No charge SUZUKI SWIFT 2008 2.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 561 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-22

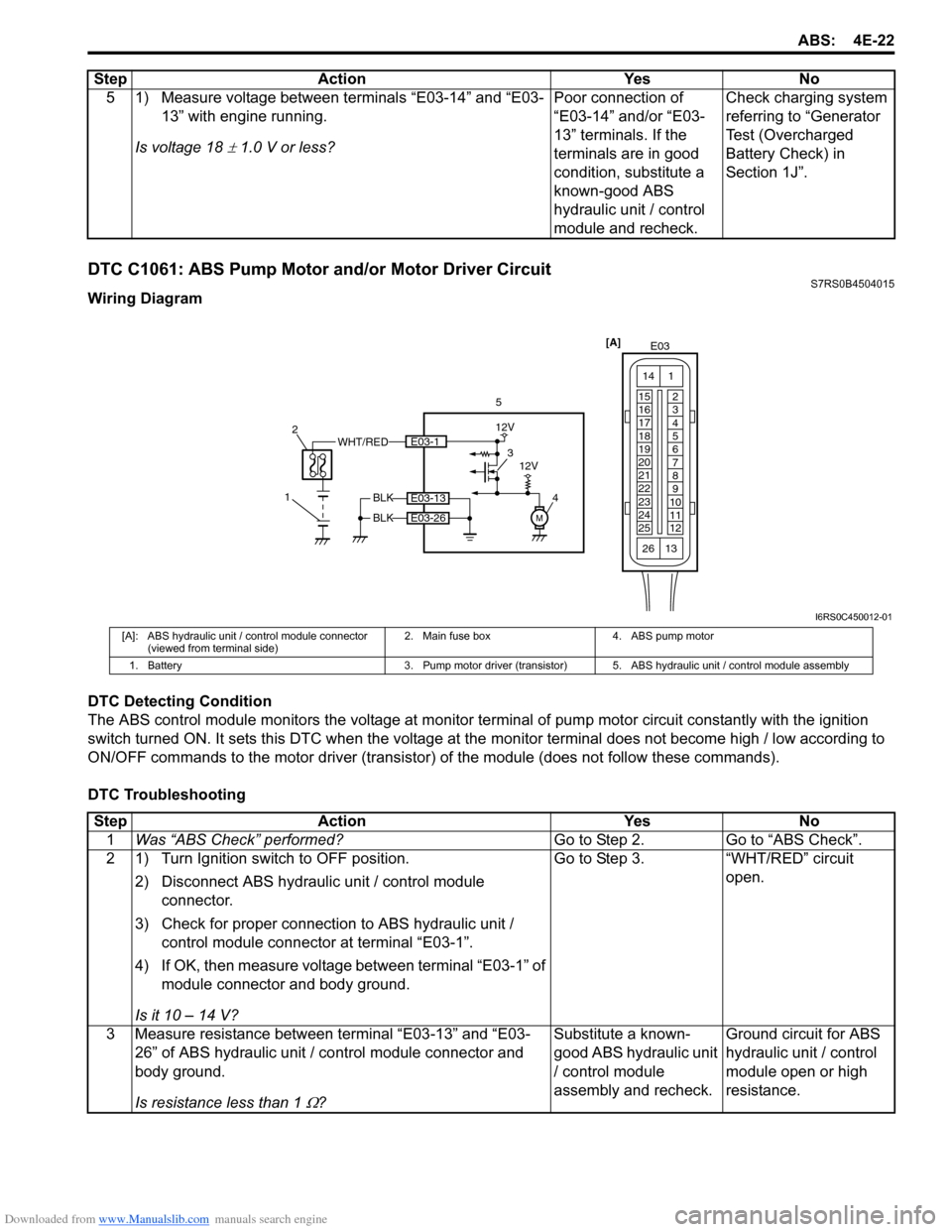

DTC C1061: ABS Pump Motor and/or Motor Driver CircuitS7RS0B4504015

Wiring Diagram

DTC Detecting Condition

The ABS control module monitors the voltage at monitor terminal of pump motor circuit constantly with the ignition

switch turned ON. It sets this DTC when the voltage at the monitor terminal does not become high / low according to

ON/OFF commands to the motor driver (transistor) of the module (does not follow these commands).

DTC Troubleshooting 5 1) Measure voltage between terminals “E03-14” and “E03-

13” with engine running.

Is voltage 18

± 1.0 V or less? Poor connection of

“E03-14” and/or “E03-

13” terminals. If the

terminals are in good

condition, substitute a

known-good ABS

hydraulic unit / control

module and recheck.Check charging system

referring to “Generator

Test (Overcharged

Battery Check) in

Section 1J”.

Step Action Yes No

WHT/RED

1 2

5

BLK

BLK

E03-13

E03-26

[A]

E03

15

16

17

18

19

20

21

22

23

24

25 2

3

4

5

6

7

8

9

10

11

12

1

13

14

26

M

3

4E03-1

12V

12V

I6RS0C450012-01

[A]: ABS hydraulic unit / control module connector (viewed from terminal side) 2. Main fuse box 4. ABS pump motor

1. Battery 3. Pump motor driver (transistor) 5. ABS hydraulic unit / control module assembly

StepAction YesNo

1 Was “ABS Check” performed? Go to Step 2.Go to “ABS Check”.

2 1) Turn Ignition switch to OFF position.

2) Disconnect ABS hydraulic unit / control module connector.

3) Check for proper connection to ABS hydraulic unit / control module connector at terminal “E03-1”.

4) If OK, then measure voltage between terminal “E03-1” of module connector and body ground.

Is it 10 – 14 V? Go to Step 3.

“WHT/RED” circuit

open.

3 Measure resistance between terminal “E03-13” and “E03- 26” of ABS hydraulic unit / co ntrol module connector and

body ground.

Is resistance less than 1

Ω? Substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.

Ground circuit for ABS

hydraulic unit / control

module open or high

resistance.

Page 562 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-23 ABS:

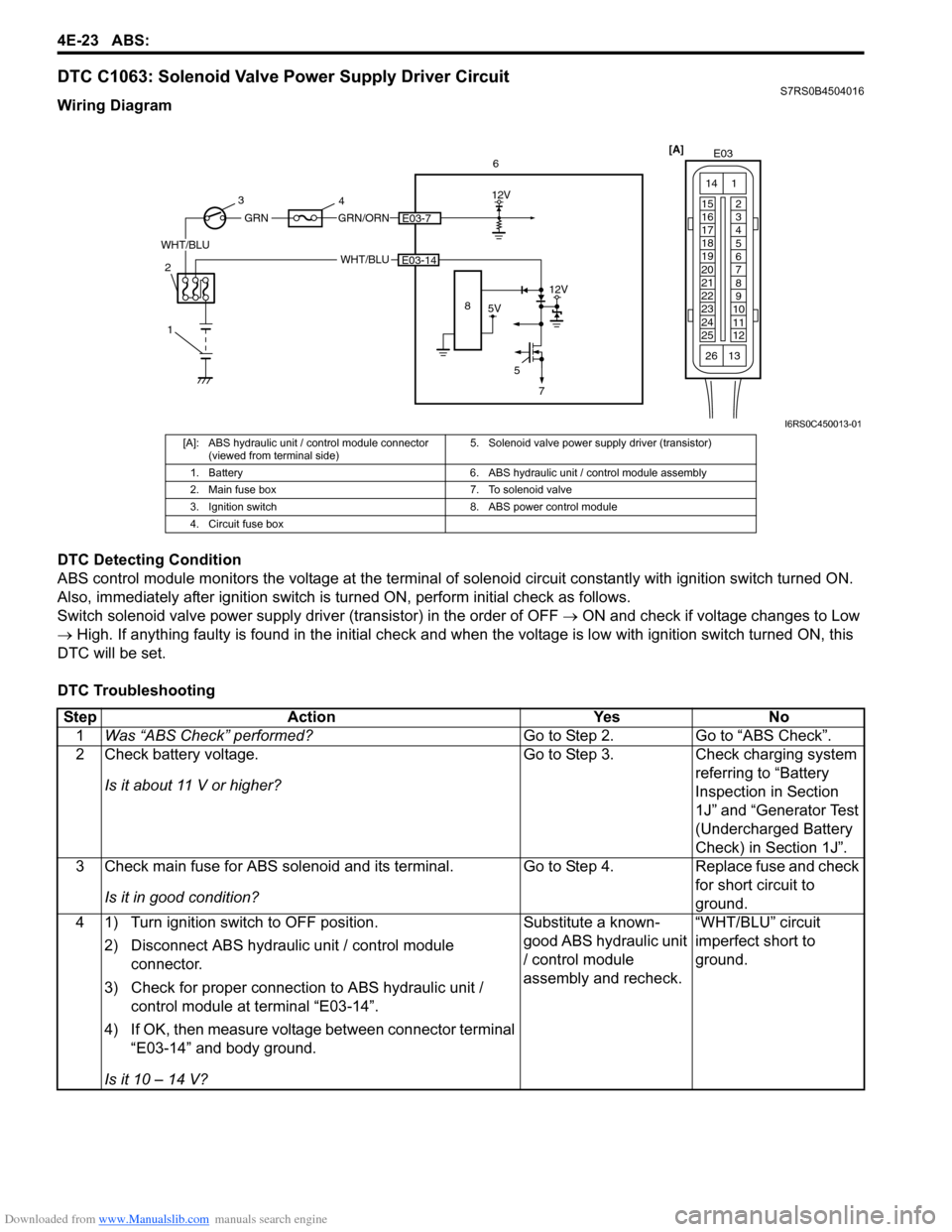

DTC C1063: Solenoid Valve Power Supply Driver CircuitS7RS0B4504016

Wiring Diagram

DTC Detecting Condition

ABS control module monitors the voltage at the terminal of solenoid circuit constantly with ignition switch turned ON.

Also, immediately after ignition switch is turned ON, perform initial check as follows.

Switch solenoid valve power supply driv er (transistor) in the order of OFF → ON and check if voltage changes to Low

→ High. If anything faulty is found in the initial check and when the voltage is low with ignition switch turned ON, this

DTC will be set.

DTC Troubleshooting

[A] E03

15

16

17

18

19

20

21

22

23

24

25 2

3

4

5

6

7

8

9

10

11

12

1

13

14

266

WHT/BLU

12V

5E03-14

5V

12V

8

GRN/ORNE03-7

WHT/BLU

GRN

1

2 3

4

7

I6RS0C450013-01

[A]: ABS hydraulic unit / control module connector

(viewed from terminal side) 5. Solenoid valve power supp

ly driver (transistor)

1. Battery 6. ABS hydraulic unit / control module assembly

2. Main fuse box 7. To solenoid valve

3. Ignition switch 8. ABS power control module

4. Circuit fuse box

Step Action YesNo

1 Was “ABS Check” performed? Go to Step 2.Go to “ABS Check”.

2 Check battery voltage.

Is it about 11 V or higher? Go to Step 3.

Check charging system

referring to “Battery

Inspection in Section

1J” and “Generator Test

(Undercharged Battery

Check) in Section 1J”.

3 Check main fuse for ABS solenoid and its terminal.

Is it in good condition? Go to Step 4.

Replace fuse and check

for short circuit to

ground.

4 1) Turn ignition switch to OFF position.

2) Disconnect ABS hydraulic unit / control module connector.

3) Check for proper connection to ABS hydraulic unit / control module at terminal “E03-14”.

4) If OK, then measure voltage between connector terminal “E03-14” and body ground.

Is it 10 – 14 V? Substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.

“WHT/BLU” circuit

imperfect short to

ground.

Page 615 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-41

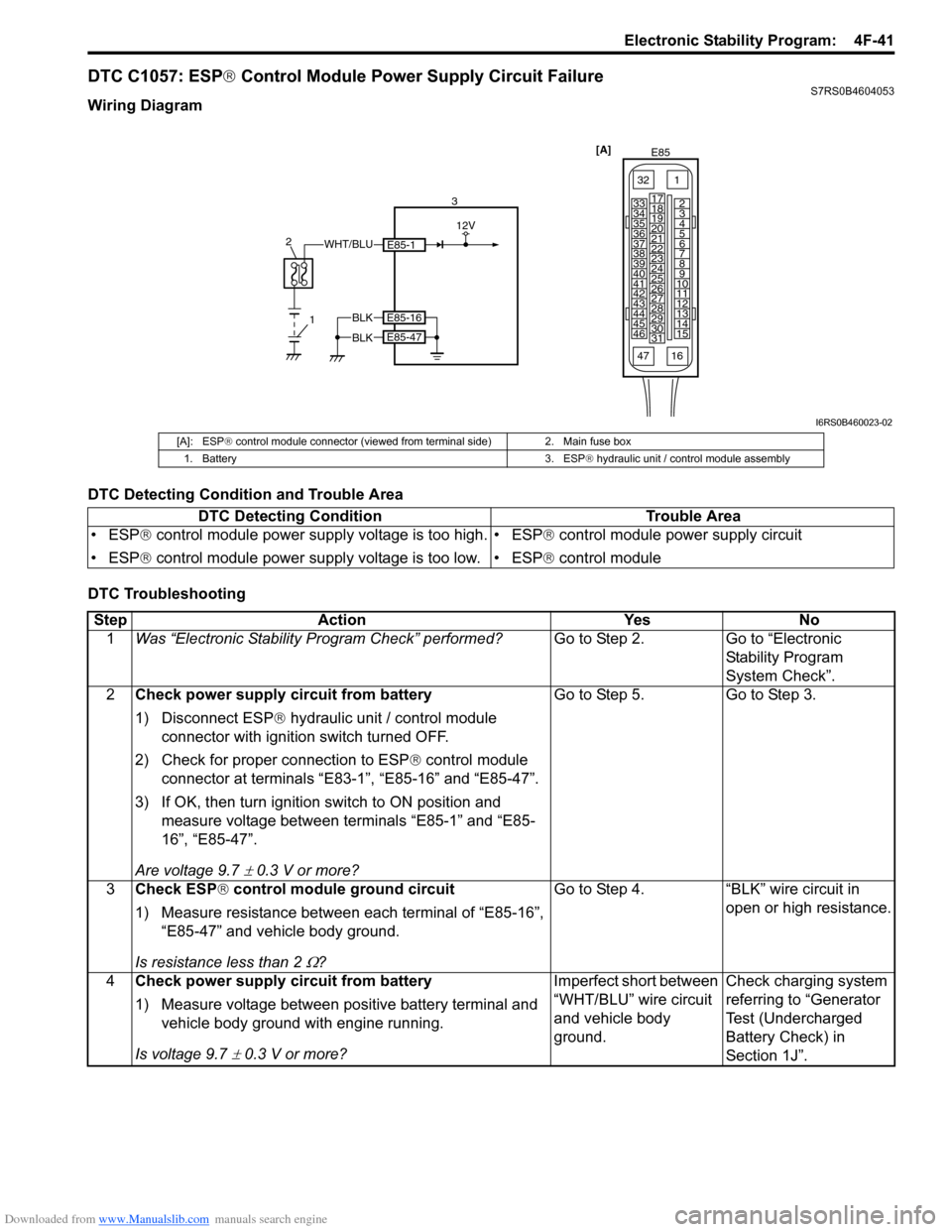

DTC C1057: ESP® Control Module Power Supply Circuit FailureS7RS0B4604053

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

[A]

E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47

WHT/BLU

1

2

3

12V

E85-1

BLKE85-16

E85-47BLK

I6RS0B460023-02

[A]: ESP

® control module connector (viewed from terminal side) 2. Main fuse box

1. Battery 3. ESP ® hydraulic unit / control module assembly

DTC Detecting Condition Trouble Area

• ESP ® control module power supply voltage is too high.

• ESP ® control module power supply voltage is too low. • ESP

® control module power supply circuit

• ESP ® control module

Step Action YesNo

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2.Go to “Electronic

Stability Program

System Check”.

2 Check power supply circuit from battery

1) Disconnect ESP ® hydraulic unit / control module

connector with ignition switch turned OFF.

2) Check for proper connection to ESP ® control module

connector at terminals “E83-1”, “E85-16” and “E85-47”.

3) If OK, then turn ignition switch to ON position and measure voltage between terminals “E85-1” and “E85-

16”, “E85-47”.

Are voltage 9.7

± 0.3 V or more? Go to Step 5. Go to Step 3.

3 Check ESP ® control module ground circuit

1) Measure resistance between each terminal of “E85-16”, “E85-47” and vehicle body ground.

Is resistance less than 2

Ω? Go to Step 4. “BLK” wire circuit in

open or high resistance.

4 Check power supply circuit from battery

1) Measure voltage between positive battery terminal and

vehicle body ground with engine running.

Is voltage 9.7

± 0.3 V or more? Imperfect short between

“WHT/BLU” wire circuit

and vehicle body

ground.

Check charging system

referring to “Generator

Test (Undercharged

Battery Check) in

Section 1J”.

Page 616 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-42 Electronic Stability Program:

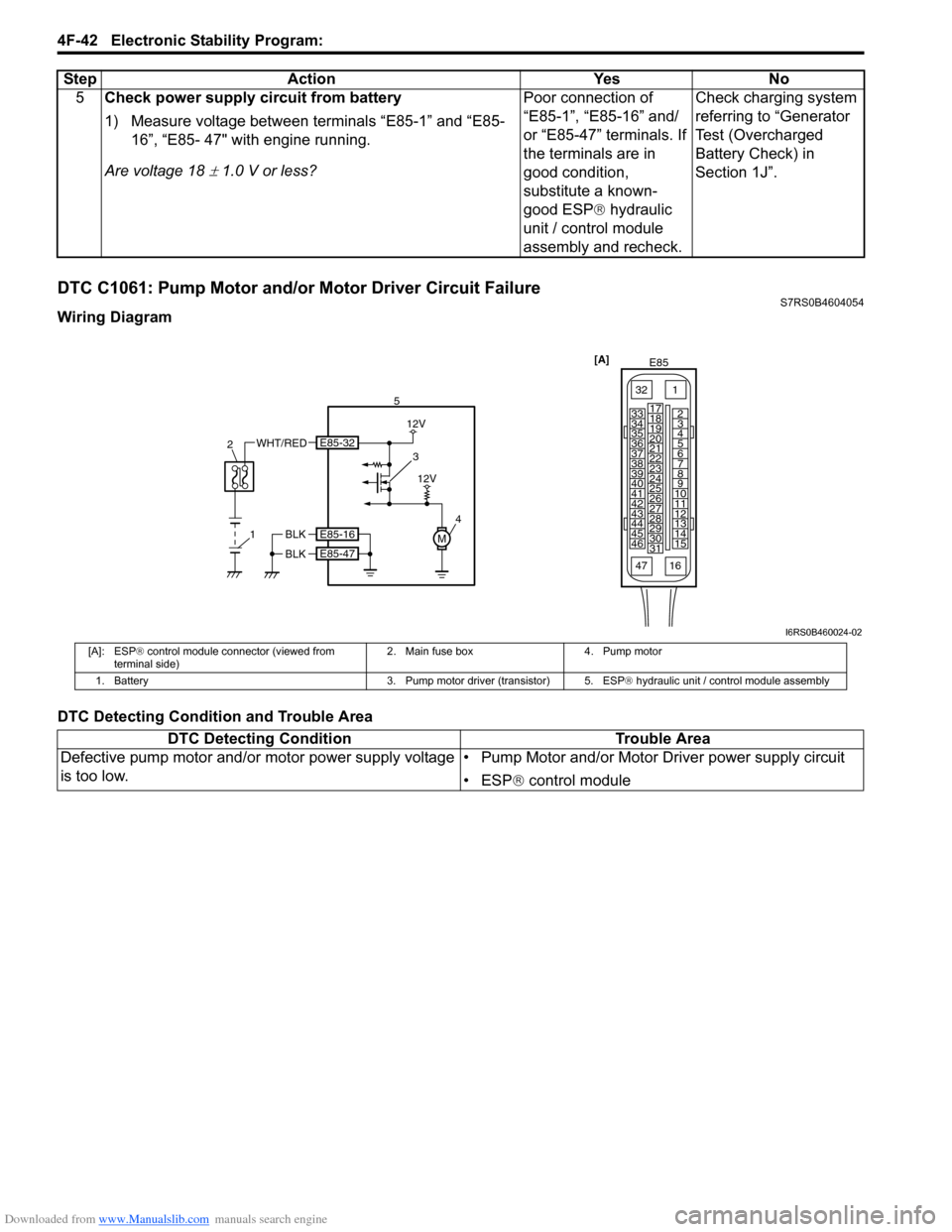

DTC C1061: Pump Motor and/or Motor Driver Circuit FailureS7RS0B4604054

Wiring Diagram

DTC Detecting Condition and Trouble Area5

Check power supply circuit from battery

1) Measure voltage between terminals “E85-1” and “E85-

16”, “E85- 47" with engine running.

Are voltage 18

± 1.0 V or less? Poor connection of

“E85-1”, “E85-16” and/

or “E85-47” terminals. If

the terminals are in

good condition,

substitute a known-

good ESP

® hydraulic

unit / control module

assembly and recheck. Check charging system

referring to “Generator

Test (Overcharged

Battery Check) in

Section 1J”.

Step Action Yes No

[A]

E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47

4

51

2

WHT/RED3

12V

M

12V

BLK

BLK

E85-16

E85-47

E85-32

I6RS0B460024-02

[A]: ESP

® control module connector (viewed from

terminal side) 2. Main fuse box 4. Pump motor

1. Battery 3. Pump motor driver (transistor) 5. ESP® hydraulic unit / control module assembly

DTC Detecting ConditionTrouble Area

Defective pump motor and/or motor power supply voltage

is too low. • Pump Motor and/or Motor Driver power supply circuit

• ESP

® control module

Page 618 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-44 Electronic Stability Program:

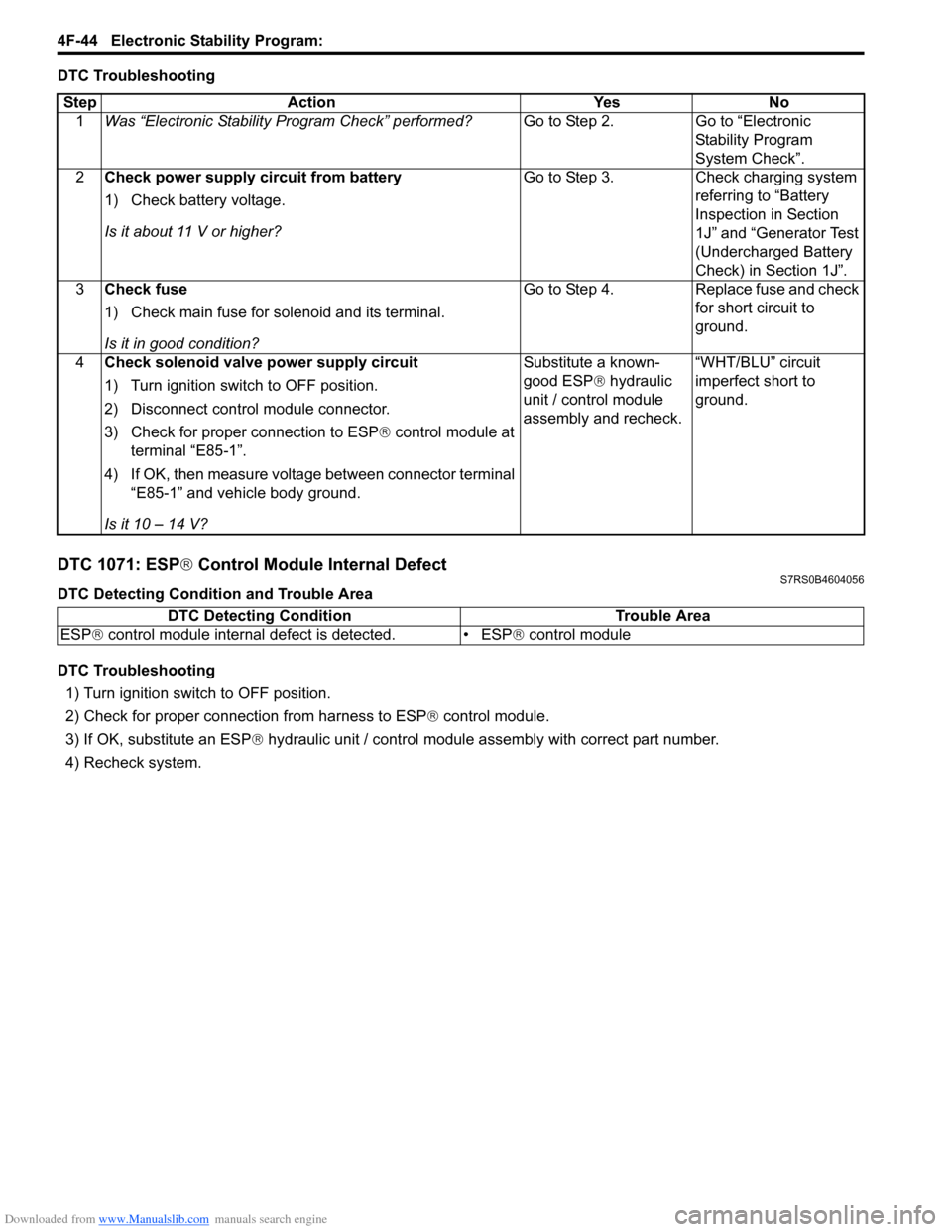

DTC Troubleshooting

DTC 1071: ESP® Control Module Internal DefectS7RS0B4604056

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

1) Turn ignition switch to OFF position.

2) Check for proper connection from harness to ESP ® control module.

3) If OK, substitute an ESP ® hydraulic unit / control module assembly with correct part number.

4) Recheck system.

Step

Action YesNo

1 Was “Electronic Stability Pr ogram Check” performed? Go to Step 2.Go to “Electronic

Stability Program

System Check”.

2 Check power supply circuit from battery

1) Check battery voltage.

Is it about 11 V or higher? Go to Step 3.

Check charging system

referring to “Battery

Inspection in Section

1J” and “Generator Test

(Undercharged Battery

Check) in Section 1J”.

3 Check fuse

1) Check main fuse for solenoid and its terminal.

Is it in good condition? Go to Step 4.

Replace fuse and check

for short circuit to

ground.

4 Check solenoid valve power supply circuit

1) Turn ignition switch to OFF position.

2) Disconnect control module connector.

3) Check for proper connection to ESP® control module at

terminal “E85-1”.

4) If OK, then measure voltage between connector terminal “E85-1” and vehicle body ground.

Is it 10 – 14 V? Substitute a known-

good ESP

® hydraulic

unit / control module

assembly and recheck. “WHT/BLU” circuit

imperfect short to

ground.

DTC Detecting Condition

Trouble Area

ESP ® control module internal defect is detected. • ESP ® control module

Page 662 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-18 Automatic Transmission/Transaxle:

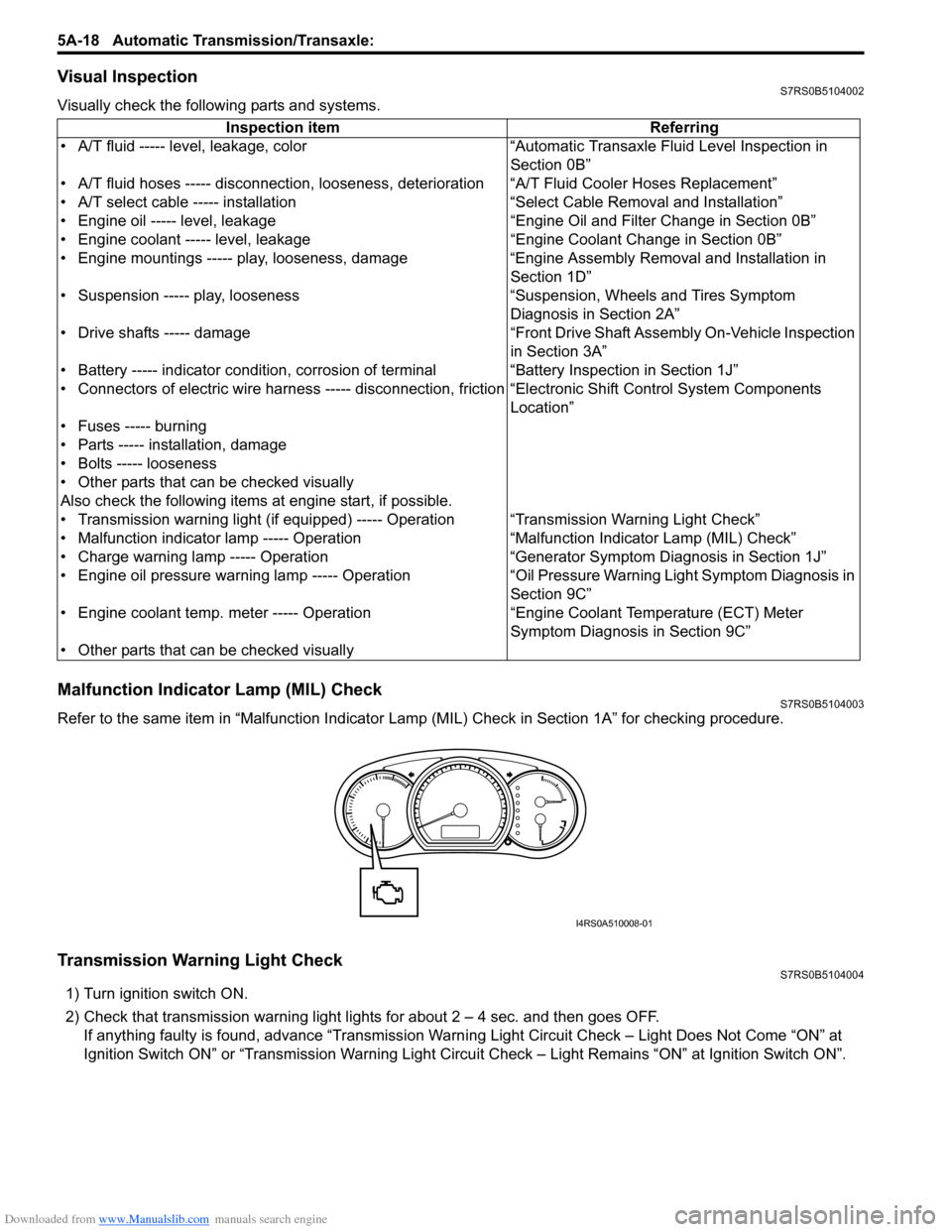

Visual InspectionS7RS0B5104002

Visually check the following parts and systems.

Malfunction Indicator Lamp (MIL) CheckS7RS0B5104003

Refer to the same item in “Malfunction Indicator Lam p (MIL) Check in Section 1A” for checking procedure.

Transmission Warning Light CheckS7RS0B5104004

1) Turn ignition switch ON.

2) Check that transmission warning light lights for about 2 – 4 sec. and then goes OFF.

If anything faulty is found, advance “Transmission Warn ing Light Circuit Check – Light Does Not Come “ON” at

Ignition Switch ON” or “Transmission Warning Light Circu it Check – Light Remains “ON” at Ignition Switch ON”.

Inspection item Referring

• A/T fluid ----- level, leakage, color “Automatic Transaxle Fluid Level Inspection in Section 0B”

• A/T fluid hoses ----- disconnection, looseness, deterioration “A/T Fluid Cooler Hoses Replacement”

• A/T select cable ----- installation “S elect Cable Removal and Installation”

• Engine oil ----- level, leakage “Engine Oil and Filter Change in Section 0B”

• Engine coolant ----- level, leakage “Engine Coolant Change in Section 0B”

• Engine mountings ----- play, looseness, damage “Engine Assembly Removal and Installation in Section 1D”

• Suspension ----- play, looseness “Suspension, Wheels and Tires Symptom Diagnosis in Section 2A”

• Drive shafts ----- damage “Front Drive Shaft Assembly On-Vehicle Inspection in Section 3A”

• Battery ----- indicator condition, corrosion of terminal “Battery Inspection in Section 1J”

• Connectors of electric wire harness ----- disconnection, friction “Electronic Shift Control System Components

Location”

• Fuses ----- burning

• Parts ----- installation, damage

• Bolts ----- looseness

• Other parts that can be checked visually

Also check the following items at engine start, if possible.

• Transmission warning light (if equipped) ----- Operation “Transmission Warning Light Check”

• Malfunction indicator lamp ----- Operation “Malfunction Indicator Lamp (MIL) Check”

• Charge warning lamp ----- Operation “Generator Symptom Diagnosis in Section 1J”

• Engine oil pressure warning lamp ----- Operation “Oil Pressure Warning Ligh t Symptom Diagnosis in

Section 9C”

• Engine coolant temp. meter ----- Operation “Engine Coolant Temperature (ECT) Meter

Symptom Diagnosis in Section 9C”

• Other parts that can be checked visually

I4RS0A510008-01

Page 893 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-11

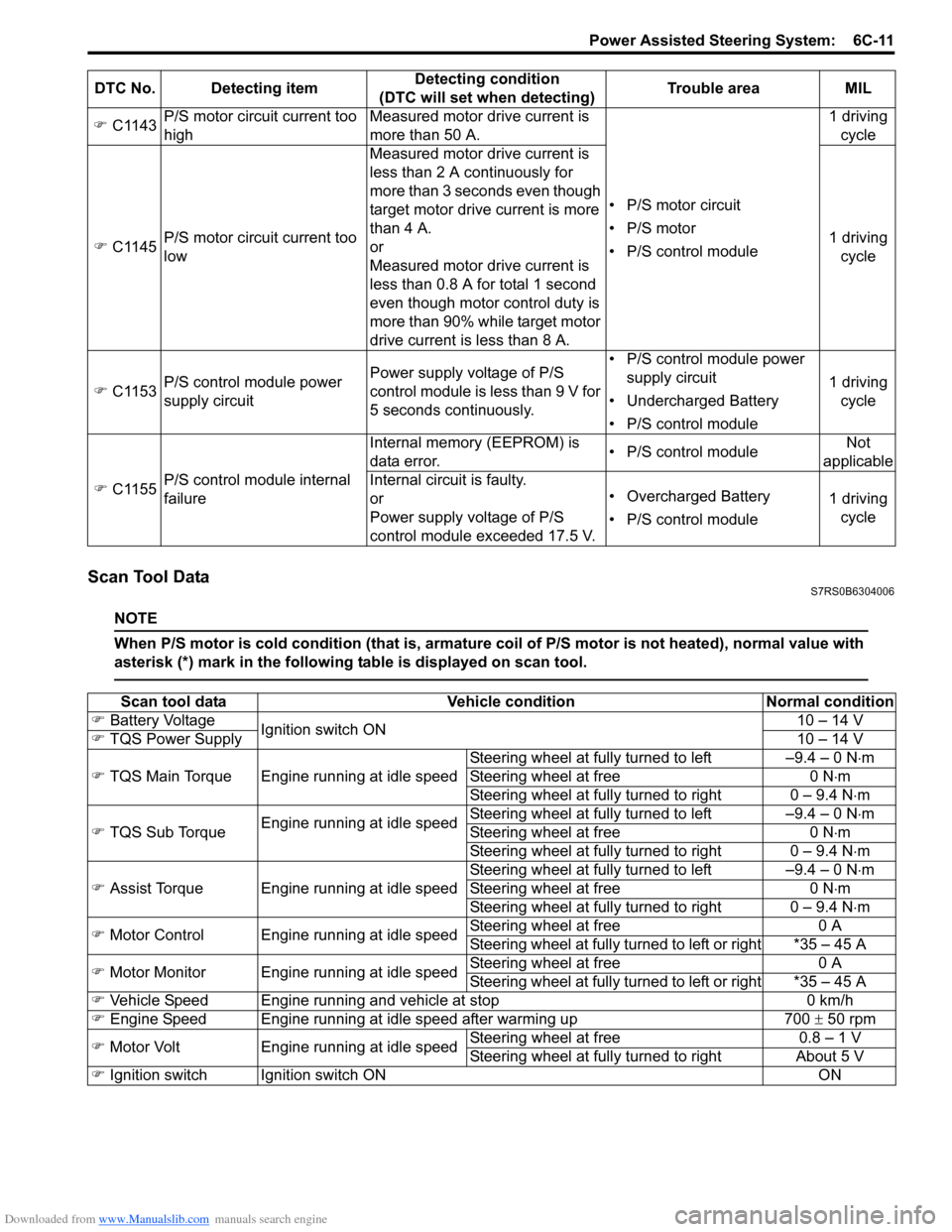

Scan Tool DataS7RS0B6304006

NOTE

When P/S motor is cold condition (that is, armature coil of P/S motor is not heated), normal value with

asterisk (*) mark in the following table is displayed on scan tool.

�) C1143 P/S motor circuit current too

high Measured motor drive current is

more than 50 A.

• P/S motor circuit

• P/S motor

• P/S control module1 driving

cycle

�) C1145 P/S motor circuit current too

low Measured motor drive current is

less than 2 A continuously for

more than 3 seconds even though

target motor drive current is more

than 4 A.

or

Measured motor drive current is

less than 0.8 A for total 1 second

even though motor control duty is

more than 90% while target motor

drive current is less than 8 A. 1 driving

cycle

�) C1153 P/S control module power

supply circuit Power supply voltage of P/S

control module is less than 9 V for

5 seconds continuously. • P/S control module power

supply circuit

• Undercharged Battery

• P/S control module 1 driving

cycle

�) C1155 P/S control module internal

failure Internal memory (EEPROM) is

data error.

• P/S control moduleNot

applicable

Internal circuit is faulty.

or

Power supply voltage of P/S

control module exceeded 17.5 V. • Overcharged Battery

• P/S control module

1 driving

cycle

DTC No. Detecting item

Detecting condition

(DTC will set when detecting) Trouble area MIL

Scan tool data

Vehicle conditionNormal condition

�) Battery Voltage

Ignition switch ON 10 – 14 V

�) TQS Power Supply 10 – 14 V

�) TQS Main Torque Engine running at idle speed Steering wheel at fully turned to left –9.4 – 0 N

⋅m

Steering wheel at free 0 N⋅m

Steering wheel at fully turned to right 0 – 9.4 N ⋅m

�) TQS Sub Torque Engine running at idle speed Steering wheel at fully turned to left –9.4 – 0 N

⋅m

Steering wheel at free 0 N⋅m

Steering wheel at fully turned to right 0 – 9.4 N ⋅m

�) Assist Torque Engine running at idle speed Steering wheel at fully turned to left –9.4 – 0 N

⋅m

Steering wheel at free 0 N⋅m

Steering wheel at fully turned to right 0 – 9.4 N ⋅m

�) Motor Control Engine running at idle speed Steering wheel at free

0 A

Steering wheel at fully turned to left or right *35 – 45 A

�) Motor Monitor Engine running at idle speed Steering wheel at free

0 A

Steering wheel at fully turned to left or right *35 – 45 A

�) Vehicle Speed Engine running and vehicle at stop 0 km/h

�) Engine Speed Engine running at idle speed after warming up 700 ± 50 rpm

�) Motor Volt Engine running at idle speed Steering wheel at free

0.8 – 1 V

Steering wheel at fully turned to right About 5 V

�) Ignition switch Ignition switch ON ON

Page 914 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-32 Power Assisted Steering System:

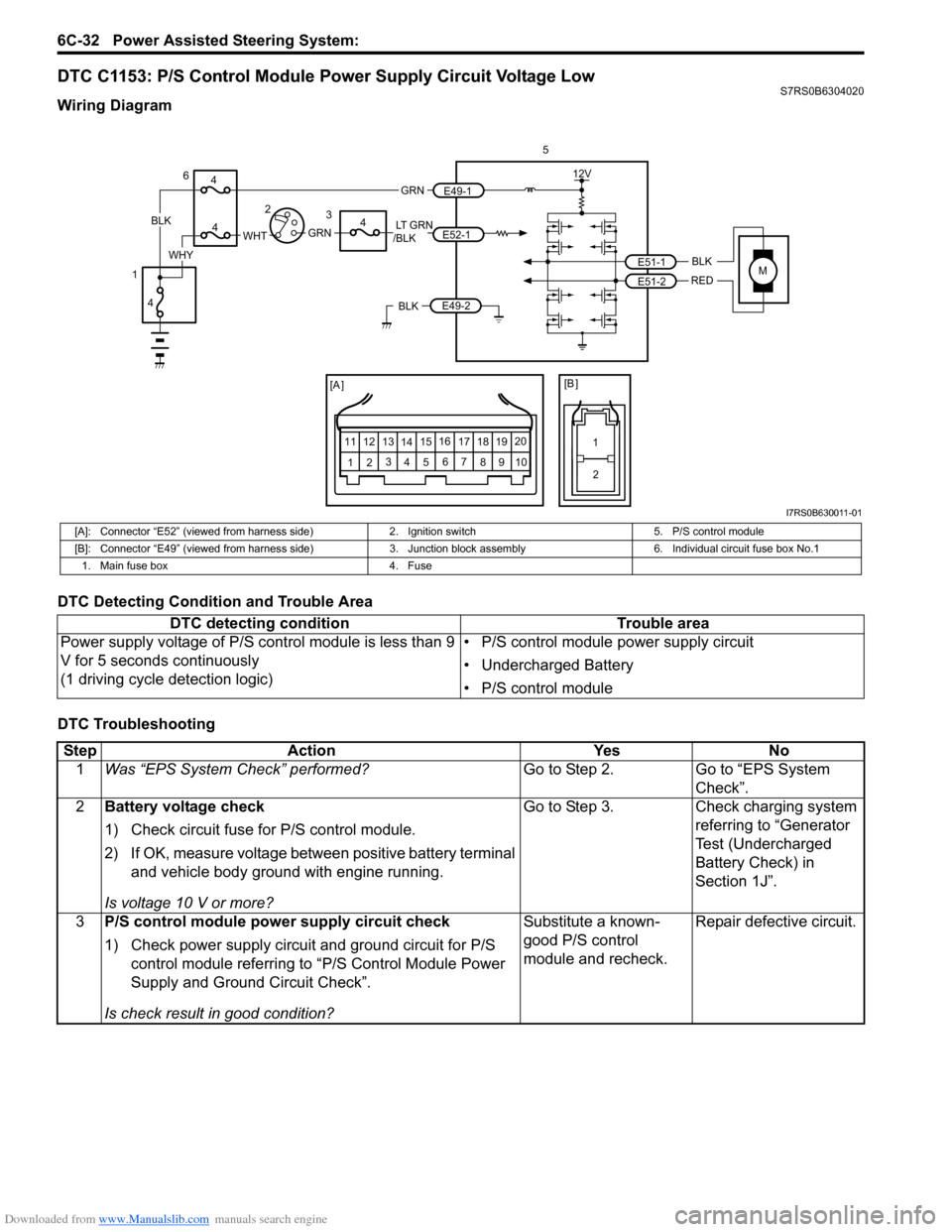

DTC C1153: P/S Control Module Power Supply Circuit Voltage LowS7RS0B6304020

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

MBLK

REDE51-1

E51-2

12V

5

[A ]

12 3

4 5 67

89

11

10

12 13

141516

17 18 19 20

[B ]

1

2

LT GRN

/BLKE52-1 E49-1

GRNGRNWHTBLK

WHY

6

3

4

4

4

4

1 2

E49-2BLK

I7RS0B630011-01

[A]: Connector “E52” (viewed from harness side)

2. Ignition switch5. P/S control module

[B]: Connector “E49” (viewed from harness side) 3. Junction block assembly 6. Individual circuit fuse box No.1

1. Main fuse box 4. Fuse

DTC detecting condition Trouble area

Power supply voltage of P/S control module is less than 9

V for 5 seconds continuously

(1 driving cycle detection logic) • P/S control module power supply circuit

• Undercharged Battery

• P/S control module

Step

Action YesNo

1 Was “EPS System Check” performed? Go to Step 2.Go to “EPS System

Check”.

2 Battery voltage check

1) Check circuit fuse for P/S control module.

2) If OK, measure voltage between positive battery terminal

and vehicle body ground with engine running.

Is voltage 10 V or more? Go to Step 3.

Check charging system

referring to “Generator

Test (Undercharged

Battery Check) in

Section 1J”.

3 P/S control module power supply circuit check

1) Check power supply circuit and ground circuit for P/S

control module referring to “P/S Control Module Power

Supply and Ground Circuit Check”.

Is check result in good condition? Substitute a known-

good P/S control

module and recheck.

Repair defective circuit.

Page 915 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-33

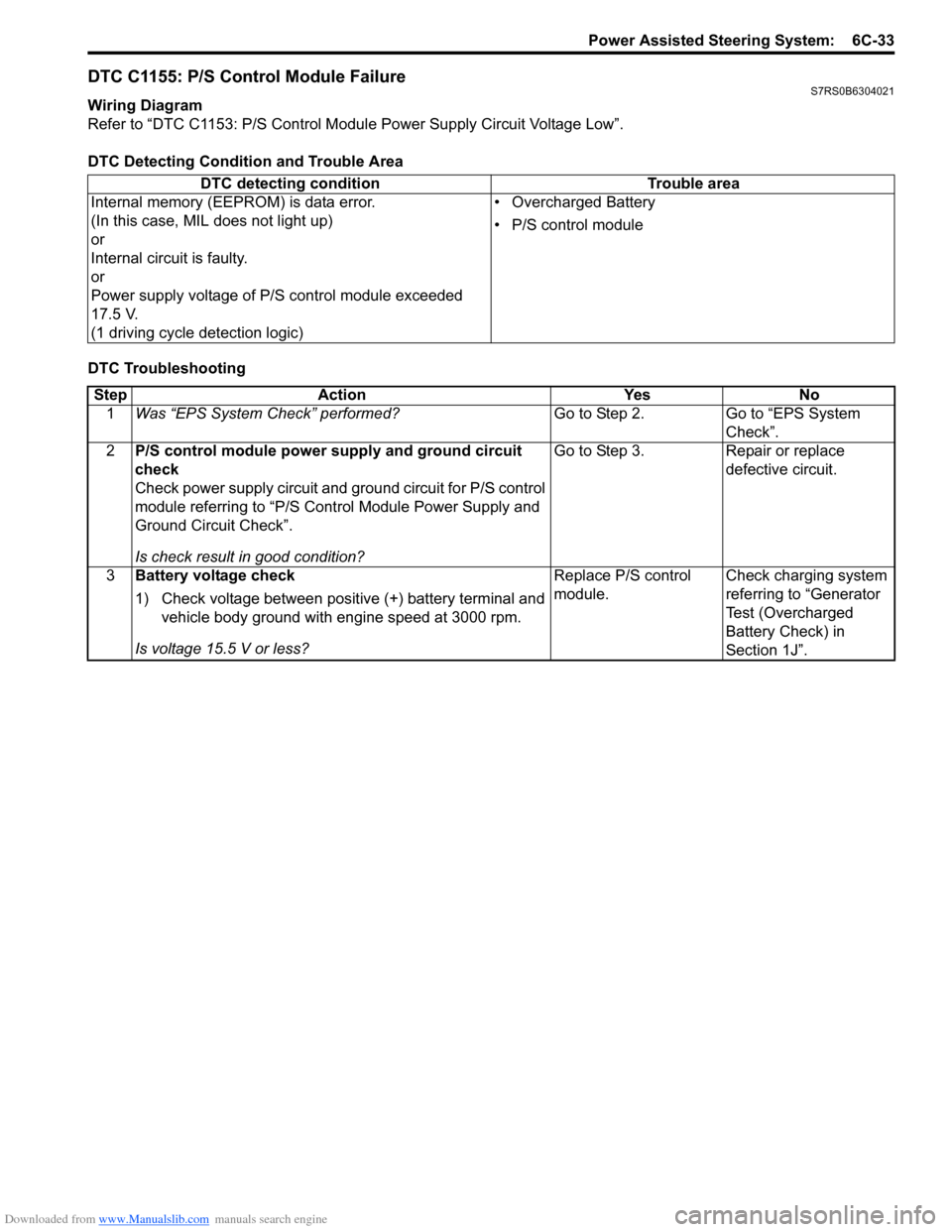

DTC C1155: P/S Control Module FailureS7RS0B6304021

Wiring Diagram

Refer to “DTC C1153: P/S Control Module Power Supply Circuit Voltage Low”.

DTC Detecting Condition and Trouble Area

DTC Troubleshooting DTC detecting condition Trouble area

Internal memory (EEPROM) is data error.

(In this case, MIL does not light up)

or

Internal circuit is faulty.

or

Power supply voltage of P/S control module exceeded

17.5 V.

(1 driving cycle detection logic) • Overcharged Battery

• P/S control module

Step

Action YesNo

1 Was “EPS System Check” performed? Go to Step 2.Go to “EPS System

Check”.

2 P/S control module power supply and ground circuit

check

Check power supply circuit and ground circuit for P/S control

module referring to “P/S Control Module Power Supply and

Ground Circuit Check”.

Is check result in good condition? Go to Step 3.

Repair or replace

defective circuit.

3 Battery voltage check

1) Check voltage between positive (+) battery terminal and

vehicle body ground with engine speed at 3000 rpm.

Is voltage 15.5 V or less? Replace P/S control

module.

Check charging system

referring to “Generator

Test (Overcharged

Battery Check) in

Section 1J”.

Page 933 of 1496

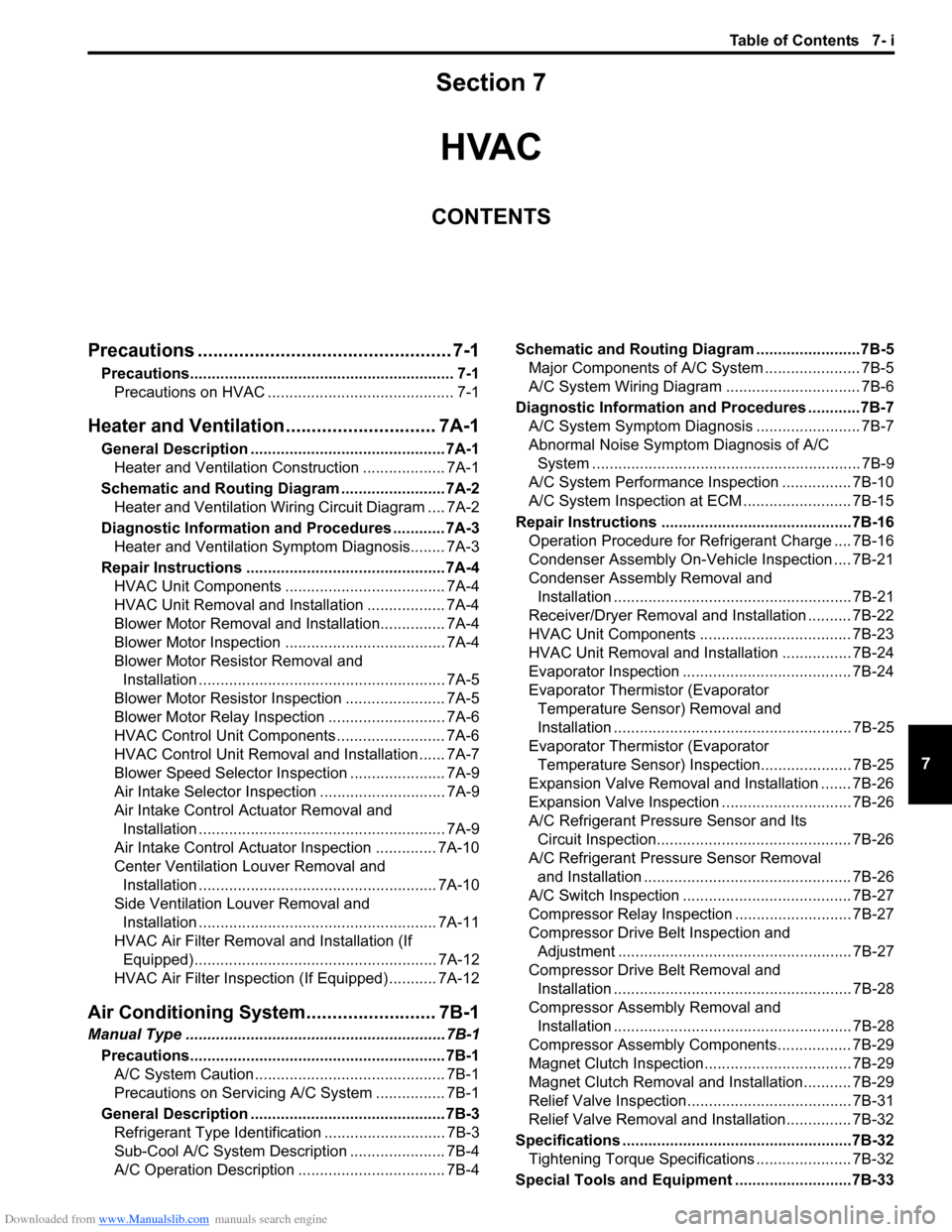

Downloaded from www.Manualslib.com manuals search engine Table of Contents 7- i

7

Section 7

CONTENTS

HVAC

Precautions ................................................. 7-1

Precautions............................................................. 7-1

Precautions on HVAC ........................................... 7-1

Heater and Ventilation.... ......................... 7A-1

General Description ............................................. 7A-1

Heater and Ventilation Construction ................... 7A-1

Schematic and Routing Diagram ........................ 7A-2 Heater and Ventilation Wiring Circuit Diagram .... 7A-2

Diagnostic Information and Procedures ............ 7A-3 Heater and Ventilation Symptom Diagnosis........ 7A-3

Repair Instructions .............................................. 7A-4 HVAC Unit Components ..................................... 7A-4

HVAC Unit Removal and Installation .................. 7A-4

Blower Motor Removal and Installation............... 7A-4

Blower Motor Inspection ..................................... 7A-4

Blower Motor Resistor Removal and Installation ......................................................... 7A-5

Blower Motor Resistor Inspection ....................... 7A-5

Blower Motor Relay Inspection ........................... 7A-6

HVAC Control Unit Components ......................... 7A-6

HVAC Control Unit Remova l and Installation ...... 7A-7

Blower Speed Selector In spection ...................... 7A-9

Air Intake Selector Inspec tion ............................. 7A-9

Air Intake Control Actuator Removal and Installation ......................................................... 7A-9

Air Intake Control Actuator Inspection .............. 7A-10

Center Ventilation Louver Removal and Installation ....................................................... 7A-10

Side Ventilation Louver Removal and Installation ....................................................... 7A-11

HVAC Air Filter Removal and Installation (If Equipped)........................................................ 7A-12

HVAC Air Filter Inspection (If Equipped) ........... 7A-12

Air Conditioning System... ...................... 7B-1

Manual Type ............................................................ 7B-1

Precautions........................................................... 7B-1A/C System Caution ............................................ 7B-1

Precautions on Servicing A/C System ................ 7B-1

General Description ............................................. 7B-3 Refrigerant Type Identifica tion ............................ 7B-3

Sub-Cool A/C System Description ...................... 7B-4

A/C Operation Description .................................. 7B-4 Schematic and Routing Diagram ........................7B-5

Major Components of A/C System ...................... 7B-5

A/C System Wiring Diagram ............................... 7B-6

Diagnostic Information and Procedures ............7B-7 A/C System Symptom Diagnosis ........................ 7B-7

Abnormal Noise Sympto m Diagnosis of A/C

System .............................................................. 7B-9

A/C System Performance Inspection ................ 7B-10

A/C System Inspection at ECM ......................... 7B-15

Repair Instructions ........... .................................7B-16

Operation Procedure for Re frigerant Charge .... 7B-16

Condenser Assembly On-Vehicle Inspection .... 7B-21

Condenser Assembly Removal and Installation ....................................................... 7B-21

Receiver/Dryer Removal and Installation .......... 7B-22

HVAC Unit Components ................................... 7B-23

HVAC Unit Removal and In stallation ................ 7B-24

Evaporator Inspection ....................................... 7B-24

Evaporator Thermistor (Evaporator Temperature Sensor) Removal and

Installation ....................................................... 7B-25

Evaporator Thermistor (Evaporator Temperature Sensor) Inspec tion..................... 7B-25

Expansion Valve Removal and Installation ....... 7B-26

Expansion Valve Inspection .............................. 7B-26

A/C Refrigerant Pressure Sensor and Its Circuit Inspection............................................. 7B-26

A/C Refrigerant Pressu re Sensor Removal

and Installation ................................................ 7B-26

A/C Switch Inspection ....................................... 7B-27

Compressor Relay Inspection ........................... 7B-27

Compressor Drive Belt Inspection and Adjustment ...................................................... 7B-27

Compressor Drive Belt Removal and Installation ....................................................... 7B-28

Compressor Assembly Removal and Installation ....................................................... 7B-28

Compressor Assembly Components................. 7B-29

Magnet Clutch Inspection.................................. 7B-29

Magnet Clutch Removal and Installation........... 7B-29

Relief Valve Inspection...................................... 7B-31

Relief Valve Removal and Installation............... 7B-32

Specifications .................... .................................7B-32

Tightening Torque Specifications ...................... 7B-32

Special Tools and Equipmen t ...........................7B-33