100 SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 1279 of 1496

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-108

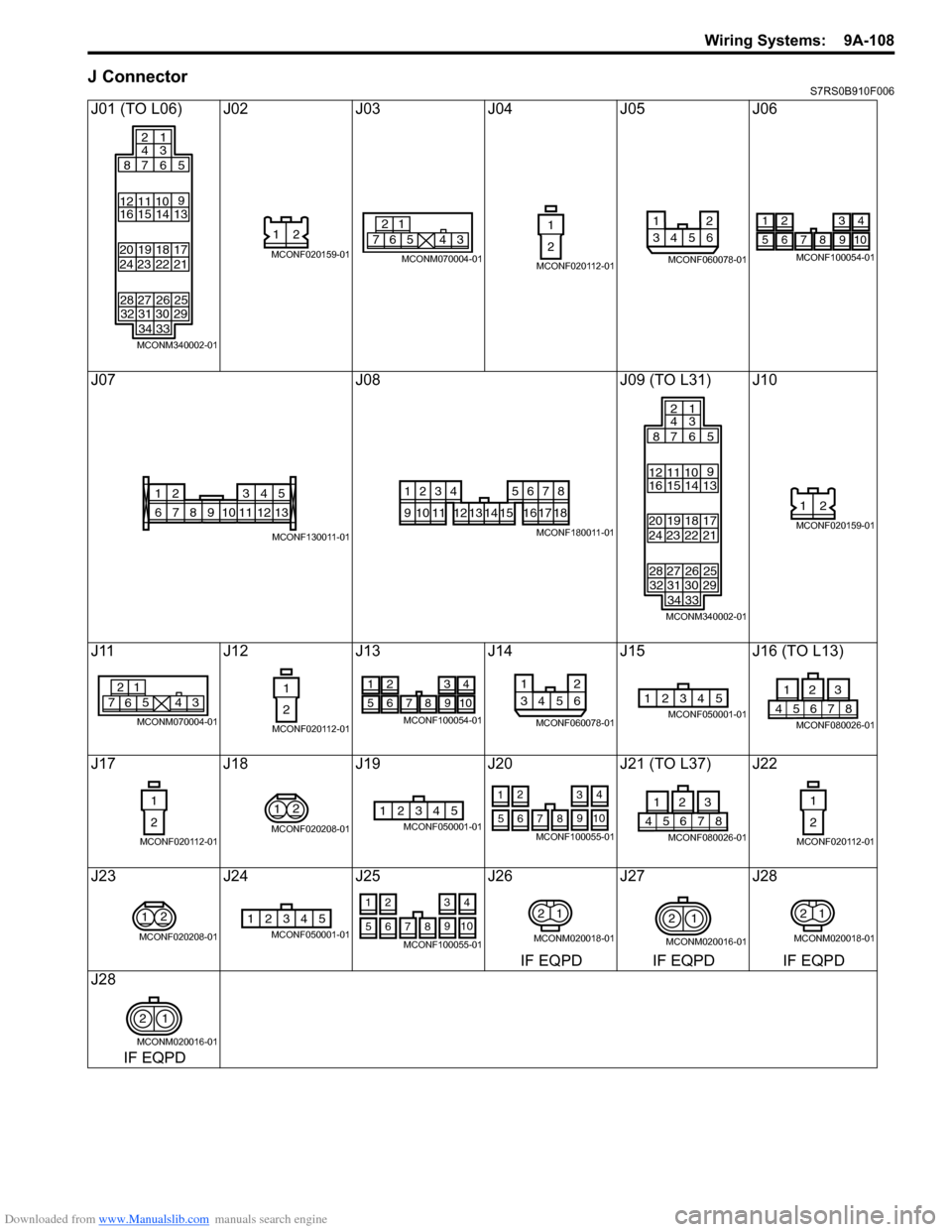

J ConnectorS7RS0B910F006

J01 (TO L06) J02J03J04J05J06

J07 J08J09 (TO L31) J10

J11 J12J13J14 J15 J16 (TO L13)

J17 J18J19 J20 J21 (TO L37) J22

J23 J24J25 J26 J27 J28

IF EQPD IF EQPD IF EQPD

J28

IF EQPD

313234 33 30 29

24

28 23

27 22

26 21

25

16

20 19 15

12 11 10

14

1813

17

87 6

2

4

1

3

5

9

MCONM340002-01

21

MCONF020159-016

21

7543

MCONM070004-01

1

2

MCONF020112-01

12

3456

MCONF060078-01

1234

5678910

MCONF100054-01

135

68910111324

712

MCONF130011-01

1234

91011

5678

12131415161718

MCONF180011-01

3132 34 33 30 29

24

28 23

27 22

26 21

25

16

20 19 15

12 11 10

14

1813

17

87 6

2

4

1

3

5

9

MCONM340002-01

21

MCONF020159-01

6

21

7543

MCONM070004-01

1

2

MCONF020112-01

1234

5678910

MCONF100054-01

12

3456

MCONF060078-01

12345MCONF050001-0187654

231

MCONF080026-01

1

2

MCONF020112-01

2

1

MCONF020208-01

12345MCONF050001-01

2

1 4

3

7 9

65 108

MCONF100055-0187654

231

MCONF080026-01

1

2

MCONF020112-01

2

1

MCONF020208-01

12345MCONF050001-01

2

1 4

3

7 9

65 108

MCONF100055-01

12

MCONM020018-01

2

1

MCONM020016-01

12

MCONM020018-01

21

MCONM020016-01

Page 1280 of 1496

Downloaded from www.Manualslib.com manuals search engine 9A-109 Wiring Systems:

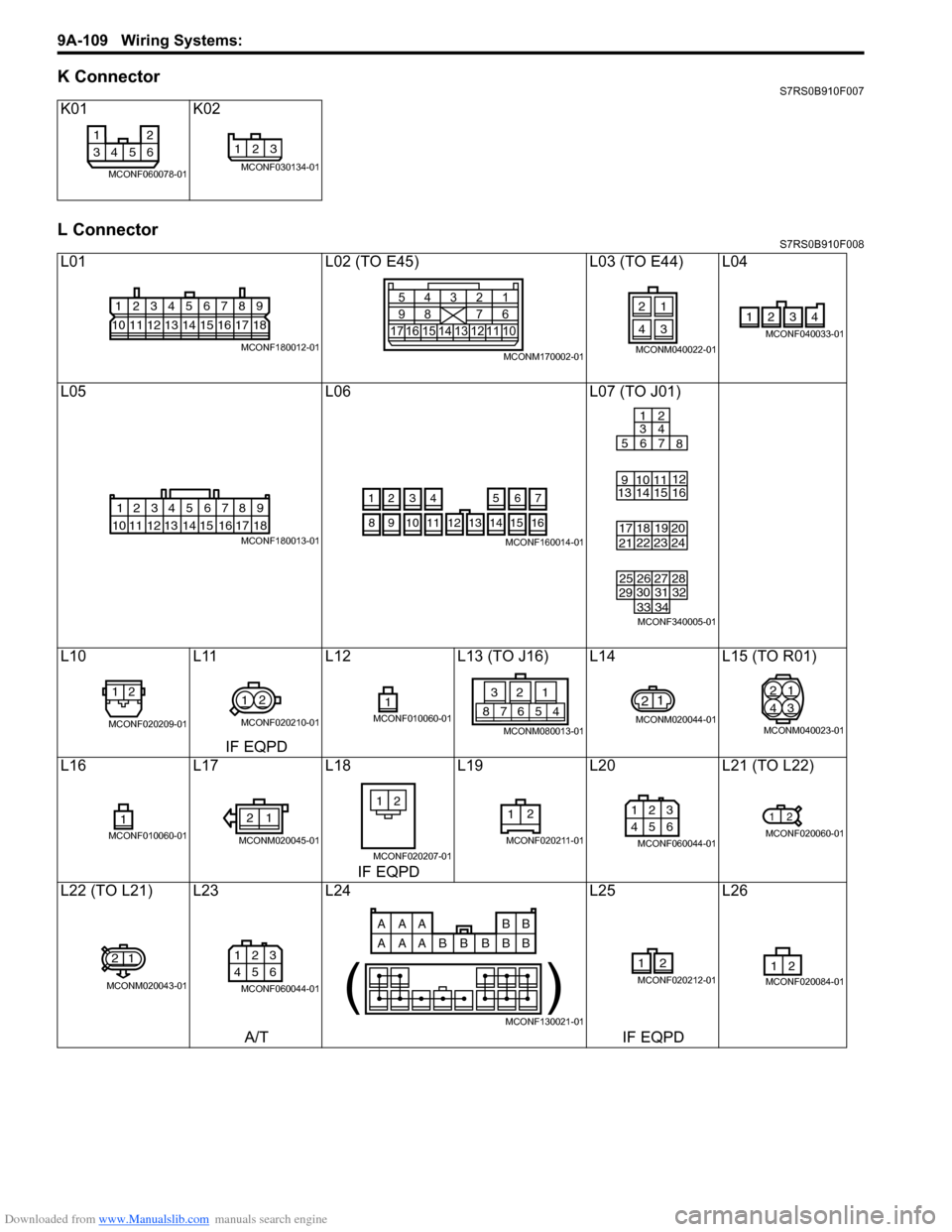

K ConnectorS7RS0B910F007

L ConnectorS7RS0B910F008

K01K02

L01 L02 (TO E45)L03 (TO E44) L04

L05 L06L07 (TO J01)

L10 L11L12L13 (TO J16) L14 L15 (TO R01)

IF EQPD

L16 L17L18L19L20 L21 (TO L22)

IF EQPD

L22 (TO L21) L23 L24L25L26

A/T IF EQPD

12

3456

MCONF060078-01

123

MCONF030134-01

123456789

101112131415161718

MCONF180012-01175

9161312 11 101514

4

832

71

6

MCONM170002-01

21

43

MCONM040022-01

2341

MCONF040033-01

123456789

15 16 17 18

1110 12 13 14

MCONF180013-01

4

3

56

1214

11

10 15

721

13

16

98

MCONF160014-01

31 32

3433

30

29

24

28

23

27

22

26

21

25

13 2019

14

91011

15

18 16

17 7

1

3

2

4

56 8

12

MCONF340005-01

12

MCONF020209-01

1 2

MCONF020210-01

1MCONF010060-0145678

213

MCONM080013-01

21

MCONM020044-01

2

4 1

3

MCONM040023-01

1MCONF010060-01

12

MCONM020045-01

21

MCONF020207-01

12

MCONF020211-01

1 23

456

MCONF060044-01

12

MCONF020060-01

21

MCONM020043-01

1 23

456

MCONF060044-01

AAA BB

AAA B

BB

BB

( )

MCONF130021-01

12

MCONF020212-0121MCONF020084-01

Page 1281 of 1496

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-110

L27L28 (TO L44) L29

L30 L31 (TO J09) L32 (TO G04) L33 (TO G03) L34

IF EQPD

L35 L36L37 (TO J21) L38 L39L40

IF EQPD

L41 L42 (TO O01) L43 L44 (TO L28) L46 L47

IF EQPD

L48 L51 (TO G43) L53L59 L60

LHD LHD

L61 L62L63L64L65 L66

LHD LHDLHDLHDIF EQPD IF EQPD

L69 L70 (TO M01) L74

IF EQPD

1MCONF010021-01

1 23

456

MCONF060044-0127 28 29 30 31 32 33 34 3536 37 38 39 40 41 42 43 4445 46 47 48 49 50 51

234567 891011 12 13 14 15 16 17 18 1920 21 22 23 24 25 26

1

MCONF510002-01

12

MCONF020212-01

31 32 3433

30

29

24

28

23

27

22

26

21

25

13 2019

14

91011

15

18 16

17 7

1

3

2

4

56 8

12

MCONF340005-01

4321

MCONF040099-01

234

1 5678 910

20191817161514131211

MCONF200003-01

1MCONF010060-01

12

MCONF020210-01

12

MCONF020209-0145678

213

MCONM080013-01

21

MCONM020044-01

1

MCONM010004-011MCONF010060-01

21

MCONF020207-01

45678

213

MCONM080013-01

1

23

456

MCONF060044-01

123

4

65

MCONM060012-01

1

2

MCONF020116-01

1

2

MCONF020013-01

1

2

MCONF020013-01

12567

8

9 1011121314

34

MCONF140012-01

21MCONF020084-01

12

MCONF020266-01

12

MCONF020060-01

12

34

MCONF040143-01

12

34

MCONF040143-01

12

3456

MCONF060025-01

12

3456

MCONF060025-01

21

MCONF020228-01

21

MCONF020228-01

12

3456

MCONF060025-01

2

4 1

3

MCONM040027-01

123 45

678 12 1110

91 3

( )

MCONF130026-01

Page 1282 of 1496

Downloaded from www.Manualslib.com manuals search engine 9A-111 Wiring Systems:

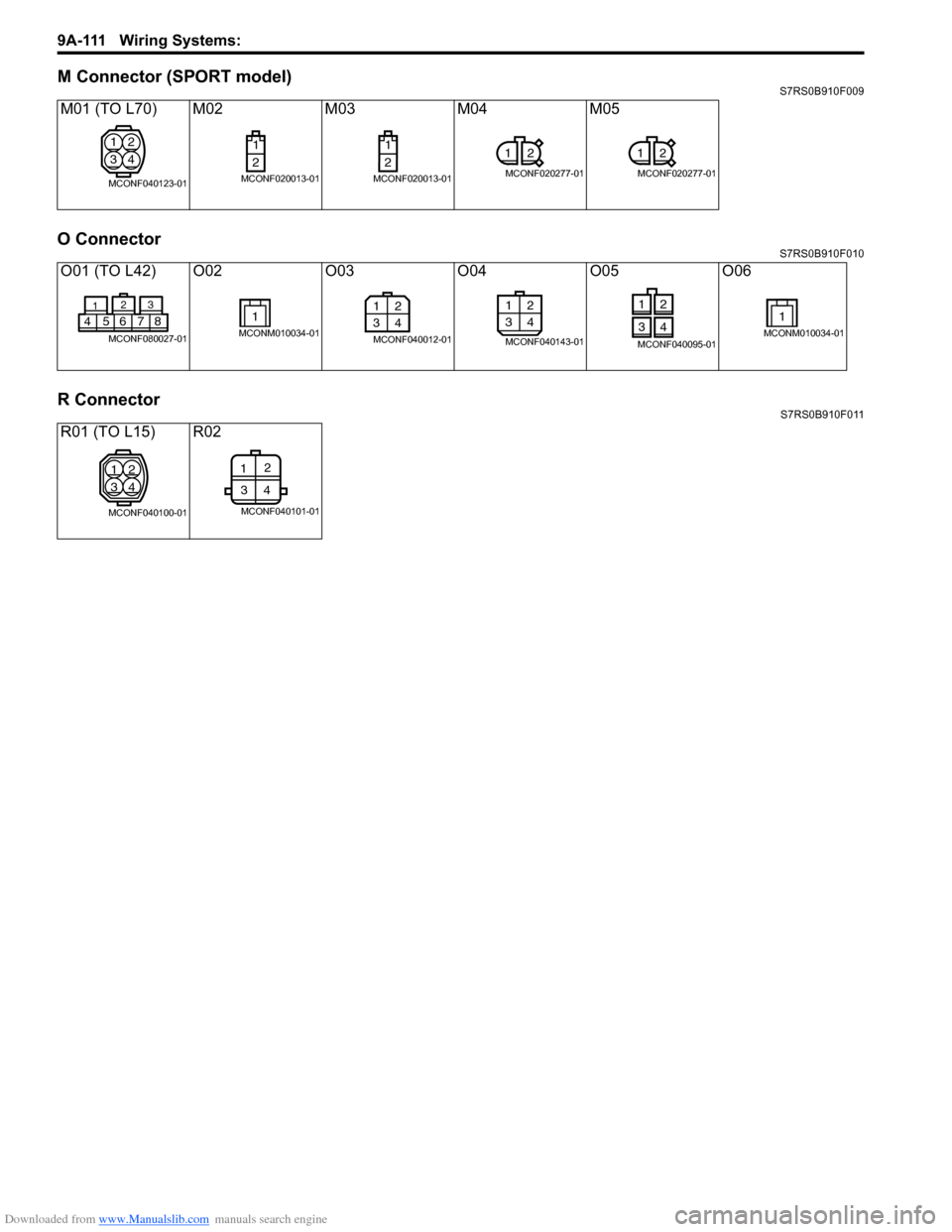

M Connector (SPORT model)S7RS0B910F009

O ConnectorS7RS0B910F010

R ConnectorS7RS0B910F011

M01 (TO L70) M02M03M04M05

O01 (TO L42) O02 O03O04 O05 O06

R01 (TO L15) R02

1

3 2

4

MCONF040123-01

1

2

MCONF020013-01

1

2

MCONF020013-01

1 2

MCONF020277-01

12

MCONF020277-01

3

2

1

45678

MCONF080027-01

1

MCONM010034-01

12

34

MCONF040012-01

12

34

MCONF040143-01

12

34

MCONF040095-01

1

MCONM010034-01

1

3 2

4

MCONF040100-01

1 2

34

MCONF040101-01

Page 1296 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-1 Instrumentation / Driver Info. / Horn:

Body, Cab and Accessories

Instrumentation / Driver Info. / Horn

Precautions

Precautions in Diagnosing Troubles for Combination MeterS7RS0B9300001

Combination meter uses signals (information) from each control module by CAN communication to control

speedometer, tachometer, engine coolant temp meter, warning light and indicator light (other than air bag warning

light, high beam indicator light, EPS warn ing light and turn signal indicator light). Therefore, check that no DTC is

detected in each module before performing combination me ter symptom diagnosis. If any DTC is detected, correct

trouble indicated by that DTC troubleshooting first.

General Description

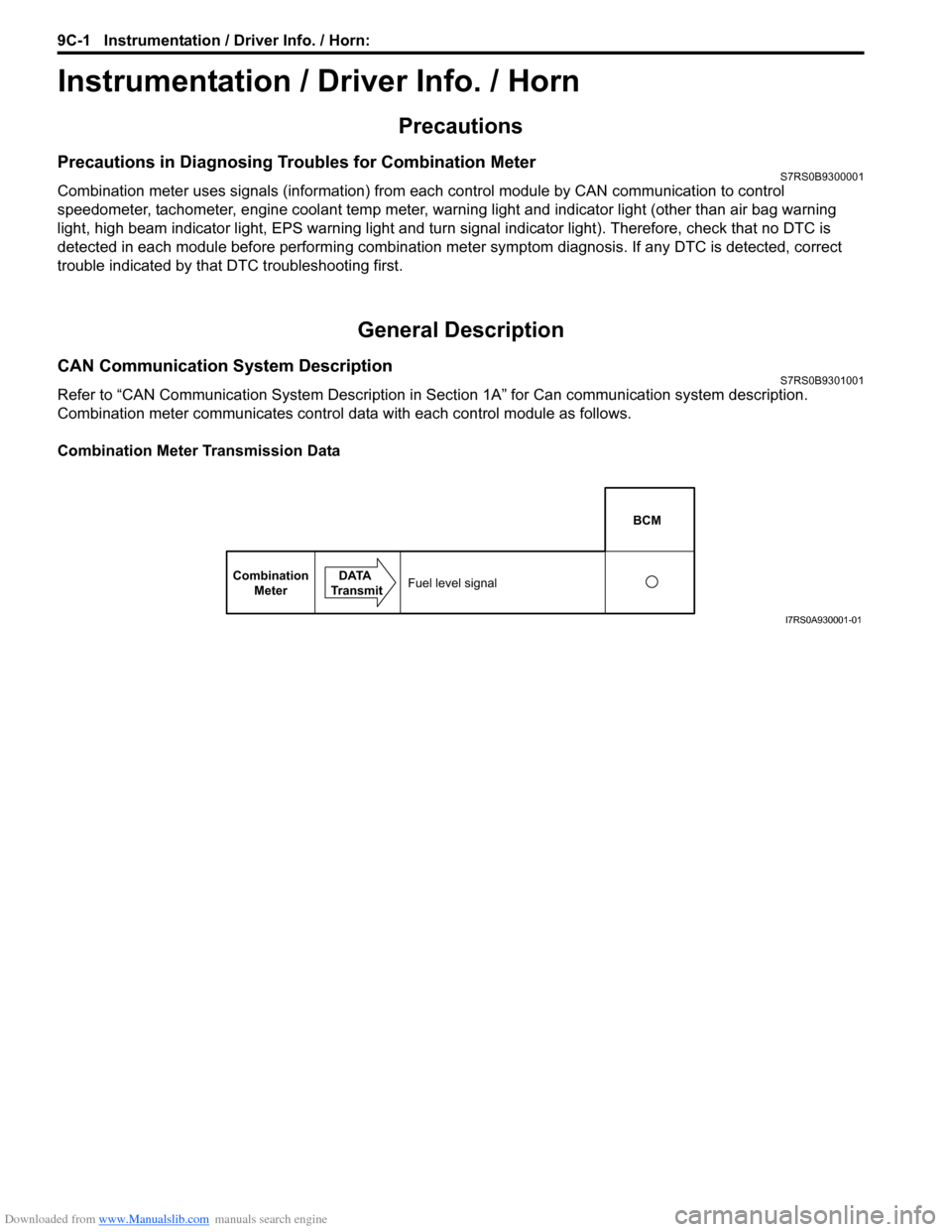

CAN Communication System DescriptionS7RS0B9301001

Refer to “CAN Communication System Description in Section 1A” for Can communication system description.

Combination meter communicates control data with each control module as follows.

Combination Meter Transmission Data

BCM

Combination Meter DATA

TransmitFuel level signal

I7RS0A930001-01

Page 1298 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-3 Instrumentation / Driver Info. / Horn:

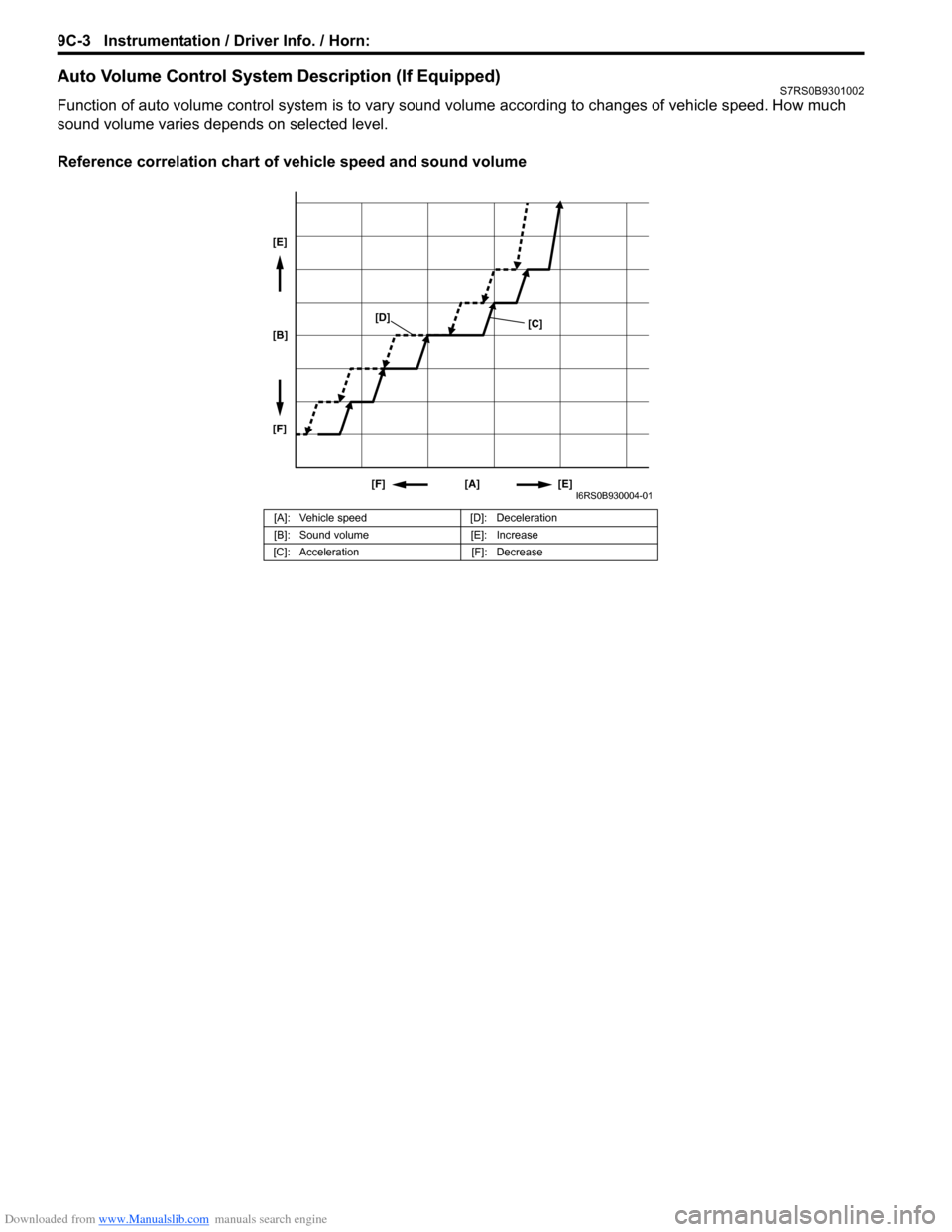

Auto Volume Control System Description (If Equipped)S7RS0B9301002

Function of auto volume control system is to vary sound volume according to changes of vehicle speed. How much

sound volume varies depends on selected level.

Reference correlation chart of vehicle speed and sound volume

[A]: Vehicle speed [D]: Deceleration

[B]: Sound volume [E]: Increase

[C]: Acceleration [F]: Decrease

[A][E]

[F]

[B] [E]

[F]

[C]

[D]

I6RS0B930004-01

Page 1307 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-12

Clock Symptom Diagnosis (If Equipped)S7RS0B9304016

Audio System Symptom Diagnosis (If Equipped)S7RS0B9304017

Radio

NOTE

Electronic part / system with undiagnosed pr oblem may cause electromagnetic interference.

Electromagnetic interference condition may have poor radio reception. To test for presence of

electromagnetic interference in part / system, perform the following procedures.

1. Turn ignition switch to OFF.

2. Systematically disconnect the electronic part / system connector(s) one at a time.

3. Turn ignition switch to ON.

4. Check any improvement in radio reception.

Display of fuel

consumption does not

change at “– – – l / 100 km

(km/l, MPG)” Vehicle is not running (instantaneous

fuel consumption mode)

—

Fuel consumption was reset (average

fuel consumption mo de, if equipped)Vehicle runs for a while.

Vehicle speed signal faulty Check ECM for DTC referring to “DTC Check

in Section 1A”.

Wiring and/or grounding faulty Repair as necessary.

ECM faulty Check input and output signal of ECM referring

to “Inspection of ECM and Its Circuits in

Section 1A”.

Information display unit faulty Replace unit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Condition Possible cause Correction / Reference Item

Condition

Possible cause Correction / Reference Item

No displaying of clock Circuit fuse Blown Replace fuse and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Clock unit faulty Replace unit.

ConditionPossible cause Correction / Reference Item

Poor radio reception Out of service area (Poor location) —

Antenna faulty Replace antenna.

Electrical part / system faulty Repair or replace electrical part / system

referring to after-mentioned NOTE.

Wiring and/or grounding faulty Repair as necessary.

Radio assembly faulty Replace radio assembly.

Radio does not operate

and speaker does not

sound Circuit fuse(s) blown

Replace fuse(s) and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Radio assembly faulty Replace radio assembly.

Radio does not operate,

but speaker sound Wiring and/or grounding faulty

Repair as necessary.

Radio assembly faulty Replace radio assembly.

Radio is operative, but all

speakers does not sound Wiring and/or grounding faulty

Repair as necessary.

Radio assembly faulty Replace radio assembly.

Individual speaker is

noisy or inoperative Wiring and/or grounding faulty

Repair as necessary.

Speaker faulty Replace speaker.

Radio assembly faulty Replace radio assembly.

Sound quality is poor Out of service area (Poor location) —

Speaker installed incorrectly Install correctly.

Wiring and/or grounding faulty Repair as necessary.

Speaker faulty Replace speaker.

Radio assembly faulty Replace radio assembly.

Page 1328 of 1496

Downloaded from www.Manualslib.com manuals search engine 9E-1 Glass / Windows / Mirrors:

Body, Cab and Accessories

Glass / Windows / Mirrors

General Description

Rear End Door Window Defogger System DescriptionS7RS0B9501001

The rear end door window defogger is controlled by BCM. For the BCM description refer to “BCM General Description

in Section 10B”.

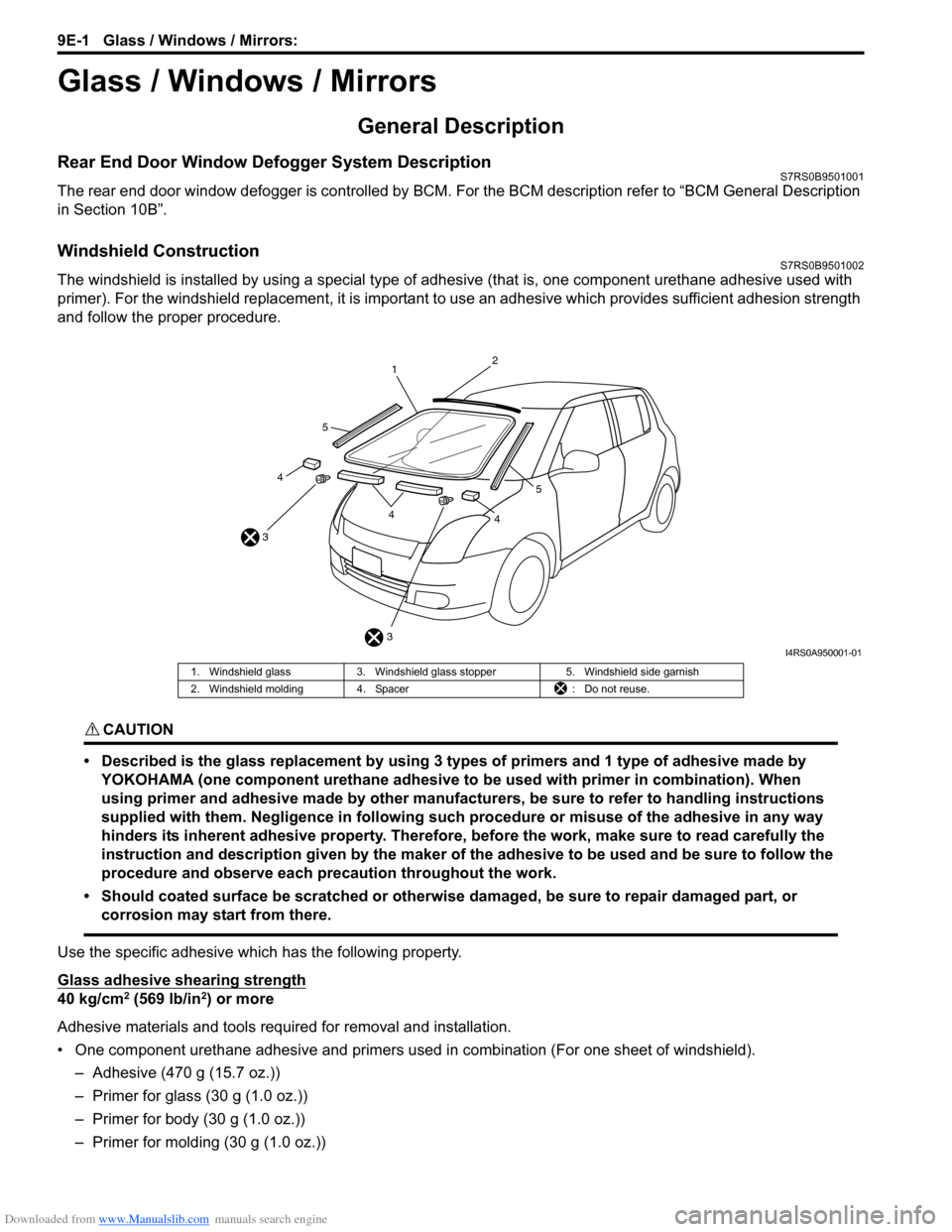

Windshield ConstructionS7RS0B9501002

The windshield is installed by using a special type of adhesive (that is, one component urethane adhesive used with

primer). For the windshield replacement, it is important to use an adhesive which provides sufficient adhesion strength

and follow the proper procedure.

CAUTION!

• Described is the glass replacement by using 3 types of primers and 1 type of adhesive made by YOKOHAMA (one component urethane adhesive to be used with primer in combination). When

using primer and adhesive made by other manufacturers, be sure to refer to handling instructions

supplied with them. Negligence in following such procedure or misuse of the adhesive in any way

hinders its inherent adhesive property. Therefore, before the work, make sure to read carefully the

instruction and description given by the maker of the adhesive to be used and be sure to follow the

procedure and observe each precaution throughout the work.

• Should coated surface be scratched or otherwise damaged, be sure to repair damaged part, or corrosion may start from there.

Use the specific adhesive which has the following property.

Glass adhesive shearing strength

40 kg/cm2 (569 lb/in2) or more

Adhesive materials and tools required for removal and installation.

• One component urethane adhesive and primers used in combination (For one sheet of windshield). – Adhesive (470 g (15.7 oz.))

– Primer for glass (30 g (1.0 oz.))

– Primer for body (30 g (1.0 oz.))

– Primer for molding (30 g (1.0 oz.))

3

3 1

2

44

4

5

5

I4RS0A950001-01

1. Windshield glass

3. Windshield glass stopper 5. Windshield side garnish

2. Windshield molding 4. Spacer : Do not reuse.

Page 1347 of 1496

Downloaded from www.Manualslib.com manuals search engine Security and Locks: 9F-1

Body, Cab and Accessories

Security and Locks

General Description

Key Coding ConstructionS7RS0B9601001

Key Usage and Identification

Key is used for ignition and door lock cylinders. Key is cut on both edges to make them reversible.

Key identification is obtained from five character key code stamped on key code tag. Using this key code, key code

cutting combination can be determined from a code list (ava ilable to owners of key cutting equipment from suppliers).

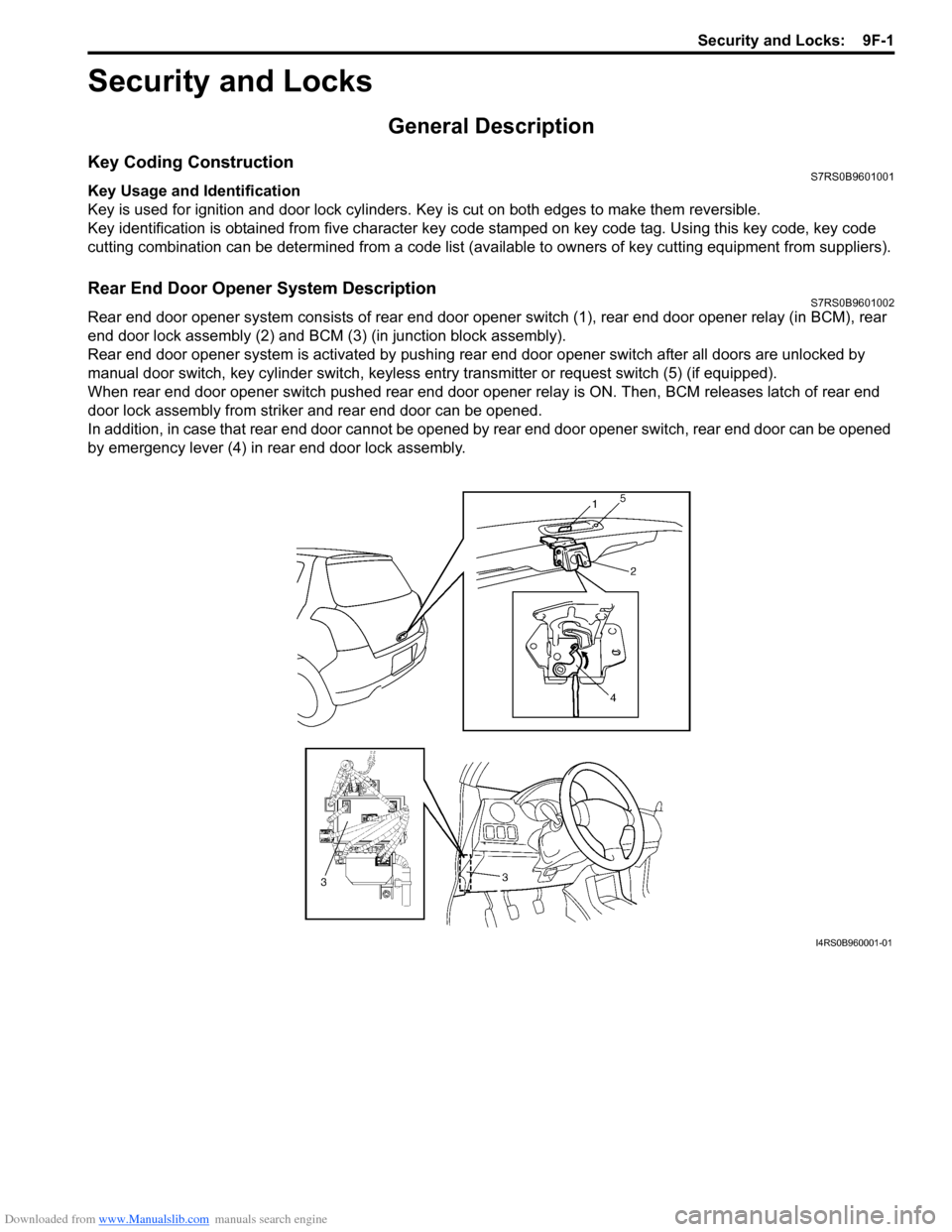

Rear End Door Opener System DescriptionS7RS0B9601002

Rear end door opener system consists of rear end door opener switch (1), rear end door opener relay (in BCM), rear

end door lock assembly (2) and BCM (3) (in junction block assembly).

Rear end door opener system is activated by pushing re ar end door opener switch after all doors are unlocked by

manual door switch, key cylinder s witch, keyless entry transmitter or request switch (5) (if equipped).

When rear end door opener switch pushed rear end door opener relay is ON. Then, BCM releases latch of rear end

door lock assembly from striker and rear end door can be opened.

In addition, in case that rear end door cannot be opened by rear end door opener switch, rear end door can be opened

by emergency lever (4) in rear end door lock assembly.

I4RS0B960001-01

Page 1363 of 1496

Downloaded from www.Manualslib.com manuals search engine Seats: 9G-1

Body, Cab and Accessories

Seats

Repair Instructions

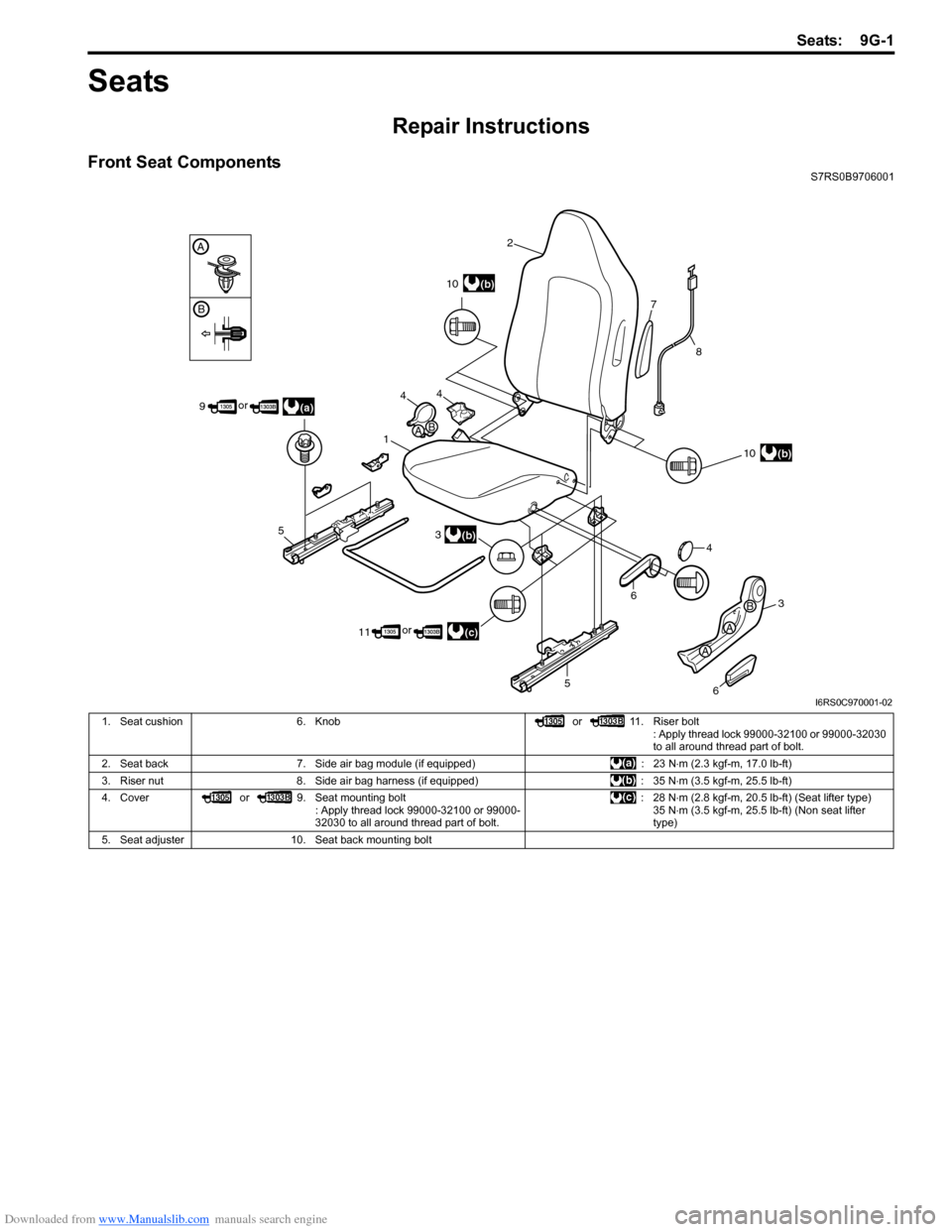

Front Seat ComponentsS7RS0B9706001

2

4

1 3

11

6

3

4

6

7

8

(b)

(b)

10

5

(a)

or

94

5

(c)

(b)

10

or

A

A

B

AB

B

A

I6RS0C970001-02

1. Seat cushion 6. Knob or 11. Riser bolt

: Apply thread lock 99000-32100 or 99000-32030

to all around thread part of bolt.

2. Seat back 7. Side air bag module (if equipped) : 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

3. Riser nut 8. Side air bag harness (if equipped) : 35 N⋅m (3.5 kgf-m, 25.5 lb-ft)

4. Cover or 9. Seat mounting bolt

: Apply thread lock 99000-32100 or 99000-

32030 to all around thread part of bolt. :28 N

⋅m (2.8 kgf-m, 20.5 lb-ft) (Seat lifter type)

35 N ⋅m (3.5 kgf-m, 25.5 lb-ft) (Non seat lifter

type)

5. Seat adjuster 10. Seat back mounting bolt