001 SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 1094 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-56 Air Bag System:

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Clear DTCs referring to “DTC Clearance”, if any.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

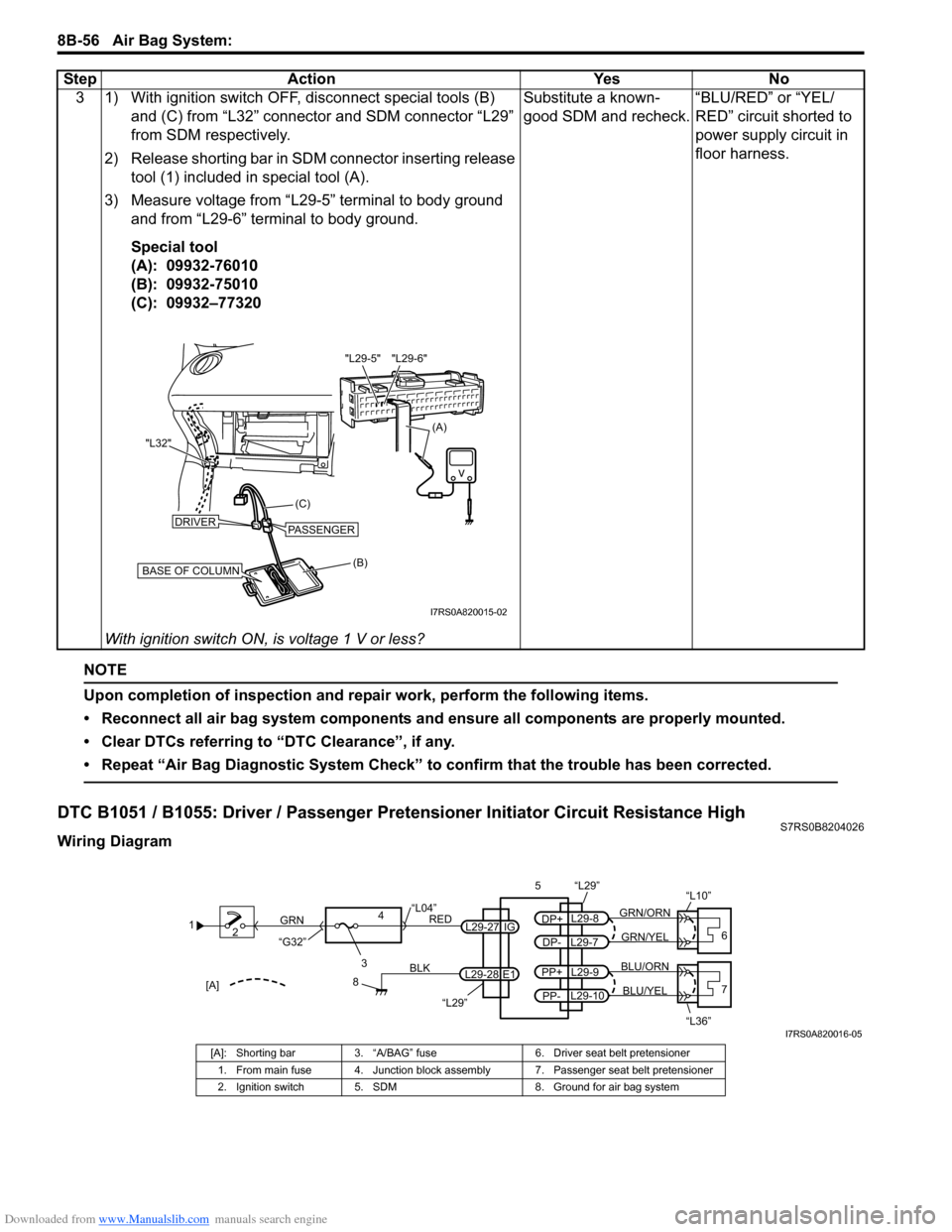

DTC B1051 / B1055: Driver / Passenger Pretensioner Initiator Circuit Resistance HighS7RS0B8204026

Wiring Diagram3 1) With ignition switch OFF, disconnect special tools (B)

and (C) from “L32” connector and SDM connector “L29”

from SDM respectively.

2) Release shorting bar in SDM connector inserting release tool (1) included in special tool (A).

3) Measure voltage from “L29-5” terminal to body ground and from “L29-6” terminal to body ground.

Special tool

(A): 09932-76010

(B): 09932-75010

(C): 09932–77320

With ignition switch ON, is voltage 1 V or less? Substitute a known-

good SDM and recheck.

“BLU/RED” or “YEL/

RED” circuit shorted to

power supply circuit in

floor harness.

Step Action Yes No

(B)

(C)

"L32"

BASE OF COLUMN

DRIVERPASSENGER

(A)

"L29-6"

"L29-5"

I7RS0A820015-02

1

2

3

GRN

RED

8

BLK

L29-27

L29-28 IG

E1

4

“L29”

“L04”

“G32”

“L29”

L29-8

DP+

L29-7

DP-GRN/YEL

GRN/ORN

56

“L10”

L29-9

PP+

L29-10

PP-BLU/YEL

BLU/ORN7

“L36”[A]

I7RS0A820016-05

[A]: Shorting bar 3. “A/BAG” fuse 6. Driver seat belt pretensioner

1. From main fuse 4. Junction block assembly 7. Passenger seat belt pretensioner

2. Ignition switch 5. SDM 8. Ground for air bag system

Page 1096 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-58 Air Bag System:

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Clear DTCs referring to “DTC Clearance”, if any.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

DTC B1052 / B1056: Driver / Passenger Pretensioner Initiator Circuit Resistance LowS7RS0B8204027

Wiring Diagram2 1) With ignition switch OFF, disconnect SDM connector

“29”.

2) Check proper connection to SDM at terminals in “L29-7” and “L29-8” (for DTC B1051) or “L29-9” and “L29-10”

(for DTC B1055).

3) If OK, release shorting bar in SDM connector inserting

release tool (1) included in special tool (A).

4) Measure resistance between “L29-7” and “L29-8” terminals (for DTC B1051) or “L29-9” and “L29-10”

terminals (for DTC B1055) with connected special tools

(B) and (C).

Special tool

(A): 09932-76010

(B): 09932-75010

(C): 09932–78310

Is resistance 2.91

Ω or less? Substitute a known-

good SDM and recheck.

DTC B1051: High

resistance or open wire

in “GRN/ORN” or “GRN/

YEL” circuit.

DTC B1055: High

resistance or open wire

in “BLU/ORN” or “BLU/

YEL” circuit.

Step Action Yes No

(A)

"L29-8" "L29-9" "L29-10"

"L29-7"

STEERING WHEEL(B)

(C)

(A)

"L10", "L36"

I7RS0A820017-03

1

2

3

GRN

RED

8

BLK

L29-27

L29-28 IG

E1

4

“L29”

“L04”

“G32”

“L29”

L29-8

DP+

L29-7

DP-GRN/YEL

GRN/ORN

56

“L10”

L29-9

PP+

L29-10

PP-BLU/YEL

BLU/ORN7

“L36”[A]

I7RS0A820016-05

[A]: Shorting bar 3. “A/BAG” fuse 6. Driver seat belt pretensioner

1. From main fuse 4. Junction block assembly 7. Passenger seat belt pretensioner

2. Ignition switch 5. SDM 8. Ground for air bag system

Page 1098 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-60 Air Bag System:

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Clear DTCs referring to “DTC Clearance”, if any.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

DTC B1053 / B1057: Driver / Passenger Pretensioner Initiator Circuit Short to GroundS7RS0B8204028

Wiring Diagram2 1) With ignition switch OFF, disconnect SDM connector

“29”.

2) Check proper connection to SDM at terminals in “L29-7” and “L29-8” (for DTC B1052) or “L29-9” and “L29-10”

(for DTC B1056).

3) If OK, release shorting bar in SDM connector inserting

release tool (1) included in special tool (A).

4) If OK, then measure resistance between “L29-7” and “L29-8” terminals (for DTC B1052) or “L29-9” and “L29-

10” terminals (for DTC B1056) with connected special

tools (B) and (C).

Special tool

(A): 09932-76010

(B): 09932-75010

(C): 09932–78310

Is resistance 1.8

Ω or more? Substitute a known-

good SDM and recheck.

DTC B1052: “GRN/

ORN” circuit shorted to

“GRN/YEL” circuit,

“GRN/ORN” circuit or

“GRN/YEL” circuit

shorted to other circuit.

DTC B1056: “BLU/

ORN” circuit shorted to

“BLU/YEL” circuit, “BLU/

ORN” circuit or “BLU/

YEL” circuit shorted to

other circuit.

Step Action Yes No

(A)

"L29-8" "L29-9" "L29-10"

"L29-7"

STEERING WHEEL(B)

(C)

(A)

"L10", "L36"

I7RS0A820017-03

1

2

3

GRN

RED

8

BLK

L29-27

L29-28 IG

E1

4

“L29”

“L04”

“G32”

“L29”

L29-8

DP+

L29-7

DP-GRN/YEL

GRN/ORN

56

“L10”

L29-9

PP+

L29-10

PP-BLU/YEL

BLU/ORN7

“L36”[A]

I7RS0A820016-05

[A]: Shorting bar 3. “A/BAG” fuse 6. Driver seat belt pretensioner

1. From main fuse 4. Junction block assembly 7. Passenger seat belt pretensioner

2. Ignition switch 5. SDM 8. Ground for air bag system

Page 1100 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-62 Air Bag System:

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Clear DTCs referring to “DTC Clearance”, if any.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

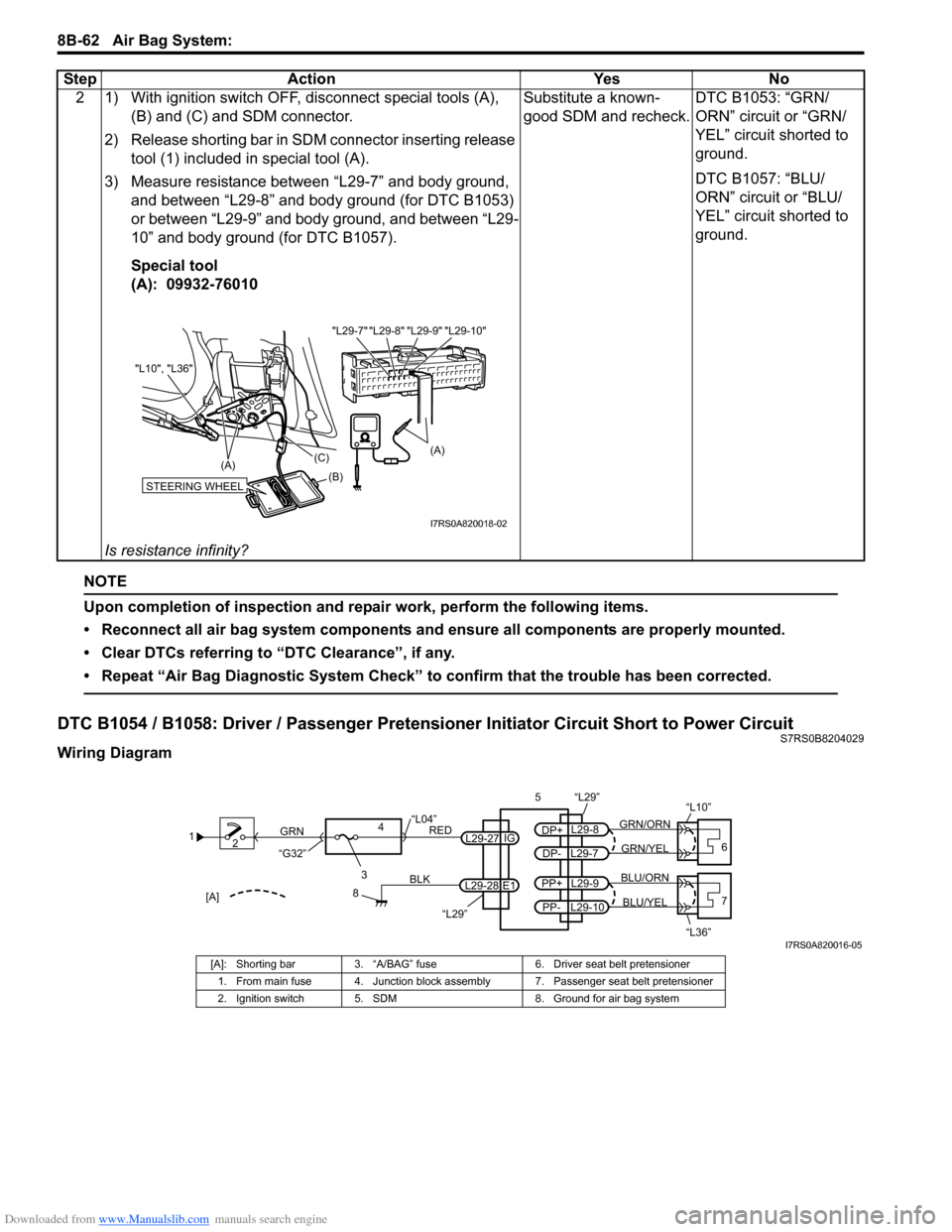

DTC B1054 / B1058: Driver / Passenger Pretensioner Initiator Circuit Short to Power CircuitS7RS0B8204029

Wiring Diagram2 1) With ignition switch OFF, disconnect special tools (A),

(B) and (C) and SDM connector.

2) Release shorting bar in SDM connector inserting release tool (1) included in special tool (A).

3) Measure resistance between “L29-7” and body ground, and between “L29-8” and body ground (for DTC B1053)

or between “L29-9” and body ground, and between “L29-

10” and body ground (for DTC B1057).

Special tool

(A): 09932-76010

Is resistance infinity? Substitute a known-

good SDM and recheck.

DTC B1053: “GRN/

ORN” circuit or “GRN/

YEL” circuit shorted to

ground.

DTC B1057: “BLU/

ORN” circuit or “BLU/

YEL” circuit shorted to

ground.

Step Action Yes No

"L29-8" "L29-9" "L29-10"

"L29-7"

(A)

STEERING WHEEL(B)

(C)

(A)

"L10", "L36"

I7RS0A820018-02

1

2

3

GRN

RED

8

BLK

L29-27

L29-28 IG

E1

4

“L29”

“L04”

“G32”

“L29”

L29-8

DP+

L29-7

DP-GRN/YEL

GRN/ORN

56

“L10”

L29-9

PP+

L29-10

PP-BLU/YEL

BLU/ORN7

“L36”[A]

I7RS0A820016-05

[A]: Shorting bar 3. “A/BAG” fuse 6. Driver seat belt pretensioner

1. From main fuse 4. Junction block assembly 7. Passenger seat belt pretensioner

2. Ignition switch 5. SDM 8. Ground for air bag system

Page 1102 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-64 Air Bag System:

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Clear DTCs referring to “DTC Clearance”, if any.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

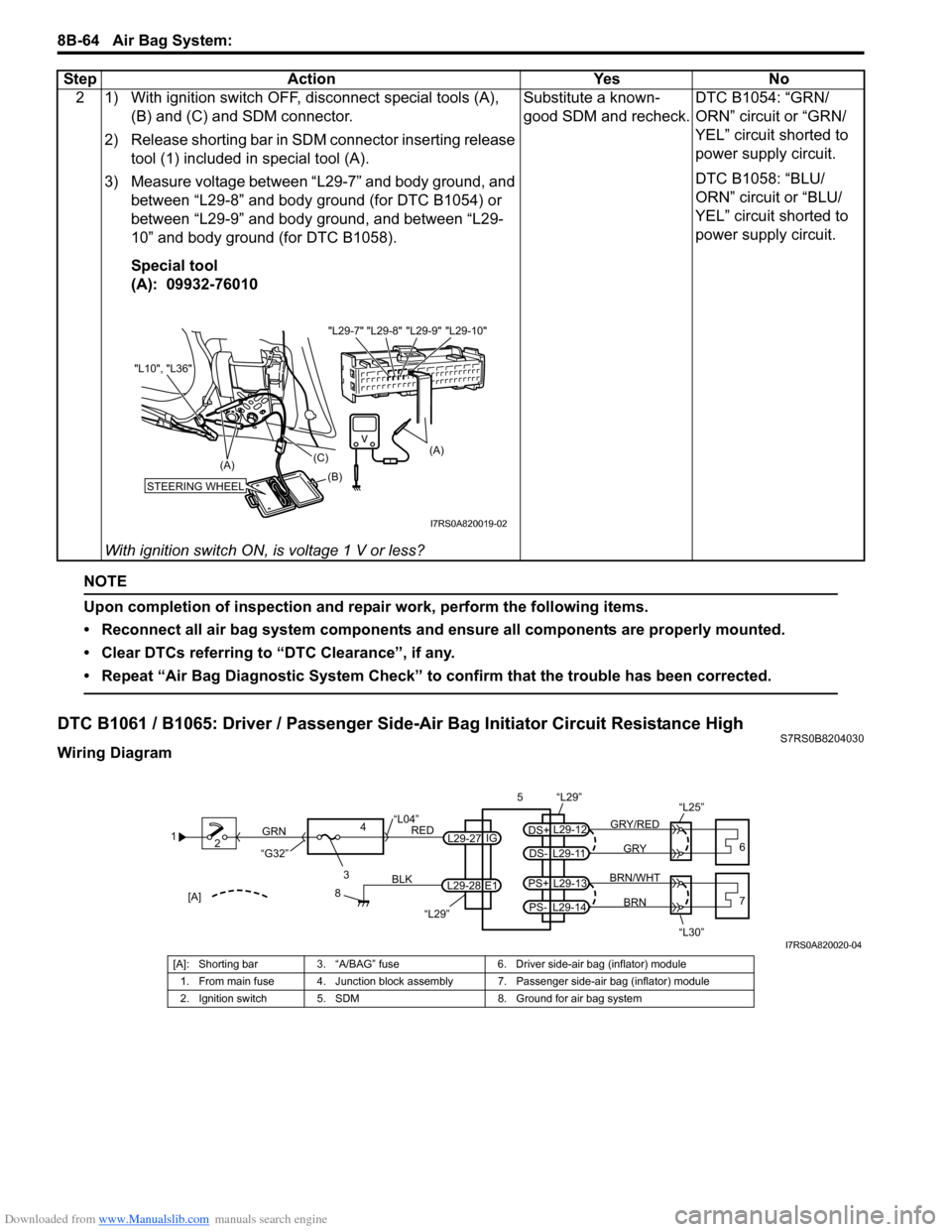

DTC B1061 / B1065: Driver / Passenger Side-Air Bag Initiator Circuit Resistance HighS7RS0B8204030

Wiring Diagram2 1) With ignition switch OFF, disconnect special tools (A),

(B) and (C) and SDM connector.

2) Release shorting bar in SDM connector inserting release tool (1) included in special tool (A).

3) Measure voltage between “L29-7” and body ground, and between “L29-8” and body ground (for DTC B1054) or

between “L29-9” and body ground, and between “L29-

10” and body ground (for DTC B1058).

Special tool

(A): 09932-76010

With ignition switch ON, is voltage 1 V or less? Substitute a known-

good SDM and recheck.

DTC B1054: “GRN/

ORN” circuit or “GRN/

YEL” circuit shorted to

power supply circuit.

DTC B1058: “BLU/

ORN” circuit or “BLU/

YEL” circuit shorted to

power supply circuit.

Step Action Yes No

"L29-8" "L29-9" "L29-10"

"L29-7"

(A)

STEERING WHEEL(B)

(C)

(A)

"L10", "L36"

I7RS0A820019-02

1

2

3

GRN

RED

8

BLK

L29-27

L29-28 IG

E1

4

“L29”

“L04”

“G32”

“L29”

L29-12

DS+

L29-11

DS-GRY

GRY/RED

56

“L25”

L29-13

PS+

L29-14

PS-BRN

BRN/WHT7

“L30”[A]

I7RS0A820020-04

[A]: Shorting bar 3. “A/BAG” fuse 6. Driver side-air bag (inflator) module

1. From main fuse 4. Junction block assembly 7. Passenger side-air bag (inflator) module

2. Ignition switch 5. SDM 8. Ground for air bag system

Page 1132 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-94 Air Bag System:

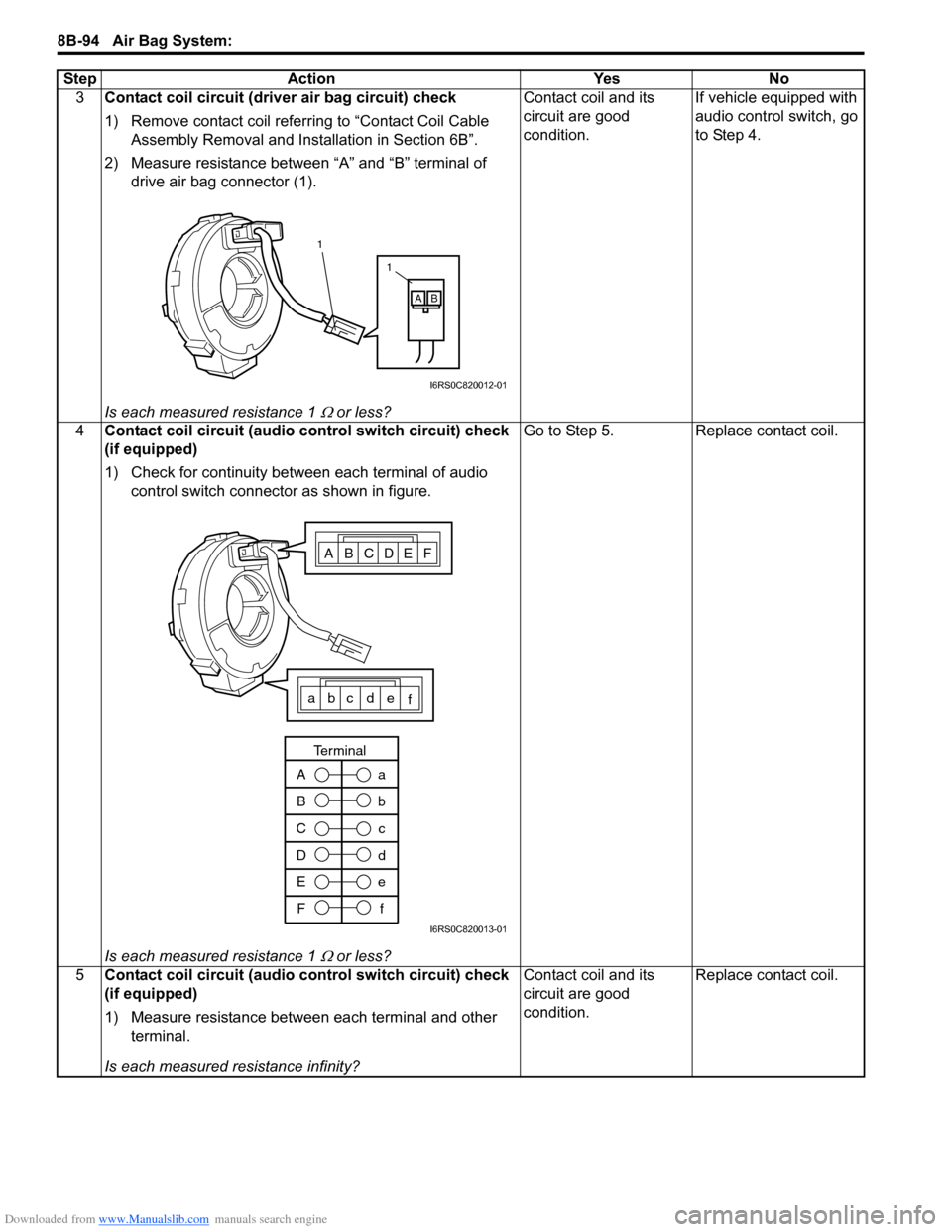

3Contact coil circuit (driver air bag circuit) check

1) Remove contact coil referr ing to “Contact Coil Cable

Assembly Removal and Inst allation in Section 6B”.

2) Measure resistance between “A” and “B” terminal of drive air bag connector (1).

Is each measured resistance 1

Ω or less? Contact coil and its

circuit are good

condition.

If vehicle equipped with

audio control switch, go

to Step 4.

4 Contact coil circuit (audio control switch circuit) check

(if equipped)

1) Check for continuity between each terminal of audio

control switch connector as shown in figure.

Is each measured resistance 1

Ω or less? Go to Step 5. Replace contact coil.

5 Contact coil circuit (audio control switch circuit) check

(if equipped)

1) Measure resistance between each terminal and other

terminal.

Is each measured resistance infinity? Contact coil and its

circuit are good

condition.

Replace contact coil.

Step Action Yes No

1

1

AB

I6RS0C820012-01

ABCDEF

abc de

f

A

Ba

b

C

D c

d

E F e

f

Terminal

I6RS0C820013-01

Page 1136 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-98 Air Bag System:

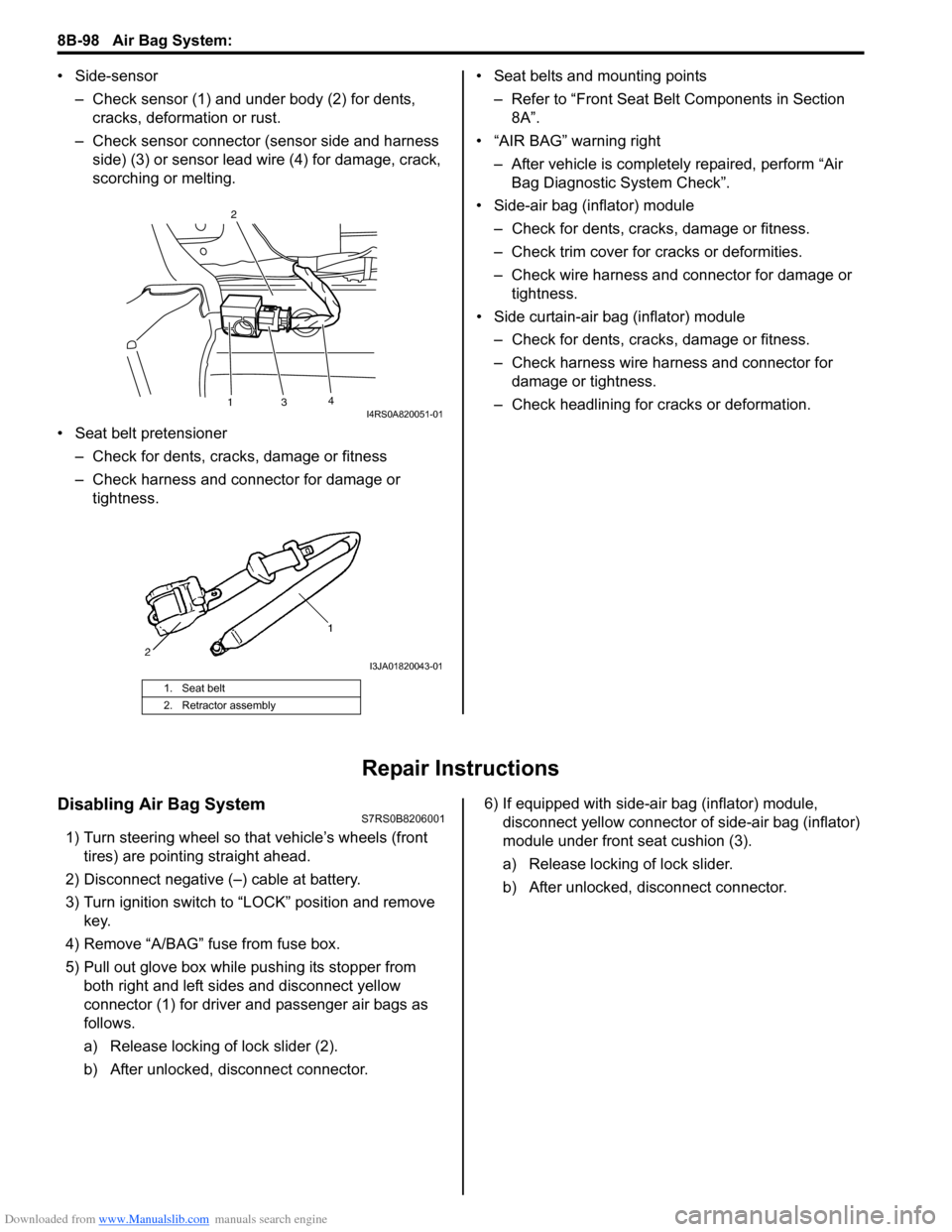

• Side-sensor– Check sensor (1) and under body (2) for dents, cracks, deformation or rust.

– Check sensor connector (sensor side and harness side) (3) or sensor lead wire (4) for damage, crack,

scorching or melting.

• Seat belt pretensioner – Check for dents, cracks , damage or fitness

– Check harness and connector for damage or tightness. • Seat belts and mounting points

– Refer to “Front Seat Belt Components in Section 8A”.

• “AIR BAG” warning right

– After vehicle is completely repaired, perform “Air Bag Diagnostic System Check”.

• Side-air bag (inflator) module – Check for dents, cra cks, damage or fitness.

– Check trim cover for cracks or deformities.

– Check wire harness and connector for damage or tightness.

• Side curtain-air bag (inflator) module – Check for dents, cra cks, damage or fitness.

– Check harness wire harness and connector for damage or tightness.

– Check headlining for cracks or deformation.

Repair Instructions

Disabling Air Bag SystemS7RS0B8206001

1) Turn steering wheel so that vehicle’s wheels (front tires) are pointing straight ahead.

2) Disconnect negative (–) cable at battery.

3) Turn ignition switch to “LOCK” position and remove key.

4) Remove “A/BAG” fu se from fuse box.

5) Pull out glove box while pushing its stopper from

both right and left sides and disconnect yellow

connector (1) for driver and passenger air bags as

follows.

a) Release locking of lock slider (2).

b) After unlocked, disconnect connector. 6) If equipped with side-air bag (inflator) module,

disconnect yellow connector of side-air bag (inflator)

module under front seat cushion (3).

a) Release locking of lock slider.

b) After unlocked, disconnect connector.

1. Seat belt

2. Retractor assembly

13 4

2I4RS0A820051-01

I3JA01820043-01

Page 1155 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-117

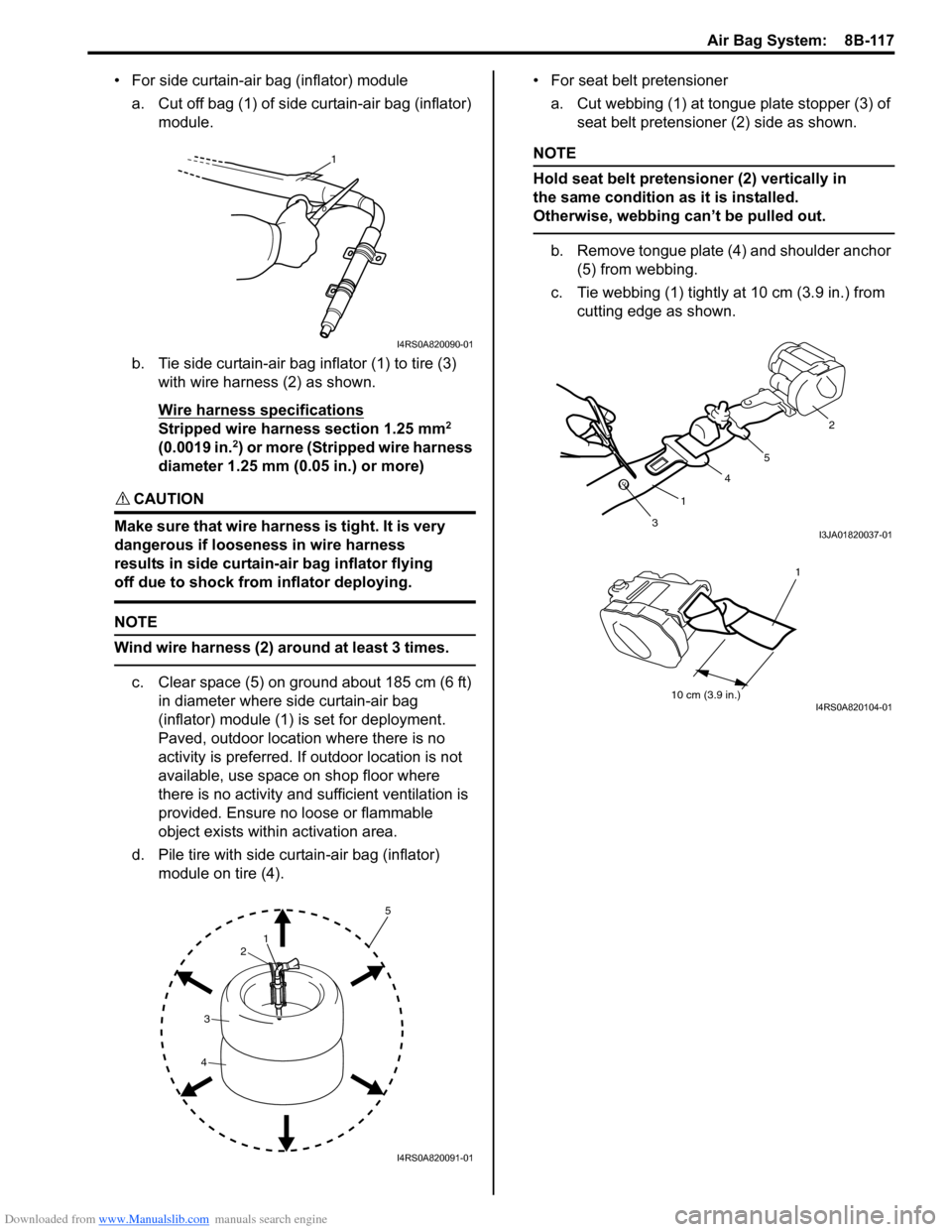

• For side curtain-air bag (inflator) modulea. Cut off bag (1) of side curtain-air bag (inflator) module.

b. Tie side curtain-air bag inflator (1) to tire (3) with wire harness (2) as shown.

Wire harness specifications

Stripped wire harness section 1.25 mm2

(0.0019 in.2) or more (Stripped wire harness

diameter 1.25 mm (0.05 in.) or more)

CAUTION!

Make sure that wire harness is tight. It is very

dangerous if looseness in wire harness

results in side curtain-air bag inflator flying

off due to shock from inflator deploying.

NOTE

Wind wire harness (2) around at least 3 times.

c. Clear space (5) on ground about 185 cm (6 ft) in diameter where side curtain-air bag

(inflator) module (1) is set for deployment.

Paved, outdoor location where there is no

activity is preferred. If outdoor location is not

available, use space on shop floor where

there is no activity and sufficient ventilation is

provided. Ensure no loose or flammable

object exists within activation area.

d. Pile tire with side curtain-air bag (inflator) module on tire (4). • For seat belt pretensioner

a. Cut webbing (1) at tongue plate stopper (3) of seat belt pretensioner (2) side as shown.

NOTE

Hold seat belt pretensioner (2) vertically in

the same condition as it is installed.

Otherwise, webbing can’t be pulled out.

b. Remove tongue plate (4) and shoulder anchor (5) from webbing.

c. Tie webbing (1) tightly at 10 cm (3.9 in.) from

cutting edge as shown.

1

I4RS0A820090-01

1

2

3

4

5

I4RS0A820091-01

3 1 4

5 2I3JA01820037-01

10 cm (3.9 in.)

1

I4RS0A820104-01

Page 1156 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-118 Air Bag System:

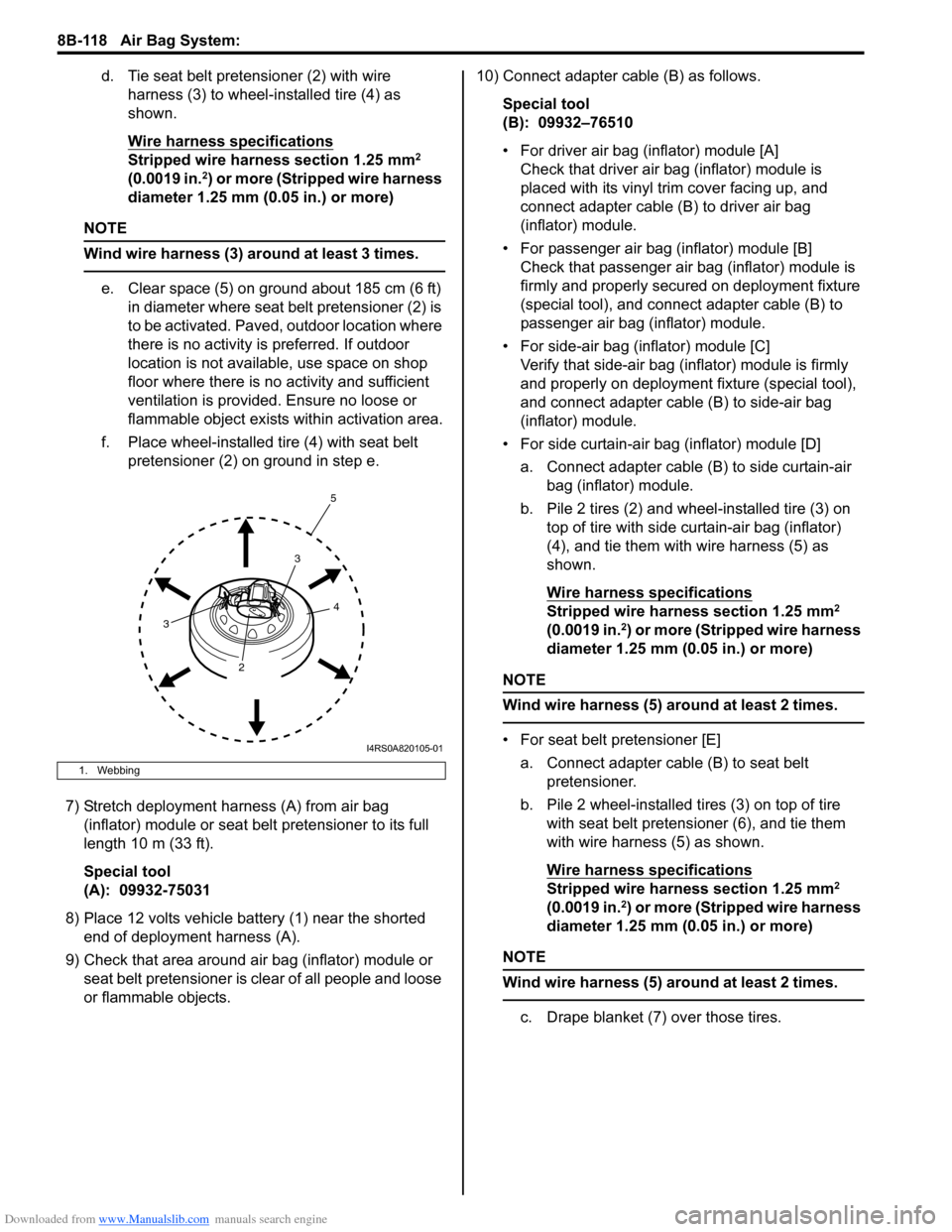

d. Tie seat belt pretensioner (2) with wire harness (3) to wheel-installed tire (4) as

shown.

Wire harness specifications

Stripped wire harness section 1.25 mm2

(0.0019 in.2) or more (Stripped wire harness

diameter 1.25 mm (0.05 in.) or more)

NOTE

Wind wire harness (3) around at least 3 times.

e. Clear space (5) on ground about 185 cm (6 ft) in diameter where seat belt pretensioner (2) is

to be activated. Paved, outdoor location where

there is no activity is preferred. If outdoor

location is not available, use space on shop

floor where there is no activity and sufficient

ventilation is provided. Ensure no loose or

flammable object exists within activation area.

f. Place wheel-installed tire (4) with seat belt pretensioner (2) on ground in step e.

7) Stretch deployment harness (A) from air bag (inflator) module or seat belt pretensioner to its full

length 10 m (33 ft).

Special tool

(A): 09932-75031

8) Place 12 volts vehicle battery (1) near the shorted end of deployment harness (A).

9) Check that area around air bag (inflator) module or seat belt pretensioner is clear of all people and loose

or flammable objects. 10) Connect adapter cable (B) as follows.

Special tool

(B): 09932–76510

• For driver air bag (inflator) module [A]Check that driver air bag (inflator) module is

placed with its vinyl trim cover facing up, and

connect adapter cable (B) to driver air bag

(inflator) module.

• For passenger air bag (inflator) module [B] Check that passenger air bag (inflator) module is

firmly and properly secured on deployment fixture

(special tool), and connect adapter cable (B) to

passenger air bag (inflator) module.

• For side-air bag (inflator) module [C] Verify that side-air bag (inflator) module is firmly

and properly on deployment fixture (special tool),

and connect adapter cable (B) to side-air bag

(inflator) module.

• For side curtain-air bag (inflator) module [D] a. Connect adapter cable (B) to side curtain-air bag (inflator) module.

b. Pile 2 tires (2) and wheel-installed tire (3) on top of tire with side curtain-air bag (inflator)

(4), and tie them with wire harness (5) as

shown.

Wire harness specifications

Stripped wire harness section 1.25 mm2

(0.0019 in.2) or more (Stripped wire harness

diameter 1.25 mm (0.05 in.) or more)

NOTE

Wind wire harness (5) around at least 2 times.

• For seat belt pretensioner [E]

a. Connect adapter cable (B) to seat belt pretensioner.

b. Pile 2 wheel-installed tires (3) on top of tire with seat belt pretensioner (6), and tie them

with wire harness (5) as shown.

Wire harness specifications

Stripped wire harness section 1.25 mm2

(0.0019 in.2) or more (Stripped wire harness

diameter 1.25 mm (0.05 in.) or more)

NOTE

Wind wire harness (5) around at least 2 times.

c. Drape blanket (7) over those tires.

1. Webbing

4

3

3 2 5

I4RS0A820105-01

Page 1163 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-125

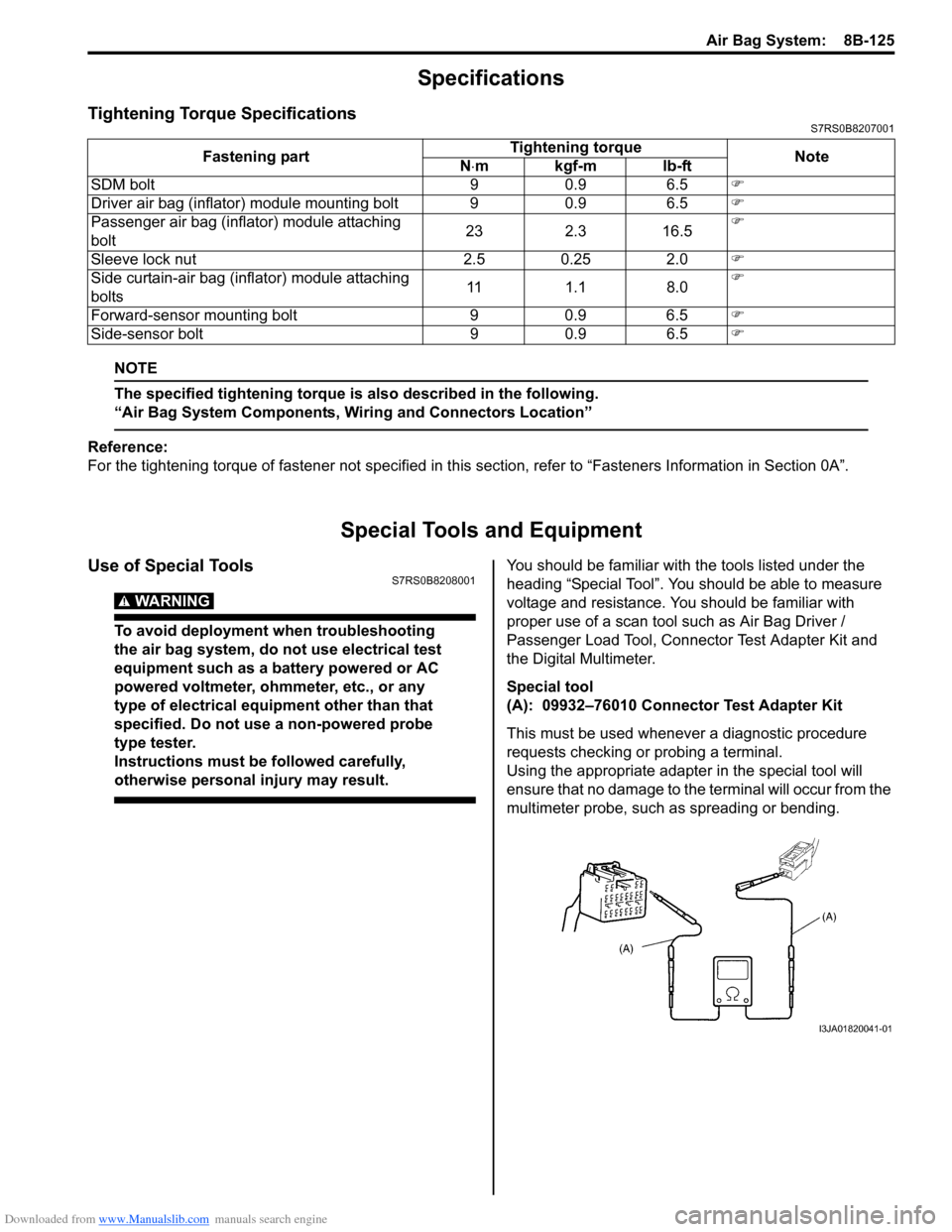

Specifications

Tightening Torque SpecificationsS7RS0B8207001

NOTE

The specified tightening torque is also described in the following.

“Air Bag System Components, Wiring and Connectors Location”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Use of Special ToolsS7RS0B8208001

WARNING!

To avoid deployment when troubleshooting

the air bag system, do not use electrical test

equipment such as a battery powered or AC

powered voltmeter, ohmmeter, etc., or any

type of electrical equipment other than that

specified. Do not use a non-powered probe

type tester.

Instructions must be followed carefully,

otherwise personal injury may result.

You should be familiar with the tools listed under the

heading “Special Tool”. You should be able to measure

voltage and resistance. You should be familiar with

proper use of a scan tool such as Air Bag Driver /

Passenger Load Tool, Connector Test Adapter Kit and

the Digital Multimeter.

Special tool

(A): 09932–76010 Connector Test Adapter Kit

This must be used whenever a diagnostic procedure

requests checking or probing a terminal.

Using the appropriate adapter in the special tool will

ensure that no damage to the terminal will occur from the

multimeter probe, such as spreading or bending.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

SDM bolt 9 0.9 6.5 �)

Driver air bag (inflator) module mounting bolt 9 0.9 6.5 �)

Passenger air bag (inflator) module attaching

bolt 23 2.3 16.5�)

Sleeve lock nut 2.5 0.25 2.0 �)

Side curtain-air bag (inflator) module attaching

bolts 11 1.1 8.0�)

Forward-sensor mounting bolt 9 0.9 6.5 �)

Side-sensor bolt 9 0.9 6.5 �)

I3JA01820041-01