instrument SUZUKI SWIFT 2008 2.G Service Service Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 1090 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-52 Air Bag System:

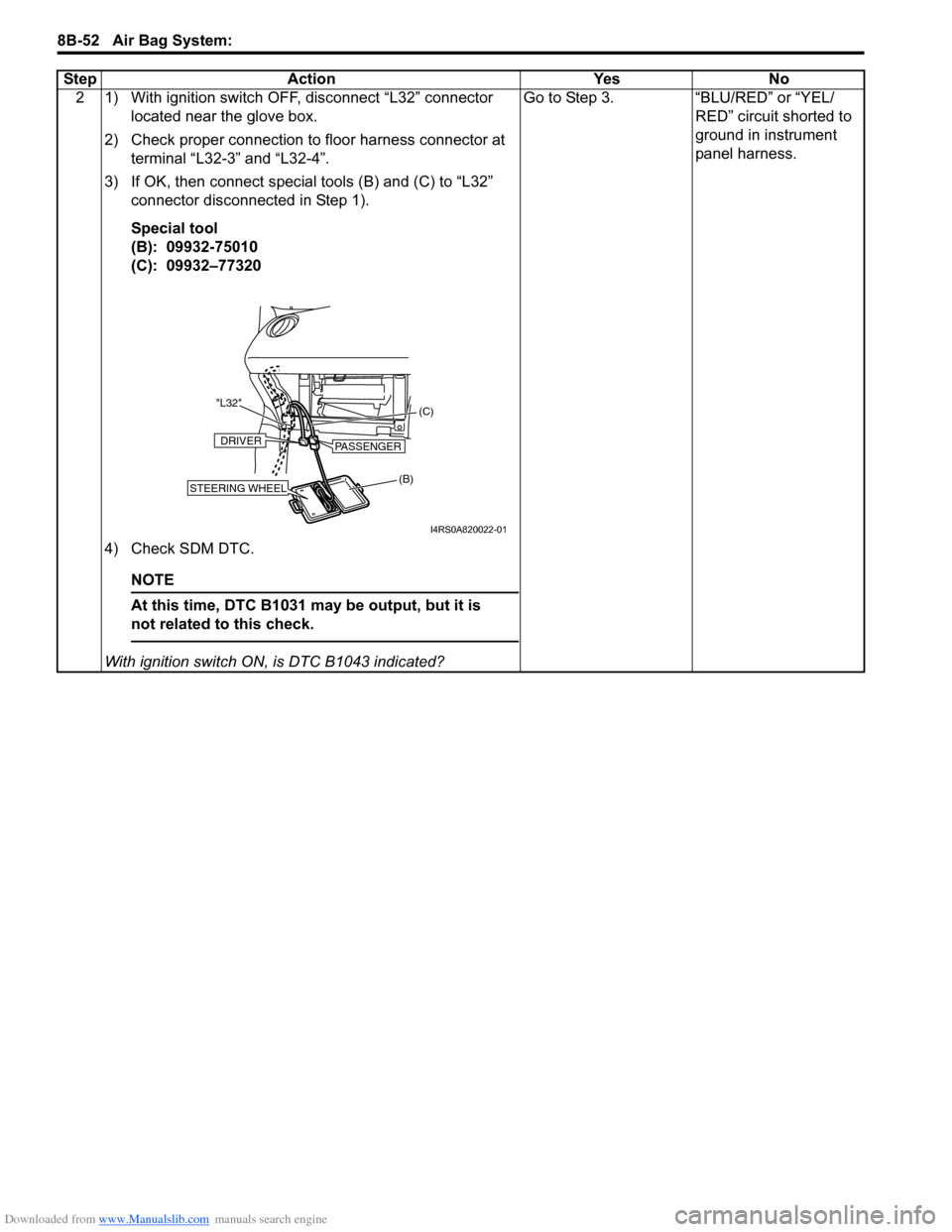

2 1) With ignition switch OFF, disconnect “L32” connector located near the glove box.

2) Check proper connection to floor harness connector at terminal “L32-3” and “L32-4”.

3) If OK, then connect special tools (B) and (C) to “L32” connector disconnected in Step 1).

Special tool

(B): 09932-75010

(C): 09932–77320

4) Check SDM DTC.

NOTE

At this time, DTC B1031 ma y be output, but it is

not related to this check.

With ignition switch ON , is DTC B1043 indicated? Go to Step 3. “BLU/RED” or “YEL/

RED” circuit shorted to

ground in instrument

panel harness.

Step Action Yes No

(B) (C)

"L32"STEERING WHEEL

DRIVERPASSENGER

I4RS0A820022-01

Page 1092 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-54 Air Bag System:

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adaptor from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

DTC Will Set when

The voltage measured at passenger air bag (initiator) circuit is above a specified value for specified time.

Flow Test Description

Step 1: Check if malfunction is in passenger air bag (inflator) module.

Step 2: Check passenger air bag (inflator) module initiator circuit. (in instrument panel harness)

Step 3: Check passenger air bag (inflator) module initiator circuit. (in floor harness)

DTC Troubleshooting Step Action YesNo

1 1) With ignition switch OFF, disconnect passenger air bag (inflator) module connector.

2) Check proper connection to passenger air bag (inflator) module at terminals in “G10” connector.

3) If OK, then connect special tools (A), (B) and (D) to “G10” connector.

Special tool

(A): 09932–76010

(B): 09932–75010

(D): 09932–78310

4) Check SDM DTC.

With ignition switch ON , is DTC B1044 indicated? Go to Step 3.

Turn ignition switch

OFF. Replace

passenger air bag

(inflator) module

referring to “Passenger

Air Bag (Inflator) Module

Removal and

Installation”.

STEERING WHEEL(B)

(D)

(A)

"G10"

I4RS0A820021-01

Page 1093 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-55

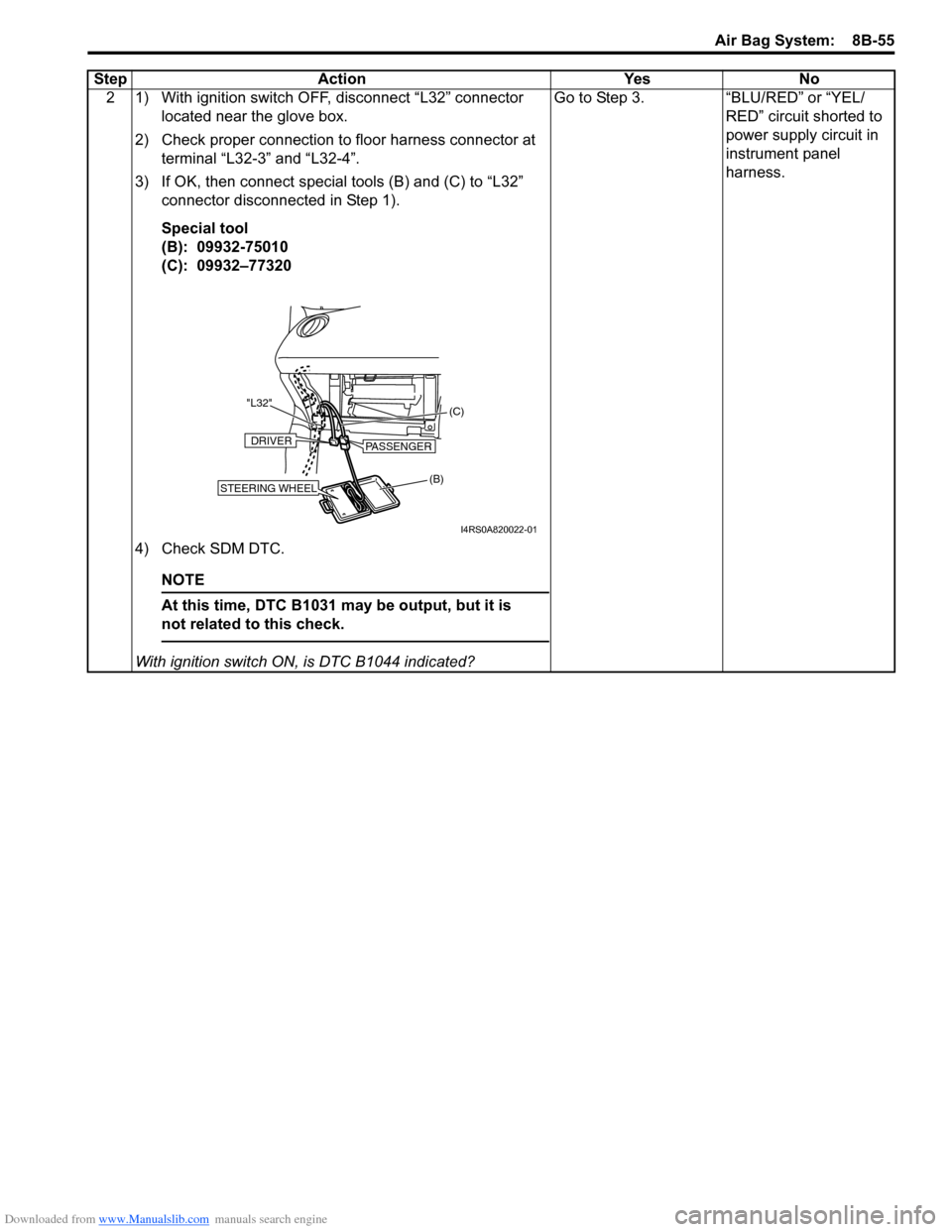

2 1) With ignition switch OFF, disconnect “L32” connector located near the glove box.

2) Check proper connection to floor harness connector at terminal “L32-3” and “L32-4”.

3) If OK, then connect special tools (B) and (C) to “L32” connector disconnected in Step 1).

Special tool

(B): 09932-75010

(C): 09932–77320

4) Check SDM DTC.

NOTE

At this time, DTC B1031 ma y be output, but it is

not related to this check.

With ignition switch ON , is DTC B1044 indicated? Go to Step 3. “BLU/RED” or “YEL/

RED” circuit shorted to

power supply circuit in

instrument panel

harness.

Step Action Yes No

(B) (C)

"L32"STEERING WHEEL

DRIVERPASSENGER

I4RS0A820022-01

Page 1134 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-96 Air Bag System:

Repair and Inspection Required after AccidentS7RS0B8204049

CAUTION!

• All air bag system components, including the electrical harness (component

mounting points), must be inspected after

an accident. If any components are

damaged or bent, they must be replaced

even if air bag system activation did not

occur.

• Never use air bag system parts from another vehicle.

• Do not attempt to service the parts below. Service of these parts is by replacement

only.

– Driver / Passenger air bag (inflator) modules

– Driver / Passenger side-air bag (inflator) modules

– Driver / Passenger side curtain-air bag (inflator) modules

– Driver / Passenger seat belt pretensioners

–Forward-sensor

– Driver / Passenger side-sensors

–SDM

– Contact coil and combination switch assembly

– Air bag wire harness in main harness, instrument panel harness and floor

harness.

• Proper operation of the sensors and air bag system requires that any repairs to the

vehicle structure return it to its original

production configuration.

CAUTION!

After detecting one time of such collision as

to meet deployment conditions, the SDM

must not be used.

Refer to “Air Bag Diagnostic System Check”

when checking the SDM.

Accident with Deployment / Activation – Component

Replacement

When driver and passenger air bags are deployed, the

following components must be replaced.

• Driver and passenger air bag (inflator) modules

• Driver and passenger seat belt pretensioners

• SDM after detecting such collision as to meet

deployment conditions

• Forward-sensor

• Instrument panel When side-air bag and side curtain-air bag are deployed,

the following components must be replaced.

• Deployed side-air bag (inflator) module

• Deployed side curtain-air bag (inflator) module

• Side-sensor

•SDM

Accident with or without Deployment / Activation –

Component Inspections

Certain air bag and restraint system components must

be inspected after any crash, whether the air bag system

activated or not. If any faul

ty condition is found in the

following checks, replace faulty part.

Those components are:

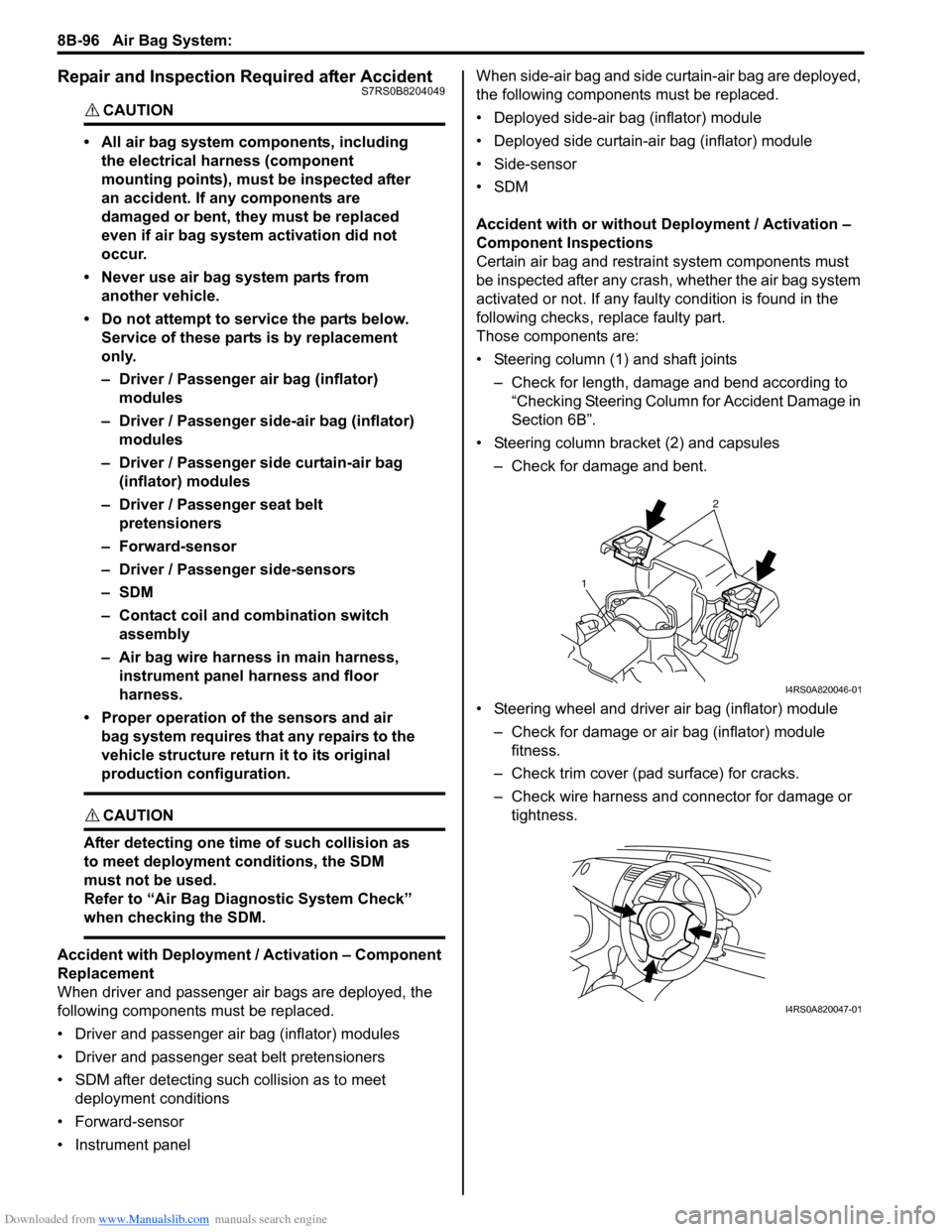

• Steering column (1) and shaft joints

– Check for length, damage and bend according to “Checking Steering Column for Accident Damage in

Section 6B”.

• Steering column bracket (2) and capsules – Check for damage and bent.

• Steering wheel and driver air bag (inflator) module – Check for damage or air bag (inflator) module fitness.

– Check trim cover (pad surface) for cracks.

– Check wire harness and connector for damage or tightness.

2

1

I4RS0A820046-01

I4RS0A820047-01

Page 1135 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-97

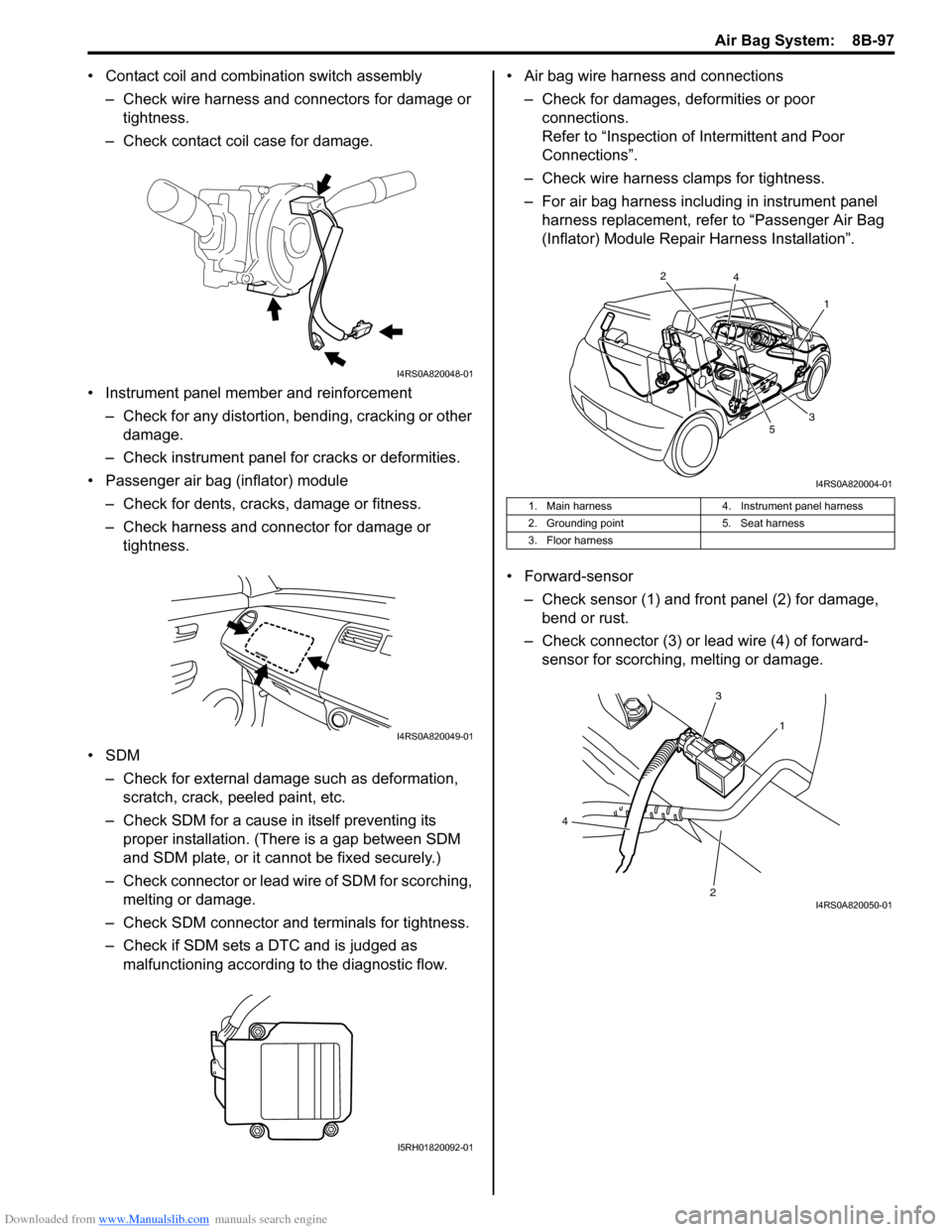

• Contact coil and combination switch assembly

– Check wire harness and connectors for damage or tightness.

– Check contact coil case for damage.

• Instrument panel member and reinforcement – Check for any distortion, bending, cracking or other damage.

– Check instrument panel fo r cracks or deformities.

• Passenger air bag (inflator) module

– Check for dents, cracks, damage or fitness.

– Check harness and connector for damage or tightness.

•SDM – Check for external damage such as deformation, scratch, crack, peeled paint, etc.

– Check SDM for a cause in itself preventing its proper installation. (There is a gap between SDM

and SDM plate, or it cannot be fixed securely.)

– Check connector or lead wire of SDM for scorching, melting or damage.

– Check SDM connector and terminals for tightness.

– Check if SDM sets a DTC and is judged as malfunctioning according to the diagnostic flow. • Air bag wire harness and connections

– Check for damages, deformities or poor connections.

Refer to “Inspection of Intermittent and Poor

Connections”.

– Check wire harness clamps for tightness.

– For air bag harness including in instrument panel harness replacement, refer to “Passenger Air Bag

(Inflator) Module Repair Harness Installation”.

• Forward-sensor – Check sensor (1) and front panel (2) for damage, bend or rust.

– Check connector (3) or lead wire (4) of forward- sensor for scorching, melting or damage.

I4RS0A820048-01

I4RS0A820049-01

I5RH01820092-01

1. Main harness 4. Instrument panel harness

2. Grounding point 5. Seat harness

3. Floor harness

1

2

3

4

5

I4RS0A820004-01

1

3

2

4

I4RS0A820050-01

Page 1141 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-103

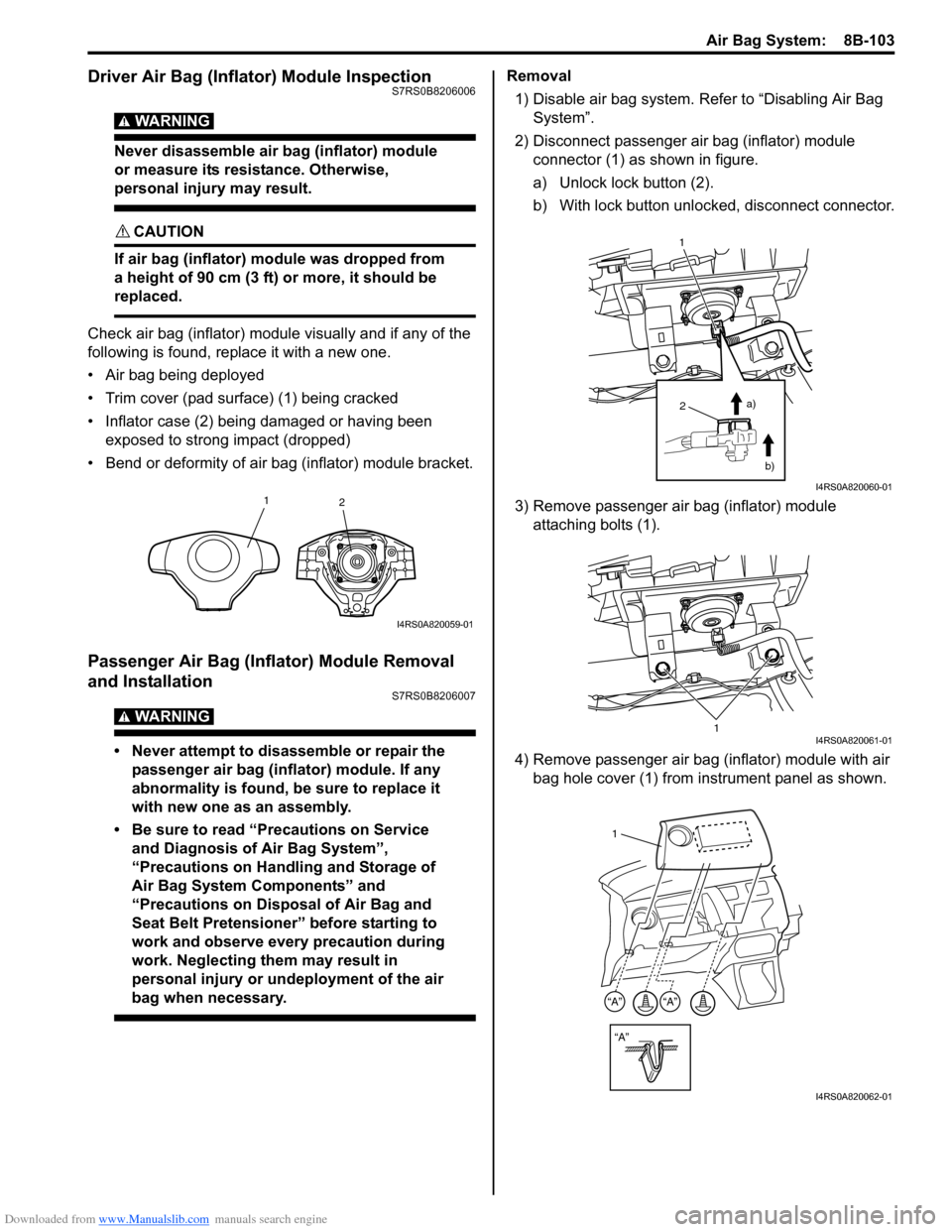

Driver Air Bag (Inflator) Module InspectionS7RS0B8206006

WARNING!

Never disassemble air bag (inflator) module

or measure its resistance. Otherwise,

personal injury may result.

CAUTION!

If air bag (inflator) module was dropped from

a height of 90 cm (3 ft) or more, it should be

replaced.

Check air bag (inflator) module visually and if any of the

following is found, replace it with a new one.

• Air bag being deployed

• Trim cover (pad surface) (1) being cracked

• Inflator case (2) being damaged or having been exposed to strong impact (dropped)

• Bend or deformity of air bag (inflator) module bracket.

Passenger Air Bag (Inflator) Module Removal

and Installation

S7RS0B8206007

WARNING!

• Never attempt to disassemble or repair the passenger air bag (inflator) module. If any

abnormality is found, be sure to replace it

with new one as an assembly.

• Be sure to read “Precautions on Service and Diagnosis of Air Bag System”,

“Precautions on Handling and Storage of

Air Bag System Components” and

“Precautions on Disposal of Air Bag and

Seat Belt Pretensioner” before starting to

work and observe every precaution during

work. Neglecting them may result in

personal injury or undeployment of the air

bag when necessary.

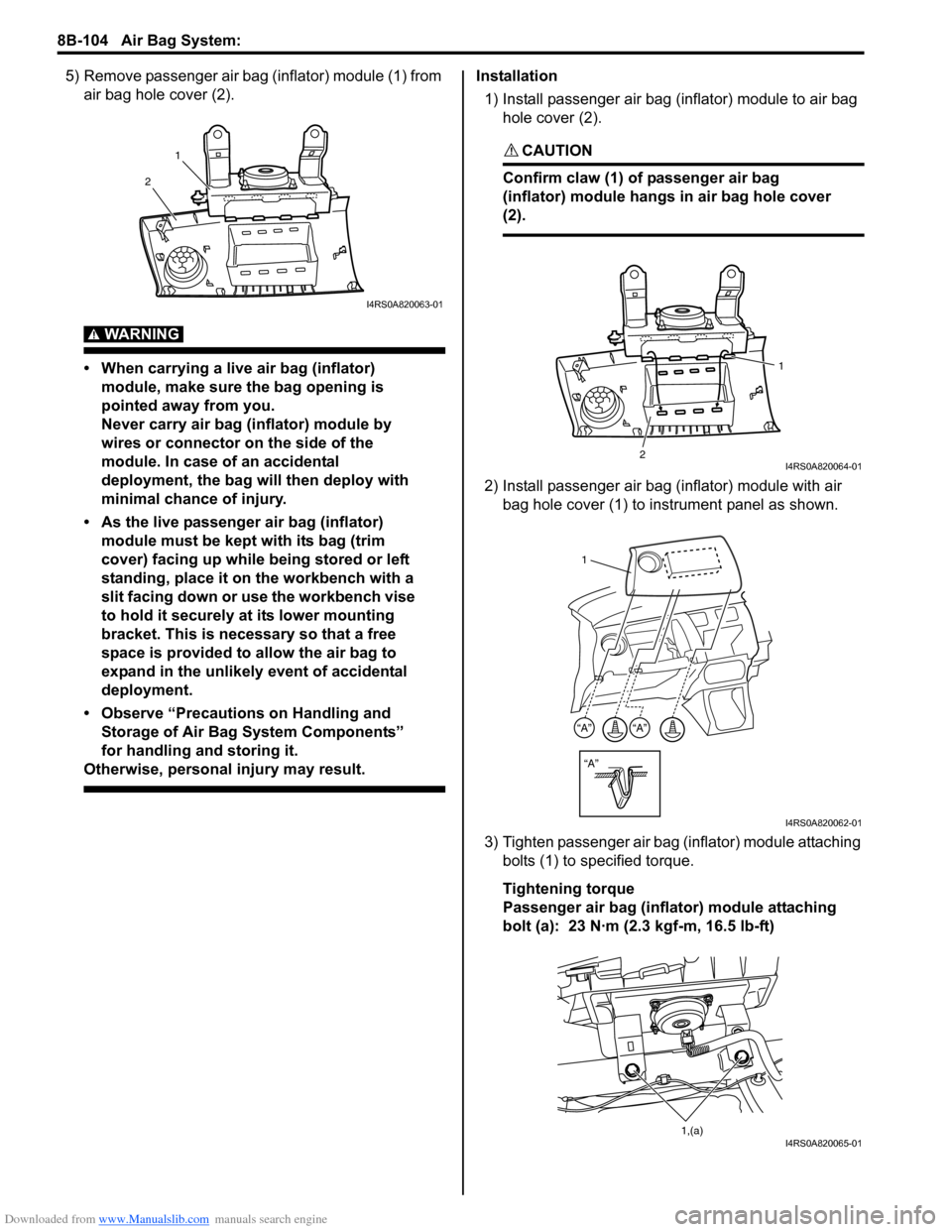

Removal

1) Disable air bag system. Re fer to “Disabling Air Bag

System”.

2) Disconnect passenger air bag (inflator) module connector (1) as shown in figure.

a) Unlock lock button (2).

b) With lock button unlocked, disconnect connector.

3) Remove passenger air bag (inflator) module attaching bolts (1).

4) Remove passenger air bag (inflator) module with air bag hole cover (1) from instrument panel as shown.

1 2

I4RS0A820059-01

2

1

a)b)

I4RS0A820060-01

1I4RS0A820061-01

“A”

“A”“A”

1

I4RS0A820062-01

Page 1142 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-104 Air Bag System:

5) Remove passenger air bag (inflator) module (1) from air bag hole cover (2).

WARNING!

• When carrying a live air bag (inflator) module, make sure the bag opening is

pointed away from you.

Never carry air bag (inflator) module by

wires or connector on the side of the

module. In case of an accidental

deployment, the bag will then deploy with

minimal chance of injury.

• As the live passenger air bag (inflator) module must be kept with its bag (trim

cover) facing up while being stored or left

standing, place it on the workbench with a

slit facing down or use the workbench vise

to hold it securely at its lower mounting

bracket. This is necessary so that a free

space is provided to allow the air bag to

expand in the unlikely event of accidental

deployment.

• Observe “Precautions on Handling and Storage of Air Bag System Components”

for handling and storing it.

Otherwise, personal injury may result.

Installation

1) Install passenger air bag (inflator) module to air bag hole cover (2).

CAUTION!

Confirm claw (1) of passenger air bag

(inflator) module hangs in air bag hole cover

(2).

2) Install passenger air bag (inflator) module with air bag hole cover (1) to instrument panel as shown.

3) Tighten passenger air bag (inflator) module attaching bolts (1) to sp ecified torque.

Tightening torque

Passenger air bag (inflator) module attaching

bolt (a): 23 N·m (2.3 kgf-m, 16.5 lb-ft)

1

2

I4RS0A820063-01

2 1I4RS0A820064-01

“A”

“A”“A”

1

I4RS0A820062-01

1,(a)I4RS0A820065-01

Page 1150 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-112 Air Bag System:

• Check sensor (1) for dents, crack, deformation.

• Check sensor connector (sensor side and harness side), lock mechanism or sensor lead wire for

damage, crack, scorching or melting.

• Check connector terminals for bent, corrosion or rust. If any faulty condition is found in above checks,

replace.

Passenger Air Bag (Inflator) Module Repair

Harness Installation

S7RS0B8206017

Replace passenger air bag (inflator) module repair

harness (4) according to the following procedure when

the harness (1) connect ed with passenger air bag

(inflator) module of the air bag harness included in

instrument panel harness (2) and passenger air bag

(inflator) module connector (3) is damaged. 1) Disable air bag system. Re

fer to “Disabling Air Bag

System”.

2) Disconnect “L32” connector from floor harness located near the glove box.

3) Cut off passenger air bag (inflator) module harness (1) included in instrument panel harness (2) as

shown, and then fasten it to instrument panel

harness with vinyl tape for avoiding interference with

other parts.

4) Install passenger air bag (inflator) module repair harness (1) to floor harness (2), instrument panel

harness (3) and passenger air bag (inflator) module.CAUTION!

To avoid interference with other parts, fasten

the repair harness to in strument wire harness

with a clamp or vinyl tape as shown in figure.

5) Connect each connector securely till click is heard.

5. Driver air bag (inflator) module 7. Floor harness

6. Passenger air bag (inflator) module 8. Vinyl tape

1I4RS0A820082-01

7

4

6

6

2

28

1

3

5

5

7I4RS0A820103-01

1

I4RS0A820083-01

1

2

3

I4RS0A820085-01

Page 1159 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-121

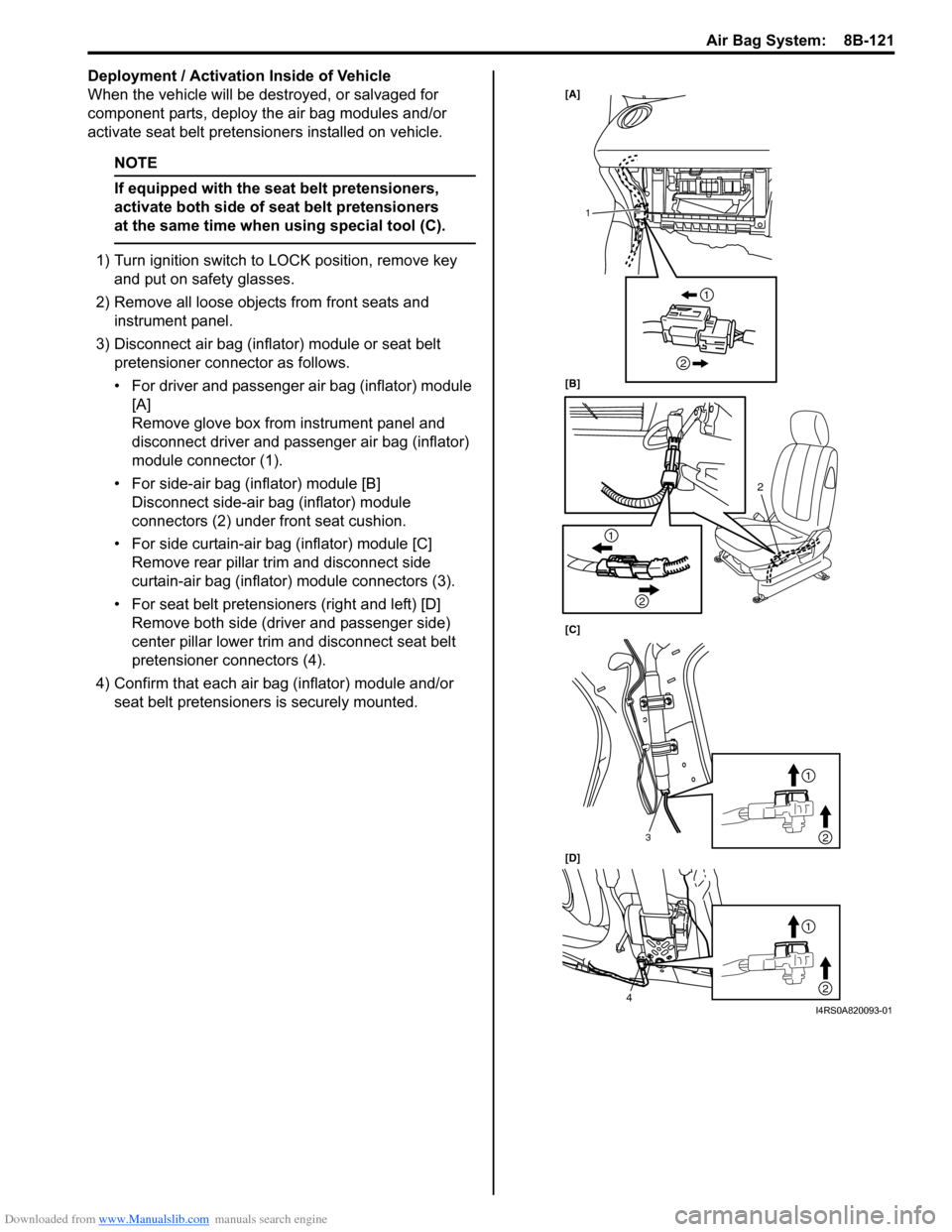

Deployment / Activation Inside of Vehicle

When the vehicle will be destroyed, or salvaged for

component parts, deploy the air bag modules and/or

activate seat belt pretensioners installed on vehicle.

NOTE

If equipped with the seat belt pretensioners,

activate both side of seat belt pretensioners

at the same time when using special tool (C).

1) Turn ignition switch to LOCK position, remove key

and put on safety glasses.

2) Remove all loose objects from front seats and instrument panel.

3) Disconnect air bag (inflator) module or seat belt pretensioner connector as follows.

• For driver and passenger air bag (inflator) module [A]

Remove glove box from instrument panel and

disconnect driver and passenger air bag (inflator)

module connector (1).

• For side-air bag (inflator) module [B] Disconnect side-air bag (inflator) module

connectors (2) under front seat cushion.

• For side curtain-air bag (inflator) module [C] Remove rear pillar trim and disconnect side

curtain-air bag (inflator) module connectors (3).

• For seat belt pretensioners (right and left) [D] Remove both side (driver and passenger side)

center pillar lower trim an d disconnect seat belt

pretensioner connectors (4).

4) Confirm that each air bag (inflator) module and/or seat belt pretensioners is securely mounted.

[A]

[B]

[C]

[D]

2

1

3

4

1

2

1

2

1

2

1

2

I4RS0A820093-01

Page 1164 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-126 Air Bag System:

The adapter (1) will also give an idea of whether or not

contact tension is sufficient, helping to find an open or

intermittent open due to poor terminal contact. An SDM

short bar release tool (2) is included in the connector test

adapter kit. Inserting it in to the SDM connector (3) will

releases the shorting bar.

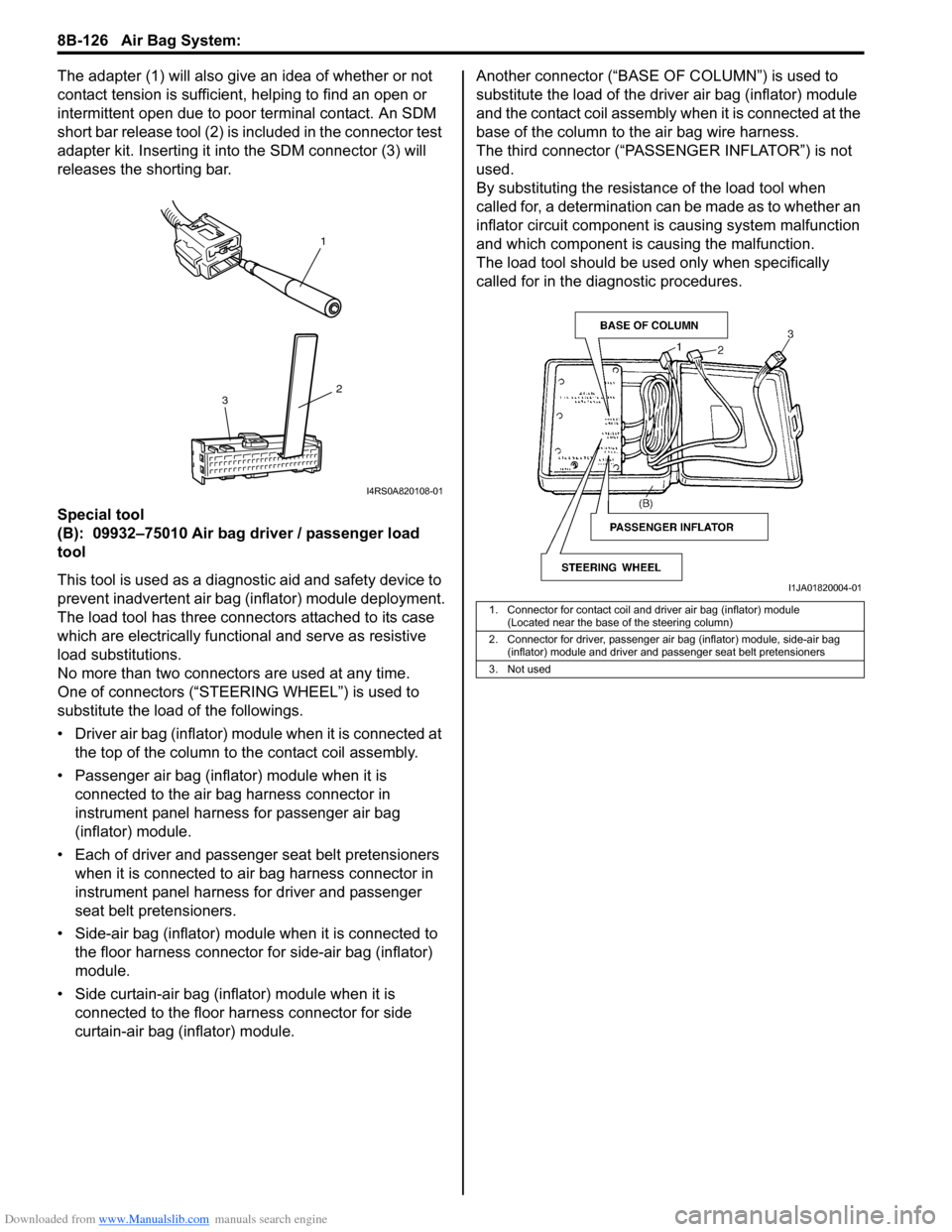

Special tool

(B): 09932–75010 Air bag driver / passenger load

tool

This tool is used as a diagno stic aid and safety device to

prevent inadvertent air bag (inflator) module deployment.

The load tool has three connectors attached to its case

which are electrically functional and serve as resistive

load substitutions.

No more than two connectors are used at any time.

One of connectors (“STEER ING WHEEL”) is used to

substitute the load of the followings.

• Driver air bag (inflator) module when it is connected at the top of the column to the contact coil assembly.

• Passenger air bag (inflator) module when it is connected to the air bag harness connector in

instrument panel harness for passenger air bag

(inflator) module.

• Each of driver and passen ger seat belt pretensioners

when it is connected to air bag harness connector in

instrument panel harness for driver and passenger

seat belt pretensioners.

• Side-air bag (inflator) module when it is connected to the floor harness connector for side-air bag (inflator)

module.

• Side curtain-air bag (inflator) module when it is connected to the floor harness connector for side

curtain-air bag (inflator) module. Another connec

tor (“BASE OF COLUMN ”) is used to

substitute the load of the driver air bag (inflator) module

and the contact coil assembly when it is connected at the

base of the column to the air bag wire harness.

The third connector (“PASSENGER INFLATOR”) is not

used.

By substituting the resistan ce of the load tool when

called for, a determination can be made as to whether an

inflator circuit component is causing system malfunction

and which component is causing the malfunction.

The load tool should be used only when specifically

called for in the diagnostic procedures.

1

2

3

I4RS0A820108-01

1. Connector for contact coil and driver air bag (inflator) module

(Located near the base of the steering column)

2. Connector for driver, passenger air bag (inflator) module, side-air bag (inflator) module and driver and passenger seat belt pretensioners

3. Not used

I1JA01820004-01