Gauge SUZUKI SWIFT 2008 2.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 355 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Lubrication System: 1E-3

6) Start engine and warm engine up to normal operating temperature.

NOTE

Be sure to shift transaxle gear shift lever in

“Neutral” (shift select lever in “P” range for

A/T vehicle), set parking brake and block

drive wheels.

7) After warming up, raise engine speed to 4,000 r/min. and measure oil pressure.

Oil pressure specification

More than 270 kPa (2.7 kg/cm2, 39.8 psi) at 4,000

r/min. (rpm)

8) After checking oil pressure, stop engine and remove oil pressure gauge and attachment.

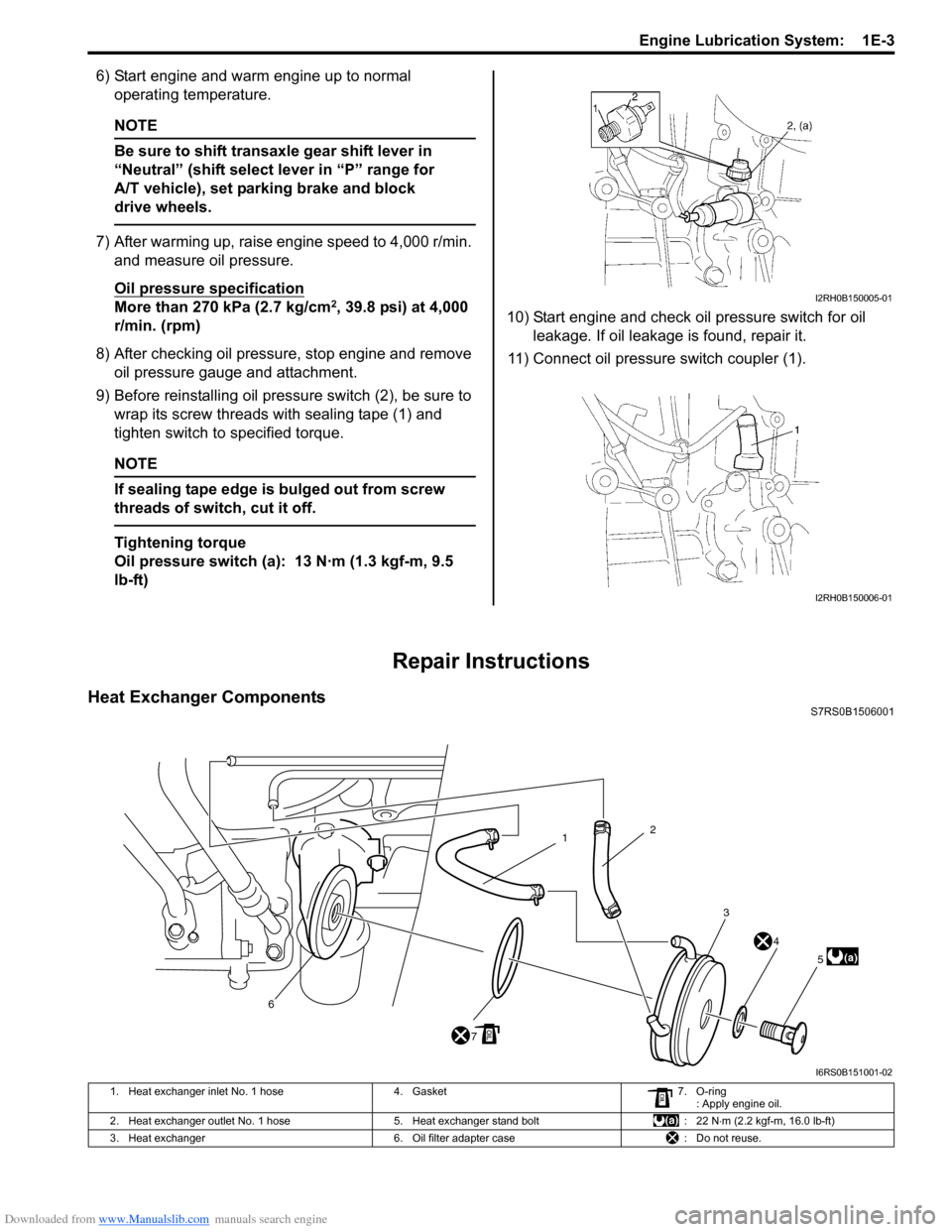

9) Before reinstalling oil pressure switch (2), be sure to

wrap its screw threads with sealing tape (1) and

tighten switch to specified torque.

NOTE

If sealing tape edge is bulged out from screw

threads of switch, cut it off.

Tightening torque

Oil pressure switch (a): 13 N·m (1.3 kgf-m, 9.5

lb-ft) 10) Start engine and check oil pressure switch for oil

leakage. If oil leakage is found, repair it.

11) Connect oil pressure switch coupler (1).

Repair Instructions

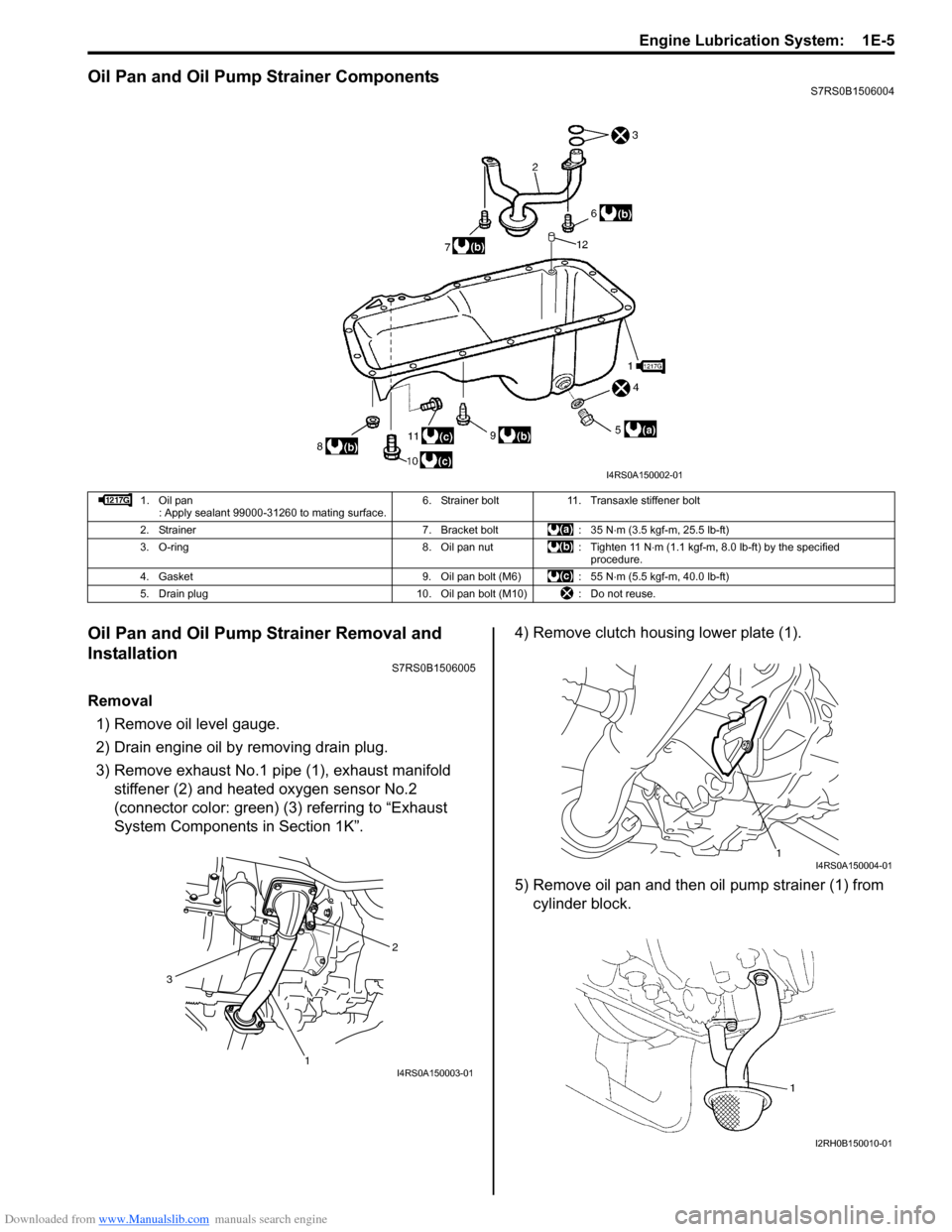

Heat Exchanger ComponentsS7RS0B1506001

I2RH0B150005-01

I2RH0B150006-01

3

4

5

7

6

(a)

2

1

I6RS0B151001-02

1. Heat exchanger inlet No. 1 hose 4. Gasket7. O-ring

: Apply engine oil.

2. Heat exchanger outlet No. 1 hose 5. Heat exchanger stand bolt : 22 N⋅m (2.2 kgf-m, 16.0 lb-ft)

3. Heat exchanger 6. Oil filter adapter case : Do not reuse.

Page 357 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Lubrication System: 1E-5

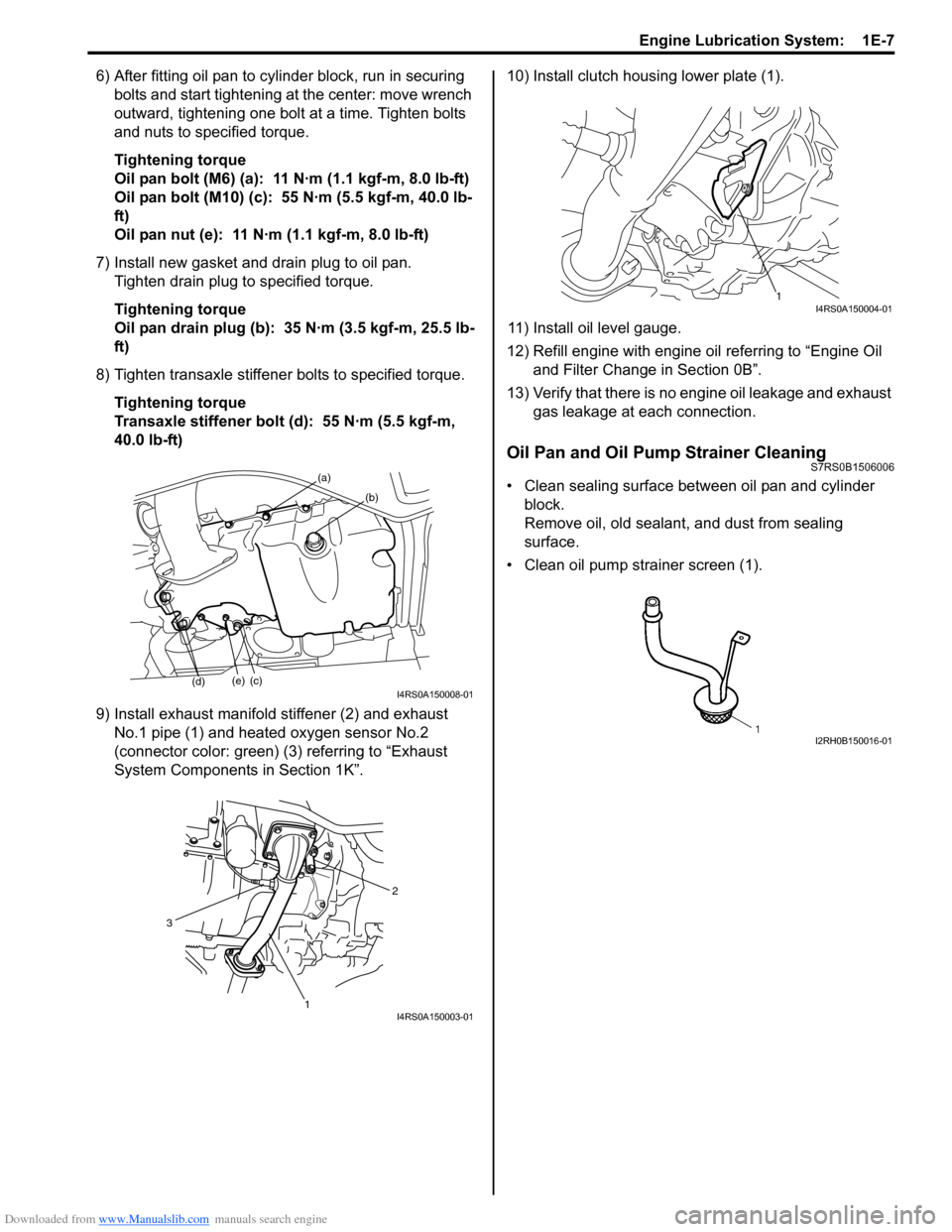

Oil Pan and Oil Pump Strainer ComponentsS7RS0B1506004

Oil Pan and Oil Pump Strainer Removal and

Installation

S7RS0B1506005

Removal1) Remove oil level gauge.

2) Drain engine oil by removing drain plug.

3) Remove exhaust No.1 pipe (1), exhaust manifold stiffener (2) and heated oxygen sensor No.2

(connector color: green) (3) referring to “Exhaust

System Components in Section 1K”. 4) Remove clutch housing lower plate (1).

5) Remove oil pan and then oil pump strainer (1) from

cylinder block.

I4RS0A150002-01

1. Oil pan : Apply sealant 99000-31260 to mating surface. 6. Strainer bolt 11. Transaxle stiffener bolt

2. Strainer 7. Bracket bolt : 35 N ⋅m (3.5 kgf-m, 25.5 lb-ft)

3. O-ring 8. Oil pan nut : Tighten 11 N ⋅m (1.1 kgf-m, 8.0 lb-ft) by the specified

procedure.

4. Gasket 9. Oil pan bolt (M6) : 55 N ⋅m (5.5 kgf-m, 40.0 lb-ft)

5. Drain plug 10. Oil pan bolt (M10) : Do not reuse.

2

1

3

I4RS0A150003-01

1I4RS0A150004-01

I2RH0B150010-01

Page 359 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Lubrication System: 1E-7

6) After fitting oil pan to cylinder block, run in securing bolts and start tightening at the center: move wrench

outward, tightening one bolt at a time. Tighten bolts

and nuts to specified torque.

Tightening torque

Oil pan bolt (M6) (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

Oil pan bolt (M10) (c): 55 N·m (5.5 kgf-m, 40.0 lb-

ft)

Oil pan nut (e): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

7) Install new gasket and drain plug to oil pan. Tighten drain plug to specified torque.

Tightening torque

Oil pan drain plug (b): 35 N·m (3.5 kgf-m, 25.5 lb-

ft)

8) Tighten transaxle stiffener bolts to specified torque. Tightening torque

Transaxle stiffener bolt (d): 55 N·m (5.5 kgf-m,

40.0 lb-ft)

9) Install exhaust manifold stiffener (2) and exhaust No.1 pipe (1) and heated oxygen sensor No.2

(connector color: green) (3) referring to “Exhaust

System Components in Section 1K”. 10) Install clutch housing lower plate (1).

11) Install oil level gauge.

12) Refill engine with engine oil referring to “Engine Oil

and Filter Change in Section 0B”.

13) Verify that there is no en gine oil leakage and exhaust

gas leakage at each connection.

Oil Pan and Oil Pump Strainer CleaningS7RS0B1506006

• Clean sealing surface between oil pan and cylinder block.

Remove oil, old sealant, and dust from sealing

surface.

• Clean oil pump strainer screen (1).(a)

(b)

(c)(e)

(d)I4RS0A150008-01

2

1

3

I4RS0A150003-01

1I4RS0A150004-01

I2RH0B150016-01

Page 362 of 1496

Downloaded from www.Manualslib.com manuals search engine 1E-10 Engine Lubrication System:

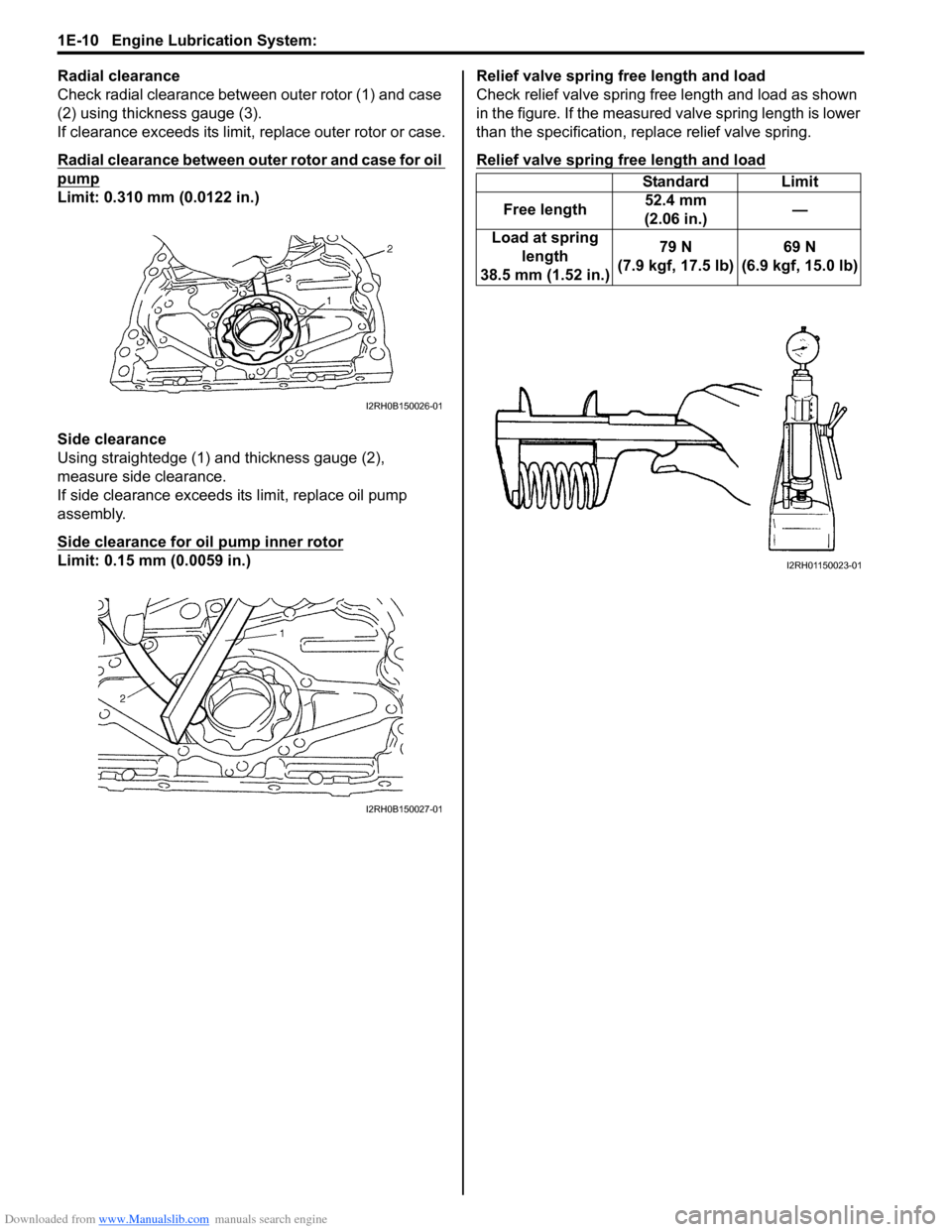

Radial clearance

Check radial clearance between outer rotor (1) and case

(2) using thickness gauge (3).

If clearance exceeds its limit, replace outer rotor or case.

Radial clearance between outer rotor and case for oil

pump

Limit: 0.310 mm (0.0122 in.)

Side clearance

Using straightedge (1) and thickness gauge (2),

measure side clearance.

If side clearance exceeds its limit, replace oil pump

assembly.

Side clearance for oil pump inner rotor

Limit: 0.15 mm (0.0059 in.)Relief valve spring free length and load

Check relief valve spring free length and load as shown

in the figure. If the measured valve spring length is lower

than the specification, replace relief valve spring.

Relief valve spring free length and load

I2RH0B150026-01

I2RH0B150027-01

Standard Limit

Free length 52.4 mm

(2.06 in.) —

Load at spring length

38.5 mm (1.52 in.) 79 N

(7.9 kgf, 17.5 lb) 69 N

(6.9 kgf, 15.0 lb)

I2RH01150023-01

Page 363 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Lubrication System: 1E-11

Specifications

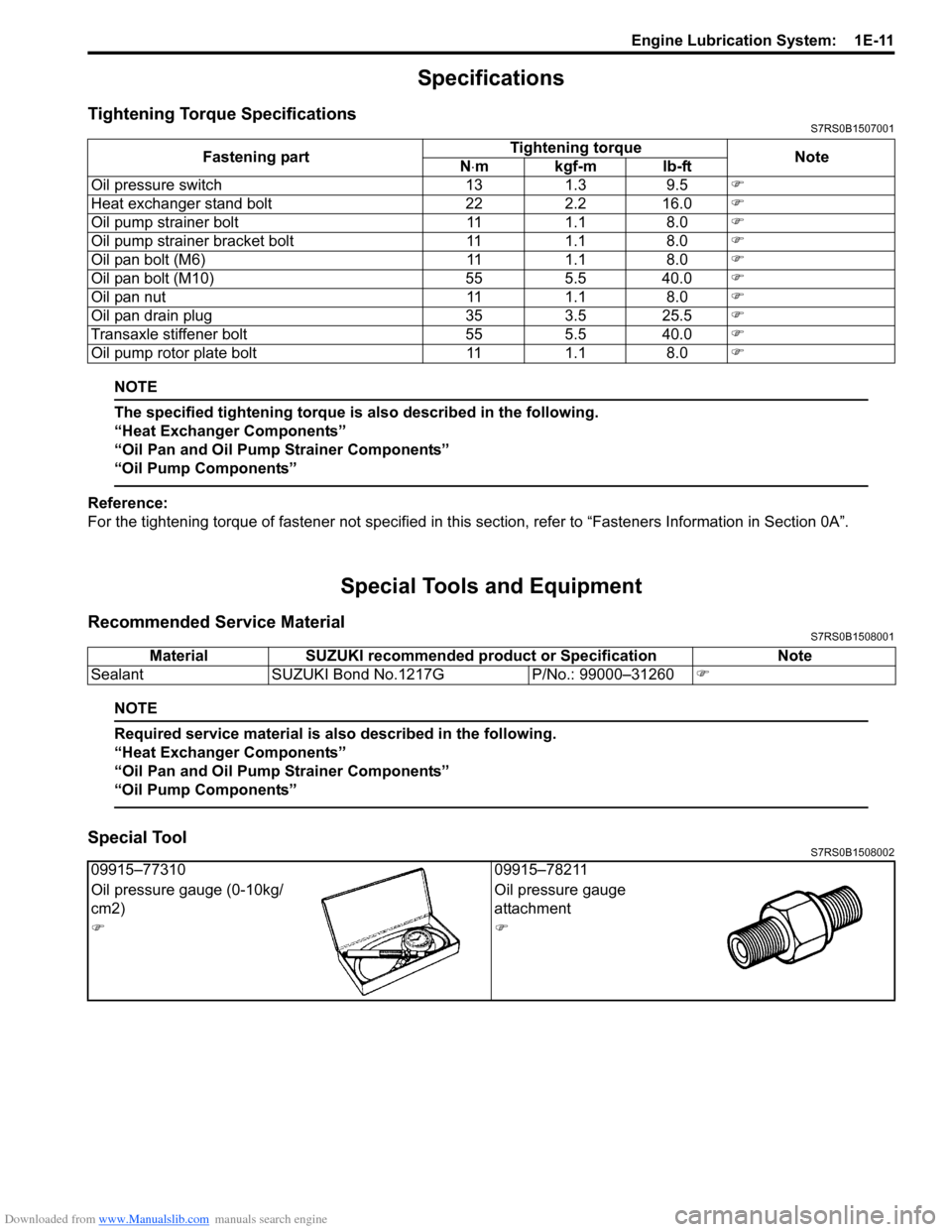

Tightening Torque SpecificationsS7RS0B1507001

NOTE

The specified tightening torque is also described in the following.

“Heat Exchanger Components”

“Oil Pan and Oil Pump Strainer Components”

“Oil Pump Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Service MaterialS7RS0B1508001

NOTE

Required service material is also described in the following.

“Heat Exchanger Components”

“Oil Pan and Oil Pump Strainer Components”

“Oil Pump Components”

Special ToolS7RS0B1508002

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Oil pressure switch 13 1.3 9.5 �)

Heat exchanger stand bolt 22 2.2 16.0 �)

Oil pump strainer bolt 11 1.1 8.0 �)

Oil pump strainer bracket bolt 11 1.1 8.0 �)

Oil pan bolt (M6) 11 1.1 8.0 �)

Oil pan bolt (M10) 55 5.5 40.0 �)

Oil pan nut 11 1.1 8.0 �)

Oil pan drain plug 35 3.5 25.5 �)

Transaxle stiffener bolt 55 5.5 40.0 �)

Oil pump rotor plate bolt 11 1.1 8.0 �)

MaterialSUZUKI recommended product or Specification Note

Sealant SUZUKI Bond No.1217G P/No.: 99000–31260�)

09915–77310 09915–78211

Oil pressure gauge (0-10kg/

cm2) Oil pressure gauge

attachment

�)�)

Page 376 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-1 Fuel System:

Engine

Fuel System

Precautions

Precautions on Fuel System ServiceS7RS0B1700001

WARNING!

Before attempting service of any type on fuel system, the following should be always observed in

order to reduce the risk of fire and personal injury.

• Disconnect negative cable at battery.

• Do not smoke, and place no smoking signs near work area.

• Be sure to have CO

2 fire extinguisher handy.

• Be sure to perform work in a well-ventilated area and away from any open flames (such as gas hot heater).

• Wear safety glasses.

• To relieve fuel vapor pressure in fuel tank, remove fuel filler cap from fuel filler neck and then

reinstall it.

• As fuel feed line is still under high fuel pr essure even after stopping engine, loosening or

disconnecting fuel feed line directly may cause dangerous spout of fuel. Before loosening or

disconnecting fuel feed line, make sure to relieve fuel pressure referring to “Fuel Pressure Relief

Procedure”.

• A small amount of fuel may be released when the fuel line is disconnected. In order to reduce the risk of personal injury, cover a shop cloth to the fitting to be disconnected. Be sure to put that cloth

in an approved container after disconnecting.

• Never run engine with fuel pump relay disconnected when engine and exhaust system are hot.

• Note that fuel hose connection varies with each type of pipe. Be sure to connect and clamp each hose correctly referring to “Fuel Hose Disconnecting and Reconnecting”.

After connecting, make sure that it has no twist or kink.

• When installing inje ctor or fuel feed pipe, lubr icate its O-ring with gasoline.

General Description

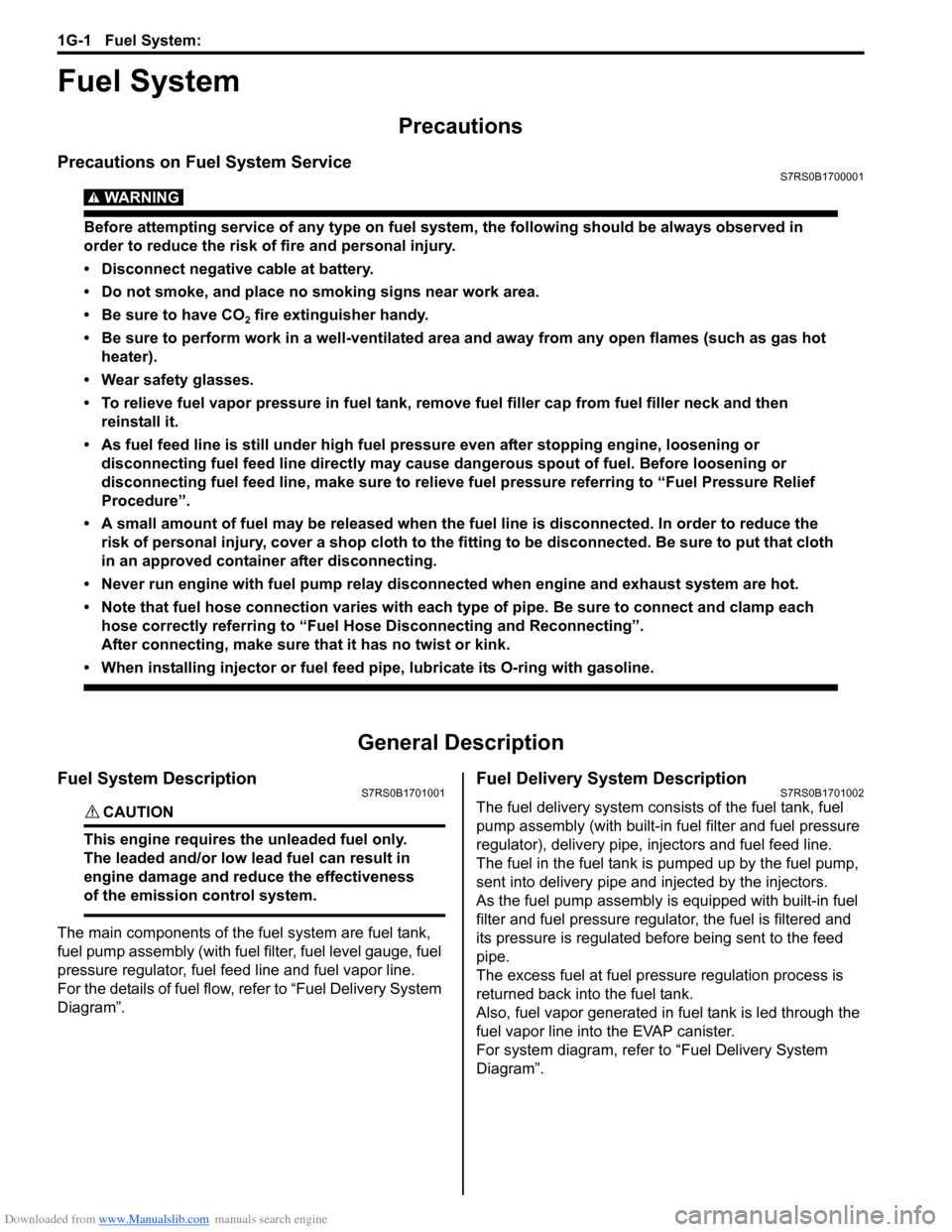

Fuel System DescriptionS7RS0B1701001

CAUTION!

This engine requires the unleaded fuel only.

The leaded and/or low lead fuel can result in

engine damage and reduce the effectiveness

of the emission control system.

The main components of the fuel system are fuel tank,

fuel pump assembly (with fuel filter, fuel level gauge, fuel

pressure regulator, fuel feed line and fuel vapor line.

For the details of fuel flow, refer to “Fuel Delivery System

Diagram”.

Fuel Delivery System DescriptionS7RS0B1701002

The fuel delivery system consists of the fuel tank, fuel

pump assembly (with built-in f uel filter and fuel pressure

regulator), delivery pipe, injectors and fuel feed line.

The fuel in the fuel tank is pumped up by the fuel pump,

sent into delivery pipe and injected by the injectors.

As the fuel pump assembly is equipped with built-in fuel

filter and fuel pressure regulator, the fuel is filtered and

its pressure is regulated before being sent to the feed

pipe.

The excess fuel at fuel pressure regulation process is

returned back into the fuel tank.

Also, fuel vapor generated in fuel tank is led through the

fuel vapor line into the EVAP canister.

For system diagram, refer to “Fuel Delivery System

Diagram”.

Page 377 of 1496

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-2

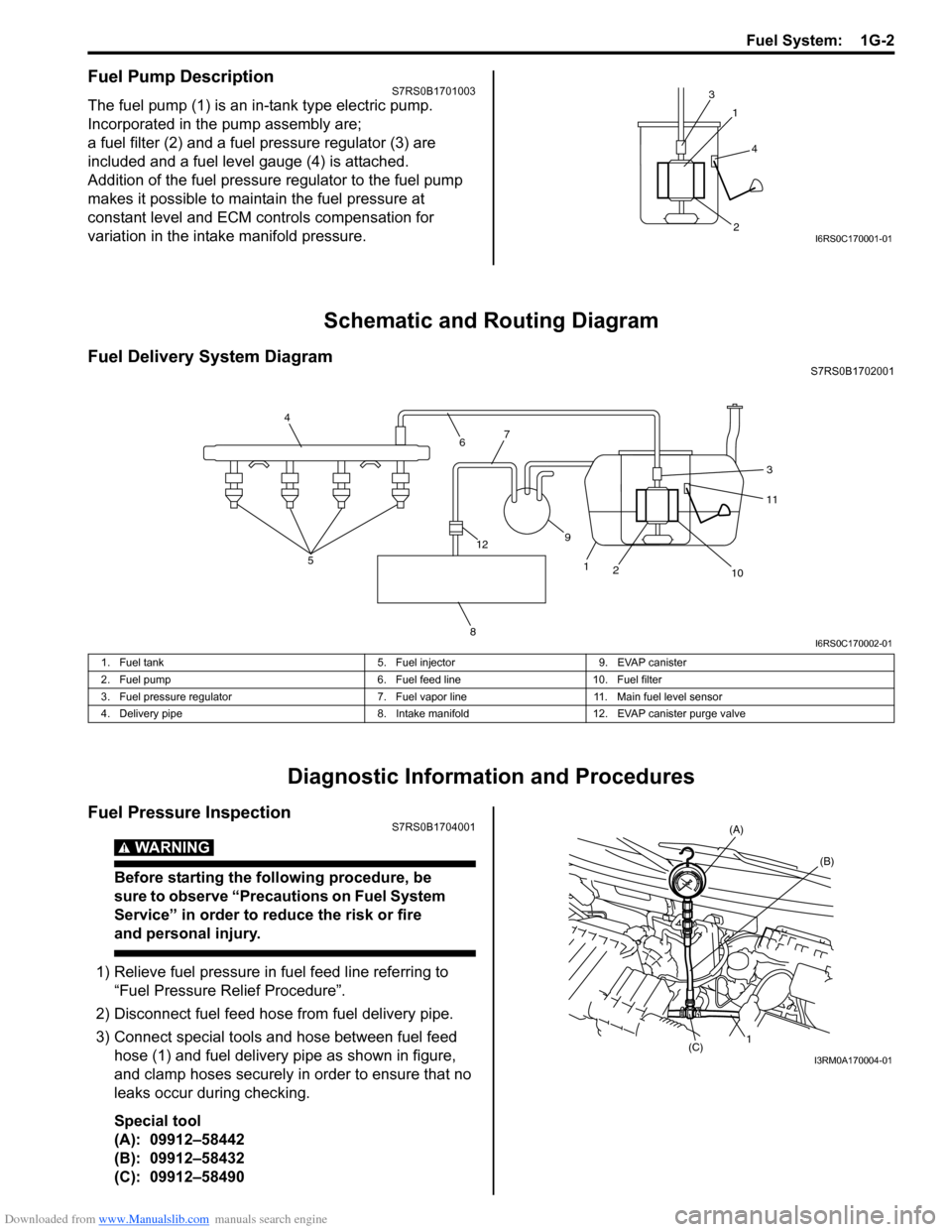

Fuel Pump DescriptionS7RS0B1701003

The fuel pump (1) is an in-tank type electric pump.

Incorporated in the pump assembly are;

a fuel filter (2) and a fuel pressure regulator (3) are

included and a fuel level gauge (4) is attached.

Addition of the fuel pressure regulator to the fuel pump

makes it possible to mainta in the fuel pressure at

constant level and ECM controls compensation for

variation in the intake manifold pressure.

Schematic and Routing Diagram

Fuel Delivery System DiagramS7RS0B1702001

Diagnostic Information and Procedures

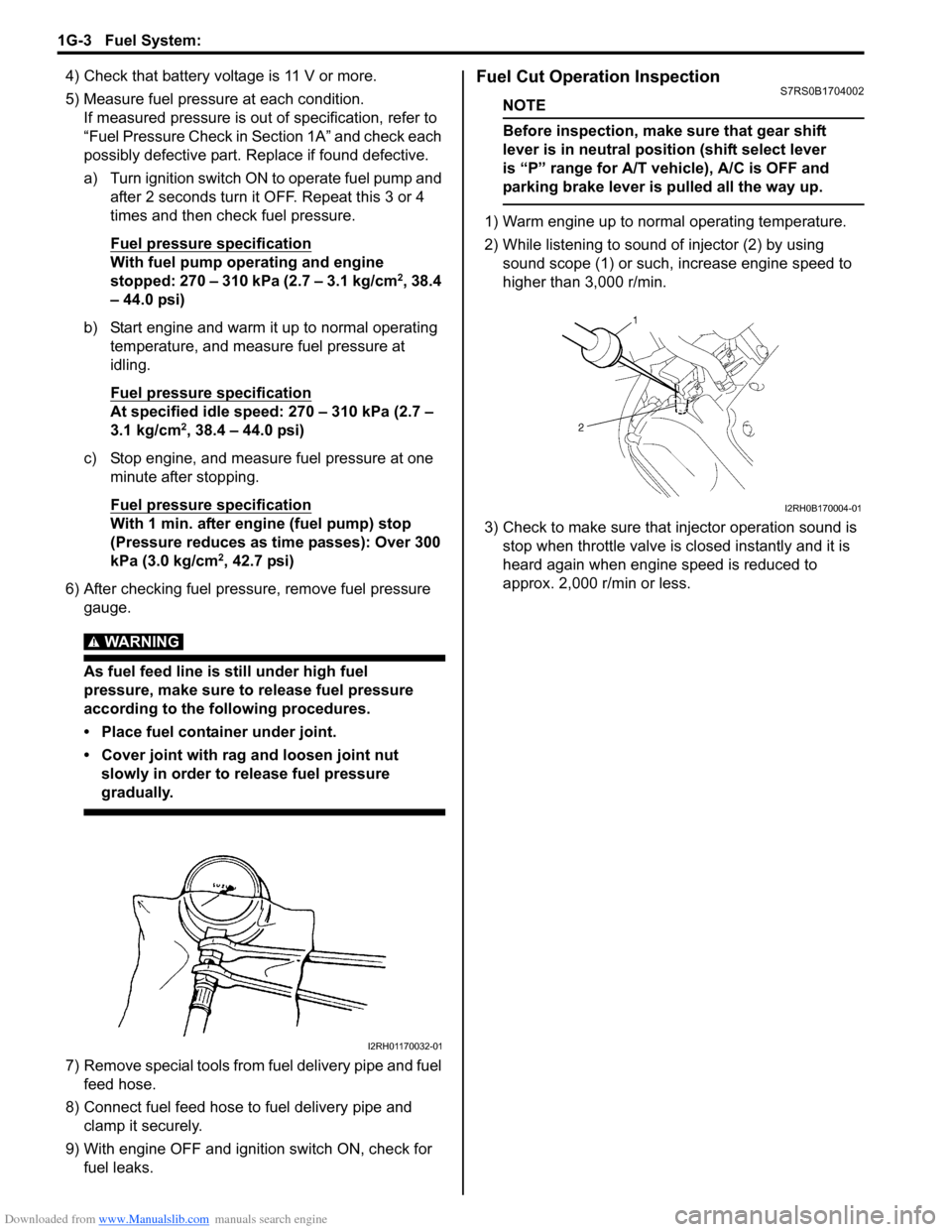

Fuel Pressure InspectionS7RS0B1704001

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

1) Relieve fuel pressure in fuel feed line referring to

“Fuel Pressure Relief Procedure”.

2) Disconnect fuel feed hose from fuel delivery pipe.

3) Connect special tools and hose between fuel feed hose (1) and fuel delivery pipe as shown in figure,

and clamp hoses securely in order to ensure that no

leaks occur during checking.

Special tool

(A): 09912–58442

(B): 09912–58432

(C): 09912–58490

1

3

2

4

I6RS0C170001-01

4

6 7

8

12

2 3

11

10

5

1

9

I6RS0C170002-01

1. Fuel tank

5. Fuel injector9. EVAP canister

2. Fuel pump 6. Fuel feed line10. Fuel filter

3. Fuel pressure regulator 7. Fuel vapor line 11. Main fuel level sensor

4. Delivery pipe 8. Intake manifold12. EVAP canister purge valve

1

(C) (B)

(A)

I3RM0A170004-01

Page 378 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-3 Fuel System:

4) Check that battery voltage is 11 V or more.

5) Measure fuel pressure at each condition.If measured pressure is out of specification, refer to

“Fuel Pressure Check in Section 1A” and check each

possibly defective part. Replace if found defective.

a) Turn ignition switch ON to operate fuel pump and after 2 seconds turn it OFF. Repeat this 3 or 4

times and then check fuel pressure.

Fuel pressure specification

With fuel pump operating and engine

stopped: 270 – 310 kPa (2.7 – 3.1 kg/cm2, 38.4

– 44.0 psi)

b) Start engine and warm it up to normal operating temperature, and measure fuel pressure at

idling.

Fuel pressure specification

At specified idle speed: 270 – 310 kPa (2.7 –

3.1 kg/cm2, 38.4 – 44.0 psi)

c) Stop engine, and measure fuel pressure at one minute after stopping.

Fuel pressure specification

With 1 min. after engine (fuel pump) stop

(Pressure reduces as time passes): Over 300

kPa (3.0 kg/cm

2, 42.7 psi)

6) After checking fuel pressure, remove fuel pressure gauge.

WARNING!

As fuel feed line is still under high fuel

pressure, make sure to release fuel pressure

according to the following procedures.

• Place fuel container under joint.

• Cover joint with rag and loosen joint nut slowly in order to release fuel pressure

gradually.

7) Remove special tools from fuel delivery pipe and fuel feed hose.

8) Connect fuel feed hose to fuel delivery pipe and clamp it securely.

9) With engine OFF and ignition switch ON, check for fuel leaks.

Fuel Cut Operation InspectionS7RS0B1704002

NOTE

Before inspection, make sure that gear shift

lever is in neutral positi on (shift select lever

is “P” range for A/T vehicle), A/C is OFF and

parking brake lever is pulled all the way up.

1) Warm engine up to normal operating temperature.

2) While listening to sound of injector (2) by using sound scope (1) or such, increase engine speed to

higher than 3,000 r/min.

3) Check to make sure that injector operation sound is stop when throttle valve is closed instantly and it is

heard again when engine speed is reduced to

approx. 2,000 r/min or less.

I2RH01170032-01

I2RH0B170004-01

Page 392 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-17 Fuel System:

Special Tools and Equipment

Special ToolS7RS0B1708001

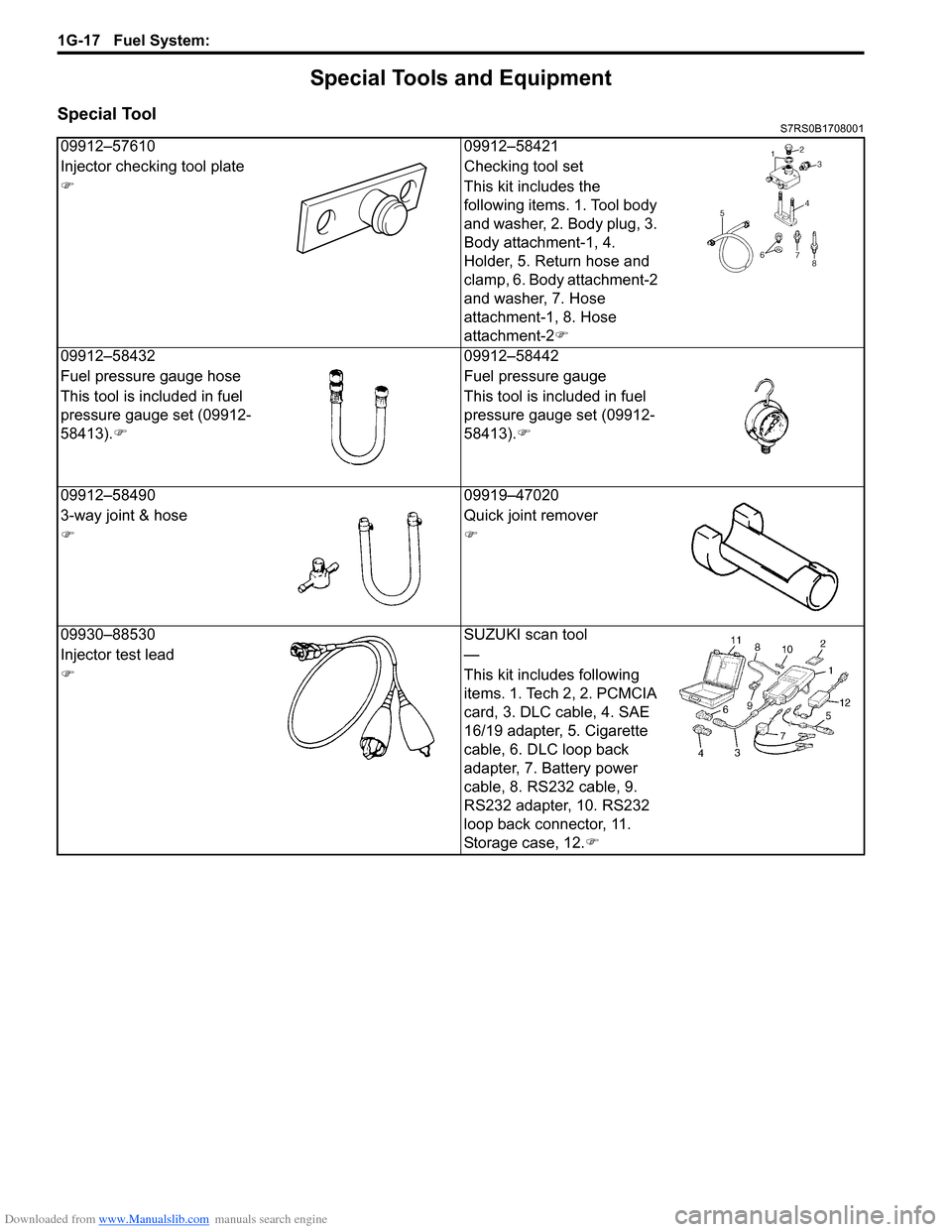

09912–5761009912–58421

Injector checking tool plate Checking tool set

�) This kit includes the

following items. 1. Tool body

and washer, 2. Body plug, 3.

Body attachment-1, 4.

Holder, 5. Return hose and

clamp, 6. Body attachment-2

and washer, 7. Hose

attachment-1, 8. Hose

attachment-2�)

09912–58432 09912–58442

Fuel pressure gauge hose Fuel pressure gauge

This tool is included in fuel

pressure gauge set (09912-

58413). �) This tool is included in fuel

pressure gauge set (09912-

58413).

�)

09912–58490 09919–47020

3-way joint & hose Quick joint remover

�)�)

09930–88530 SUZUKI scan tool

Injector test lead —

�) This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12.�)

Page 408 of 1496

Downloaded from www.Manualslib.com manuals search engine 1I-7 Starting System:

Spring

Inspect brush springs for wear, damage or other

abnormal conditions. Replace if necessary.

Brush spring tension

Standard: 2.2 kg (4.85 lb)

Limit: 0.6 kg (1.33 lb)

Brush Holder

• Check movement of brush in brush holder. If brush movement within brush holder is sluggish, check

brush holder for distortion and sliding faces for

contamination.

Clean or correct as necessary.

• Check for continuity across insulated brush (positive side) and grounded brush (negative side).

If continuity exists, brus h holder is grounded due to

defective insulation and should be replaced.

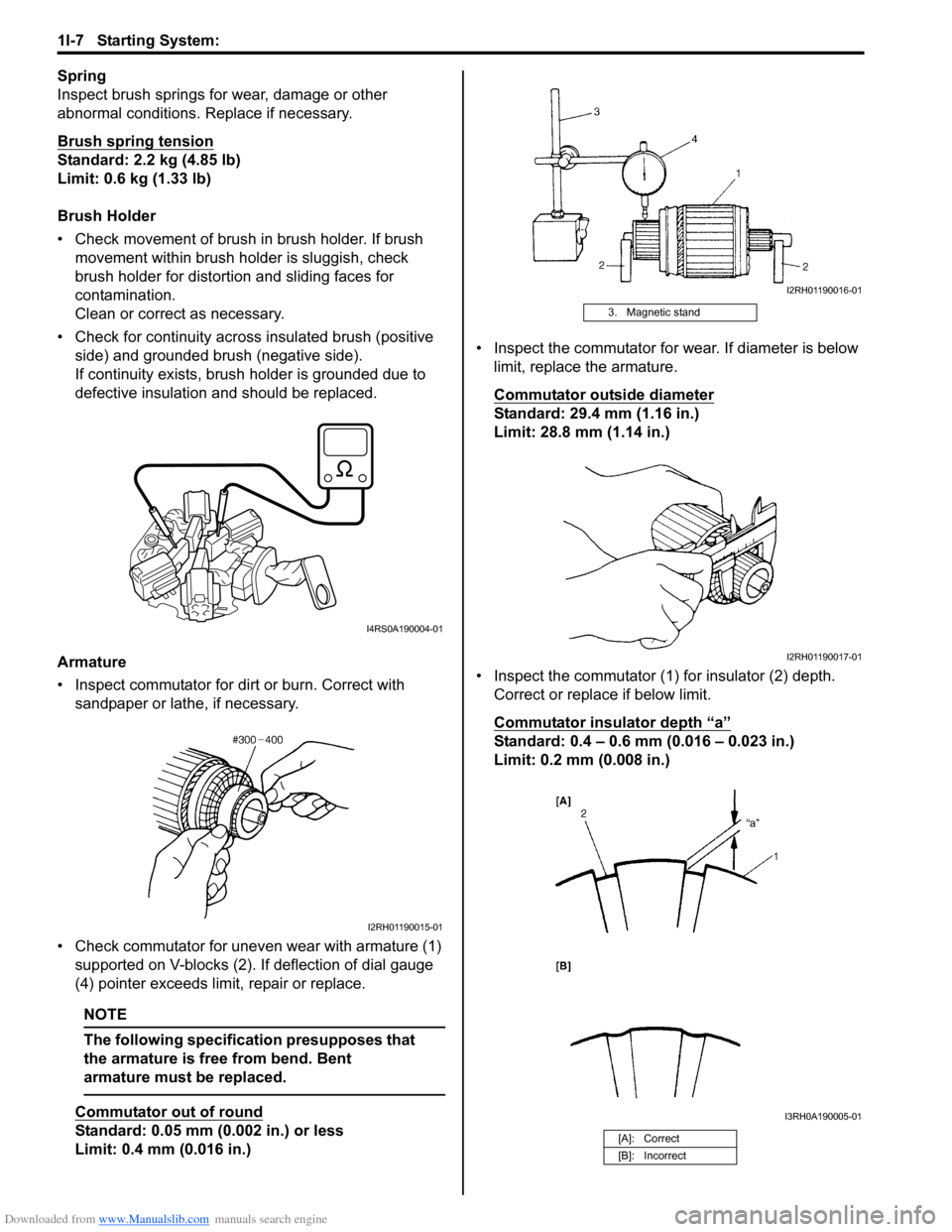

Armature

• Inspect commutator for dirt or burn. Correct with sandpaper or lathe, if necessary.

• Check commutator for uneven wear with armature (1) supported on V-blocks (2). If deflection of dial gauge

(4) pointer exceeds limit, repair or replace.

NOTE

The following specification presupposes that

the armature is free from bend. Bent

armature must be replaced.

Commutator out of round

Standard: 0.05 mm (0.002 in.) or less

Limit: 0.4 mm (0.016 in.) • Inspect the commutator for wear. If diameter is below

limit, replace the armature.

Commutator outside diameter

Standard: 29.4 mm (1.16 in.)

Limit: 28.8 mm (1.14 in.)

• Inspect the commutator (1) for insulator (2) depth. Correct or replace if below limit.

Commutator insulator depth “a”

Standard: 0.4 – 0.6 mm (0.016 – 0.023 in.)

Limit: 0.2 mm (0.008 in.)

I4RS0A190004-01

I2RH01190015-01

3. Magnetic stand

[A]: Correct

[B]: Incorrect

I2RH01190016-01

I2RH01190017-01

I3RH0A190005-01