Axle seal SUZUKI SWIFT 2008 2.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 779 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-135

Reassembly

Reverse disassembly procedure for assembly, noting the

following points.

• Use new O-rings. Apply A/T fluid to the O-rings, before installation.

• Install 2nd brake piston (1) to which A/T fluid is applied to 2nd brake cylinder (2).

Do not damage O-ring wh en installing 2nd brake

piston.

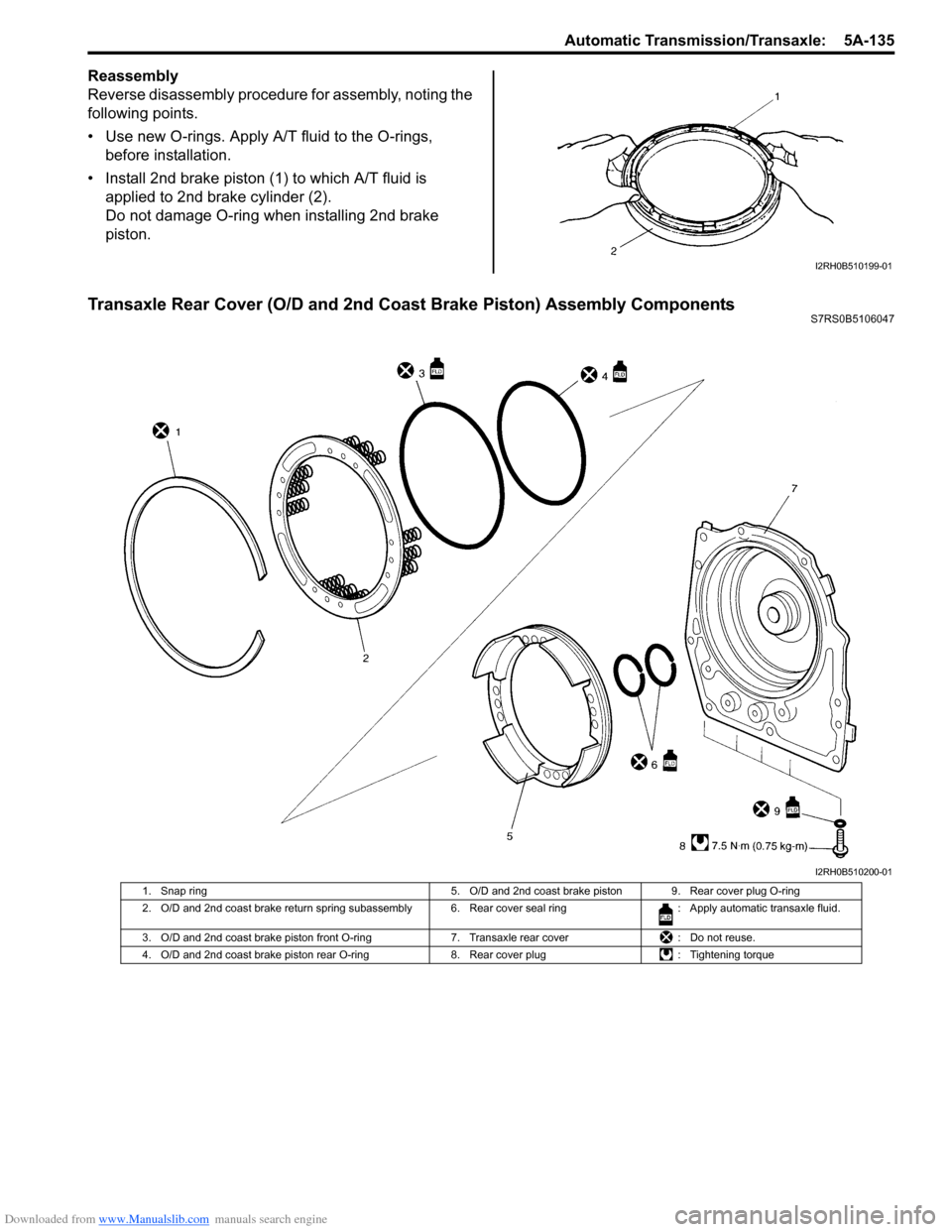

Transaxle Rear Cover (O/D and 2nd Coast Brake Piston) Assembly ComponentsS7RS0B5106047

I2RH0B510199-01

I2RH0B510200-01

1. Snap ring 5. O/D and 2nd coast brake piston 9. Rear cover plug O-ring

2. O/D and 2nd coast brake return spring subassembly 6. R ear cover seal ring: Apply automatic transaxle fluid.

3. O/D and 2nd coast brake piston front O- ring7. Transaxle rear cover : Do not reuse.

4. O/D and 2nd coast brake piston rear O- ring8. Rear cover plug : Tightening torque

Page 780 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-136 Automatic Transmission/Transaxle:

Transaxle Rear Cover (O/D and 2nd Coast Brake

Piston) Assembly Disassembly and

Reassembly

S7RS0B5106048

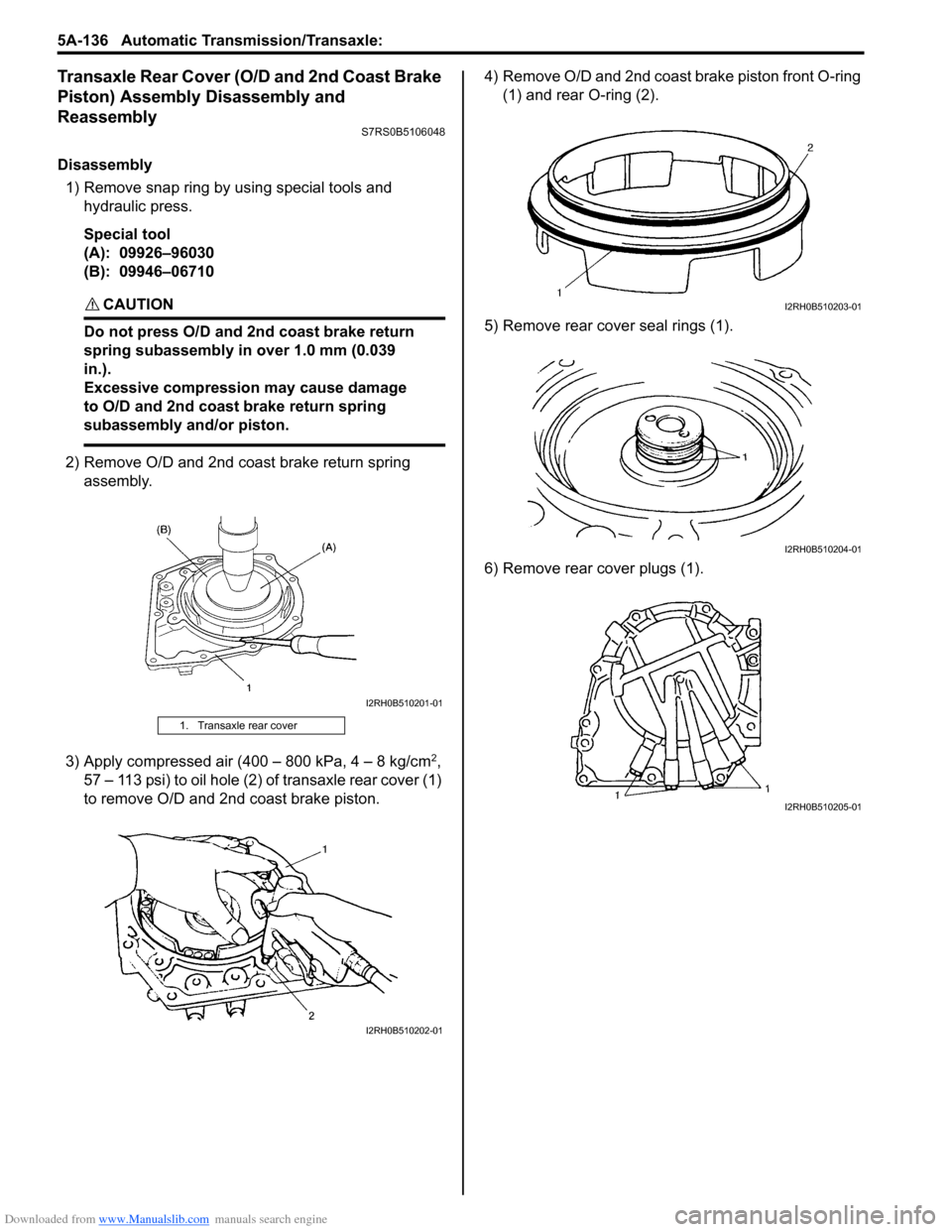

Disassembly1) Remove snap ring by using special tools and hydraulic press.

Special tool

(A): 09926–96030

(B): 09946–06710

CAUTION!

Do not press O/D and 2nd coast brake return

spring subassembly in over 1.0 mm (0.039

in.).

Excessive compression may cause damage

to O/D and 2nd coast brake return spring

subassembly and/or piston.

2) Remove O/D and 2nd coast brake return spring assembly.

3) Apply compressed air (400 – 800 kPa, 4 – 8 kg/cm

2,

57 – 113 psi) to oil hole (2) of transaxle rear cover (1)

to remove O/D and 2nd coast brake piston. 4) Remove O/D and 2nd coast brake piston front O-ring

(1) and rear O-ring (2).

5) Remove rear cove r seal rings (1).

6) Remove rear cover plugs (1).

1. Transaxle rear cover

I2RH0B510201-01

I2RH0B510202-01

I2RH0B510203-01

I2RH0B510204-01

I2RH0B510205-01

Page 781 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-137

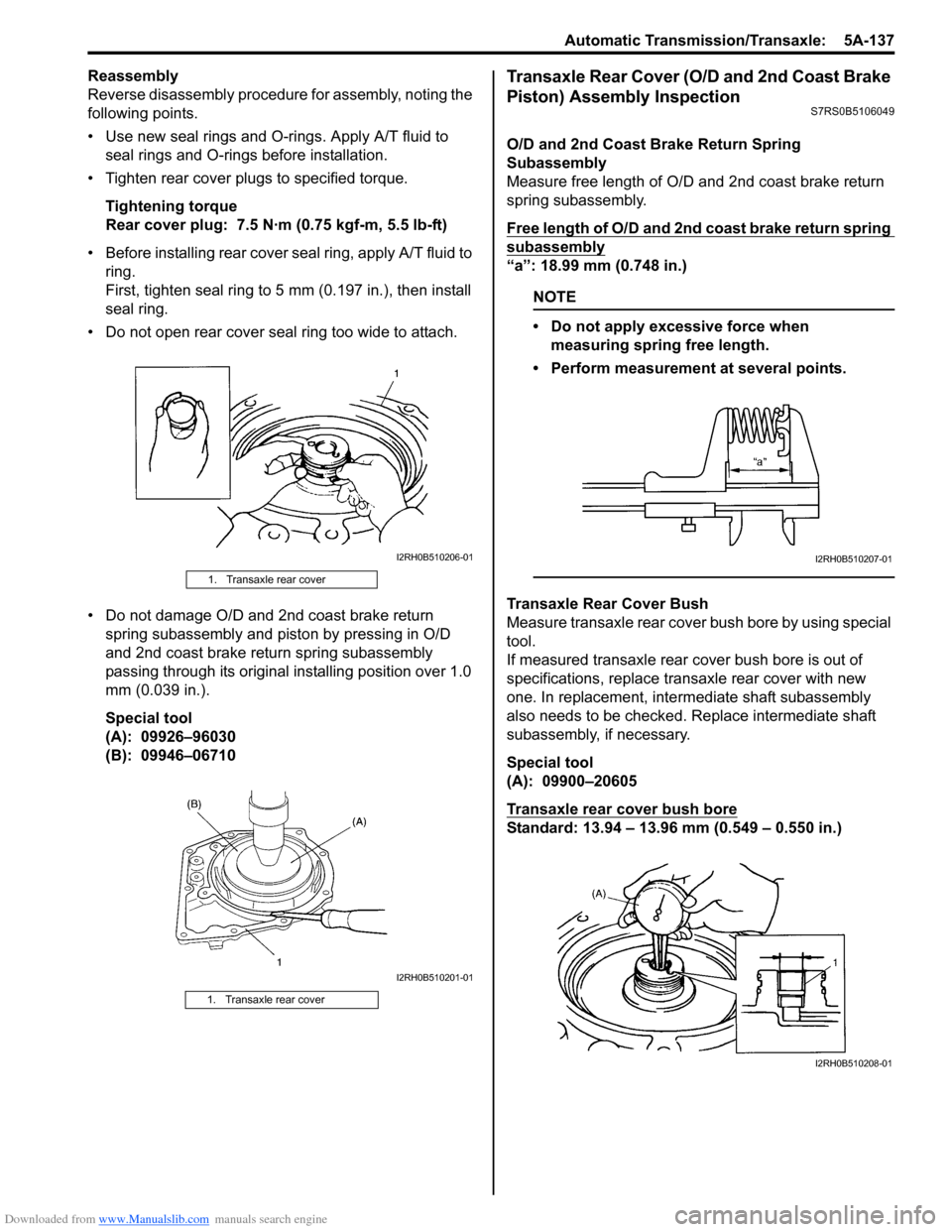

Reassembly

Reverse disassembly procedure for assembly, noting the

following points.

• Use new seal rings and O-rings. Apply A/T fluid to seal rings and O-rings before installation.

• Tighten rear cover plugs to specified torque.

Tightening torque

Rear cover plug: 7.5 N·m (0.75 kgf-m, 5.5 lb-ft)

• Before installing rear cover seal ring, apply A/T fluid to ring.

First, tighten seal ring to 5 mm (0.197 in.), then install

seal ring.

• Do not open rear cover seal ring too wide to attach.

• Do not damage O/D and 2nd coast brake return spring subassembly and piston by pressing in O/D

and 2nd coast brake return spring subassembly

passing through its original installing position over 1.0

mm (0.039 in.).

Special tool

(A): 09926–96030

(B): 09946–06710Transaxle Rear Cover (O/D and 2nd Coast Brake

Piston) Assembly Inspection

S7RS0B5106049

O/D and 2nd Coast Brake Return Spring

Subassembly

Measure free length of O/D and 2nd coast brake return

spring subassembly.

Free length of O/D and 2nd coast brake return spring

subassembly

“a”: 18.99 mm (0.748 in.)

NOTE

• Do not apply excessive force when measuring spring free length.

• Perform measurement at several points.

Transaxle Rear Cover Bush

Measure transaxle rear cover bush bore by using special

tool.

If measured transaxle rear cover bush bore is out of

specifications, replace transaxle rear cover with new

one. In replacement, inte rmediate shaft subassembly

also needs to be checked. Replace intermediate shaft

subassembly, if necessary.

Special tool

(A): 09900–20605

Transaxle rear cover bush bore

Standard: 13.94 – 13.96 mm (0.549 – 0.550 in.)

1. Transaxle rear cover

1. Transaxle rear cover

I2RH0B510206-01

I2RH0B510201-01

I2RH0B510207-01

I2RH0B510208-01

Page 788 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-144 Automatic Transmission/Transaxle:

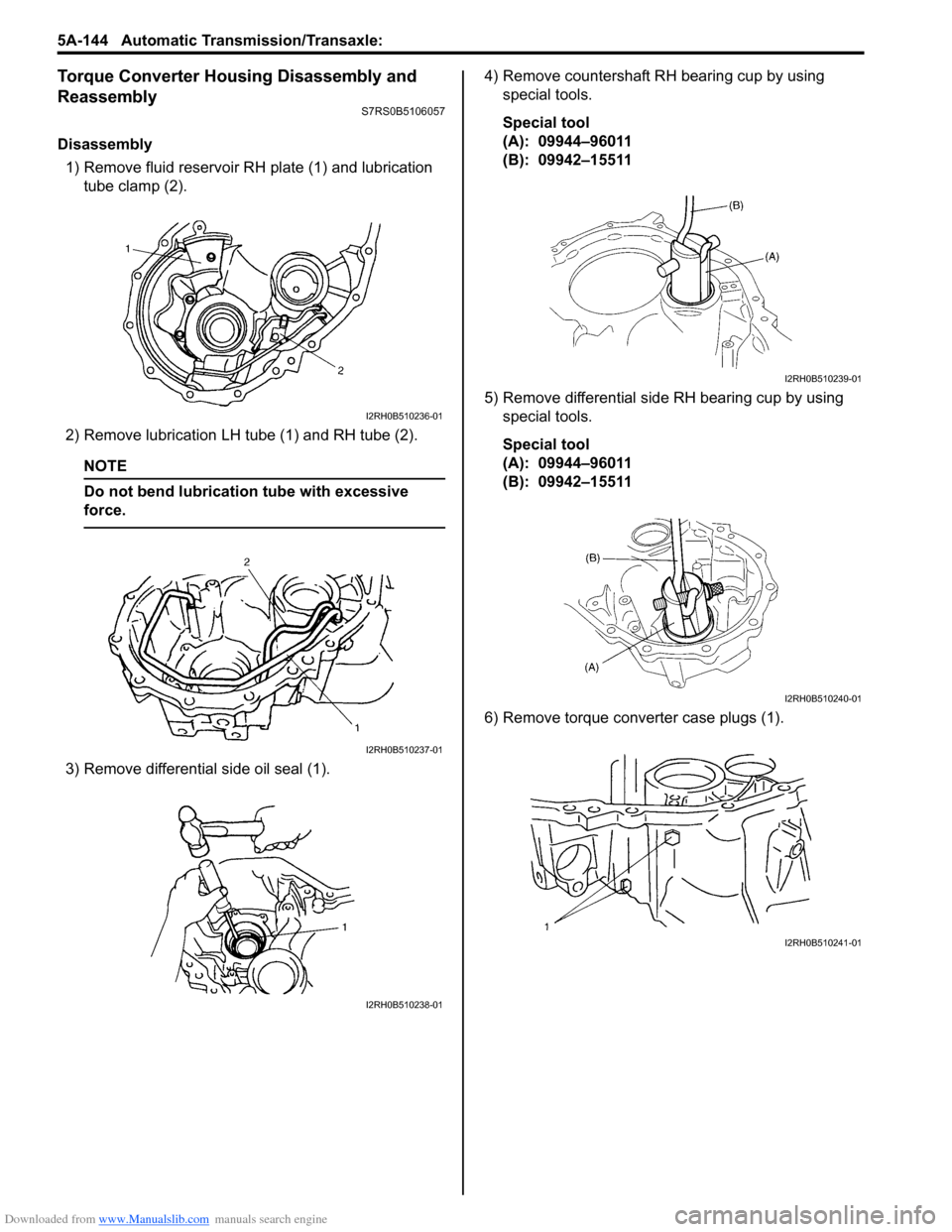

Torque Converter Housing Disassembly and

Reassembly

S7RS0B5106057

Disassembly1) Remove fluid reservoir RH plate (1) and lubrication tube clamp (2).

2) Remove lubrication LH tube (1) and RH tube (2).

NOTE

Do not bend lubrication tube with excessive

force.

3) Remove differential side oil seal (1). 4) Remove countershaft RH bearing cup by using

special tools.

Special tool

(A): 09944–96011

(B): 09942–15511

5) Remove differential side RH bearing cup by using special tools.

Special tool

(A): 09944–96011

(B): 09942–15511

6) Remove torque converter case plugs (1).

I2RH0B510236-01

I2RH0B510237-01

I2RH0B510238-01

I2RH0B510239-01

I2RH0B510240-01

I2RH0B510241-01

Page 789 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-145

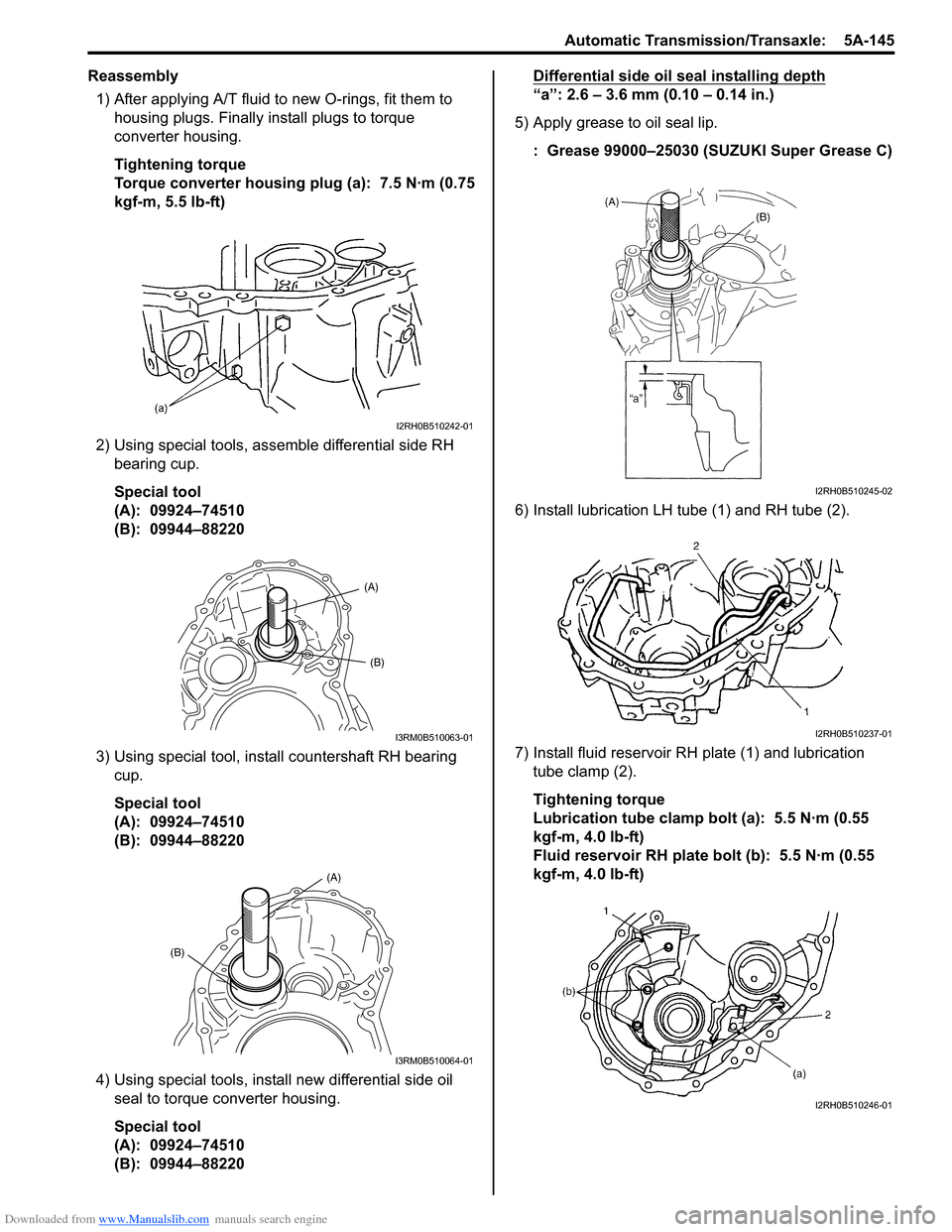

Reassembly1) After applying A/T fluid to new O-rings, fit them to housing plugs. Finally install plugs to torque

converter housing.

Tightening torque

Torque converter housing plug (a): 7.5 N·m (0.75

kgf-m, 5.5 lb-ft)

2) Using special tools, assemble differential side RH bearing cup.

Special tool

(A): 09924–74510

(B): 09944–88220

3) Using special tool, install countershaft RH bearing cup.

Special tool

(A): 09924–74510

(B): 09944–88220

4) Using special tools, install new differential side oil seal to torque converter housing.

Special tool

(A): 09924–74510

(B): 09944–88220 Differential side oil seal installing depth

“a”: 2.6 – 3.6 mm (0.10 – 0.14 in.)

5) Apply grease to oil seal lip. : Grease 99000–25030 (SUZUKI Super Grease C)

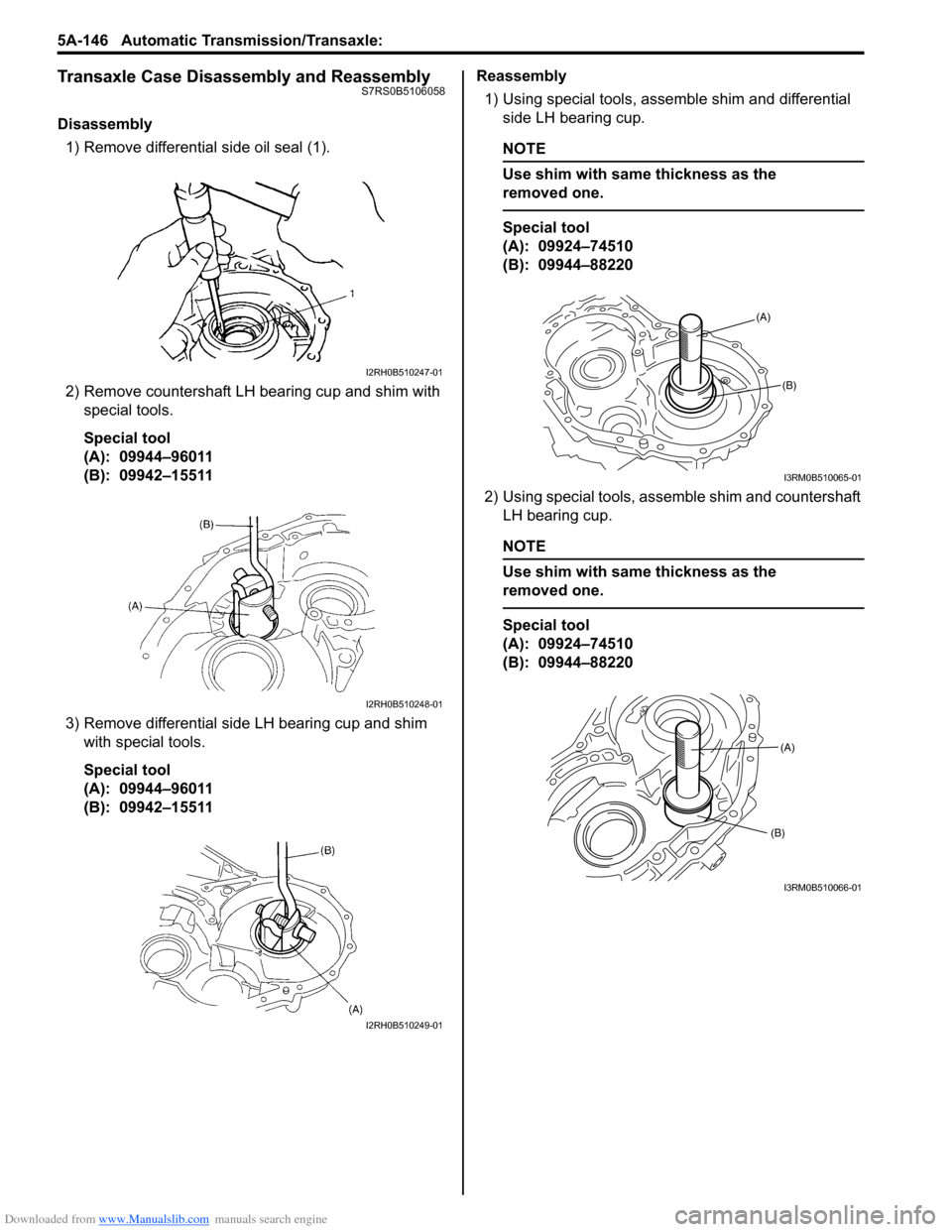

6) Install lubrication LH tube (1) and RH tube (2).

7) Install fluid reservoir RH plate (1) and lubrication tube clamp (2).

Tightening torque

Lubrication tube clamp bolt (a): 5.5 N·m (0.55

kgf-m, 4.0 lb-ft)

Fluid reservoir RH plate bolt (b): 5.5 N·m (0.55

kgf-m, 4.0 lb-ft)

I2RH0B510242-01

(A)

(B)

I3RM0B510063-01

(B) (A)

I3RM0B510064-01

I2RH0B510245-02

I2RH0B510237-01

I2RH0B510246-01

Page 790 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-146 Automatic Transmission/Transaxle:

Transaxle Case Disassembly and ReassemblyS7RS0B5106058

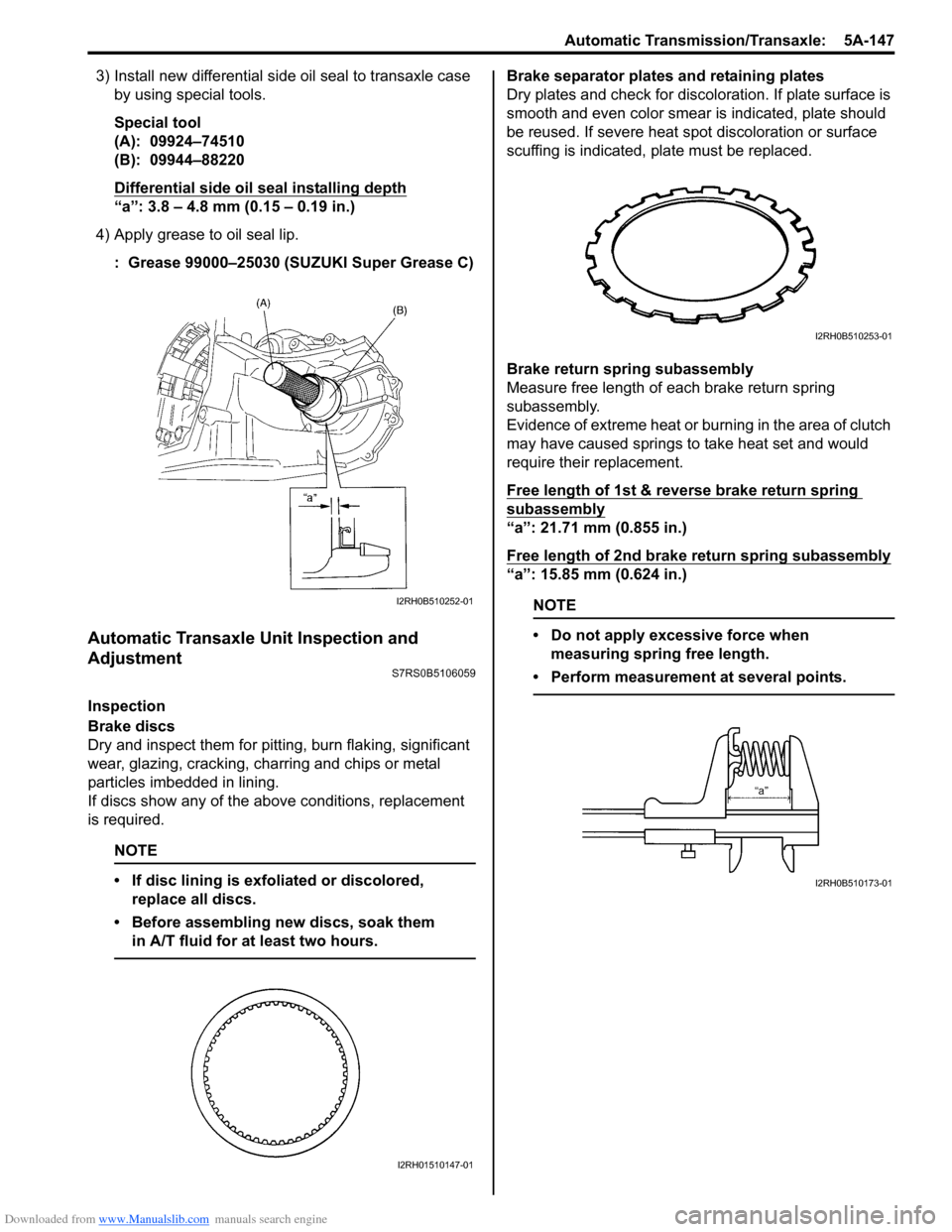

Disassembly1) Remove differential side oil seal (1).

2) Remove countershaft LH bearing cup and shim with special tools.

Special tool

(A): 09944–96011

(B): 09942–15511

3) Remove differential side LH bearing cup and shim with special tools.

Special tool

(A): 09944–96011

(B): 09942–15511 Reassembly

1) Using special tools, assemb le shim and differential

side LH bearing cup.

NOTE

Use shim with same thickness as the

removed one.

Special tool

(A): 09924–74510

(B): 09944–88220

2) Using special tools, assemble shim and countershaft LH bearing cup.

NOTE

Use shim with same thickness as the

removed one.

Special tool

(A): 09924–74510

(B): 09944–88220

I2RH0B510247-01

I2RH0B510248-01

I2RH0B510249-01

(B)

(A)

I3RM0B510065-01

(B) (A)

I3RM0B510066-01

Page 791 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-147

3) Install new differential side oil seal to transaxle case by using special tools.

Special tool

(A): 09924–74510

(B): 09944–88220

Differential side oil seal installing depth

“a”: 3.8 – 4.8 mm (0.15 – 0.19 in.)

4) Apply grease to oil seal lip. : Grease 99000–25030 (SUZUKI Super Grease C)

Automatic Transaxle Unit Inspection and

Adjustment

S7RS0B5106059

Inspection

Brake discs

Dry and inspect them for pitting, burn flaking, significant

wear, glazing, cracking, charring and chips or metal

particles imbedded in lining.

If discs show any of the ab ove conditions, replacement

is required.

NOTE

• If disc lining is exfoliated or discolored, replace all discs.

• Before assembling new discs, soak them in A/T fluid for at least two hours.

Brake separator plates and retaining plates

Dry plates and check for discol oration. If plate surface is

smooth and even color smear is indicated, plate should

be reused. If severe heat spot discoloration or surface

scuffing is indicated, plate must be replaced.

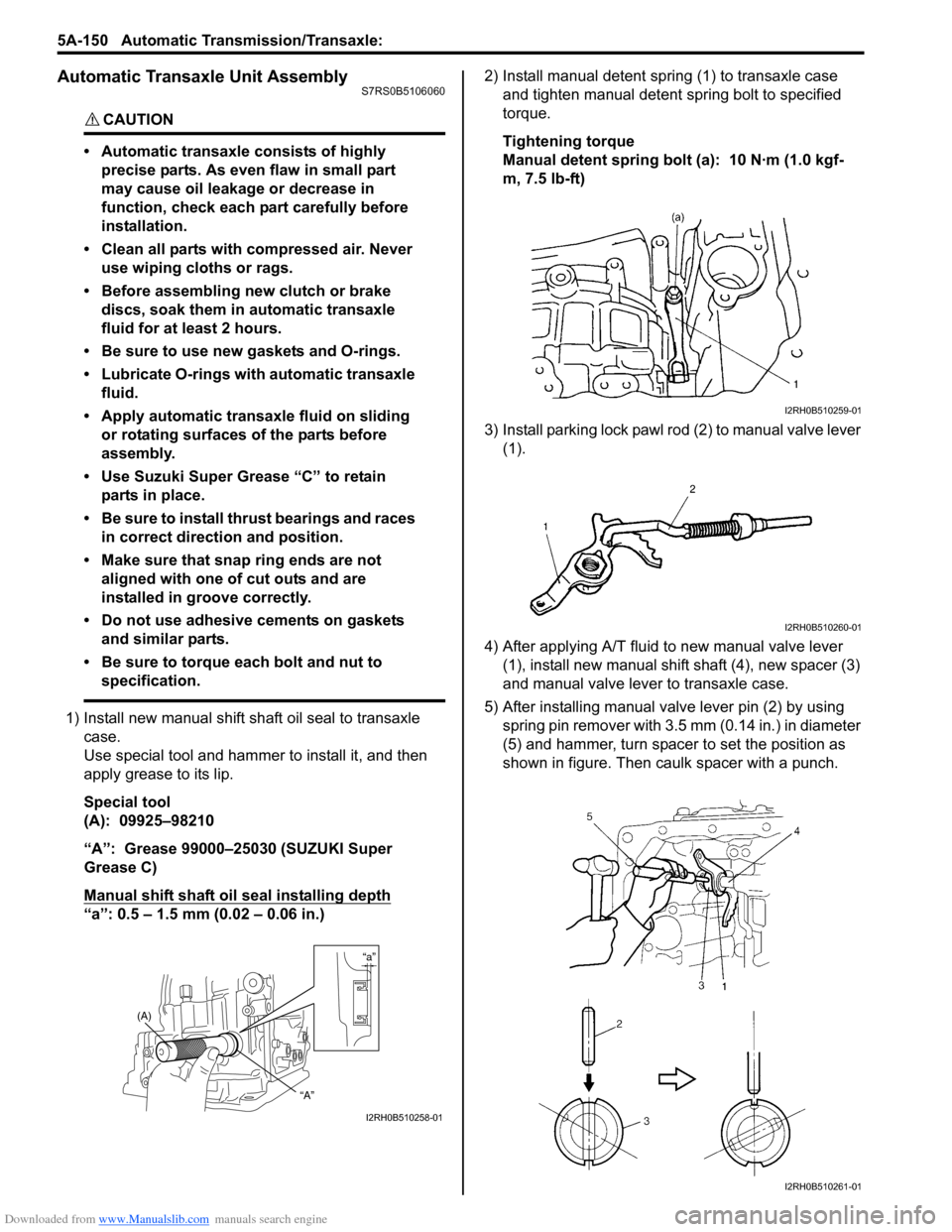

Brake return spring subassembly

Measure free length of each brake return spring

subassembly.

Evidence of extreme heat or burning in the area of clutch

may have caused springs to take heat set and would

require their replacement.

Free length of 1st & reverse brake return spring

subassembly

“a”: 21.71 mm (0.855 in.)

Free length of 2nd brake return spring subassembly

“a”: 15.85 mm (0.624 in.)

NOTE

• Do not apply excessive force when measuring spring free length.

• Perform measurement at several points.

I2RH0B510252-01

I2RH01510147-01

I2RH0B510253-01

I2RH0B510173-01

Page 794 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-150 Automatic Transmission/Transaxle:

Automatic Transaxle Unit AssemblyS7RS0B5106060

CAUTION!

• Automatic transaxle consists of highly precise parts. As even flaw in small part

may cause oil leakage or decrease in

function, check each part carefully before

installation.

• Clean all parts with compressed air. Never use wiping cloths or rags.

• Before assembling new clutch or brake discs, soak them in automatic transaxle

fluid for at least 2 hours.

• Be sure to use new gaskets and O-rings.

• Lubricate O-rings with automatic transaxle

fluid.

• Apply automatic transaxle fluid on sliding or rotating surfaces of the parts before

assembly.

• Use Suzuki Super Grease “C” to retain parts in place.

• Be sure to install thrust bearings and races in correct direction and position.

• Make sure that snap ring ends are not aligned with one of cut outs and are

installed in groove correctly.

• Do not use adhesive cements on gaskets and similar parts.

• Be sure to torque each bolt and nut to specification.

1) Install new manual shift sh aft oil seal to transaxle

case.

Use special tool and hammer to install it, and then

apply grease to its lip.

Special tool

(A): 09925–98210

“A”: Grease 99000–25030 (SUZUKI Super

Grease C)

Manual shift shaft oil seal installing depth

“a”: 0.5 – 1.5 mm (0.02 – 0.06 in.) 2) Install manual detent spring (1) to transaxle case

and tighten manual detent spring bolt to specified

torque.

Tightening torque

Manual detent spring bolt (a): 10 N·m (1.0 kgf-

m, 7.5 lb-ft)

3) Install parking lock pawl ro d (2) to manual valve lever

(1).

4) After applying A/T fluid to new manual valve lever (1), install new manual shift shaft (4), new spacer (3)

and manual valve lever to transaxle case.

5) After installing manual valve lever pin (2) by using spring pin remover with 3.5 mm (0.14 in.) in diameter

(5) and hammer, turn spacer to set the position as

shown in figure. Then caulk spacer with a punch.

“a”

(A)

“A”

I2RH0B510258-01

I2RH0B510259-01

I2RH0B510260-01

I2RH0B510261-01

Page 802 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-158 Automatic Transmission/Transaxle:

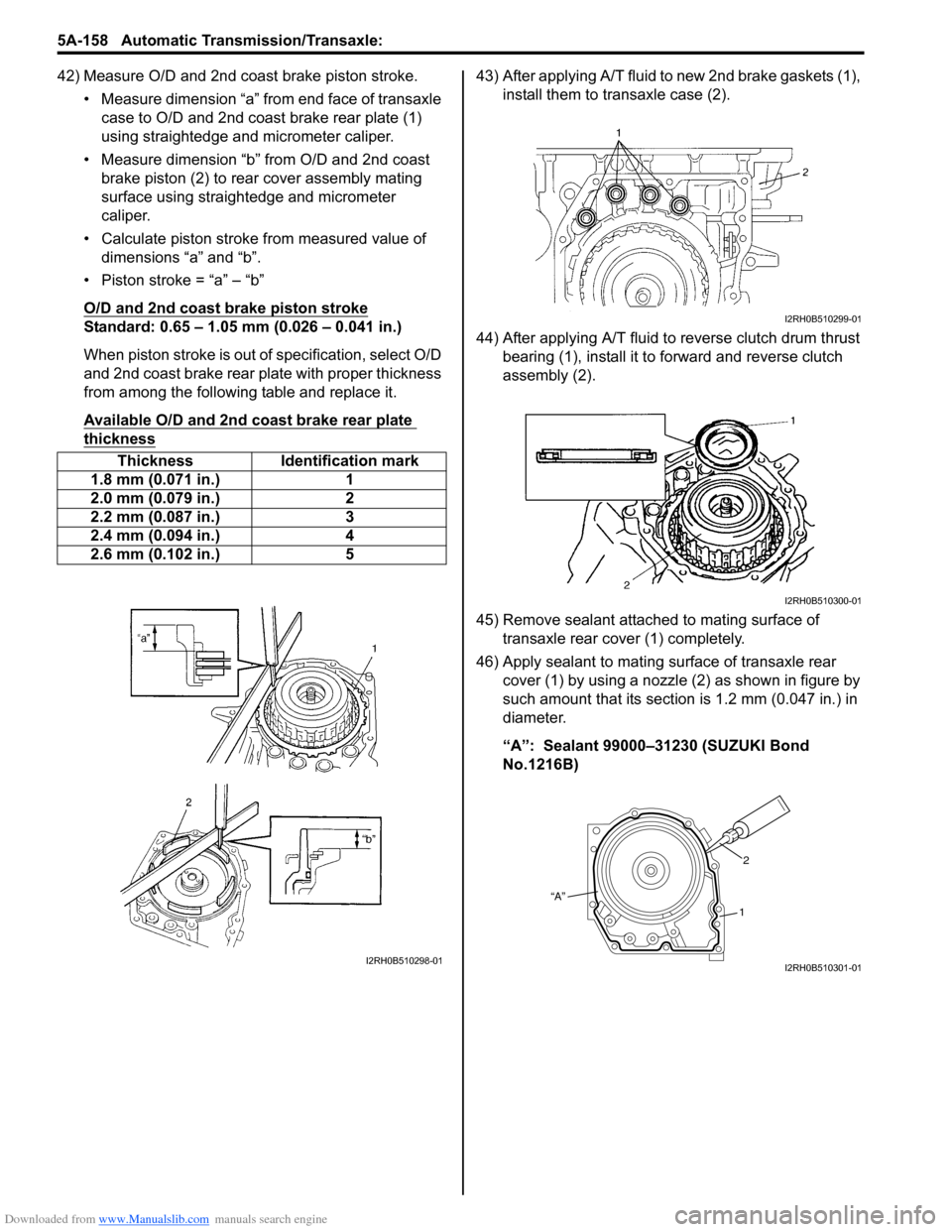

42) Measure O/D and 2nd coast brake piston stroke.• Measure dimension “a” from end face of transaxle case to O/D and 2nd coast brake rear plate (1)

using straightedge and micrometer caliper.

• Measure dimension “b” from O/D and 2nd coast brake piston (2) to rear cover assembly mating

surface using straightedge and micrometer

caliper.

• Calculate piston stroke from measured value of dimensions “a” and “b”.

• Piston stroke = “a” – “b”

O/D and 2nd coast brake piston stroke

Standard: 0.65 – 1.05 mm (0.026 – 0.041 in.)

When piston stroke is out of specification, select O/D

and 2nd coast brake rear plate with proper thickness

from among the following table and replace it.

Available O/D and 2nd coast brake rear plate

thickness

43) After applying A/T fluid to new 2nd brake gaskets (1), install them to transaxle case (2).

44) After applying A/T fluid to reverse clutch drum thrust bearing (1), install it to forward and reverse clutch

assembly (2).

45) Remove sealant attached to mating surface of transaxle rear cover (1) completely.

46) Apply sealant to mating surface of transaxle rear cover (1) by using a nozzle (2) as shown in figure by

such amount that its section is 1.2 mm (0.047 in.) in

diameter.

“A”: Sealant 99000–31230 (SUZUKI Bond

No.1216B)

Thickness Identification mark

1.8 mm (0.071 in.) 1

2.0 mm (0.079 in.) 2

2.2 mm (0.087 in.) 3

2.4 mm (0.094 in.) 4

2.6 mm (0.102 in.) 5

I2RH0B510298-01

I2RH0B510299-01

I2RH0B510300-01

“A” 2

1

I2RH0B510301-01

Page 805 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-161

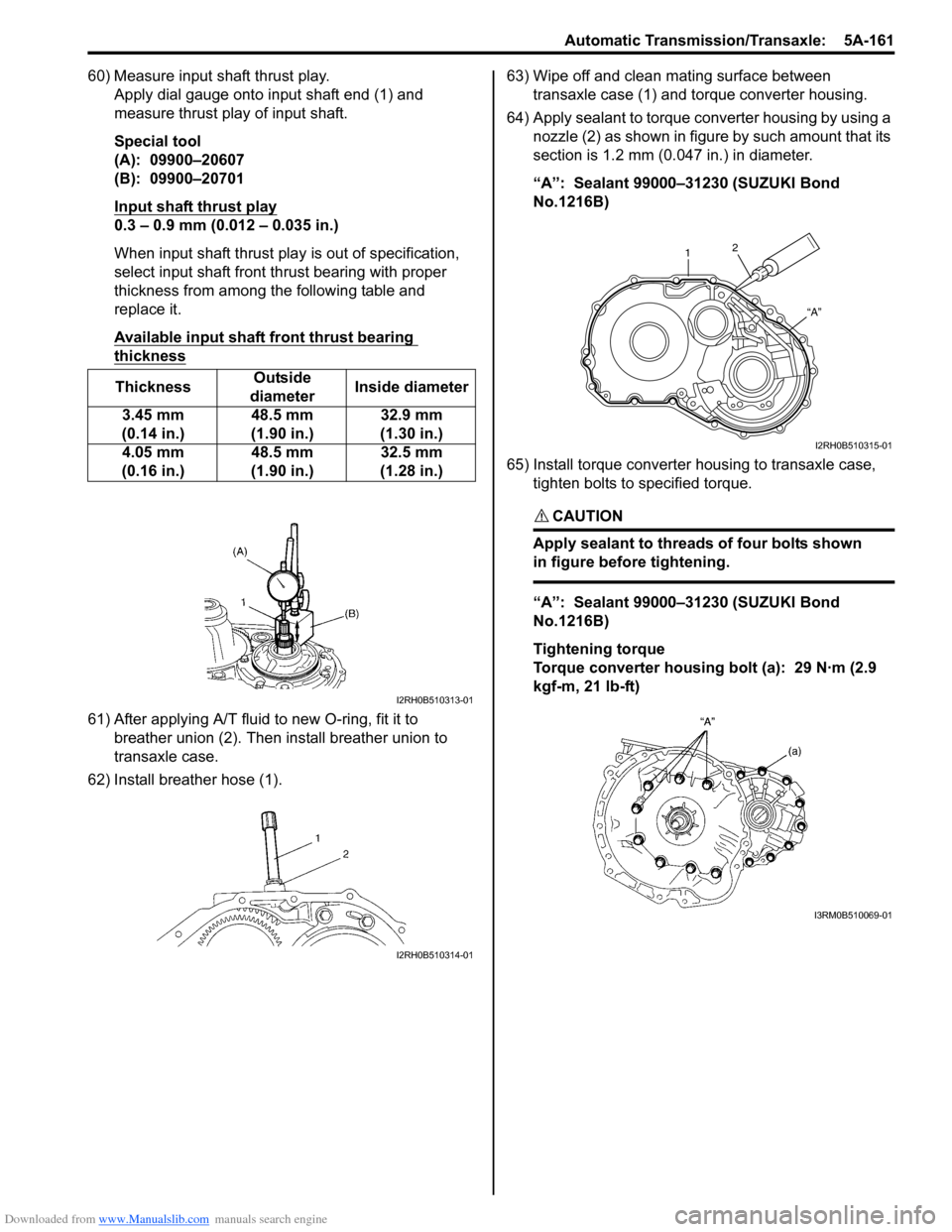

60) Measure input shaft thrust play.Apply dial gauge onto input shaft end (1) and

measure thrust play of input shaft.

Special tool

(A): 09900–20607

(B): 09900–20701

Input shaft thrust play

0.3 – 0.9 mm (0.012 – 0.035 in.)

When input shaft thrust play is out of specification,

select input shaft front th rust bearing with proper

thickness from among the following table and

replace it.

Available input shaft front thrust bearing

thickness

61) After applying A/T fluid to new O-ring, fit it to breather union (2). Then install breather union to

transaxle case.

62) Install breather hose (1). 63) Wipe off and clean mating surface between

transaxle case (1) and torque converter housing.

64) Apply sealant to torque converter housing by using a nozzle (2) as shown in figure by such amount that its

section is 1.2 mm (0.047 in.) in diameter.

“A”: Sealant 99000–31230 (SUZUKI Bond

No.1216B)

65) Install torque converter housing to transaxle case, tighten bolts to specified torque.

CAUTION!

Apply sealant to threads of four bolts shown

in figure before tightening.

“A”: Sealant 99000–31230 (SUZUKI Bond

No.1216B)

Tightening torque

Torque converter housing bolt (a): 29 N·m (2.9

kgf-m, 21 lb-ft)

Thickness

Outside

diameter Inside diameter

3.45 mm

(0.14 in.) 48.5 mm

(1.90 in.) 32.9 mm

(1.30 in.)

4.05 mm

(0.16 in.) 48.5 mm

(1.90 in.) 32.5 mm

(1.28 in.)

I2RH0B510313-01

I2RH0B510314-01

1 2

“A”

I2RH0B510315-01

I3RM0B510069-01