stop light SUZUKI SWIFT 2008 2.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 885 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-3

EPS Diagnosis General DescriptionS7RS0B6301002

The P/S system in this vehicle is controlled by the P/S control module. T he P/S control module has an on-board

diagnostic system which detects a malfunction in this system. When diagnosing troubles, be sure to have full

understanding of the outline of “On-Board Diagnostic Sy stem Description” and each item in “Precautions in

Diagnosing Troubles”, and then execute diagnosis according to “EPS System Check”.

On-Board Diagnostic System DescriptionS7RS0B6301003

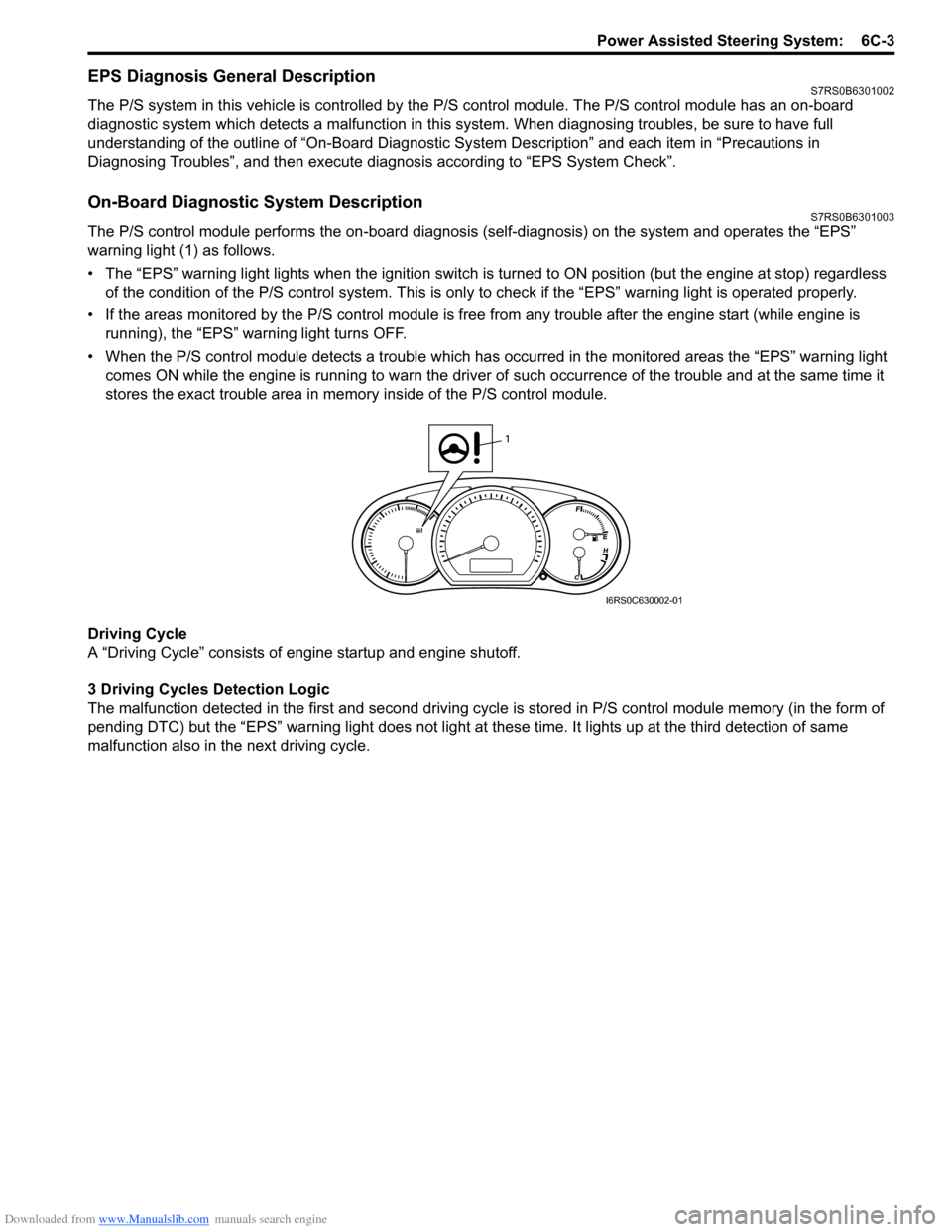

The P/S control module performs the on -board diagnosis (self-diagnosis) on the system and operates the “EPS”

warning light (1) as follows.

• The “EPS” warning light lights when the ignition switch is turned to ON position (but the engine at stop) regardless

of the condition of the P/S co ntrol system. This is only to check if the “EPS” warning light is operated properly.

• If the areas monitored by the P/S control module is free from any trouble after the engine start (while engine is

running), the “EPS” warning light turns OFF.

• When the P/S control module detects a trouble which has occurred in th e monitored areas the “EPS” warning light

comes ON while the engine is running to warn the driver of such occurrence of the trouble and at the same time it

stores the exact trouble area in memory inside of the P/S control module.

Driving Cycle

A “Driving Cycle” consists of en gine startup and engine shutoff.

3 Driving Cycles Detection Logic

The malfunction detected in the first and second driving cycl e is stored in P/S control module memory (in the form of

pending DTC) but the “EPS” wa rning light does not light at these time. It lights up at t he third detection of same

malfunction also in the next driving cycle.

1

I6RS0C630002-01

Page 890 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-8 Power Assisted Steering System:

Step 2: DTC Check, Record and Clearance

First, check DTC, referring to “DTC Check”. If DTC is

indicated, print it or write them down and then clear them

by referring to “DTC Clearance”. DTC indicates

malfunction that occurred in the system but does not

indicate whether it exists now or it occurred in the past

and the normal condition has been restored now. To

check which case applies, check the symptom in

question according to Step 5 and recheck DTC

according to Step 6 and 7.

Attempt to diagnose a trouble based on DTC in this step

only or failure to clear the DTC in this step will lead to

incorrect diagnosis, trouble diagnosis of a normal circuit

or difficulty in troubleshooting.

Step 3 and 4: Visual Inspection

As a preliminary step, be sure to perform visual check of

the items that support proper function of the P/S system

referring to “Visual Inspection”.

Step 5: Trouble Symptom Confirmation

Based on information obtained in “Step 1: Customer

Complaint Analysis: ” and “S tep 2: DTC Check, Record

and Clearance: ”, confirm trouble symptoms. Also,

reconfirm trouble symptom by performing test drive and

turning steering wheel fully to right and left at stopped

vehicle.

Step 6 and 7: Rechecking and Record of DTC

Refer to “DTC Check” for checking procedure.

Step 8: Steering Symptom Diagnosis and P/S

System Symptom Diagnosis

Perform basic steering system check according to

“Steering Symptom Diagnosis in Section 6A” first. When

the end of the flow has been reached, check the parts of

the system suspected as a possible cause referring to

“P/S System Symptom Diagnosis” and based on

symptoms appearing on the vehicle (symptoms obtained

through steps of customer complaint analysis, trouble

symptom confirmation and/or basic P/S system check)

and repair or replace faulty parts, if any.

Step 9: Troubleshooting for DTC (See each DTC

Diag. Flow)

Based on the DTC indicated in Step 6 or 7 and referring

to the applicable DTC diag. flow, locate the cause of the

trouble, namely in a sensor, switch, wire harness,

connector, actuator, P/S control module or other part and

repair or replace faulty parts.

Step 10: Intermittent Problems Check

Check parts where an intermittent trouble is easy to

occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connection Inspection in Section

00” and related circuit of DTC recorded in Step 2. Step 11: Final Confirmation Test

Confirm that the problem symptom has gone and the P/

S system is free from any abnormal conditions. If what

has been repaired is related to the DTC, clear the DTC

once, perform DTC confirmation procedure and confirm

that no DTC is indicated.

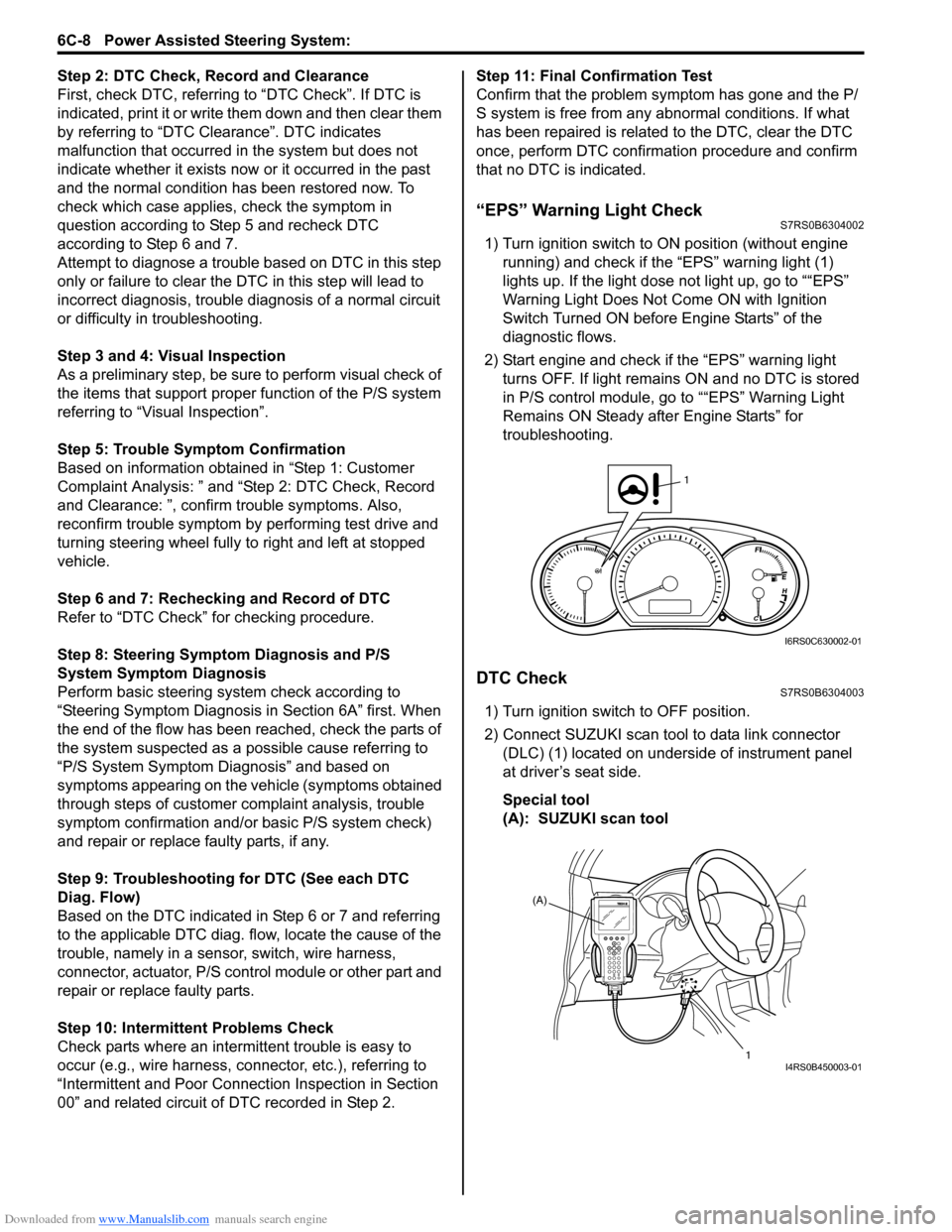

“EPS” Warning Light CheckS7RS0B6304002

1) Turn ignition switch to ON position (without engine

running) and chec k if the “EPS” warning light (1)

lights up. If the light dose not light up, go to ““EPS”

Warning Light Does Not Come ON with Ignition

Switch Turned ON before Engine Starts” of the

diagnostic flows.

2) Start engine and check if the “EPS” warning light turns OFF. If light remains ON and no DTC is stored

in P/S control module, go to ““EPS” Warning Light

Remains ON Steady after Engine Starts” for

troubleshooting.

DTC CheckS7RS0B6304003

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (DLC) (1) located on underside of instrument panel

at driver’s seat side.

Special tool

(A): SUZUKI scan tool

1

I6RS0C630002-01

(A)

1

I4RS0B450003-01

Page 958 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-10 Air Conditioning System: Manual Type

Abnormal Noise from Tension Pulley

Abnormal Noise from A/C Evaporator

Abnormal Noise from Blower Motor

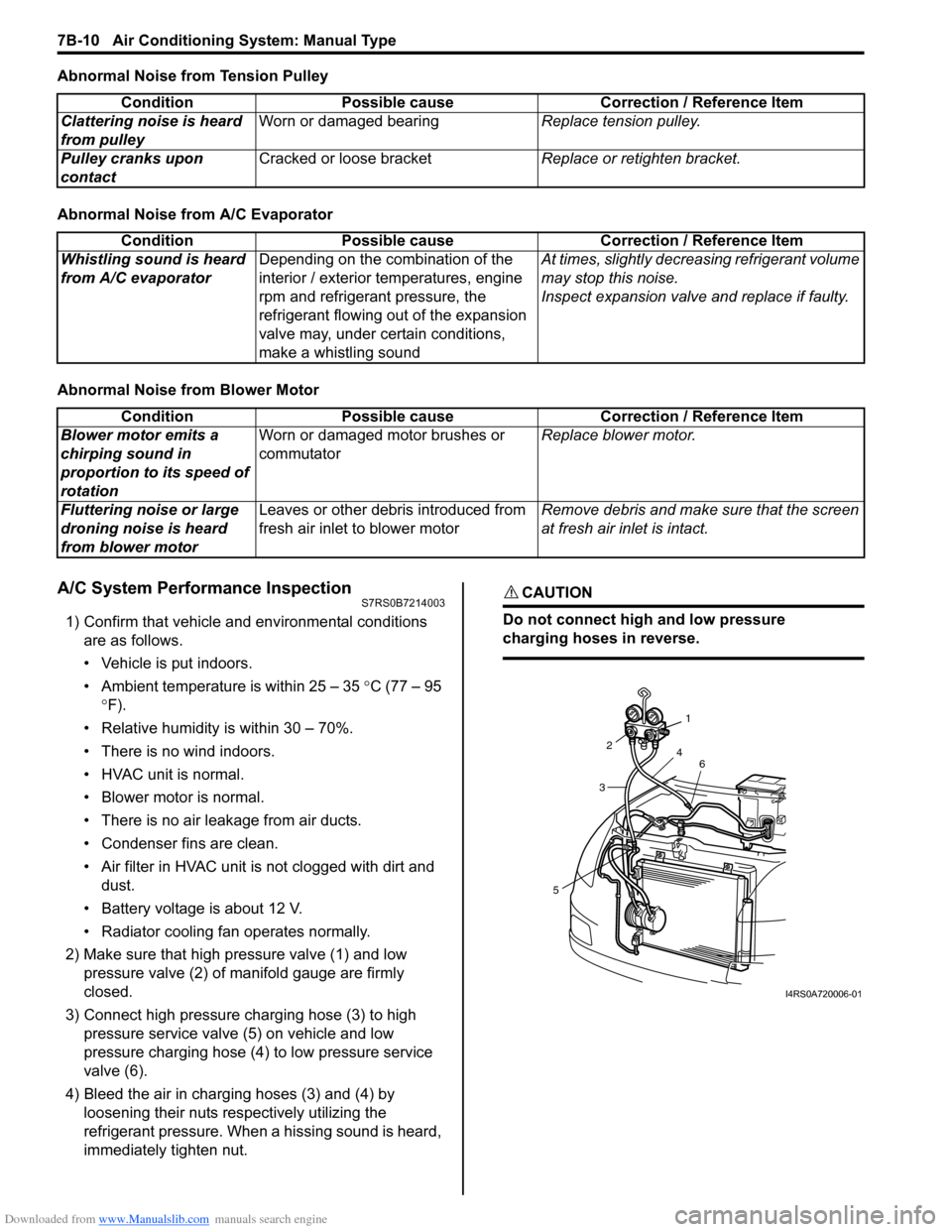

A/C System Performance InspectionS7RS0B7214003

1) Confirm that vehicle and environmental conditions are as follows.

• Vehicle is put indoors.

• Ambient temperature is within 25 – 35 °C (77 – 95

° F).

• Relative humidity is within 30 – 70%.

• There is no wind indoors.

• HVAC unit is normal.

• Blower motor is normal.

• There is no air leakage from air ducts.

• Condenser fins are clean.

• Air filter in HVAC unit is not clogged with dirt and

dust.

• Battery voltage is about 12 V.

• Radiator cooling fan operates normally.

2) Make sure that high pressure valve (1) and low pressure valve (2) of manifold gauge are firmly

closed.

3) Connect high pressure charging hose (3) to high pressure service valve (5) on vehicle and low

pressure charging hose (4) to low pressure service

valve (6).

4) Bleed the air in charging hoses (3) and (4) by loosening their nuts respectively utilizing the

refrigerant pressure. When a hissing sound is heard,

immediately tighten nut.

CAUTION!

Do not connect high and low pressure

charging hoses in reverse.

Condition Possible cause Correction / Reference Item

Clattering noise is heard

from pulley Worn or damaged bearing

Replace tension pulley.

Pulley cranks upon

contact Cracked or loose bracket

Replace or retighten bracket.

ConditionPossible cause Correction / Reference Item

Whistling sound is heard

from A/C evaporator Depending on the combination of the

interior / exterior temperatures, engine

rpm and refrigerant pressure, the

refrigerant flowing out of the expansion

valve may, under certain conditions,

make a whistling sound At times, slightly decrea

sing refrigerant volume

may stop this noise.

Inspect expansion valve and replace if faulty.

Condition Possible cause Correction / Reference Item

Blower motor emits a

chirping sound in

proportion to its speed of

rotation Worn or damaged motor brushes or

commutator

Replace blower motor.

Fluttering noise or large

droning noise is heard

from blower motor Leaves or other debris introduced from

fresh air inlet to blower motor

Remove debris and make sure that the screen

at fresh air inlet is intact.

53

2

1

4 6

I4RS0A720006-01

Page 964 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-16 Air Conditioning System: Manual Type

Repair Instructions

Operation Procedure for Refrigerant ChargeS7RS0B7216001

WARNING!

• Your eyes should not be exposed to refrigerant (liquid).Any liquid HFC-134a (R-134a) escaping by accident shows a temperature as low as approximately –

6 °C (21.2 ° F) below freezing point. Should liquid HFC-134a (R-134a) is exposed to your eyes, it may

cause a serious injury. To protect your eyes from such accident, it is necessary to always wear

goggles. Should it occur that HFC-134a (R-134a) is exposed to your eyes, consult a doctor

immediately.

– Do not use your hand to rub the affected eye(s). Instead, use fresh cold water to splash it over the affected area to gradually raise temperature of such area above freezing point.

– Obtain proper treatment as soon as possible from a doctor or eye specialist.

• Should the liquid refrigerant HFC-134a (R-134a) is exposed to your skin, the affected area should be treated in the same manner as when skin is frostbitten or frozen.

• Do not handle refrigerant near any place where welding or steam cleaning is performed.

• Refrigerant should be kept in a cold and dark pl ace. It should never be stored in any place where

temperature is high, e.g. where exposed to direct su n light, close to fire or inside vehicle (including

trunk room).

• Avoid breathing fume produced when HFC-134a (R-134a) is burned. Such fume may be hazardous to your health.

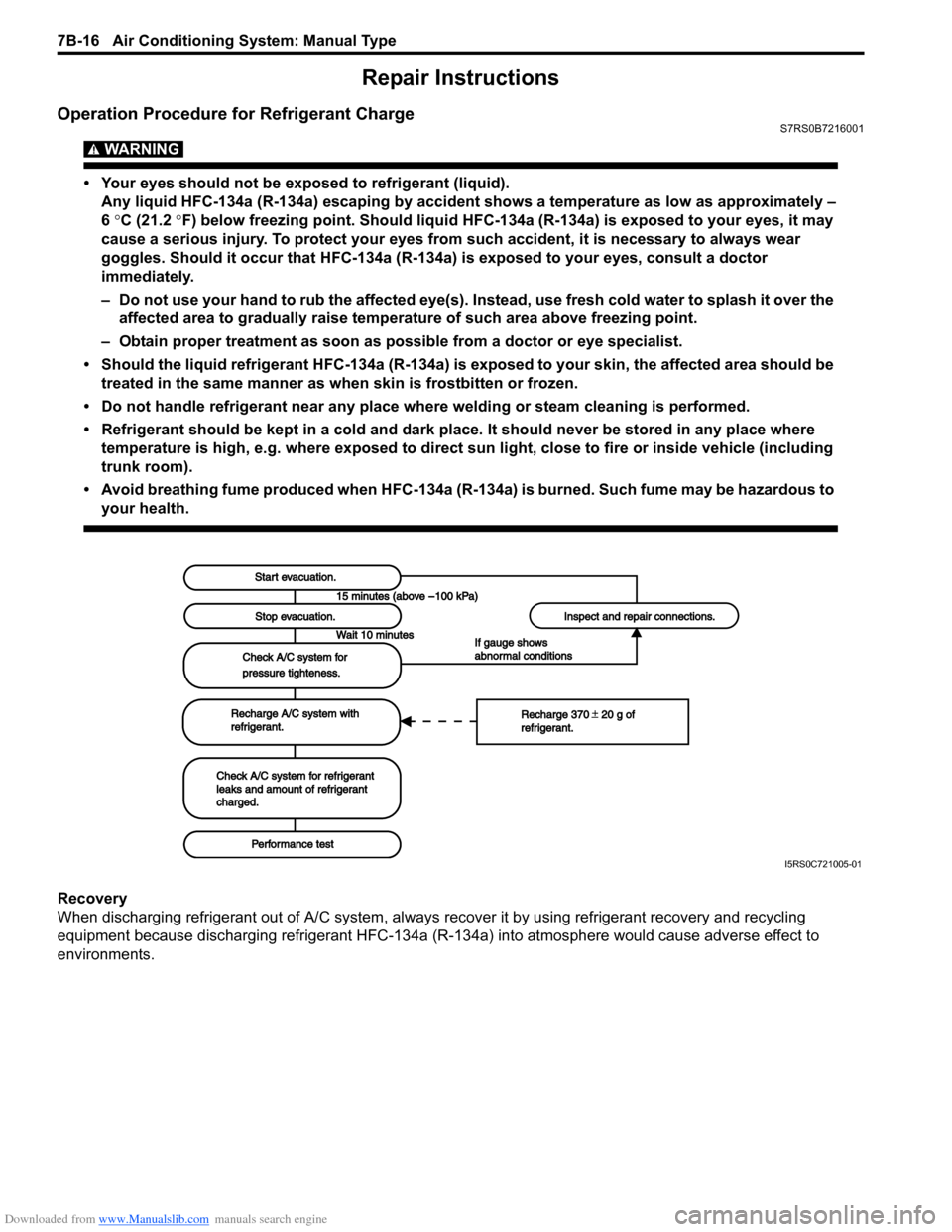

Recovery

When discharging refrigerant out of A/C system, always recover it by using refrigerant recovery and recycling

equipment because discharging refrigerant HFC-134a (R-1 34a) into atmosphere would cause adverse effect to

environments.

Start evacuation.Start evacuation.

Stop evacuation.Stop evacuation.

Wait 10 minutesWait 10 minutes

Check A/C system forCheck A/C system for

pressure tighteness.pressure tighteness.

Recharge A/C system withRecharge A/C system withrefrigerant.refrigerant.

Check A/C system for refrigerantCheck A/C system for refrigerantleaks and amount of refrigerantleaks and amount of refrigerantcharged.charged.

Performance testPerformance test

Inspect and repair connections.Inspect and repair connections.

If gauge showsIf gauge showsabnormal conditionsabnormal conditions

Recharge 370 20 g ofRecharge 370 20 g ofrefrigerant.refrigerant.

I5RS0C721005-01

Page 994 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-46 Air Conditioning System: Automatic Type

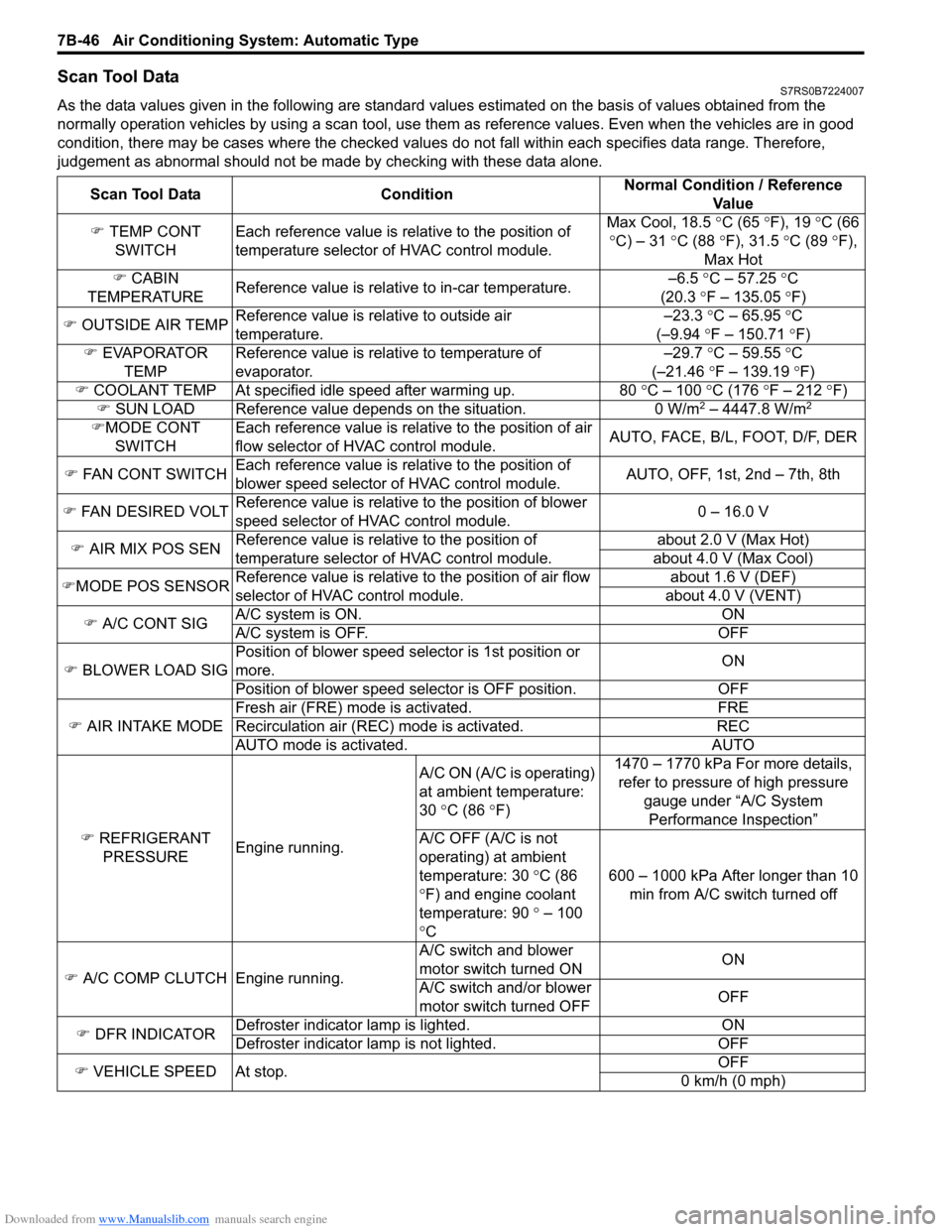

Scan Tool DataS7RS0B7224007

As the data values given in the following are standard values estimated on the basis of values obtained from the

normally operation vehicles by using a scan tool, use them as reference values. Even when the vehicles are in good

condition, there may be cases where the checked values do not fall within each specifies data range. Therefore,

judgement as abnormal should not be ma de by checking with these data alone.

Scan Tool Data Condition Normal Condition / Reference

Va l u e

�) TEMP CONT

SWITCH Each reference value is relative to the position of

temperature selector of HVAC control module. Max Cool, 18.5

°C (65 ° F), 19 °C (66

° C) – 31 °C (88 °F), 31.5 °C (89 °F),

Max Hot

�) CABIN

TEMPERATURE Reference value is relative to in-car temperature. –6.5

°C – 57.25 ° C

(20.3 °F – 135.05 °F)

�) OUTSIDE AIR TEMP Reference value is relative to outside air

temperature. –23.3

°C – 65.95 °C

(–9.94 °F – 150.71 °F)

�) EVAPORATOR

TEMP Reference value is relative to temperature of

evaporator. –29.7

°C – 59.55 °C

(–21.46 °F – 139.19 °F)

�) COOLANT TEMP At specified id le speed after warming up. 80 °C – 100 °C (176 ° F – 212 ° F)

�) SUN LOAD Reference value depends on the situation. 0 W/m

2 – 4447.8 W/m2

�)MODE CONT

SWITCH Each reference value is relative to the position of air

flow selector of HVAC control module.

AUTO, FACE, B/L, FOOT, D/F, DER

�) FAN CONT SWITCH Each reference value is relative to the position of

blower speed selector of HVAC control module. AUTO, OFF, 1st, 2nd – 7th, 8th

�) FAN DESIRED VOLT Reference value is relative to the position of blower

speed selector of HVAC control module. 0 – 16.0 V

�) AIR MIX POS SEN Reference value is relative to the position of

temperature selector of HVAC control module. about 2.0 V (Max Hot)

about 4.0 V (Max Cool)

�) MODE POS SENSOR Reference value is relative to the position of air flow

selector of HVAC control module. about 1.6 V (DEF)

about 4.0 V (VENT)

�) A/C CONT SIG A/C system is ON. ON

A/C system is OFF. OFF

�) BLOWER LOAD SIG Position of blower speed selector is 1st position or

more.

ON

Position of blower speed selector is OFF position. OFF

�) AIR INTAKE MODE Fresh air (FRE) mode is activated. FRE

Recirculation air (REC) mode is activated. REC

AUTO mode is activated. AUTO

�) REFRIGERANT

PRESSURE Engine running. A/C ON (A/C is operating)

at ambient temperature:

30

°C (86 °F) 1470 – 1770 kPa For more details,

refer to pressure of high pressure

gauge under “A/C System Performance Inspection”

A/C OFF (A/C is not

operating) at ambient

temperature: 30 °C (86

° F) and engine coolant

temperature: 90 ° – 100

° C 600 – 1000 kPa After longer than 10

min from A/C switch turned off

�) A/C COMP CLUTCH Engine running. A/C switch and blower

motor switch turned ON

ON

A/C switch and/or blower

motor switch turned OFF OFF

�) DFR INDICATOR Defroster indicator

lamp is lighted. ON

Defroster indicator la mp is not lighted. OFF

�) VEHICLE SPEED At stop. OFF

0 km/h (0 mph)

Page 1033 of 1496

Downloaded from www.Manualslib.com manuals search engine Seat Belts: 8A-2

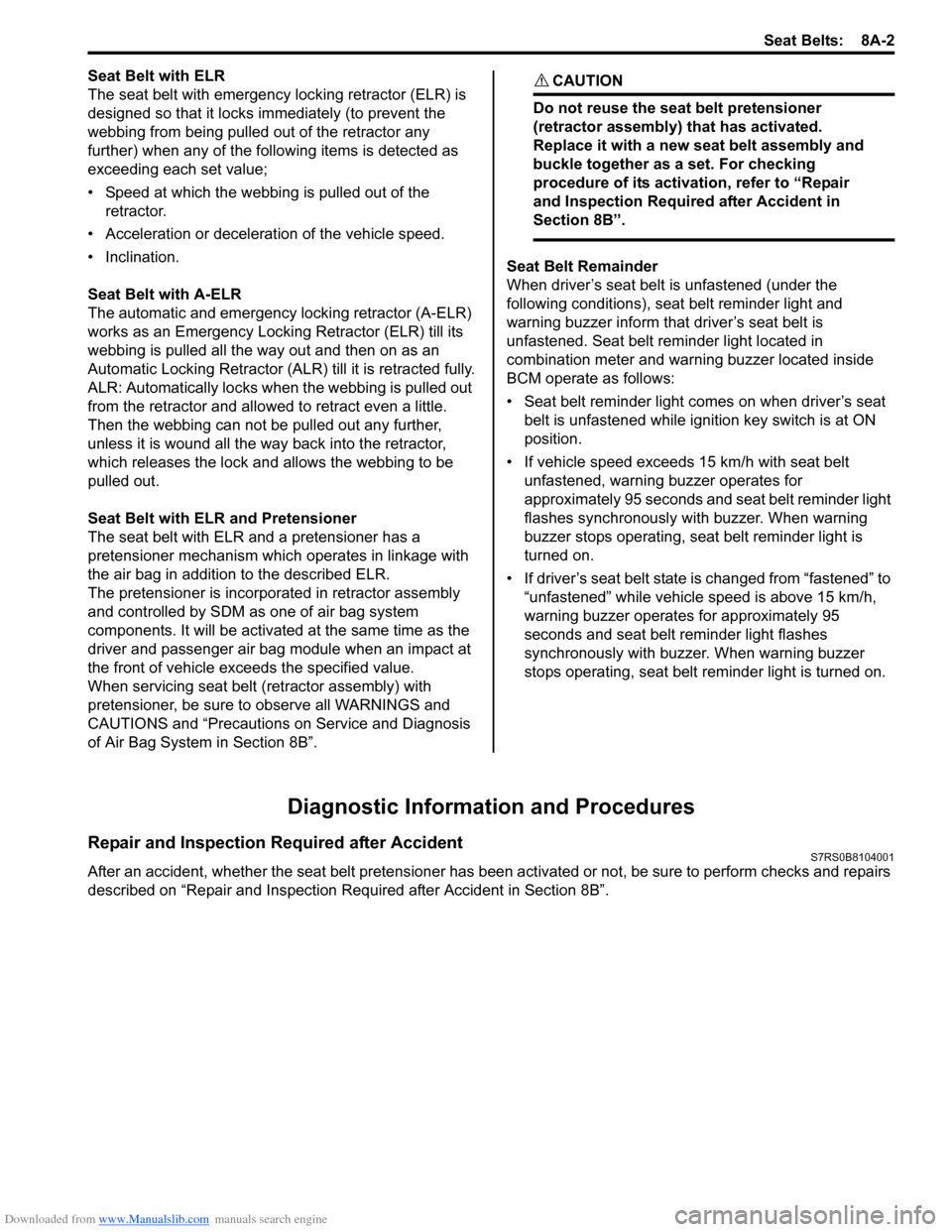

Seat Belt with ELR

The seat belt with emergency locking retractor (ELR) is

designed so that it locks immediately (to prevent the

webbing from being pulled out of the retractor any

further) when any of the following items is detected as

exceeding each set value;

• Speed at which the webbing is pulled out of the retractor.

• Acceleration or deceleration of the vehicle speed.

• Inclination.

Seat Belt with A-ELR

The automatic and emergency locking retractor (A-ELR)

works as an Emergency Locking Retractor (ELR) till its

webbing is pulled all the way out and then on as an

Automatic Locking Retractor (ALR ) till it is retracted fully.

ALR: Automatically locks when the webbing is pulled out

from the retractor and allowed to retract even a little.

Then the webbing can not be pulled out any further,

unless it is wound all the way back into the retractor,

which releases the lock and allows the webbing to be

pulled out.

Seat Belt with ELR and Pretensioner

The seat belt with ELR and a pretensioner has a

pretensioner mechanism whic h operates in linkage with

the air bag in addition to the described ELR.

The pretensioner is incorporated in retractor assembly

and controlled by SDM as one of air bag system

components. It will be activated at the same time as the

driver and passenger air bag module when an impact at

the front of vehicle exceeds the specified value.

When servicing seat belt (retractor assembly) with

pretensioner, be sure to observe all WARNINGS and

CAUTIONS and “Precautions on Service and Diagnosis

of Air Bag System in Section 8B”. CAUTION!

Do not reuse the seat belt pretensioner

(retractor assembly) that has activated.

Replace it with a new seat belt assembly and

buckle together as a set. For checking

procedure of its activation, refer to “Repair

and Inspection Required after Accident in

Section 8B”.

Seat Belt Remainder

When driver’s seat belt is unfastened (under the

following conditions), seat belt reminder light and

warning buzzer inform that driver’s seat belt is

unfastened. Seat belt reminder light located in

combination meter and warning buzzer located inside

BCM operate as follows:

• Seat belt reminder light comes on when driver’s seat belt is unfastened while igni tion key switch is at ON

position.

• If vehicle speed exceeds 15 km/h with seat belt unfastened, warning buzzer operates for

approximately 95 seconds and seat belt reminder light

flashes synchronously with buzzer. When warning

buzzer stops operating, seat belt reminder light is

turned on.

• If driver’s seat belt state is changed from “fastened” to “unfastened” while vehicle speed is above 15 km/h,

warning buzzer operates for approximately 95

seconds and seat belt reminder light flashes

synchronously with buzzer. When warning buzzer

stops operating, seat belt reminder light is turned on.

Diagnostic Information and Procedures

Repair and Inspection Required after AccidentS7RS0B8104001

After an accident, whether the seat belt pretensioner has been activated or not, be sure to perform checks and repairs

described on “Repair and Inspection Required after Accident in Section 8B”.

Page 1195 of 1496

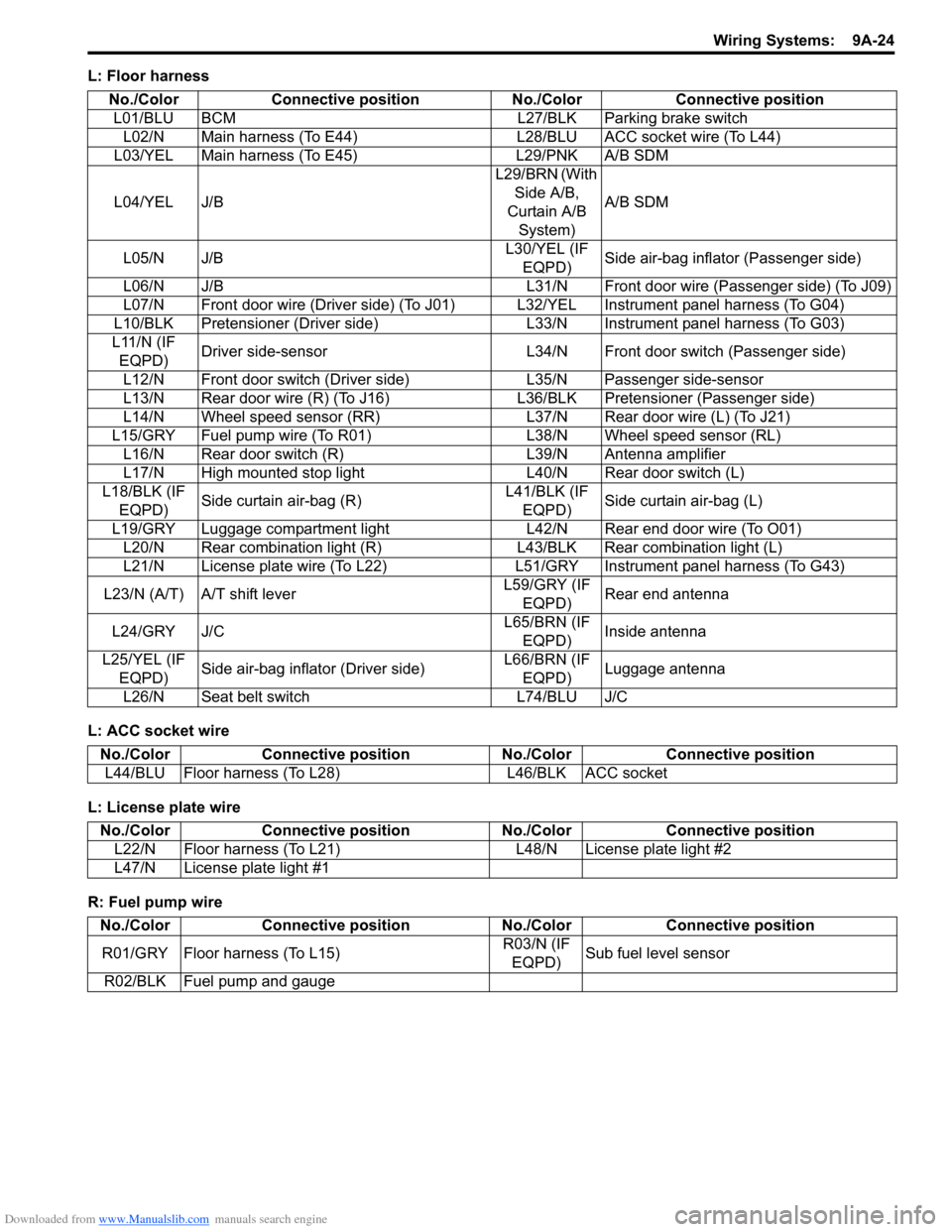

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-24

L: Floor harness

L: ACC socket wire

L: License plate wire

R: Fuel pump wireNo./Color Connective position No./Color Connective position

L01/BLU BCM L27/BLK Parking brake switch L02/N Main harness (To E44) L28/BLU ACC socket wire (To L44)

L03/YEL Main harness (To E45) L29/PNK A/B SDM

L04/YEL J/B L29/BRN (With

Side A/B,

Curtain A/B System) A/B SDM

L05/N J/B L30/YEL (IF

EQPD) Side air-bag inflator (Passenger side)

L06/N J/B L31/N Front door wire (Passenger side) (To J09)

L07/N Front door wire (Driver side) (To J01) L32/YEL Instrument panel harness (To G04)

L10/BLK Pretensioner (Driver side) L33/N Instrument panel harness (To G03)

L11/N (IF EQPD) Driver side-sensor L34/N Front door switch (Passenger side)

L12/N Front door switch (Driver side) L35/N Passenger side-sensor

L13/N Rear door wire (R) (To J16) L 36/BLK Pretensioner (Passenger side)

L14/N Wheel speed sensor (RR) L37/N Rear door wire (L) (To J21)

L15/GRY Fuel pump wire (To R01) L38/N Wheel speed sensor (RL)

L16/N Rear door switch (R) L39/N Antenna amplifier

L17/N High mounted stop light L40/N Rear door switch (L)

L18/BLK (IF EQPD) Side curtain air-bag (R) L41/BLK (IF

EQPD) Side curtain air-bag (L)

L19/GRY Luggage compartment light L42/N Rear end door wire (To O01) L20/N Rear combination light (R) L43/BLK Rear combination light (L)

L21/N License plate wire (To L22) L51/ GRY Instrument panel harness (To G43)

L23/N (A/T) A/T shift lever L59/GRY (IF

EQPD) Rear end antenna

L24/GRY J/C L65/BRN (IF

EQPD) Inside antenna

L25/YEL (IF EQPD) Side air-bag inflator (Driver side) L66/BRN (IF

EQPD) Luggage antenna

L26/N Seat belt switch L74/BLU J/C

No./Color Connective position No./Color Connective position

L44/BLU Floor harness (To L28) L46/BLK ACC socket

No./ColorConnective position No./Color Connective position

L22/N Floor harness (To L21) L48/N License plate light #2

L47/N License plate light #1

No./Color Connective position No./Color Connective position

R01/GRY Floor harness (To L15) R03/N (IF

EQPD) Sub fuel level sensor

R02/BLK Fuel pump and gauge

Page 1197 of 1496

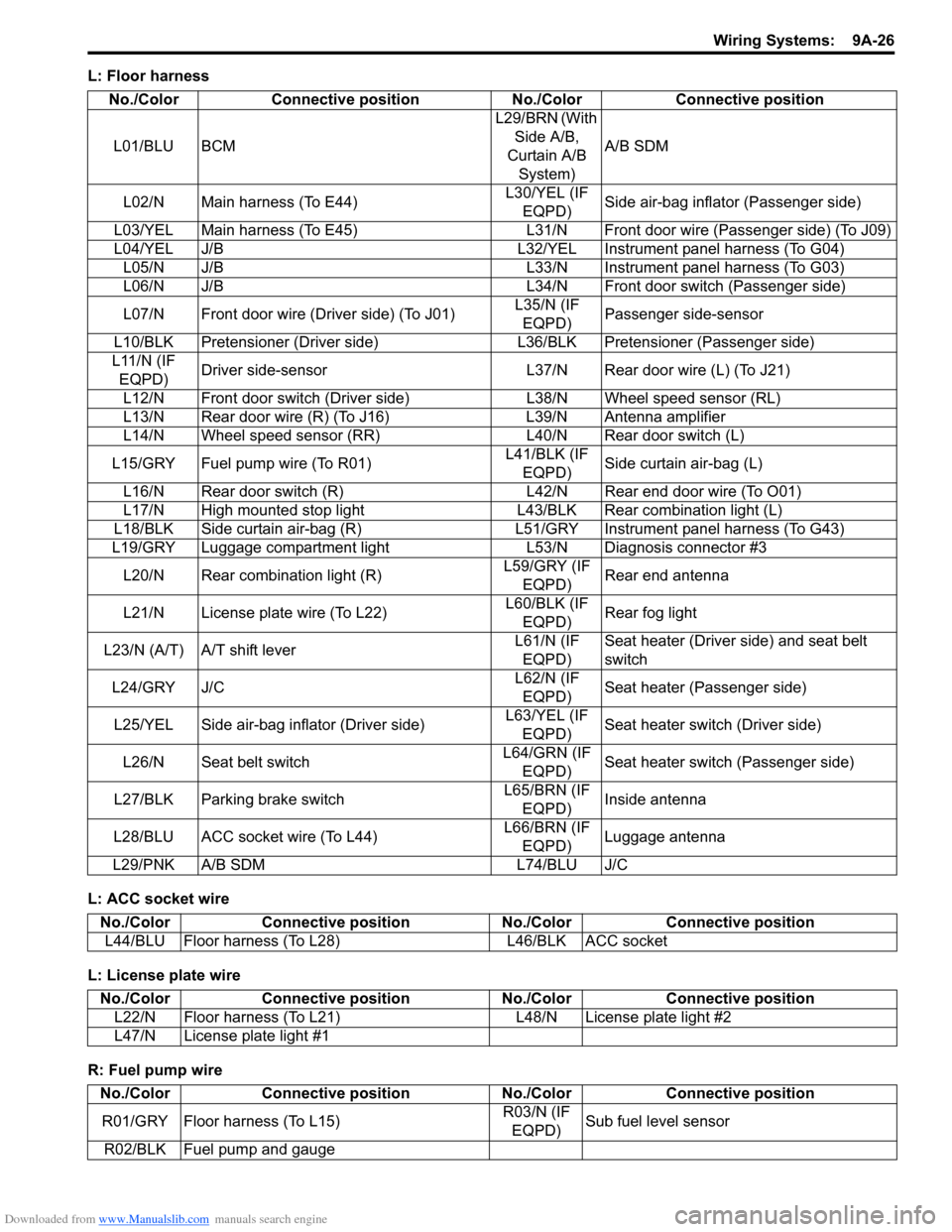

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-26

L: Floor harness

L: ACC socket wire

L: License plate wire

R: Fuel pump wireNo./Color Connective position No./Color Connective position

L01/BLU BCM L29/BRN (With

Side A/B,

Curtain A/B System) A/B SDM

L02/N Main harness (To E44) L30/YEL (IF

EQPD) Side air-bag inflator (Passenger side)

L03/YEL Main harness (To E45) L31/N Front door wire (Passenger side) (To J09)

L04/YEL J/B L32/YEL Instrument panel harness (To G04) L05/N J/B L33/N Instrument panel harness (To G03)

L06/N J/B L34/N Front door switch (Passenger side)

L07/N Front door wire (Driver side) (To J01) L35/N (IF

EQPD) Passenger side-sensor

L10/BLK Pretensioner (Driver side) L36/ BLK Pretensioner (Passenger side)

L11/N (IF EQPD) Driver side-sensor L37/N Rear door wire (L) (To J21)

L12/N Front door switch (Driver side) L38/N Wheel speed sensor (RL)

L13/N Rear door wire (R) (To J16) L39/N Antenna amplifier

L14/N Wheel speed sensor (RR) L40/N Rear door switch (L)

L15/GRY Fuel pump wire (To R01) L41/BLK (IF

EQPD) Side curtain air-bag (L)

L16/N Rear door switch (R) L42/N Rear end door wire (To O01)

L17/N High mounted stop light L43/BLK Rear combination light (L)

L18/BLK Side curtain air-bag (R) L51/GRY Instrument panel harness (To G43)

L19/GRY Luggage compartment light L53/N Diagnosis connector #3

L20/N Rear combin ation light (R) L59/GRY (IF

EQPD) Rear end antenna

L21/N License plate wire (To L22) L60/BLK (IF

EQPD) Rear fog light

L23/N (A/T) A/T shift lever L61/N (IF

EQPD) Seat heater (Driver side) and seat belt

switch

L24/GRY J/C L62/N (IF

EQPD) Seat heater (Passenger side)

L25/YEL Side air-bag inflator (Driver side) L63/YEL (IF

EQPD) Seat heater switch (Driver side)

L26/N Seat belt switch L64/GRN (IF

EQPD) Seat heater switch (Passenger side)

L27/BLK Parking brake switch L65/BRN (IF

EQPD) Inside antenna

L28/BLU ACC socket wire (To L44) L66/BRN (IF

EQPD) Luggage antenna

L29/PNK A/B SDM L74/BLU J/C

No./Color Connective position No./Color Connective position

L44/BLU Floor harness (To L28) L46/BLK ACC socket

No./ColorConnective position No./Color Connective position

L22/N Floor harness (To L21) L48/N License plate light #2

L47/N License plate light #1

No./Color Connective position No./Color Connective position

R01/GRY Floor harness (To L15) R03/N (IF

EQPD) Sub fuel level sensor

R02/BLK Fuel pump and gauge

Page 1199 of 1496

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-28

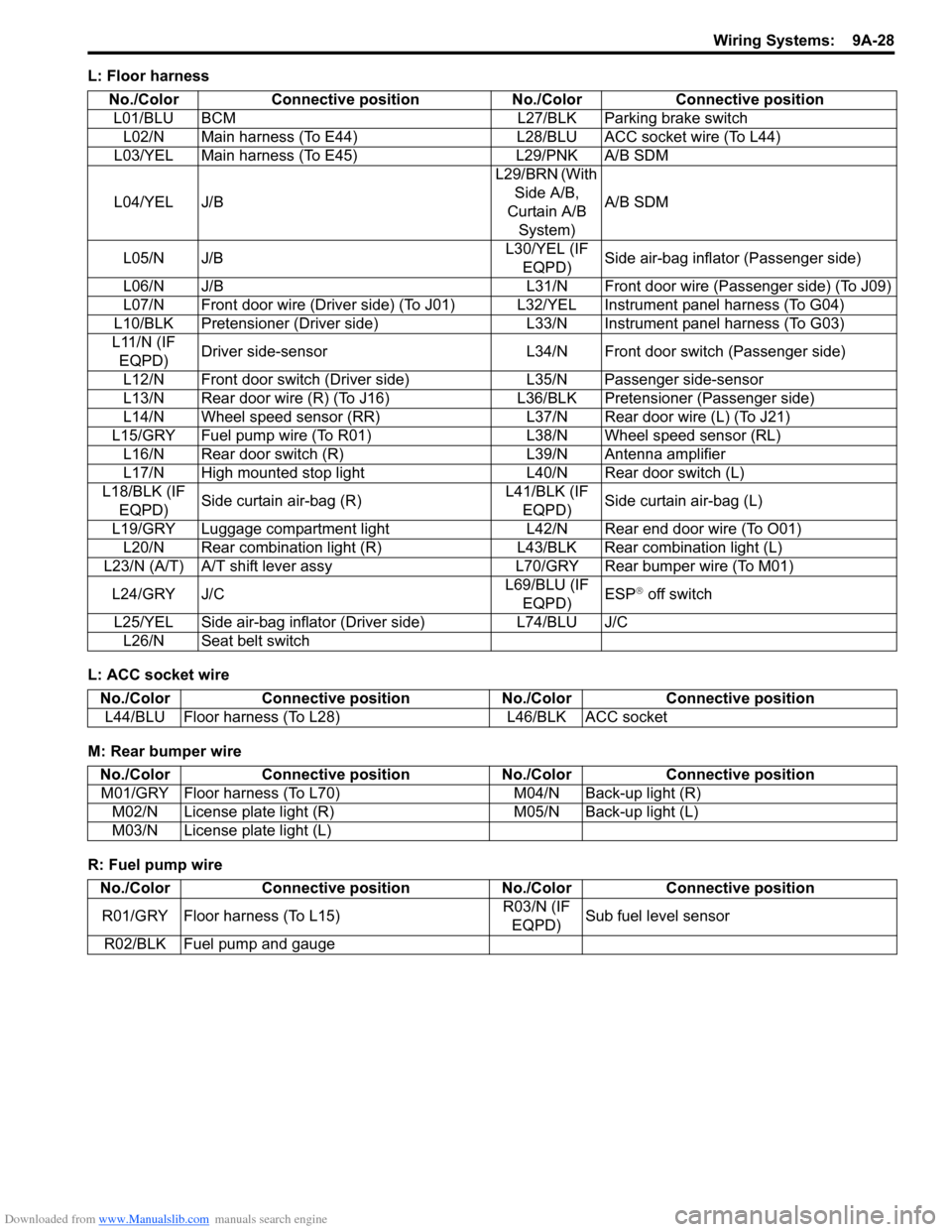

L: Floor harness

L: ACC socket wire

M: Rear bumper wire

R: Fuel pump wireNo./Color Connective position No./Color Connective position

L01/BLU BCM L27/BLK Parking brake switch L02/N Main harness (To E44) L28/BLU ACC socket wire (To L44)

L03/YEL Main harness (To E45) L29/PNK A/B SDM

L04/YEL J/B L29/BRN (With

Side A/B,

Curtain A/B System) A/B SDM

L05/N J/B L30/YEL (IF

EQPD) Side air-bag inflator (Passenger side)

L06/N J/B L31/N Front door wire (Passenger side) (To J09)

L07/N Front door wire (Driver side) (To J01) L32/YEL Instrument panel harness (To G04)

L10/BLK Pretensioner (Driver side) L33/N Instrument panel harness (To G03)

L11/N (IF EQPD) Driver side-sensor L34/N Front door switch (Passenger side)

L12/N Front door switch (Driver side) L35/N Passenger side-sensor

L13/N Rear door wire (R) (To J16) L 36/BLK Pretensioner (Passenger side)

L14/N Wheel speed sensor (RR) L37/N Rear door wire (L) (To J21)

L15/GRY Fuel pump wire (To R01) L38/N Wheel speed sensor (RL)

L16/N Rear door switch (R) L39/N Antenna amplifier

L17/N High mounted stop light L40/N Rear door switch (L)

L18/BLK (IF EQPD) Side curtain air-bag (R) L41/BLK (IF

EQPD) Side curtain air-bag (L)

L19/GRY Luggage compartment light L42/N Rear end door wire (To O01) L20/N Rear combination light (R) L43/BLK Rear combination light (L)

L23/N (A/T) A/T shift lever assy L70/GRY Rear bumper wire (To M01)

L24/GRY J/C L69/BLU (IF

EQPD) ESP

® off switch

L25/YEL Side air-bag inflator (Driver side) L74/BLU J/C L26/N Seat belt switch

No./Color Connective position No./Color Connective position

L44/BLU Floor harness (To L28) L46/BLK ACC socket

No./ColorConnective position No./Color Connective position

M01/GRY Floor harness (To L70) M04/N Back-up light (R)

M02/N License plate light (R) M05/N Back-up light (L)

M03/N License plate light (L)

No./Color Connective position No./Color Connective position

R01/GRY Floor harness (To L15) R03/N (IF

EQPD) Sub fuel level sensor

R02/BLK Fuel pump and gauge

Page 1205 of 1496

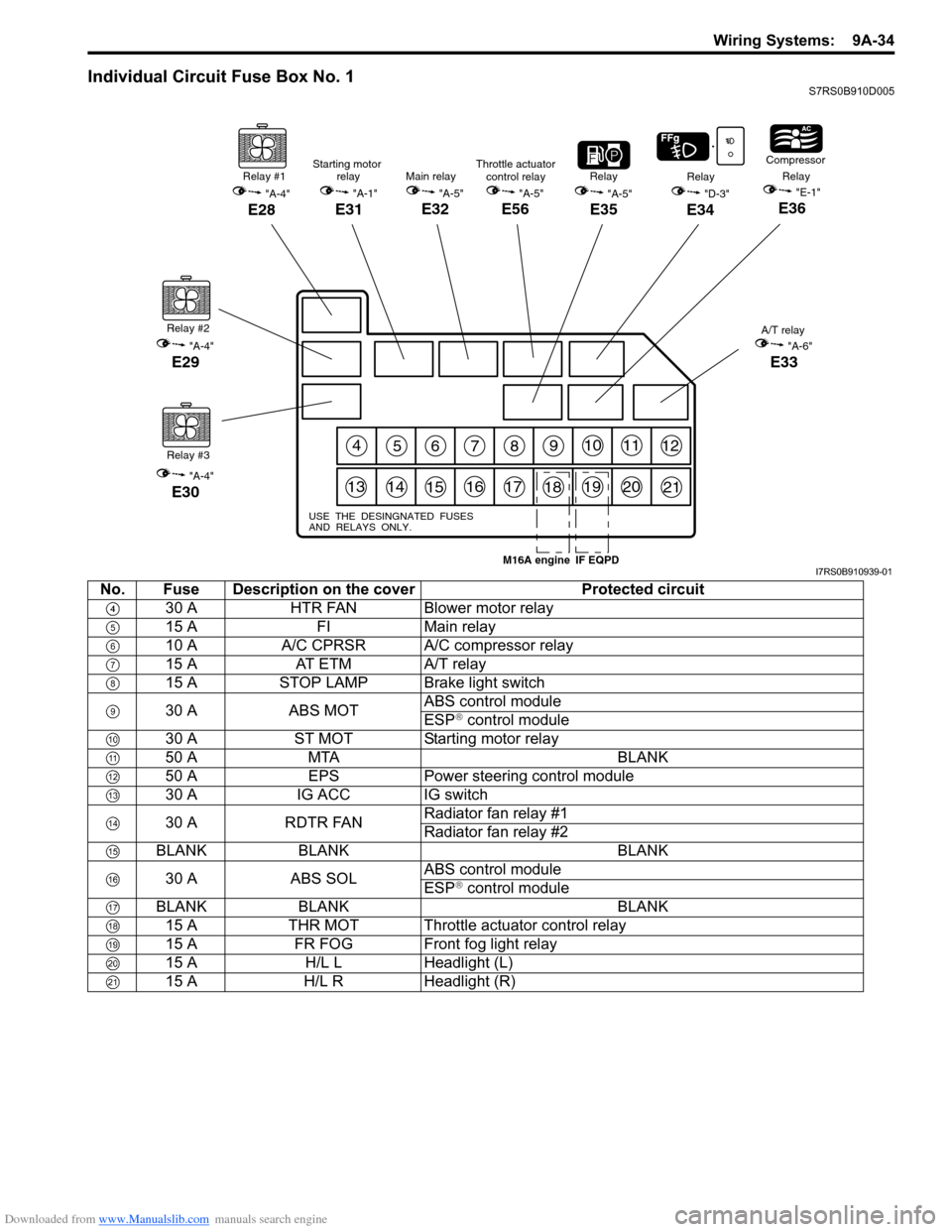

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-34

Individual Circuit Fuse Box No. 1S7RS0B910D005

456789101112

131415161718192021

USE THE DESINGNATED FUSES

AND RELAYS ONLY.

Relay #1

"A-4"

E28

Relay #2

"A-4"

E29

Relay #3

"A-4"

E30

"A-5"

E35

RelayRelay

"D-3"

E34

Compressor

Relay"E-1"

E36

A/T relay

"A-6"

E33

Main relay

"A-5"

E32

Starting motor relay

"A-1"

E31

Throttle actuatorcontrol relay

"A-5"

E56

IF EQPDM16A engineI7RS0B910939-01

No. Fuse Description on the cover Protected circuit

30 A HTR FAN Blower motor relay

15 A FIMain relay

10 A A/C CPRSR A/C compressor relay

15 A AT ETM A/T relay

15 A STOP LAMP Brake light switch

30 A ABS MOT ABS control module

ESP

® control module

30 A ST MOT Starting motor relay

50 A MTA BLANK

50 A EPS Power steering control module

30 A IG ACC IG switch

30 A RDTR FAN Radiator fan relay #1

Radiator fan relay #2

BLANK BLANK BLANK

30 A ABS SOL ABS control module

ESP

® control module

BLANK BLANK BLANK 15 A THR MOT Throttle actuator control relay

15 A FR FOG Front fog light relay

15 A H/L L Headlight (L)

15 A H/L R Headlight (R)