WIRE SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 1200 of 1496

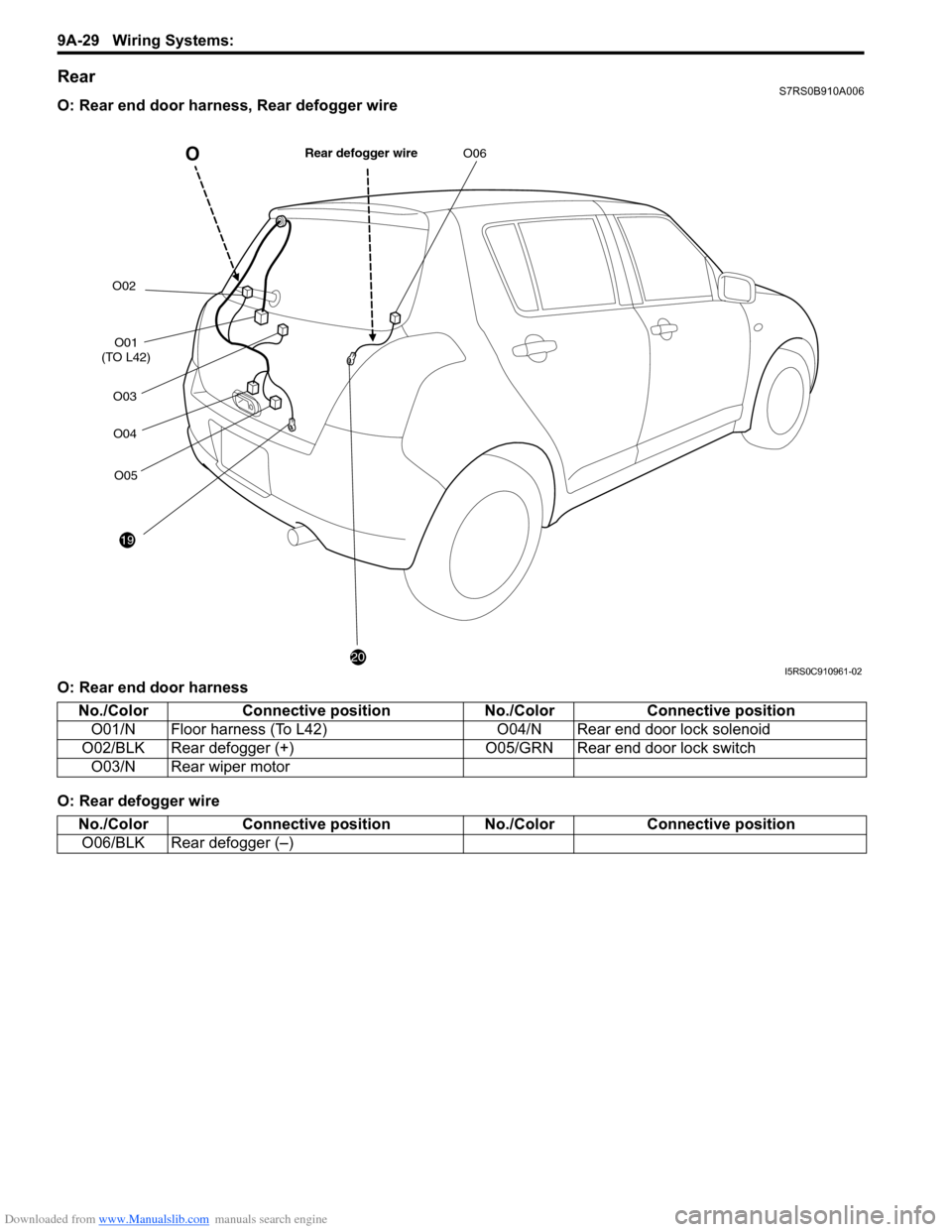

Downloaded from www.Manualslib.com manuals search engine 9A-29 Wiring Systems:

RearS7RS0B910A006

O: Rear end door harness, Rear defogger wire

O: Rear end door harness

O: Rear defogger wire

ORear defogger wire

O01

(TO L42) O02

O03

19

O04

O05

O06

20I5RS0C910961-02

No./Color Connective position No./ColorConnective position

O01/N Floor harness (To L42) O04/N Rear end door lock solenoid

O02/BLK Rear defogger (+) O05/GRN Rear end door lock switch

O03/N Rear wiper motor

No./Color Connective position No./ColorConnective position

O06/BLK Rear defogger (–)

Page 1292 of 1496

Downloaded from www.Manualslib.com manuals search engine 9B-10 Lighting Systems:

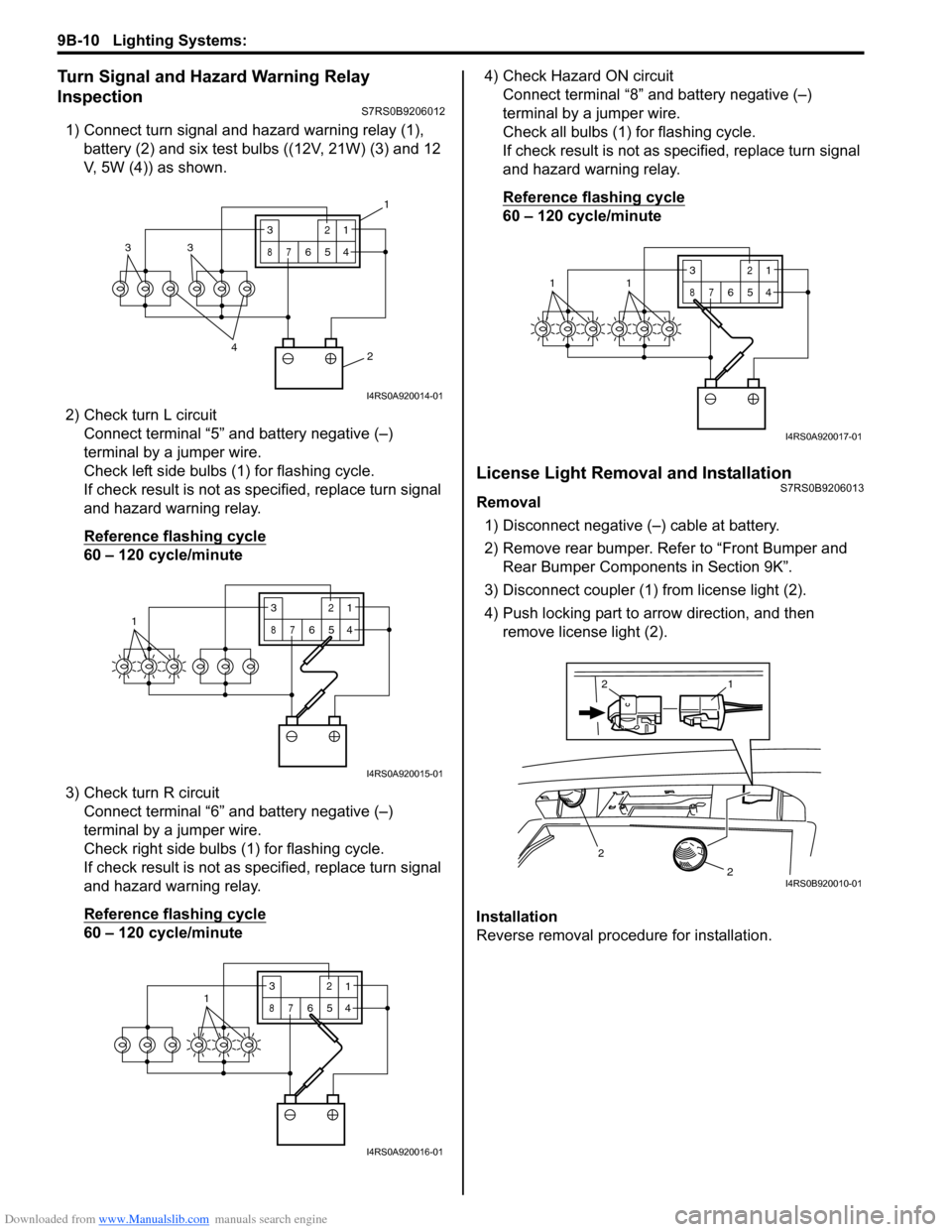

Turn Signal and Hazard Warning Relay

Inspection

S7RS0B9206012

1) Connect turn signal and hazard warning relay (1), battery (2) and six test bulbs ((12V, 21W) (3) and 12

V, 5W (4)) as shown.

2) Check turn L circuit Connect terminal “5” and battery negative (–)

terminal by a jumper wire.

Check left side bulbs (1) for flashing cycle.

If check result is not as specified, replace turn signal

and hazard warning relay.

Reference flashing cycle

60 – 120 cycle/minute

3) Check turn R circuit Connect terminal “6” and battery negative (–)

terminal by a jumper wire.

Check right side bulbs (1) for flashing cycle.

If check result is not as specified, replace turn signal

and hazard warning relay.

Reference flashing cycle

60 – 120 cycle/minute 4) Check Hazard ON circuit

Connect terminal “8” and battery negative (–)

terminal by a jumper wire.

Check all bulbs (1) for flashing cycle.

If check result is not as sp ecified, replace turn signal

and hazard warning relay.

Reference flashing cycle

60 – 120 cycle/minute

License Light Removal and InstallationS7RS0B9206013

Removal

1) Disconnect negative (–) cable at battery.

2) Remove rear bumper. Refe r to “Front Bumper and

Rear Bumper Components in Section 9K”.

3) Disconnect coupler (1) from license light (2).

4) Push locking part to arrow direction, and then remove license light (2).

Installation

Reverse removal procedure for installation.

2

4

33

3

87

12

654

1

I4RS0A920014-01

13

87

12

654

I4RS0A920015-01

3

87

12

6541

I4RS0A920016-01

3

87

12

6

5411

I4RS0A920017-01

2

2

1

2

I4RS0B920010-01

Page 1311 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-16

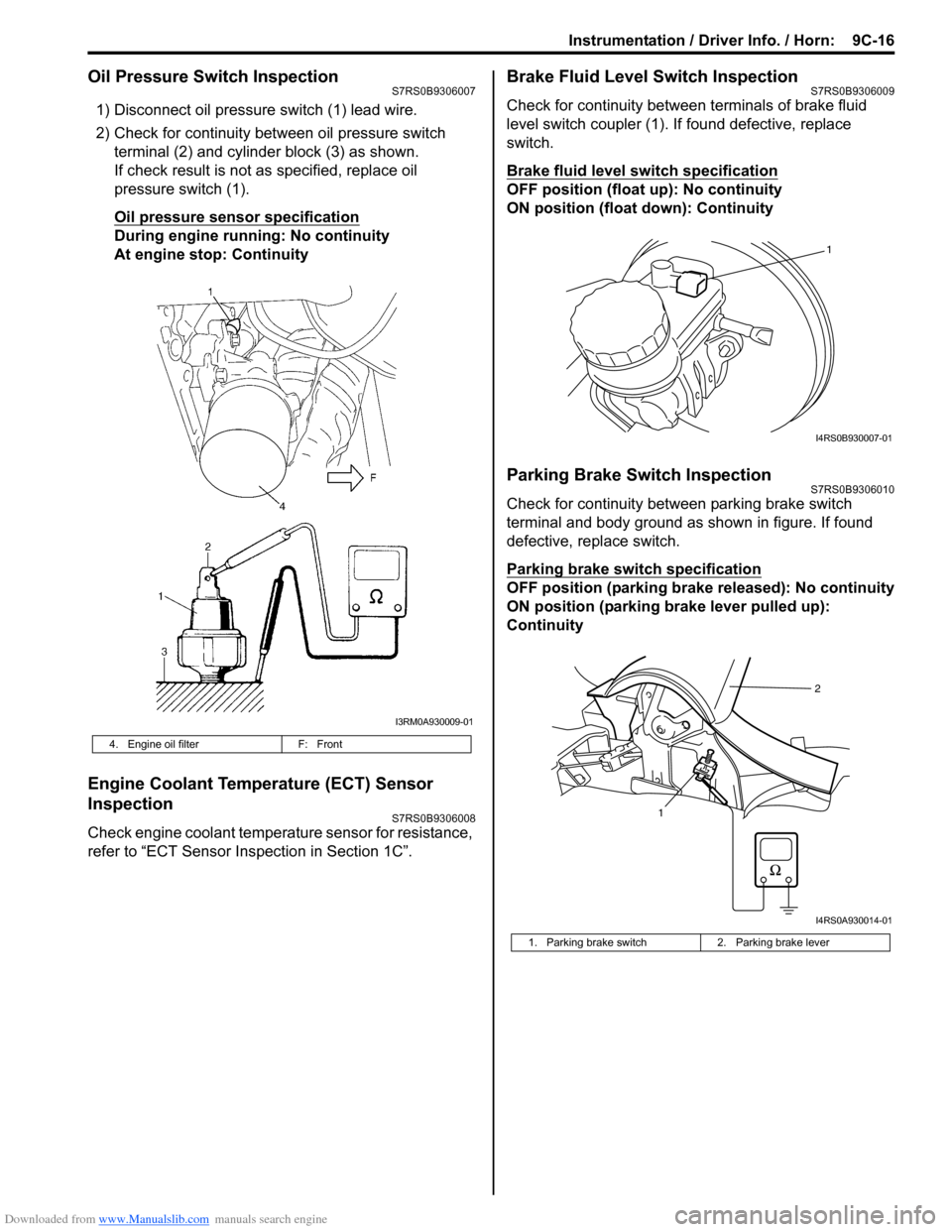

Oil Pressure Switch InspectionS7RS0B9306007

1) Disconnect oil pressure switch (1) lead wire.

2) Check for continuity between oil pressure switch terminal (2) and cylinder block (3) as shown.

If check result is not as specified, replace oil

pressure switch (1).

Oil pressure sensor specification

During engine running: No continuity

At engine stop: Continuity

Engine Coolant Temperature (ECT) Sensor

Inspection

S7RS0B9306008

Check engine coolant temperat ure sensor for resistance,

refer to “ECT Sensor Inspection in Section 1C”.

Brake Fluid Level Switch InspectionS7RS0B9306009

Check for continuity between terminals of brake fluid

level switch coupler (1). If found defective, replace

switch.

Brake fluid level switch specification

OFF position (float up): No continuity

ON position (float down): Continuity

Parking Brake Switch InspectionS7RS0B9306010

Check for continuity between parking brake switch

terminal and body ground as shown in figure. If found

defective, replace switch.

Parking brake switch specification

OFF position (parking brake released): No continuity

ON position (parking brake lever pulled up):

Continuity

4. Engine oil filter F: Front

I3RM0A930009-01

1. Parking brake switch 2. Parking brake lever

1

I4RS0B930007-01

12

I4RS0A930014-01

Page 1313 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-18

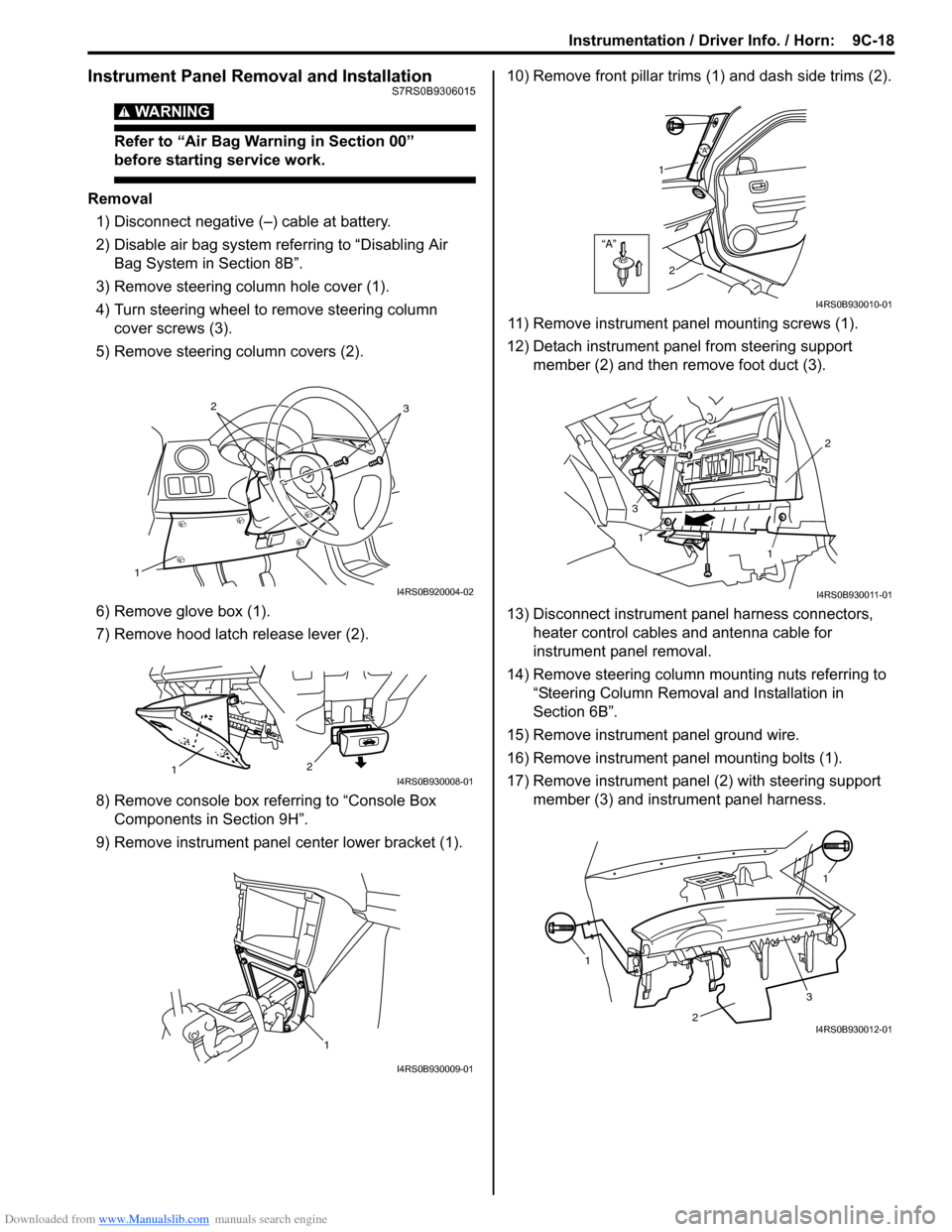

Instrument Panel Removal and InstallationS7RS0B9306015

WARNING!

Refer to “Air Bag Warning in Section 00”

before starting service work.

Removal

1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove steering column hole cover (1).

4) Turn steering wheel to remove steering column cover screws (3).

5) Remove steering column covers (2).

6) Remove glove box (1).

7) Remove hood latch release lever (2).

8) Remove console box referring to “Console Box Components in Section 9H”.

9) Remove instrument panel center lower bracket (1). 10) Remove front pillar trims

(1) and dash side trims (2).

11) Remove instrument panel mounting screws (1).

12) Detach instrument panel from steering support member (2) and then remove foot duct (3).

13) Disconnect instrument panel harness connectors, heater control cables and antenna cable for

instrument panel removal.

14) Remove steering column mounting nuts referring to “Steering Column Remova l and Installation in

Section 6B”.

15) Remove instrument panel ground wire.

16) Remove instrument panel mounting bolts (1).

17) Remove instrument panel (2) with steering support member (3) and instrument panel harness.

1

32

I4RS0B920004-02

2

1I4RS0B930008-01

1

I4RS0B930009-01

“A”

“A”

1

2

I4RS0B930010-01

1

1 2

3

I4RS0B930011-01

1 1

2

3I4RS0B930012-01

Page 1320 of 1496

Downloaded from www.Manualslib.com manuals search engine 9D-3 Wipers / Washers:

Washer Tank and Washer Pump Removal and

Installation

S7RS0B9406002

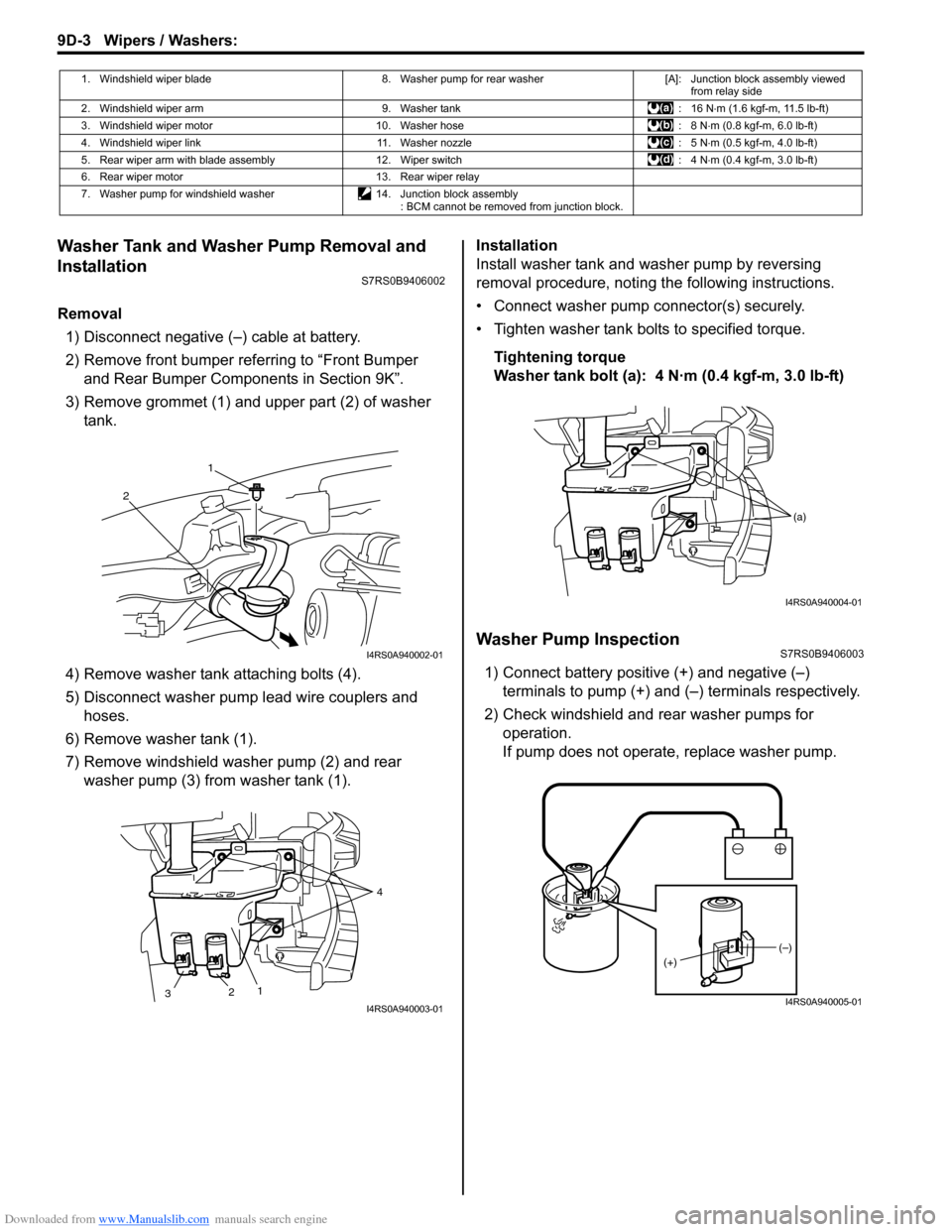

Removal1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Remove grommet (1) and upper part (2) of washer tank.

4) Remove washer tank attaching bolts (4).

5) Disconnect washer pump lead wire couplers and hoses.

6) Remove washer tank (1).

7) Remove windshield washer pump (2) and rear washer pump (3) from washer tank (1). Installation

Install washer tank and washer pump by reversing

removal procedure, noting the following instructions.

• Connect washer pump connector(s) securely.

• Tighten washer tank bolts to specified torque.

Tightening torque

Washer tank bolt (a): 4 N·m (0.4 kgf-m, 3.0 lb-ft)

Washer Pump InspectionS7RS0B9406003

1) Connect battery positive (+) and negative (–) terminals to pump (+) and (–) terminals respectively.

2) Check windshield and rear washer pumps for

operation.

If pump does not operate, replace washer pump.

1. Windshield wiper blade 8. Washer pump for rear washer[A]: Junction block assembly viewed

from relay side

2. Windshield wiper arm 9. Washer tank: 16 N⋅m (1.6 kgf-m, 11.5 lb-ft)

3. Windshield wiper motor 10. Washer hose : 8 N⋅m (0.8 kgf-m, 6.0 lb-ft)

4. Windshield wiper link 11. Washer nozzle : 5 N⋅m (0.5 kgf-m, 4.0 lb-ft)

5. Rear wiper arm with blade assembly 12. Wiper switch : 4 N⋅m (0.4 kgf-m, 3.0 lb-ft)

6. Rear wiper motor 13. Rear wiper relay

7. Washer pump for windshield washer 14. Junction block assembly

: BCM cannot be removed from junction block.

1

2

I4RS0A940002-01

2 1 4

3

I4RS0A940003-01

(a)

I4RS0A940004-01

(–)

(+)

I4RS0A940005-01

Page 1322 of 1496

Downloaded from www.Manualslib.com manuals search engine 9D-5 Wipers / Washers:

Windshield Wiper Motor InspectionS7RS0B9406005

NOTE

Make sure that battery voltage is 12 V or

more.

1) Disconnect negative (–) cable at battery.

2) Remove windshield wiper arms with wiper blades

referring to “Windshield Wiper Removal and

Installation”.

3) Remove cowl top garnish referring to “Cowl Top Components in Section 9K”.

4) Disconnect coupler from windshield wiper motor.

5) Reinstall windshield wiper arms with wiper blade. For

details, refer to Step 4) of “Installation” in “Windshield

Wiper Removal and Installation”.

6) Check windshield wiper motor for operation as

follows

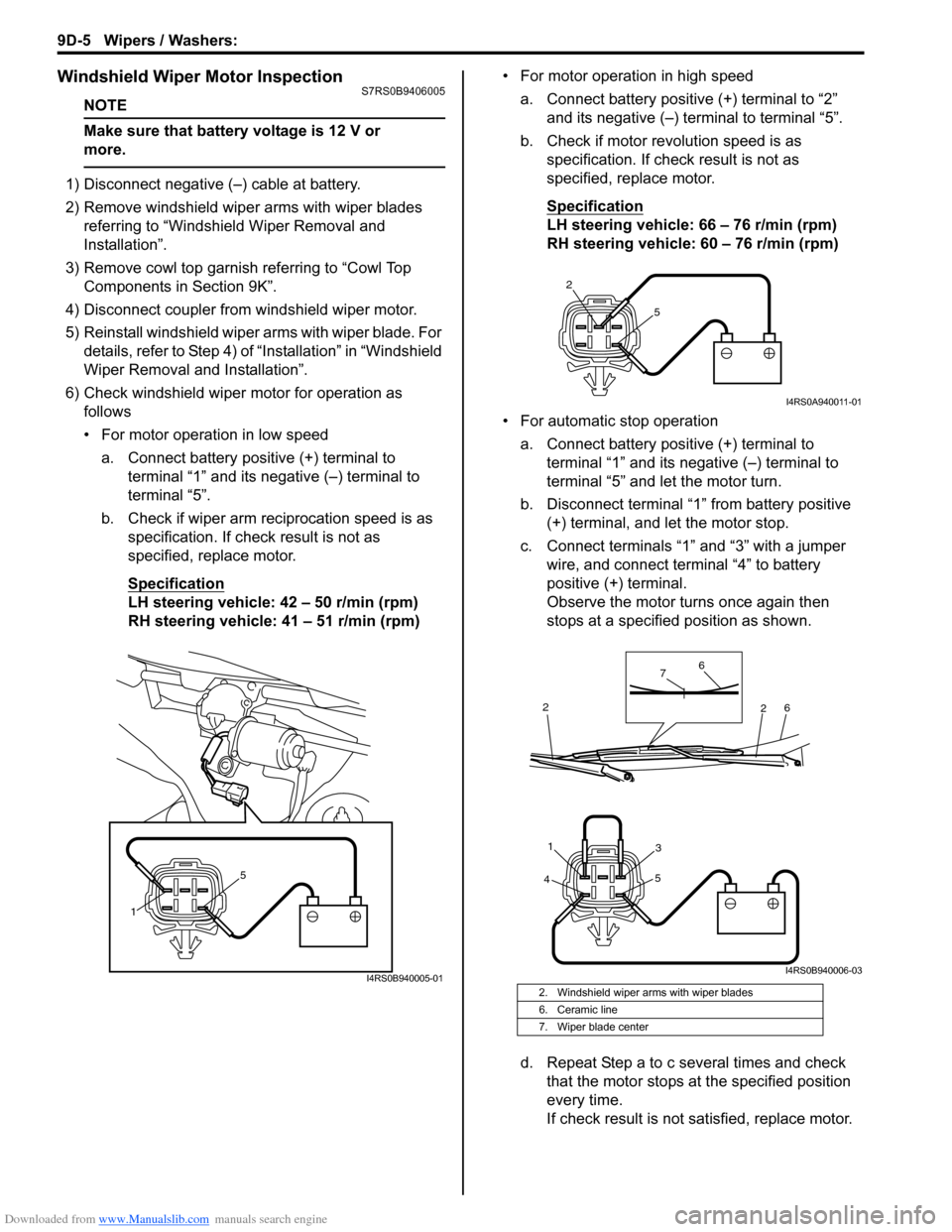

• For motor operation in low speed

a. Connect battery positive (+) terminal to terminal “1” and its negative (–) terminal to

terminal “5”.

b. Check if wiper arm reciprocation speed is as specification. If check result is not as

specified, replace motor.

Specification

LH steering vehicle: 42 – 50 r/min (rpm)

RH steering vehicle: 41 – 51 r/min (rpm) • For motor operation in high speed

a. Connect battery positive (+) terminal to “2” and its negative (–) terminal to terminal “5”.

b. Check if motor revolution speed is as specification. If chec k result is not as

specified, replace motor.

Specification

LH steering vehicle: 66 – 76 r/min (rpm)

RH steering vehicle: 60 – 76 r/min (rpm)

• For automatic stop operation a. Connect battery positive (+) terminal to terminal “1” and its negative (–) terminal to

terminal “5” and let the motor turn.

b. Disconnect terminal “1” from battery positive (+) terminal, and let the motor stop.

c. Connect terminals “1” and “3” with a jumper wire, and connect terminal “4” to battery

positive (+) terminal.

Observe the motor turns once again then

stops at a specified position as shown.

d. Repeat Step a to c several times and check that the motor stops at the specified position

every time.

If check result is not satisfied, replace motor.

1 5

I4RS0B940005-012. Windshield wiper arms with wiper blades

6. Ceramic line

7. Wiper blade center

2

5

I4RS0A940011-01

4 5

31

6

6

7

2

2

I4RS0B940006-03

Page 1325 of 1496

Downloaded from www.Manualslib.com manuals search engine Wipers / Washers: 9D-8

4) Remove windshield wiper and washer switch (1) from combination swit ch assembly (2) and

disconnect its coupler (3).

Installation

Reverse removal procedure.

Windshield Wiper and Washer Switch

Inspection

S7RS0B9406009

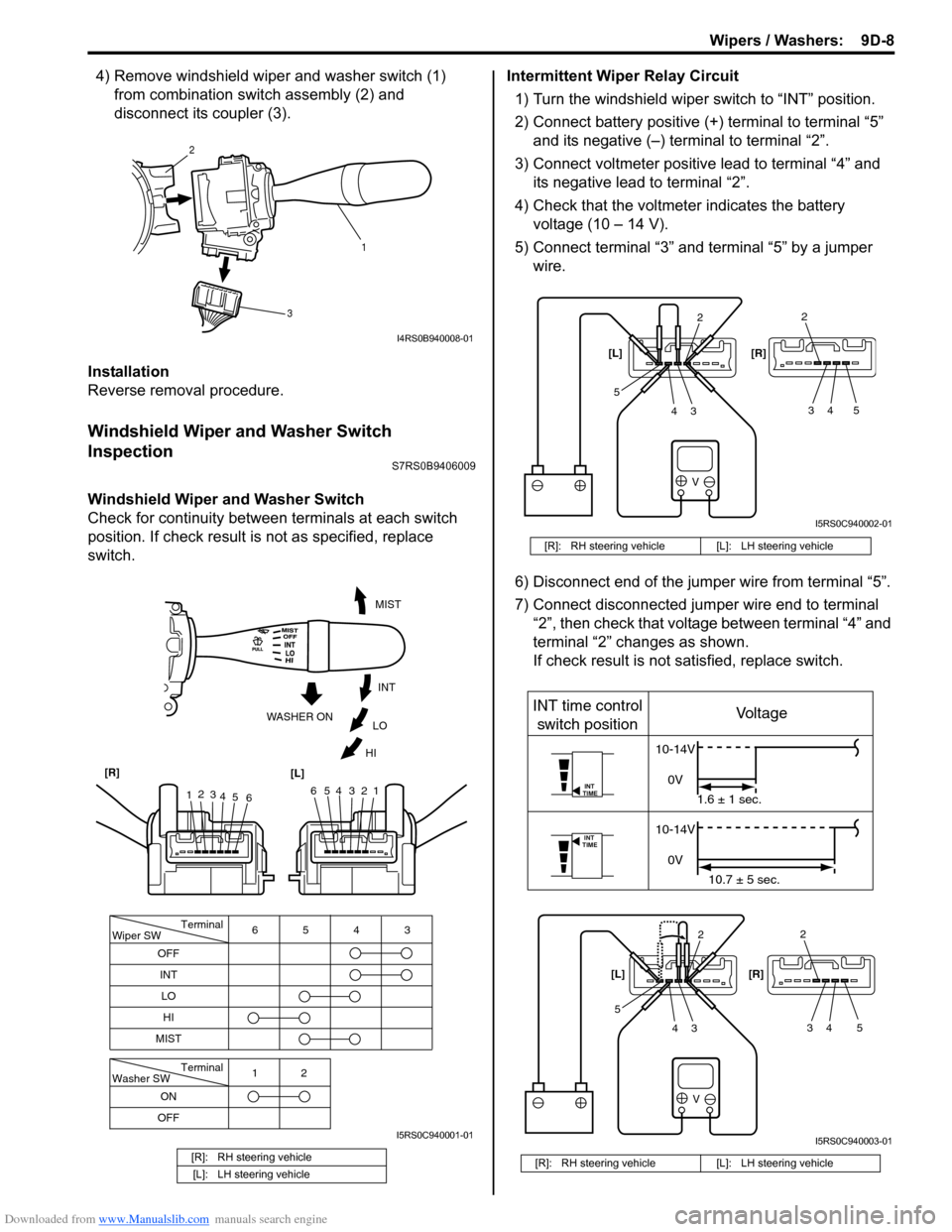

Windshield Wiper and Washer Switch

Check for continuity between terminals at each switch

position. If check result is not as specified, replace

switch. Intermittent Wiper Relay Circuit

1) Turn the windshield wiper switch to “INT” position.

2) Connect battery positive (+ ) terminal to terminal “5”

and its negative (–) terminal to terminal “2”.

3) Connect voltmeter positive lead to terminal “4” and its negative lead to terminal “2”.

4) Check that the voltmeter indicates the battery voltage (10 – 14 V).

5) Connect terminal “3” and terminal “5” by a jumper wire.

6) Disconnect end of the jumper wire from terminal “5”.

7) Connect disconnected jumper wire end to terminal “2”, then check that voltage between terminal “4” and

terminal “2” changes as shown.

If check result is not satisfied, replace switch.

[R]: RH steering vehicle

[L]: LH steering vehicle

1

2

3

I4RS0B940008-01

Terminal

Wiper SW

OFF

INT 6543

MIST

Terminal

Washer SW

OFF 12

ONLO

HI

654321

MIST

INT

LO

HI

WASHER ON

1

2

3

4 5 6

[R]

[L]

I5RS0C940001-01

[R]: RH steering vehicle [L]: LH steering vehicle

[R]: RH steering vehicle [L]: LH steering vehicle

V

2

34

52

34 5

[L] [R]

I5RS0C940002-01

V

INT

TIME

INT

TIME

INT time control

switch position Voltage

10-14V

0V 1.6 ± 1 sec.

10-14V

0V 10.7 ± 5 sec.

2

34

52

34 5

[L]

[R]

I5RS0C940003-01

Page 1329 of 1496

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-2

• Eyeleteer

• Piano string

• Windshield knife

• Brush for primer application (2 pcs)

•Knife

• Rubber sucker grip

• Sealant gun (for filling adhesive)

• Putty spatula (for correcting adhered parts)

Diagnostic Information and Procedures

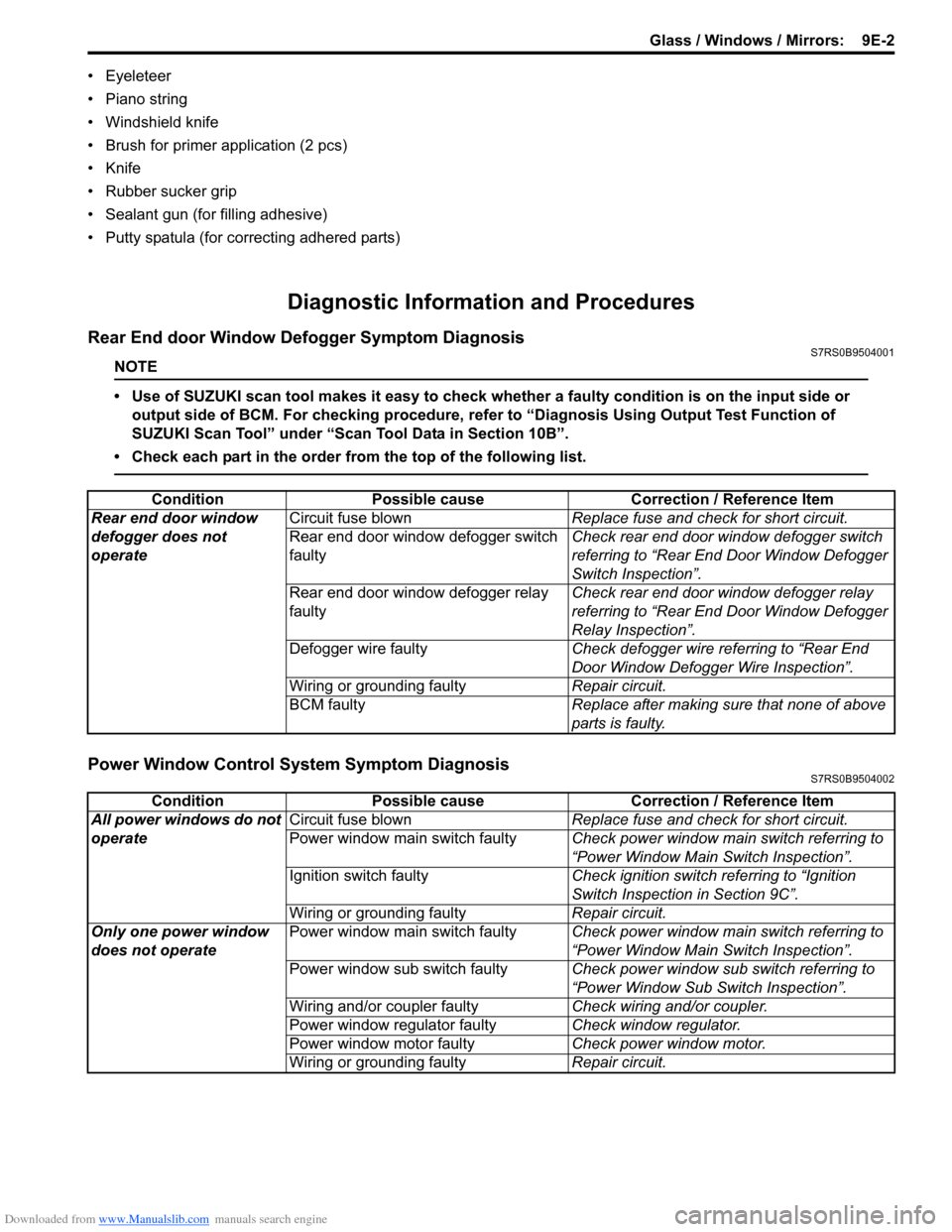

Rear End door Window Defogger Symptom DiagnosisS7RS0B9504001

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, re fer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Power Window Control System Symptom DiagnosisS7RS0B9504002

Condition Possible cause Correction / Reference Item

Rear end door window

defogger does not

operate Circuit fuse blown

Replace fuse and check for short circuit.

Rear end door window defogger switch

faulty Check rear end door window defogger switch

referring to “Rear End Door Window Defogger

Switch Inspection”.

Rear end door window defogger relay

faulty Check rear end door window defogger relay

referring to “Rear End Door Window Defogger

Relay Inspection”.

Defogger wire faulty Check defogger wire referring to “Rear End

Door Window Defogger Wire Inspection”.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

ConditionPossible cause Correction / Reference Item

All power windows do not

operate Circuit fuse blown

Replace fuse and check for short circuit.

Power window main switch faulty Check power window main switch referring to

“Power Window Main Switch Inspection”.

Ignition switch faulty Check ignition switch referring to “Ignition

Switch Inspection in Section 9C”.

Wiring or grounding faulty Repair circuit.

Only one power window

does not operate Power window main switch faulty

Check power window main switch referring to

“Power Window Main Switch Inspection”.

Power window sub switch faulty Check power window sub switch referring to

“Power Window Sub Switch Inspection”.

Wiring and/or coupler faulty Check wiring and/or coupler.

Power window regulator faulty Check window regulator.

Power window motor faulty Check power window motor.

Wiring or grounding faulty Repair circuit.

Page 1331 of 1496

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-4

Repair Instructions

Windshield Removal and InstallationS7RS0B9506001

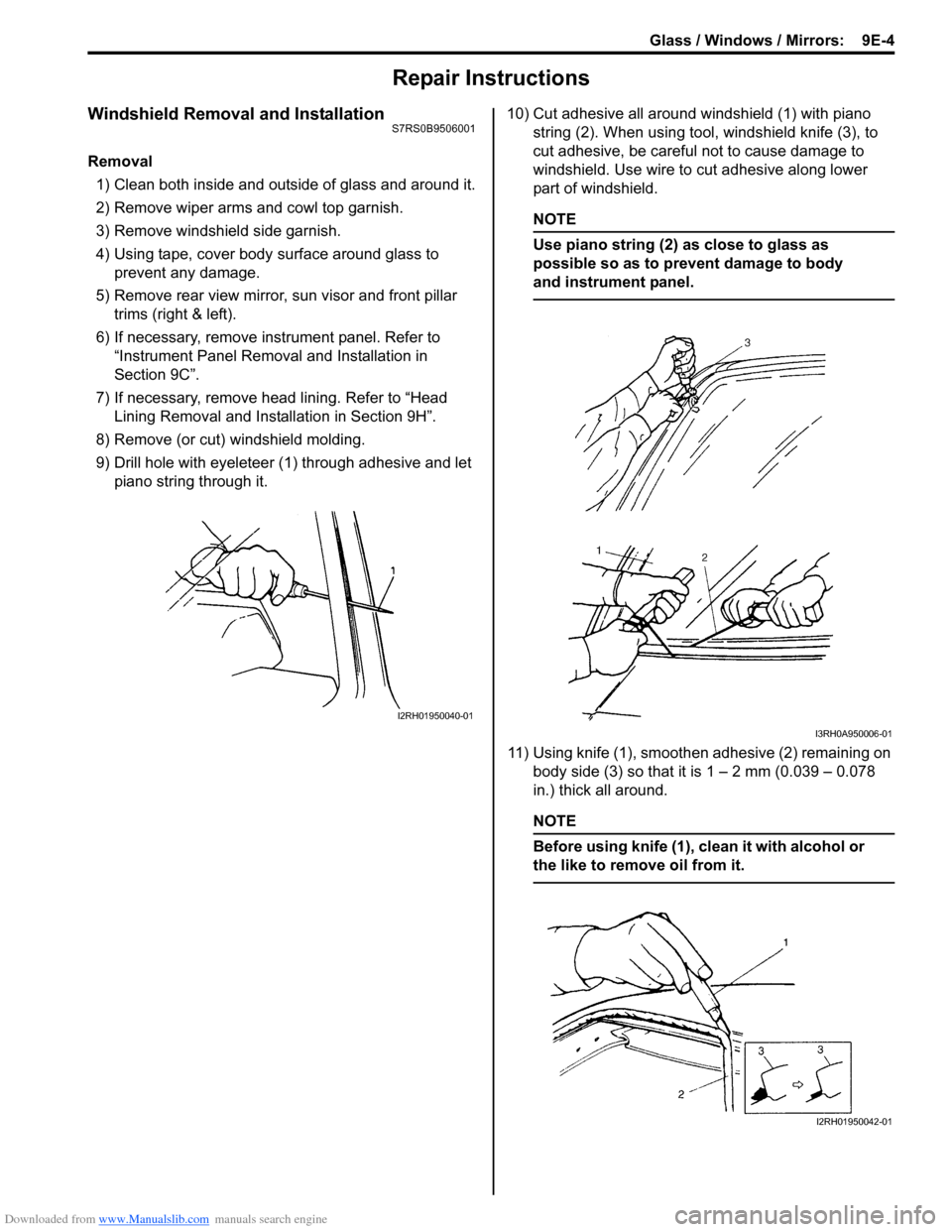

Removal1) Clean both inside and outside of glass and around it.

2) Remove wiper arms and cowl top garnish.

3) Remove windshield side garnish.

4) Using tape, cover body surface around glass to prevent any damage.

5) Remove rear view mirror , sun visor and front pillar

trims (right & left).

6) If necessary, remove instrument panel. Refer to “Instrument Panel Removal and Installation in

Section 9C”.

7) If necessary, remove he ad lining. Refer to “Head

Lining Removal and Installation in Section 9H”.

8) Remove (or cut) windshield molding.

9) Drill hole with eyeleteer (1 ) through adhesive and let

piano string through it. 10) Cut adhesive all around windshield (1) with piano

string (2). When using tool, windshield knife (3), to

cut adhesive, be careful not to cause damage to

windshield. Use wire to cut adhesive along lower

part of windshield.

NOTE

Use piano string (2) as close to glass as

possible so as to prevent damage to body

and instrument panel.

11) Using knife (1), smoothen adhesive (2) remaining on body side (3) so that it is 1 – 2 mm (0.039 – 0.078

in.) thick all around.

NOTE

Before using knife (1), clean it with alcohol or

the like to remove oil from it.

I2RH01950040-01

I3RH0A950006-01

I2RH01950042-01

Page 1335 of 1496

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-8

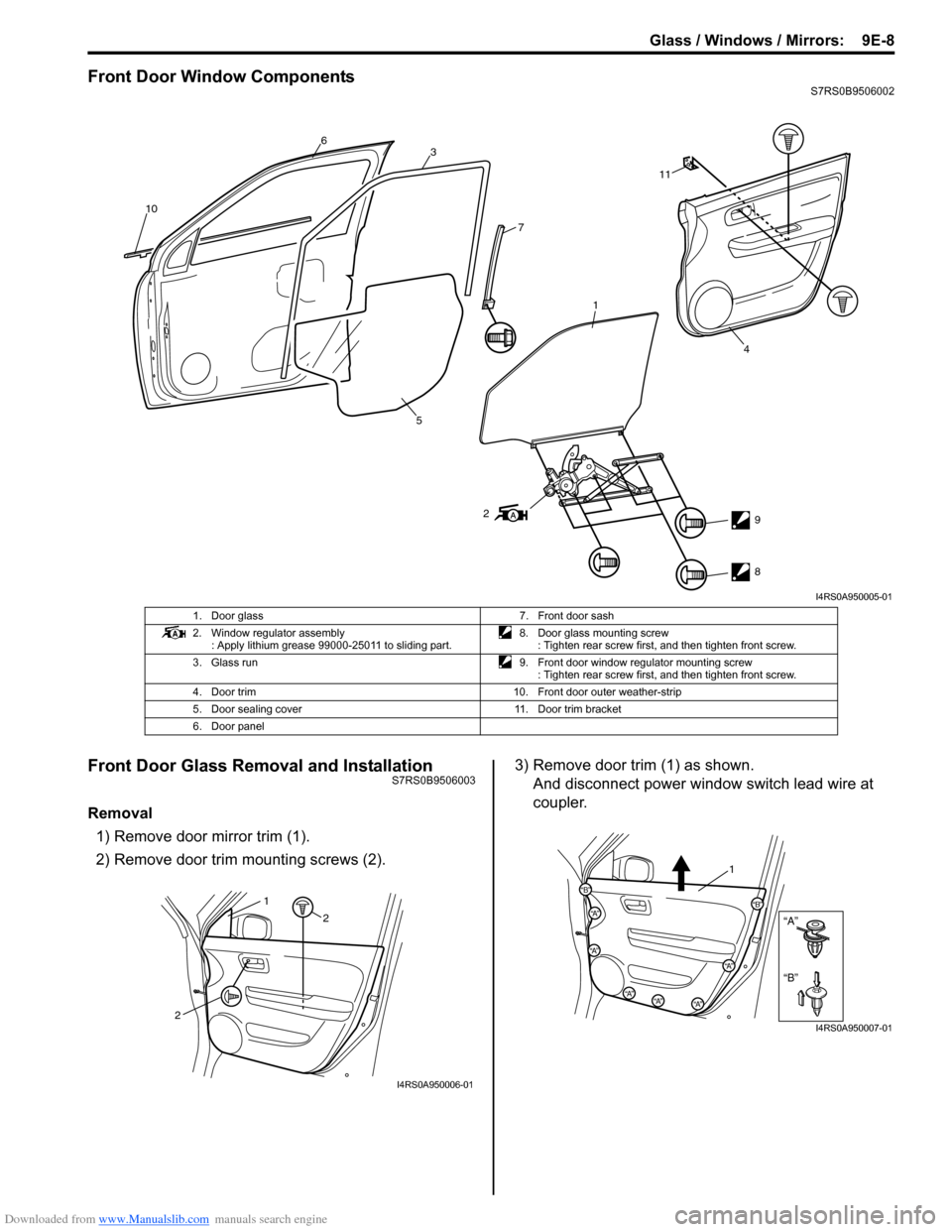

Front Door Window ComponentsS7RS0B9506002

Front Door Glass Removal and InstallationS7RS0B9506003

Removal1) Remove door mirror trim (1).

2) Remove door trim mounting screws (2). 3) Remove door trim (1) as shown.

And disconnect power window switch lead wire at

coupler.

10 6

3

1

7

11

5

2 9

8

4

I4RS0A950005-01

1. Door glass 7. Front door sash

2. Window regulator assembly : Apply lithium grease 99000-25011 to sliding part. 8. Door glass mounting screw

: Tighten rear screw first, and then tighten front screw.

3. Glass run 9. Front door window regulator mounting screw

: Tighten rear screw first, and then tighten front screw.

4. Door trim 10. Front door outer weather-strip

5. Door sealing cover 11. Door trim bracket

6. Door panel

2 2

1

I4RS0A950006-01

“B”

“A”

“B”

“A”

“B”“A”

“A”

“A”“A”“A”

1

I4RS0A950007-01