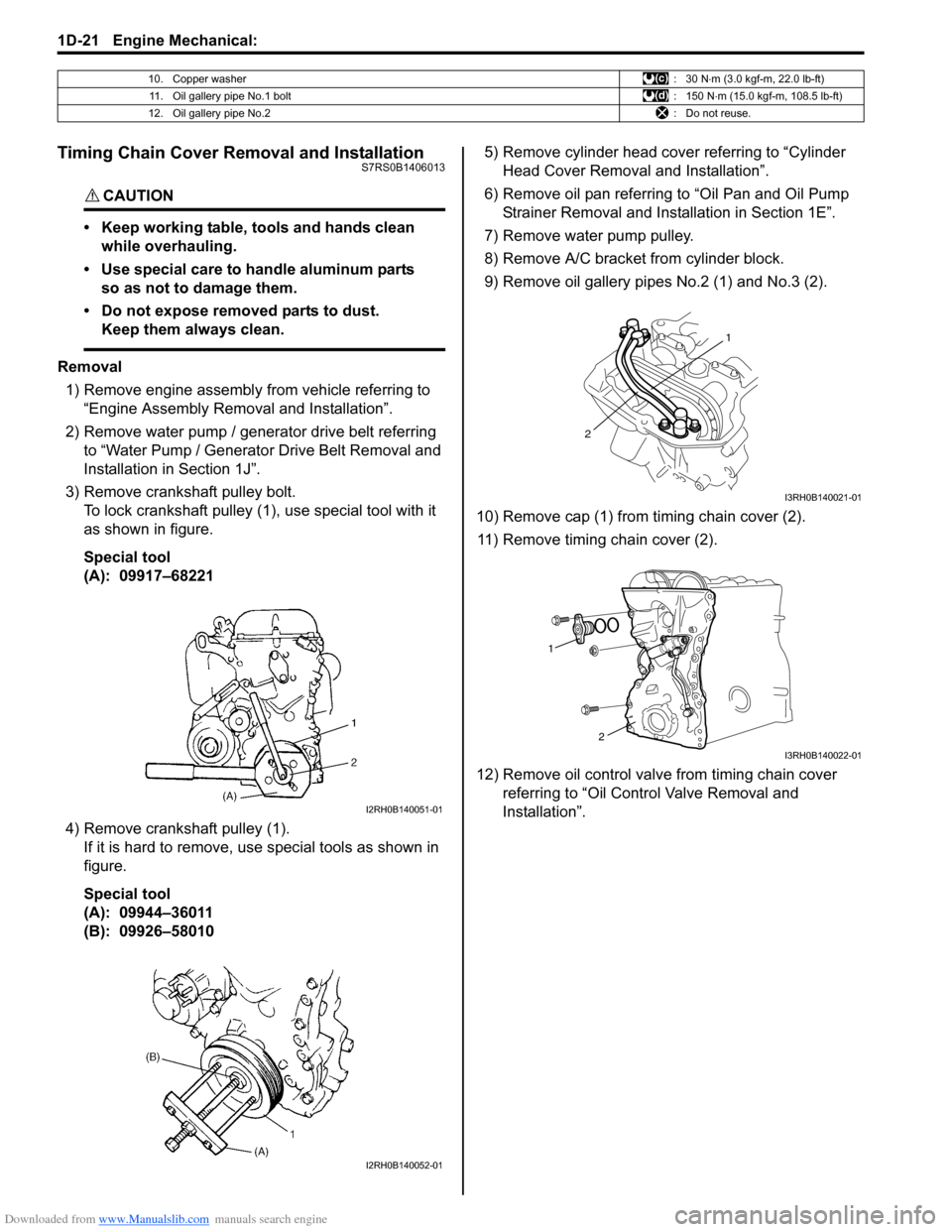

Timing Chain Cover ComponentsS7RS0B1406012

I6RS0C140015-02

1. Crankshaft pulley bolt 13. Oil gallery pipe No.2 bolt

2. Crankshaft pulley 14. Oil gallery pipe No.3

3. Oil seal : Apply engine oil to oil seal lip. 15. Oil gallery pipe No.3 bolt

4. Timing chain cover : Apply sealant 99000-31140 to the mating surface of cylinder and cylinder head.

: Apply sealant 99000-31260 to the mating surface of timing chain cover referring to the

figure of Step 4) of “Installation” under “Timing Chain Cover Removal and Installation”. 16. O-ring

: Apply engine oil.

5. Pin 17. Oil control valve

6. Cap bolt 18. Oil control valve mounting nut

7. Timing chain cover mounting bolts 19. Cap

8. Timing chain cover mounting nut : 11 N ⋅m (1.1 kgf-m, 8.0 lb-ft)

9. Oil gallery pipe No.1 :25 N⋅m (2.5 kgf-m, 18.0 lb-ft)

Page 306 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-21 Engine Mechanical:

Timing Chain Cover Removal and InstallationS7RS0B1406013

CAUTION!

• Keep working table, tools and hands clean while overhauling.

• Use special care to handle aluminum parts so as not to damage them.

• Do not expose removed parts to dust. Keep them always clean.

Removal

1) Remove engine assembly from vehicle referring to “Engine Assembly Removal and Installation”.

2) Remove water pump / generator drive belt referring to “Water Pump / Generator Drive Belt Removal and

Installation in Section 1J”.

3) Remove crankshaft pulley bolt. To lock crankshaft pulley (1), use special tool with it

as shown in figure.

Special tool

(A): 09917–68221

4) Remove crankshaft pulley (1). If it is hard to remove, use special tools as shown in

figure.

Special tool

(A): 09944–36011

(B): 09926–58010 5) Remove cylinder head cove

r referring to “Cylinder

Head Cover Removal and Installation”.

6) Remove oil pan referring to “Oil Pan and Oil Pump

Strainer Removal and Inst allation in Section 1E”.

7) Remove water pump pulley.

8) Remove A/C bracket from cylinder block.

9) Remove oil gallery pipe s No.2 (1) and No.3 (2).

10) Remove cap (1) from timing chain cover (2). 11) Remove timing chain cover (2).

12) Remove oil control valve from timing chain cover referring to “Oil Cont rol Valve Removal and

Installation”.

10. Copper washer :30 N⋅m (3.0 kgf-m, 22.0 lb-ft)

11. Oil gallery pipe No.1 bolt : 150 N⋅m (15.0 kgf-m, 108.5 lb-ft)

12. Oil gallery pipe No.2 : Do not reuse.

I2RH0B140051-01

I2RH0B140052-01

1

2

I3RH0B140021-01

1 2

I3RH0B140022-01

Page 307 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-22

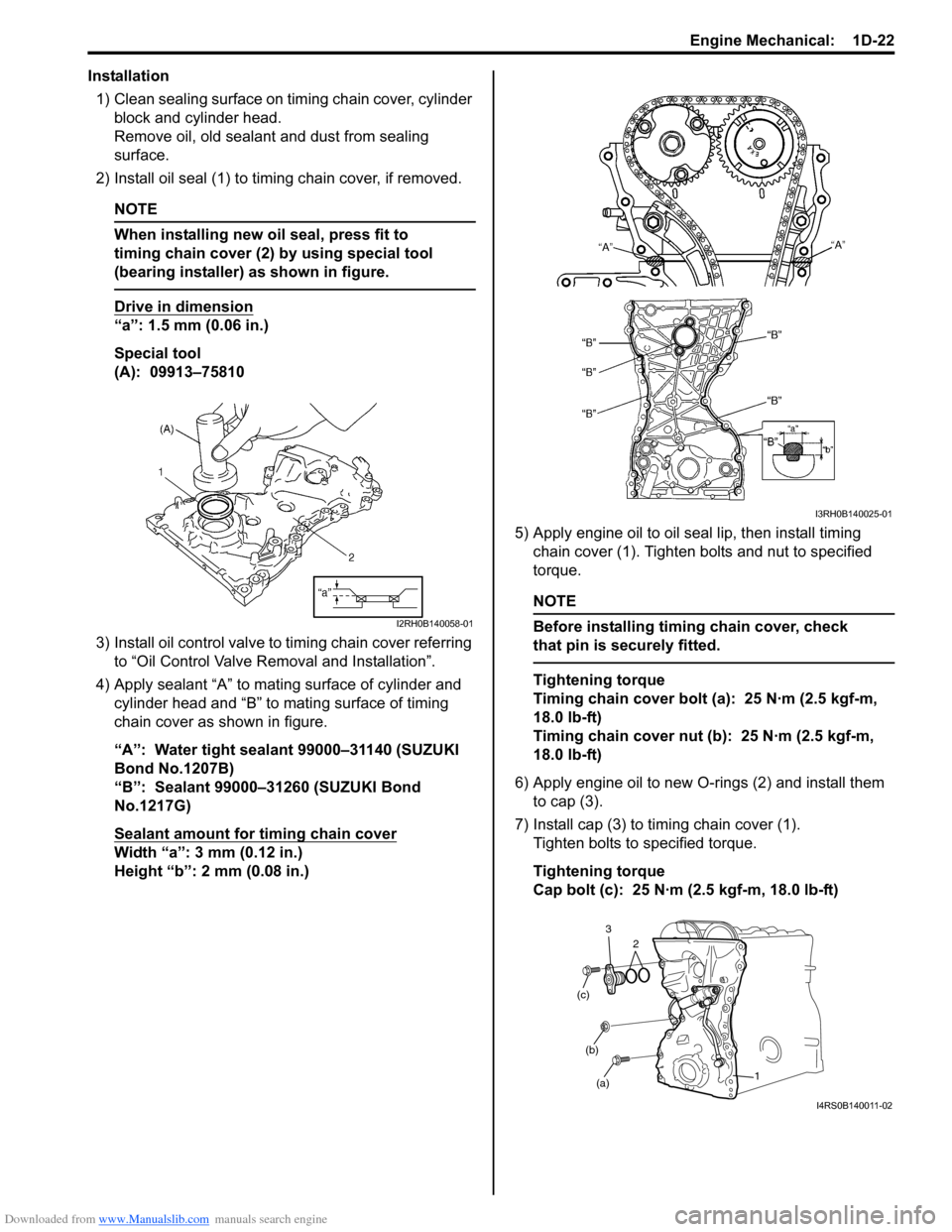

Installation1) Clean sealing surface on timing chain cover, cylinder block and cylinder head.

Remove oil, old sealant and dust from sealing

surface.

2) Install oil seal (1) to timi ng chain cover, if removed.

NOTE

When installing new oil seal, press fit to

timing chain cover (2) by using special tool

(bearing installer) as shown in figure.

Drive in dimension

“a”: 1.5 mm (0.06 in.)

Special tool

(A): 09913–75810

3) Install oil control valve to timing chain cover referring to “Oil Control Valve Removal and Installation”.

4) Apply sealant “A” to mating surface of cylinder and cylinder head and “B” to mating surface of timing

chain cover as shown in figure.

“A”: Water tight sealant 99000–31140 (SUZUKI

Bond No.1207B)

“B”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Sealant amount for timing chain cover

Width “a”: 3 mm (0.12 in.)

Height “b”: 2 mm (0.08 in.) 5) Apply engine oil to oil seal lip, then install timing

chain cover (1). Tighten bolts and nut to specified

torque.

NOTE

Before installing timing chain cover, check

that pin is securely fitted.

Tightening torque

Timing chain cover bolt (a): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

Timing chain cover nut (b): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

6) Apply engine oil to new O-rings (2) and install them to cap (3).

7) Install cap (3) to ti ming chain cover (1).

Tighten bolts to specified torque.

Tightening torque

Cap bolt (c): 25 N·m (2.5 kgf-m, 18.0 lb-ft)

I2RH0B140058-01

I3RH0B140025-01

(a)

(b)

(c)

1

2

3

I4RS0B140011-02

Page 308 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-23 Engine Mechanical:

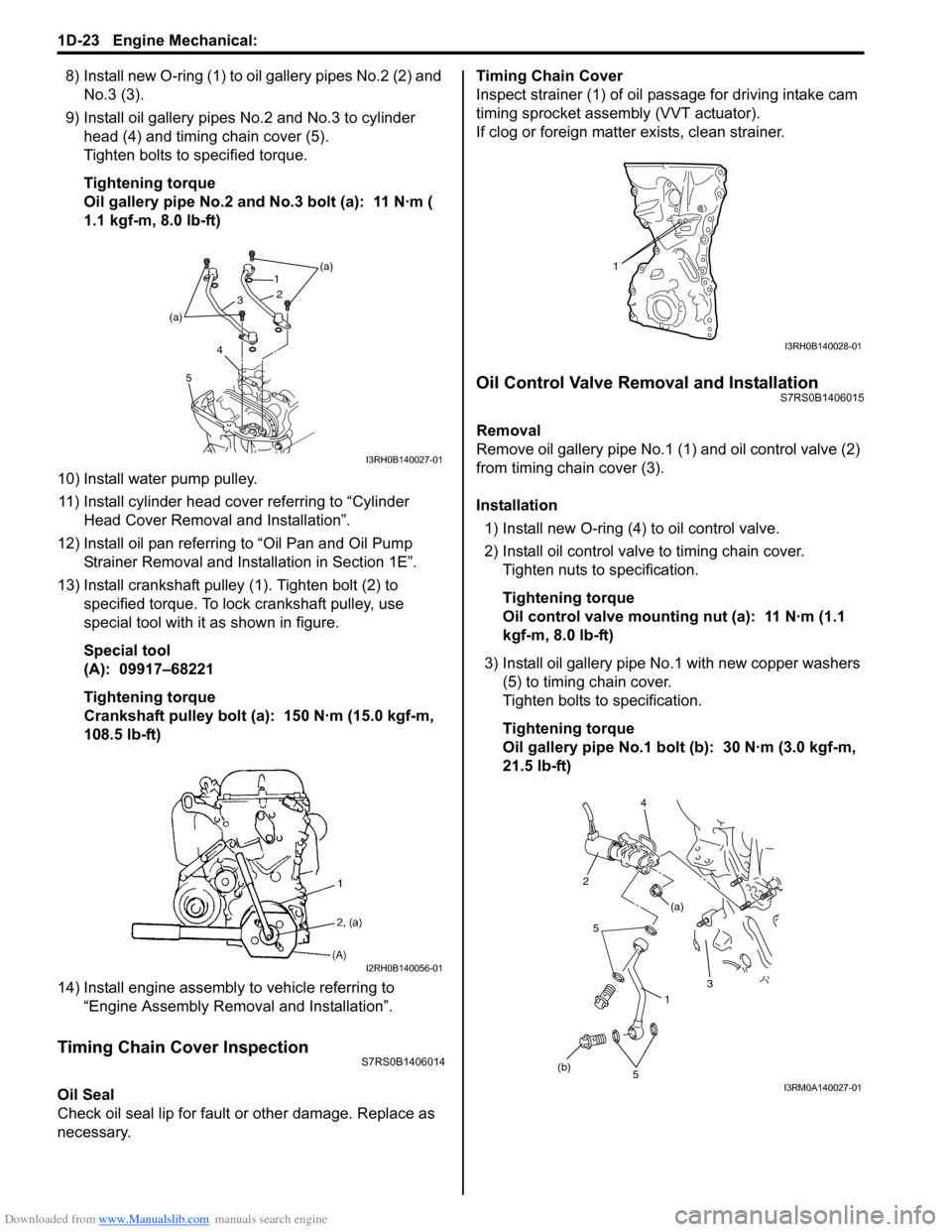

8) Install new O-ring (1) to oil gallery pipes No.2 (2) and

No.3 (3).

9) Install oil gallery pipes No.2 and No.3 to cylinder

head (4) and timing chain cover (5).

Tighten bolts to specified torque.

Tightening torque

Oil gallery pipe No.2 and No.3 bolt (a): 11 N·m (

1.1 kgf-m, 8.0 lb-ft)

10) Install water pump pulley. 11) Install cylinder head cover referring to “Cylinder Head Cover Removal and Installation”.

12) Install oil pan referring to “Oil Pan and Oil Pump

Strainer Removal and Installation in Section 1E”.

13) Install crankshaft pulley (1). Tighten bolt (2) to specified torque. To lock crankshaft pulley, use

special tool with it as shown in figure.

Special tool

(A): 09917–68221

Tightening torque

Crankshaft pulley bolt (a): 150 N·m (15.0 kgf-m,

108.5 lb-ft)

14) Install engine assembly to vehicle referring to “Engine Assembly Removal and Installation”.

Timing Chain Cover InspectionS7RS0B1406014

Oil Seal

Check oil seal lip for fault or other damage. Replace as

necessary. Timing Chain Cover

Inspect strainer (1) of oil passage for driving intake cam

timing sprocket assembly (VVT actuator).

If clog or foreign matter exists, clean strainer.

Oil Control Valve Removal and InstallationS7RS0B1406015

Removal

Remove oil gallery pipe No.1

(1) and oil control valve (2)

from timing chain cover (3).

Installation

1) Install new O-ring (4) to oil control valve.

2) Install oil control valve to timing chain cover. Tighten nuts to specification.

Tightening torque

Oil control valve mounting nut (a): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

3) Install oil gallery pipe No .1 with new copper washers

(5) to timing chain cover.

Tighten bolts to specification.

Tightening torque

Oil gallery pipe No.1 bolt (b): 30 N·m (3.0 kgf-m,

21.5 lb-ft)

(a)

(a) 1

2

3

4

5

I3RH0B140027-01

I2RH0B140056-01

1

I3RH0B140028-01

1

5

(b) 3

(a)

2 4

5

I3RM0A140027-01

Page 310 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-25 Engine Mechanical:

Timing Chain and Chain Tensioner Removal

and Installation

S7RS0B1406018

Removal

CAUTION!

After timing chain is removed, never turn

crankshaft and camshafts independently

more than its allowable turning range

described in “Installation”.

If turned, interferen ce may occur between

piston and valves and valves themselves,

and parts related to piston and valves may be

damaged.

1) Remove timing chain cover referring to “Timing Chain Cover Removal and Installation”.

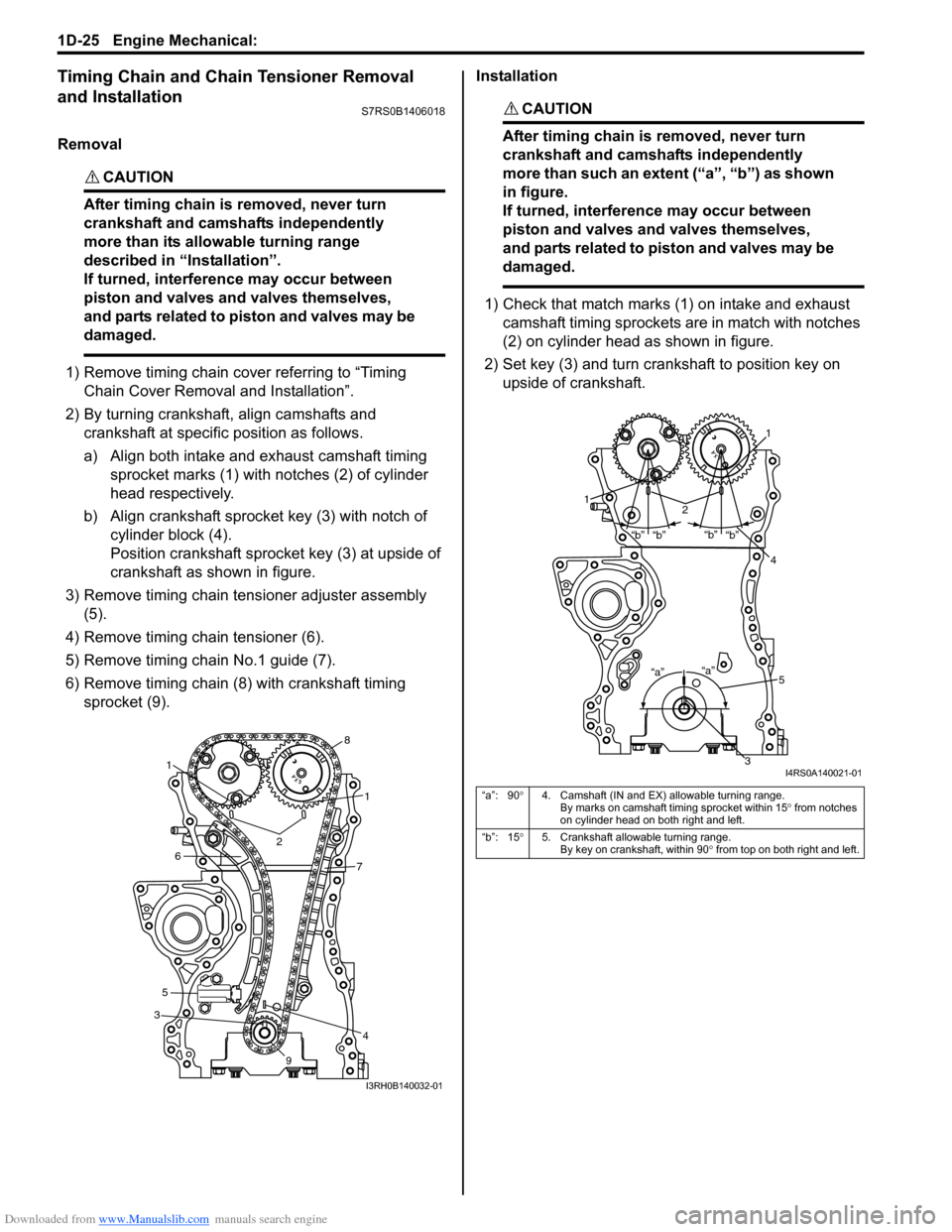

2) By turning crankshaft, align camshafts and crankshaft at specific position as follows.

a) Align both intake and exhaust camshaft timing sprocket marks (1) with notches (2) of cylinder

head respectively.

b) Align crankshaft sprocket key (3) with notch of cylinder block (4).

Position crankshaft sprocke t key (3) at upside of

crankshaft as shown in figure.

3) Remove timing chain tensioner adjuster assembly (5).

4) Remove timing chain tensioner (6).

5) Remove timing chain No.1 guide (7).

6) Remove timing chain (8) with crankshaft timing sprocket (9). Installation

CAUTION!

After timing chain is removed, never turn

crankshaft and camshafts independently

more than such an extent (“a”, “b”) as shown

in figure.

If turned, interferen

ce may occur between

piston and valves and valves themselves,

and parts related to piston and valves may be

damaged.

1) Check that match marks (1) on intake and exhaust camshaft timing sprockets are in match with notches

(2) on cylinder head as shown in figure.

2) Set key (3) and turn crankshaft to position key on upside of crankshaft.

3

4

1

1

2

5

67

8

9

I3RH0B140032-01

“a”: 90 °4. Camshaft (IN and EX) allowable turning range.

By marks on camshaft timing sprocket within 15 ° from notches

on cylinder head on both right and left.

“b”: 15 °5. Crankshaft allowable turning range.

By key on crankshaft, within 90 ° from top on both right and left.

“a”

“b”

“b”“b”

“b”

“a”

1

12

4

3

5

I4RS0A140021-01

Page 312 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-27 Engine Mechanical:

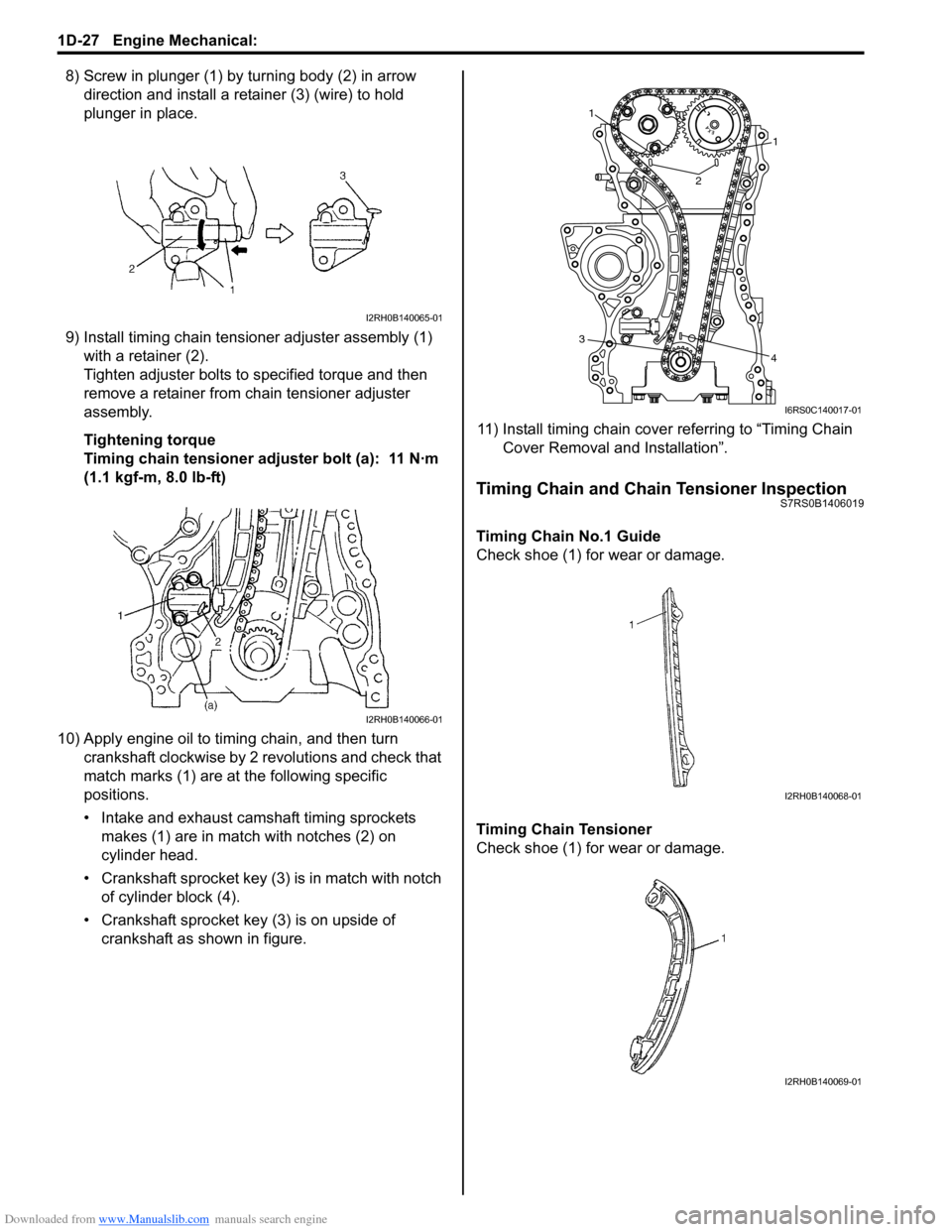

8) Screw in plunger (1) by turning body (2) in arrow direction and install a reta iner (3) (wire) to hold

plunger in place.

9) Install timing chain tensioner adjuster assembly (1) with a retainer (2).

Tighten adjuster bolts to specified torque and then

remove a retainer from chain tensioner adjuster

assembly.

Tightening torque

Timing chain tensioner adjuster bolt (a): 11 N·m

(1.1 kgf-m, 8.0 lb-ft)

10) Apply engine oil to timing chain, and then turn crankshaft clockwise by 2 revolutions and check that

match marks (1) are at the following specific

positions.

• Intake and exhaust camshaft timing sprockets makes (1) are in match with notches (2) on

cylinder head.

• Crankshaft sprocket key (3) is in match with notch of cylinder block (4).

• Crankshaft sprocket key (3) is on upside of crankshaft as shown in figure. 11) Install timing chain cover referring to “Timing Chain

Cover Removal and Installation”.

Timing Chain and Chain Tensioner InspectionS7RS0B1406019

Timing Chain No.1 Guide

Check shoe (1) for wear or damage.

Timing Chain Tensioner

Check shoe (1) for wear or damage.

I2RH0B140065-01

I2RH0B140066-01

1

1

2

3 4

I6RS0C140017-01

I2RH0B140068-01

I2RH0B140069-01

Page 314 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-29 Engine Mechanical:

Camshaft, Tappet and Shim Removal and

Installation

S7RS0B1406021

CAUTION!

• Keep working table, tools and hands clean while overhauling.

• Use special care to handle aluminum parts so as not to damage them.

• Do not expose removed parts to dust. Keep them always clean.

Removal

1) Remove timing chain cover referring to “Timing Chain Cover Removal and Installation”.

2) Remove timing chain referring to “Timing Chain and Chain Tensioner Removal and Installation”.

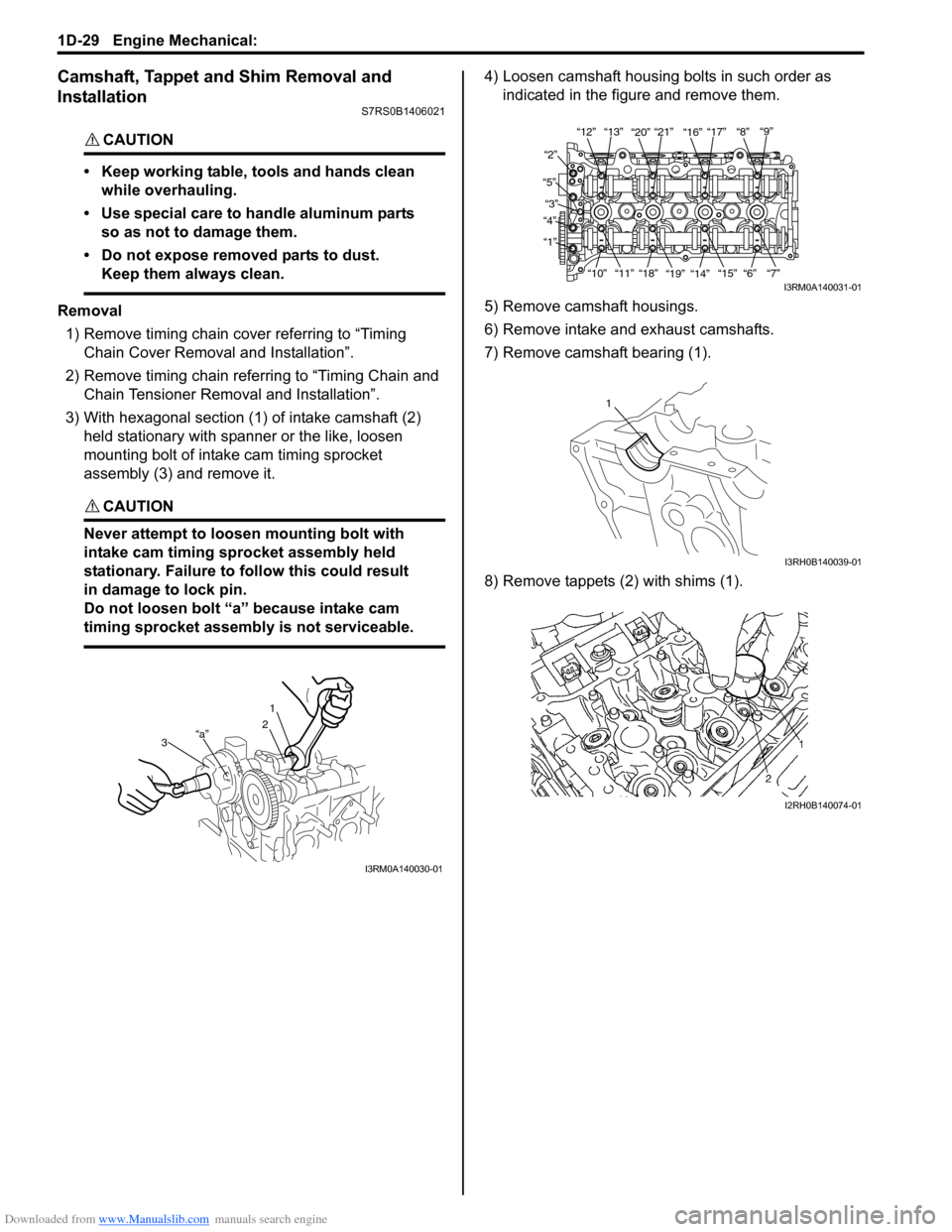

3) With hexagonal section (1) of intake camshaft (2) held stationary with spanner or the like, loosen

mounting bolt of intake cam timing sprocket

assembly (3) and remove it.

CAUTION!

Never attempt to loosen mounting bolt with

intake cam timing sprocket assembly held

stationary. Failure to fo llow this could result

in damage to lock pin.

Do not loosen bolt “a” because intake cam

timing sprocket assembly is not serviceable.

4) Loosen camshaft housing bolts in such order as indicated in the figure and remove them.

5) Remove camshaft housings.

6) Remove intake and exhaust camshafts.

7) Remove camshaft bearing (1).

8) Remove tappets (2) with shims (1).

3“a”

1

2

I3RM0A140030-01

“12”“13” “20”“21”

“16”“17” “8” “9”

“2”

“5” “3”

“4”

“1”

“10”“11”“18”

“19” “14” “15” “6” “7”

I3RM0A140031-01

1

I3RH0B140039-01

I2RH0B140074-01

Page 316 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-31 Engine Mechanical:

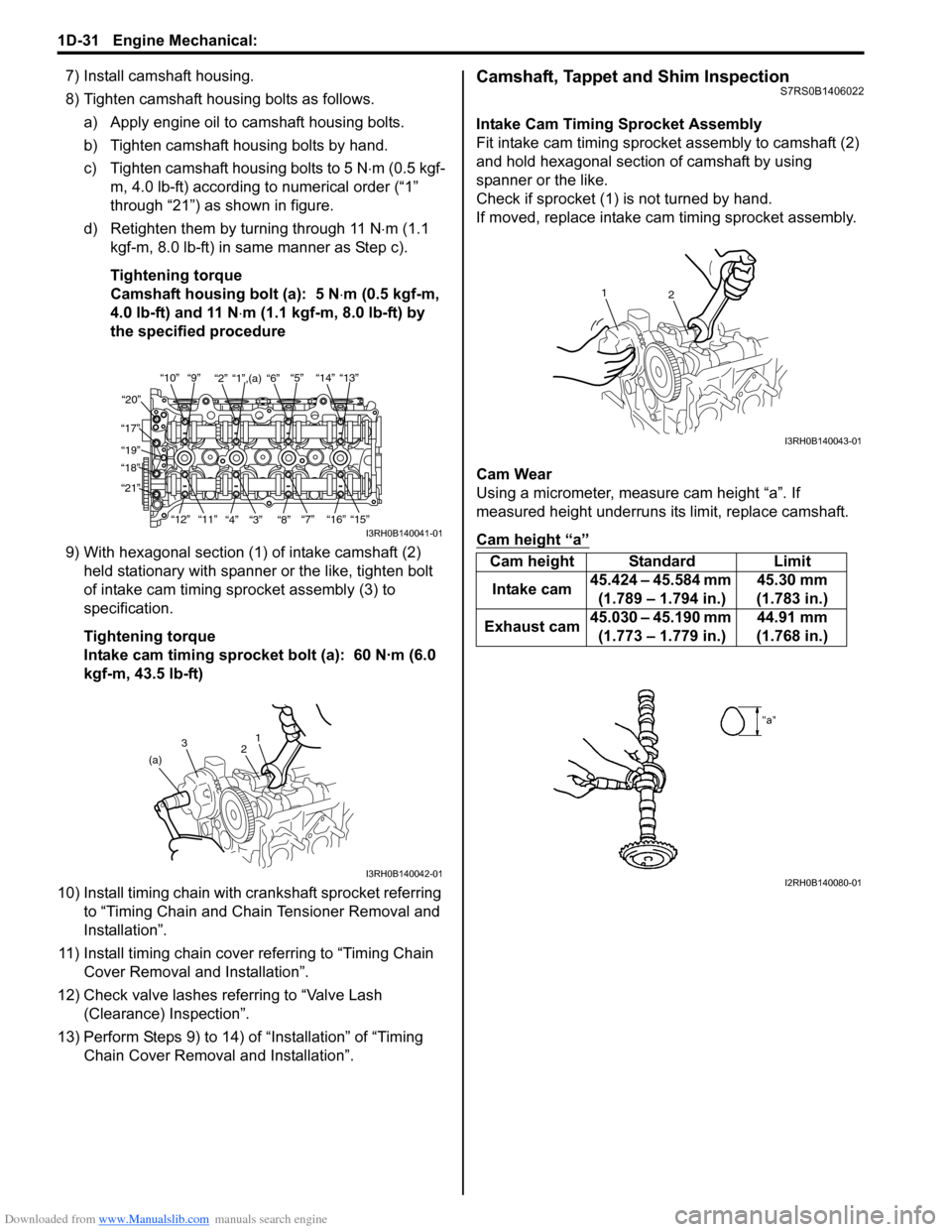

7) Install camshaft housing.

8) Tighten camshaft housing bolts as follows.a) Apply engine oil to camshaft housing bolts.

b) Tighten camshaft housing bolts by hand.

c) Tighten camshaft housing bolts to 5 N ⋅m (0.5 kgf-

m, 4.0 lb-ft) according to numerical order (“1”

through “21”) as shown in figure.

d) Retighten them by turning through 11 N⋅ m (1.1

kgf-m, 8.0 lb-ft) in same manner as Step c).

Tightening torque

Camshaft housing bolt (a): 5 N ⋅m (0.5 kgf-m,

4.0 lb-ft) and 11 N ⋅m (1.1 kgf-m, 8.0 lb-ft) by

the specified procedure

9) With hexagonal section (1) of intake camshaft (2) held stationary with spanner or the like, tighten bolt

of intake cam timing sp rocket assembly (3) to

specification.

Tightening torque

Intake cam timing sprocket bolt (a): 60 N·m (6.0

kgf-m, 43.5 lb-ft)

10) Install timing chain with cr ankshaft sprocket referring

to “Timing Chain and Chain Tensioner Removal and

Installation”.

11) Install timing chain cover referring to “Timing Chain Cover Removal and Installation”.

12) Check valve lashes referring to “Valve Lash (Clearance) Inspection”.

13) Perform Steps 9) to 14) of “Installation” of “Timing Chain Cover Removal and Installation”.Camshaft, Tappet and Shim InspectionS7RS0B1406022

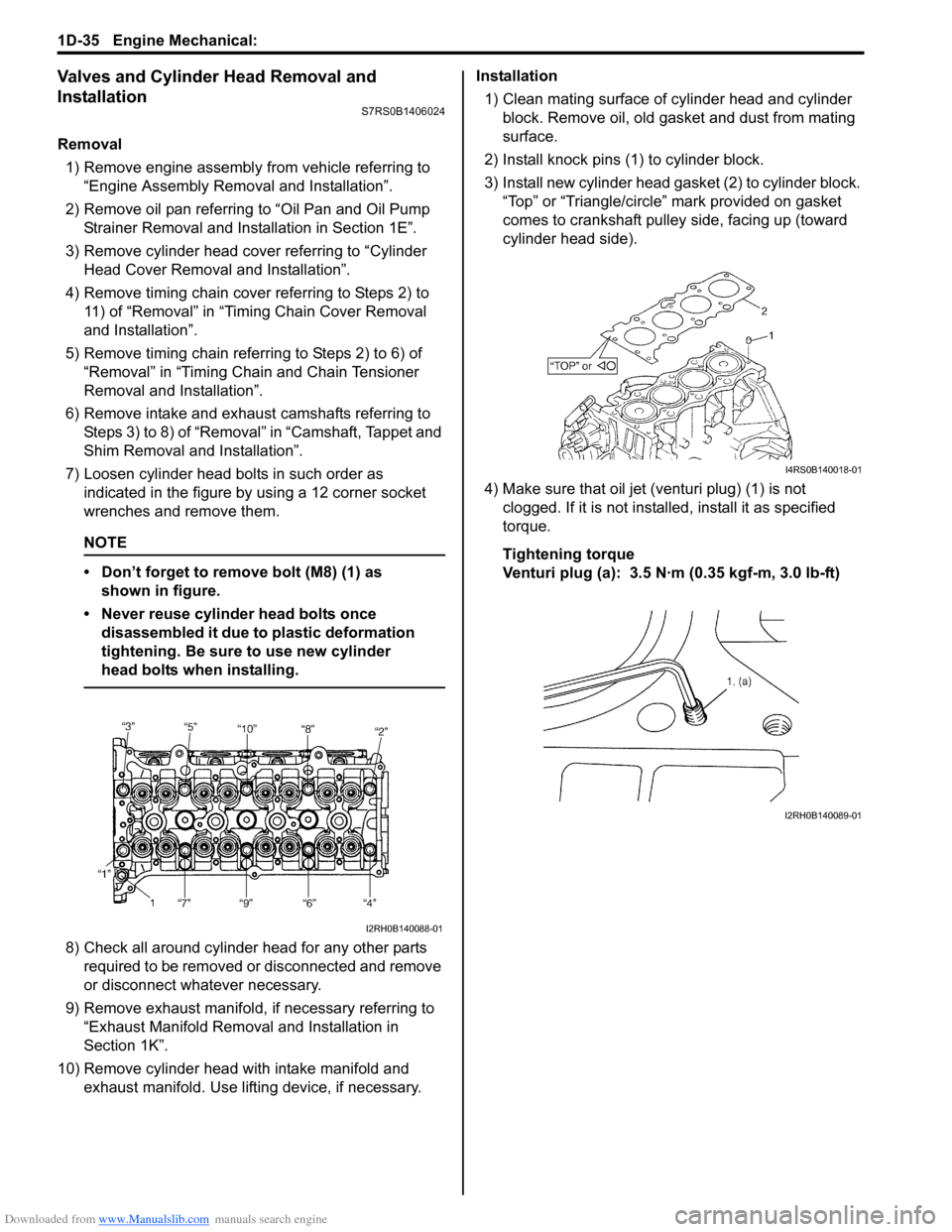

Intake Cam Timing Sprocket Assembly

Fit intake cam timing sprocket assembly to camshaft (2)

and hold hexagonal section of camshaft by using

spanner or the like.

Check if sprocket (1) is not turned by hand.

If moved, replace intake ca m timing sprocket assembly.

Cam Wear

Using a micrometer, measure cam height “a”. If

measured height underruns its limit, replace camshaft.

Cam height “a”

“10”“9” “2” “1”,(a) “6” “5” “14” “13”

“20”

“17” “19”

“18”

“21”

“12”“11”

“4” “3” “8” “7” “16” “15”

I3RH0B140041-01

1

2

3

(a)

I3RH0B140042-01

Cam height Standard Limit

Intake cam 45.424 – 45.584 mm

(1.789 – 1.794 in.) 45.30 mm

(1.783 in.)

Exhaust cam 45.030 – 45.190 mm

(1.773 – 1.779 in.) 44.91 mm

(1.768 in.)

2

1

I3RH0B140043-01

I2RH0B140080-01

Page 320 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-35 Engine Mechanical:

Valves and Cylinder Head Removal and

Installation

S7RS0B1406024

Removal1) Remove engine assembly from vehicle referring to “Engine Assembly Removal and Installation”.

2) Remove oil pan referring to “Oil Pan and Oil Pump

Strainer Removal and Installation in Section 1E”.

3) Remove cylinder head cover referring to “Cylinder Head Cover Removal and Installation”.

4) Remove timing chain cover referring to Steps 2) to 11) of “Removal” in “Tim ing Chain Cover Removal

and Installation”.

5) Remove timing chain referring to Steps 2) to 6) of “Removal” in “Timing Chain and Chain Tensioner

Removal and Installation”.

6) Remove intake and exhaust camshafts referring to Steps 3) to 8) of “Removal” in “Camshaft, Tappet and

Shim Removal and Installation”.

7) Loosen cylinder head bolts in such order as indicated in the figure by using a 12 corner socket

wrenches and remove them.

NOTE

• Don’t forget to remove bolt (M8) (1) as shown in figure.

• Never reuse cylinder head bolts once disassembled it due to plastic deformation

tightening. Be sure to use new cylinder

head bolts when installing.

8) Check all around cylinder head for any other parts required to be removed or disconnected and remove

or disconnect whatever necessary.

9) Remove exhaust manifold, if necessary referring to

“Exhaust Manifold Removal and Installation in

Section 1K”.

10) Remove cylinder head wi th intake manifold and

exhaust manifold. Use lifting device, if necessary. Installation

1) Clean mating surface of cylinder head and cylinder block. Remove oil, old gasket and dust from mating

surface.

2) Install knock pins (1) to cylinder block.

3) Install new cylinder head gasket (2) to cylinder block. “Top” or “Triangle/circle” mark provided on gasket

comes to crankshaft pulley side, facing up (toward

cylinder head side).

4) Make sure that oil jet (venturi plug) (1) is not clogged. If it is not install ed, install it as specified

torque.

Tightening torque

Venturi plug (a): 3.5 N·m (0.35 kgf-m, 3.0 lb-ft)

I2RH0B140088-01

I4RS0B140018-01

I2RH0B140089-01