instrument SUZUKI SWIFT 2008 2.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 1021 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-73

HVAC Unit Removal and InstallationS7RS0B7226003

Refer to “HVAC Unit Removal and Installation”.

Temperature Control Actuator Removal and

Installation

S7RS0B7226004

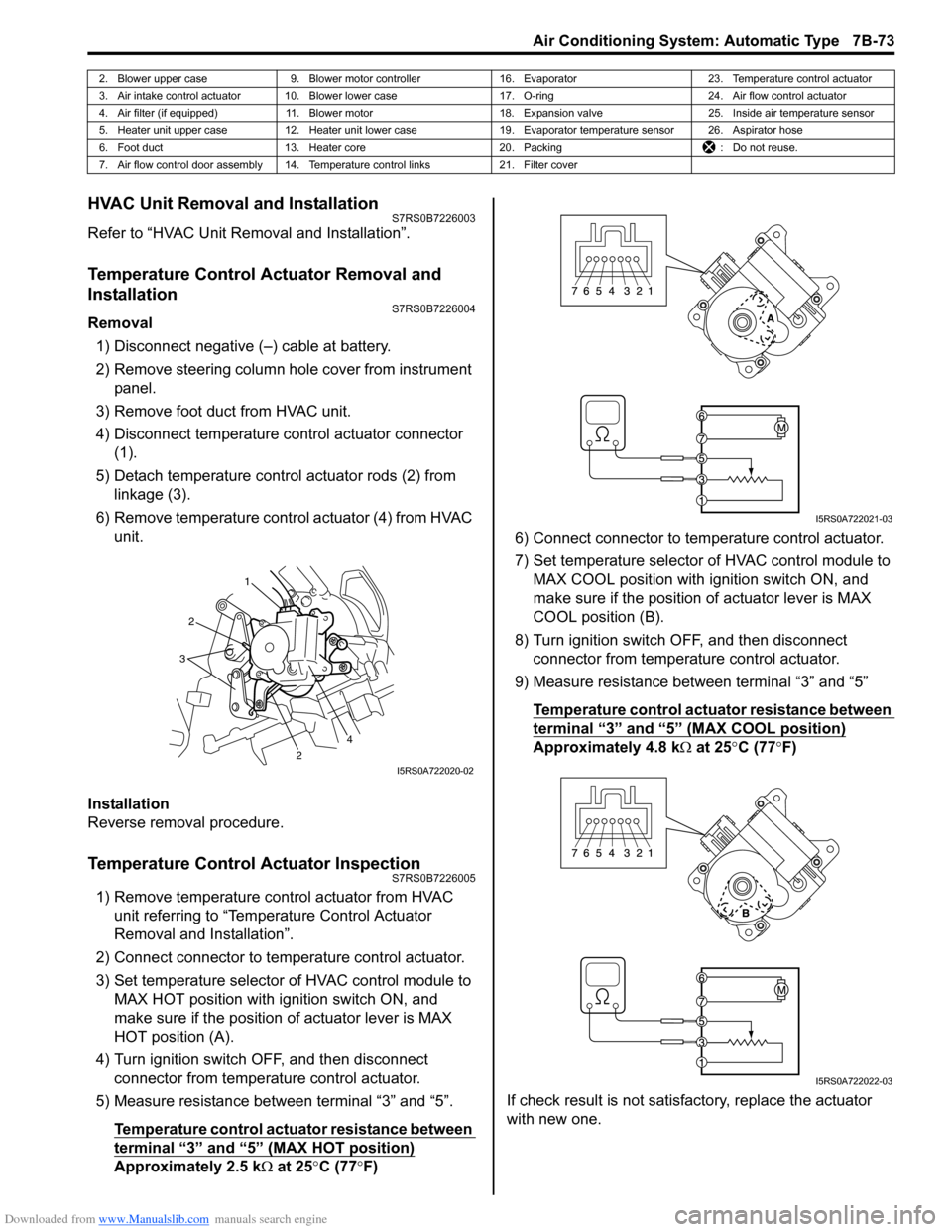

Removal1) Disconnect negative (–) cable at battery.

2) Remove steering column hol e cover from instrument

panel.

3) Remove foot duct from HVAC unit.

4) Disconnect temperature control actuator connector (1).

5) Detach temperature control actuator rods (2) from linkage (3).

6) Remove temperature control actuator (4) from HVAC unit.

Installation

Reverse removal procedure.

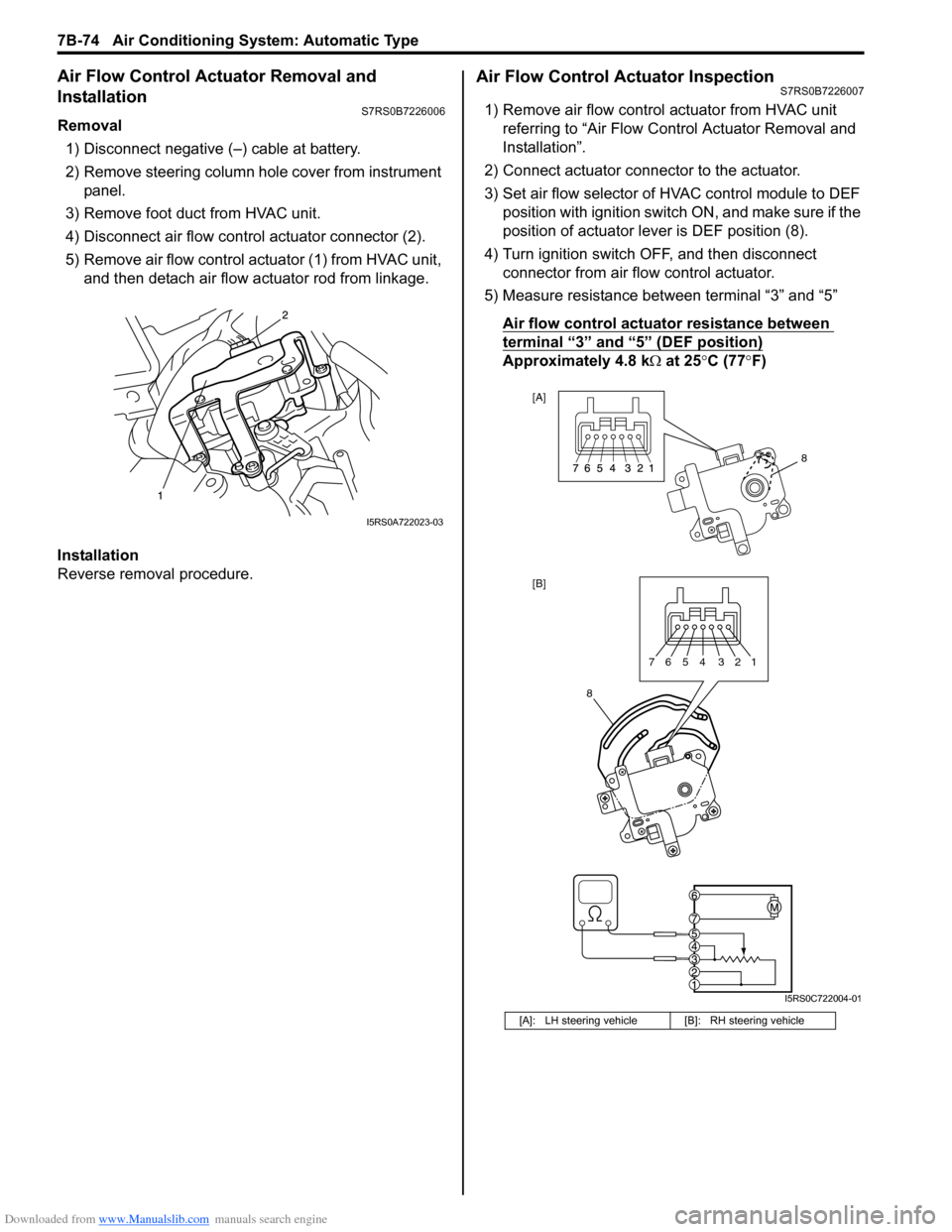

Temperature Control Actuator InspectionS7RS0B7226005

1) Remove temperature control actuator from HVAC unit referring to “Temperature Control Actuator

Removal and Installation”.

2) Connect connector to temperature control actuator.

3) Set temperature selector of HVAC control module to MAX HOT position with ignition switch ON, and

make sure if the position of actuator lever is MAX

HOT position (A).

4) Turn ignition switch OFF, and then disconnect connector from temperature control actuator.

5) Measure resistance between terminal “3” and “5”.

Temperature control actuator resistance between

terminal “3” and “5” (MAX HOT position)

Approximately 2.5 k Ω at 25 °C (77 °F) 6) Connect connector to tem

perature control actuator.

7) Set temperature selector of HVAC control module to MAX COOL position with ignition switch ON, and

make sure if the position of actuator lever is MAX

COOL position (B).

8) Turn ignition switch OFF, and then disconnect connector from temperature control actuator.

9) Measure resistance between terminal “3” and “5”

Temperature control actuator resistance between

terminal “3” and “5” (MAX COOL position)

Approximately 4.8 k Ω at 25 °C (77 °F)

If check result is not satisfactory, replace the actuator

with new one.

2. Blower upper case 9. Blower motor controller 16. Evaporator 23. Temperature control actuator

3. Air intake control actuator 10. Blower lower case 17. O-ring24. Air flow control actuator

4. Air filter (if equipped) 11. Blower motor 18. Expansion valve25. Inside air temperature sensor

5. Heater unit upper case 12. Heater unit lower case 19. Evaporator temperature sensor 26. Aspirator hose

6. Foot duct 13. Heater core 20. Packing : Do not reuse.

7. Air flow control door assembly 14. Temperature control links 21. Filter cover

1

2

2

3

4

I5RS0A722020-02

I5RS0A722021-03

I5RS0A722022-03

Page 1022 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-74 Air Conditioning System: Automatic Type

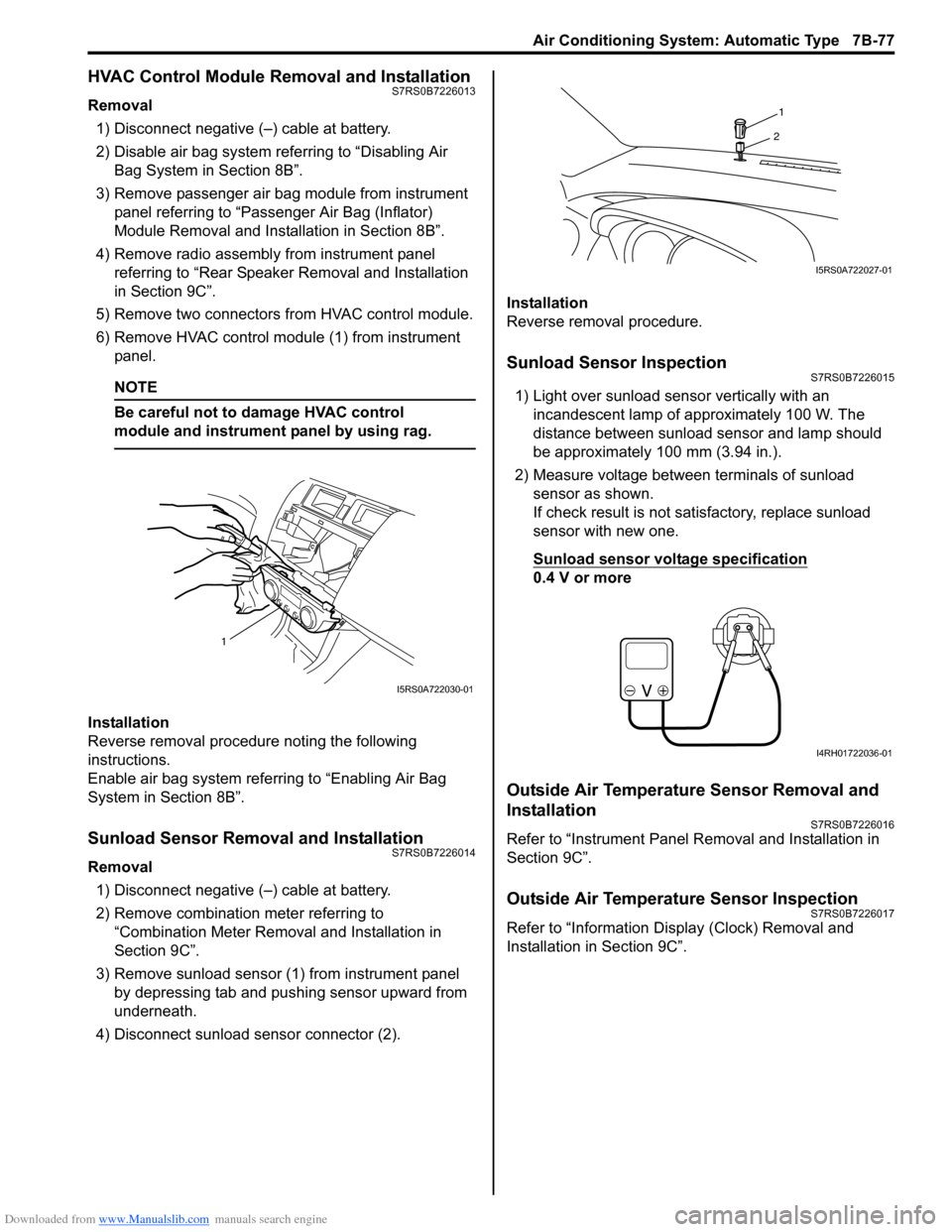

Air Flow Control Actuator Removal and

Installation

S7RS0B7226006

Removal1) Disconnect negative (–) cable at battery.

2) Remove steering column hol e cover from instrument

panel.

3) Remove foot duct from HVAC unit.

4) Disconnect air flow contro l actuator connector (2).

5) Remove air flow control actuator (1) from HVAC unit, and then detach air flow actuator rod from linkage.

Installation

Reverse removal procedure.

Air Flow Control Actuator InspectionS7RS0B7226007

1) Remove air flow control actuator from HVAC unit referring to “Air Flow C ontrol Actuator Removal and

Installation”.

2) Connect actuator connector to the actuator.

3) Set air flow selector of HVAC control module to DEF position with ignition switch ON, and make sure if the

position of actuator lever is DEF position (8).

4) Turn ignition switch OFF, and then disconnect connector from air flow control actuator.

5) Measure resistance between terminal “3” and “5”

Air flow control actuator resistance between

terminal “3” and “5” (DEF position)

Approximately 4.8 k Ω at 25 °C (77 °F)

I5RS0A722023-03

[A]: LH steering vehicle [B]: RH steering vehicle

8

[A]

[B]

8

7654 321

I5RS0C722004-01

Page 1025 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-77

HVAC Control Module Removal and InstallationS7RS0B7226013

Removal1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove passenger air bag module from instrument panel referring to “Passenger Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

4) Remove radio assembly from instrument panel referring to “Rear Speaker Removal and Installation

in Section 9C”.

5) Remove two connectors fr om HVAC control module.

6) Remove HVAC control modu le (1) from instrument

panel.

NOTE

Be careful not to damage HVAC control

module and instrument panel by using rag.

Installation

Reverse removal procedure noting the following

instructions.

Enable air bag system referring to “Enabling Air Bag

System in Section 8B”.

Sunload Sensor Removal and InstallationS7RS0B7226014

Removal

1) Disconnect negative (–) cable at battery.

2) Remove combination meter referring to “Combination Meter Removal and Installation in

Section 9C”.

3) Remove sunload sensor (1) from instrument panel by depressing tab and pushing sensor upward from

underneath.

4) Disconnect sunload sensor connector (2). Installation

Reverse removal procedure.

Sunload Sensor InspectionS7RS0B7226015

1) Light over sunload sensor vertically with an

incandescent lamp of approximately 100 W. The

distance between sunload sensor and lamp should

be approximately 100 mm (3.94 in.).

2) Measure voltage between terminals of sunload sensor as shown.

If check result is not satisfactory, replace sunload

sensor with new one.

Sunload sensor voltage specification

0.4 V or more

Outside Air Temperature Sensor Removal and

Installation

S7RS0B7226016

Refer to “Instrument Panel Re moval and Installation in

Section 9C”.

Outside Air Temperature Sensor InspectionS7RS0B7226017

Refer to “Information Display (Clock) Removal and

Installation in Section 9C”.

1

I5RS0A722030-01

1

2

I5RS0A722027-01

I4RH01722036-01

Page 1026 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-78 Air Conditioning System: Automatic Type

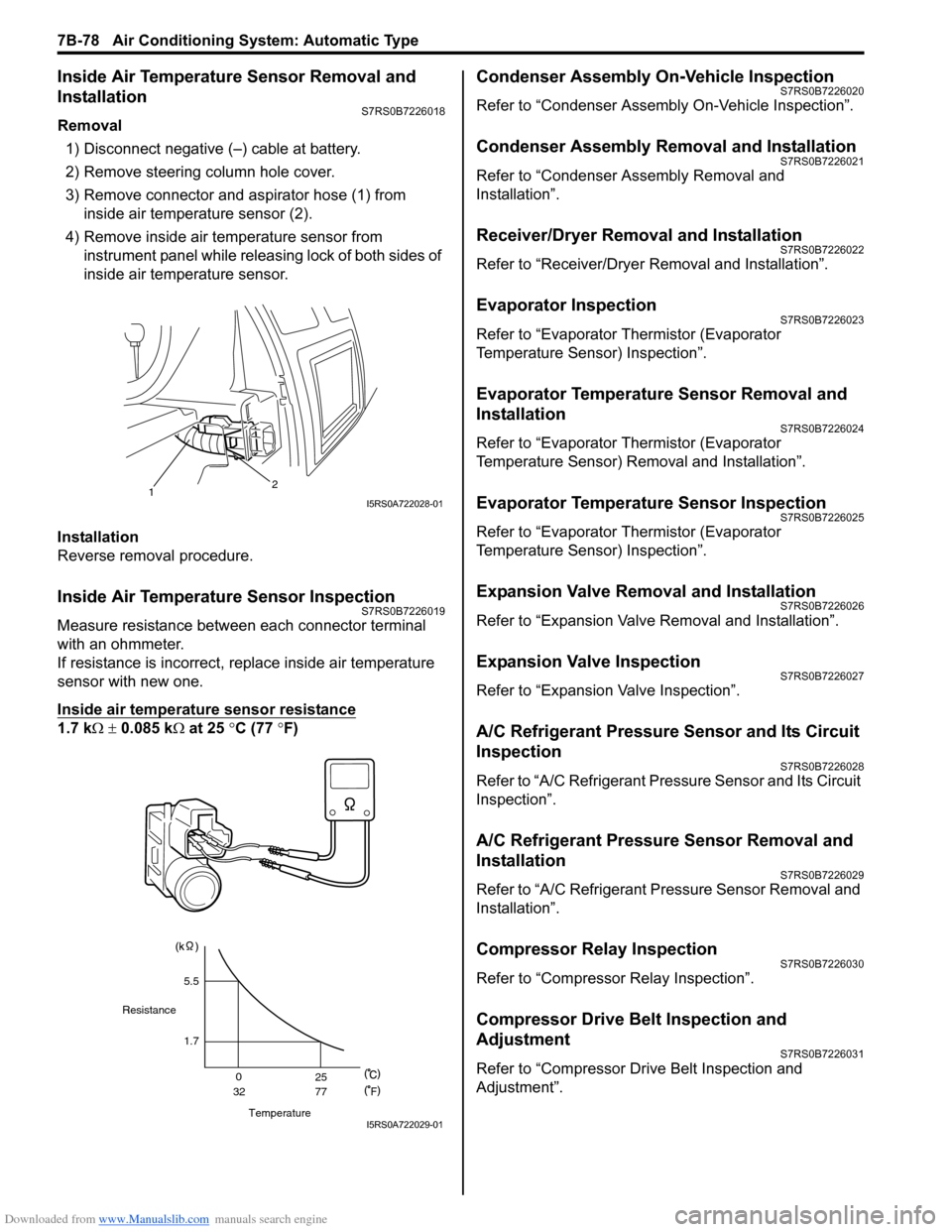

Inside Air Temperature Sensor Removal and

Installation

S7RS0B7226018

Removal1) Disconnect negative (–) cable at battery.

2) Remove steering column hole cover.

3) Remove connector and aspirator hose (1) from inside air temperature sensor (2).

4) Remove inside air temperature sensor from instrument panel while releas ing lock of both sides of

inside air temperature sensor.

Installation

Reverse removal procedure.

Inside Air Temperature Sensor InspectionS7RS0B7226019

Measure resistance between each connector terminal

with an ohmmeter.

If resistance is incorrect, replace inside air temperature

sensor with new one.

Inside air temperature sensor resistance

1.7 k Ω ± 0.085 k Ω at 25 °C (77 ° F)

Condenser Assembly On-Vehicle InspectionS7RS0B7226020

Refer to “Condenser Assembly On-Vehicle Inspection”.

Condenser Assembly Removal and InstallationS7RS0B7226021

Refer to “Condenser Assembly Removal and

Installation”.

Receiver/Dryer Removal and InstallationS7RS0B7226022

Refer to “Receiver/Dryer Removal and Installation”.

Evaporator InspectionS7RS0B7226023

Refer to “Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Evaporator Temperature Sensor Removal and

Installation

S7RS0B7226024

Refer to “Evaporator Thermistor (Evaporator

Temperature Sensor) Removal and Installation”.

Evaporator Temperature Sensor InspectionS7RS0B7226025

Refer to “Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection”.

Expansion Valve Removal and InstallationS7RS0B7226026

Refer to “Expansion Valve Removal and Installation”.

Expansion Valve InspectionS7RS0B7226027

Refer to “Expansion Valve Inspection”.

A/C Refrigerant Pressure Sensor and Its Circuit

Inspection

S7RS0B7226028

Refer to “A/C Refrigerant Pressure Sensor and Its Circuit

Inspection”.

A/C Refrigerant Pressure Sensor Removal and

Installation

S7RS0B7226029

Refer to “A/C Refrigerant Pressure Sensor Removal and

Installation”.

Compressor Relay InspectionS7RS0B7226030

Refer to “Compressor Relay Inspection”.

Compressor Drive Belt Inspection and

Adjustment

S7RS0B7226031

Refer to “Compressor Drive Belt Inspection and

Adjustment”.

12I5RS0A722028-01

Temperature

Resistance

1.7

0

32 25

77

F

5.5

I5RS0A722029-01

Page 1042 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-4 Air Bag System:

WARNING!

Never attempt to measure the resistance of

the seat belt pretensioners. It is very

dangerous as the electric current from the

tester may activate pretensioner.

• Never attempt to disassemble the seat belt

pretensioners (retractor assembly).

• If any abnormality is found, be sure to replace it with

new one as an assembly.

• When an abnormality is noted as existing in the live (inactivated) seat belt preten sioner, be sure to activate

it before discarding it.

• When grease, cleaning agent oil, water, etc., got on the seat belt pretensioners (r etractor assembly), wipe

it off immediately with a dry cloth.

• If seat belt pretensioner was dropped from a height of 30 cm (1 ft) or more, it should be replaced with a new

one as an assembly.

WARNING!

• For handling and storage of a live seat belt pretensioner, select a place where the

ambient temperature below 65 °C (150 ° F),

without high humidity and away from

electric noise.

• Never carry the seat belt pretensioner by webbing.

• When placing a live seat belt pretensioner on the workbench or other surface, be sure

not to lay it with its exhaust hole (1)

provided side facing down. It is also

prohibited to put something on its face

with an exhaust hole (1) or to put a seat

belt pretensioner on top of another.

Otherwise, personal injury may result.

Deployed Air Bag (Inflator) Module and Activated

Seat Belt Pretensioner

WARNING!

• The air bag (inflator) module and seat belt

pretensioner immediately after

deployment/activation is very hot. Wait for

at least 30 minutes to cool it off before

proceeding the work.

• Do not apply water, oil, etc. to deployed air bag (inflator) module and to activate seat

belt pretensioner.

• After an air bag (inflator) module has been deployed, the surface of the air bag may

contain a powdery residue. This powder

consists primarily of cornstarch (used to

lubricate the bag as it inflates) and by-

products of the chemical reaction. As with

many service procedures, gloves and

safety glasses should be worn.

• Wash your hands with mild soap and water after completing the work.

Refer to the procedure described under “Deployed Air

Bag (Inflator) Module and Activated Seat Belt

Pretensioner Disposal” for disposal.

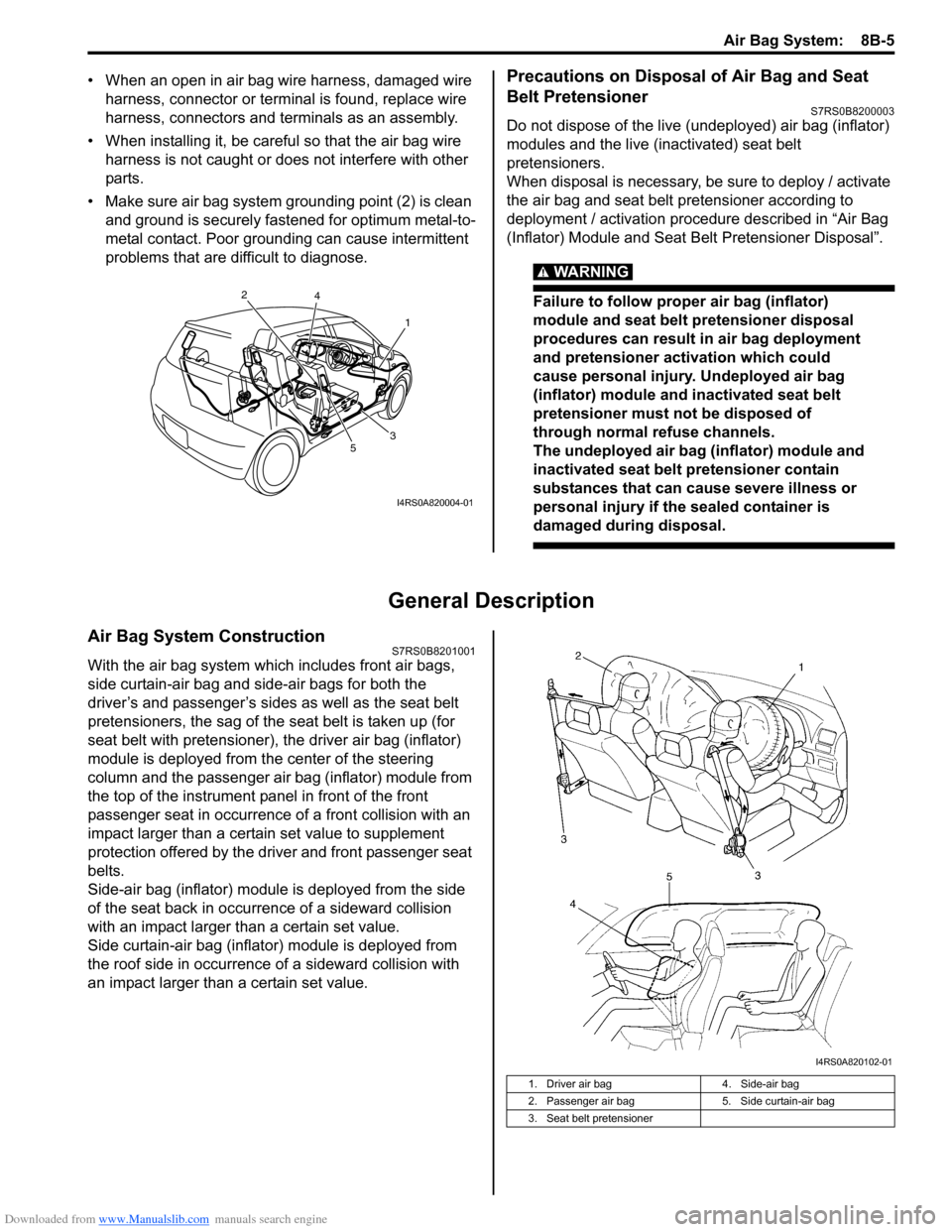

Air Bag Wire Harness and Connector

Air bag wire harness is includ ed in main harness (1),

instrument panel harness (4), floor harness (3) and seat

harness (5). Air bag wire harness can be identified easily

as the part of connector side wire harness is covered

with a yellow protection tube. Be very careful when

handling it.

I2RH01820047-01

1

I2RH01820048-01

Page 1043 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-5

• When an open in air bag wire harness, damaged wire harness, connector or terminal is found, replace wire

harness, connectors and terminals as an assembly.

• When installing it, be careful so that the air bag wire harness is not caught or does not interfere with other

parts.

• Make sure air bag system grounding point (2) is clean and ground is securely fastened for optimum metal-to-

metal contact. Poor grounding can cause intermittent

problems that are difficult to diagnose.Precautions on Disposal of Air Bag and Seat

Belt Pretensioner

S7RS0B8200003

Do not dispose of the live (undeployed) air bag (inflator)

modules and the live (inactivated) seat belt

pretensioners.

When disposal is necessary, be sure to deploy / activate

the air bag and seat belt pretensioner according to

deployment / activation procedure described in “Air Bag

(Inflator) Module and Seat Belt Pretensioner Disposal”.

WARNING!

Failure to follow proper air bag (inflator)

module and seat belt pretensioner disposal

procedures can result in air bag deployment

and pretensioner activation which could

cause personal injury. Undeployed air bag

(inflator) module and inactivated seat belt

pretensioner must not be disposed of

through normal refuse channels.

The undeployed air bag (inflator) module and

inactivated seat belt pretensioner contain

substances that can cause severe illness or

personal injury if the sealed container is

damaged during disposal.

General Description

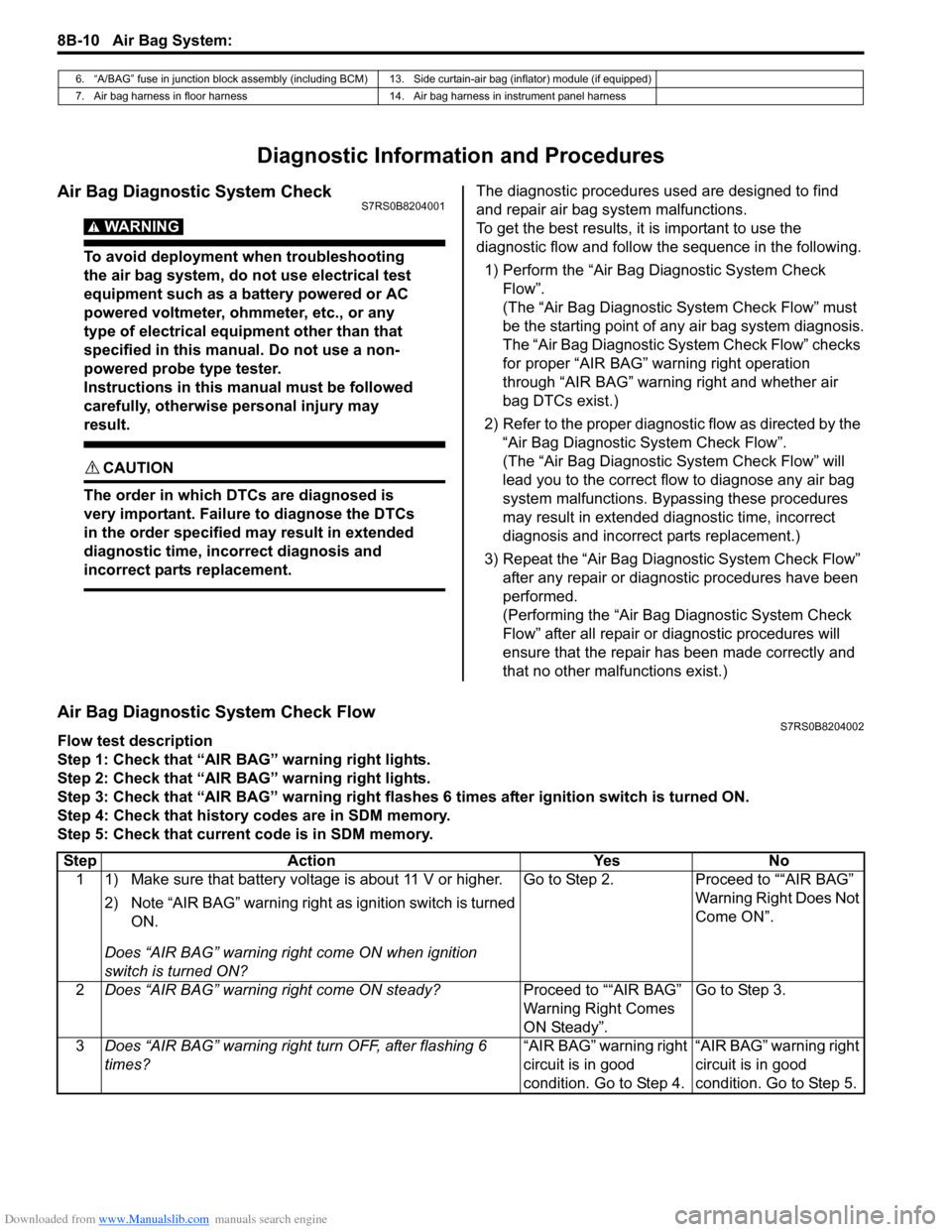

Air Bag System ConstructionS7RS0B8201001

With the air bag system which includes front air bags,

side curtain-air bag and side-air bags for both the

driver’s and passenger’s sides as well as the seat belt

pretensioners, the sag of the s eat belt is taken up (for

seat belt with pretensioner), the driver air bag (inflator)

module is deployed from th e center of the steering

column and the passenger air bag (inflator) module from

the top of the instrument panel in front of the front

passenger seat in occurrence of a front collision with an

impact larger than a certain set value to supplement

protection offered by the driver and front passenger seat

belts.

Side-air bag (inflator) module is deployed from the side

of the seat back in occurrence of a sideward collision

with an impact larger than a certain set value.

Side curtain-air bag (inflator) module is deployed from

the roof side in occurrence of a sideward collision with

an impact larger than a certain set value.

1

2

3

4

5

I4RS0A820004-01

1. Driver air bag 4. Side-air bag

2. Passenger air bag 5. Side curtain-air bag

3. Seat belt pretensioner

I4RS0A820102-01

Page 1048 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-10 Air Bag System:

Diagnostic Information and Procedures

Air Bag Diagnostic System CheckS7RS0B8204001

WARNING!

To avoid deployment when troubleshooting

the air bag system, do not use electrical test

equipment such as a battery powered or AC

powered voltmeter, ohmmeter, etc., or any

type of electrical equipment other than that

specified in this manual. Do not use a non-

powered probe type tester.

Instructions in this manual must be followed

carefully, otherwise personal injury may

result.

CAUTION!

The order in which DTCs are diagnosed is

very important. Failure to diagnose the DTCs

in the order specified may result in extended

diagnostic time, incorrect diagnosis and

incorrect parts replacement.

The diagnostic procedures used are designed to find

and repair air bag system malfunctions.

To get the best results, it is important to use the

diagnostic flow and follow the sequence in the following.1) Perform the “Air Bag Diagnostic System Check Flow”.

(The “Air Bag Diagnostic System Check Flow” must

be the starting point of any air bag system diagnosis.

The “Air Bag Diagnostic System Check Flow” checks

for proper “AIR BAG” warning right operation

through “AIR BAG” warning right and whether air

bag DTCs exist.)

2) Refer to the proper diagnost ic flow as directed by the

“Air Bag Diagnostic System Check Flow”.

(The “Air Bag Diagnostic System Check Flow” will

lead you to the correct flow to diagnose any air bag

system malfunctions. Bypassing these procedures

may result in extended diagnostic time, incorrect

diagnosis and incorrect parts replacement.)

3) Repeat the “Air Bag Diagnostic System Check Flow” after any repair or diagnostic procedures have been

performed.

(Performing the “Air Bag Diagnostic System Check

Flow” after all repair or diagnostic procedures will

ensure that the repair has been made correctly and

that no other malfunctions exist.)

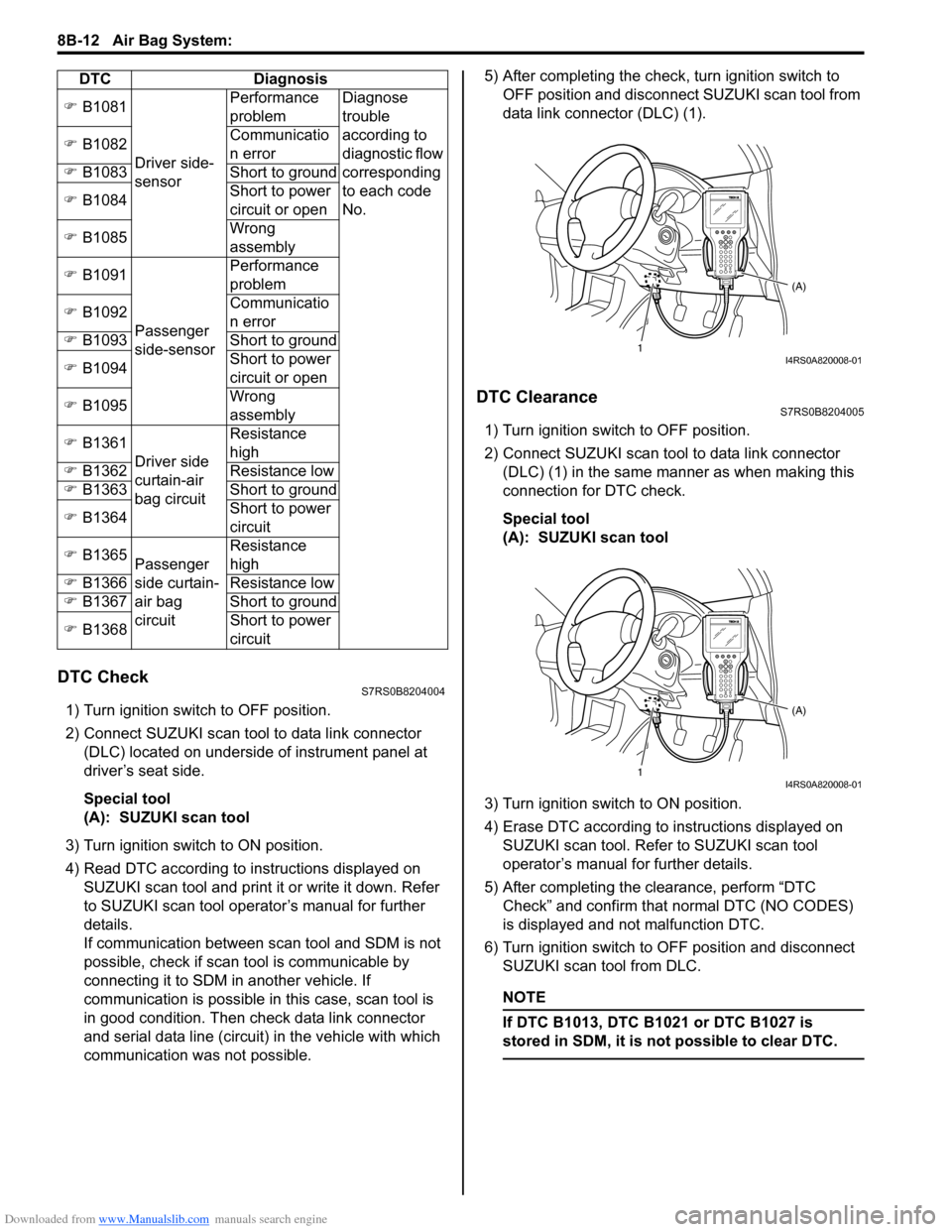

Air Bag Diagnostic System Check FlowS7RS0B8204002

Flow test description

Step 1: Check that “AIR BAG” warning right lights.

Step 2: Check that “AIR BAG” warning right lights.

Step 3: Check that “AIR BAG” warning right flas hes 6 times after ignition switch is turned ON.

Step 4: Check that history codes are in SDM memory.

Step 5: Check that current code is in SDM memory.

6. “A/BAG” fuse in junction block assembly (including BCM) 13. Side curtain-air bag (inflator) module (if equipped)

7. Air bag harness in floor harness 14. Air bag harness in instrument panel harness

Step Action YesNo

1 1) Make sure that battery voltage is about 11 V or higher.

2) Note “AIR BAG” warning right as ignition switch is turned

ON.

Does “AIR BAG” warning ri ght come ON when ignition

switch is turned ON? Go to Step 2.

Proceed to ““AIR BAG”

Warning Right Does Not

Come ON”.

2 Does “AIR BAG” warning right come ON steady? Proceed to ““AIR BAG”

Warning Right Comes

ON Steady”.Go to Step 3.

3 Does “AIR BAG” warning right turn OFF, after flashing 6

times? “AIR BAG” warning right

circuit is in good

condition. Go to Step 4.“AIR BAG” warning right

circuit is in good

condition. Go to Step 5.

Page 1050 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-12 Air Bag System:

DTC CheckS7RS0B8204004

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (DLC) located on underside of instrument panel at

driver’s seat side.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch to ON position.

4) Read DTC according to instructions displayed on SUZUKI scan tool and print it or write it down. Refer

to SUZUKI scan tool operator’s manual for further

details.

If communication between scan tool and SDM is not

possible, check if scan tool is communicable by

connecting it to SDM in another vehicle. If

communication is possible in this case, scan tool is

in good condition. Then check data link connector

and serial data line (circuit) in the vehicle with which

communication was not possible. 5) After completing the check,

turn ignition switch to

OFF position and disconnect SUZUKI scan tool from

data link connector (DLC) (1).

DTC ClearanceS7RS0B8204005

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (DLC) (1) in the same manner as when making this

connection for DTC check.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch to ON position.

4) Erase DTC according to instructions displayed on

SUZUKI scan tool. Refer to SUZUKI scan tool

operator’s manual for further details.

5) After completing the clearance, perform “DTC Check” and confirm that normal DTC (NO CODES)

is displayed and not malfunction DTC.

6) Turn ignition switch to OFF position and disconnect SUZUKI scan tool from DLC.

NOTE

If DTC B1013, DTC B1 021 or DTC B1027 is

stored in SDM, it is not possible to clear DTC.

�) B1081

Driver side-

sensor Performance

problem

Diagnose

trouble

according to

diagnostic flow

corresponding

to each code

No.

�)

B1082 Communicatio

n error

�) B1083 Short to ground

�) B1084 Short to power

circuit or open

�) B1085 Wrong

assembly

�) B1091

Passenger

side-sensor Performance

problem

�) B1092 Communicatio

n error

�) B1093 Short to ground

�) B1094 Short to power

circuit or open

�) B1095 Wrong

assembly

�) B1361

Driver side

curtain-air

bag circuit Resistance

high

�) B1362 Resistance low

�) B1363 Short to ground

�) B1364 Short to power

circuit

�) B1365

Passenger

side curtain-

air bag

circuit Resistance

high

�) B1366 Resistance low

�) B1367 Short to ground

�) B1368 Short to power

circuit

DTC Diagnosis

1

(A)I4RS0A820008-01

1(A)I4RS0A820008-01

Page 1063 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-25

DTC Will Set when

The combined resistance of the driver air bag (inflator) module, contact coil assembly, harness wiring and connector

terminal contact is above a spec ified value for specified time.

Flow Test Description

Step 1: Check whether malfunction is in contact coil and driver air bag (inflator) module or the others.

Step 2: Check driver air bag (inflator) module initiator circuit. (in instrument panel and floor harness)

Step 3: Check driver air bag (inflator) module initiator circuit. (in floor harness)

Step 4: Check whether malfunction is in contact coil or driver air bag (inflator) module.

DTC Troubleshooting

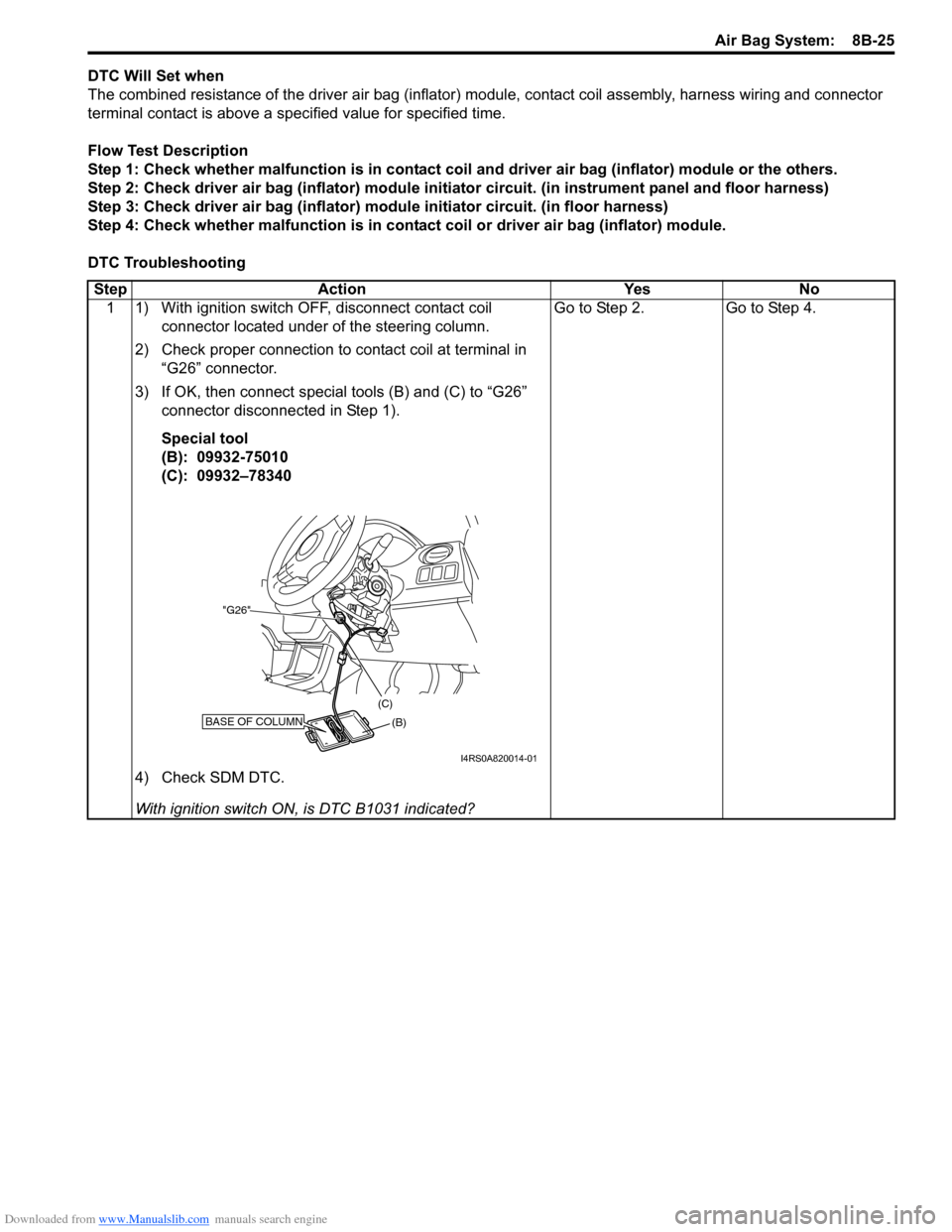

Step Action Yes No 1 1) With ignition switch OFF, disconnect contact coil connector located under of the steering column.

2) Check proper connection to contact coil at terminal in “G26” connector.

3) If OK, then connect special tools (B) and (C) to “G26” connector disconnected in Step 1).

Special tool

(B): 09932-75010

(C): 09932–78340

4) Check SDM DTC.

With ignition switch ON , is DTC B1031 indicated? Go to Step 2. Go to Step 4.

BASE OF COLUMN(B)

(C)

"G26"

I4RS0A820014-01

Page 1064 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-26 Air Bag System:

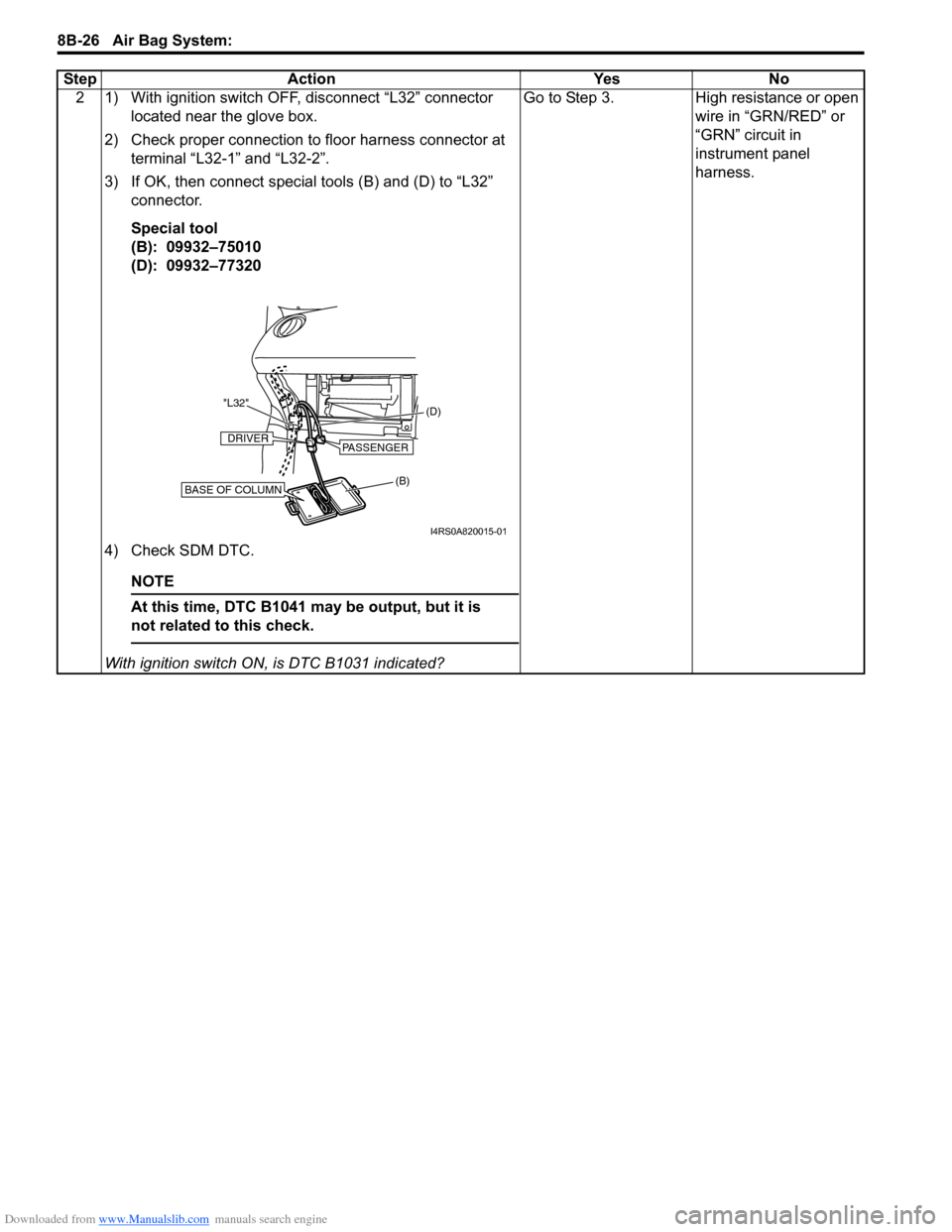

2 1) With ignition switch OFF, disconnect “L32” connector located near the glove box.

2) Check proper connection to floor harness connector at terminal “L32-1” and “L32-2”.

3) If OK, then connect special tools (B) and (D) to “L32” connector.

Special tool

(B): 09932–75010

(D): 09932–77320

4) Check SDM DTC.

NOTE

At this time, DTC B1041 ma y be output, but it is

not related to this check.

With ignition switch ON , is DTC B1031 indicated? Go to Step 3. High resistance or open

wire in “GRN/RED” or

“GRN” circuit in

instrument panel

harness.

Step Action Yes No

(B) (D)

"L32"BASE OF COLUMN

DRIVERPASSENGER

I4RS0A820015-01