No charge SUZUKI SWIFT 2008 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 402 of 1496

Downloaded from www.Manualslib.com manuals search engine 1I-1 Starting System:

Engine

Starting System

Schematic and Routing Diagram

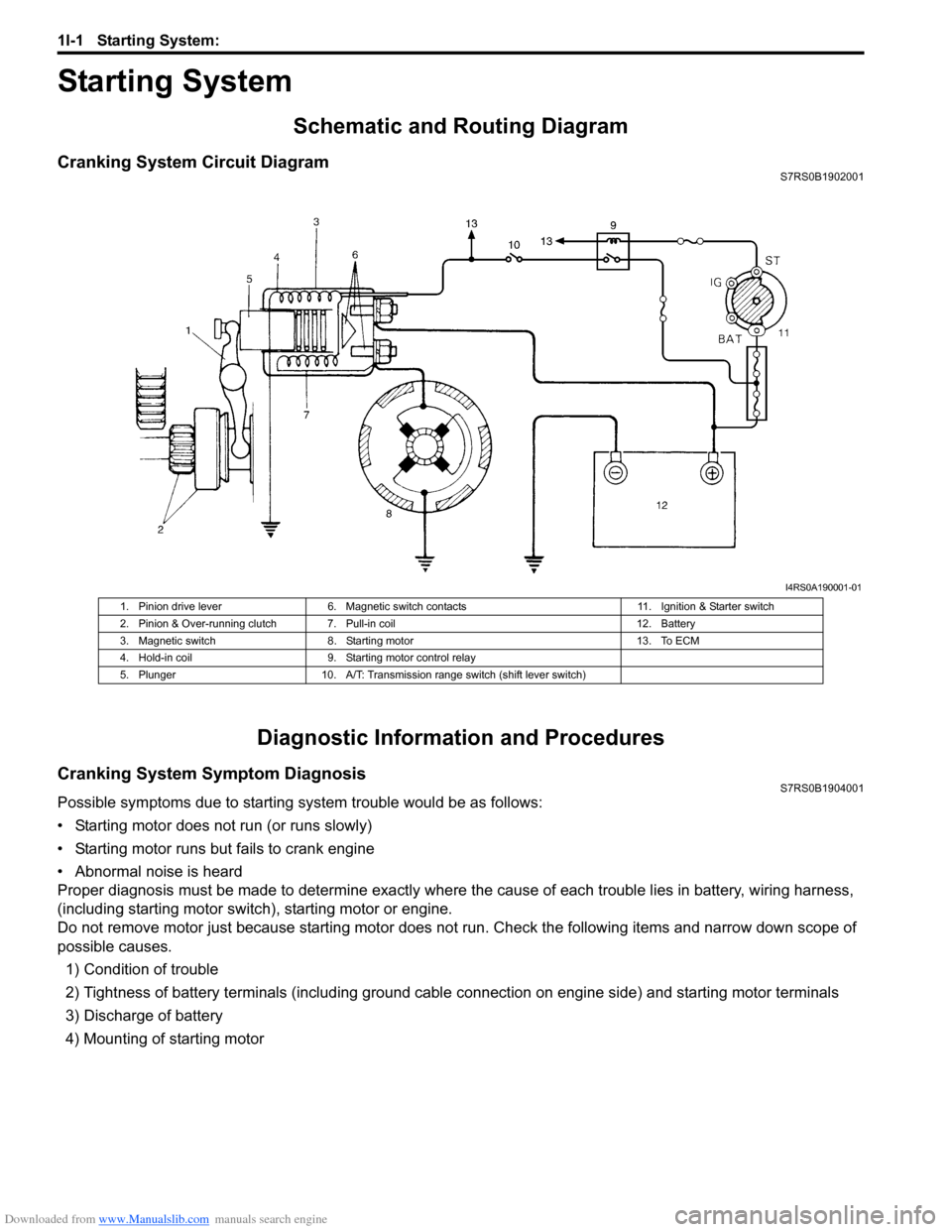

Cranking System Circuit DiagramS7RS0B1902001

Diagnostic Information and Procedures

Cranking System Symptom DiagnosisS7RS0B1904001

Possible symptoms due to starting system trouble would be as follows:

• Starting motor does not run (or runs slowly)

• Starting motor runs but fails to crank engine

• Abnormal noise is heard

Proper diagnosis must be made to determine exactly where the cause of each trouble lies in battery, wiring harness,

(including starting motor switch), starting motor or engine.

Do not remove motor just because starting motor does not run. Check the following items and narrow down scope of

possible causes.

1) Condition of trouble

2) Tightness of battery terminals (including ground cable connection on engine side) and starting motor terminals

3) Discharge of battery

4) Mounting of starting motor

I4RS0A190001-01

1. Pinion drive lever 6. Magnetic switch contacts 11. Ignition & Starter switch

2. Pinion & Over-running clutch 7. Pull-in coil 12. Battery

3. Magnetic switch 8. Starting motor 13. To ECM

4. Hold-in coil 9. Starting motor control relay

5. Plunger 10. A/T: Transmission range switch (shift lever switch)

Page 403 of 1496

Downloaded from www.Manualslib.com manuals search engine Starting System: 1I-2

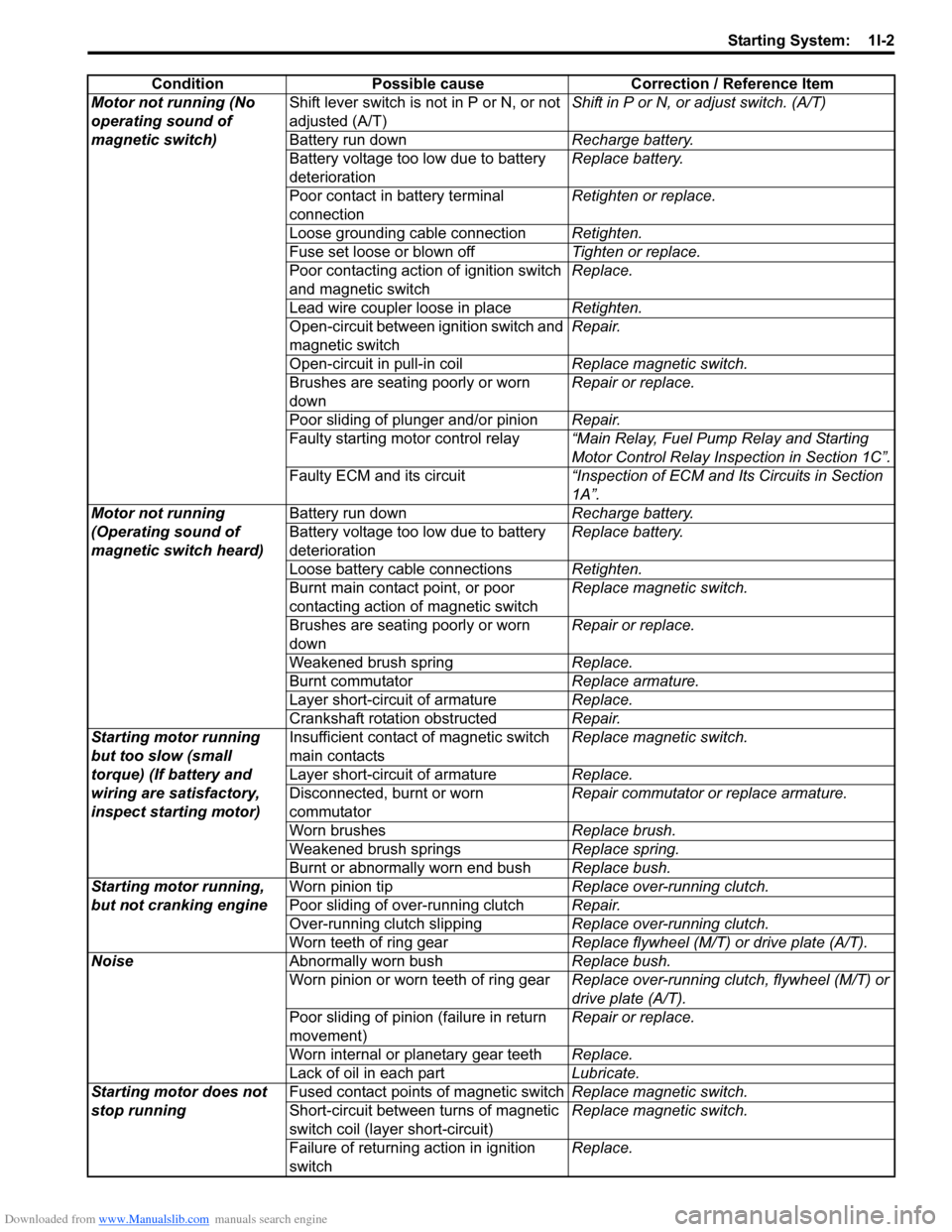

ConditionPossible cause Correction / Reference Item

Motor not running (No

operating sound of

magnetic switch) Shift lever switch is not in P or N, or not

adjusted (A/T)

Shift in P or N, or

adjust switch. (A/T)

Battery run down Recharge battery.

Battery voltage too low due to battery

deterioration Replace battery.

Poor contact in battery terminal

connection Retighten or replace.

Loose grounding cable connection Retighten.

Fuse set loose or blown off Tighten or replace.

Poor contacting action of ignition switch

and magnetic switch Replace.

Lead wire coupler loose in place Retighten.

Open-circuit between ignition switch and

magnetic switch Repair.

Open-circuit in pull-in coil Replace magnetic switch.

Brushes are seating poorly or worn

down Repair or replace.

Poor sliding of plunger and/or pinion Repair.

Faulty starting motor control relay “Main Relay, Fuel Pump Relay and Starting

Motor Control Relay Inspection in Section 1C”.

Faulty ECM and its circuit “Inspection of ECM and Its Circuits in Section

1A”.

Motor not running

(Operating sound of

magnetic switch heard) Battery run down

Recharge battery.

Battery voltage too low due to battery

deterioration Replace battery.

Loose battery cable connections Retighten.

Burnt main contact point, or poor

contacting action of magnetic switch Replace magnetic switch.

Brushes are seating poorly or worn

down Repair or replace.

Weakened brush spring Replace.

Burnt commutator Replace armature.

Layer short-circuit of armature Replace.

Crankshaft rotation obstructed Repair.

Starting motor running

but too slow (small

torque) (If battery and

wiring are satisfactory,

inspect starting motor) Insufficient contact

of magnetic switch

main contacts Replace magnetic switch.

Layer short-circuit of armature Replace.

Disconnected, burnt or worn

commutator Repair commutator or replace armature.

Worn brushes Replace brush.

Weakened brush springs Replace spring.

Burnt or abnormally worn end bush Replace bush.

Starting motor running,

but not cranking engine Worn pinion tip

Replace over-running clutch.

Poor sliding of over-running clutch Repair.

Over-running clutch slipping Replace over-running clutch.

Worn teeth of ring gear Replace flywheel (M/T) or drive plate (A/T).

Noise Abnormally worn bush Replace bush.

Worn pinion or worn teeth of ring gear Replace over-running clutch, flywheel (M/T) or

drive plate (A/T).

Poor sliding of pinion (failure in return

movement) Repair or replace.

Worn internal or planetary gear teeth Replace.

Lack of oil in each part Lubricate.

Starting motor does not

stop running Fused contact points of magnetic switch

Replace magnetic switch.

Short-circuit between turns of magnetic

switch coil (layer short-circuit) Replace magnetic switch.

Failure of returning action in ignition

switch Replace.

Page 411 of 1496

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-1

Engine

Charging System

General Description

Battery DescriptionS7RS0B1A01001

The battery has three major functions in the electrical

system.

• It is a source of electrical energy for cranking the engine.

• It acts as a voltage stabilizer for the electrical system.

• It can, for a limited time, provide energy when the electrical load exceeds the output of the generator.

Carrier and Hold-Down

The battery carrier should be in good condition so that it

will support the battery securely and keep it level. Before

installing the battery, the ba ttery carrier and hold-down

clamp should be clean and free from corrosion and

make certain there are no parts in carrier.

To prevent the battery from shaking in its carrier, the

hold-down bolts should be tight enough but not over-

tightened.

Electrolyte Freezing

The freezing point of electrolyte depends on its specific

gravity. Since freezing may ruin a battery, it should be

protected against freezing by keeping it in a fully

charged condition. If a battery is frozen accidentally, it

should not be charged until it is warmed.

Sulfation

If the battery is allowed to stand for a long period in

discharged condition, the lead sulfate becomes

converted into a hard, cryst alline substance, which will

not easily turn back to the active material again during

the subsequent recharging. “Sulfation” means the result

as well as the process of that reaction. Such a battery

can be revived by very slow charging and may be

restored to usable condition but its capacity is lower than

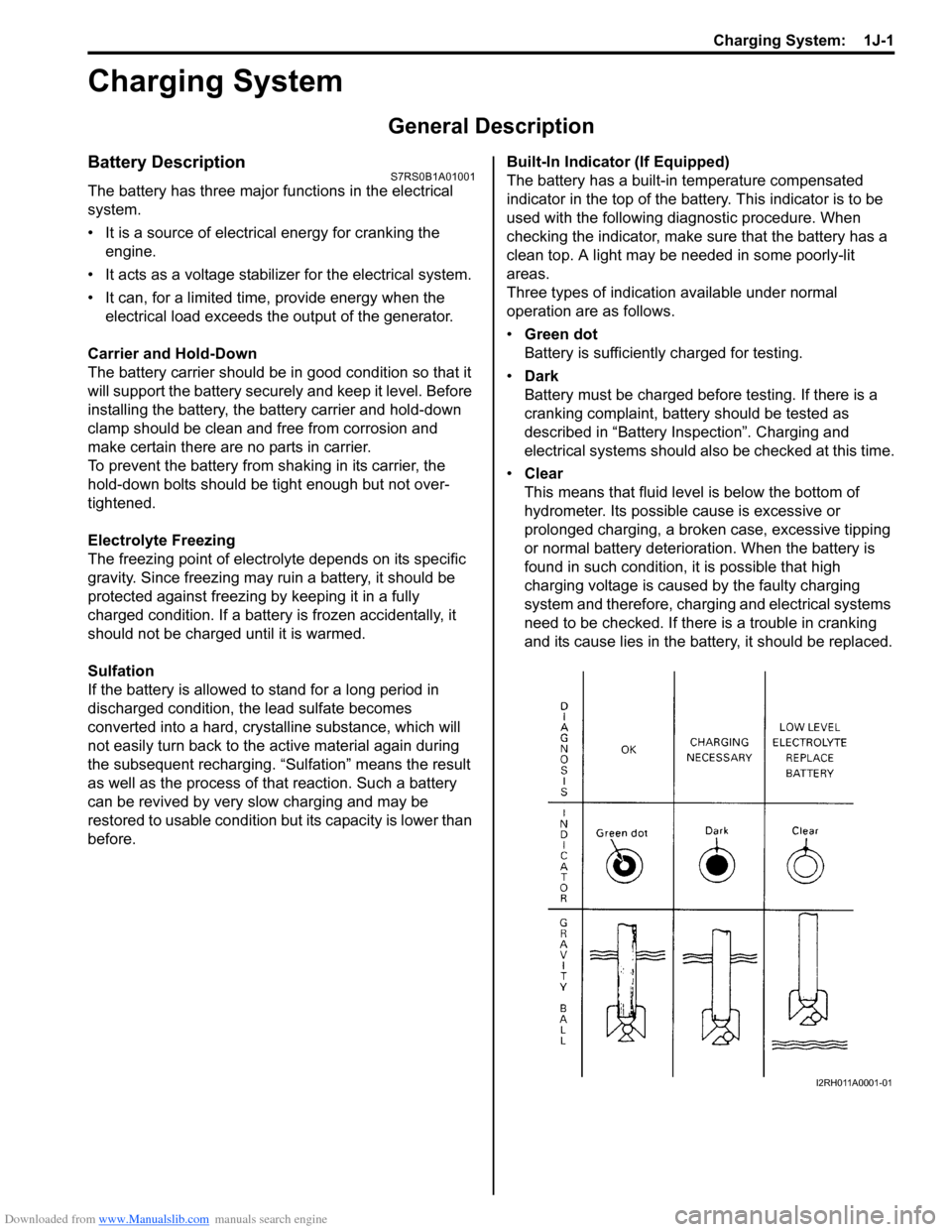

before. Built-In Indicator (If Equipped)

The battery has a built-in temperature compensated

indicator in the top of the battery. This indicator is to be

used with the following diagnostic procedure. When

checking the indicator, make sure that the battery has a

clean top. A light may be needed in some poorly-lit

areas.

Three types of indication available under normal

operation are as follows.

•

Green dot

Battery is sufficiently charged for testing.

• Dark

Battery must be charged before testing. If there is a

cranking complaint, battery should be tested as

described in “Battery Inspection”. Charging and

electrical systems should also be checked at this time.

• Clear

This means that fluid level is below the bottom of

hydrometer. Its possible cause is excessive or

prolonged charging, a broken case, excessive tipping

or normal battery deteriorat ion. When the battery is

found in such condition, it is possible that high

charging voltage is caused by the faulty charging

system and therefore, charging and electrical systems

need to be checked. If there is a trouble in cranking

and its cause lies in the battery, it should be replaced.

I2RH011A0001-01

Page 413 of 1496

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-3

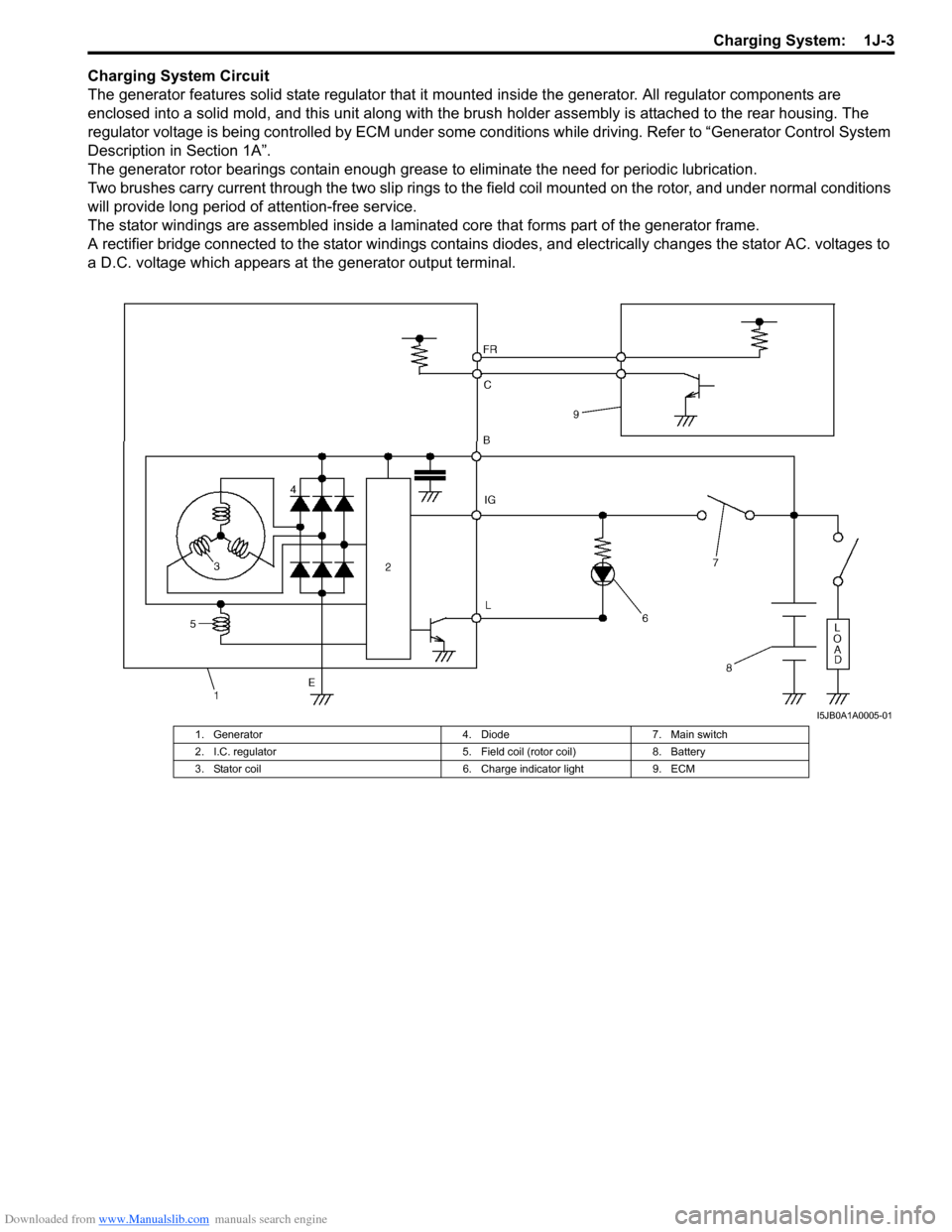

Charging System Circuit

The generator features solid state regulator that it mounted inside the generator. All regulator components are

enclosed into a solid mold, and this unit along with the brus h holder assembly is attached to the rear housing. The

regulator voltage is being controlled by ECM under some cond itions while driving. Refer to “Generator Control System

Description in Section 1A”.

The generator rotor bearings contain enough grease to eliminate the need for periodic lubrication.

Two brushes carry current through the two slip rings to the field coil mounted on the rotor, and under normal conditions

will provide long period of attention-free service.

The stator windings are assembled inside a laminate d core that forms part of the generator frame.

A rectifier bridge connected to the stator windings contains diodes, and electrically changes the stator AC. voltages to

a D.C. voltage which appears at the generator output terminal.

I5JB0A1A0005-01

1. Generator 4. Diode7. Main switch

2. I.C. regulator 5. Field coil (rotor coil)8. Battery

3. Stator coil 6. Charge indicator light9. ECM

Page 414 of 1496

Downloaded from www.Manualslib.com manuals search engine 1J-4 Charging System:

Diagnostic Information and Procedures

Battery InspectionS7RS0B1A04001

Common Causes of Failure

A battery is not designed to last indefinitely; however, with proper care, it will provide many years of service. If the

battery performs satisfactorily during te st but fails to operate properly for no apparent reason, the following are some

factors that may point to the cause of trouble:

• Accessories left on overnight or for an extended period without the generator operating.

• Slow average driving speeds for short periods.

• Electrical load exceeding generator output partic ularly with addition of aftermarket equipment.

• Defects in charging system such as high resistance, s lipping drive belt, loose generator output terminal, faulty

generator or voltage regulator, Refer to “Generator Symptom Diagnosis”.

• Battery abuse, including failure to keep battery cable terminals clean and tight or loose battery hold down.

• Mechanical problems in electrical sys tem such as shorted or pinched wires.

Visual Inspection

Check for obvious damage, such as cracked or broken case or cover, that could permit loss of electrolyte. If obvious

damage is noted, replace battery. Determine cause of damage and correct as needed.

Generator Symptom DiagnosisS7RS0B1A04002

CAUTION!

• Do not mistake polarities of “IG” terminal and “L” terminal.

• Do not create short circuit between “IG” and “L” terminals. Always connect these terminals through a lamp.

• Do not connect any load between “L” and “E” terminals.

• When connecting charger or booster battery to vehicle battery, refer to “Jump Starting in Case of Emergency”.

Trouble in charging system will show up as one or more of the following conditions:

1) Faulty indicator lamp operation.

2) An undercharged battery as evidenced by slow cranking or indicator dark.

3) An overcharged battery as evidenced by ex cessive spewing of electrolyte from vents.

Condition Possible cause Correction / Reference Item

Noisy generator Loose drive belt Adjust or replace drive belt.

Loose drive belt pulley Tighten by specified torque.

Loose mounting bolts Tighten by specified torque.

Worn or dirty bearings Replace.

Defective diode or stator Replace.

Charge light does not

light with ignition ON and

engine off Fuse blown

Replace fuse and check for shorted circuit.

Indicator lamp (LED) faulty Replace combination meter.

Wiring connection loose Tighten loose connection.

IC regulator or field coil faulty Replace.

Poor contact between brush and slip

ring Repair or replace.

Charge light does not go

out with engine running

(battery requires frequent

recharging) Drive belt loose or worn

Adjust or replace drive belt.

IC regulator or generator faulty Replace.

Wiring faulty Repair wiring.

Page 415 of 1496

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-5

Generator Test (Undercharged Battery Check)S7RS0B1A04003

This condition, as evidenced by slow cranking or

indicator clear with dark or light yellow dot can be

caused by one or more of the following conditions even

though indicator lamp may be operating normal.

The following procedure also applies to cars with

voltmeter and ammeter.1) Make sure that undercharged condition has not been caused by accessories left on for extended period of

time.

2) Check drive belt for proper tension.

3) If battery defect is suspected, refer to “Battery Description”.

4) Inspect wiring for defects. Check all connections for tightness and cleanliness, battery cable connections

at battery, starting motor, ignition ground cable and

no “C” terminal circuit at ground.

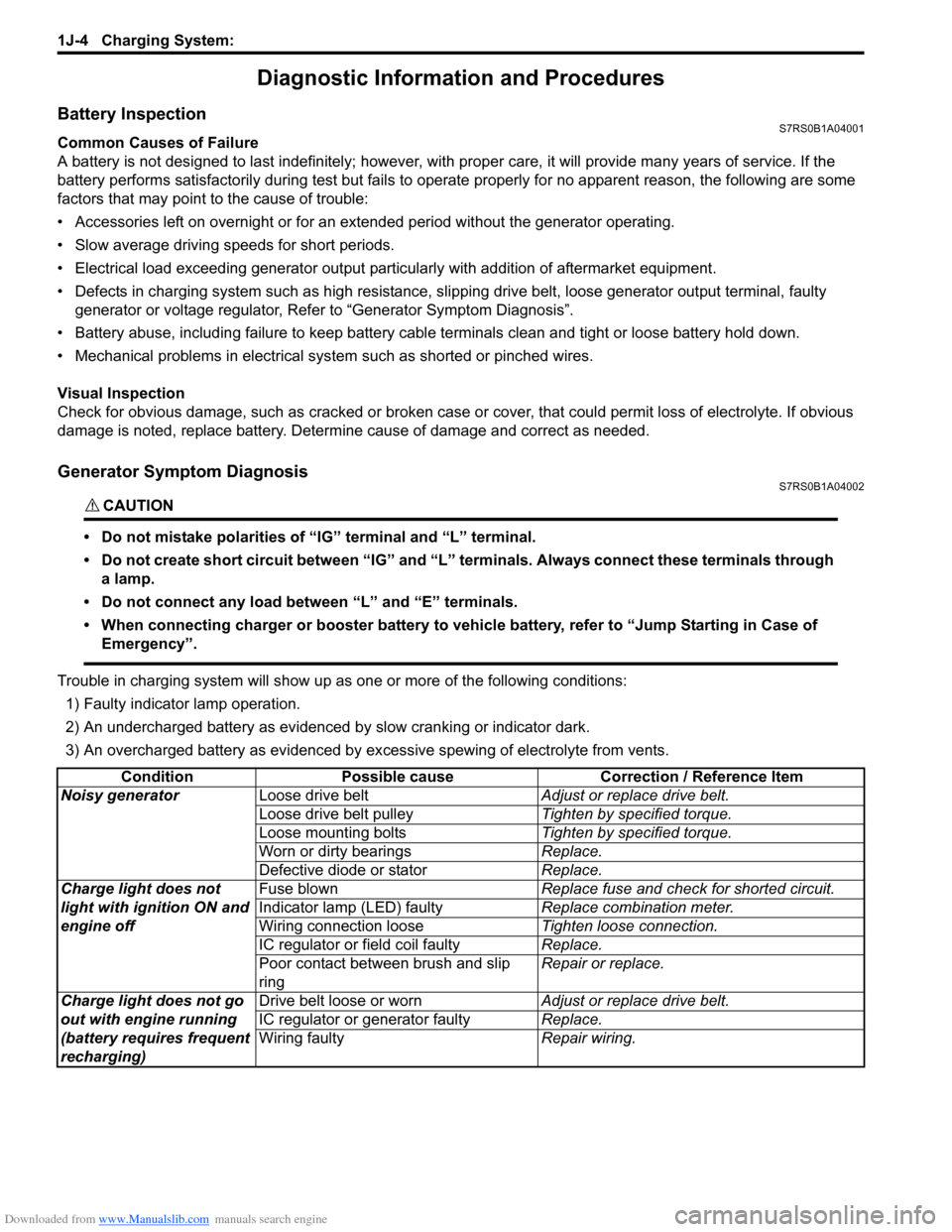

5) Connect switch (6), load (5), battery (4), voltmeter (3) and ammeter (2) to generator (1) as shown in

figure.

Voltmeter: Set between generator “B” terminal

and ground.

Ammeter: Set between generator “B” terminal

and battery (+) terminal.

NOTE

Use fully charged battery.

6) Measure current and voltage.

No-Load Check 1) Run engine from idling up to 2000 rpm and read meters.

NOTE

Turn off switches of all accessories (wiper,

heater etc.).

Specification for undercharged battery (No-load

check)

Current: 10 A

Voltage: 14.2 – 14.8 V (at 20 °C, 68 °F)

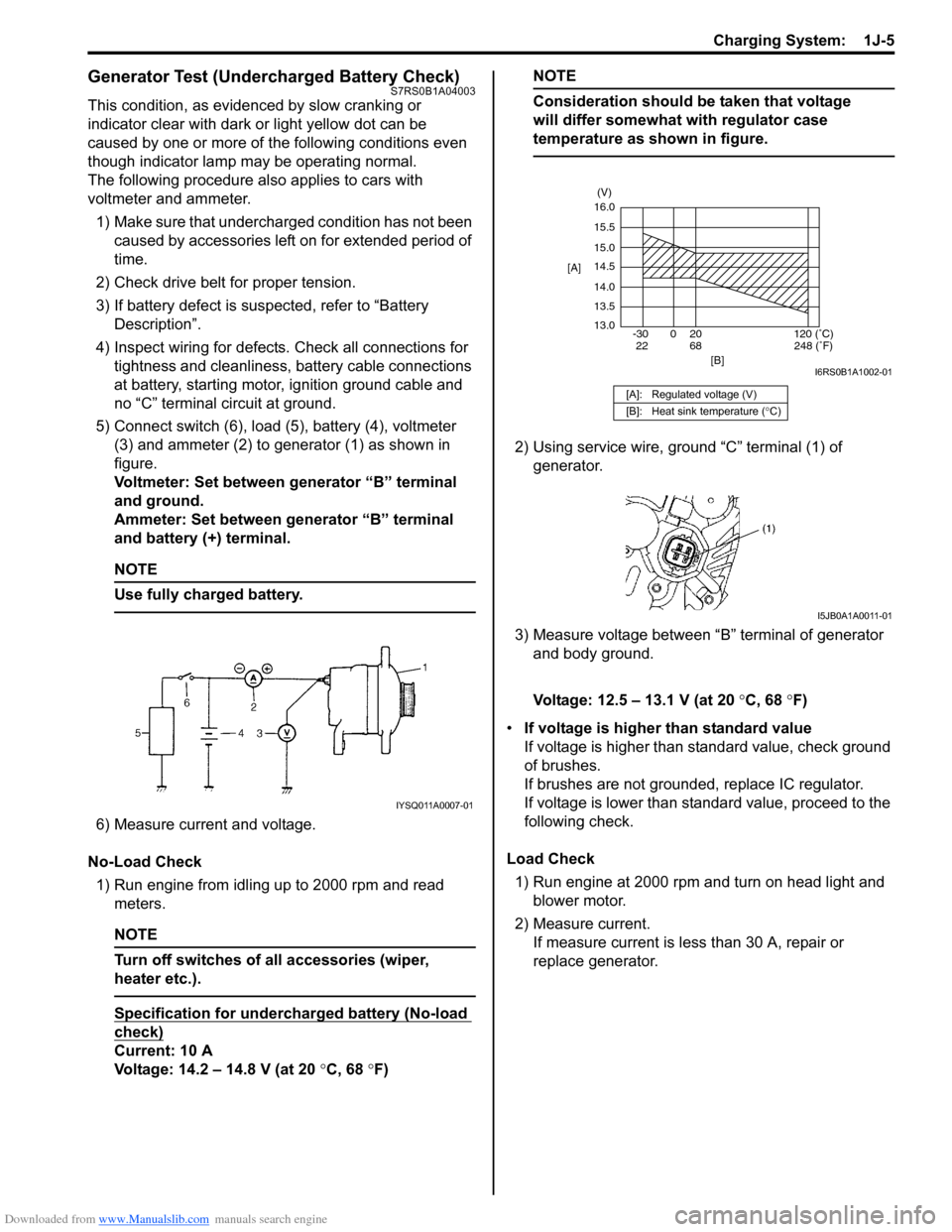

NOTE

Consideration should be taken that voltage

will differ somewhat with regulator case

temperature as shown in figure.

2) Using service wire, ground “C” terminal (1) of

generator.

3) Measure voltage between “B” terminal of generator and body ground.

Voltage: 12.5 – 13.1 V (at 20 °C, 68 °F)

• If voltage is higher than standard value

If voltage is higher than standard value, check ground

of brushes.

If brushes are not grounded, replace IC regulator.

If voltage is lower than standard value, proceed to the

following check.

Load Check 1) Run engine at 2000 rpm and turn on head light and blower motor.

2) Measure current. If measure current is less than 30 A, repair or

replace generator.

IYSQ011A0007-01

[A]: Regulated voltage (V)

[B]: Heat sink temperature ( °C)

16.0

15.5

15.0

14.5

14.0

13.5

13.0

-30 0 20

[A]

[B]

68

22120 (˚C)

248 (˚F)

(V)

I6RS0B1A1002-01

I5JB0A1A0011-01

Page 416 of 1496

Downloaded from www.Manualslib.com manuals search engine 1J-6 Charging System:

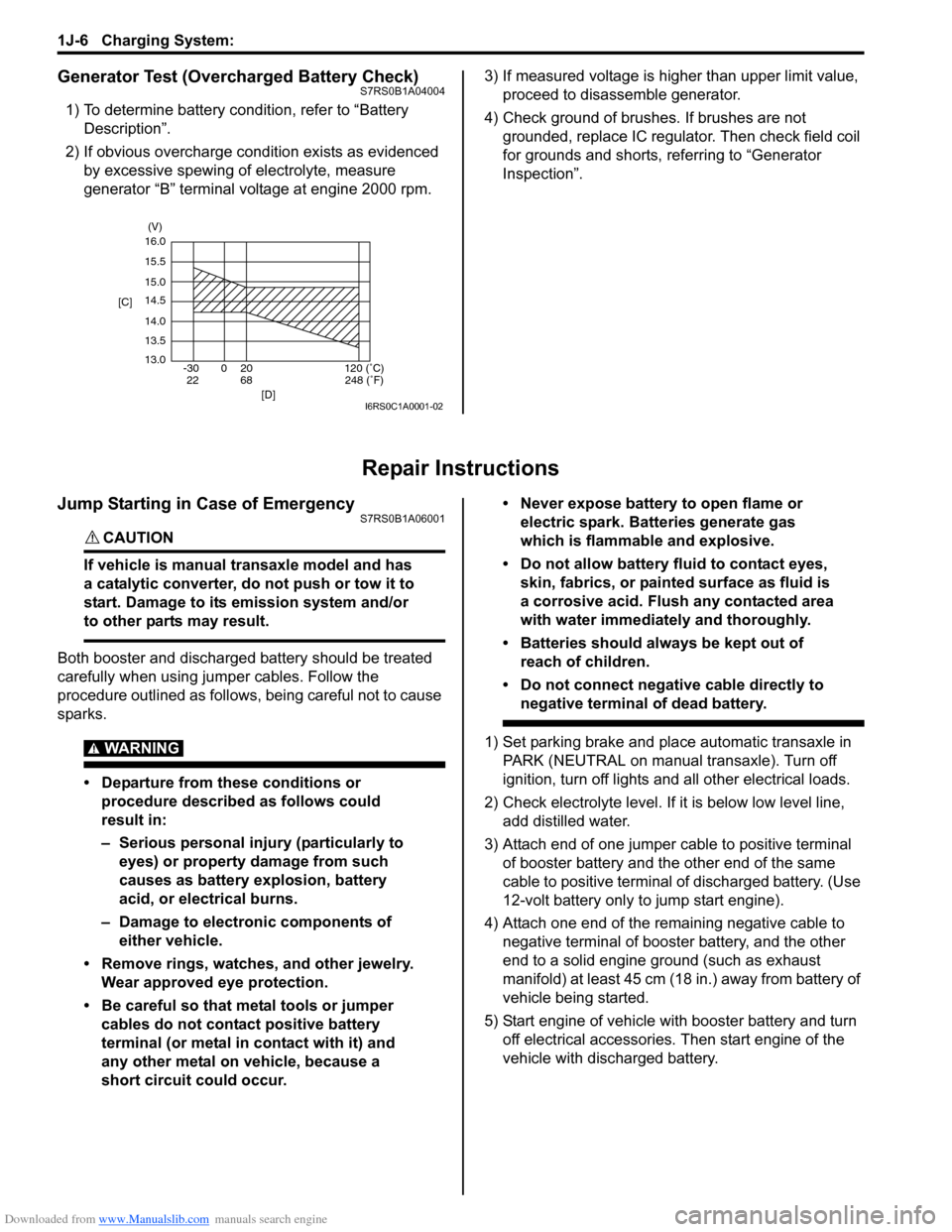

Generator Test (Overcharged Battery Check)S7RS0B1A04004

1) To determine battery condition, refer to “Battery Description”.

2) If obvious overcharge condition exists as evidenced by excessive spewing of electrolyte, measure

generator “B” terminal voltage at engine 2000 rpm. 3) If measured voltage is higher than upper limit value,

proceed to disassemble generator.

4) Check ground of brushes. If brushes are not grounded, replace IC regulator. Then check field coil

for grounds and shorts, referring to “Generator

Inspection”.

Repair Instructions

Jump Starting in Case of EmergencyS7RS0B1A06001

CAUTION!

If vehicle is manual transaxle model and has

a catalytic converter, do not push or tow it to

start. Damage to its emission system and/or

to other parts may result.

Both booster and discharged battery should be treated

carefully when using ju mper cables. Follow the

procedure outlined as follows, being careful not to cause

sparks.

WARNING!

• Departure from these conditions or procedure described as follows could

result in:

– Serious personal injury (particularly to eyes) or property damage from such

causes as battery explosion, battery

acid, or electrical burns.

– Damage to electronic components of either vehicle.

• Remove rings, watches, and other jewelry. Wear approved eye protection.

• Be careful so that metal tools or jumper cables do not contact positive battery

terminal (or metal in contact with it) and

any other metal on vehicle, because a

short circuit could occur. • Never expose battery to open flame or

electric spark. Batteries generate gas

which is flammable and explosive.

• Do not allow battery fluid to contact eyes, skin, fabrics, or painted surface as fluid is

a corrosive acid. Flush any contacted area

with water immediately and thoroughly.

• Batteries should always be kept out of reach of children.

• Do not connect negative cable directly to negative terminal of dead battery.

1) Set parking brake and place automatic transaxle in PARK (NEUTRAL on manual transaxle). Turn off

ignition, turn off lights and all other electrical loads.

2) Check electrolyte level. If it is below low level line, add distilled water.

3) Attach end of one jumper cable to positive terminal of booster battery and the other end of the same

cable to positive terminal of discharged battery. (Use

12-volt battery only to jump start engine).

4) Attach one end of the remaining negative cable to negative terminal of booster battery, and the other

end to a solid engine ground (such as exhaust

manifold) at least 45 cm (18 in.) away from battery of

vehicle being started.

5) Start engine of vehicle with booster battery and turn off electrical accessories. Then start engine of the

vehicle with discharged battery.

16.0

15.5

15.0

14.5

14.0

13.5

13.0 -30 0 20

[C]

[D]

68

22120 (˚C)

248 (˚F)

(V)

I6RS0C1A0001-02

Page 515 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-17

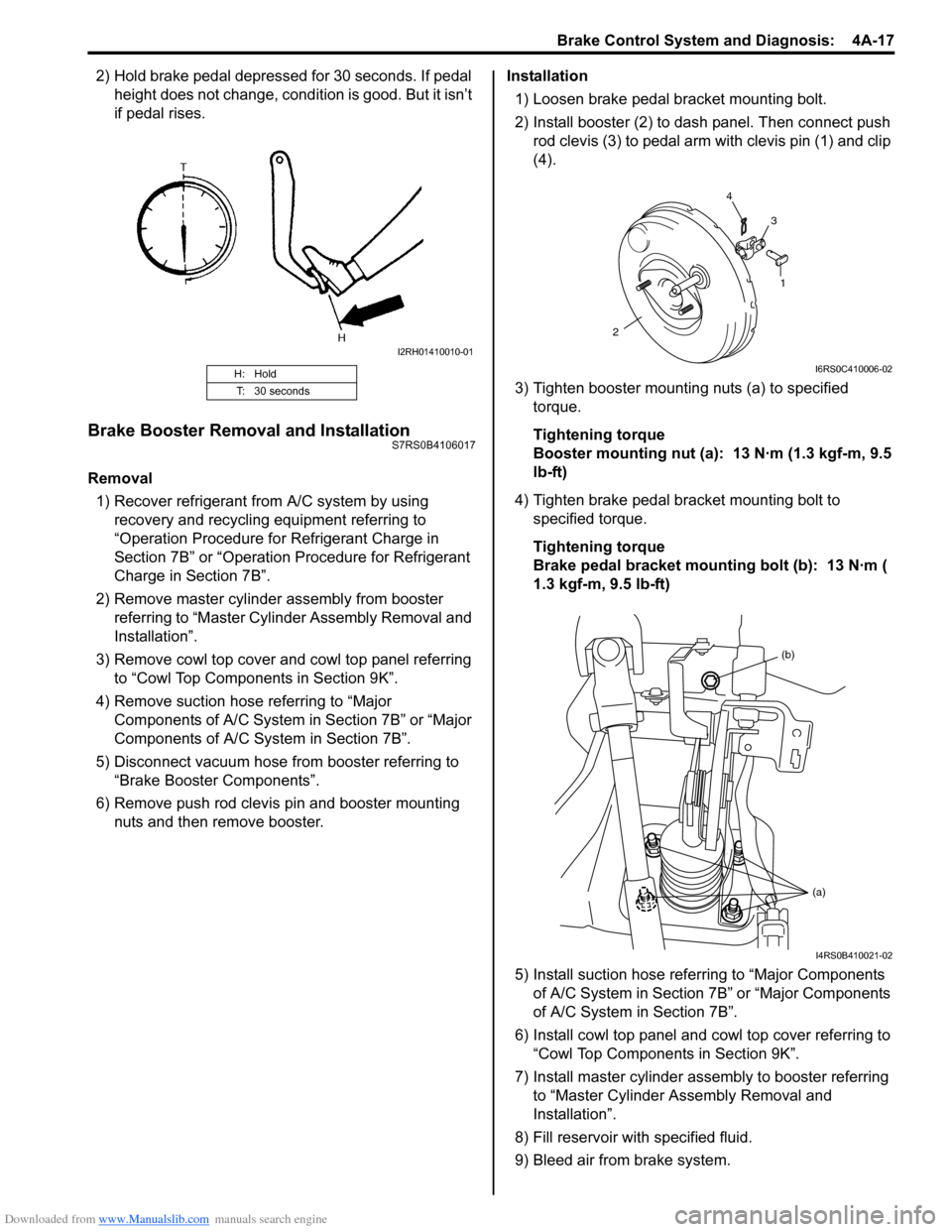

2) Hold brake pedal depressed for 30 seconds. If pedal height does not change, condition is good. But it isn’t

if pedal rises.

Brake Booster Removal and InstallationS7RS0B4106017

Removal

1) Recover refrigerant from A/C system by using recovery and recycling equipment referring to

“Operation Procedure for Refrigerant Charge in

Section 7B” or “Operation Procedure for Refrigerant

Charge in Section 7B”.

2) Remove master cylinder assembly from booster referring to “Master Cylin der Assembly Removal and

Installation”.

3) Remove cowl top cover and cowl top panel referring to “Cowl Top Components in Section 9K”.

4) Remove suction hose referring to “Major Components of A/C System in Section 7B” or “Major

Components of A/C System in Section 7B”.

5) Disconnect vacuum hose from booster referring to “Brake Booster Components”.

6) Remove push rod clevis pin and booster mounting nuts and then remove booster. Installation

1) Loosen brake pedal bracket mounting bolt.

2) Install booster (2) to dash panel. Then connect push rod clevis (3) to pedal arm with clevis pin (1) and clip

(4).

3) Tighten booster mounting nuts (a) to specified torque.

Tightening torque

Booster mounting nut (a): 13 N·m (1.3 kgf-m, 9.5

lb-ft)

4) Tighten brake pedal bracket mounting bolt to specified torque.

Tightening torque

Brake pedal bracket mounting bolt (b): 13 N·m (

1.3 kgf-m, 9.5 lb-ft)

5) Install suction hose referring to “Major Components of A/C System in Section 7B” or “Major Components

of A/C System in Section 7B”.

6) Install cowl top panel and cowl top cover referring to

“Cowl Top Components in Section 9K”.

7) Install master cylinder assembly to booster referring to “Master Cylinder Assembly Removal and

Installation”.

8) Fill reservoir with specified fluid.

9) Bleed air from brake system.

H: Hold

T: 30 seconds

I2RH01410010-01

1

2 4

3

I6RS0C410006-02

(b)

(a)

I4RS0B410021-02

Page 516 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-18 Brake Control System and Diagnosis:

10) Check pedal height and play referring to “Brake Pedal Free Height Inspection” and “Brake Pedal

Play Inspection”.

11) Check each installed part for fluid leakage and perform brake test.

12) Evacuate and charge refrigerant by referring to “Evacuating of A/C Syst em” and “Procedure of

Charging” under “Operation Procedure for

Refrigerant Charge in Section 7B” or “Operation

Procedure for Refrigerant Charge in Section 7B”.

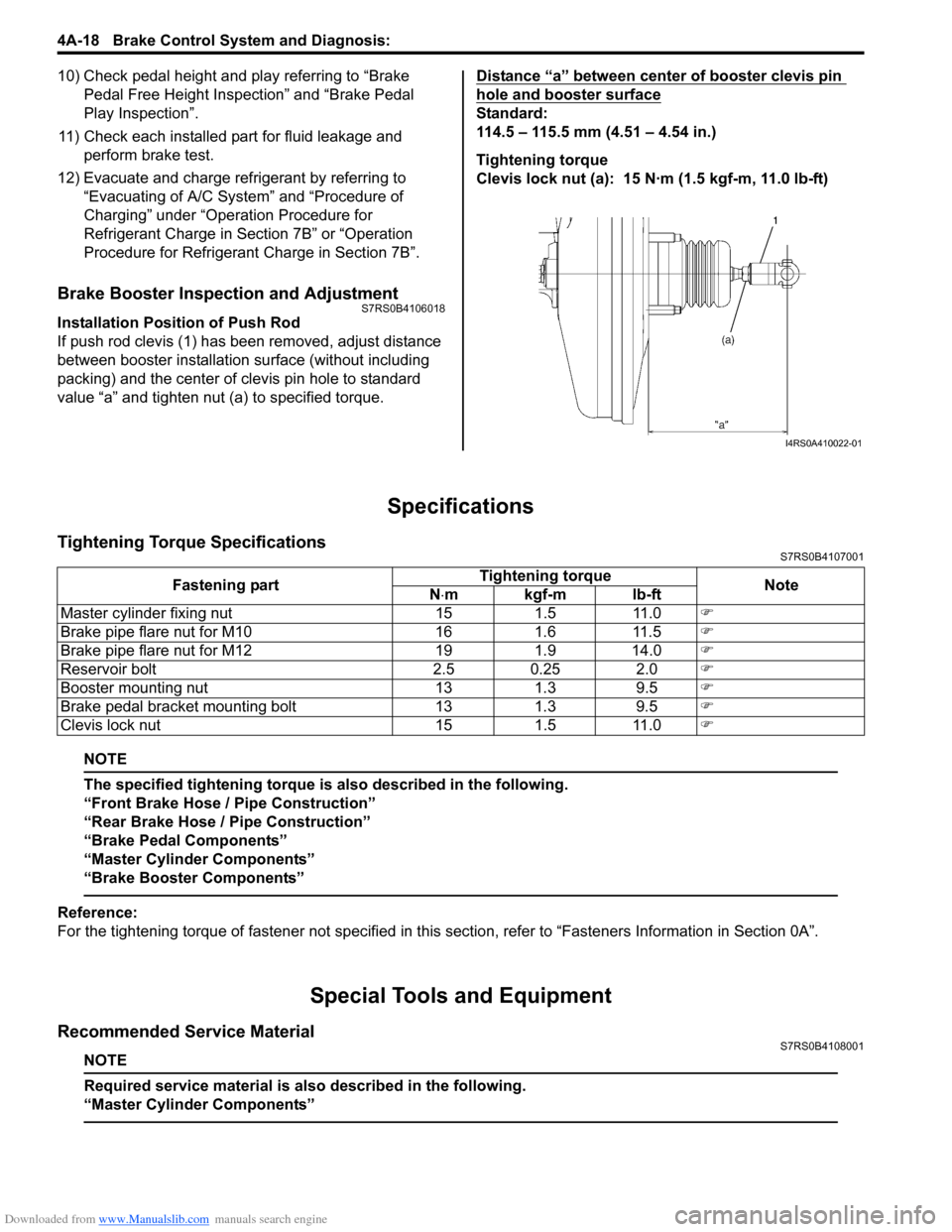

Brake Booster Inspection and AdjustmentS7RS0B4106018

Installation Position of Push Rod

If push rod clevis (1) has b een removed, adjust distance

between booster installation surface (without including

packing) and the center of clevis pin hole to standard

value “a” and tighten nut (a) to specified torque. Distance “a” between center of booster clevis pin

hole and booster surface

Standard:

114.5 – 115.5 mm (4.51 – 4.54 in.)

Tightening torque

Clevis lock nut (a): 15 N·m (1.5 kgf-m, 11.0 lb-ft)

Specifications

Tightening Torque SpecificationsS7RS0B4107001

NOTE

The specified tightening torque is also described in the following.

“Front Brake Hose / Pipe Construction”

“Rear Brake Hose / Pipe Construction”

“Brake Pedal Components”

“Master Cylinder Components”

“Brake Booster Components”

Reference:

For the tightening torque of fastener not specified in this

section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Service MaterialS7RS0B4108001

NOTE

Required service material is also described in the following.

“Master Cylinder Components”

I4RS0A410022-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Master cylinder fixing nut 15 1.5 11.0 �)

Brake pipe flare nut for M10 16 1.6 11.5 �)

Brake pipe flare nut for M12 19 1.9 14.0 �)

Reservoir bolt 2.5 0.25 2.0 �)

Booster mounting nut 13 1.3 9.5 �)

Brake pedal bracket mounting bolt 13 1.3 9.5 �)

Clevis lock nut 15 1.5 11.0 �)

Page 560 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-21 ABS:

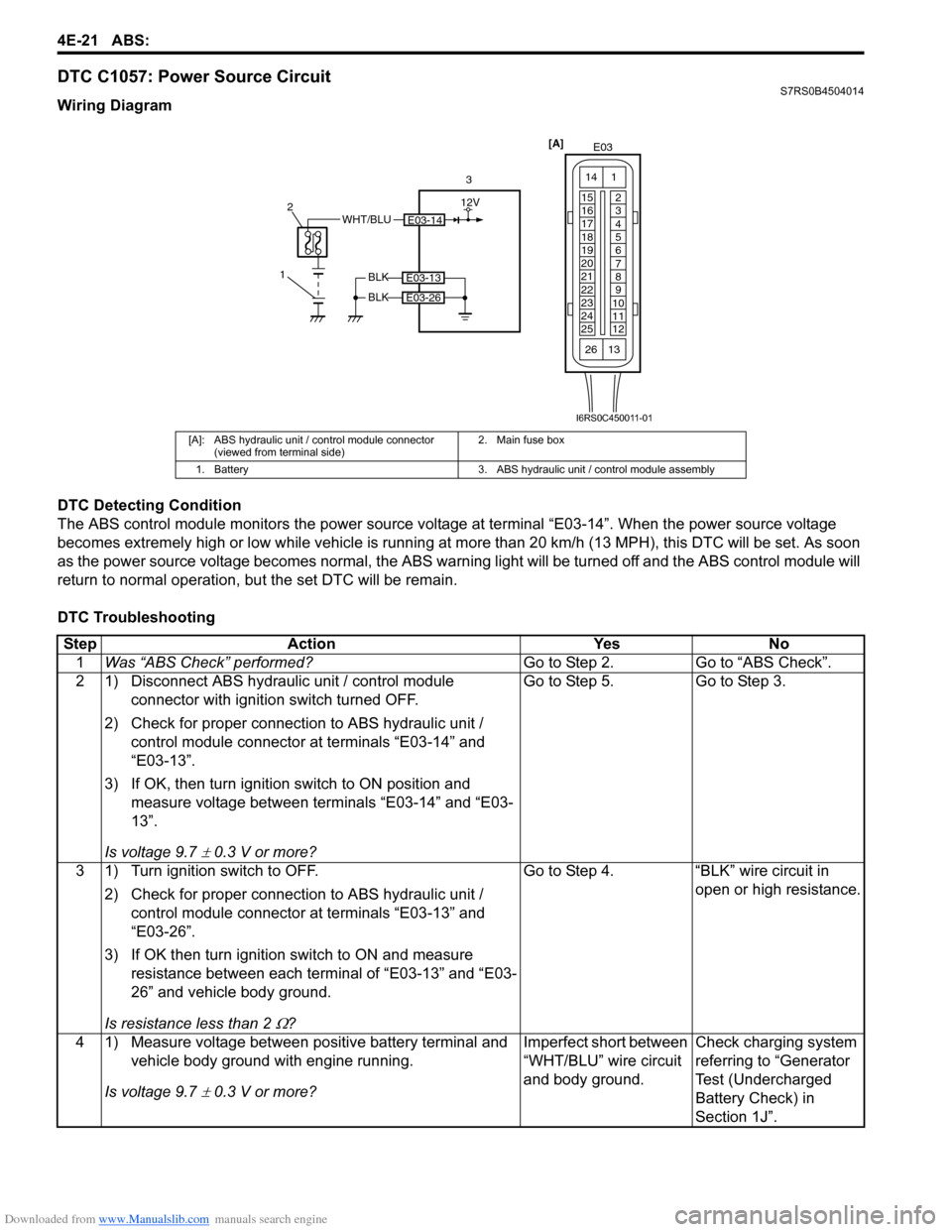

DTC C1057: Power Source CircuitS7RS0B4504014

Wiring Diagram

DTC Detecting Condition

The ABS control module monitors the power source voltage at terminal “E03-14”. When the power source voltage

becomes extremely high or low while vehicle is running at more than 20 km/h (13 MPH), this DTC will be set. As soon

as the power source volta ge becomes normal, the ABS warning light will be turned off and the ABS control module will

return to normal operation, bu t the set DTC will be remain.

DTC Troubleshooting

[A]: ABS hydraulic unit / control module connector (viewed from terminal side) 2. Main fuse box

1. Battery 3. ABS hydraulic unit / control module assembly

E03-14WHT/BLU

1 2

3

BLK

BLK

E03-13

E03-26

[A]

E03

15

16

17

18

19

20

21

22

23

24

25 2

3

4

5

6

7

8

9

10

11

12

1

13

14

26

12V

I6RS0C450011-01

Step

Action YesNo

1 Was “ABS Check” performed? Go to Step 2.Go to “ABS Check”.

2 1) Disconnect ABS hydraulic unit / control module connector with ignition switch turned OFF.

2) Check for proper connection to ABS hydraulic unit / control module connector at terminals “E03-14” and

“E03-13”.

3) If OK, then turn ignition switch to ON position and measure voltage between terminals “E03-14” and “E03-

13”.

Is voltage 9.7

± 0.3 V or more? Go to Step 5. Go to Step 3.

3 1) Turn ignition switch to OFF. 2) Check for proper connection to ABS hydraulic unit / control module connector at terminals “E03-13” and

“E03-26”.

3) If OK then turn ignition switch to ON and measure resistance between each terminal of “E03-13” and “E03-

26” and vehicle body ground.

Is resistance less than 2

Ω? Go to Step 4. “BLK” wire circuit in

open or high resistance.

4 1) Measure voltage between positive battery terminal and vehicle body ground with engine running.

Is voltage 9.7

± 0.3 V or more? Imperfect short between

“WHT/BLU” wire circuit

and body ground.

Check charging system

referring to “Generator

Test (Undercharged

Battery Check) in

Section 1J”.