wheel bolt torque SUZUKI SWIFT 2008 2.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 533 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Brakes: 4C-9

Rear Brake Disc Removal and InstallationS7RS0B4306008

Removal1) Hoist vehicle and remove wheel.

2) Remove caliper assembly by removing caliper

carrier bolts (1) (2 pcs).

CAUTION!

During removal, be ca reful not to damage

brake flexible hose and not to depress brake

pedal.

NOTE

Hang removed caliper with a wire hook or the

like so as to prevent brake hose from

bending and twisting excessively or being

pulled.

Don’t operate brake pedal with brake pads

removed.

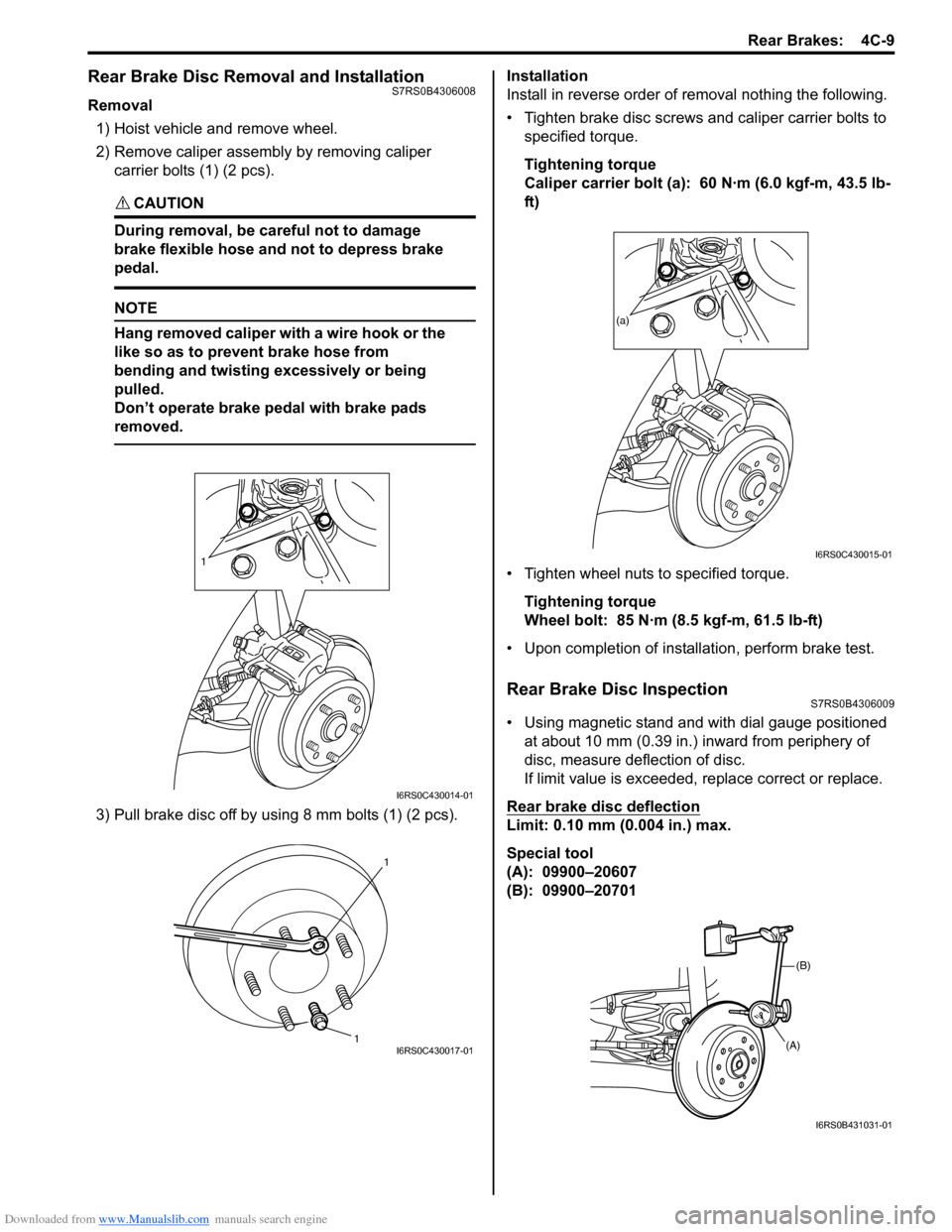

3) Pull brake disc off by using 8 mm bolts (1) (2 pcs). Installation

Install in reverse order of removal nothing the following.

• Tighten brake disc screws and caliper carrier bolts to

specified torque.

Tightening torque

Caliper carrier bolt (a): 60 N·m (6.0 kgf-m, 43.5 lb-

ft)

• Tighten wheel nuts to specified torque. Tightening torque

Wheel bolt: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

• Upon completion of installation, perform brake test.

Rear Brake Disc InspectionS7RS0B4306009

• Using magnetic stand and with dial gauge positioned at about 10 mm (0.39 in.) inward from periphery of

disc, measure deflection of disc.

If limit value is exceeded, replace correct or replace.

Rear brake disc deflection

Limit: 0.10 mm (0.004 in.) max.

Special tool

(A): 09900–20607

(B): 09900–20701

1

I6RS0C430014-01

1 1I6RS0C430017-01

(a)

I6RS0C430015-01

(B)

(A)

I6RS0B431031-01

Page 534 of 1496

Downloaded from www.Manualslib.com manuals search engine 4C-10 Rear Brakes:

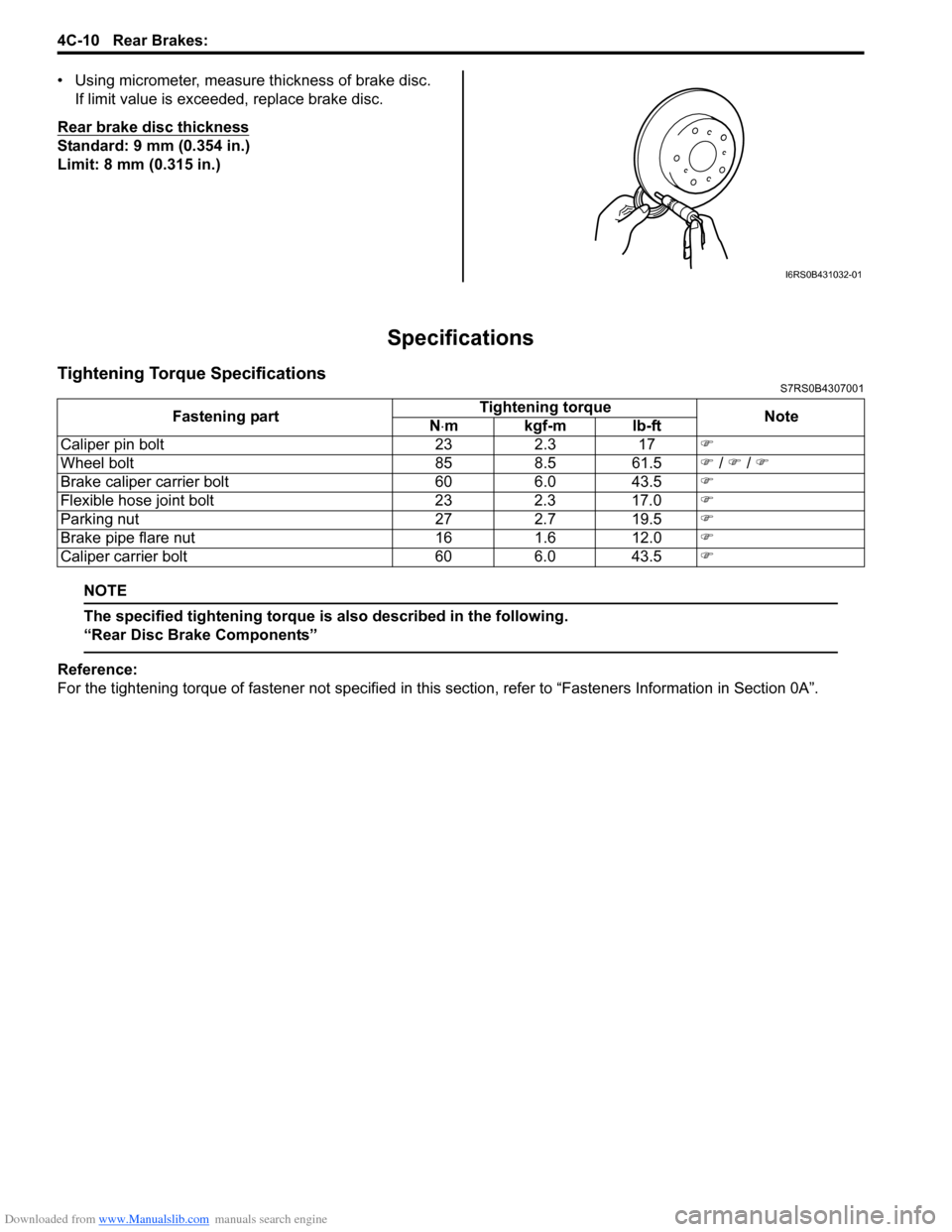

• Using micrometer, measure thickness of brake disc.If limit value is exceeded, replace brake disc.

Rear brake disc thickness

Standard: 9 mm (0.354 in.)

Limit: 8 mm (0.315 in.)

Specifications

Tightening Torque SpecificationsS7RS0B4307001

NOTE

The specified tightening torque is also described in the following.

“Rear Disc Brake Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

I6RS0B431032-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Caliper pin bolt 23 2.3 17 �)

Wheel bolt 85 8.5 61.5 �) / �) / �)

Brake caliper carrier bolt 60 6.0 43.5 �)

Flexible hose joint bolt 23 2.3 17.0 �)

Parking nut 27 2.7 19.5 �)

Brake pipe flare nut 16 1.6 12.0 �)

Caliper carrier bolt 60 6.0 43.5 �)

Page 538 of 1496

Downloaded from www.Manualslib.com manuals search engine 4D-3 Parking Brake:

6) Release parking brake lever and then make sure that there is no drag in rear wheel.

If there is, repeats go to step 2).

7) Make sure that the number of notch is between 4 and 9 when operating parking brake lever.

8) If the number of notch is not between 4 and 9, replace parking brake cable and/or inspect rear

brake caliper.

Parking brake stroke

When lever is pulled up at 200 N (20kg, 44lbs) : 4

to 9 notches

Parking Brake Cable Removal and InstallationS7RS0B4406002

Removal

NOTE

When it is necessary to remove both right

and left parking brake cables, repeat below

steps 2) and 5) on right and left wheels.

1) Hoist vehicle.

2) Remove wheel.

3) Disconnect parking brake cable from equalizer (parking brake lever) and clamps.

4) Disconnect parking brake cable from lever referring to “Rear Disc Brake Caliper Removal and Installation

in Section 4C”.

5) Remove parking brake cable and parking cable bracket.

Installation

Install it by reversing removal procedure, noting the

following points.

• Install clamps properly referring to “Parking Brake Cable Construction”.

• Tighten bolts and nuts to specified torque referring to “Parking Brake Cable Construction”.

Tightening torque

Parking brake lever bolt: 25 N·m (2.5 kgf-m, 18.0

lb-ft)

Parking cable clamp bolt: 11 N·m (1.1 kgf-m, 8.0

lb-ft)

Parking cable bracket bolt: 25 N·m (2.5 kgf-m,

18.0 lb-ft)

• Adjust parking brake cable. Refer to “Parking Brake Inspection and Adjustment”.

• Check brake disc for dragging and brake system for proper performance. Brake test should be performed.

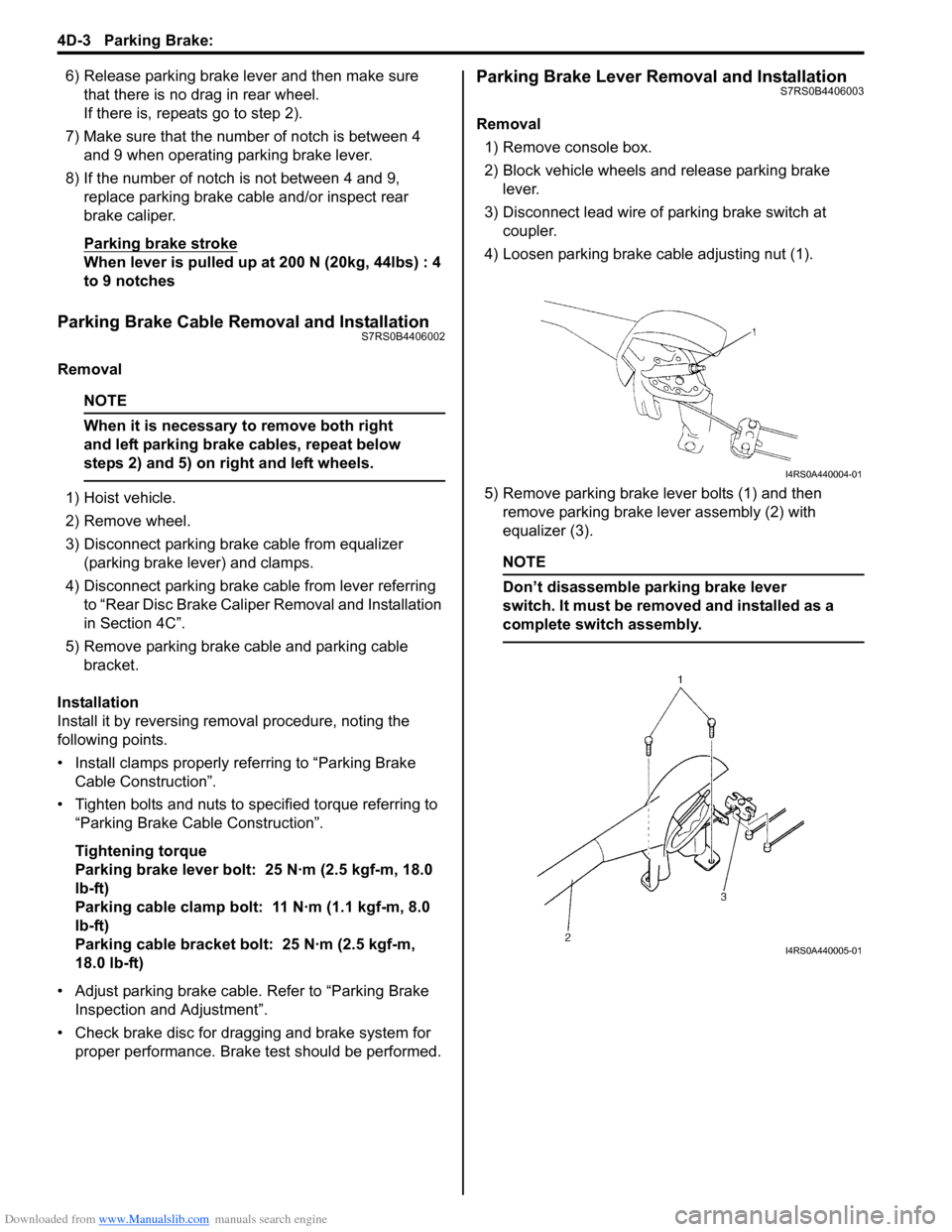

Parking Brake Lever Removal and InstallationS7RS0B4406003

Removal

1) Remove console box.

2) Block vehicle wheels and release parking brake lever.

3) Disconnect lead wire of parking brake switch at coupler.

4) Loosen parking brake cable adjusting nut (1).

5) Remove parking brake lever bolts (1) and then remove parking brake lever assembly (2) with

equalizer (3).

NOTE

Don’t disassemble parking brake lever

switch. It must be removed and installed as a

complete switch assembly.

I4RS0A440004-01

I4RS0A440005-01

Page 558 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-19 ABS:

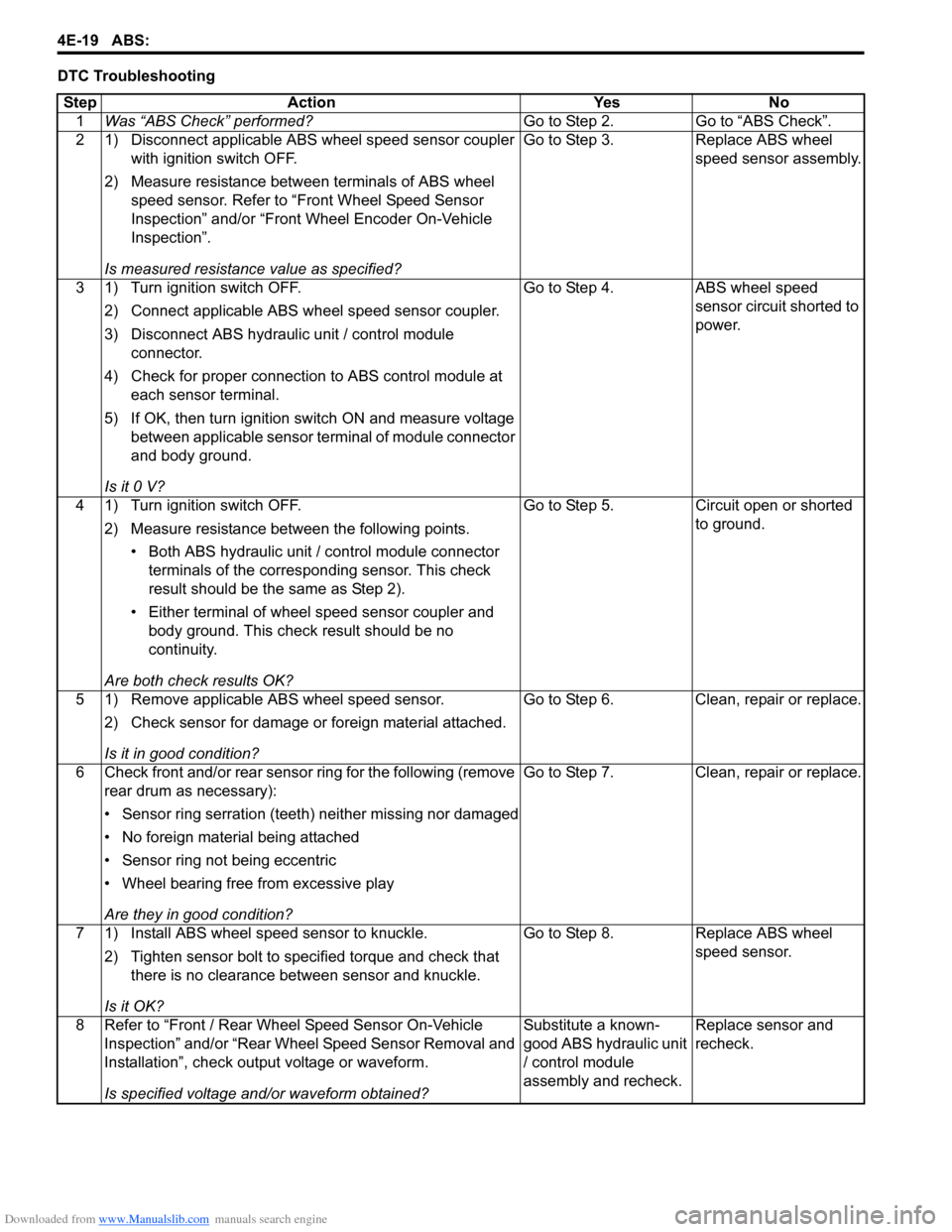

DTC TroubleshootingStep Action Yes No 1 Was “ABS Check” performed? Go to Step 2. Go to “ABS Check”.

2 1) Disconnect applicable ABS wheel speed sensor coupler with ignition switch OFF.

2) Measure resistance betw een terminals of ABS wheel

speed sensor. Refer to “Front Wheel Speed Sensor

Inspection” and/or “Front Wheel Encoder On-Vehicle

Inspection”.

Is measured resistance value as specified? Go to Step 3. Replace ABS wheel

speed sensor assembly.

3 1) Turn ignition switch OFF. 2) Connect applicable ABS wh eel speed sensor coupler.

3) Disconnect ABS hydraulic unit / control module connector.

4) Check for proper connection to ABS control module at each sensor terminal.

5) If OK, then turn ignition switch ON and measure voltage between applicable sensor terminal of module connector

and body ground.

Is it 0 V? Go to Step 4. ABS wheel speed

sensor circuit shorted to

power.

4 1) Turn ignition switch OFF. 2) Measure resistance between the following points.• Both ABS hydraulic unit / control module connector terminals of the correspo nding sensor. This check

result should be the same as Step 2).

• Either terminal of wheel speed sensor coupler and body ground. This check result should be no

continuity.

Are both check results OK? Go to Step 5. Circuit open or shorted

to ground.

5 1) Remove applicable ABS wheel speed sensor. 2) Check sensor for damage or foreign material attached.

Is it in good condition? Go to Step 6. Clean, repair or replace.

6 Check front and/or rear sensor ring for the following (remove rear drum as necessary):

• Sensor ring serration (teeth) neither missing nor damaged

• No foreign material being attached

• Sensor ring not being eccentric

• Wheel bearing free from excessive play

Are they in good condition? Go to Step 7. Clean, repair or replace.

7 1) Install ABS wheel speed sensor to knuckle. 2) Tighten sensor bolt to specified torque and check that there is no clearance between sensor and knuckle.

Is it OK? Go to Step 8. Replace ABS wheel

speed sensor.

8 Refer to “Front / Rear Wheel Speed Sensor On-Vehicle Inspection” and/or “Rear Wheel Speed Sensor Removal and

Installation”, check output voltage or waveform.

Is specified voltage and/or waveform obtained? Substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.

Replace sensor and

recheck.

Page 571 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-32

Front Wheel Speed Sensor Removal and

Installation

S7RS0B4506006

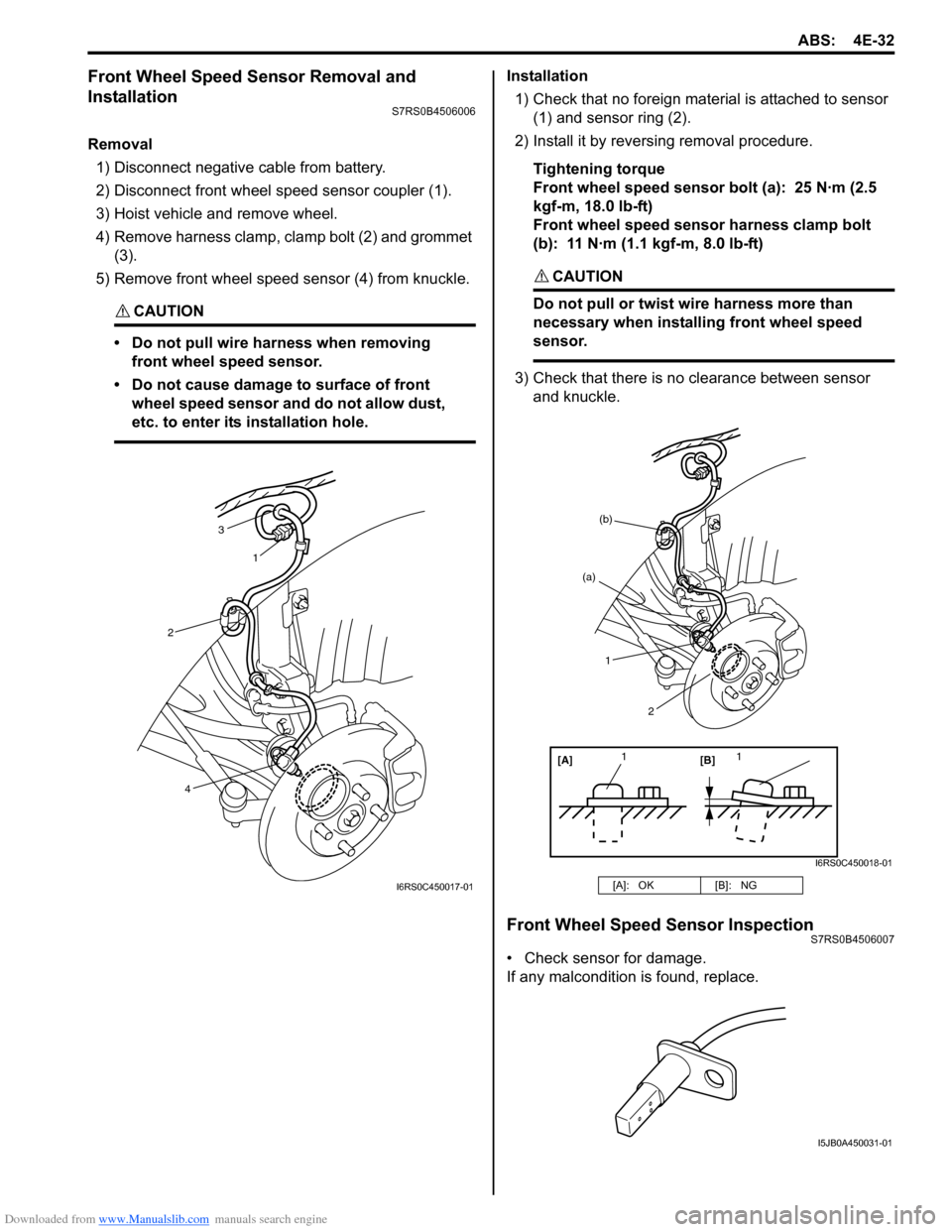

Removal1) Disconnect negative cable from battery.

2) Disconnect front wheel speed sensor coupler (1).

3) Hoist vehicle and remove wheel.

4) Remove harness clamp, clamp bolt (2) and grommet (3).

5) Remove front wheel speed sensor (4) from knuckle.

CAUTION!

• Do not pull wire ha rness when removing

front wheel speed sensor.

• Do not cause damage to surface of front wheel speed sensor and do not allow dust,

etc. to enter its installation hole.

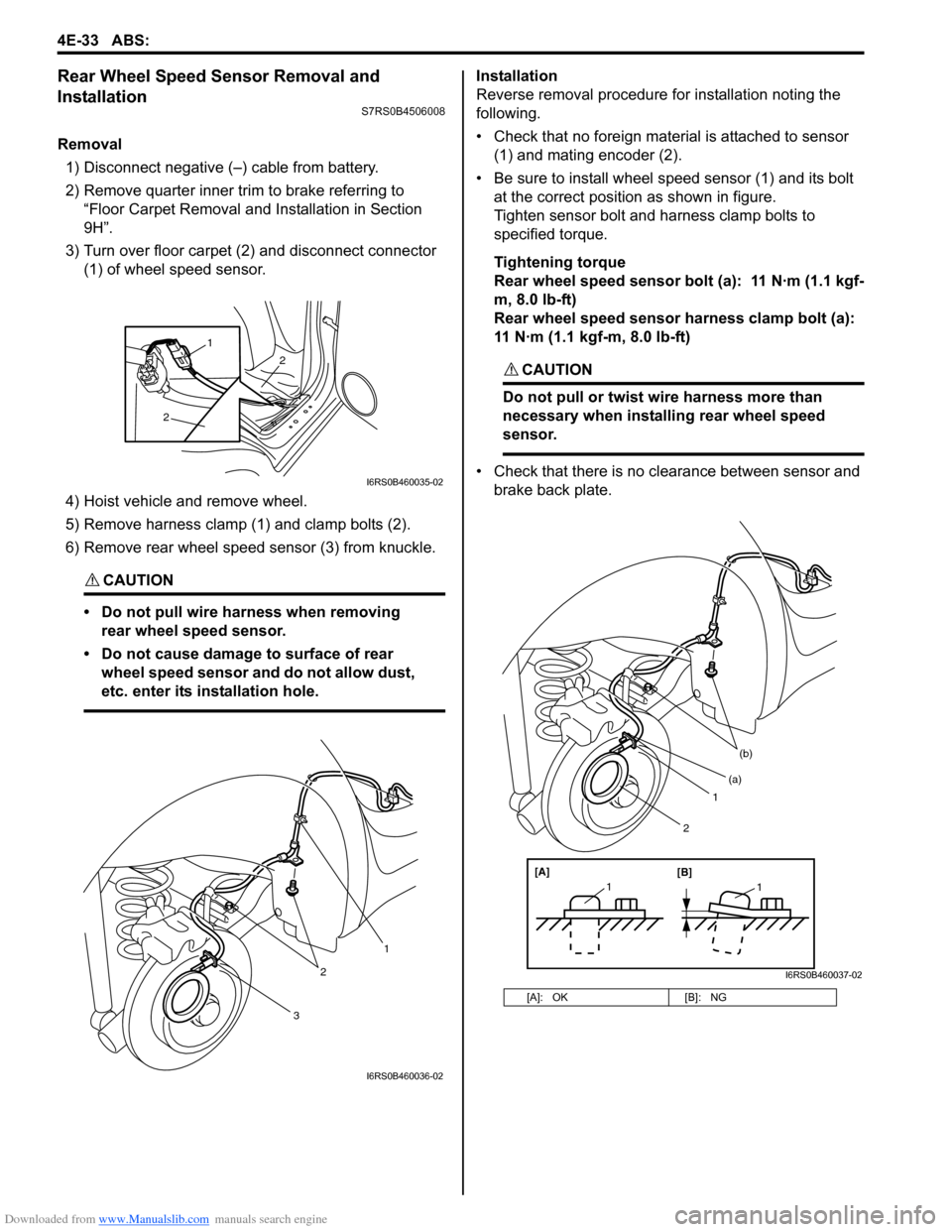

Installation

1) Check that no foreign material is attached to sensor (1) and sensor ring (2).

2) Install it by reversing removal procedure.

Tightening torque

Front wheel speed sensor bolt (a): 25 N·m (2.5

kgf-m, 18.0 lb-ft)

Front wheel speed sensor harness clamp bolt

(b): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

CAUTION!

Do not pull or twist wire harness more than

necessary when installing front wheel speed

sensor.

3) Check that there is no clearance between sensor

and knuckle.

Front Wheel Speed Sensor InspectionS7RS0B4506007

• Check sensor for damage.

If any malcondition is found, replace.

3

1

2

4

I6RS0C450017-01[A]: OK [B]: NG

[A][B]

11

(a)

(b)

1

2

I6RS0C450018-01

I5JB0A450031-01

Page 572 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-33 ABS:

Rear Wheel Speed Sensor Removal and

Installation

S7RS0B4506008

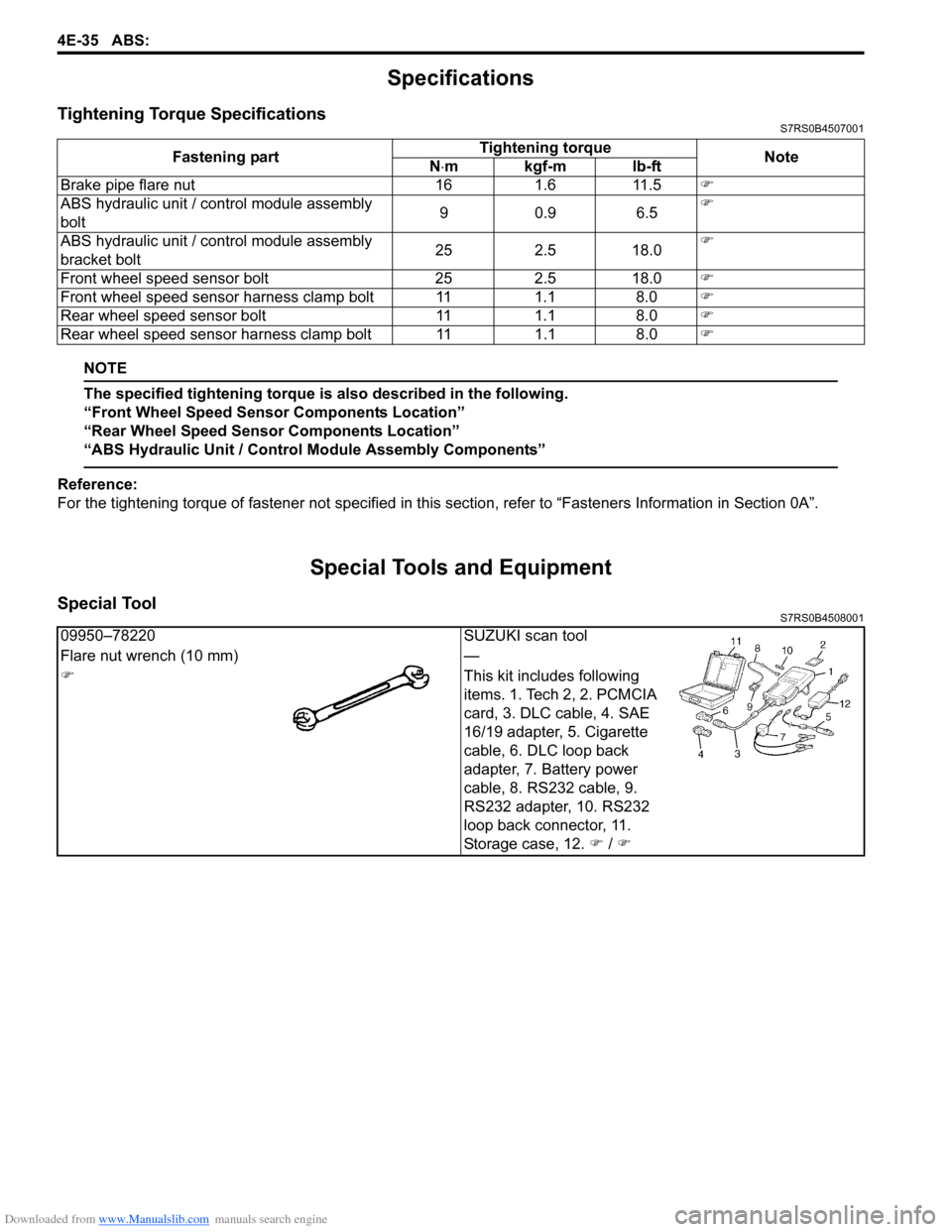

Removal1) Disconnect negative (–) cable from battery.

2) Remove quarter inner trim to brake referring to “Floor Carpet Removal a nd Installation in Section

9H”.

3) Turn over floor carpet (2) and disconnect connector (1) of wheel speed sensor.

4) Hoist vehicle and remove wheel.

5) Remove harness clamp (1) and clamp bolts (2).

6) Remove rear wheel speed sensor (3) from knuckle.

CAUTION!

• Do not pull wire harness when removing rear wheel speed sensor.

• Do not cause damage to surface of rear wheel speed sensor and do not allow dust,

etc. enter its installation hole.

Installation

Reverse removal procedure for installation noting the

following.

• Check that no foreign material is attached to sensor (1) and mating encoder (2).

• Be sure to install wheel speed sensor (1) and its bolt at the correct position as shown in figure.

Tighten sensor bolt and harness clamp bolts to

specified torque.

Tightening torque

Rear wheel speed sensor bolt (a): 11 N·m (1.1 kgf-

m, 8.0 lb-ft)

Rear wheel speed sensor harness clamp bolt (a):

11 N·m (1.1 kgf-m, 8.0 lb-ft)

CAUTION!

Do not pull or twist wire harness more than

necessary when installing rear wheel speed

sensor.

• Check that there is no clearance between sensor and brake back plate.

2

2

1

I6RS0B460035-02

3

2

1

I6RS0B460036-02

[A]: OK [B]: NG

1

(b)

[A][B]

11

(a)

2

I6RS0B460037-02

Page 574 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-35 ABS:

Specifications

Tightening Torque SpecificationsS7RS0B4507001

NOTE

The specified tightening torque is also described in the following.

“Front Wheel Speed Sensor Components Location”

“Rear Wheel Speed Sensor Components Location”

“ABS Hydraulic Unit / Control Module Assembly Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Special ToolS7RS0B4508001

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Brake pipe flare nut 16 1.6 11.5 �)

ABS hydraulic unit / c ontrol module assembly

bolt 90.9 6.5�)

ABS hydraulic unit / c ontrol module assembly

bracket bolt 25 2.5 18.0�)

Front wheel speed sensor bolt 25 2.5 18.0 �)

Front wheel speed sensor harness clamp bolt 11 1.1 8.0 �)

Rear wheel speed sensor bolt 11 1.1 8.0 �)

Rear wheel speed sensor har ness clamp bolt 11 1.1 8.0 �)

09950–78220SUZUKI scan tool

Flare nut wrench (10 mm) —

�) This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12. �) / �)

Page 607 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-33

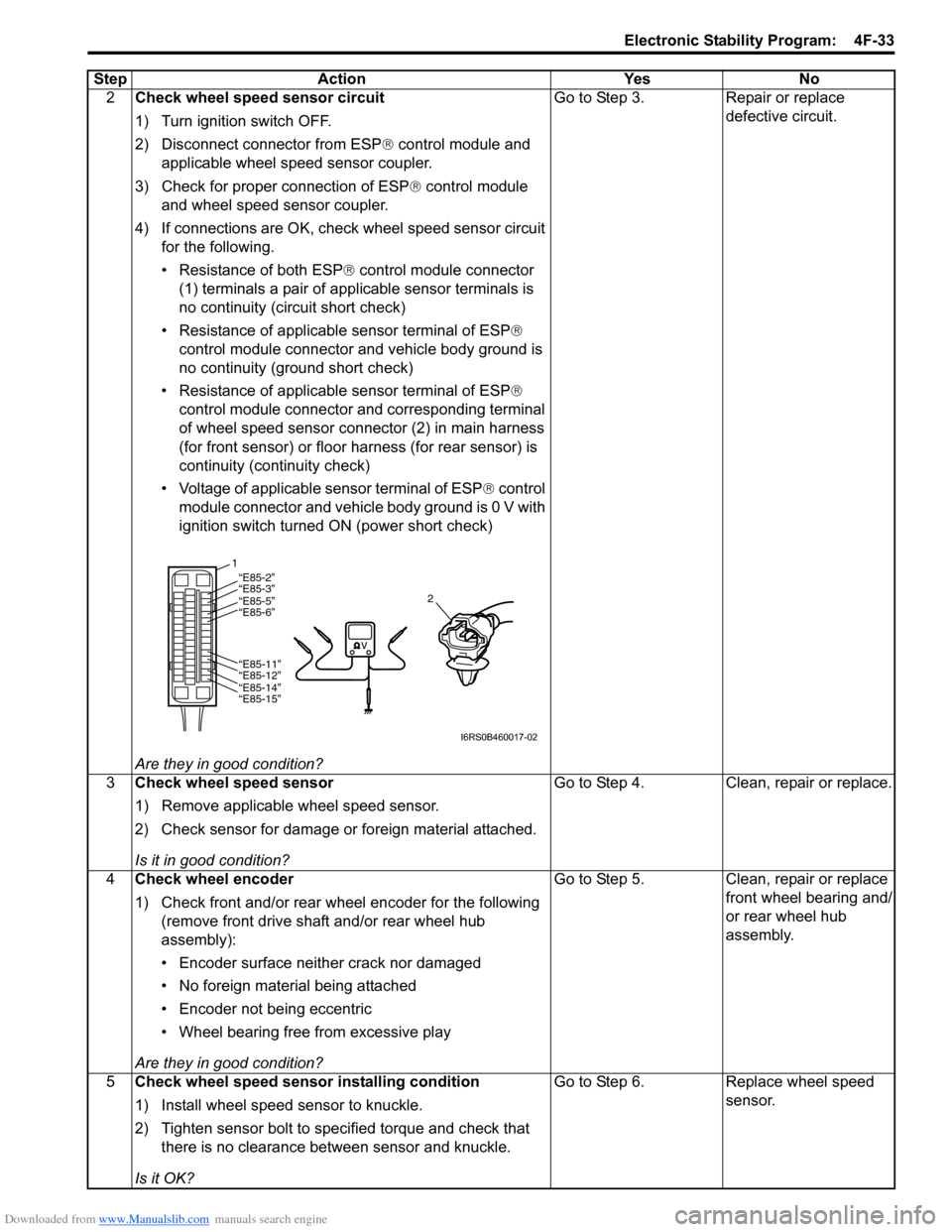

2Check wheel speed sensor circuit

1) Turn ignition switch OFF.

2) Disconnect connector from ESP ® control module and

applicable wheel speed sensor coupler.

3) Check for proper connection of ESP ® control module

and wheel speed sensor coupler.

4) If connections are OK, che ck wheel speed sensor circuit

for the following.

• Resistance of both ESP ® control module connector

(1) terminals a pair of app licable sensor terminals is

no continuity (circuit short check)

• Resistance of applicable sensor terminal of ESP ®

control module connector and vehicle body ground is

no continuity (ground short check)

• Resistance of applicable sensor terminal of ESP ®

control module connector and corresponding terminal

of wheel speed sensor connector (2) in main harness

(for front sensor) or floor harness (for rear sensor) is

continuity (continuity check)

• Voltage of applicable sensor terminal of ESP ® control

module connector and vehicle body ground is 0 V with

ignition switch turned ON (power short check)

Are they in good condition? Go to Step 3. Repair or replace

defective circuit.

3 Check wheel speed sensor

1) Remove applicable wheel speed sensor.

2) Check sensor for damage or foreign material attached.

Is it in good condition? Go to Step 4. Clean, repair or replace.

4 Check wheel encoder

1) Check front and/or rear wheel encoder for the following

(remove front drive shaft and/or rear wheel hub

assembly):

• Encoder surface neither crack nor damaged

• No foreign material being attached

• Encoder not being eccentric

• Wheel bearing free from excessive play

Are they in good condition? Go to Step 5. Clean, repair or replace

front wheel bearing and/

or rear wheel hub

assembly.

5 Check wheel speed sensor installing condition

1) Install wheel speed sensor to knuckle.

2) Tighten sensor bolt to specified torque and check that

there is no clearance between sensor and knuckle.

Is it OK? Go to Step 6. Replace wheel speed

sensor.

Step Action Yes No

1

2“E85-2”“E85-3”“E85-5”

“E85-6”

“E85-11”

“E85-12”

“E85-14”

“E85-15”

I6RS0B460017-02

Page 631 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-57

3) Remove front brake pipe referring to “Front Brake Hose / Pipe Removal and In stallation in Section 4A”.

4) Remove ESP ® hydraulic unit / control module with

bracket from vehicle by removing bracket bolts.

5) Remove bolt (4) and pull out ESP ® hydraulic unit /

control module assembly (1) from bracket (3) using

flat end rod or the like (2).

Installation 1) Install hydraulic unit / co ntrol module assembly and

by reversing removal procedure.

Tightening torque

Brake pipe flare nut: 16 N·m (1.6 kgf-m, 11.5 lb-

ft)

ESP ® hydraulic unit / control module assembly

bolt: 9 N·m (0.9 kgf-m, 6.5 lb-ft)

ESP ® hydraulic unit / control module assembly

bracket bolt: 25 N·m (2.5 kgf-m, 18.0 lb-ft)

2) Bleed air from brake system referring to “Air Bleeding of Brake System in Section 4A”.

3) Check each installed part for fluid leakage.

4) Connect SUZUKI Scan Tool.

5) Turn ignition switch to ON position. And SLIP indicator lamp flush. (Other than replace with new

one) If other than SLIP indicator lamp light, check

DTC and repair it.

6) Turn ignition switch to ON position. And ESP®

warning lamp, SLIP indicator lamp, ESP ® OFF

lamp, Brake warning lamp lights and ABS warning

lamp flush. (Replace new one)

7) Check DTC.

NOTE

If any DTC(s) other than C1075, C1076 or

C1078 are detected, sensor calibration can

not be completed. Repair the detected it(s)

first.

8) Perform “Sensor Calibration”.

9) Perform “ESP ® Hydraulic Unit Operation Check”.

10) Turn ignition switch to OFF position once and then

ON position. In this state, make sure that indicator

light and warning light turns off.

11) Check DTC(s) are not stored in hydraulic unit / control module.

Front / Rear Wheel Speed Sensor On-Vehicle

Inspection

S7RS0B4606028

CAUTION!

Incorrect voltage and/or wrong connection

cause damage to wheel speed sensor.

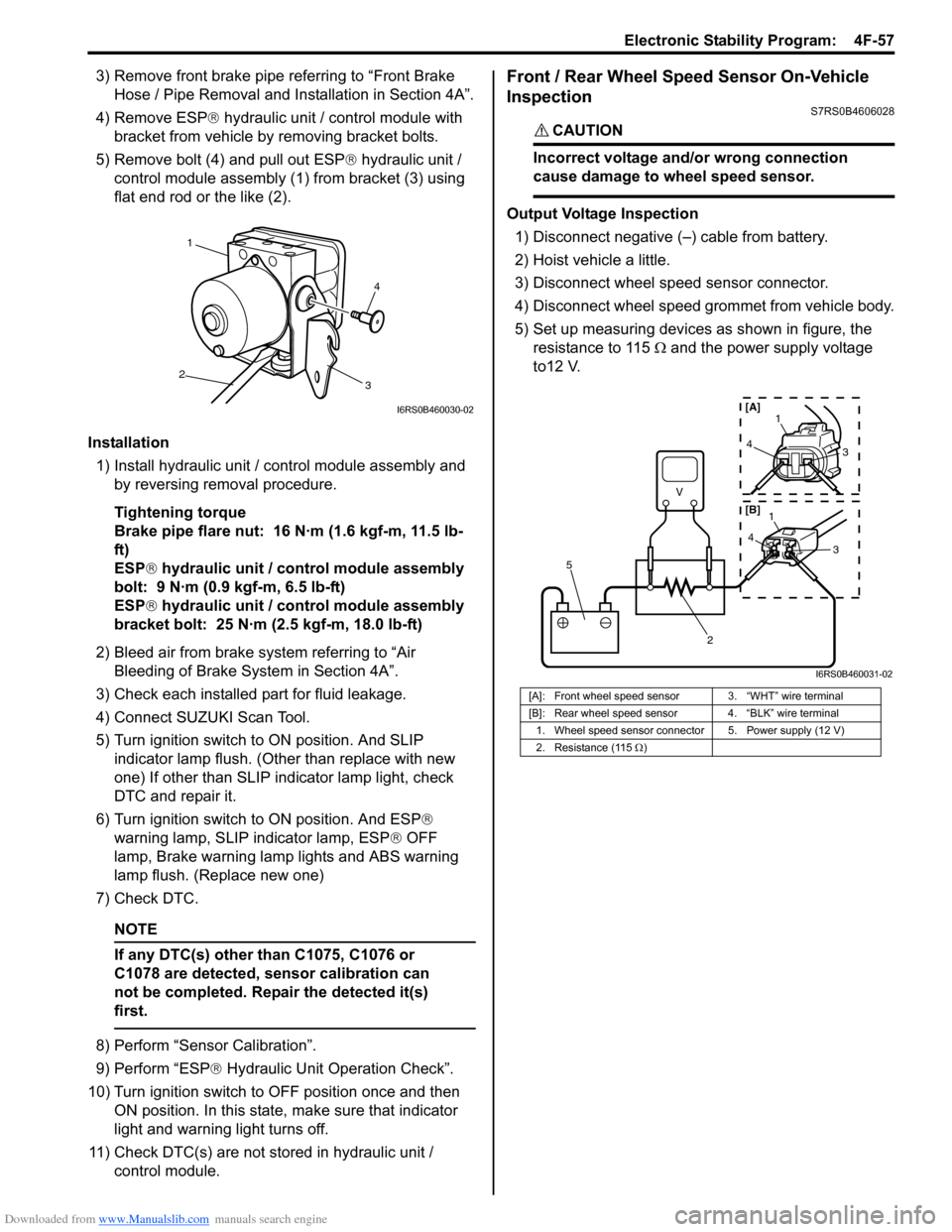

Output Voltage Inspection

1) Disconnect negative (–) cable from battery.

2) Hoist vehicle a little.

3) Disconnect wheel speed sensor connector.

4) Disconnect wheel speed grommet from vehicle body.

5) Set up measuring devices as shown in figure, the resistance to 115 Ω and the power supply voltage

to12 V.

4

1

2 3

I6RS0B460030-02

[A]: Front wheel speed sensor 3. “WHT” wire terminal

[B]: Rear wheel speed sensor 4. “BLK” wire terminal

1. Wheel speed sensor connector 5. Power supply (12 V)

2. Resistance (115 Ω)

V

2

5

4 1

3

43

1

[A]

[B]

I6RS0B460031-02

Page 633 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-59

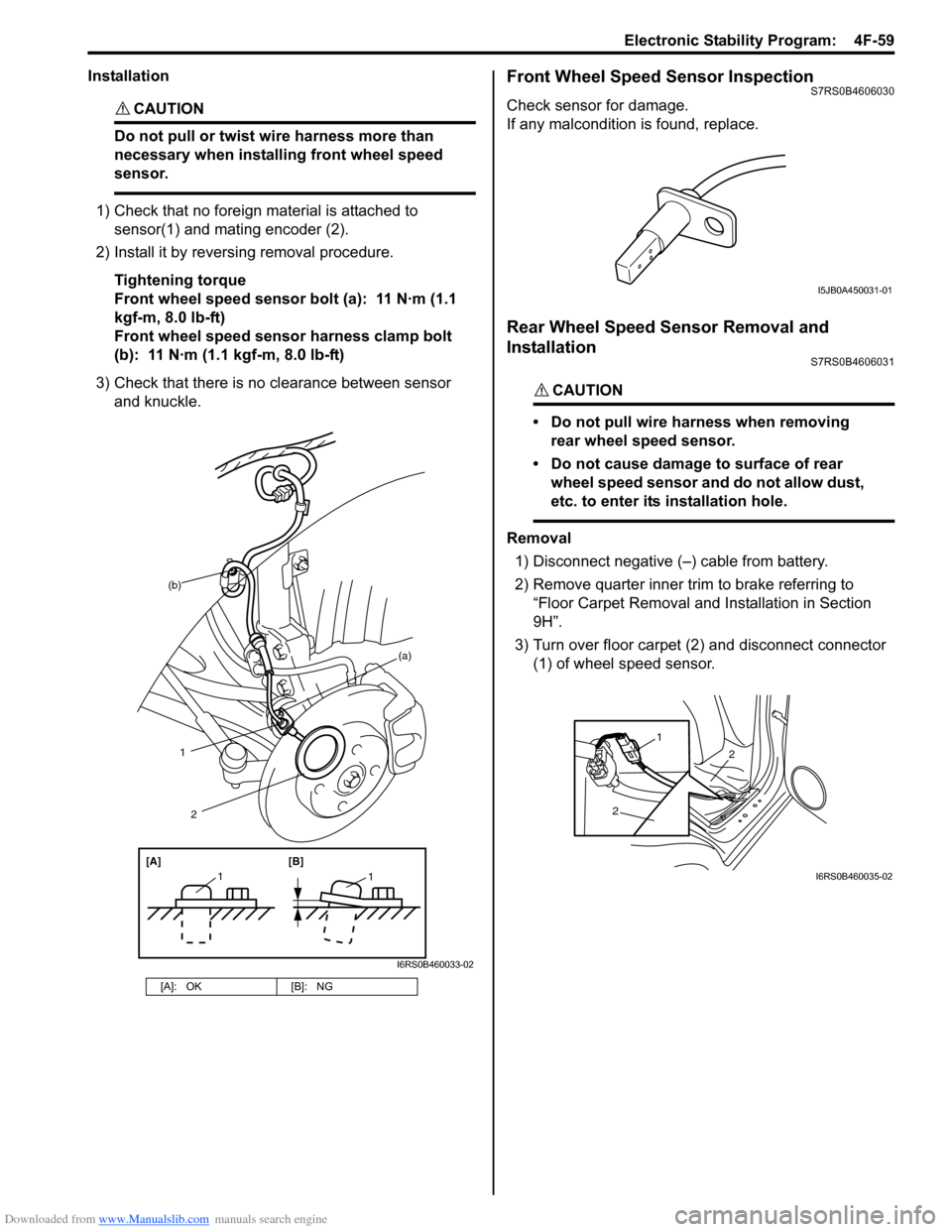

Installation

CAUTION!

Do not pull or twist wire harness more than

necessary when installing front wheel speed

sensor.

1) Check that no foreign material is attached to sensor(1) and mating encoder (2).

2) Install it by reversing removal procedure.

Tightening torque

Front wheel speed sensor bolt (a): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

Front wheel speed sensor harness clamp bolt

(b): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

3) Check that there is no clearance between sensor and knuckle.

Front Wheel Speed Sensor InspectionS7RS0B4606030

Check sensor for damage.

If any malcondition is found, replace.

Rear Wheel Speed Sensor Removal and

Installation

S7RS0B4606031

CAUTION!

• Do not pull wire harness when removing rear wheel speed sensor.

• Do not cause damage to surface of rear wheel speed sensor and do not allow dust,

etc. to enter its installation hole.

Removal

1) Disconnect negative (–) cable from battery.

2) Remove quarter inner trim to brake referring to

“Floor Carpet Removal and Installation in Section

9H”.

3) Turn over floor carpet (2) and disconnect connector (1) of wheel speed sensor.

[A]: OK [B]: NG

(b)

1

[A][B]

11

2

(a)

I6RS0B460033-02

I5JB0A450031-01

2

2

1

I6RS0B460035-02