Axle seal SUZUKI SWIFT 2008 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 483 of 1496

Downloaded from www.Manualslib.com manuals search engine Drive Shaft / Axle: 3A-5

8) Disconnect front suspension control arm ball joint

stud from steering knuckle.

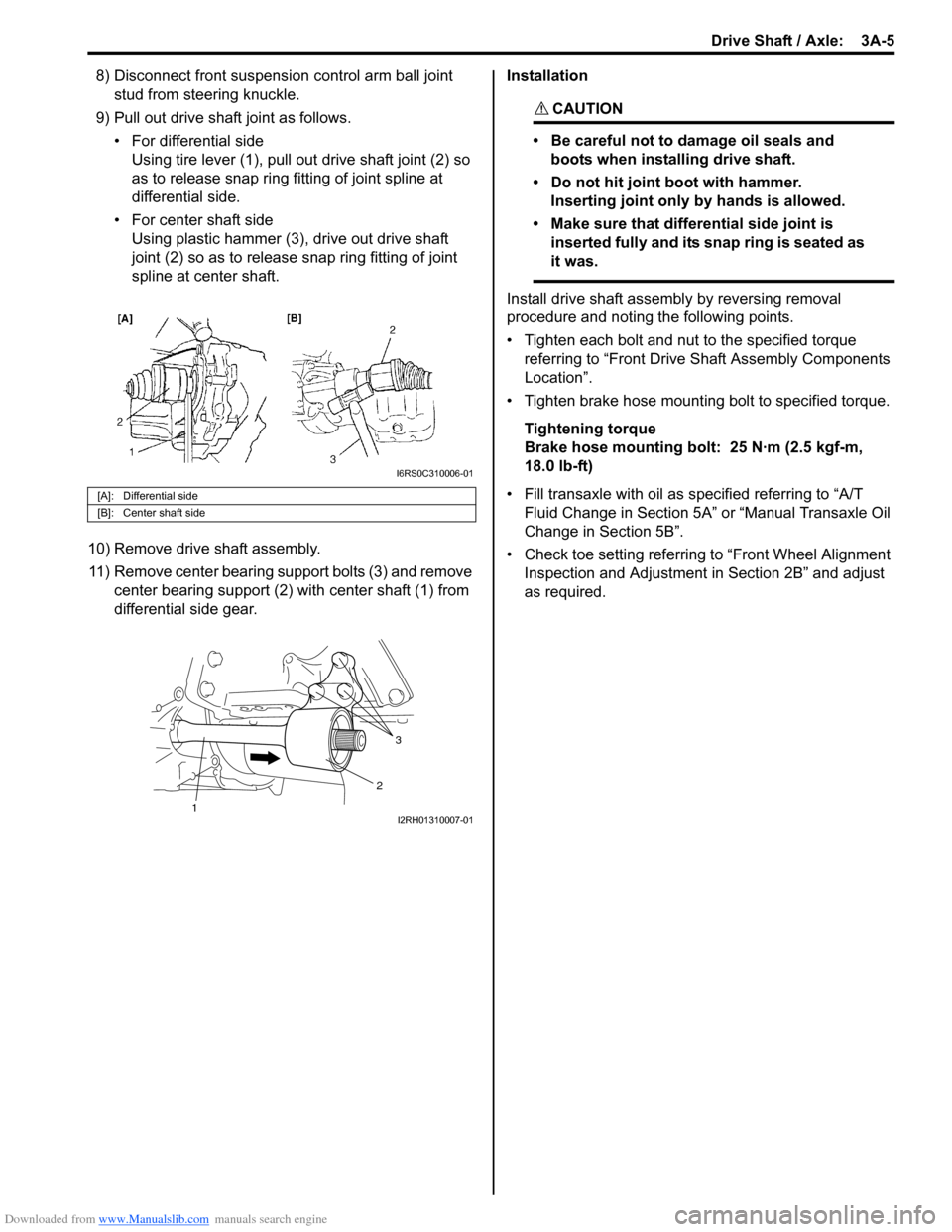

9) Pull out drive shaft joint as follows. • For differential sideUsing tire lever (1), pull out drive shaft joint (2) so

as to release snap ring fitting of joint spline at

differential side.

• For center shaft side Using plastic hammer (3), drive out drive shaft

joint (2) so as to release snap ring fitting of joint

spline at center shaft.

10) Remove drive shaft assembly. 11) Remove center bearing support bolts (3) and remove center bearing support (2) with center shaft (1) from

differential side gear. Installation

CAUTION!

• Be careful not to damage oil seals and

boots when installing drive shaft.

• Do not hit joint boot with hammer. Inserting joint only by hands is allowed.

• Make sure that differential side joint is inserted fully and its snap ring is seated as

it was.

Install drive shaft assemb ly by reversing removal

procedure and noting the following points.

• Tighten each bolt and nut to the specified torque referring to “Front Drive Shaft Assembly Components

Location”.

• Tighten brake hose mounting bolt to specified torque.

Tightening torque

Brake hose mounting bolt: 25 N·m (2.5 kgf-m,

18.0 lb-ft)

• Fill transaxle with oil as sp ecified referring to “A/T

Fluid Change in Section 5A” or “Manual Transaxle Oil

Change in Section 5B”.

• Check toe setting referring to “Front Wheel Alignment Inspection and Adjustment in Section 2B” and adjust

as required.

[A]: Differential side

[B]: Center shaft side

I6RS0C310006-01

3

2

1I2RH01310007-01

Page 492 of 1496

Downloaded from www.Manualslib.com manuals search engine 3A-14 Drive Shaft / Axle:

Center Shaft and Center Bearing Support

Disassembly and Reassembly

S7RS0B3106005

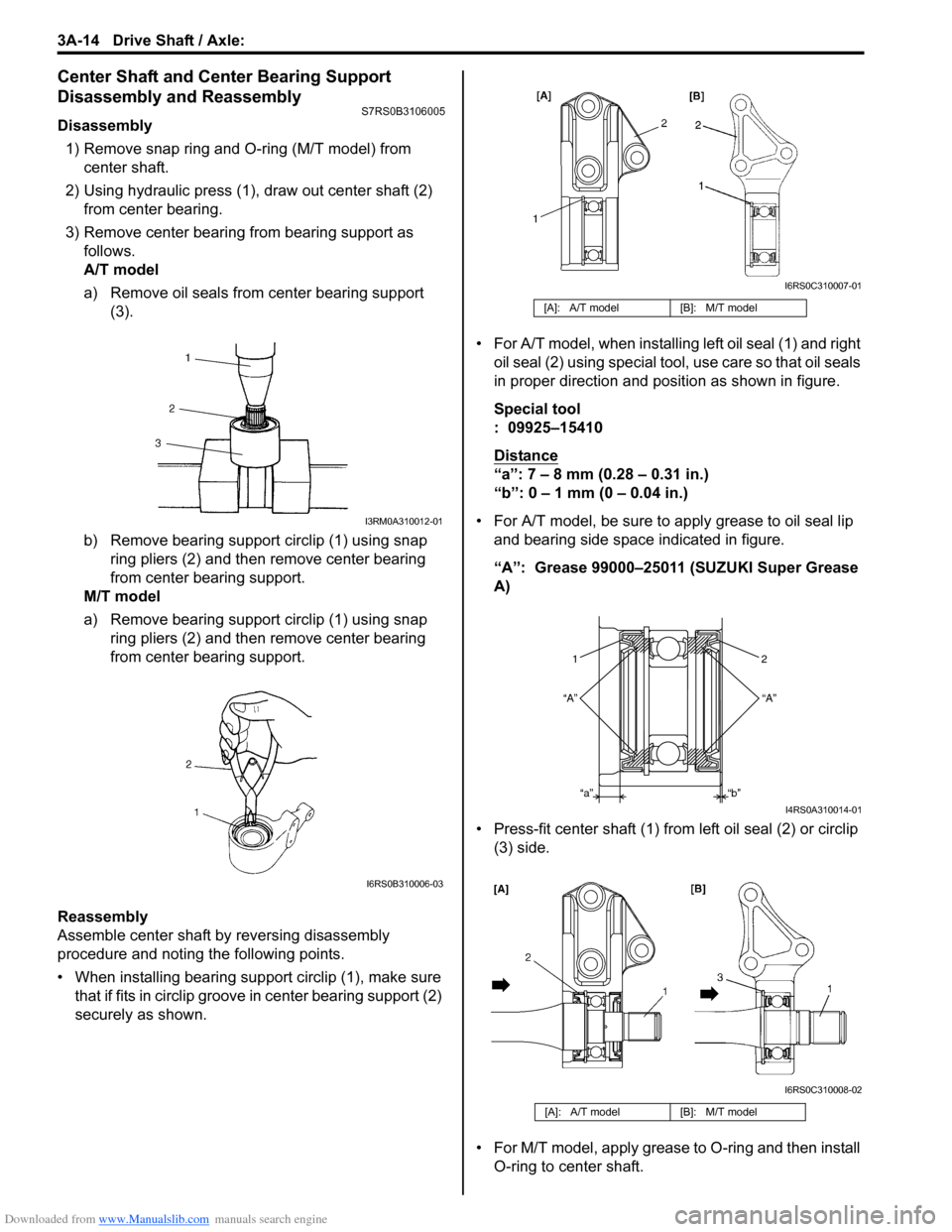

Disassembly1) Remove snap ring and O-ring (M/T model) from center shaft.

2) Using hydraulic press (1), draw out center shaft (2) from center bearing.

3) Remove center bearing from bearing support as follows.

A/T model

a) Remove oil seals from center bearing support (3).

b) Remove bearing support circlip (1) using snap ring pliers (2) and then remove center bearing

from center bearing support.

M/T model

a) Remove bearing support circlip (1) using snap ring pliers (2) and then remove center bearing

from center bearing support.

Reassembly

Assemble center shaft by reversing disassembly

procedure and noting the following points.

• When installing bearing support circlip (1), make sure

that if fits in circlip groove in center bearing support (2)

securely as shown. • For A/T model, when installing

left oil seal (1) and right

oil seal (2) using special tool, use care so that oil seals

in proper direction and position as shown in figure.

Special tool

: 09925–15410

Distance

“a”: 7 – 8 mm (0.28 – 0.31 in.)

“b”: 0 – 1 mm (0 – 0.04 in.)

• For A/T model, be sure to apply grease to oil seal lip and bearing side space indicated in figure.

“A”: Grease 99000–25011 (SUZUKI Super Grease

A)

• Press-fit center shaft (1) from left oil seal (2) or circlip

(3) side.

• For M/T model, apply grease to O-ring and then install O-ring to center shaft.

I3RM0A310012-01

I6RS0B310006-03

[A]: A/T model [B]: M/T model

[A]: A/T model [B]: M/T model

I6RS0C310007-01

12

“A” “A”

“a” “b”

I4RS0A310014-01

I6RS0C310008-02

Page 493 of 1496

Downloaded from www.Manualslib.com manuals search engine Drive Shaft / Axle: 3A-15

Specifications

Tightening Torque SpecificationsS7RS0B3107001

NOTE

The specified tightening torque is also described in the following.

“Front Drive Shaft Assembly Components Location”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Service MaterialS7RS0B3108001

NOTE

Required service material is also described in the following.

“Front Drive Shaft Components”

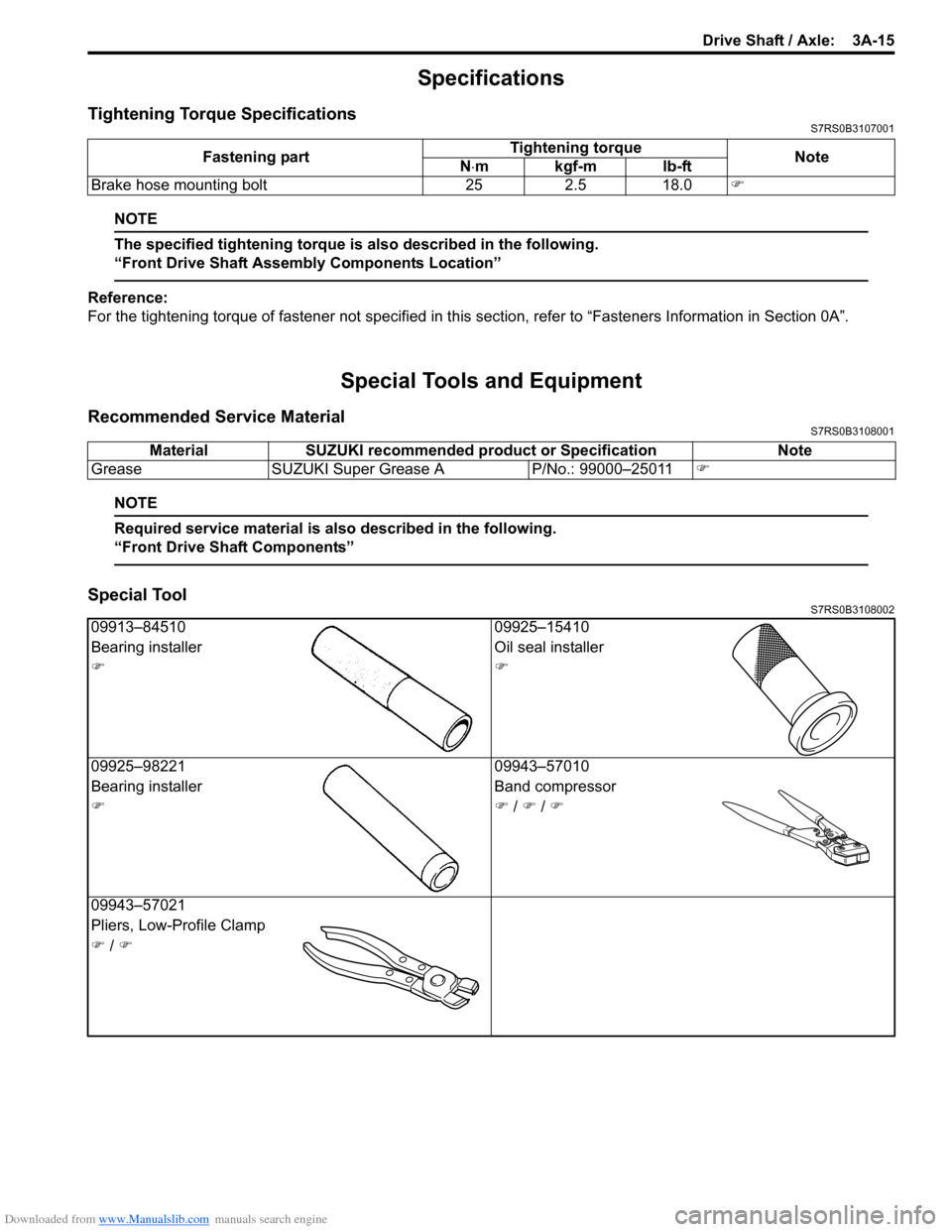

Special ToolS7RS0B3108002

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Brake hose mounting bolt 25 2.5 18.0 �)

MaterialSUZUKI recommended product or Specification Note

Grease SUZUKI Super Grease A P/No.: 99000–25011�)

09913–84510 09925–15410

Bearing installer Oil seal installer

�)�)

09925–98221 09943–57010

Bearing installer Band compressor

�)�) / �) / �)

09943–57021

Pliers, Low-Profile Clamp

�) / �)

Page 503 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-5

If deterioration of rubber is evident, disassemble all

hydraulic parts and wash with alcohol. Dry these parts

with compressed air before assembly to keep alcohol out

of the system. Replace all rubber parts in the system,

including hoses. Also, when working on the brake

mechanisms, check for fluid on the linings.

If excessive fluid is found, replace the pads. If master cylinder piston seals

are satisfactory, check for

leakage or excessive heat co nditions. If leakage is not

found, drain fluid, flush with brake fluid, refill and bleed

system.

The system must be flushed if there is any doubt as to

the grade of fluid in the system or if fluid has been used

which contained parts that have been subjected to

contaminated fluid.

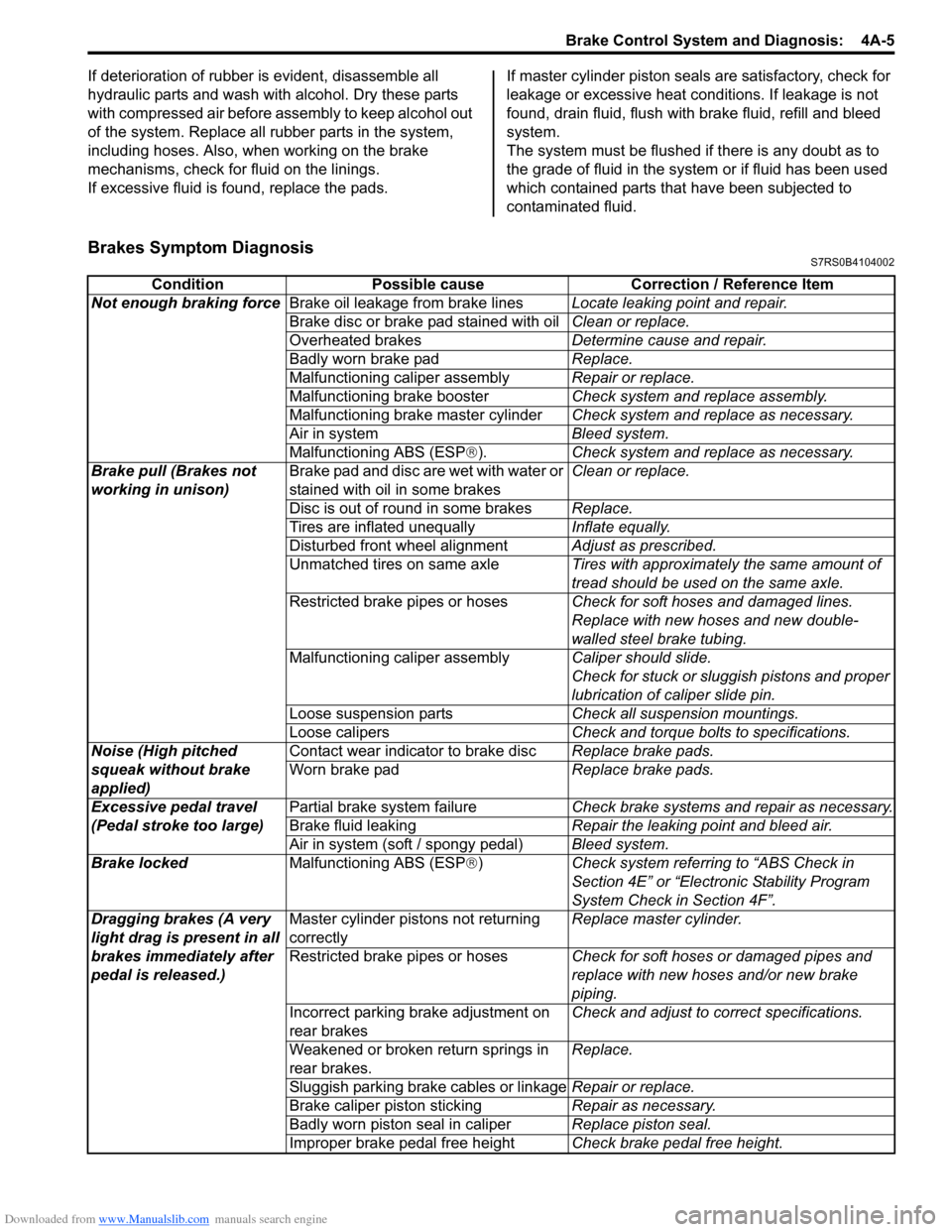

Brakes Symptom DiagnosisS7RS0B4104002

Condition Possible cause Correction / Reference Item

Not enough braking force Brake oil leakage from brake lines Locate leaking point and repair.

Brake disc or brake pad stained with oil Clean or replace.

Overheated brakes Determine cause and repair.

Badly worn brake pad Replace.

Malfunctioning caliper assembly Repair or replace.

Malfunctioning brake booster Check system and replace assembly.

Malfunctioning brake master cylinder Check system and replace as necessary.

Air in system Bleed system.

Malfunctioning ABS (ESP ®). Check system and replace as necessary.

Brake pull (Brakes not

working in unison) Brake pad and disc are wet with water or

stained with oil in some brakes Clean or replace.

Disc is out of round in some brakes Replace.

Tires are inflated unequally Inflate equally.

Disturbed front wheel alignment Adjust as prescribed.

Unmatched tires on same axle Tires with approximately the same amount of

tread should be used on the same axle.

Restricted brake pipes or hoses Check for soft hoses and damaged lines.

Replace with new hoses and new double-

walled steel brake tubing.

Malfunctioning caliper assembly Caliper should slide.

Check for stuck or sluggish pistons and proper

lubrication of caliper slide pin.

Loose suspension parts Check all suspension mountings.

Loose calipers Check and torque bolts to specifications.

Noise (High pitched

squeak without brake

applied) Contact wear indicator to brake disc

Replace brake pads.

Worn brake pad Replace brake pads.

Excessive pedal travel

(Pedal stroke too large) Partial brake system failure

Check brake systems and repair as necessary.

Brake fluid leaking Repair the leaking point and bleed air.

Air in system (soft / spongy pedal) Bleed system.

Brake locked Malfunctioning ABS (ESP®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

Dragging brakes (A very

light drag is present in all

brakes immediately after

pedal is released.) Master cylinder pistons not returning

correctly

Replace master cylinder.

Restricted brake pipes or hoses Check for soft hoses or damaged pipes and

replace with new hoses and/or new brake

piping.

Incorrect parking brake adjustment on

rear brakes Check and adjust to correct specifications.

Weakened or broken return springs in

rear brakes. Replace.

Sluggish parking brake cables or linkage Repair or replace.

Brake caliper piston sticking Repair as necessary.

Badly worn piston seal in caliper Replace piston seal.

Improper brake pedal free height Check brake pedal free height.

Page 642 of 1496

Downloaded from www.Manualslib.com manuals search engine 5-ii Table of Contents

DTC P1878: Torque Converter Clutch Shudder .......................................................... 5A-75

DTC P2762: Torque Converter Clutch (TCC) Pressure Control Sole noid Control Circuit

Range /Performance ....................................... 5A-76

DTC P2763: Torque Converter Clutch Pressure Control Sole noid Control Circuit

High ................................................................. 5A-78

DTC P2764: Torque Converter Clutch Circuit Pressure Control Sole noid Control Circuit

Low ................................................................. 5A-80

Inspection of TCM and Its Circuits .................... 5A-82

TCM Power and Ground Circuit Check ............. 5A-86

Brake Interlock System Inspection .................... 5A-87

Repair Instructions ........... .................................5A-88

Learning Control Initializat ion ............................ 5A-88

A/T Fluid Level Check ....................................... 5A-89

A/T Fluid Change .............................................. 5A-90

Select Lever Components ... .............................. 5A-90

Select Lever Assembly Removal and Installation ....................................................... 5A-90

Select Lever Knob Installa tion........................... 5A-90

Select Lever Inspection .... ................................. 5A-91

“3” Position Switch Inspec tion ........................... 5A-91

Shift Lock Solenoid Inspec tion .......................... 5A-91

Shift Lock Solenoid Replacement ..................... 5A-91

Select Cable Components ................................ 5A-92

Select Cable Removal and Installation ............. 5A-92

Select Cable Adjustment ................................... 5A-93

Key Interlock Cable Removal and Installation... 5A-93

Transmission Range Sensor (Shift Switch) Inspection and Adjustment .............................. 5A-95

Output Shaft Speed Sensor Removal and Installation ....................................................... 5A-96

Output Shaft Speed Sensor Inspection ............. 5A-96

Input Shaft Speed Sensor Removal and Installation ....................................................... 5A-96

Input Shaft Speed Sensor Inspection................ 5A-97

Transmission Fluid Temperature Sensor Removal and Installation ................................. 5A-97

Transmission Fluid Temperature Sensor Inspection ........................................................ 5A-98

Solenoid Valves (Shift Solenoid Valves and Timing Solenoid Valve) Removal and

Installation ....................................................... 5A-98

Solenoid Valves (Shift Solenoid Valves, and Timing Solenoid Valve) Inspection .................. 5A-99

Pressure Control Soleno id Valves (Pressure

Control Solenoid and TCC Pressure Control

Solenoid) Removal and Inst allation .............. 5A-101

Pressure Control Solenoid Valve Inspection ... 5A-101

Transmission Control Module (TCM) Removal and Installation ............................... 5A-102

A/T Relay Inspection ....................................... 5A-103

Differential Side Oil Seal Replacement ........... 5A-103

A/T Fluid Cooler Hoses Replacement ............. 5A-104

Automatic Transaxle Unit Components........... 5A-105

Automatic Transaxle Unit Dismounting and Remounting ................................................... 5A-106

Automatic Transaxle Asse mbly Components . 5A-108 Automatic Transaxle Unit

Disassembly........... 5A-110

Oil Pump Assembly Components ................... 5A-121

Oil Pump Assembly Disassembly and Reassembly .................................................. 5A-122

Oil Pump Assembly Inspection ....................... 5A-122

Direct Clutch Assembly Components.............. 5A-124

Direct Clutch Assembly Preliminary Check ..... 5A-124

Direct Clutch Assembly Disassembly and Reassembly .................................................. 5A-125

Direct Clutch Assembly Inspection.................. 5A-127

Forward and Reverse Clutch Assembly Components .................................................. 5A-128

Forward and Reverse Clutch Assembly Preliminary Check ......................................... 5A-129

Forward and Reverse Clutch Assembly Disassembly and Reassembly ...................... 5A-129

Forward and Reverse Clutch Assembly Inspection ...................................................... 5A-133

2nd Brake Piston Assembly Components ....... 5A-134

2nd Brake Piston Assembly Disassembly and Reassembly .................................................. 5A-134

Transaxle Rear Cover (O/D and 2nd Coast Brake Piston) Assembly Components........... 5A-135

Transaxle Rear Cover (O/D and 2nd Coast Brake Piston) Assembly Disassembly and

Reassembly .................................................. 5A-136

Transaxle Rear Cover (O/D and 2nd Coast Brake Piston) Assembly Inspection............... 5A-137

Countershaft Assembly Co mponents.............. 5A-138

Countershaft Assembly Disassembly and Reassembly .................................................. 5A-138

Valve Body Assembly Components ................ 5A-139

Valve Body Assembly Disassembly and Reassembly .................................................. 5A-140

Differential Assembly Components ................. 5A-141

Differential Assembly Disassembly and Reassembly .................................................. 5A-142

Differential Assembly Inspection ..................... 5A-143

Torque Converter Housing Disassembly and Reassembly .................................................. 5A-144

Transaxle Case Disassembly and Reassembly .................................................. 5A-146

Automatic Transaxle Unit Inspection and Adjus

tment .................................................... 5A-147

Automatic Transaxle Unit Assembly ............... 5A-150

Specifications .................. .................................5A-167

Tightening Torque Specifications .................... 5A-167

Special Tools and Equipmen t .........................5A-168

Recommended Service Material ..................... 5A-168

Special Tool .................................................... 5A-168

Manual Transmission/Tr ansaxle ............ 5B-1

General Description .............................................5B-1

Manual Transaxle Construction and Servicing .... 5B-1

Diagnostic Information and Procedures ............5B-3 Manual Transaxle Symptom Diagnosis............... 5B-3

Repair Instructions ............ ..................................5B-3

Manual Transaxle Oil Change............................. 5B-3

Differential Side Oil Seal Replacement ............... 5B-4

Page 645 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-1

Transmission / Transaxle

Automatic Transmission/Transaxle

Precautions

Precautions in Diagnosing TroubleS7RS0B5100001

• Do not disconnect couplers from TCM, battery cable from battery, TCM ground wire harness from engine or

main fuse before checking the diagnostic information

(DTC, freeze frame data, etc.) stored in TCM memory.

Such disconnection will clea r memorized information

in TCM memory.

• Diagnostic information stored in TCM memory can be cleared as well as checked by using SUZUKI scan

tool or generic scan tool. Before using scan tool, read

its Operator’s (Instruction) Manual carefully to have

good understanding as to what functions are available

and how to use it.

It is indistinguishable wh ich module turns on MIL

because not only ECM but also TCM turns on MIL.

Therefore, check both ECM and TCM for DTC when

MIL lights on.

When checking TCM for DTC, keep in mind that DTC

is displayed on the scan tool as follows depending on

the scan tool used.

– SUZUKI scan tool displays DTC detected by TCM.

– Generic scan tool displays DTC detected by each of ECM and TCM simultaneously.

• Using SUZUKI scan tool the diagnostic information stored in TCM memory can be checked and cleared

as well. Before its use, be sure to read Operator’s

Manual supplied with it carefully to have good

understanding of its functions and usage.

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” befo re inspection and observe

what is written there.

• TCM replacement

– When substituting a known-good TCM, check that all relays and actuators have resistance of

specified value.

Neglecting this check may result in damage to good

TCM.

• Communication of ECUs , ECM, TCM, ABS control

module, keyless start control module and BCM is

established by CAN (Controller Area Network).

Therefore, handle CAN communication line with care

referring to “Precaution for CAN Communication

System in Section 00”.

Precautions for Disassembly and ReassemblyS7RS0B5100002

When repairing automatic transaxle, it is necessary to

conduct the on-vehicle test to investigate where the

cause of the trouble lies first.

Then whether overhaul should be done or not is

determined. If the transaxle is disassembled without

such preliminary procedure, not only the cause of the

trouble would be unknown, but also a secondary trouble

may occur and often time would be wasted.

As the automatic transaxle consists of high precision

component, the following cautions should be strictly

observed when handling its parts in disassembly and

reassembly.

• Disassembling valve body assembly is prohibited

essentially. However, a few parts can be

disassembled. When disassembling valve body

component parts, confirm whether their parts are

allowed to disassemble or not referring to “Valve Body

Assembly Disassembly and Reassembly”.

• When component part of forward clutch, direct clutch, 2nd brake and/or O/D and 2nd coast brake, namely

clutch disc, brake disc, retaining plate and/or

separator plate, have been replaced, all learned

contents, which have been stored in TCM memory by

executing learning control, should be initialized

referring to “Learning Control Initialization”.

• Make sure to wash dirt off from the transaxle so that no such dirt will enter the transaxle during

dismounting and remounting.

• Select a clean place free from dust and dirt for overhauling.

• Place a rubber mat on the work bench to protect parts from damage.

• Work gloves or shop cloth should not be used. (Use a nylon cloth or a paper towel.)

• When separating the case joint, do not pry with a screwdriver or such but tap with a plastic hammer

lightly.

• Make sure to wash dirt off from the transaxle so that no such dirt will enter the transaxle during

disassembly and reassembly.

• Wash the disassembled parts in ATF (Automatic Transaxle Fluid) or kerosene (using care not to allow

ATF or kerosene to get on your face, etc.) and confirm

that each fluid passage is not clogged by blowing air

into it. But use kerosene to wash the discs, resin

washers and rubber parts.

• Replace each gasket, oil seal and O-ring with a new one.

• Apply ATF to sliding or rotating parts before

reassembly.

Page 646 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-2 Automatic Transmission/Transaxle:

CAUTION!

• Keep component parts in group for each subassembly and avoid mixing them up.

• Clean all parts with cleaning solvent thoroughly and air dry them.

• Use kerosene or automatic transaxle fluid as cleaning solvent.

• Do not use wiping cloths or rags to clean or dry parts.

• All oil passages should be blown out and checked to make sure that they are not

obstructed.

• Keep face and eyes away from solvent spray while air blowing parts.

• Check mating surface for irregularities and remove them, if any, and clean it again.

• Soak new clutch discs and brake discs in transaxle fluid for at least 2 hours before

assembly.

• Replace all gaskets and O-ring with new ones.

• Apply automatic transaxle fluid to all O- rings.

• When installing seal ring, be careful so that it is not expanded excessively, extruded or

caught.

• Replace oil seals that are removed and apply grease to their lips.

• Before installing, be sure to apply automatic transaxle fluid to sliding, rolling

and thrusting surface of all component

part. Also after installation, make sure to

check each part for proper operation.

• Always use torque wrench when tightening bolts.

• A new discs should be soaked in ATF at least 2 hours before use.

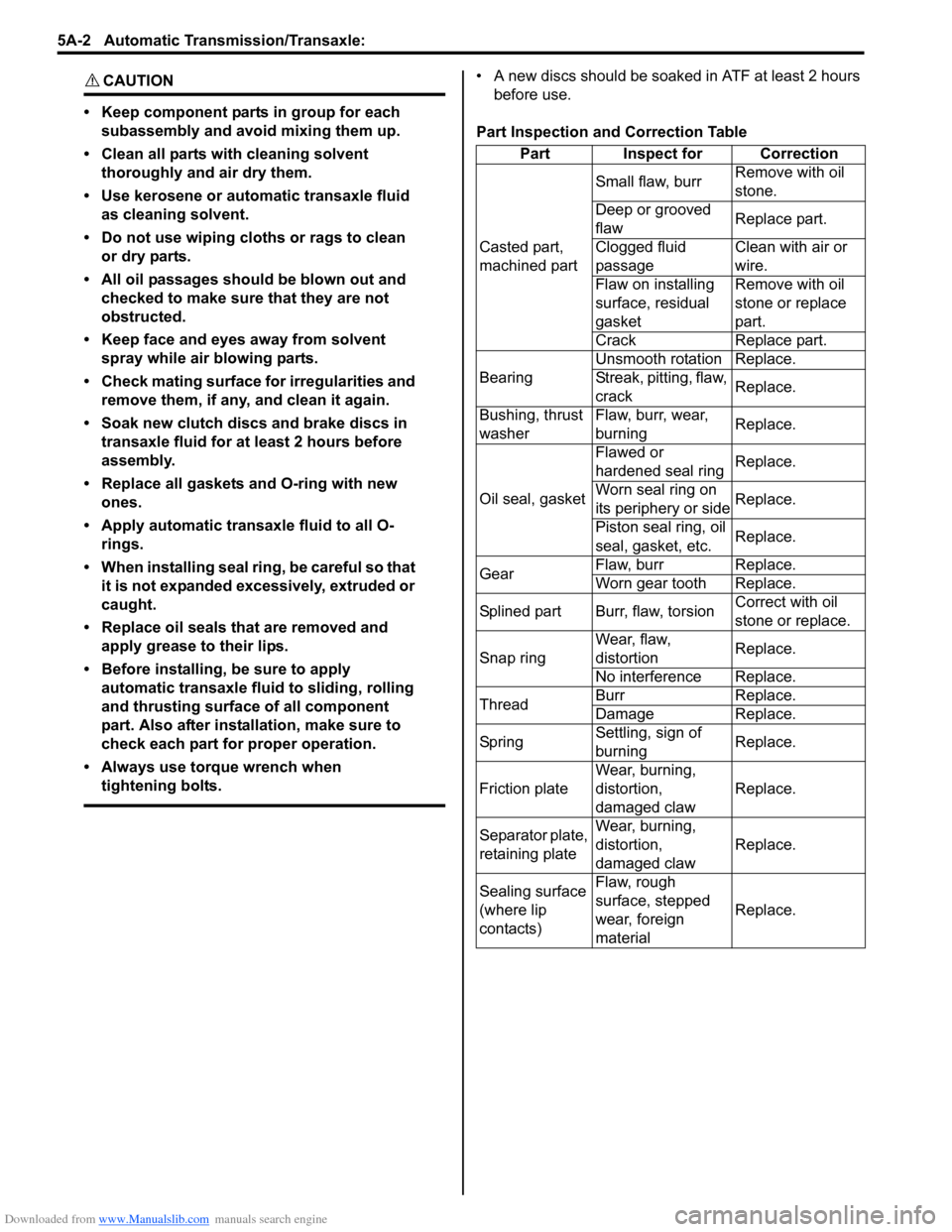

Part Inspection and Correction Table Part Inspect for Correction

Casted part,

machined part Small flaw, burr

Remove with oil

stone.

Deep or grooved

flaw Replace part.

Clogged fluid

passage Clean with air or

wire.

Flaw on installing

surface, residual

gasket Remove with oil

stone or replace

part.

Crack Replace part.

Bearing Unsmooth rotation Replace.

Streak, pitting, flaw,

crack

Replace.

Bushing, thrust

washer Flaw, burr, wear,

burning

Replace.

Oil seal, gasket Flawed or

hardened seal ring

Replace.

Worn seal ring on

its periphery or side Replace.

Piston seal ring, oil

seal, gasket, etc. Replace.

Gear Flaw, burr Replace.

Worn gear tooth Replace.

Splined part Burr, flaw, torsion Correct with oil

stone or replace.

Snap ring Wear, flaw,

distortion

Replace.

No interference Replace.

Thread Burr Replace.

Damage Replace.

Sp rin g Settling, sign of

burning Replace.

Friction plate Wear, burning,

distortion,

damaged claw Replace.

Separator plate,

retaining plate Wear, burning,

distortion,

damaged claw

Replace.

Sealing surface

(where lip

contacts) Flaw, rough

surface, stepped

wear, foreign

material

Replace.

Page 747 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-103

Installation

Reverse removal procedure noting the following.

• Connect TCM connectors securely.

• If the vehicle is equipped with air bag system, be sure to enable air bag system after TCM is back in place.

Refer to “Enabling Air Bag System in Section 8B”.

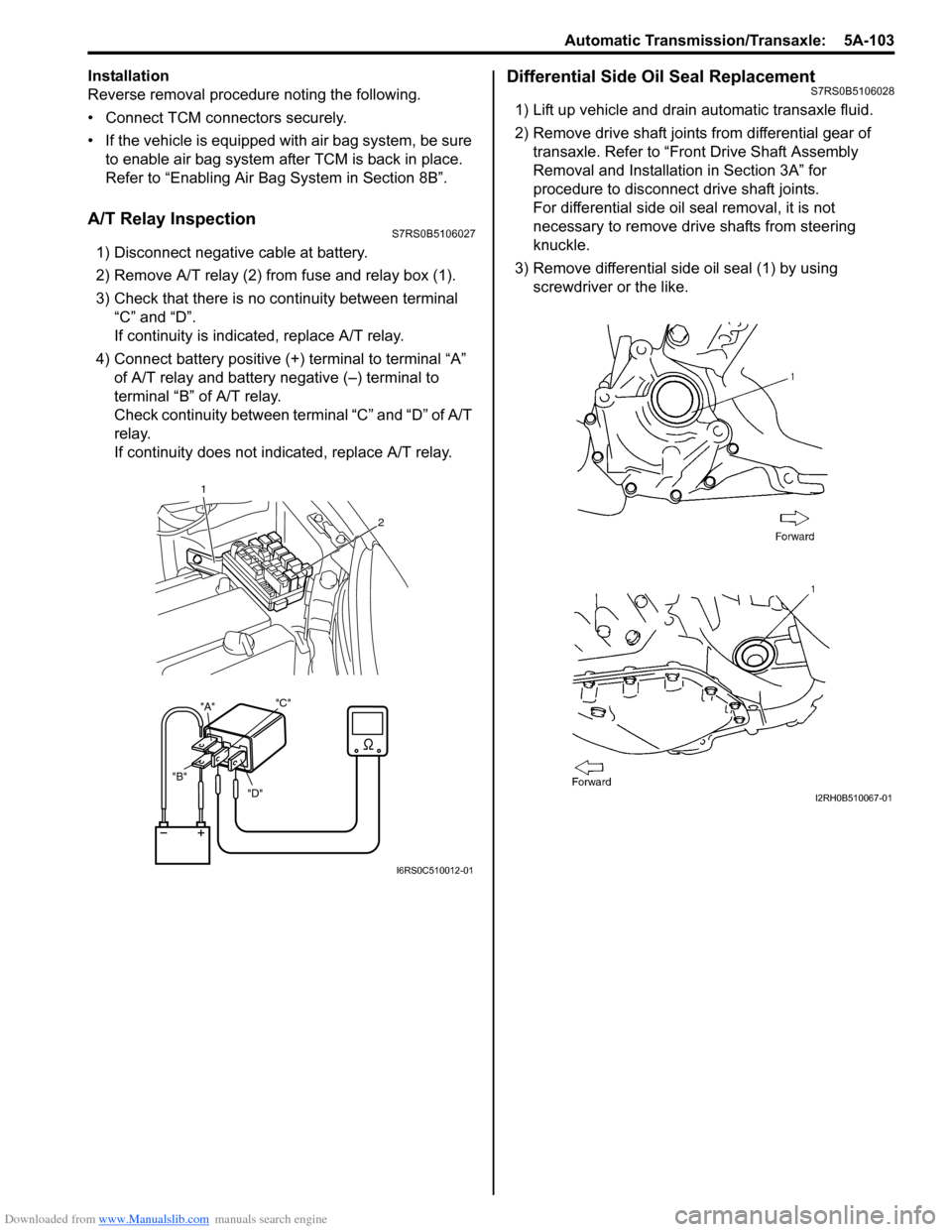

A/T Relay InspectionS7RS0B5106027

1) Disconnect negative cable at battery.

2) Remove A/T relay (2) from fuse and relay box (1).

3) Check that there is no continuity between terminal “C” and “D”.

If continuity is indicated, replace A/T relay.

4) Connect battery positive (+ ) terminal to terminal “A”

of A/T relay and battery negative (–) terminal to

terminal “B” of A/T relay.

Check continuity between terminal “C” and “D” of A/T

relay.

If continuity does not indicated, replace A/T relay.

Differential Side Oil Seal ReplacementS7RS0B5106028

1) Lift up vehicle and drain automatic transaxle fluid.

2) Remove drive shaft joints from differential gear of transaxle. Refer to “Front Drive Shaft Assembly

Removal and Installation in Section 3A” for

procedure to disconnect drive shaft joints.

For differential side oil seal removal, it is not

necessary to remove drive shafts from steering

knuckle.

3) Remove differential side oil seal (1) by using screwdriver or the like.

"D"

"B" "A"

"C"

1

2

I6RS0C510012-01

I2RH0B510067-01

Page 748 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-104 Automatic Transmission/Transaxle:

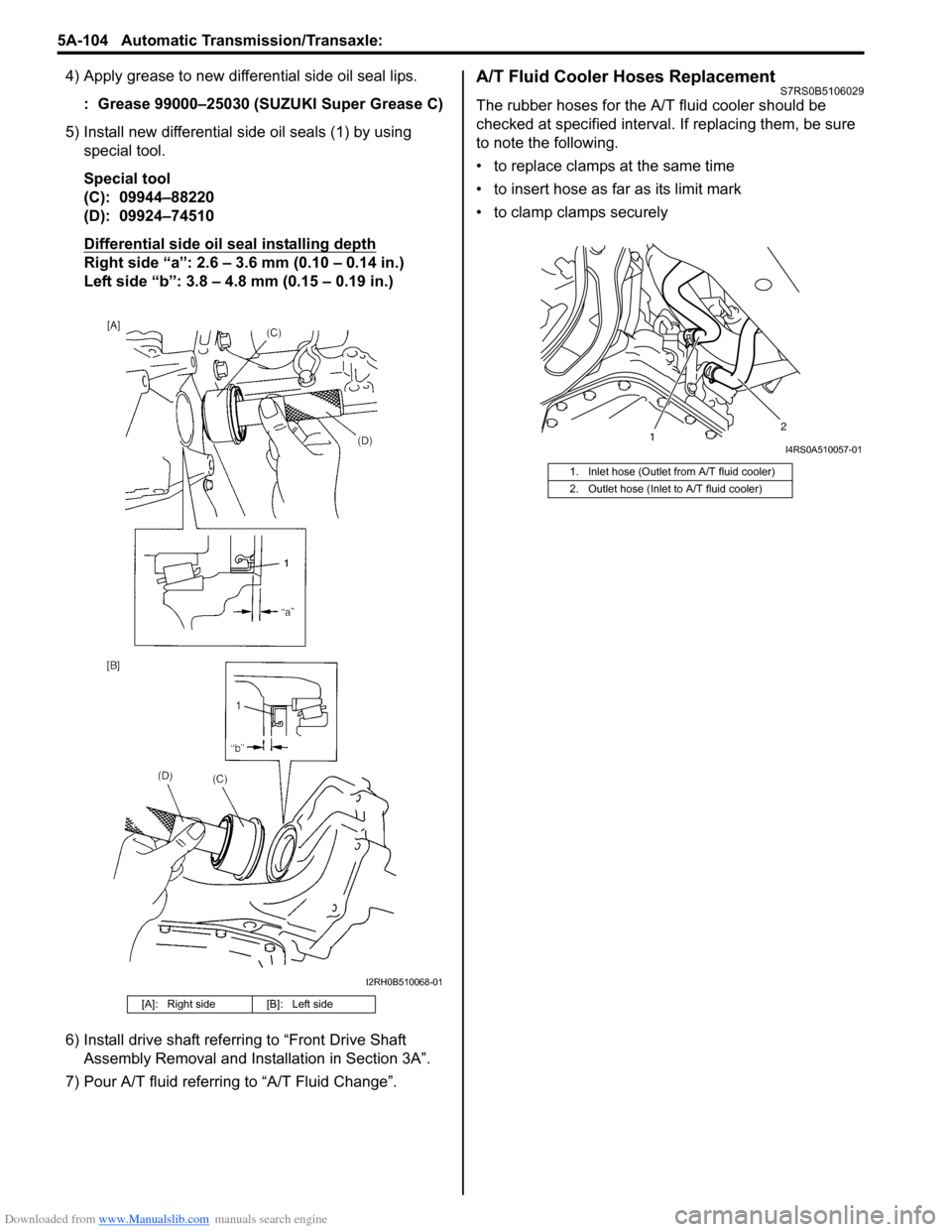

4) Apply grease to new differential side oil seal lips.: Grease 99000–25030 (SUZUKI Super Grease C)

5) Install new differential side oil seals (1) by using special tool.

Special tool

(C): 09944–88220

(D): 09924–74510

Differential side oil seal installing depth

Right side “a”: 2.6 – 3.6 mm (0.10 – 0.14 in.)

Left side “b”: 3.8 – 4.8 mm (0.15 – 0.19 in.)

6) Install drive shaft referring to “Front Drive Shaft Assembly Removal and Installation in Section 3A”.

7) Pour A/T fluid referring to “A/T Fluid Change”.

A/T Fluid Cooler Hoses ReplacementS7RS0B5106029

The rubber hoses for the A/T fluid cooler should be

checked at specified interval. If replacing them, be sure

to note the following.

• to replace clamps at the same time

• to insert hose as far as its limit mark

• to clamp clamps securely

[A]: Right side [B]: Left side

I2RH0B510068-01

1. Inlet hose (Outlet from A/T fluid cooler)

2. Outlet hose (Inlet to A/T fluid cooler)

1 2I4RS0A510057-01

Page 749 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-105

Automatic Transaxle Unit ComponentsS7RS0B5106030

I4RS0A510035-01

1. Drive plate4. Torque converter7. Transaxle and engine fastening nut

2. Drive plate bolt : Apply sealant 99000-31230 to thread. 5. Transaxle stiffener bolt

: Tightening torque

3. Drive plate to torque converter bolt 6. Transaxle and engine fastening bolt