Washer SUZUKI SWIFT 2008 2.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 646 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-2 Automatic Transmission/Transaxle:

CAUTION!

• Keep component parts in group for each subassembly and avoid mixing them up.

• Clean all parts with cleaning solvent thoroughly and air dry them.

• Use kerosene or automatic transaxle fluid as cleaning solvent.

• Do not use wiping cloths or rags to clean or dry parts.

• All oil passages should be blown out and checked to make sure that they are not

obstructed.

• Keep face and eyes away from solvent spray while air blowing parts.

• Check mating surface for irregularities and remove them, if any, and clean it again.

• Soak new clutch discs and brake discs in transaxle fluid for at least 2 hours before

assembly.

• Replace all gaskets and O-ring with new ones.

• Apply automatic transaxle fluid to all O- rings.

• When installing seal ring, be careful so that it is not expanded excessively, extruded or

caught.

• Replace oil seals that are removed and apply grease to their lips.

• Before installing, be sure to apply automatic transaxle fluid to sliding, rolling

and thrusting surface of all component

part. Also after installation, make sure to

check each part for proper operation.

• Always use torque wrench when tightening bolts.

• A new discs should be soaked in ATF at least 2 hours before use.

Part Inspection and Correction Table Part Inspect for Correction

Casted part,

machined part Small flaw, burr

Remove with oil

stone.

Deep or grooved

flaw Replace part.

Clogged fluid

passage Clean with air or

wire.

Flaw on installing

surface, residual

gasket Remove with oil

stone or replace

part.

Crack Replace part.

Bearing Unsmooth rotation Replace.

Streak, pitting, flaw,

crack

Replace.

Bushing, thrust

washer Flaw, burr, wear,

burning

Replace.

Oil seal, gasket Flawed or

hardened seal ring

Replace.

Worn seal ring on

its periphery or side Replace.

Piston seal ring, oil

seal, gasket, etc. Replace.

Gear Flaw, burr Replace.

Worn gear tooth Replace.

Splined part Burr, flaw, torsion Correct with oil

stone or replace.

Snap ring Wear, flaw,

distortion

Replace.

No interference Replace.

Thread Burr Replace.

Damage Replace.

Sp rin g Settling, sign of

burning Replace.

Friction plate Wear, burning,

distortion,

damaged claw Replace.

Separator plate,

retaining plate Wear, burning,

distortion,

damaged claw

Replace.

Sealing surface

(where lip

contacts) Flaw, rough

surface, stepped

wear, foreign

material

Replace.

Page 689 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-45

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) Connect scan tool to DLC with ignition switch OFF.

2) Clear DTCs in TCM memo ry by using scan tool.

3) Start engine and shift select lever to “D” range.

4) Keep engine running at idle speed for 25 seconds or more.

5) Stop vehicle and check DTC.

DTC Troubleshooting DTC detecting condition Trouble area

Multiple or more signals are inputted simultaneously for 10

seconds. • Select cable maladjusted

• Transmission range sensor (switch) maladjusted

• Transmission range sensor (switch) or its circuit

malfunction

•TCM

Step Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

2 Do you have SUZUKI scan tool? Go to Step 3.Go to Step 4.

3 Check transmission range sensor (switch) circuit for

operation

Check by using SUZUKI scan tool:

1) Connect SUZUKI scan tool to DLC with ignition switch

OFF.

2) Turn ignition switch ON and check transmission range signal (“P”, “R”, “N”, “D”, “3”, “2” or “L”) on display when

shifting select lever to each range.

Is applicable range indicated? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 5.

4 Check transmission range sensor (switch) circuit for

operation

Check by not using SUZUKI scan tool:

1) Turn ignition switch ON.

2) Check voltage at terminals “C35-1”, “C35-7”, “C35-8”,

“C35-18”, “C35-19” and “C35-20” respectively with

select lever shifted to each range.

Taking terminal “C35-19” as an example, is battery

voltage indicated only when se lect lever is shifted to “2”

range and 0 V for other ranges as shown in the following

table.

Check voltage at other terminals likewise, referring to the

following table.

Are check results satisfactory? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 5.

5 1) Check select cable for adjustment referring to “Select Cable Adjustment”.

Is it adjusted correctly? Go to Step 6.

Adjust.

6 Check transmission range sensor (switch) for

installation position

1) Shift select lever to “N” range.

2) Check that “N” reference line on sensor and needle

direction shaped on lock washer are aligned.

Are they aligned? Go to Step 7.

Adjust.

Page 691 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-47

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ignition switch OFF.

2) Clear DTCs in TCM memo ry by using scan tool.

3) Start engine and shift select lever to “D” range.

4) Start vehicle and increase vehicle speed to 40 km/h (25 mile/h) or more for 1 minutes.

5) Stop vehicle and turn ignition switch OFF.

6) Repeat Step 3) to 4) one time.

7) Stop vehicle and check DTC.

DTC Troubleshooting Step Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

2 Do you have SUZUKI scan tool? Go to Step 3.Go to Step 4.

3 Check transmission range sensor (switch) circuit for

operation

Check by using SUZUKI scan tool:

1) Connect SUZUKI scan tool to DLC with ignition switch

OFF.

2) Turn ignition switch ON and check transmission range signal (P, R, N, D, 3, 2 or L) on display when shifting

select lever to each range.

Is applicable range indicated? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”

Go to Step 5.

4 Check transmission range sensor (switch) circuit for

operation

Check by not using SUZUKI scan tool:

1) Turn ignition switch ON.

2) Check voltage at terminals “C35-1”, “C35-7”, “C35-8”,

“C35-18”, “C35-19” and “C35-20” respectively with

select lever shifted to each range.

Taking terminal “C35-19” as an example, is battery

voltage indicated only when se lect lever is shifted to “2”

range and 0 V for other ranges as shown in the following

table.

Check voltage at other terminals likewise, referring to the

following table.

Are check results satisfactory? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 5.

5 1) Check select cable for adjustment referring to “Select Cable Adjustment”.

Is it adjusted correctly? Go to Step 6.

Adjust.

6 Check transmission range sensor (switch) for

installation position

1) Shift select lever to “N” range.

2) Check that “N” reference line on sensor and needle

direction shaped on lock washer are aligned.

Are they aligned? Go to Step 7.

Adjust.

Page 739 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-95

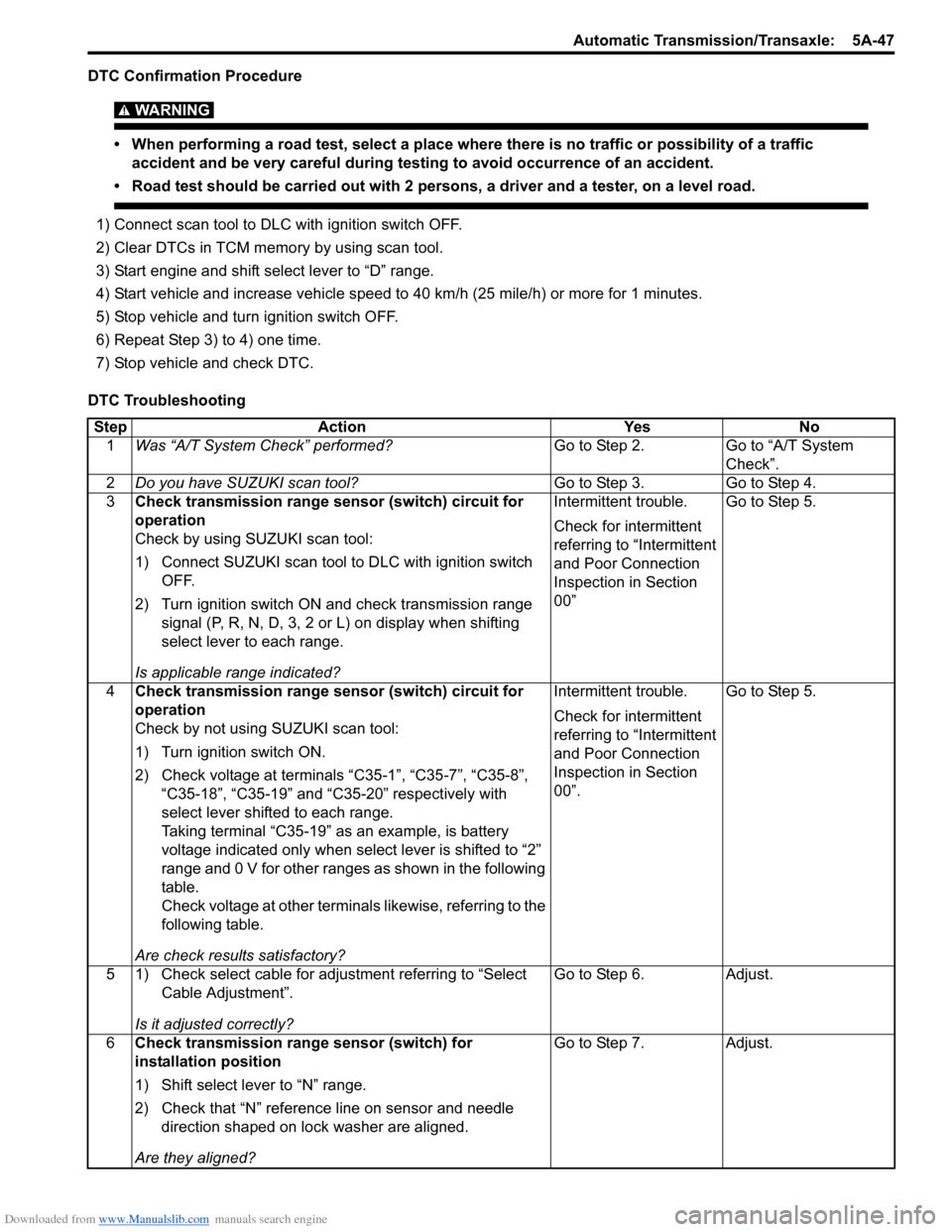

5) Shift select lever to “N” position.

NOTE

If select lever is in “P” position, shift select

lever referring to “Select Lever Inspection”.

6) Install cable casing cap (3) to selector bracket (4).

7) Connect cable end (1) to interlock cam (2) with ignition switch turned to ACC position.

8) Drive lock button (5) in cable end until it locks cable expansion and contraction.

9) With select lever set at “P ” position, turn ignition key

to ACC position and then check for the following

conditions.

• With knob button released, ignition key can be turned from ACC position to LOCK position.

• With knob button pressed, ignition key cannot be

turned from ACC position to LOCK position.

10) Install steering column cover. 11) If the vehicle is equipped with air bag system, connect negative cable at battery and enable air bag

system, referring to “Enabling Air Bag System in

Section 8B”.

Transmission Range Sensor (Shift Switch)

Inspection and Adjustment

S7RS0B5106015

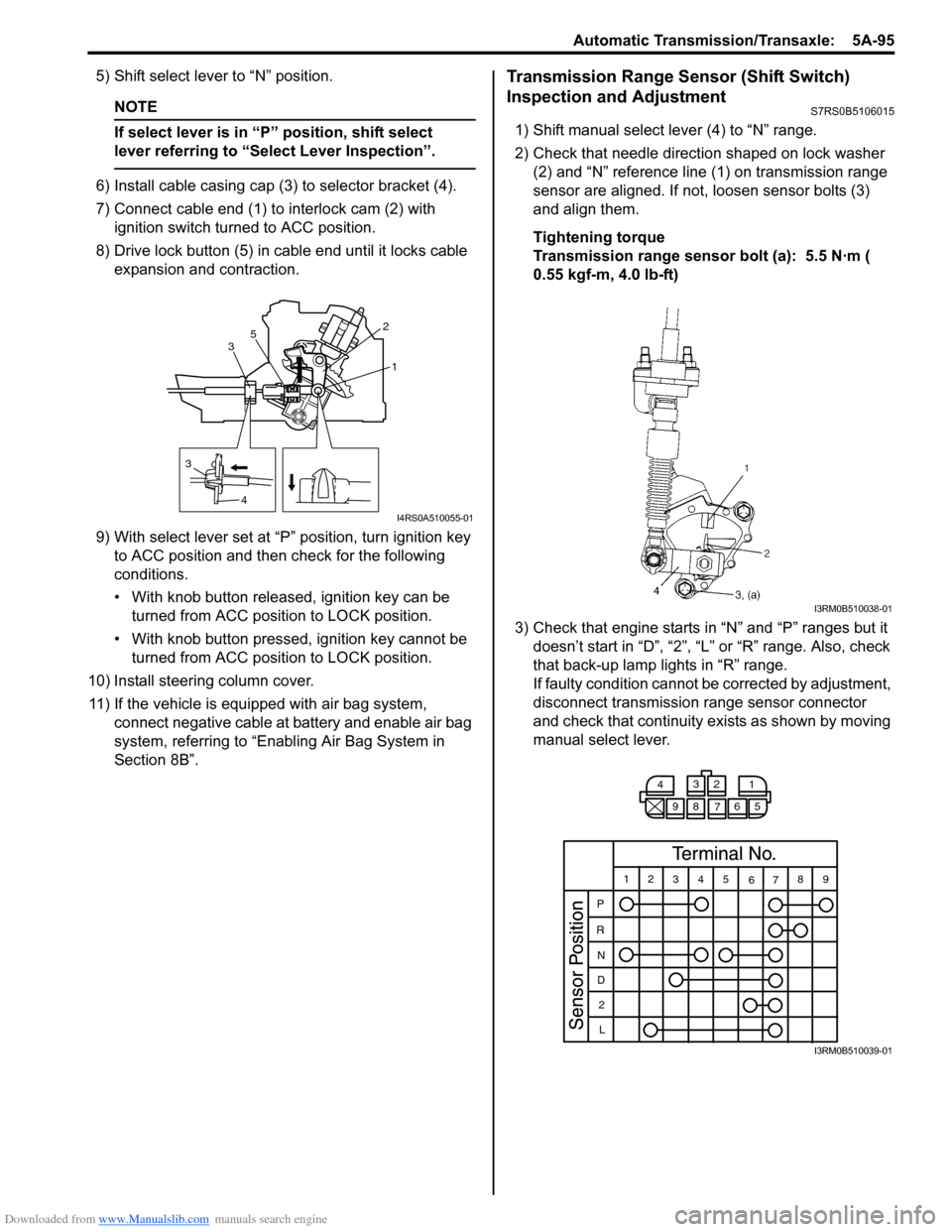

1) Shift manual select lever (4) to “N” range.

2) Check that needle direction shaped on lock washer (2) and “N” reference line (1) on transmission range

sensor are aligned. If not, loosen sensor bolts (3)

and align them.

Tightening torque

Transmission range sensor bolt (a): 5.5 N·m (

0.55 kgf-m, 4.0 lb-ft)

3) Check that engine starts in “N” and “P” ranges but it doesn’t start in “D”, “2”, “L” or “R” range. Also, check

that back-up lamp lights in “R” range.

If faulty condition cannot be corrected by adjustment,

disconnect transmission range sensor connector

and check that continuity ex ists as shown by moving

manual select lever.

3

4 1

2

3 5

I4RS0A510055-01

I3RM0B510038-01

4

3

2

1

98 76 5

12 345

6789

P

R N

D 2

L

I3RM0B510039-01

Page 753 of 1496

Downloaded from www.Manualslib.com manuals search engine A u to m a tic Tra n s m is s io n /Tra n s a x le : 5 A -1 0 9

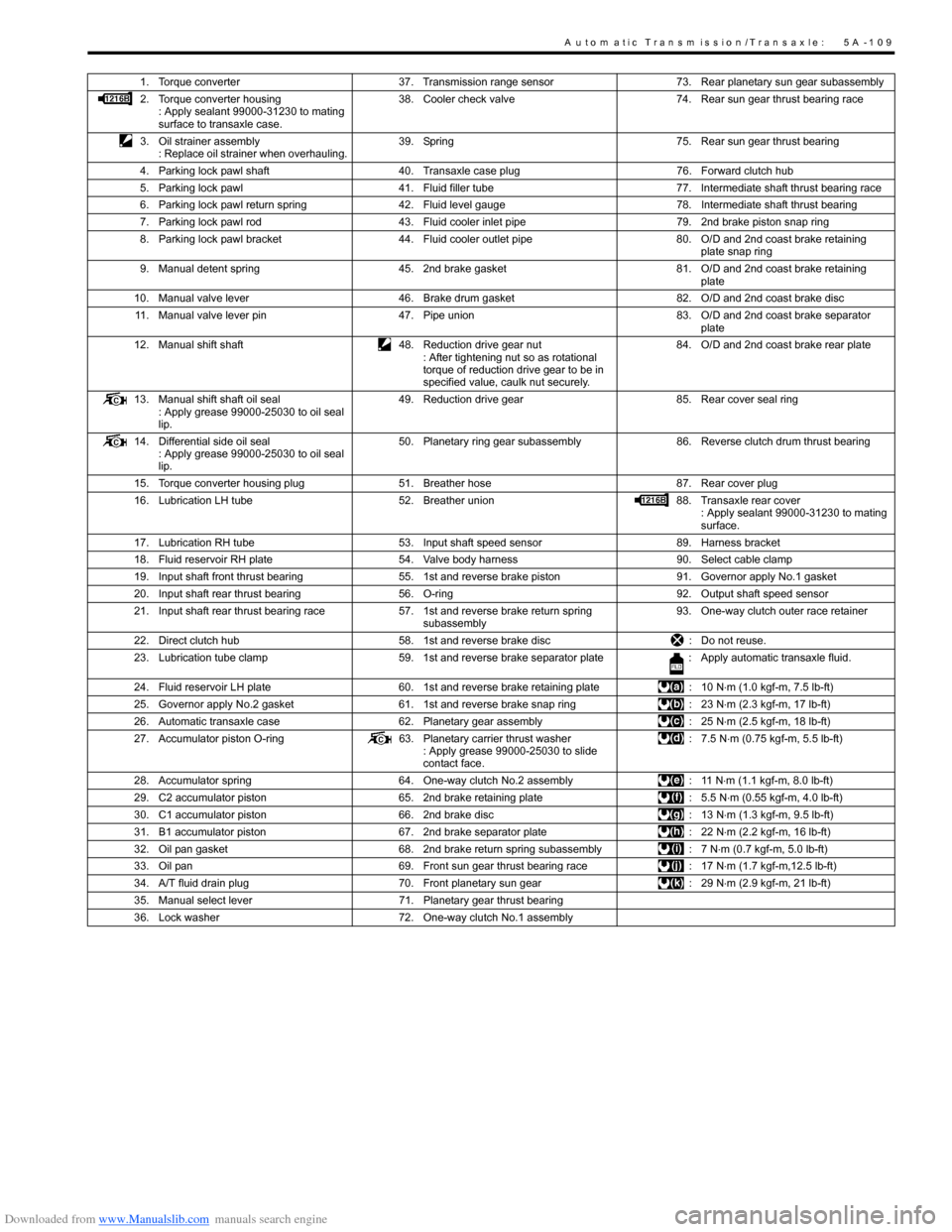

1. Torque converter37. Transmission range sensor 73. Rear planetary sun gear subassembly

2. Torque converter housing : Apply sealant 99000-31230 to mating

surface to transaxle case. 38. Cooler check valve

74. Rear sun gear thrust bearing race

3. Oil strainer assembly : Replace oil strainer when overhauling. 39. Spring

75. Rear sun gear thrust bearing

4. Parking lock pawl shaft 40. Transaxle case plug 76. Forward clutch hub

5. Parking lock pawl 41. Fluid filler tube 77. Intermediate shaft thrust bearing race

6. Parking lock pawl return spring 42. Fluid level gauge 78. Intermediate shaft thrust bearing

7. Parking lock pawl rod 43. Fluid cooler inlet pipe 79. 2nd brake piston snap ring

8. Parking lock pawl bracket 44. Fluid cooler outlet pipe 80. O/D and 2nd coast brake retaining

plate snap ring

9. Manual detent spring 45. 2nd brake gasket 81. O/D and 2nd coast brake retaining

plate

10. Manual valve lever 46. Brake drum gasket 82. O/D and 2nd coast brake disc

11. Manual valve lever pin 47. Pipe union 83. O/D and 2nd coast brake separator

plate

12. Manual shift shaft 48. Reduction drive gear nut

: After tightening nut so as rotational

torque of reduction drive gear to be in

specified value, caulk nut securely. 84. O/D and 2nd coast brake rear plate

13. Manual shift shaft oil seal : Apply grease 99000-25030 to oil seal

lip. 49. Reduction drive gear

85. Rear cover seal ring

14. Differential side oil seal : Apply grease 99000-25030 to oil seal

lip. 50. Planetary ring gear subassembly

86. Reverse clutch drum thrust bearing

15. Torque converter housing plug 51. Breather hose 87. Rear cover plug

16. Lubrication LH tube 52. Breather union 88. Transaxle rear cover

: Apply sealant 99000-31230 to mating

surface.

17. Lubrication RH tube 53. Input shaft speed sensor 89. Harness bracket

18. Fluid reservoir RH plate 54. Valve body harness 90. Select cable clamp

19. Input shaft front thrust bearing 55. 1st and reverse brake piston 91. Governor apply No.1 gasket

20. Input shaft rear thrust bearing 56. O-ring 92. Output shaft speed sensor

21. Input shaft rear thrust bearing race 57. 1st and reverse brake return spring

subassembly 93. One-way clutch outer race retainer

22. Direct clutch hub 58. 1st and reverse brake disc : Do not reuse.

23. Lubrication tube clamp 59. 1st and reverse brake separator plate : Apply automatic transaxle fluid.

24. Fluid reservoir LH plate 60. 1st and reverse brake retaining plate : 10 N⋅m (1.0 kgf-m, 7.5 lb-ft)

25. Governor apply No.2 gasket 61. 1st and reverse brake snap ring : 23 N⋅m (2.3 kgf-m, 17 lb-ft)

26. Automatic transaxle case 62. Planetary gear assembly : 25 N⋅m (2.5 kgf-m, 18 lb-ft)

27. Accumulator piston O-ring 63. Planetary carrier thrust washer

: Apply grease 99000-25030 to slide

contact face. : 7.5 N

⋅m (0.75 kgf-m, 5.5 lb-ft)

28. Accumulator spring 64. One-way clutch No.2 assembly : 11 N⋅m (1.1 kgf-m, 8.0 lb-ft)

29. C2 accumulator piston 65. 2nd brake retaining plate : 5.5 N⋅m (0.55 kgf-m, 4.0 lb-ft)

30. C1 accumulator piston 66. 2nd brake disc : 13 N⋅m (1.3 kgf-m, 9.5 lb-ft)

31. B1 accumulator piston 67. 2nd brake separator plate : 22 N⋅m (2.2 kgf-m, 16 lb-ft)

32. Oil pan gasket 68. 2nd brake return spring subassembly : 7 N⋅m (0.7 kgf-m, 5.0 lb-ft)

33. Oil pan 69. Front sun gear thrust bearing race : 17 N⋅m (1.7 kgf-m,12.5 lb-ft)

34. A/T fluid drain plug 70. Front planetary sun gear : 29 N⋅m (2.9 kgf-m, 21 lb-ft)

35. Manual select lever 71. Planetary gear thrust bearing

36. Lock washer 72. One-way clutch No.1 assembly

Page 754 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-110 Automatic Transmission/Transaxle:

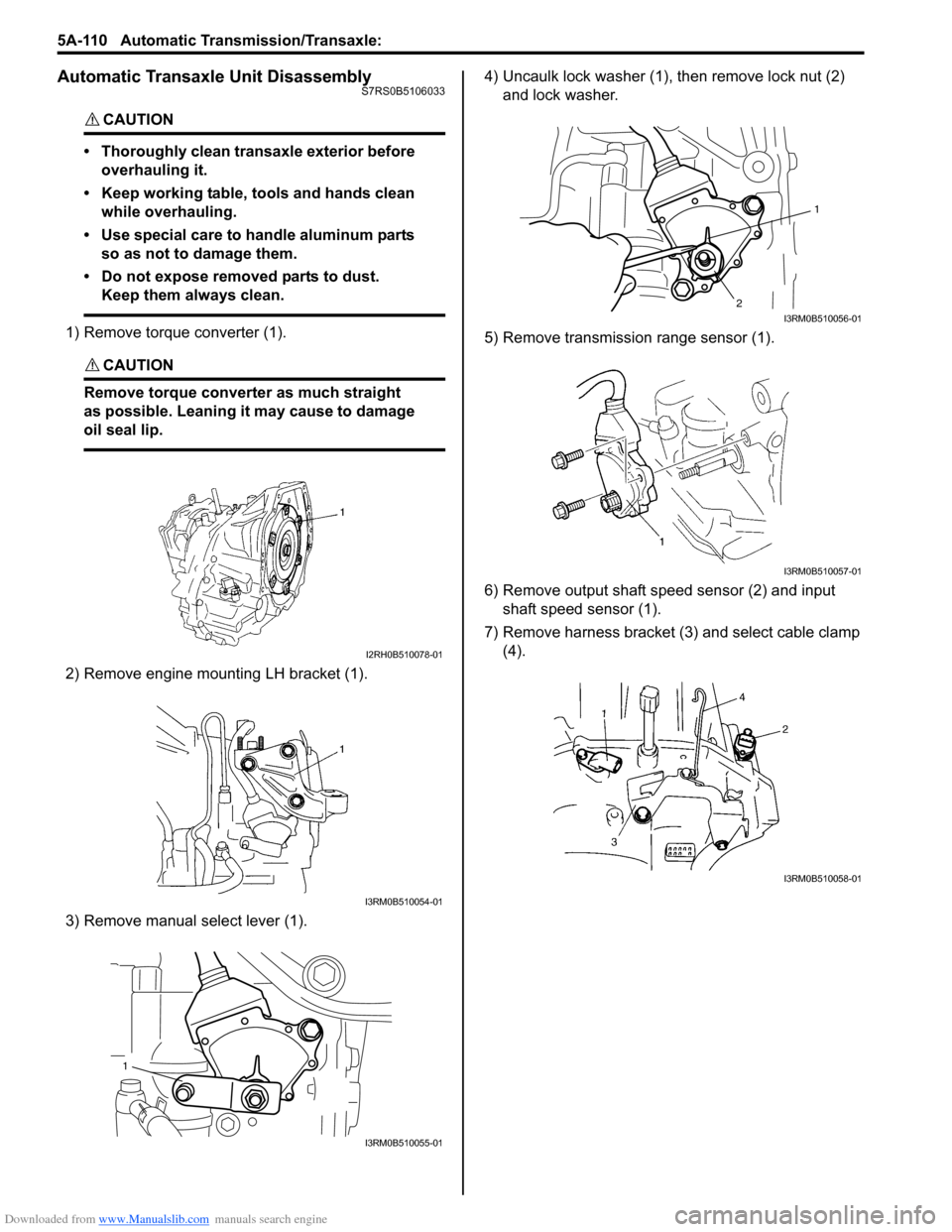

Automatic Transaxle Unit DisassemblyS7RS0B5106033

CAUTION!

• Thoroughly clean transaxle exterior before overhauling it.

• Keep working table, tools and hands clean while overhauling.

• Use special care to handle aluminum parts so as not to damage them.

• Do not expose removed parts to dust. Keep them always clean.

1) Remove torque converter (1).

CAUTION!

Remove torque converte r as much straight

as possible. Leaning it may cause to damage

oil seal lip.

2) Remove engine mounting LH bracket (1).

3) Remove manual select lever (1). 4) Uncaulk lock washer (1),

then remove lock nut (2)

and lock washer.

5) Remove transmission range sensor (1).

6) Remove output shaft speed sensor (2) and input shaft speed sensor (1).

7) Remove harness bracket (3) and select cable clamp (4).

I2RH0B510078-01

I3RM0B510054-01

1

I3RM0B510055-01

1

2

I3RM0B510056-01

I3RM0B510057-01

I3RM0B510058-01

Page 760 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-116 Automatic Transmission/Transaxle:

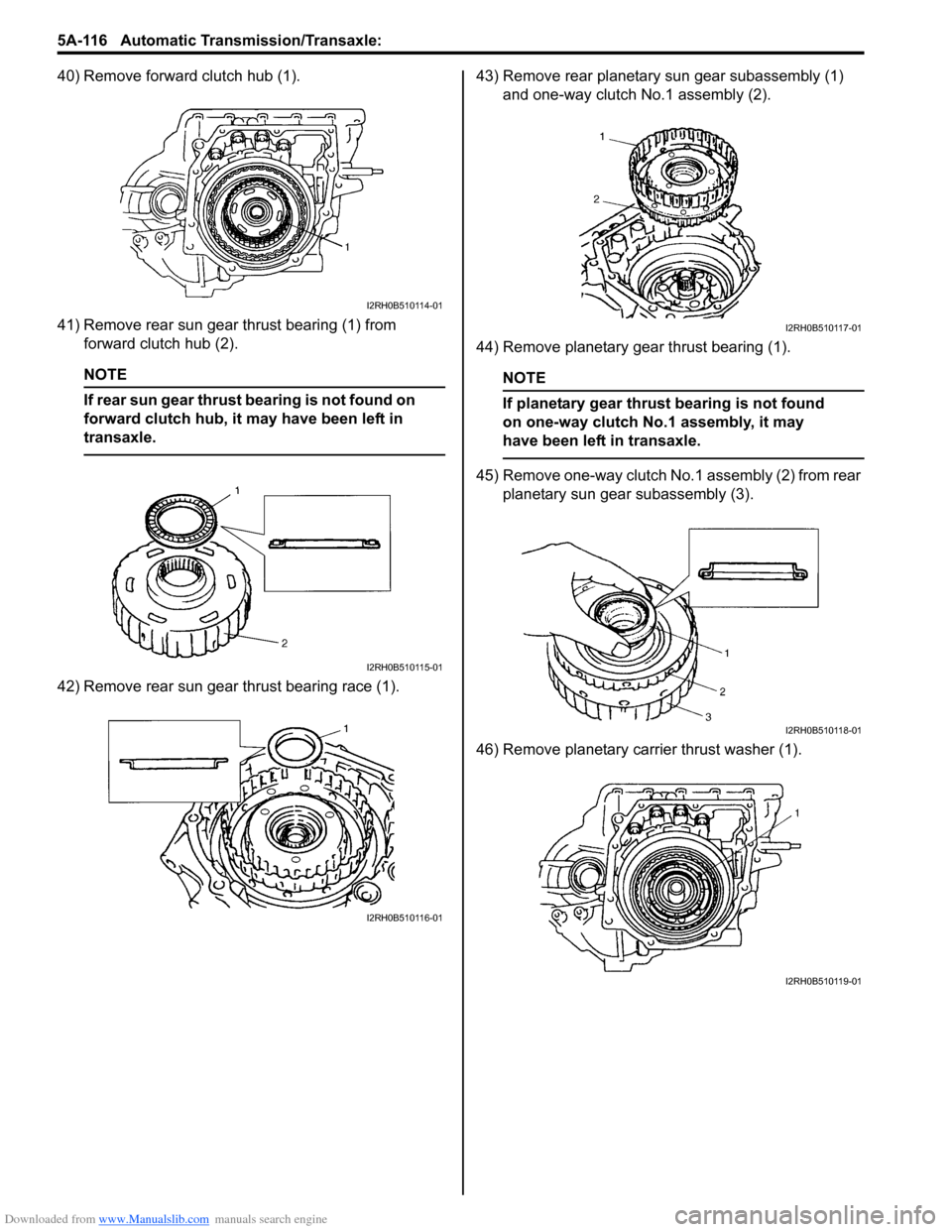

40) Remove forward clutch hub (1).

41) Remove rear sun gear thrust bearing (1) from forward clutch hub (2).

NOTE

If rear sun gear thrust bearing is not found on

forward clutch hub, it may have been left in

transaxle.

42) Remove rear sun gear thrust bearing race (1). 43) Remove rear planetary sun gear subassembly (1)

and one-way clutch No.1 assembly (2).

44) Remove planetary gear thrust bearing (1).

NOTE

If planetary gear thrust bearing is not found

on one-way clutch No.1 assembly, it may

have been left in transaxle.

45) Remove one-way clutch No.1 assembly (2) from rear planetary sun gear subassembly (3).

46) Remove planetary carrier thrust washer (1).

I2RH0B510114-01

I2RH0B510115-01

I2RH0B510116-01

I2RH0B510117-01

I2RH0B510118-01

I2RH0B510119-01

Page 799 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-155

26) Apply A/T fluid to 2nd brake piston assembly (1), and align the projection of 2nd brake piston assembly

with the groove of transaxle case, then put together.

27) Install 2nd brake piston snap ring (1) by using special tool and hydraulic press.

CAUTION!

Do not damage 2nd brake piston assembly,

return spring subassembly, plates and discs

by pressing in 2nd brake assembly passing

through its original installing position over

0.4 mm (0.016 in.).

Special tool

(A): 09926–96050

28) After applying A/T fluid to front sun gear thrust bearing race (2), install it to front planetary sun gear

(1). 29) Apply A/T fluid to front planetary sun gear (1) and

install it to planetary gear assembly (2).

30) Install O/D and 2nd coast brake retaining plate snap ring (1).

CAUTION!

Be sure to install O/D and 2nd coast brake

retaining plate snap ring correctly in groove

of transaxle case.

31) After applying grease to slide contact face of planetary carrier thrust washer (1), install it to

planetary gear assembly.

“A”: Grease 99000–25030 (SUZUKI Super

Grease C)

I2RH0B510282-01

I2RH0B510283-01

I2RH0B510285-01

I2RH0B510286-01

I2RH0B510287-01

I2RH0B510288-01

Page 809 of 1496

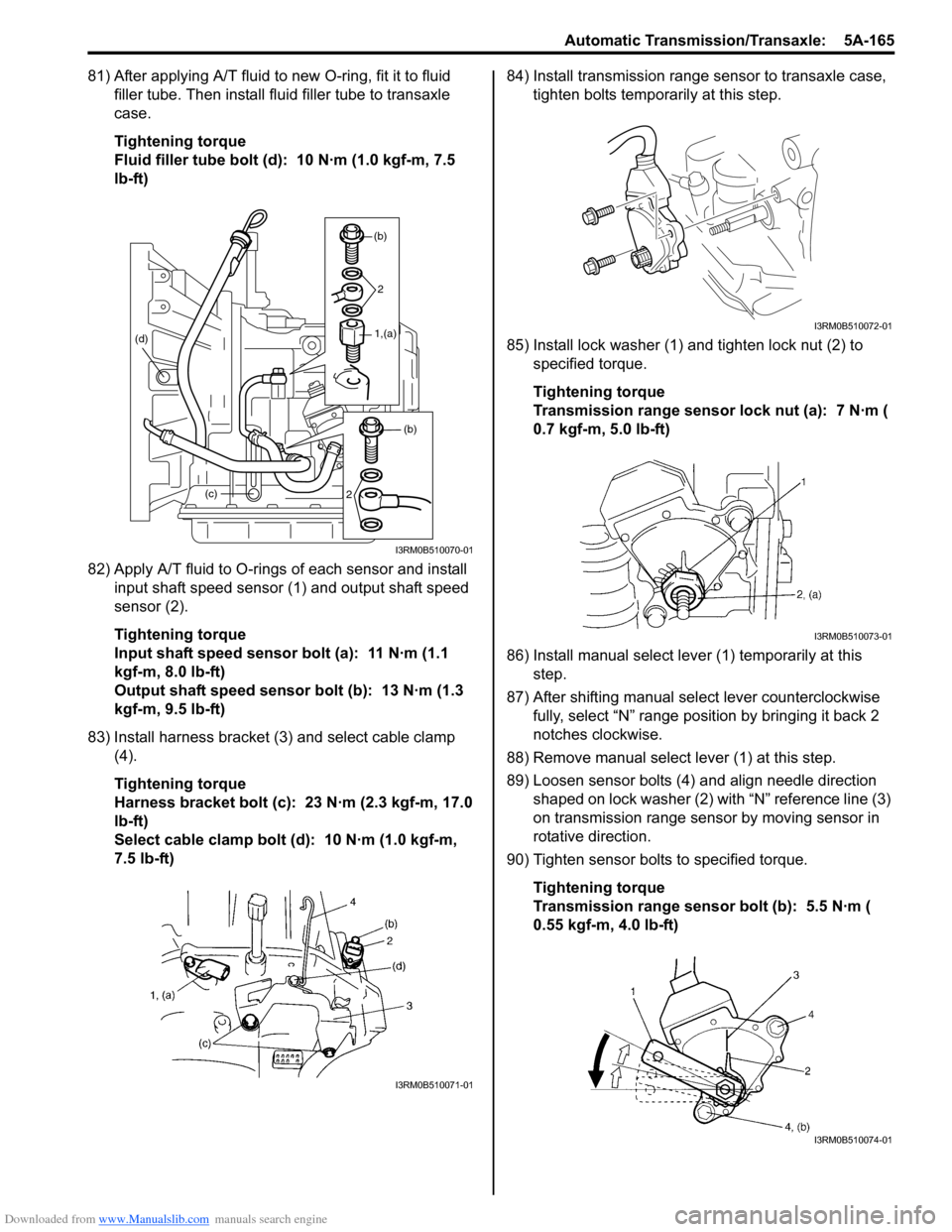

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-165

81) After applying A/T fluid to new O-ring, fit it to fluid filler tube. Then install fl uid filler tube to transaxle

case.

Tightening torque

Fluid filler tube bolt (d): 10 N·m (1.0 kgf-m, 7.5

lb-ft)

82) Apply A/T fluid to O-rings of each sensor and install input shaft speed sensor (1) and output shaft speed

sensor (2).

Tightening torque

Input shaft speed sensor bolt (a): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

Output shaft speed sensor bolt (b): 13 N·m (1.3

kgf-m, 9.5 lb-ft)

83) Install harness bracket (3) and select cable clamp (4).

Tightening torque

Harness bracket bolt (c): 23 N·m (2.3 kgf-m, 17.0

lb-ft)

Select cable clamp bolt (d): 10 N·m (1.0 kgf-m,

7.5 lb-ft) 84) Install transmission range sensor to transaxle case,

tighten bolts temporarily at this step.

85) Install lock washer (1) and tighten lock nut (2) to specified torque.

Tightening torque

Transmission range sensor lock nut (a): 7 N·m (

0.7 kgf-m, 5.0 lb-ft)

86) Install manual select leve r (1) temporarily at this

step.

87) After shifting manual se lect lever counterclockwise

fully, select “N” range position by bringing it back 2

notches clockwise.

88) Remove manual select lever (1) at this step.

89) Loosen sensor bolts (4) and align needle direction shaped on lock washer (2) with “N” reference line (3)

on transmission range sensor by moving sensor in

rotative direction.

90) Tighten sensor bolts to specified torque.

Tightening torque

Transmission range sensor bolt (b): 5.5 N·m (

0.55 kgf-m, 4.0 lb-ft)

(c)

(d)

(b)

2

1,(a)

(b)

2

I3RM0B510070-01

I3RM0B510071-01

I3RM0B510072-01

I3RM0B510073-01

I3RM0B510074-01

Page 810 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-166 Automatic Transmission/Transaxle:

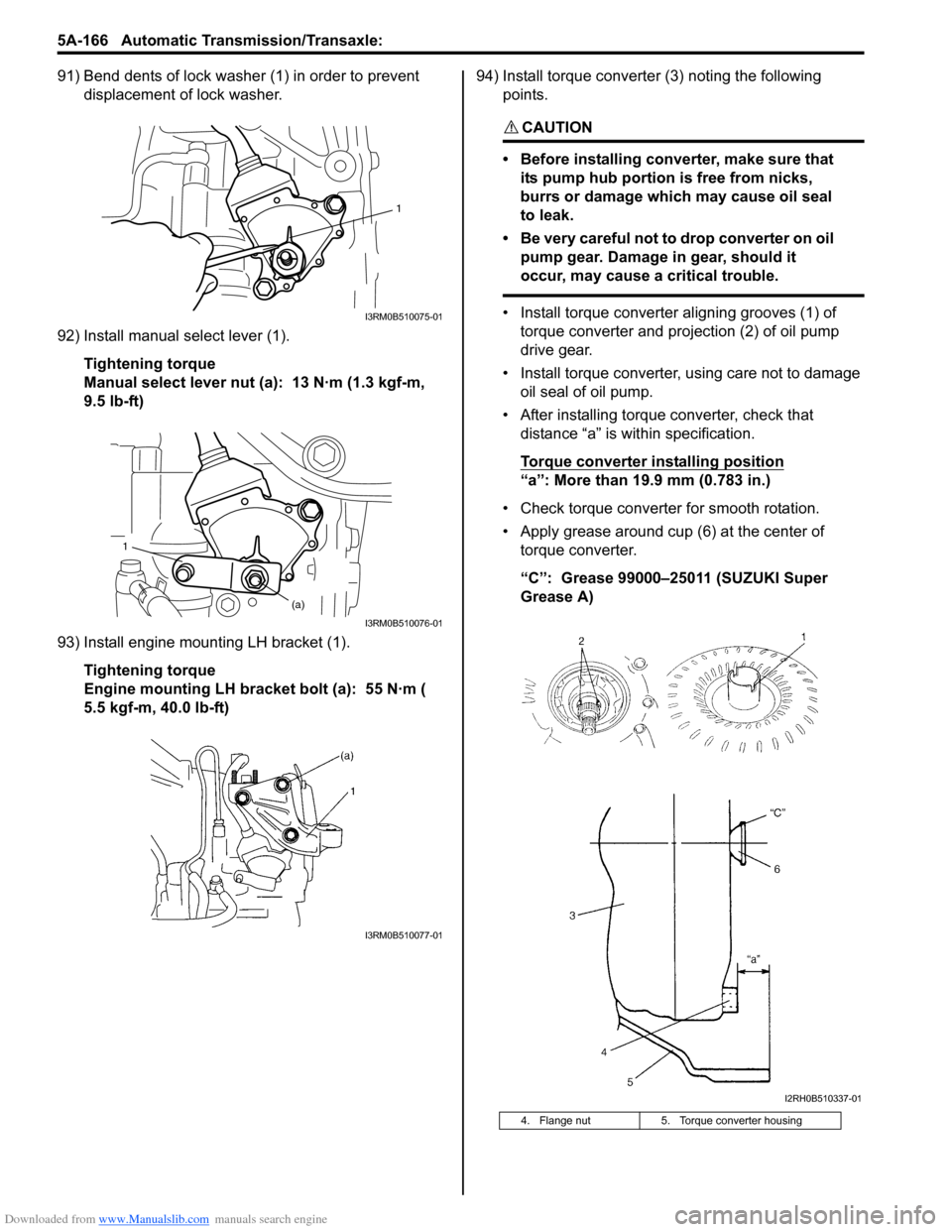

91) Bend dents of lock washer (1) in order to prevent displacement of lock washer.

92) Install manual select lever (1). Tightening torque

Manual select lever nut (a): 13 N·m (1.3 kgf-m,

9.5 lb-ft)

93) Install engine mounting LH bracket (1). Tightening torque

Engine mounting LH bracket bolt (a): 55 N·m (

5.5 kgf-m, 40.0 lb-ft) 94) Install torque converter (3) noting the following

points.

CAUTION!

• Before installing converter, make sure that its pump hub portion is free from nicks,

burrs or damage which may cause oil seal

to leak.

• Be very careful not to drop converter on oil pump gear. Damage in gear, should it

occur, may cause a critical trouble.

• Install torque converter aligning grooves (1) of torque converter and projection (2) of oil pump

drive gear.

• Install torque converter, using care not to damage oil seal of oil pump.

• After installing torque converter, check that distance “a” is within specification.

Torque converter installing position

“a”: More than 19.9 mm (0.783 in.)

• Check torque converter for smooth rotation.

• Apply grease around cup (6) at the center of torque converter.

“C”: Grease 99000–25011 (SUZUKI Super

Grease A)

1

I3RM0B510075-01

1

(a)

I3RM0B510076-01

I3RM0B510077-01

4. Flange nut 5. Torque converter housing

I2RH0B510337-01