Rear wheel SUZUKI SWIFT 2008 2.G Service Service Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 507 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-9

Air Bleeding of Brake SystemS7RS0B4106006

CAUTION!

Brake fluid is extremely damaging to paint. If

fluid should accidentally touch painted

surface, immediately wipe fluid from paint

and clean painted surface.

Bleeding operation is necessary to remove air whenever

it entered hydraulic brake system.

Hydraulic lines of brake system are based on the

diagonal split system. When a brake pipe or hose was

disconnected at the wheel, bleeding operation must be

performed at both ends of the line of the removed pipe or

hose. When any joint part of the master cylinder of other

joint part between the master cylinder and each brake

(wheel) was removed, the hydraulic brake system must

be bled at all 4 wheel brakes.

NOTE

Perform bleeding operation starting with rear

brake caliper farthest from master cylinder

and then at front caliper of the same brake

line. Do the same on the other brake line.

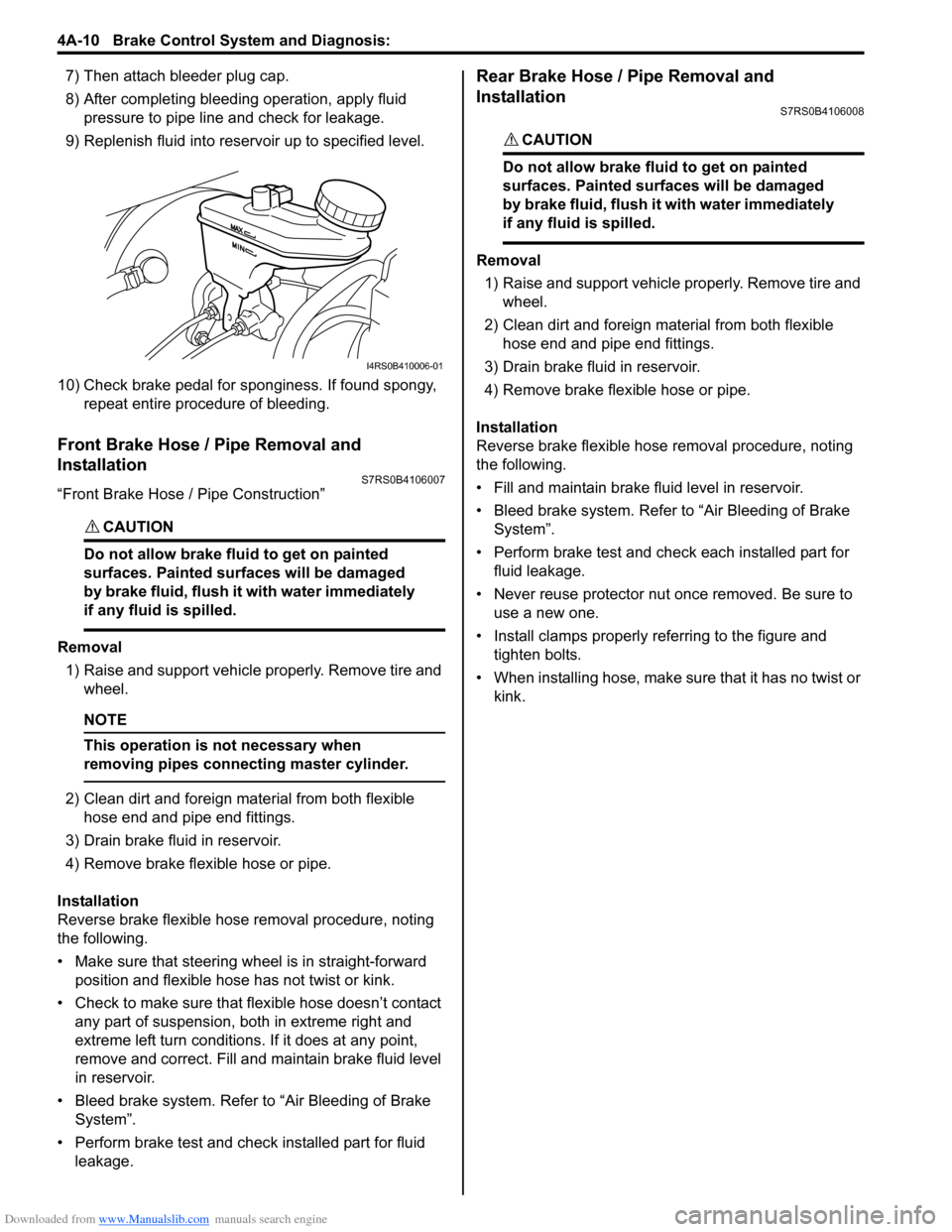

1) Fill master cylinder rese rvoir with brake fluid and

keep at least one-half full of fluid during bleeding

operation.

Brake fluid

: Refer to reservoir cap (1) 2) Remove bleeder plug cap. Attach a vinyl tube (1) to

bleeder plug, and insert the other end into container

(2).

3) Depress brake pedal several times, and then while holding it depressed, loosen bleeder plug about one-

third to one-half turn.

4) When fluid pressure in cy linder is almost depleted,

retighten bleeder plug.

5) Repeat this operation until there are no more air bubbles in hydraulic line.

6) When bubbles stop, depress and hold brake pedal and tighten bleeder plug referring to “Front Disc

Brake Components in Section 4B” and “Rear Disc

Brake Components in Section 4C”.

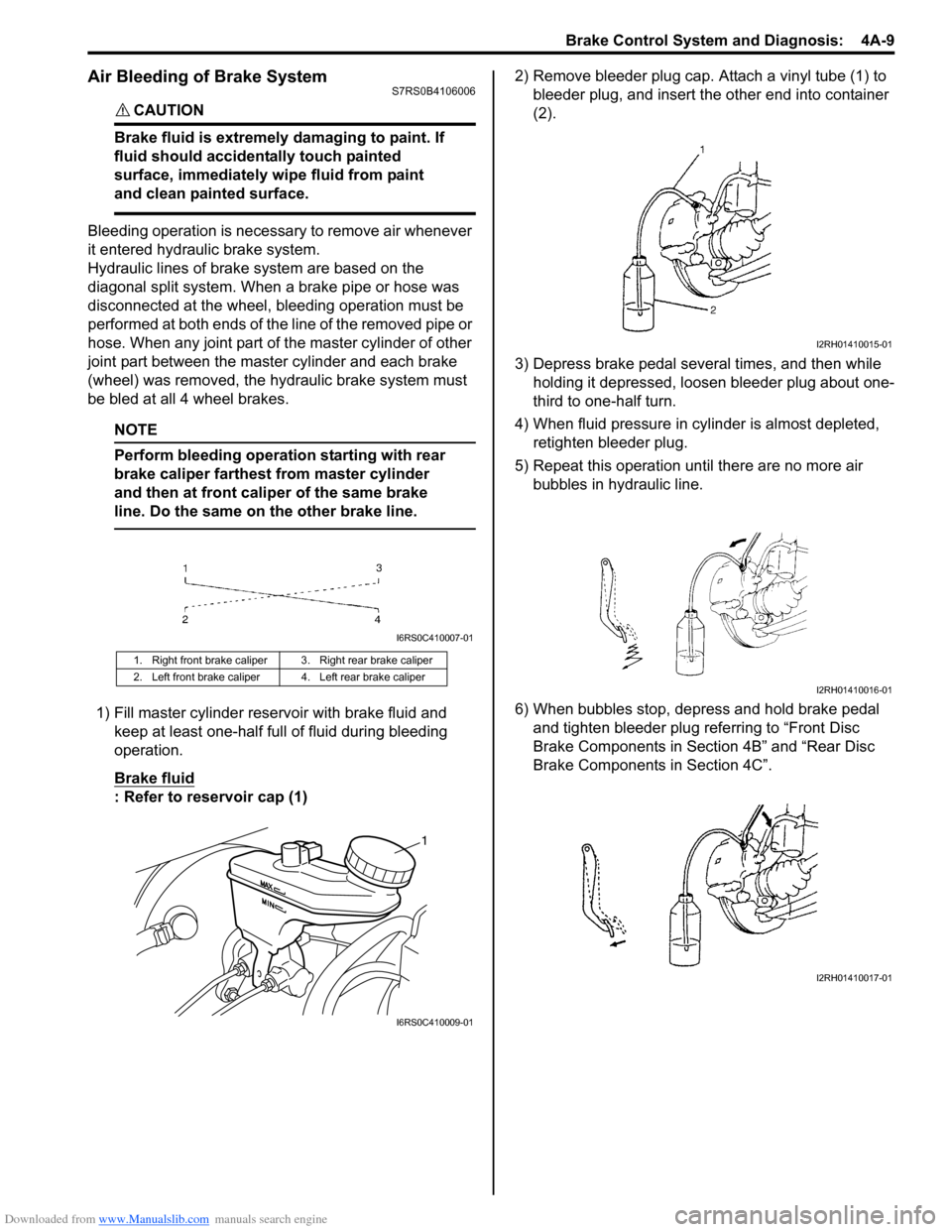

1. Right front brake caliper 3. Right rear brake caliper

2. Left front brake caliper 4. Left rear brake caliper

I6RS0C410007-01

1

I6RS0C410009-01

I2RH01410015-01

I2RH01410016-01

I2RH01410017-01

Page 508 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-10 Brake Control System and Diagnosis:

7) Then attach bleeder plug cap.

8) After completing bleeding operation, apply fluid pressure to pipe line and check for leakage.

9) Replenish fluid into reserv oir up to specified level.

10) Check brake pedal for sponginess. If found spongy, repeat entire procedure of bleeding.

Front Brake Hose / Pipe Removal and

Installation

S7RS0B4106007

“Front Brake Hose / Pipe Construction”

CAUTION!

Do not allow brake fluid to get on painted

surfaces. Painted surfaces will be damaged

by brake fluid, flush it with water immediately

if any fluid is spilled.

Removal

1) Raise and support vehicle properly. Remove tire and wheel.

NOTE

This operation is not necessary when

removing pipes connecting master cylinder.

2) Clean dirt and foreign mate rial from both flexible

hose end and pipe end fittings.

3) Drain brake fluid in reservoir.

4) Remove brake flexible hose or pipe.

Installation

Reverse brake flexible hose removal procedure, noting

the following.

• Make sure that steering wh eel is in straight-forward

position and flexible hose has not twist or kink.

• Check to make sure that flexible hose doesn’t contact any part of suspension, both in extreme right and

extreme left turn conditions. If it does at any point,

remove and correct. Fill and maintain brake fluid level

in reservoir.

• Bleed brake system. Refer to “Air Bleeding of Brake System”.

• Perform brake test and check installed part for fluid leakage.

Rear Brake Hose / Pipe Removal and

Installation

S7RS0B4106008

CAUTION!

Do not allow brake fluid to get on painted

surfaces. Painted surfaces will be damaged

by brake fluid, flush it with water immediately

if any fluid is spilled.

Removal

1) Raise and support vehicle properly. Remove tire and wheel.

2) Clean dirt and foreign material from both flexible hose end and pipe end fittings.

3) Drain brake fluid in reservoir.

4) Remove brake flexible hose or pipe.

Installation

Reverse brake flexible hose removal procedure, noting

the following.

• Fill and maintain brake fluid level in reservoir.

• Bleed brake system. Refer to “Air Bleeding of Brake System”.

• Perform brake test and check each installed part for fluid leakage.

• Never reuse protector nut once removed. Be sure to use a new one.

• Install clamps properly referring to the figure and tighten bolts.

• When installing hose, make sure that it has no twist or

kink.

I4RS0B410006-01

Page 526 of 1496

Downloaded from www.Manualslib.com manuals search engine 4C-2 Rear Brakes:

Rear Disc Brake Pad Removal and InstallationS7RS0B4306002

NOTE

When replacing brake pad, replace it on the

right and left.

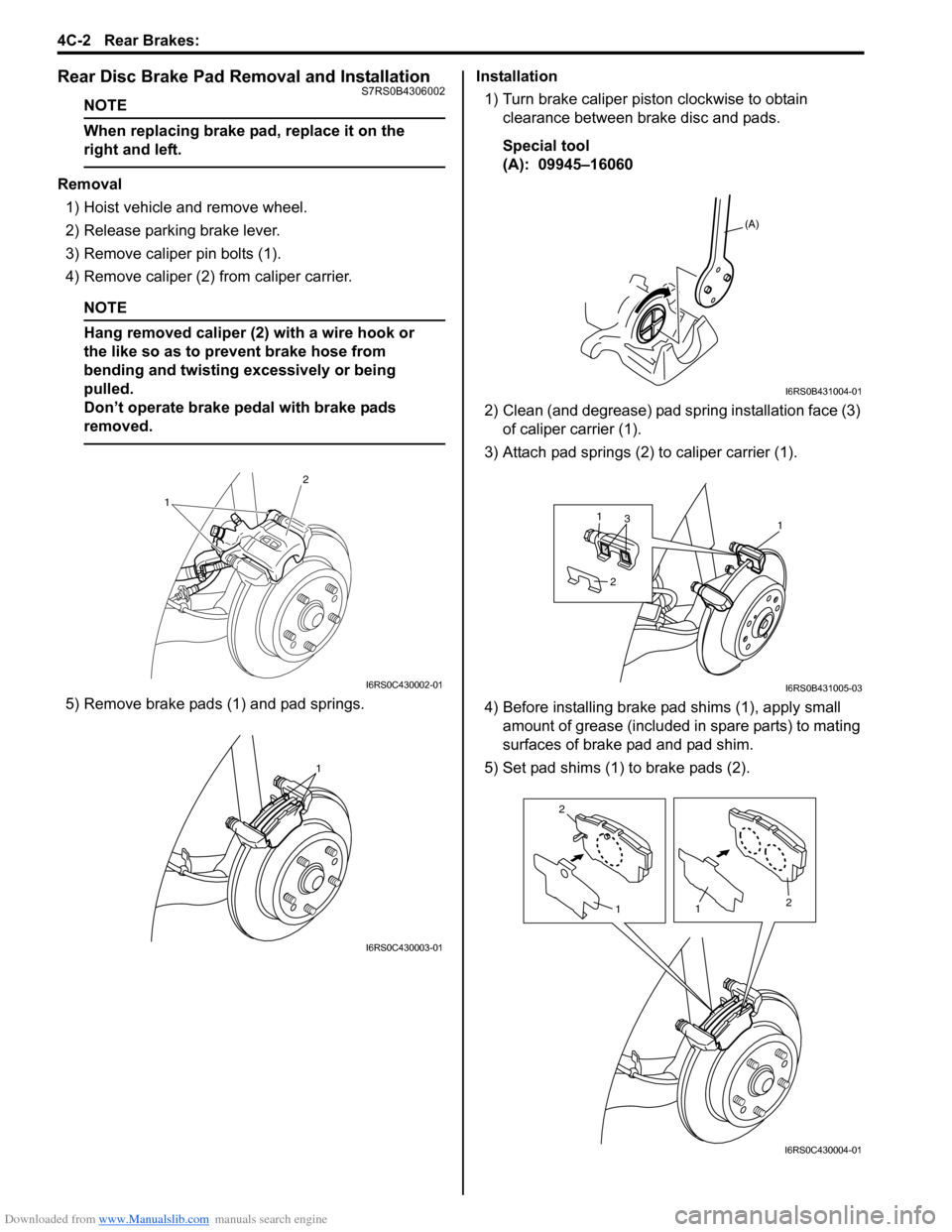

Removal1) Hoist vehicle and remove wheel.

2) Release parking brake lever.

3) Remove caliper pin bolts (1).

4) Remove caliper (2) from caliper carrier.

NOTE

Hang removed caliper (2) with a wire hook or

the like so as to prevent brake hose from

bending and twisting excessively or being

pulled.

Don’t operate brake pedal with brake pads

removed.

5) Remove brake pads (1) and pad springs. Installation

1) Turn brake caliper piston clockwise to obtain clearance between brake disc and pads.

Special tool

(A): 09945–16060

2) Clean (and degrease) pad spring installation face (3) of caliper carrier (1).

3) Attach pad springs (2) to caliper carrier (1).

4) Before installing brake p ad shims (1), apply small

amount of grease (included in spare parts) to mating

surfaces of brake pad and pad shim.

5) Set pad shims (1) to brake pads (2).

1 2

I6RS0C430002-01

1

I6RS0C430003-01

(A)

I6RS0B431004-01

113

2

I6RS0B431005-03

2

1

1 2

I6RS0C430004-01

Page 527 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Brakes: 4C-3

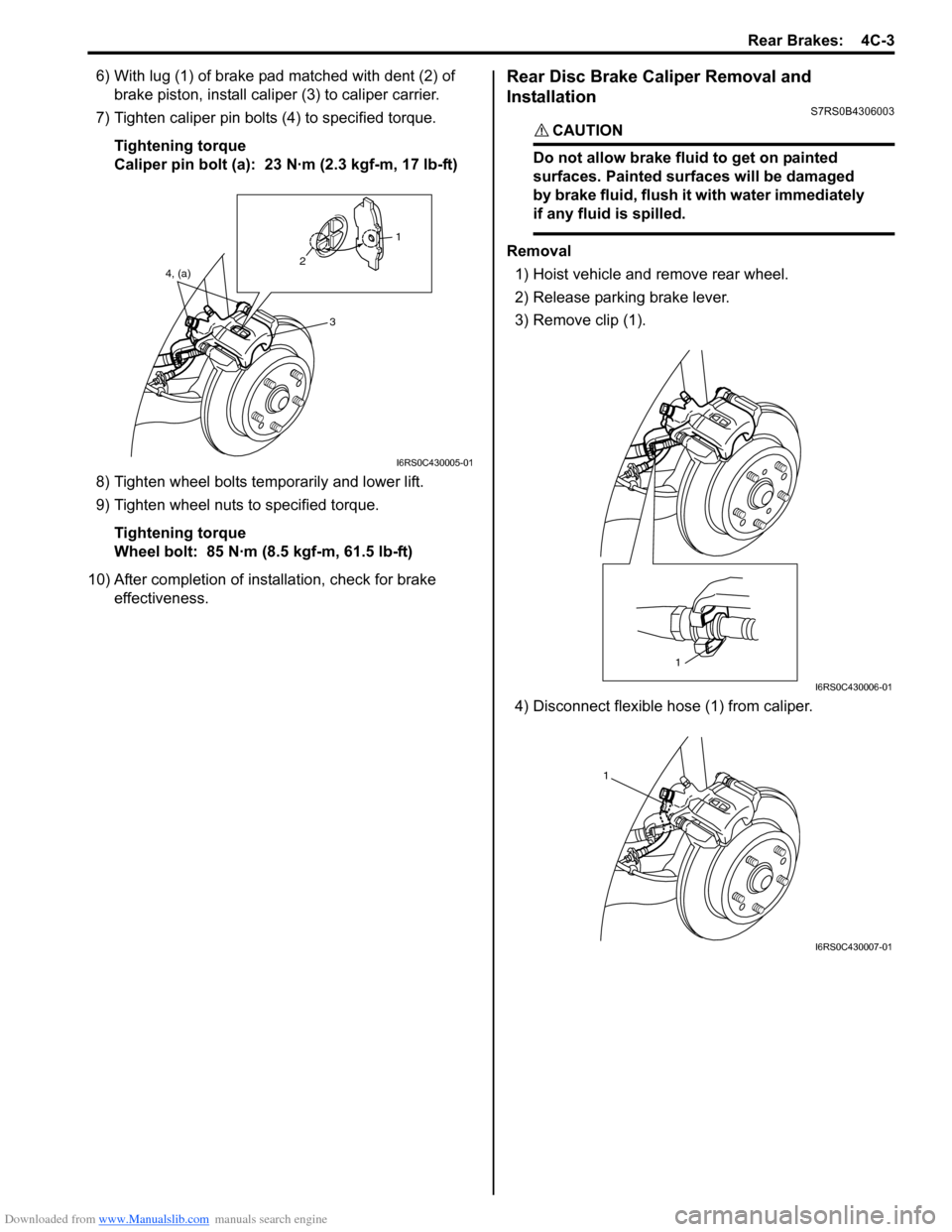

6) With lug (1) of brake pad matched with dent (2) of brake piston, install caliper (3) to caliper carrier.

7) Tighten caliper pin bolts (4) to specified torque.

Tightening torque

Caliper pin bolt (a): 23 N·m (2.3 kgf-m, 17 lb-ft)

8) Tighten wheel bolts temporarily and lower lift.

9) Tighten wheel nuts to specified torque. Tightening torque

Wheel bolt: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

10) After completion of installation, check for brake effectiveness.Rear Disc Brake Caliper Removal and

Installation

S7RS0B4306003

CAUTION!

Do not allow brake fluid to get on painted

surfaces. Painted surfaces will be damaged

by brake fluid, flush it with water immediately

if any fluid is spilled.

Removal

1) Hoist vehicle and remove rear wheel.

2) Release parking brake lever.

3) Remove clip (1).

4) Disconnect flexible hose (1) from caliper.

4, (a) 21

3

I6RS0C430005-01

1

I6RS0C430006-01

1

I6RS0C430007-01

Page 529 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Brakes: 4C-5

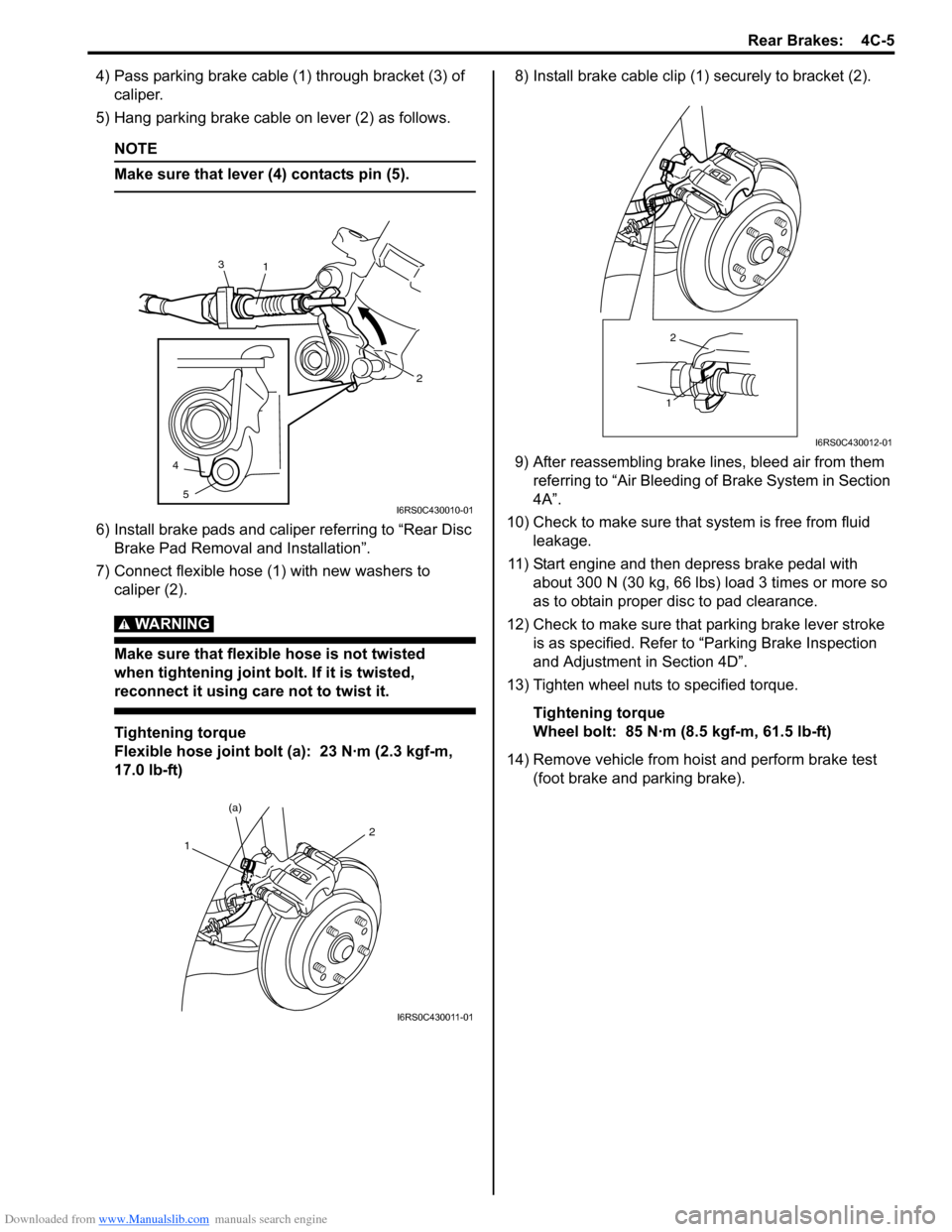

4) Pass parking brake cable (1) through bracket (3) of caliper.

5) Hang parking brake cable on lever (2) as follows.

NOTE

Make sure that lever (4) contacts pin (5).

6) Install brake pads and caliper referring to “Rear Disc Brake Pad Removal and Installation”.

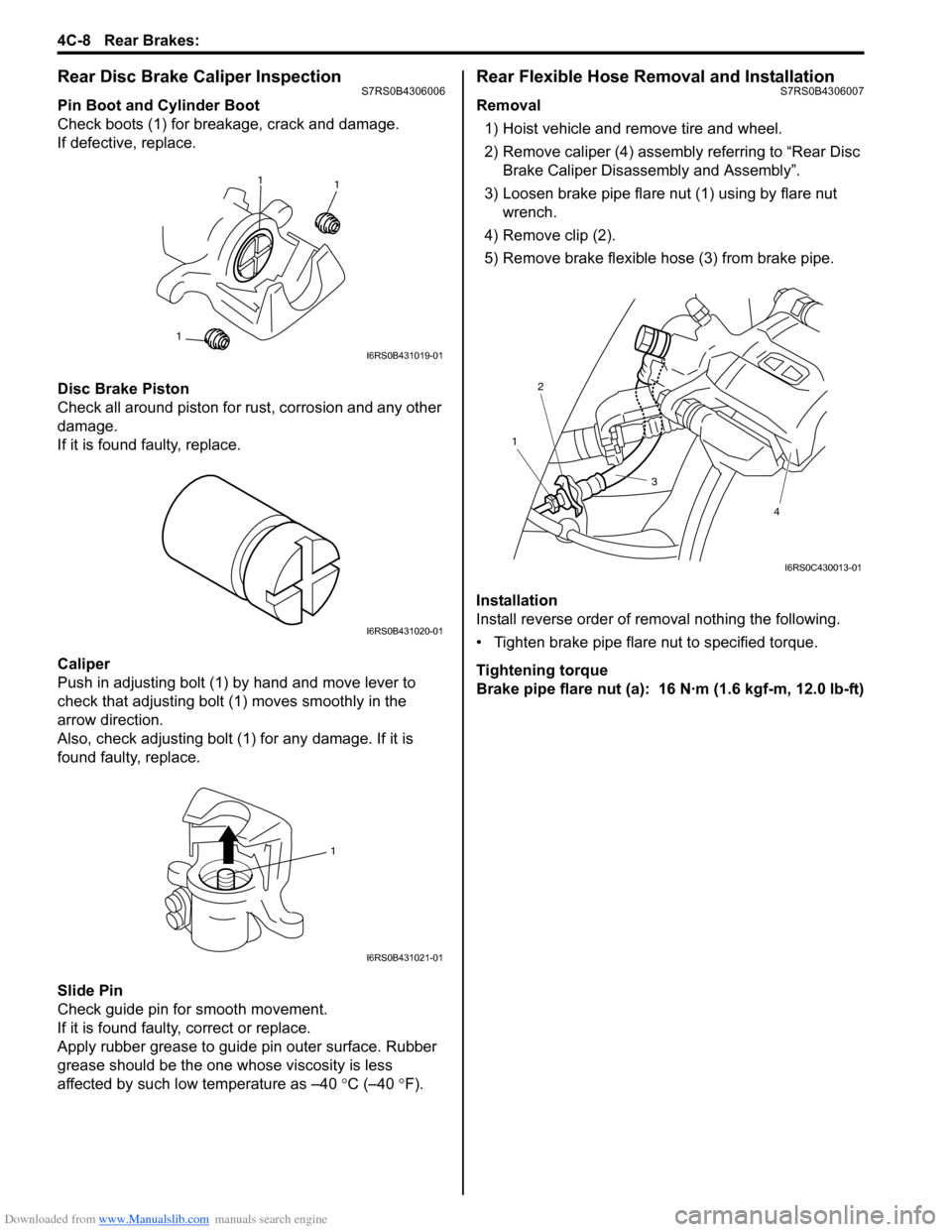

7) Connect flexible hose (1) with new washers to caliper (2).

WARNING!

Make sure that flexible hose is not twisted

when tightening joint bolt. If it is twisted,

reconnect it using care not to twist it.

Tightening torque

Flexible hose joint bolt (a): 23 N·m (2.3 kgf-m,

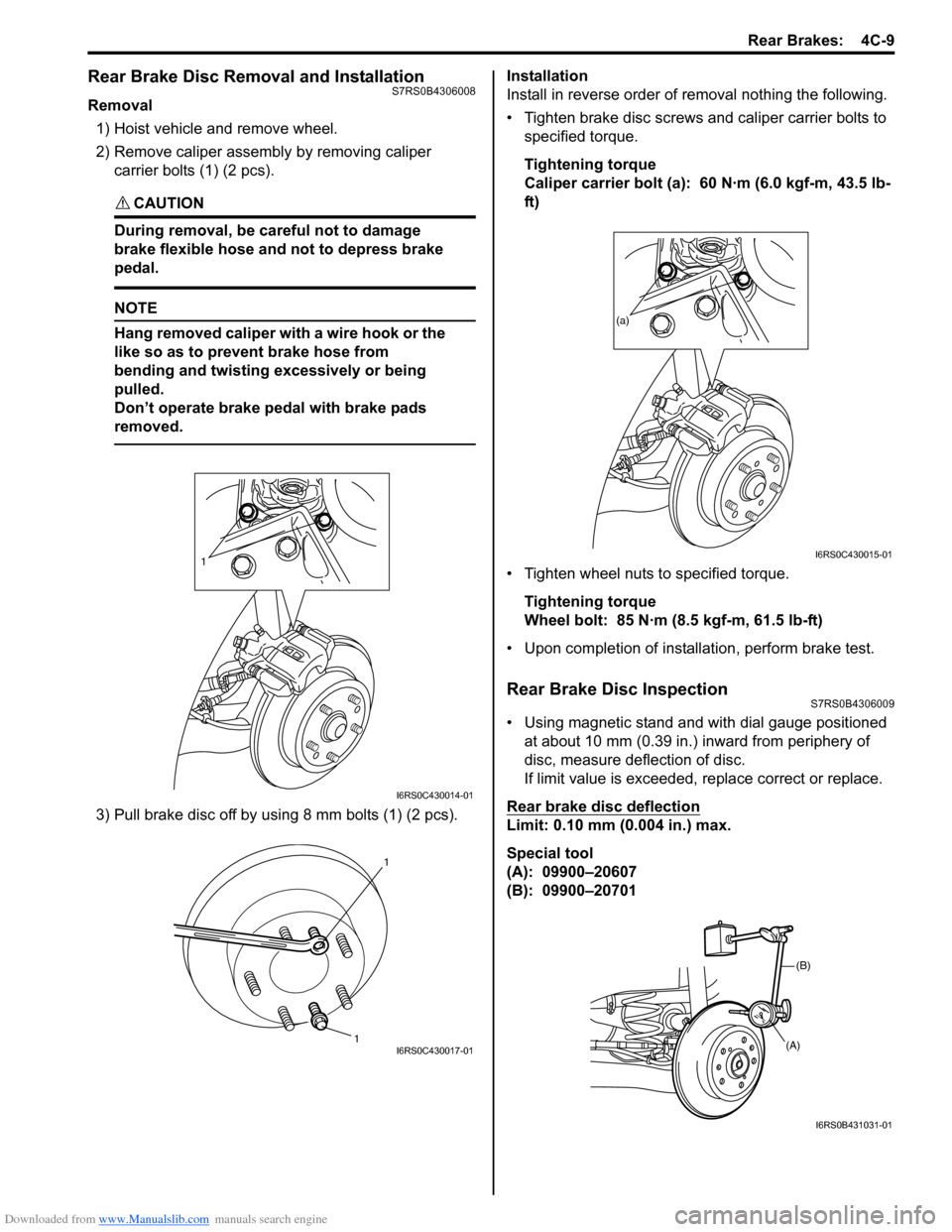

17.0 lb-ft) 8) Install brake cable clip (1) securely to bracket (2).

9) After reassembling brake lines, bleed air from them

referring to “Air Bleeding of Brake System in Section

4A”.

10) Check to make sure that system is free from fluid

leakage.

11) Start engine and then depress brake pedal with about 300 N (30 kg, 66 lbs) load 3 times or more so

as to obtain proper disc to pad clearance.

12) Check to make sure that parking brake lever stroke is as specified. Refer to “Parking Brake Inspection

and Adjustment in Section 4D”.

13) Tighten wheel nuts to specified torque.

Tightening torque

Wheel bolt: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

14) Remove vehicle from hoist and perform brake test (foot brake and parking brake).

1

23

45

I6RS0C430010-01

1 (a)2

I6RS0C430011-01

1

2

I6RS0C430012-01

Page 532 of 1496

Downloaded from www.Manualslib.com manuals search engine 4C-8 Rear Brakes:

Rear Disc Brake Caliper InspectionS7RS0B4306006

Pin Boot and Cylinder Boot

Check boots (1) for breakage, crack and damage.

If defective, replace.

Disc Brake Piston

Check all around piston for rust, corrosion and any other

damage.

If it is found faulty, replace.

Caliper

Push in adjusting bolt (1) by hand and move lever to

check that adjusting bolt (1) moves smoothly in the

arrow direction.

Also, check adjusting bolt (1) for any damage. If it is

found faulty, replace.

Slide Pin

Check guide pin for smooth movement.

If it is found faulty, correct or replace.

Apply rubber grease to guide pin outer surface. Rubber

grease should be the one whose viscosity is less

affected by such low temperature as –40 °C (–40 ° F).

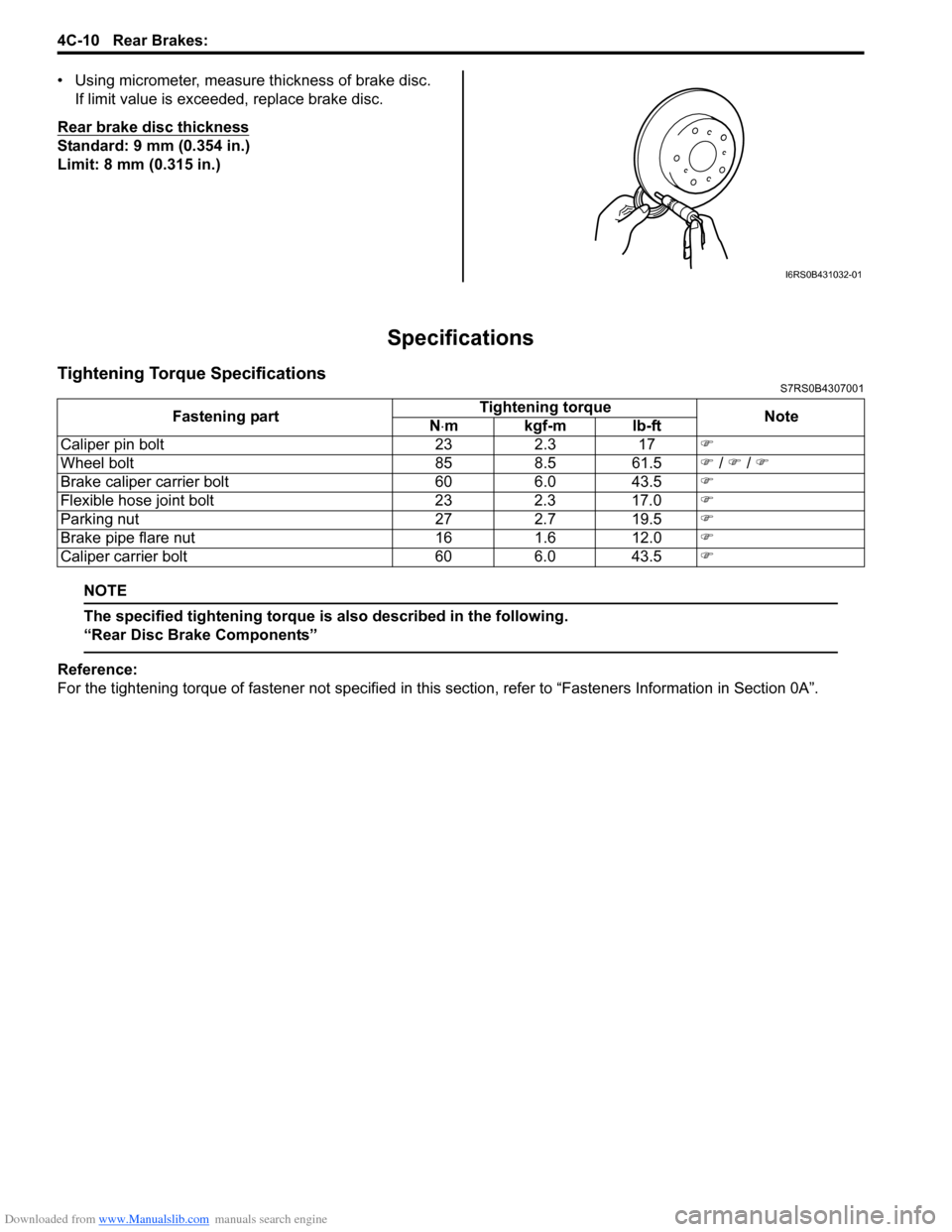

Rear Flexible Hose Removal and InstallationS7RS0B4306007

Removal

1) Hoist vehicle and remove tire and wheel.

2) Remove caliper (4) assembly referring to “Rear Disc Brake Caliper Disassembly and Assembly”.

3) Loosen brake pipe flare nut (1) using by flare nut wrench.

4) Remove clip (2).

5) Remove brake flexible hose (3) from brake pipe.

Installation

Install reverse order of removal nothing the following.

• Tighten brake pipe flare nut to specified torque.

Tightening torque

Brake pipe flare nut (a): 16 N·m (1.6 kgf-m, 12.0 lb-ft)

1 1

1

I6RS0B431019-01

I6RS0B431020-01

1

I6RS0B431021-01

1

2

3

4

I6RS0C430013-01

Page 533 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Brakes: 4C-9

Rear Brake Disc Removal and InstallationS7RS0B4306008

Removal1) Hoist vehicle and remove wheel.

2) Remove caliper assembly by removing caliper

carrier bolts (1) (2 pcs).

CAUTION!

During removal, be ca reful not to damage

brake flexible hose and not to depress brake

pedal.

NOTE

Hang removed caliper with a wire hook or the

like so as to prevent brake hose from

bending and twisting excessively or being

pulled.

Don’t operate brake pedal with brake pads

removed.

3) Pull brake disc off by using 8 mm bolts (1) (2 pcs). Installation

Install in reverse order of removal nothing the following.

• Tighten brake disc screws and caliper carrier bolts to

specified torque.

Tightening torque

Caliper carrier bolt (a): 60 N·m (6.0 kgf-m, 43.5 lb-

ft)

• Tighten wheel nuts to specified torque. Tightening torque

Wheel bolt: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

• Upon completion of installation, perform brake test.

Rear Brake Disc InspectionS7RS0B4306009

• Using magnetic stand and with dial gauge positioned at about 10 mm (0.39 in.) inward from periphery of

disc, measure deflection of disc.

If limit value is exceeded, replace correct or replace.

Rear brake disc deflection

Limit: 0.10 mm (0.004 in.) max.

Special tool

(A): 09900–20607

(B): 09900–20701

1

I6RS0C430014-01

1 1I6RS0C430017-01

(a)

I6RS0C430015-01

(B)

(A)

I6RS0B431031-01

Page 534 of 1496

Downloaded from www.Manualslib.com manuals search engine 4C-10 Rear Brakes:

• Using micrometer, measure thickness of brake disc.If limit value is exceeded, replace brake disc.

Rear brake disc thickness

Standard: 9 mm (0.354 in.)

Limit: 8 mm (0.315 in.)

Specifications

Tightening Torque SpecificationsS7RS0B4307001

NOTE

The specified tightening torque is also described in the following.

“Rear Disc Brake Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

I6RS0B431032-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Caliper pin bolt 23 2.3 17 �)

Wheel bolt 85 8.5 61.5 �) / �) / �)

Brake caliper carrier bolt 60 6.0 43.5 �)

Flexible hose joint bolt 23 2.3 17.0 �)

Parking nut 27 2.7 19.5 �)

Brake pipe flare nut 16 1.6 12.0 �)

Caliper carrier bolt 60 6.0 43.5 �)

Page 537 of 1496

Downloaded from www.Manualslib.com manuals search engine Parking Brake: 4D-2

Repair Instructions

Parking Brake Inspection and AdjustmentS7RS0B4406001

Inspection

Hold center of parking brake lever grip and pull it up with

200 N (20 kg, 44 lbs) force.

With parking brake lever pulled up as shown, count

ratchet notches. There should be 4 to 9 notches.

Also, check if both right and left rear wheels are locked

firmly.

To count number of notches easily, listen to click sounds

that ratchet makes while pulling parking brake lever

without pressing its button.

One click sound corresponds to one notch.

If number of notches is out of specification, adjust cable

referring to adjustment procedure so as to obtain

specified parking brake stroke.

NOTE

Check tooth tip of each notch for damage or

wear.

If any damage or wear is found, replace

parking brake lever.

Adjustment

NOTE

Make sure for the following conditions before

cable adjustment.

• No air is trapped in brake system.

• Brake pedal travel is proper.

• Start engine and then brake pedal has been depressed at least 3 times with about

160 N (16.0 kg, 35.3 lbs) load.

• Parking brake lever (1) has been pulled up a few times with about 200 N (20 kg, 44 lbs)

load.

If parking brake cable is replaced with new

one, pull up parking brake lever a few

times with about 500 N ⋅m (50 kg, 110 lbs)

force.

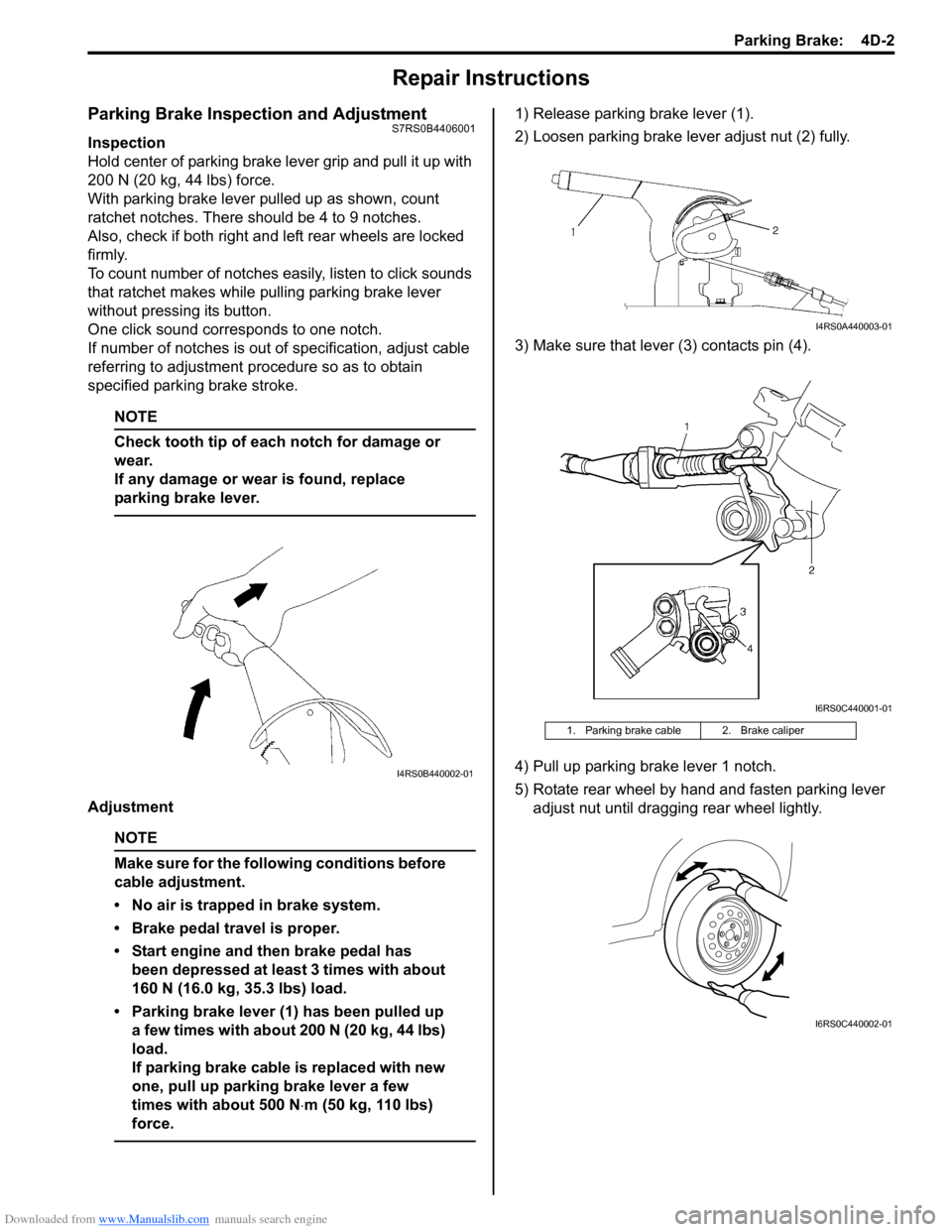

1) Release parking brake lever (1).

2) Loosen parking brake lever adjust nut (2) fully.

3) Make sure that lever (3) contacts pin (4).

4) Pull up parking brake lever 1 notch.

5) Rotate rear wheel by hand and fasten parking lever adjust nut until dragging rear wheel lightly.

I4RS0B440002-01

1. Parking brake cable 2. Brake caliper

I4RS0A440003-01

I6RS0C440001-01

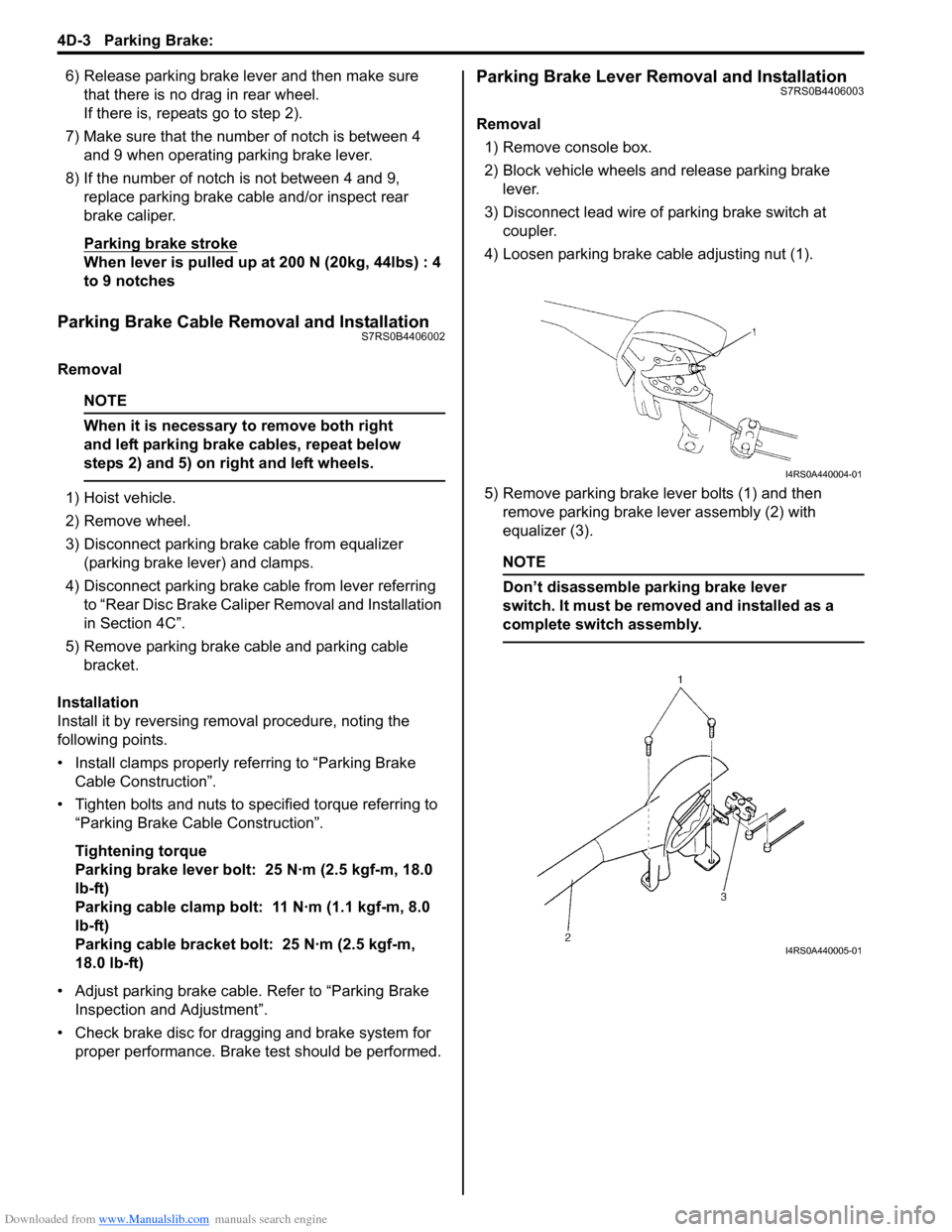

I6RS0C440002-01

Page 538 of 1496

Downloaded from www.Manualslib.com manuals search engine 4D-3 Parking Brake:

6) Release parking brake lever and then make sure that there is no drag in rear wheel.

If there is, repeats go to step 2).

7) Make sure that the number of notch is between 4 and 9 when operating parking brake lever.

8) If the number of notch is not between 4 and 9, replace parking brake cable and/or inspect rear

brake caliper.

Parking brake stroke

When lever is pulled up at 200 N (20kg, 44lbs) : 4

to 9 notches

Parking Brake Cable Removal and InstallationS7RS0B4406002

Removal

NOTE

When it is necessary to remove both right

and left parking brake cables, repeat below

steps 2) and 5) on right and left wheels.

1) Hoist vehicle.

2) Remove wheel.

3) Disconnect parking brake cable from equalizer (parking brake lever) and clamps.

4) Disconnect parking brake cable from lever referring to “Rear Disc Brake Caliper Removal and Installation

in Section 4C”.

5) Remove parking brake cable and parking cable bracket.

Installation

Install it by reversing removal procedure, noting the

following points.

• Install clamps properly referring to “Parking Brake Cable Construction”.

• Tighten bolts and nuts to specified torque referring to “Parking Brake Cable Construction”.

Tightening torque

Parking brake lever bolt: 25 N·m (2.5 kgf-m, 18.0

lb-ft)

Parking cable clamp bolt: 11 N·m (1.1 kgf-m, 8.0

lb-ft)

Parking cable bracket bolt: 25 N·m (2.5 kgf-m,

18.0 lb-ft)

• Adjust parking brake cable. Refer to “Parking Brake Inspection and Adjustment”.

• Check brake disc for dragging and brake system for proper performance. Brake test should be performed.

Parking Brake Lever Removal and InstallationS7RS0B4406003

Removal

1) Remove console box.

2) Block vehicle wheels and release parking brake lever.

3) Disconnect lead wire of parking brake switch at coupler.

4) Loosen parking brake cable adjusting nut (1).

5) Remove parking brake lever bolts (1) and then remove parking brake lever assembly (2) with

equalizer (3).

NOTE

Don’t disassemble parking brake lever

switch. It must be removed and installed as a

complete switch assembly.

I4RS0A440004-01

I4RS0A440005-01