WIRE SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 1414 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-11 Body Electrical Control System:

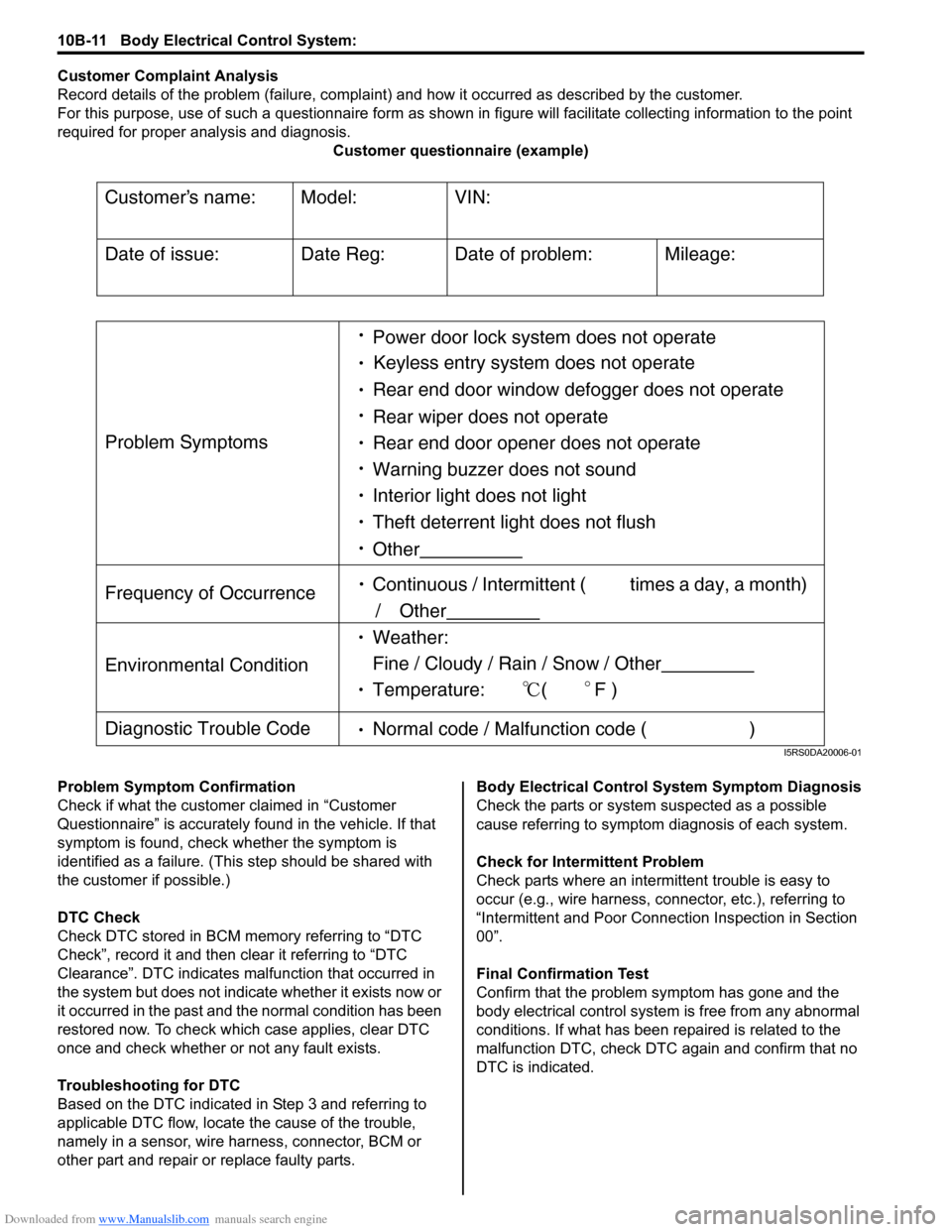

Customer Complaint Analysis

Record details of the problem (failure, complaint) and how it occurred as described by the customer.

For this purpose, use of such a questionnaire form as shown in figure will facilitate collectin g information to the point

required for proper analysis and diagnosis. Customer questionnaire (example)

Problem Symptom Confirmation

Check if what the custom er claimed in “Customer

Questionnaire” is accurately f ound in the vehicle. If that

symptom is found, check whether the symptom is

identified as a failure. (This step should be shared with

the customer if possible.)

DTC Check

Check DTC stored in BCM me mory referring to “DTC

Check”, record it and then clear it referring to “DTC

Clearance”. DTC indicates malfunction that occurred in

the system but does not indicate whether it exists now or

it occurred in the past and the normal condition has been

restored now. To check which case applies, clear DTC

once and check whether or not any fault exists.

Troubleshooting for DTC

Based on the DTC indicated in Step 3 and referring to

applicable DTC flow, locate the cause of the trouble,

namely in a sensor, wire harness, connector, BCM or

other part and repair or replace faulty parts. Body Electrical Control System Symptom Diagnosis

Check the parts or system

suspected as a possible

cause referring to symptom diagnosis of each system.

Check for Intermi ttent Problem

Check parts where an intermit tent trouble is easy to

occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connec tion Inspection in Section

00”.

Final Confirmation Test

Confirm that the problem symptom has gone and the

body electrical control system is free from any abnormal

conditions. If what has been repaired is related to the

malfunction DTC, check DTC again and confirm that no

DTC is indicated.

Customers name:

Model:

VIN:

Date of issue:

Date Reg:

Date of problem:

Mileage:

Problem Symptoms

Power door lock system does not operate

Keyless entry system does not operate

Rear end door window defogger does not operate

Rear wiper does not operate

Rear end door opener does not operate

Other

Frequency of Occurrence

Continuous / Intermittent ( times a day, a month)

/ Other

Environmental Condition

Weather:

Fine / Cloudy / Rain / Snow / Other

Temperature: (F )

Diagnostic Trouble Code Normal code / Malfunction code ( )

Warning buzzer does not sound

Interior light does not light

Theft deterrent light does not flush

I5RS0DA20006-01

Page 1422 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-19 Body Electrical Control System:

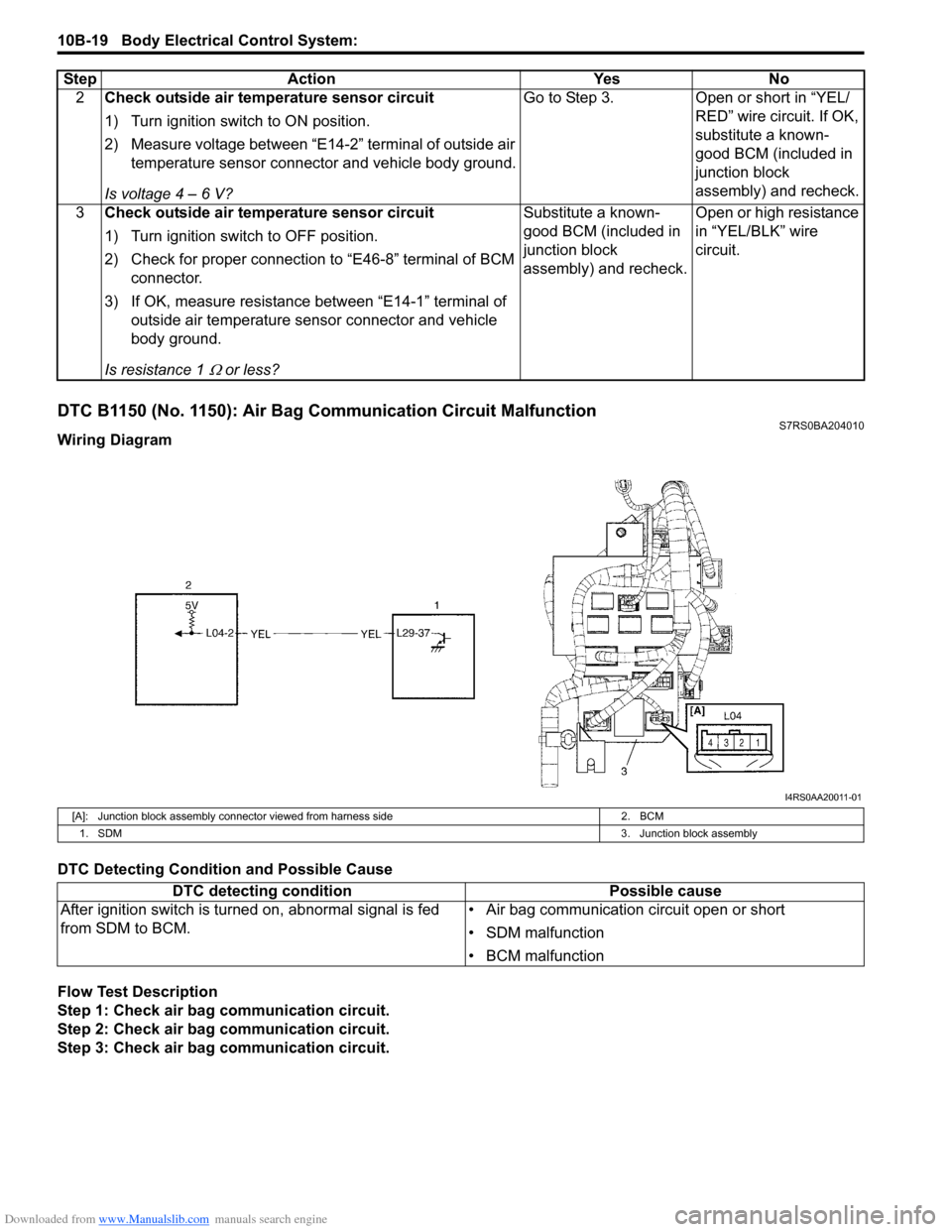

DTC B1150 (No. 1150): Air Bag Communication Circuit MalfunctionS7RS0BA204010

Wiring Diagram

DTC Detecting Condition and Possible Cause

Flow Test Description

Step 1: Check air bag communication circuit.

Step 2: Check air bag communication circuit.

Step 3: Check air bag communication circuit. 2

Check outside air temperature sensor circuit

1) Turn ignition switch to ON position.

2) Measure voltage between “E14-2” terminal of outside air

temperature sensor connector and vehicle body ground.

Is voltage 4 – 6 V? Go to Step 3. Open or short in “YEL/

RED” wire circuit. If OK,

substitute a known-

good BCM (included in

junction block

assembly) and recheck.

3 Check outside air temperature sensor circuit

1) Turn ignition switch to OFF position.

2) Check for proper connection to “E46-8” terminal of BCM

connector.

3) If OK, measure resistance between “E14-1” terminal of outside air temperature sens or connector and vehicle

body ground.

Is resistance 1

Ω or less? Substitute a known-

good BCM (included in

junction block

assembly) and recheck.

Open or high resistance

in “YEL/BLK” wire

circuit.

Step Action Yes No

I4RS0AA20011-01

[A]: Junction block assembly connect

or viewed from harness side 2. BCM

1. SDM 3. Junction block assembly

DTC detecting conditionPossible cause

After ignition switch is turned on, abnormal signal is fed

from SDM to BCM. • Air bag communication circuit open or short

• SDM malfunction

• BCM malfunction

Page 1438 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-35 Body Electrical Control System:

Junction block connector “L06”

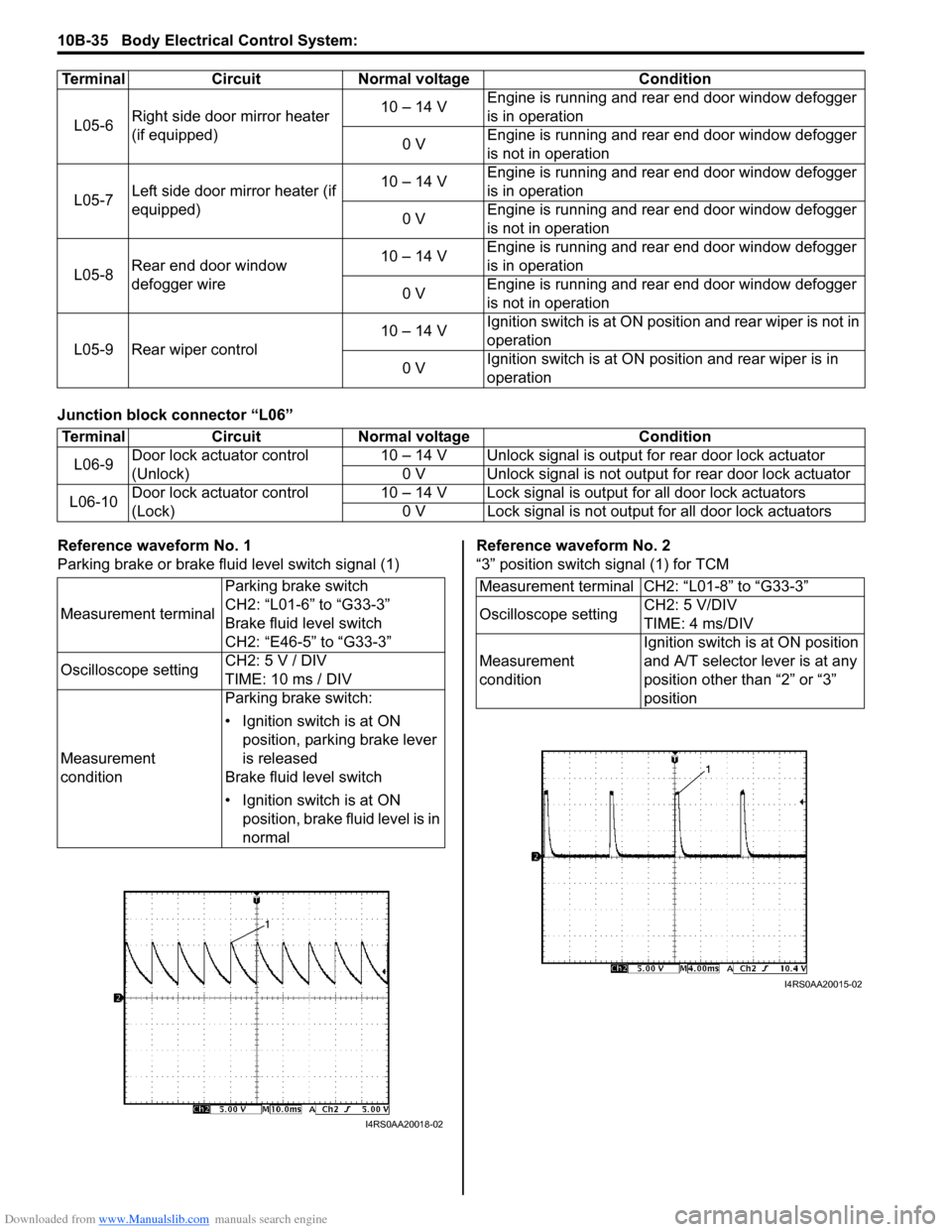

Reference waveform No. 1

Parking brake or brake fluid level switch signal (1)Reference waveform No. 2

“3” position switch signal (1) for TCM

L05-6

Right side door mirror heater

(if equipped) 10 – 14 V

Engine is running and rear end door window defogger

is in operation

0 V Engine is running and rear end door window defogger

is not in operation

L05-7 Left side door mirror heater (if

equipped) 10 – 14 V

Engine is running and rear end door window defogger

is in operation

0 V Engine is running and rear end door window defogger

is not in operation

L05-8 Rear end door window

defogger wire 10 – 14 V

Engine is running and rear end door window defogger

is in operation

0 V Engine is running and rear end door window defogger

is not in operation

L05-9 Rear wiper control 10 – 14 V

Ignition switch is at ON posi

tion and rear wiper is not in

operation

0 V Ignition switch is at ON pos

ition and rear wiper is in

operation

Terminal Circuit Normal voltage Condition

Terminal

CircuitNormal voltage Condition

L06-9 Door lock actuator control

(Unlock) 10 – 14 V Unlock signal is outpu

t for rear door lock actuator

0 V Unlock signal is not output for rear door lock actuator

L06-10 Door lock actuator control

(Lock) 10 – 14 V Lock signal is output for all door lock actuators

0 V Lock signal is not output for all door lock actuators

Measurement terminal Parking brake switch

CH2: “L01-6” to “G33-3”

Brake fluid level switch

CH2: “E46-5” to “G33-3”

Oscilloscope setting CH2: 5 V / DIV

TIME: 10 ms / DIV

Measurement

condition Parking brake switch:

• Ignition switch is at ON

position, parking brake lever

is released

Brake fluid level switch

• Ignition switch is at ON position, brake fluid level is in

normal

I4RS0AA20018-02

Measurement terminal CH2: “L01-8” to “G33-3”

Oscilloscope setting CH2: 5 V/DIV

TIME: 4 ms/DIV

Measurement

condition Ignition switch is at ON position

and A/T selector lever is at any

position other than “2” or “3”

position

I4RS0AA20015-02

Page 1444 of 1496

Downloaded from www.Manualslib.com manuals search engine 10C-1 Immobilizer Control System:

Control Systems

Immobilizer Control System

Precautions

Precautions in Diagnosing TroublesS7RS0BA300001

• Before confirming the diagnostic trouble code (DTC),

do not disconnect connector from ECM, battery cable

from battery, ground wire harness, or main fuse. Such

disconnection will erase DTC stored in ECM.

• DTC stored in ECM memory can be checked as well as cleared by using SUZUKI scan tool. Before using

SUZUKI scan tool, read its operator’s manual

carefully to know how to use it and what functions are

available.

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” before inspection.

• Communication of ECM, BCM, keyless start control module (if equipped), ABS / ESP ® control module,

steering angle sensor (ESP ® model), combination

meter and TCM (A/T model) is established by CAN

(Controller Area Network). Therefore, handle CAN

communication lines with care referring to “Precaution

for CAN Communication System in Section 00”. For

CAN communication system, refer to description on

“CAN Communication System Description in Section

1A”.

Precaution in Replacing ECMS7RS0BA300002

• If ECM is replaced with new or used one without immobilizer control function , the engine will not be

started. In case of the above, check if the newly

installed ECM has immobilizer control function.

• After ECM is replaced with new one or used one, the transponder code in the transponder built in the

ignition key has to be registered with ECM. Or, the

engine cannot be started up. For the registration

procedure, refer to “Procedure after ECM

Replacement”.

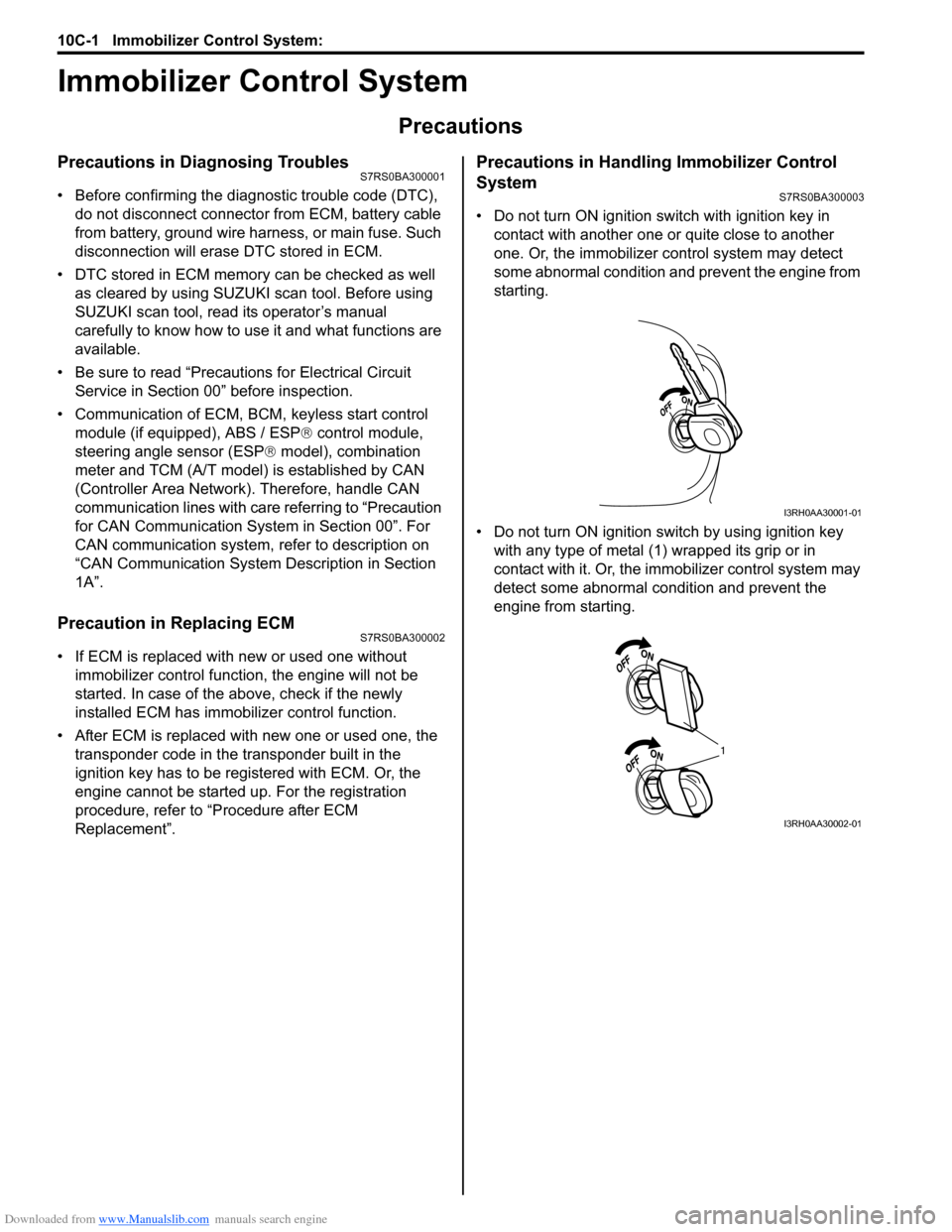

Precautions in Handling Immobilizer Control

System

S7RS0BA300003

• Do not turn ON ignition sw itch with ignition key in

contact with another one or quite close to another

one. Or, the immobilizer co ntrol system may detect

some abnormal condition and prevent the engine from

starting.

• Do not turn ON ignition switch by using ignition key with any type of metal (1) wrapped its grip or in

contact with it. Or, the i mmobilizer control system may

detect some abnormal condition and prevent the

engine from starting.

I3RH0AA30001-01

1

I3RH0AA30002-01

Page 1453 of 1496

Downloaded from www.Manualslib.com manuals search engine Immobilizer Control System: 10C-10

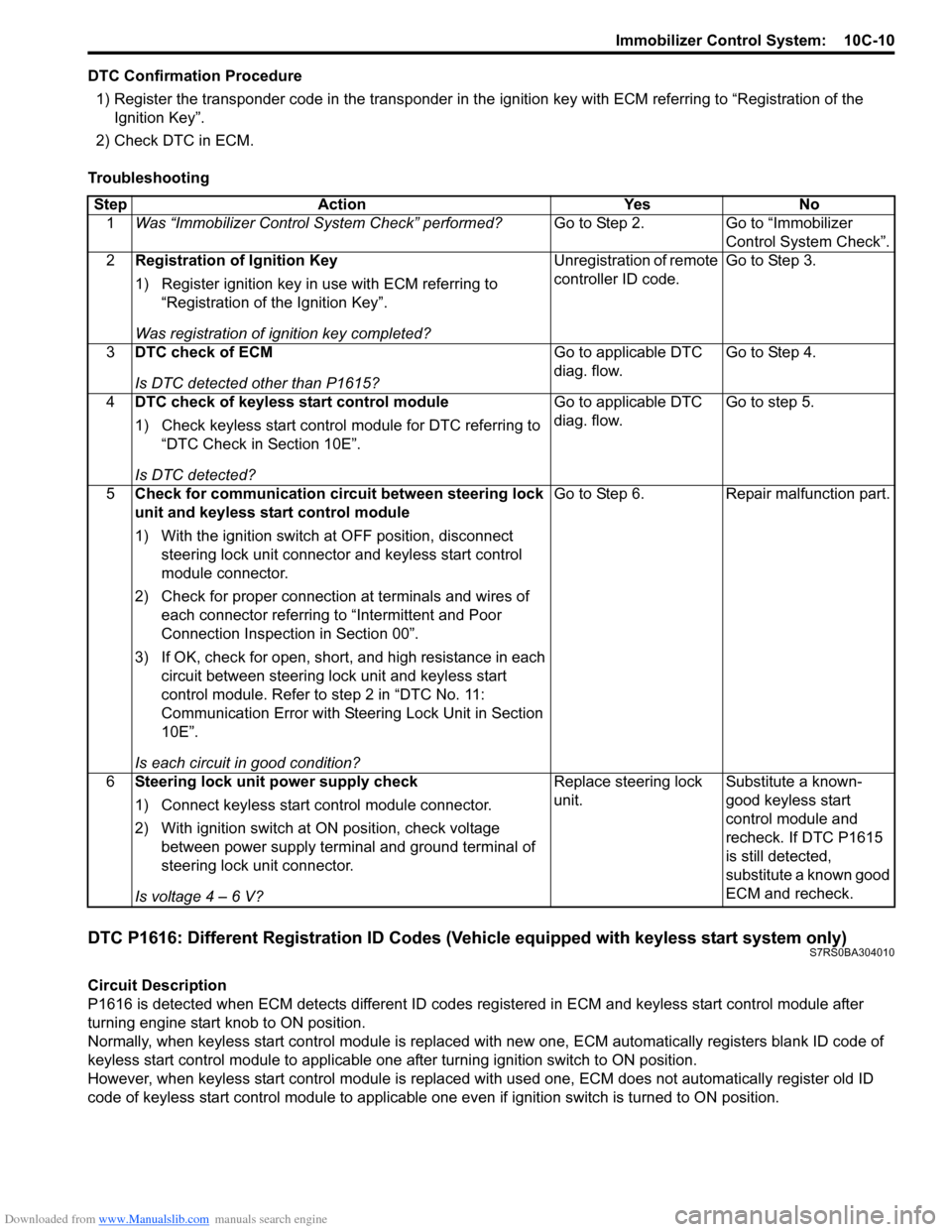

DTC Confirmation Procedure1) Register the transponder code in the transponder in the ignition key with ECM referring to “Registration of the

Ignition Key”.

2) Check DTC in ECM.

Troubleshooting

DTC P1616: Different Registration ID Codes (Vehicle equipped with keyless start system only)S7RS0BA304010

Circuit Description

P1616 is detected when ECM detects different ID codes registered in ECM and keyless start control module after

turning engine start knob to ON position.

Normally, when keyless start control module is replaced with new one, ECM automatically registers blank ID code of

keyless start control module to applicable one after turning ignition switch to ON position.

However, when keyless start control module is replaced wit h used one, ECM does not automatically register old ID

code of keyless start control module to applicable one ev en if ignition switch is turned to ON position.

Step Action Yes No

1 Was “Immobilizer Control S ystem Check” performed? Go to Step 2. Go to “Immobilizer

Control System Check”.

2 Registration of Ignition Key

1) Register ignition key in use with ECM referring to

“Registration of the Ignition Key”.

Was registration of ignition key completed? Unregistration of remote

controller ID code.

Go to Step 3.

3 DTC check of ECM

Is DTC detected other than P1615? Go to applicable DTC

diag. flow.

Go to Step 4.

4 DTC check of keyless start control module

1) Check keyless start control module for DTC referring to

“DTC Check in Section 10E”.

Is DTC detected? Go to applicable DTC

diag. flow.

Go to step 5.

5 Check for communication circuit between steering lock

unit and keyless start control module

1) With the ignition switch at OFF position, disconnect

steering lock unit connector and keyless start control

module connector.

2) Check for proper connection at terminals and wires of

each connector referring to “Intermittent and Poor

Connection Inspection in Section 00”.

3) If OK, check for open, short, and high resistance in each circuit between steering lock unit and keyless start

control module. Refer to step 2 in “DTC No. 11:

Communication Error with Steeri ng Lock Unit in Section

10E”.

Is each circuit in good condition? Go to Step 6. Repair malfunction part.

6 Steering lock unit power supply check

1) Connect keyless start control module connector.

2) With ignition switch at ON position, check voltage

between power supply terminal and ground terminal of

steering lock unit connector.

Is voltage 4 – 6 V? Replace steering lock

unit.

Substitute a known-

good keyless start

control module and

recheck. If DTC P1615

is still detected,

substitute a known good

ECM and recheck.

Page 1457 of 1496

Downloaded from www.Manualslib.com manuals search engine Immobilizer Control System: 10C-14

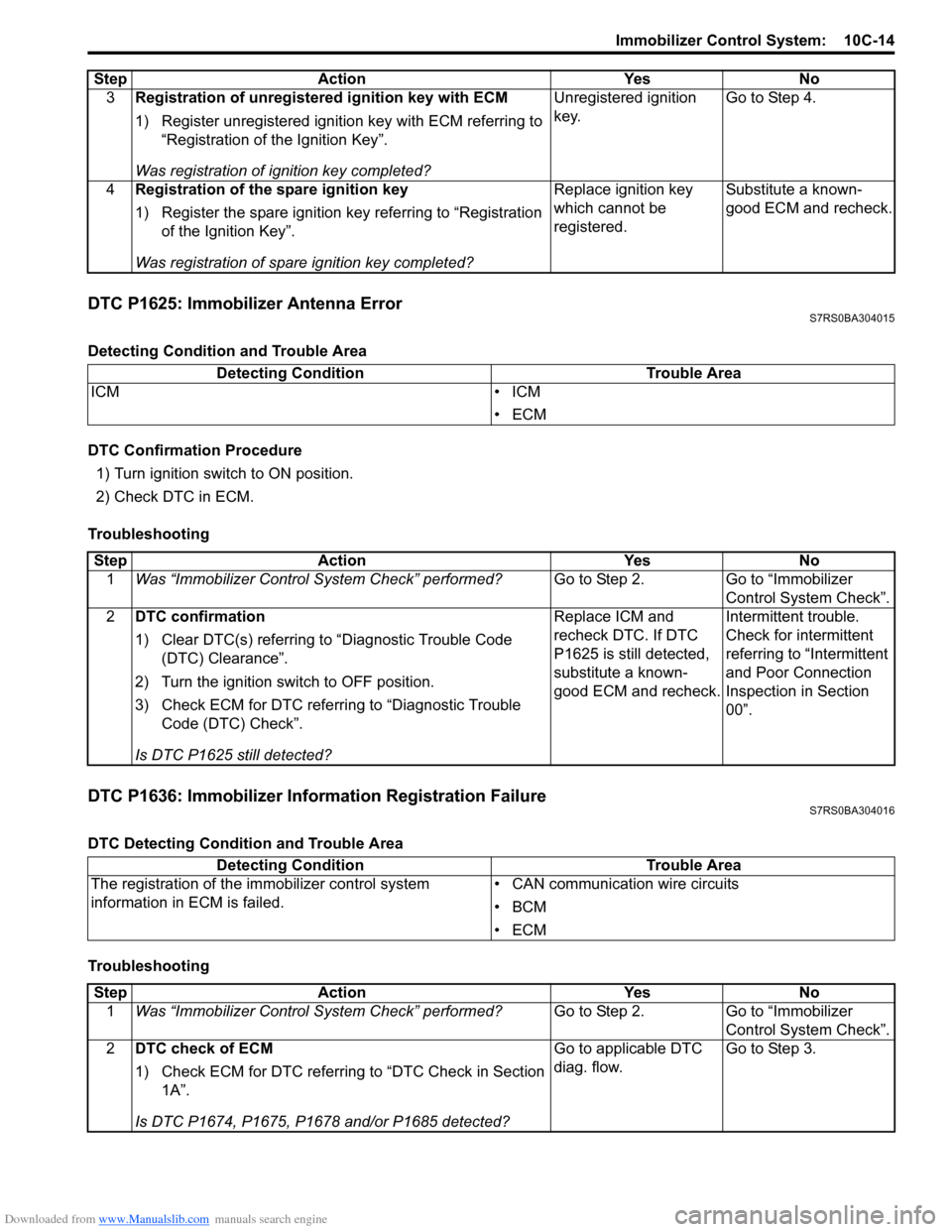

DTC P1625: Immobilizer Antenna ErrorS7RS0BA304015

Detecting Condition and Trouble Area

DTC Confirmation Procedure1) Turn ignition switch to ON position.

2) Check DTC in ECM.

Troubleshooting

DTC P1636: Immobilizer Information Registration FailureS7RS0BA304016

DTC Detecting Condition and Trouble Area

Troubleshooting 3

Registration of unregistered ignition key with ECM

1) Register unregistered igniti on key with ECM referring to

“Registration of the Ignition Key”.

Was registration of ignition key completed? Unregistered ignition

key.

Go to Step 4.

4 Registration of the spare ignition key

1) Register the spare ignition key referring to “Registration

of the Ignition Key”.

Was registration of spare ignition key completed? Replace ignition key

which cannot be

registered.

Substitute a known-

good ECM and recheck.

Step Action Yes No

Detecting Condition

Trouble Area

ICM • ICM

•ECM

StepAction YesNo

1 Was “Immobilizer Control S ystem Check” performed? Go to Step 2.Go to “Immobilizer

Control System Check”.

2 DTC confirmation

1) Clear DTC(s) referring to “Diagnostic Trouble Code

(DTC) Clearance”.

2) Turn the ignition switch to OFF position.

3) Check ECM for DTC referring to “Diagnostic Trouble Code (DTC) Check”.

Is DTC P1625 still detected? Replace ICM and

recheck DTC. If DTC

P1625 is still detected,

substitute a known-

good ECM and recheck.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Detecting Condition

Trouble Area

The registration of the immobilizer control system

information in ECM is failed. • CAN communication wire circuits

•BCM

•ECM

Step

Action YesNo

1 Was “Immobilizer Control S ystem Check” performed? Go to Step 2.Go to “Immobilizer

Control System Check”.

2 DTC check of ECM

1) Check ECM for DTC referring to “DTC Check in Section

1A”.

Is DTC P1674, P1675, P1678 and/or P1685 detected? Go to applicable DTC

diag. flow.

Go to Step 3.

Page 1483 of 1496

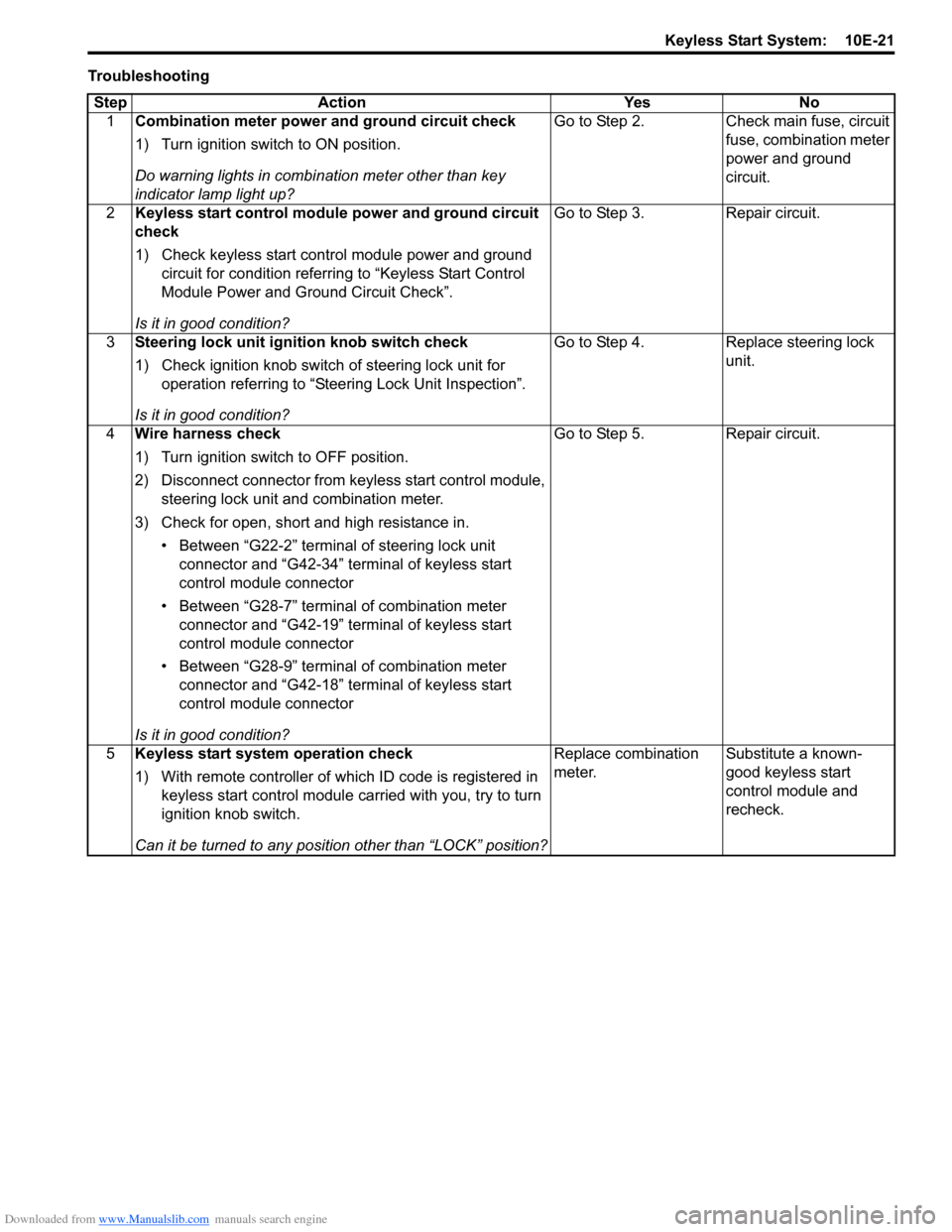

Downloaded from www.Manualslib.com manuals search engine Keyless Start System: 10E-21

TroubleshootingStep Action Yes No 1 Combination meter power and ground circuit check

1) Turn ignition switch to ON position.

Do warning lights in combi nation meter other than key

indicator lamp light up? Go to Step 2. Check main fuse, circuit

fuse, combination meter

power and ground

circuit.

2 Keyless start control module power and ground circuit

check

1) Check keyless start control module power and ground

circuit for condition referrin g to “Keyless Start Control

Module Power and Ground Circuit Check”.

Is it in good condition? Go to Step 3. Repair circuit.

3 Steering lock unit ignition knob switch check

1) Check ignition knob switch of steering lock unit for

operation referring to “Steering Lock Unit Inspection”.

Is it in good condition? Go to Step 4. Replace steering lock

unit.

4 Wire harness check

1) Turn ignition switch to OFF position.

2) Disconnect connector from ke yless start control module,

steering lock unit and combination meter.

3) Check for open, short and high resistance in. • Between “G22-2” terminal of steering lock unit connector and “G42-34” terminal of keyless start

control module connector

• Between “G28-7” terminal of combination meter connector and “G42-19” terminal of keyless start

control module connector

• Between “G28-9” terminal of combination meter connector and “G42-18” terminal of keyless start

control module connector

Is it in good condition? Go to Step 5. Repair circuit.

5 Keyless start system operation check

1) With remote controller of which ID code is registered in

keyless start control module carried with you, try to turn

ignition knob switch.

Can it be turned to any position other than “LOCK” position? Replace combination

meter.

Substitute a known-

good keyless start

control module and

recheck.

Page 1486 of 1496

Downloaded from www.Manualslib.com manuals search engine 10E-24 Keyless Start System:

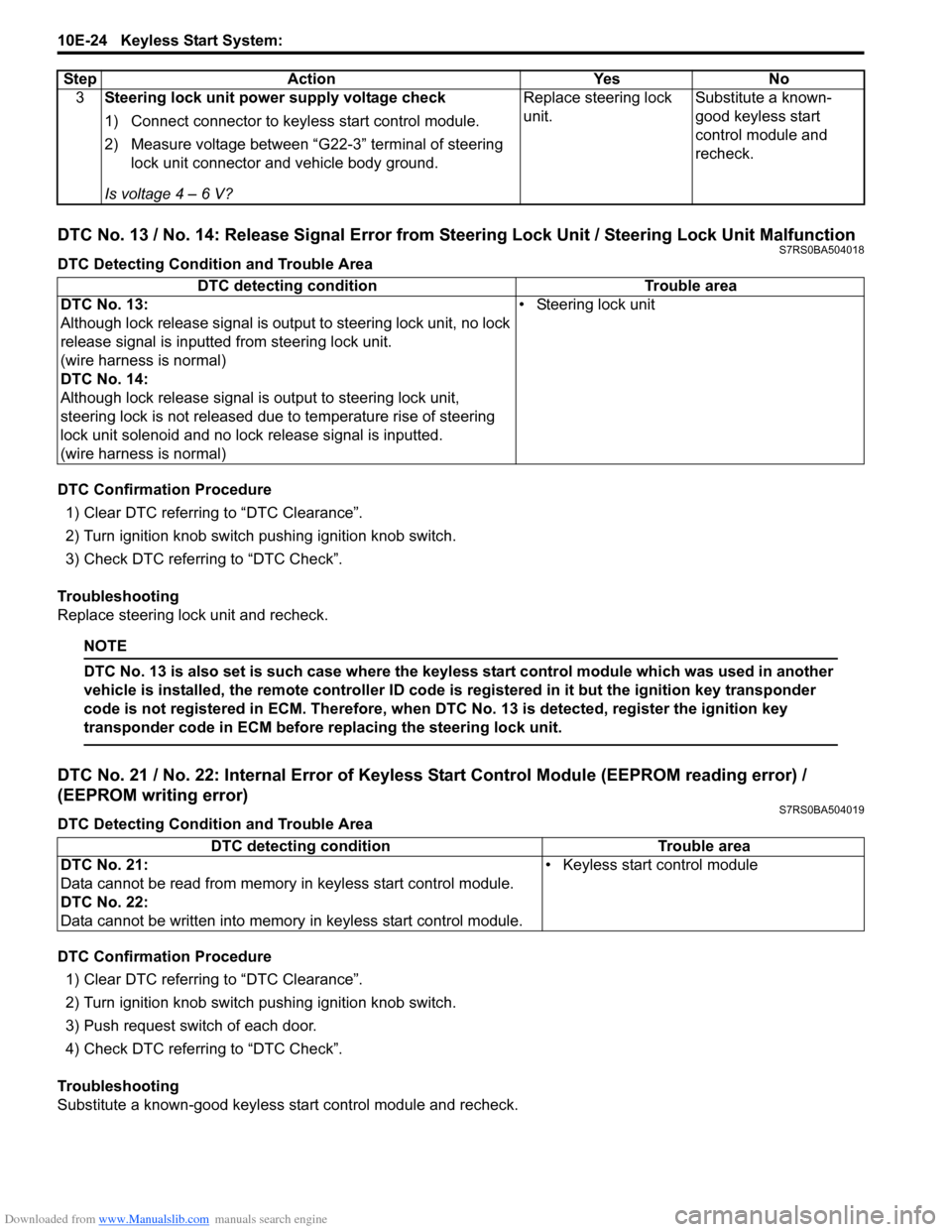

DTC No. 13 / No. 14: Release Signal Error from Steering Lock Unit / Steering Lock Unit MalfunctionS7RS0BA504018

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) Clear DTC referring to “DTC Clearance”.

2) Turn ignition knob switch pushing ignition knob switch.

3) Check DTC referring to “DTC Check”.

Troubleshooting

Replace steering lock unit and recheck.

NOTE

DTC No. 13 is also set is such case where the keyless start control module which was used in another

vehicle is installed, the remote controller ID code is registered in it but the ignition key transponder

code is not registered in ECM. Therefore, when DTC No. 13 is detected, register the ignition key

transponder code in ECM before replacing the steering lock unit.

DTC No. 21 / No. 22: Internal Error of Keyle ss Start Control Module (EEPROM reading error) /

(EEPROM writing error)

S7RS0BA504019

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Clear DTC referring to “DTC Clearance”.

2) Turn ignition knob switch pushing ignition knob switch.

3) Push request switch of each door.

4) Check DTC referring to “DTC Check”.

Troubleshooting

Substitute a known-good keyless start control module and recheck. 3

Steering lock unit power supply voltage check

1) Connect connector to keyl ess start control module.

2) Measure voltage between “G22-3” terminal of steering lock unit connector and vehicle body ground.

Is voltage 4 – 6 V? Replace steering lock

unit.

Substitute a known-

good keyless start

control module and

recheck.

Step Action Yes No

DTC detecting condition

Trouble area

DTC No. 13:

Although lock release signal is ou tput to steering lock unit, no lock

release signal is inputted from steering lock unit.

(wire harness is normal)

DTC No. 14:

Although lock release signal is output to steering lock unit,

steering lock is not released due to temperature rise of steering

lock unit solenoid and no lock release signal is inputted.

(wire harness is normal) • Steering lock unit

DTC detecting condition Trouble area

DTC No. 21:

Data cannot be read from memory in keyless start control module.

DTC No. 22:

Data cannot be written into memory in keyless start control module.• Keyless start control module

Page 1491 of 1496

Downloaded from www.Manualslib.com manuals search engine Keyless Start System: 10E-29

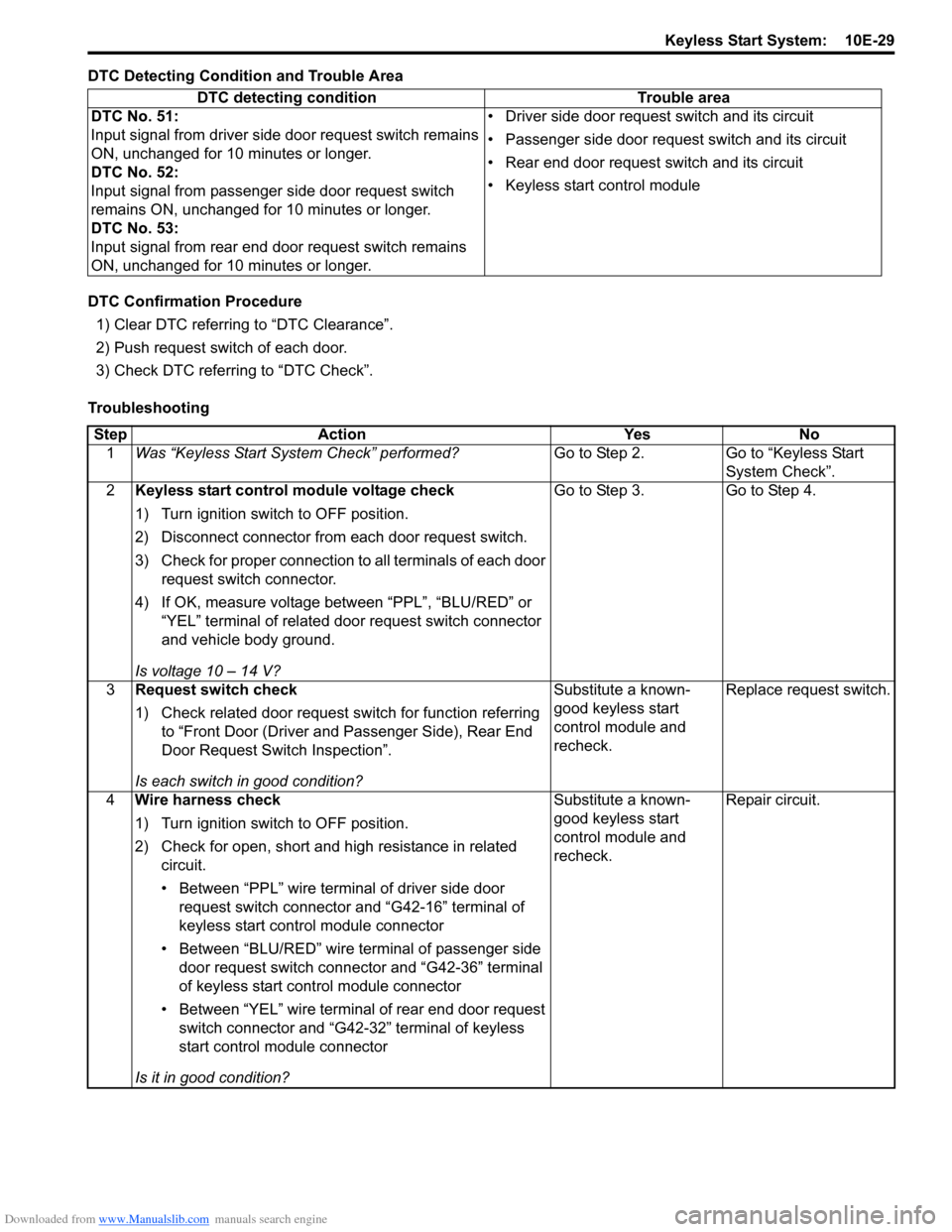

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) Clear DTC referring to “DTC Clearance”.

2) Push request switch of each door.

3) Check DTC referring to “DTC Check”.

Troubleshooting DTC detecting condition Trouble area

DTC No. 51:

Input signal from driver side door request switch remains

ON, unchanged for 10 minutes or longer.

DTC No. 52:

Input signal from passenger side door request switch

remains ON, unchanged for 10 minutes or longer.

DTC No. 53:

Input signal from rear end door request switch remains

ON, unchanged for 10 minutes or longer. • Driver side door request switch and its circuit

• Passenger side door request switch and its circuit

• Rear end door request switch and its circuit

• Keyless start control module

Step

Action YesNo

1 Was “Keyless Start System Check” performed? Go to Step 2.Go to “Keyless Start

System Check”.

2 Keyless start control module voltage check

1) Turn ignition switch to OFF position.

2) Disconnect connector from each door request switch.

3) Check for proper connection to all terminals of each door

request switch connector.

4) If OK, measure voltage between “PPL”, “BLU/RED” or “YEL” terminal of related door request switch connector

and vehicle body ground.

Is voltage 10 – 14 V? Go to Step 3.

Go to Step 4.

3 Request switch check

1) Check related door request switch for function referring

to “Front Door (Driver and Passenger Side), Rear End

Door Request Switch Inspection”.

Is each switch in good condition? Substitute a known-

good keyless start

control module and

recheck.

Replace request switch.

4 Wire harness check

1) Turn ignition switch to OFF position.

2) Check for open, short and high resistance in related

circuit.

• Between “PPL” wire terminal of driver side door request switch connector and “G42-16” terminal of

keyless start control module connector

• Between “BLU/RED” wire terminal of passenger side door request switch connector and “G42-36” terminal

of keyless start control module connector

• Between “YEL” wire terminal of rear end door request switch connector and “G42-32” terminal of keyless

start control module connector

Is it in good condition? Substitute a known-

good keyless start

control module and

recheck.

Repair circuit.