Matic SUZUKI SWIFT 2008 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 663 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-19

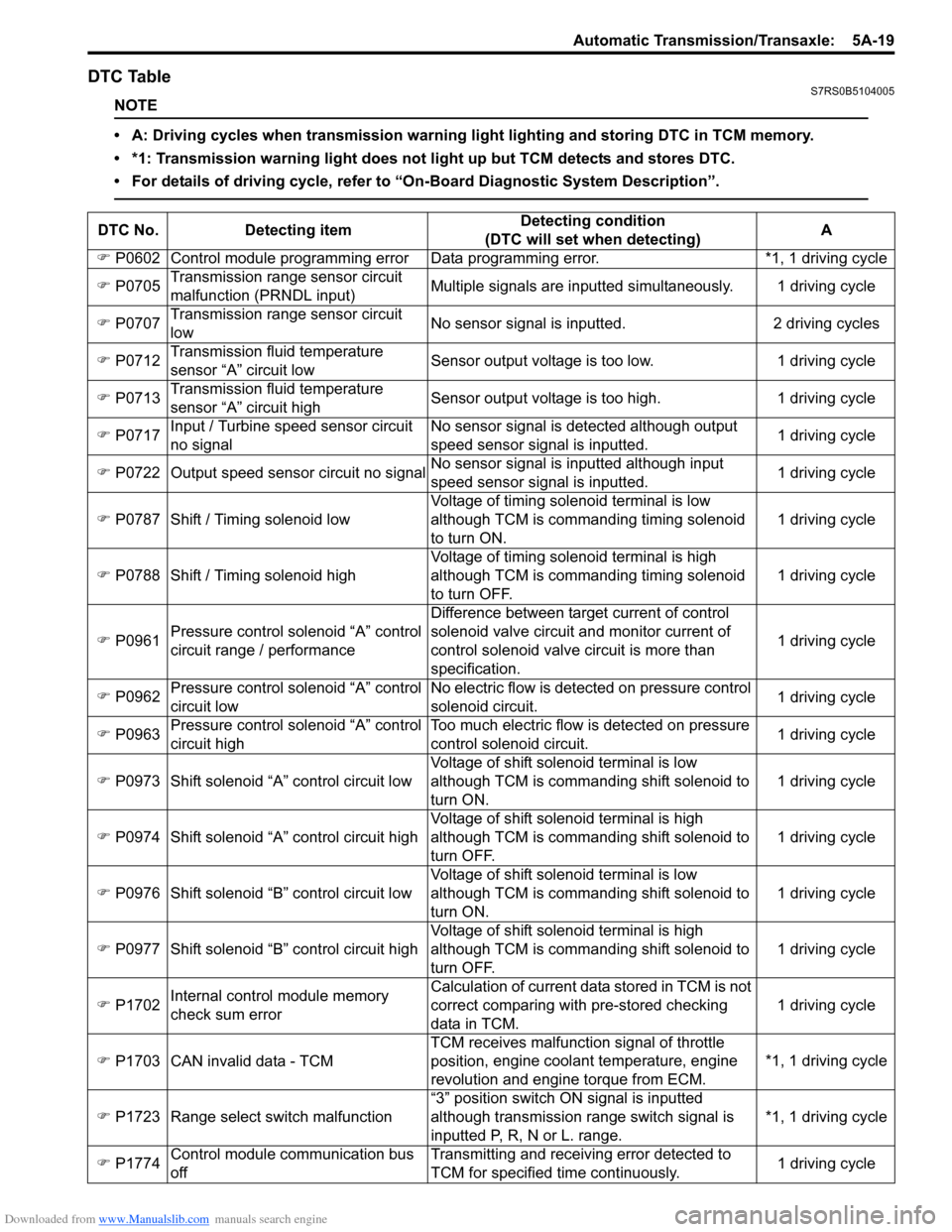

DTC TableS7RS0B5104005

NOTE

• A: Driving cycles when transmission warning light lighting and storing DTC in TCM memory.

• *1: Transmission warning light does not light up but TCM detects and stores DTC.

• For details of driving cycle, refer to “On-Board Diagnostic System Description”.

DTC No.Detecting item Detecting condition

(DTC will set when detecting) A

�) P0602 Control module programming error D ata programming error. *1, 1 driving cycle

�) P0705 Transmission range sensor circuit

malfunction (PRNDL input) Multiple signals are inputted

simultaneously. 1 driving cycle

�) P0707 Transmission range sensor circuit

low No sensor signal is inputted.

2 driving cycles

�) P0712 Transmission fluid temperature

sensor “A” circuit low Sensor output voltage is too low.

1 driving cycle

�) P0713 Transmission fluid temperature

sensor “A” circuit high Sensor output voltage is too high.

1 driving cycle

�) P0717 Input / Turbine speed sensor circuit

no signal No sensor signal is detected although output

speed sensor signal is inputted.

1 driving cycle

�) P0722 Output speed sensor circuit no signal No sensor signal is inputted although input

speed sensor signal is inputted. 1 driving cycle

�) P0787 Shift / Timing solenoid low Voltage of timing solenoid terminal is low

although TCM is commanding timing solenoid

to turn ON. 1 driving cycle

�) P0788 Shift / Timing solenoid high Voltage of timing solenoid terminal is high

although TCM is commanding timing solenoid

to turn OFF. 1 driving cycle

�) P0961 Pressure control solenoid “A” control

circuit range / performance Difference between target current of control

solenoid valve circuit and monitor current of

control solenoid valve circuit is more than

specification.

1 driving cycle

�) P0962 Pressure control solenoid “A” control

circuit low No electric flow is detected on pressure control

solenoid circuit.

1 driving cycle

�) P0963 Pressure control solenoid “A” control

circuit high Too much electric flow is detected on pressure

control solenoid circuit.

1 driving cycle

�) P0973 Shift solenoid “A” control circuit low Voltage of shift solenoid terminal is low

although TCM is commanding shift solenoid to

turn ON. 1 driving cycle

�) P0974 Shift solenoid “A” control circuit high Voltage of shift solenoid terminal is high

although TCM is commanding shift solenoid to

turn OFF. 1 driving cycle

�) P0976 Shift solenoid “B” control circuit low Voltage of shift solenoid terminal is low

although TCM is commanding shift solenoid to

turn ON. 1 driving cycle

�) P0977 Shift solenoid “B” control circuit high Voltage of shift solenoid terminal is high

although TCM is commanding shift solenoid to

turn OFF. 1 driving cycle

�) P1702 Internal control module memory

check sum error Calculation of current data stored in TCM is not

correct comparing with pre-stored checking

data in TCM.

1 driving cycle

�) P1703 CAN invalid data - TCM TCM receives malfunction signal of throttle

position

, engine coolan t temperature, engine

revolution and engine torque from ECM. *1, 1 driving cycle

�) P1723 Range select switch malfunction “3” position switch ON signal is inputted

although transmission range switch signal is

inputted P, R, N or L. range. *1, 1 driving cycle

�) P1774 Control module communication bus

off Transmitting and receiving error detected to

TCM for specified time continuously.

1 driving cycle

Page 664 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-20 Automatic Transmission/Transaxle:

DTC CheckS7RS0B5104006

1) Turn ignition switch OFF.

2) Connect SUZUKI scan tool to DLC (1).

Special tool

(A): SUZUKI scan tool

3) Read DTC according to instructions displayed on SUZUKI scan tool and wr ite it down. Refer to

SUZUKI scan tool operator’s manual for further

details.

4) After completing the check, turn ignition switch OFF

and disconnect SUZUKI scan tool from DLC.

DTC ClearanceS7RS0B5104007

NOTE

DTC and freeze frame data stored in TCM

memory are also cleared in following cases.

Be careful not to clear them before keeping

their record.

• When power to TCM is cut off (by disconnecting battery cable, removing

fuse or disconnecting TCM connector).

• When the same malfunction (DTC) is not detected again during 40 engine warm-up

cycles.

1) Turn ignition switch OFF.

2) Connect SUZUKI scan tool to data link connector (DLC) (1).

Special tool

(A): SUZUKI scan tool

3) Clear DTC according to instructions displayed on SUZUKI scan tool. Refer to SUZUKI scan tool

operator’s manual for further details.

4) After completing the clearance, turn ignition switch OFF and disconnected SUZUKI scan tool from data

link connector (DLC).

�)

P1777 TCM lost communication with ECM

(Reception error) Receiving error from ECM detected to TCM for

specified time continuously.

1 driving cycle

�) P1778 TCM lost communication with BCM

(Reception error) Receiving error from BCM detected to TCM for

specified time continuously.

*1, 1 driving cycle

�) P1878 Torque converter clutch shudder Variation in the output revolution speed of the

specified amplitude and specified cycle is

detected under slip lock-up condition. *1, 20 driving cycle

�) P2762 Torque converter clutch pressure

control solenoid control circuit range /

performance Difference between target current of TCC

solenoid valve circuit and monitor current of

TCC solenoid valve ci

rcuit is more than

specification. 1 driving cycle

�) P2763 Torque converter clutch pressure

control solenoid control circuit high Too much electric flow is detected on TCC

solenoid circuit.

1 driving cycle

�) P2764 Torque converter clutch pressure

control solenoid control circuit range /

performance Difference between target current of TCC

solenoid valve circuit and current of TCC

solenoid valve circuit is more than

specification.

1 driving cycle

DTC No. Detecting item

Detecting condition

(DTC will set when detecting) A

1

(A)I4RS0B510004-01

1

(A)I4RS0B510004-01

Page 665 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-21

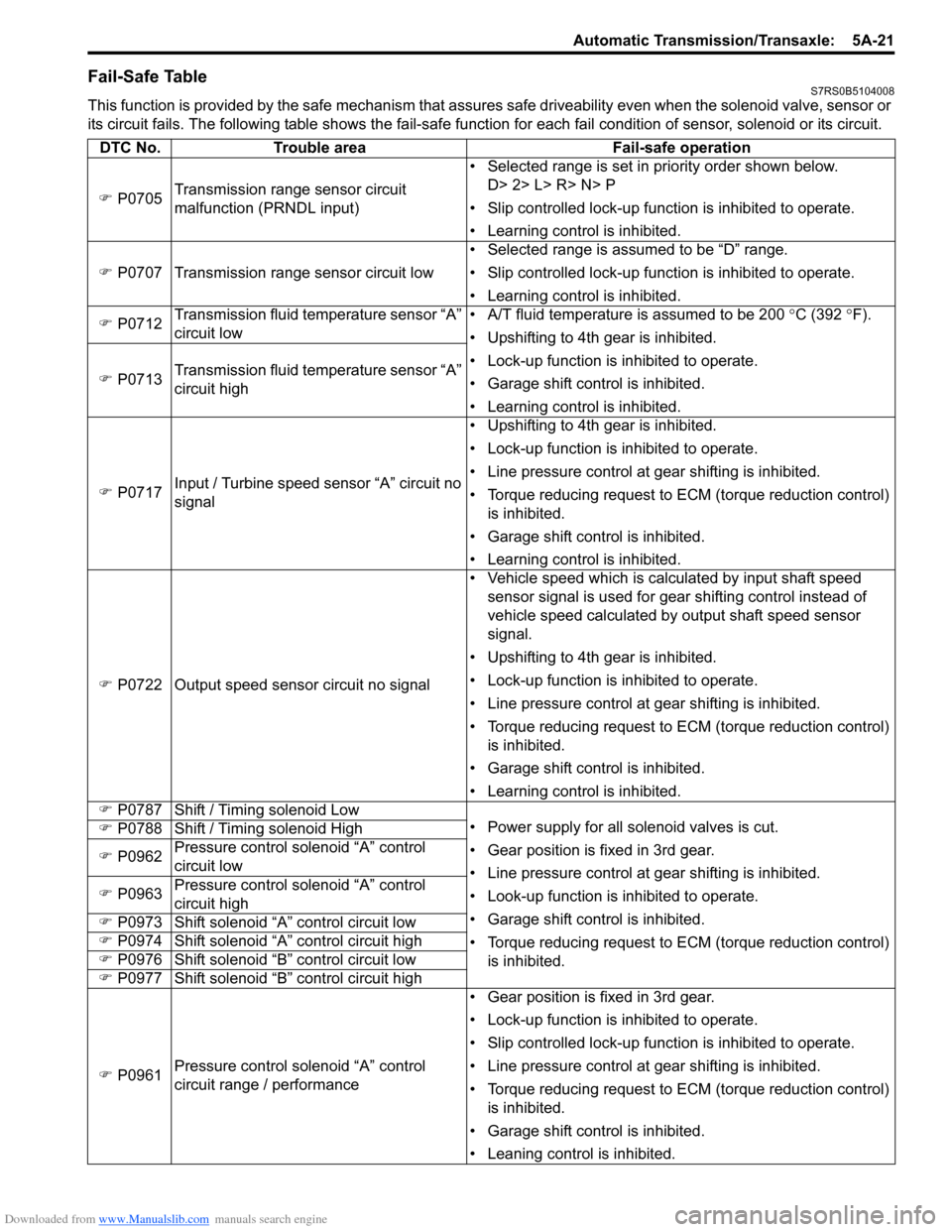

Fail-Safe TableS7RS0B5104008

This function is provided by the safe mechanism that assures safe driveability even when the solenoid valve, sensor or

its circuit fails. The following table shows th e fail-safe function for each fail condition of sensor, solenoid or its circuit.

DTC No. Trouble area Fail-safe operation

�) P0705 Transmission range sensor circuit

malfunction (PRNDL input) • Selected range is set in priority order shown below.

D> 2> L> R> N> P

• Slip controlled lock-up function is inhibited to operate.

• Learning control is inhibited.

�) P0707 Transmission range sensor circuit low • Selected range is assumed to be “D” range.

• Slip controlled lock-up function is inhibited to operate.

• Learning control is inhibited.

�) P0712 Transmission fluid temperature sensor “A”

circuit low • A/T fluid temperature is assumed to be 200

°C (392 °F).

• Upshifting to 4th gear is inhibited.

• Lock-up function is inhibited to operate.

• Garage shift control is inhibited.

• Learning control is inhibited.

�)

P0713 Transmission fluid temperature sensor “A”

circuit high

�) P0717 Input / Turbine speed sensor “A” circuit no

signal • Upshifting to 4th gear is inhibited.

• Lock-up function is inhibited to operate.

• Line pressure control at gear shifting is inhibited.

• Torque reducing request to ECM (torque reduction control)

is inhibited.

• Garage shift control is inhibited.

• Learning control is inhibited.

�) P0722 Output speed sensor circuit no signal • Vehicle speed which is calculated by input shaft speed

sensor signal is used for gear shifting control instead of

vehicle speed calculated by output shaft speed sensor

signal.

• Upshifting to 4th gear is inhibited.

• Lock-up function is inhibited to operate.

• Line pressure control at gear shifting is inhibited.

• Torque reducing request to ECM (torque reduction control) is inhibited.

• Garage shift control is inhibited.

• Learning control is inhibited.

�) P0787 Shift / Timing solenoid Low

• Power supply for all solenoid valves is cut.

• Gear position is fixed in 3rd gear.

• Line pressure control at gear shifting is inhibited.

• Look-up function is inhibited to operate.

• Garage shift control is inhibited.

• Torque reducing request to ECM (torque reduction control)

is inhibited.

�)

P0788 Shift / Timing solenoid High

�) P0962 Pressure control solenoid “A” control

circuit low

�) P0963 Pressure control solenoid “A” control

circuit high

�) P0973 Shift solenoid “A” control circuit low

�) P0974 Shift solenoid “A” control circuit high

�) P0976 Shift solenoid “B” control circuit low

�) P0977 Shift solenoid “B” control circuit high

�) P0961 Pressure control solenoid “A” control

circuit range / performance • Gear position is fixed in 3rd gear.

• Lock-up function is inhibited to operate.

• Slip controlled lock-up function is inhibited to operate.

• Line pressure control at gear shifting is inhibited.

• Torque reducing request to ECM (torque reduction control)

is inhibited.

• Garage shift control is inhibited.

• Leaning control is inhibited.

Page 666 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-22 Automatic Transmission/Transaxle:

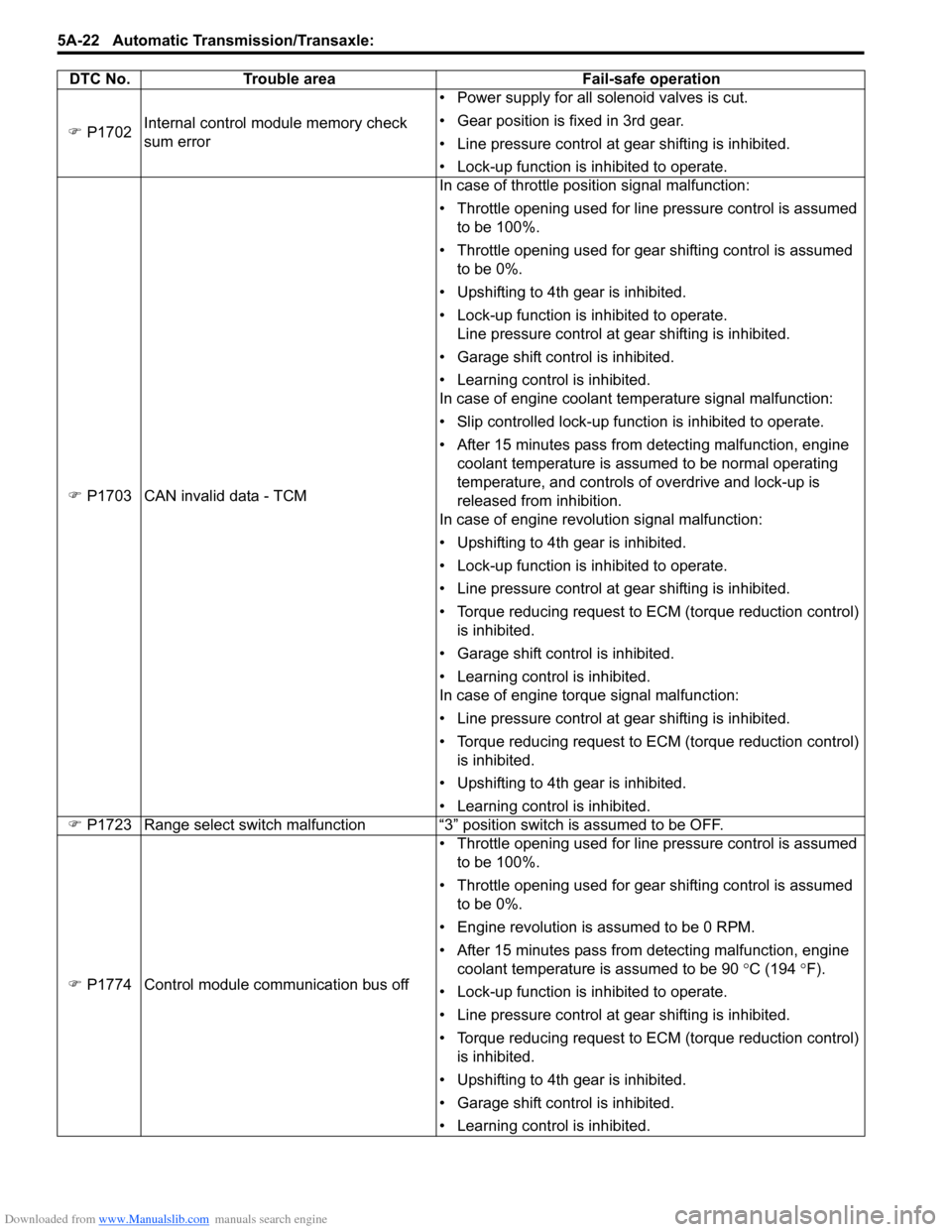

�) P1702 Internal control module memory check

sum error • Power supply for all solenoid valves is cut.

• Gear position is fixed in 3rd gear.

• Line pressure control at gear shifting is inhibited.

• Lock-up function is inhibited to operate.

�) P1703 CAN invalid data - TCM In case of throttle position signal malfunction:

• Throttle opening used for line pressure control is assumed

to be 100%.

• Throttle opening used for gear shifting control is assumed to be 0%.

• Upshifting to 4th gear is inhibited.

• Lock-up function is inhibited to operate. Line pressure control at gear shifting is inhibited.

• Garage shift control is inhibited.

• Learning control is inhibited.

In case of engine coolant temperature signal malfunction:

• Slip controlled lock-up function is inhibited to operate.

• After 15 minutes pass from detecting malfunction, engine coolant temperature is assumed to be normal operating

temperature, and controls of overdrive and lock-up is

released from inhibition.

In case of engine revolution signal malfunction:

• Upshifting to 4th gear is inhibited.

• Lock-up function is inhibited to operate.

• Line pressure control at gear shifting is inhibited.

• Torque reducing request to ECM (torque reduction control) is inhibited.

• Garage shift control is inhibited.

• Learning control is inhibited.

In case of engine torque signal malfunction:

• Line pressure control at gear shifting is inhibited.

• Torque reducing request to ECM (torque reduction control) is inhibited.

• Upshifting to 4th gear is inhibited.

• Learning control is inhibited.

�) P1723 Range select switch malfunction “3” position switch is assumed to be OFF.

�) P1774 Control module communication bus off • Throttle opening used for line pressure control is assumed

to be 100%.

• Throttle opening used for gear shifting control is assumed to be 0%.

• Engine revolution is assumed to be 0 RPM.

• After 15 minutes pass from detecting malfunction, engine coolant temperature is assumed to be 90 °C (194 °F).

• Lock-up function is inhibited to operate.

• Line pressure control at gear shifting is inhibited.

• Torque reducing request to ECM (torque reduction control) is inhibited.

• Upshifting to 4th gear is inhibited.

• Garage shift control is inhibited.

• Learning control is inhibited.

DTC No. Trouble area Fail-safe operation

Page 667 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-23

Scan Tool DataS7RS0B5104009

As the data values given in the following table are standard values estimated on the basis of values obtained from the

normally operating vehicles by using a scan tool, use them as reference values. Even when the vehicle is in good

condition, there may be cases where the checked value does not fall within each specified data range. Therefore,

judgment as abnormal should not be made by checking with these data alone.

Also, condition in the following table that can be checked by the scan tool are those detected by TCM and output from

TCM as commands and there may be cases where the auto matic transaxle or actuator is not operating (in the

condition) as indicated by the scan tool.

NOTE

The following scan tool data related to automatic transaxle can be checked only by communicating

with TCM.

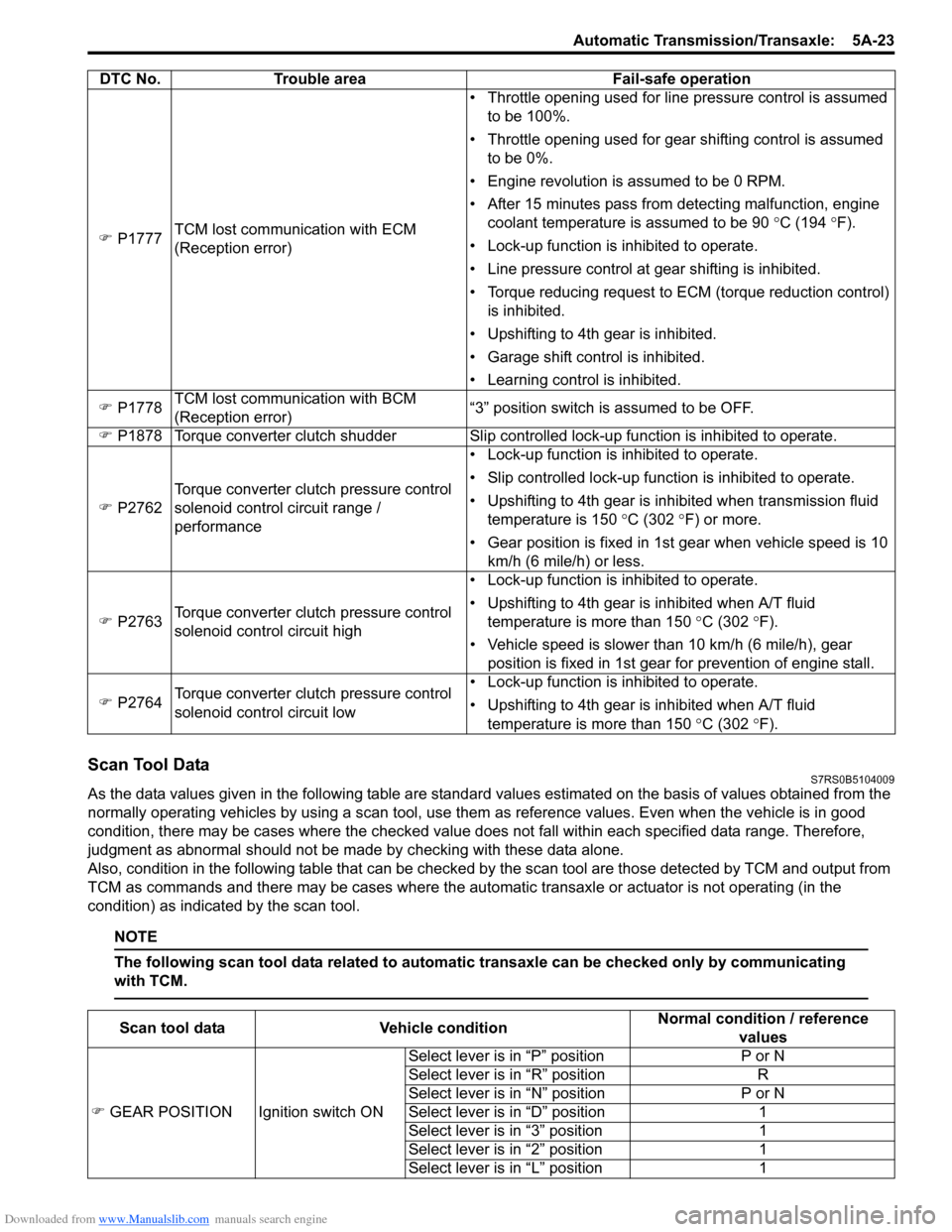

�) P1777 TCM lost communication with ECM

(Reception error) • Throttle opening used for line pressure control is assumed

to be 100%.

• Throttle opening used for gear shifting control is assumed to be 0%.

• Engine revolution is assumed to be 0 RPM.

• After 15 minutes pass from detecting malfunction, engine coolant temperature is assumed to be 90 °C (194 °F).

• Lock-up function is inhibited to operate.

• Line pressure control at gear shifting is inhibited.

• Torque reducing request to ECM (torque reduction control) is inhibited.

• Upshifting to 4th gear is inhibited.

• Garage shift control is inhibited.

• Learning control is inhibited.

�) P1778 TCM lost communication with BCM

(Reception error) “3” position switch is assumed to be OFF.

�) P1878 Torque converter clutch shudder Slip contro lled lock-up function is inhibited to operate.

�) P2762 Torque converter clutch pressure control

solenoid control circuit range /

performance • Lock-up function is inhibited to operate.

• Slip controlled lock-up function is inhibited to operate.

• Upshifting to 4th gear is inhibited when transmission fluid

temperature is 150 °C (302 ° F) or more.

• Gear position is fixed in 1st gear when vehicle speed is 10 km/h (6 mile/h) or less.

�) P2763 Torque converter clutch pressure control

solenoid control circuit high • Lock-up function is inhibited to operate.

• Upshifting to 4th gear is inhibited when A/T fluid

temperature is more than 150 °C (302 °F).

• Vehicle speed is slower than 10 km/h (6 mile/h), gear position is fixed in 1st gear for prevention of engine stall.

�) P2764 Torque converter clutch pressure control

solenoid control circuit low • Lock-up function is inhibited to operate.

• Upshifting to 4th gear is inhibited when A/T fluid

temperature is more than 150 °C (302 °F).

DTC No. Trouble area Fail-safe operation

Scan tool data

Vehicle condition Normal condition / reference

values

�) GEAR POSITION Ignition switch ON Select lever is in “P” position

P or N

Select lever is in “R” position R

Select lever is in “N” position P or N

Select lever is in “D” position 1

Select lever is in “3” position 1

Select lever is in “2” position 1

Select lever is in “L” position 1

Page 668 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-24 Automatic Transmission/Transaxle:

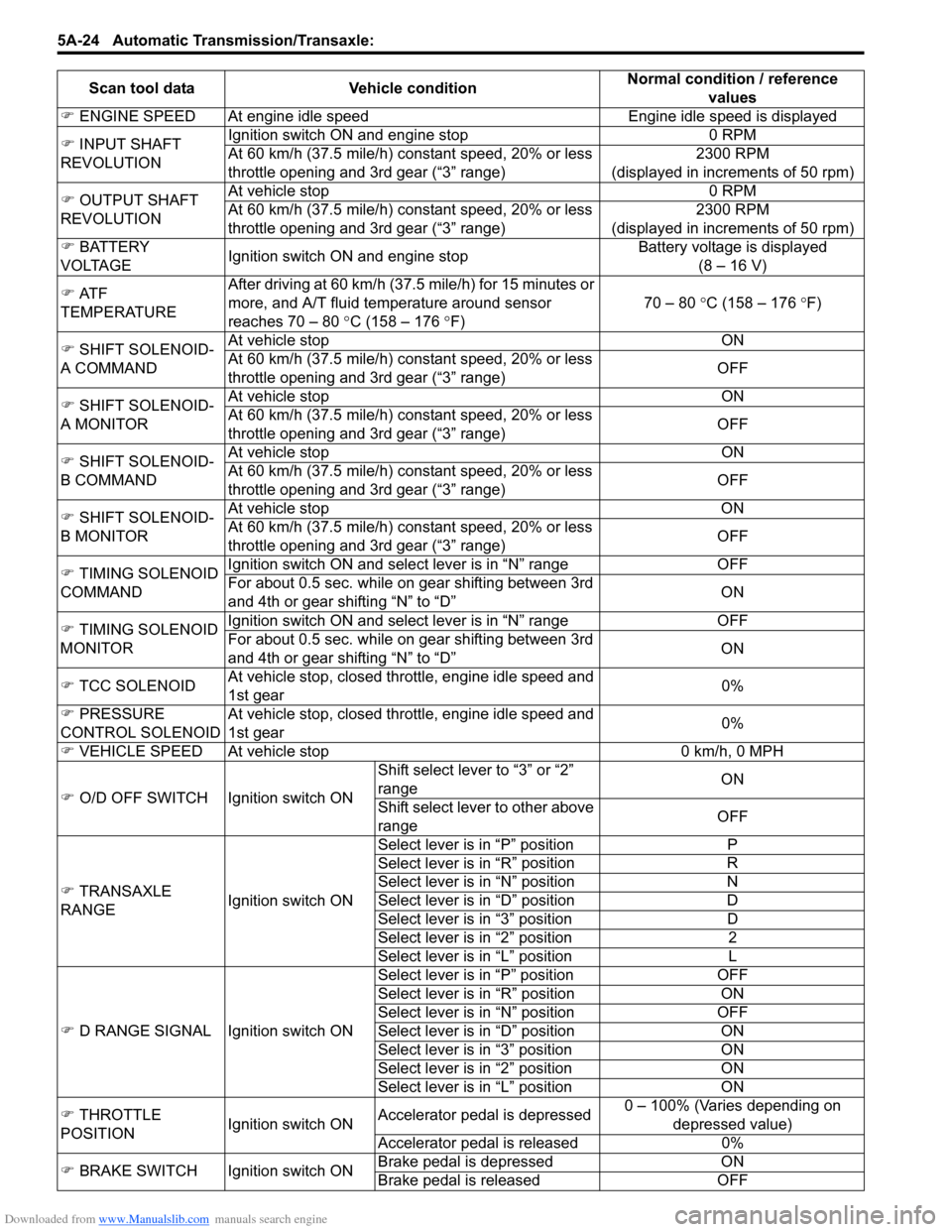

�) ENGINE SPEED At engine idle spee d Engine idle speed is displayed

�) INPUT SHAFT

REVOLUTION Ignition switch ON and engine stop 0 RPM

At 60 km/h (37.5 mile/h) constant speed, 20% or less

throttle opening and 3rd gear (“3” range)

2300 RPM

(displayed in increments of 50 rpm)

�) OUTPUT SHAFT

REVOLUTION At vehicle stop 0 RPM

At 60 km/h (37.5 mile/h) constant speed, 20% or less

throttle opening and 3rd gear (“3” range)

2300 RPM

(displayed in increments of 50 rpm)

�) BATTERY

VOLTAGE Ignition switch ON and engine stop Battery voltage is displayed

(8 – 16 V)

�) AT F

TEMPERATURE After driving at 60 km/h (37.5 mile/h) for 15 minutes or

more, and A/T fluid temperature around sensor

reaches 70 – 80

°C (158 – 176 °F) 70 – 80

°C (158 – 176 °F)

�) SHIFT SOLENOID-

A COMMAND At vehicle stop ON

At 60 km/h (37.5 mile/h) constant speed, 20% or less

throttle opening and 3rd gear (“3” range)

OFF

�) SHIFT SOLENOID-

A MONITOR At vehicle stop ON

At 60 km/h (37.5 mile/h) constant speed, 20% or less

throttle opening and 3rd gear (“3” range)

OFF

�) SHIFT SOLENOID-

B COMMAND At vehicle stop ON

At 60 km/h (37.5 mile/h) constant speed, 20% or less

throttle opening and 3rd gear (“3” range)

OFF

�) SHIFT SOLENOID-

B MONITOR At vehicle stop ON

At 60 km/h (37.5 mile/h) constant speed, 20% or less

throttle opening and 3rd gear (“3” range)

OFF

�) TIMING SOLENOID

COMMAND Ignition switch ON and sele

ct lever is in “N” range OFF

For about 0.5 sec. while on gear shifting between 3rd

and 4th or gear shifting “N” to “D” ON

�) TIMING SOLENOID

MONITOR Ignition switch ON and sele

ct lever is in “N” range OFF

For about 0.5 sec. while on gear shifting between 3rd

and 4th or gear shifting “N” to “D” ON

�) TCC SOLENOID At vehicle stop, closed throttle, engine idle speed and

1st gear 0%

�) PRESSURE

CONTROL SOLENOID At vehicle stop, closed throttle, engine idle speed and

1st gear

0%

�) VEHICLE SPEED At vehicle stop 0 km/h, 0 MPH

�) O/D OFF SWITCH Ignition switch ON Shift select lever to “3” or “2”

range

ON

Shift select lever to other above

range OFF

�) TRANSAXLE

RANGE Ignition switch ONSelect lever is in “P” position P

Select lever is in “R

” position R

Select lever is in “N” position N

Select lever is in “D” position D

Select lever is in “3” position D

Select lever is in “2” position 2

Select lever is in “L” position L

�) D RANGE SIGNAL Ignition switch ON Select lever is in “P” position

OFF

Select lever is in “R” position ON

Select lever is in “N” position OFF

Select lever is in “D” position ON

Select lever is in “3” position ON

Select lever is in “2” position ON

Select lever is in “L” position ON

�) THROTTLE

POSITION Ignition switch ONAccelerator peda

l is depressed 0 – 100% (Varies depending on

depressed value)

Accelerator peda l is released 0%

�) BRAKE SWITCH Ignition switch ON Brake pedal is depressed

ON

Brake pedal is released OFF

Scan tool data

Vehicle condition Normal condition / reference

values

Page 669 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-25

Scan Tool Data Definitions:

GEAR POSITION

Current gear position computed by throttle position

coming from ECM and vehicle speed.

ENGINE SPEED (RPM)

Engine speed computed by reference pulses from

crankshaft position sensor.

INPUT SHAFT REVOLUTION (RPM)

Input shaft revolution computed by reference pulses

coming from input shaft speed sensor on transaxle case.

OUTPUT SHAFT REVOLUTION (RPM)

Output shaft revolution computed by reference pulses

coming from output shaft speed sensor on transaxle

case.

BATTERY VOLTAGE (V)

Battery voltage read by TCM as analog input signal by

TCM.

ATF TEMPERATURE (°C, °F)

ATF temperature decided by signal from transmission

fluid temperature sensor installed on valve body.

SHIFT SOLENOID-A COMMAND

ON: ON command being outputted to shift solenoid

valve-A (No.1)

OFF: ON command not being outputted to shift solenoid

valve-A (No.1)

SHIFT SOLENOID-A MONITOR

ON: Electricity being passed to shift solenoid valve-A

(No.1)

OFF: Electricity not being passed to shift solenoid valve-

A (No.1)

SHIFT SOLENOID-B COMMAND

ON: ON command being outputted to shift solenoid

valve-B (No.2) OFF: ON command not being outputted to shift solenoid

valve-B (No.2)

SHIFT SOLENOID-B MONITOR

ON: Electricity being passed to shift solenoid valve-B

(No.2)

OFF: Electricity not being passed to shift solenoid valve-

B (No.2)

TIMING SOLENOID COMMAND

ON: ON command being outputted to timing solenoid

valve

OFF: ON command not being outputted to timing

solenoid valve

TIMING SOLENOID MONITOR

ON: Electricity being passed to timing solenoid valve

OFF: Electricity not being passed to timing solenoid

valve

TCC SOLENOID

Electric current value ratio between electric current value

being outputted from TCM to solenoid and maximum

value can be outputted by TCM.

PRESSURE CONTROL SOLENOID

Electric current value ratio between electric current value

being outputted from TCM to solenoid and maximum

value can be outputted by TCM.

VEHICLE SPEED (KPH/MPH)

Vehicle speed computed by reference pulse signals

coming from vehicle speed sensor on transaxle case.

O/D OFF SWITCH (“3” position switch)

Inputted signal from “3” position switch in select lever

assembly.

ON: Shift select lever to “3” or “2” range

OFF: Shift select lever to other above range

�)

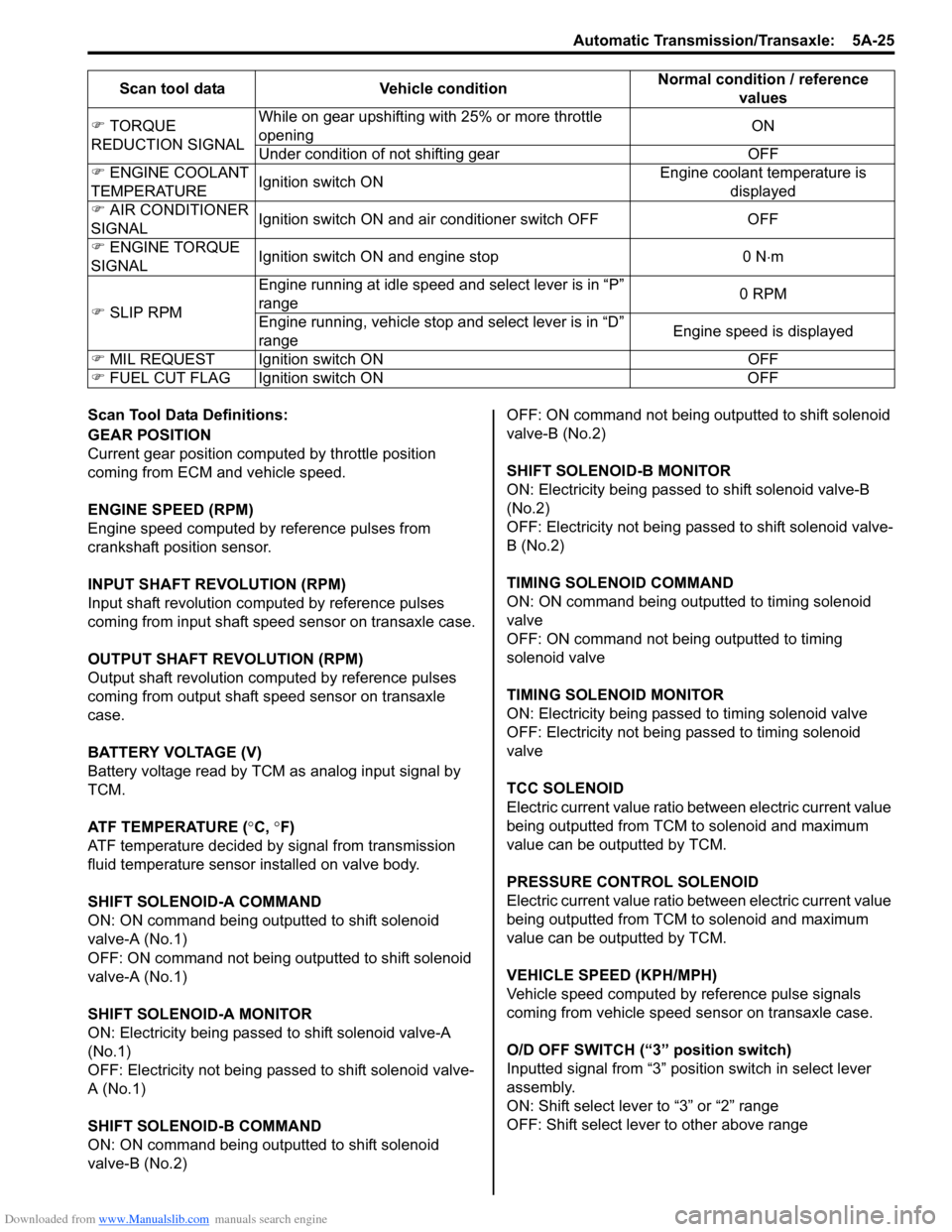

TORQUE

REDUCTION SIGNAL While on gear upshifting with 25% or more throttle

opening

ON

Under condition of not shifting gear OFF

�) ENGINE COOLANT

TEMPERATURE Ignition switch ON Engine coolant temperature is

displayed

�) AIR CONDITIONER

SIGNAL Ignition switch ON and air conditioner switch OFF OFF

�) ENGINE TORQUE

SIGNAL Ignition switch ON and engine stop 0 N

⋅m

�) SLIP RPM Engine running at idle speed

and select lever is in “P”

range 0 RPM

Engine running, vehicle stop and select lever is in “D”

range Engine speed is displayed

�) MIL REQUEST Ignition switch ON OFF

�) FUEL CUT FLAG Ignition switch ON OFFScan tool data Vehicle condition

Normal condition / reference

values

Page 670 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-26 Automatic Transmission/Transaxle:

TRANSAXLE RANGE

Transaxle range detected by signal fed from

transmission range sensor.

D RANGE SIGNAL

ON: Signal which TCM require ECM to increase idle

speed

OFF: Signal which TCM does not require ECM to

increase idle speed

THROTTLE POSITION (%)

Throttle opening ratio computed by CAN signal from

ECM.

BRAKE SWITCH

Inputted signal from brake light switch on pedal bracket.

ON: Brake pedal depressed

OFF: Brake pedal released

TORQUE REDUCTION SIGNAL

ON: Signal which TCM require ECM to reduce output

torque at shifting gear

OFF: Signal which TCM does not require ECM to reduce

output torque

ENGINE COOLANT TEMPERATURE ( °C, °F)

Engine coolant temperature computed by CAN signal

from ECM. AIR CONDITIONER SIGNAL

ON: Signal which inform that air conditioner compressor

is turned ON.

OFF: Signal which inform that air conditioner

compressor is not turned ON.

ENGINE TORQUE SIGNAL (N

⋅m)

Engine torque computed by duty pulse signal outputted

from ECM.

SLIP RPM (RPM)

This parameter indicates slip ping rotation in the torque

converter (difference between input shaft rotation and

engine rotation)

MIL REQUEST

ON: Signal which TCM requires combination meter to

turn on malfunction indicator lamp.

OFF: Signal which TCM does not require combination

meter to turn on malf unction indicator lamp.

FUEL CUT FLAG

ON: Signal which inform that fuel cut is operating.

OFF: Signal which inform that fuel cut is not operating.

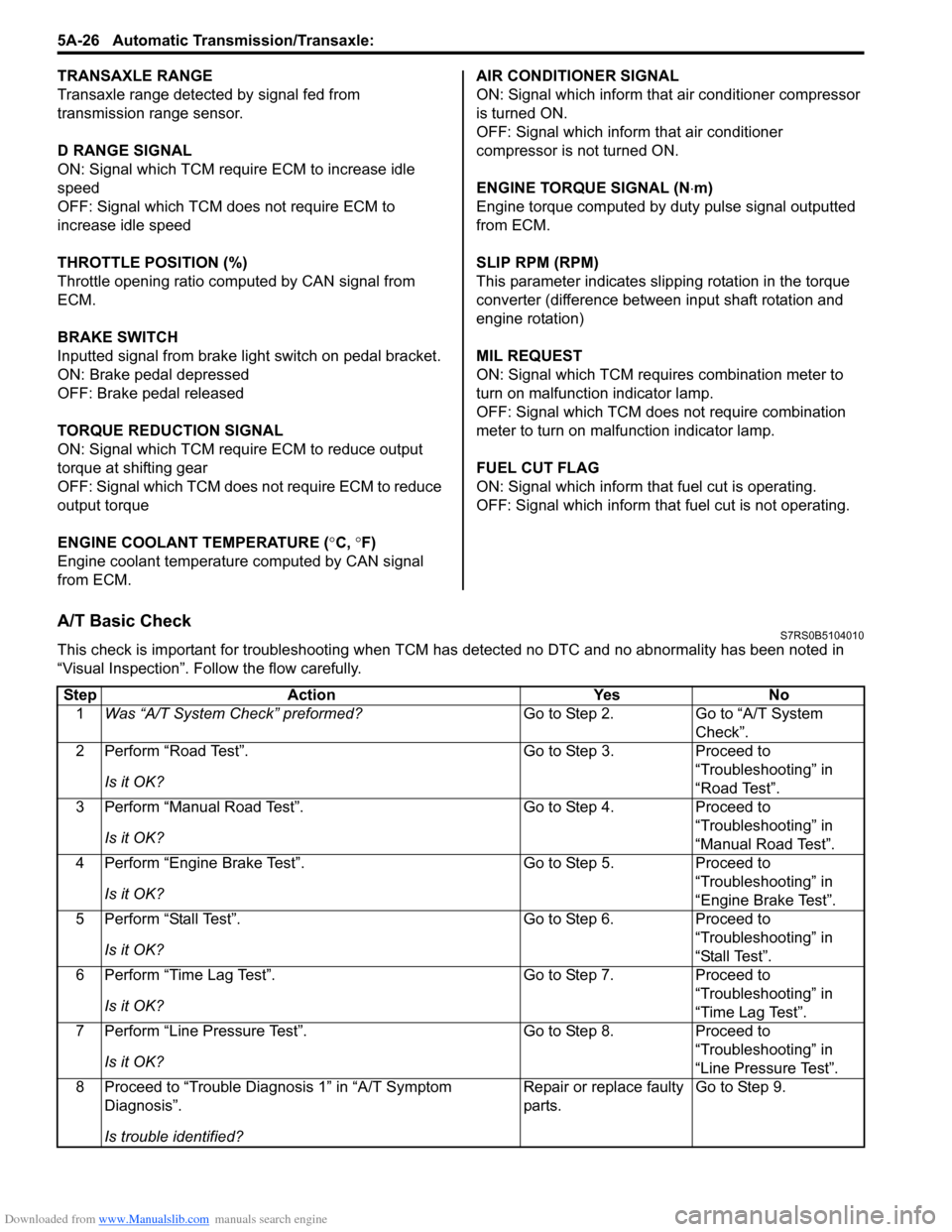

A/T Basic CheckS7RS0B5104010

This check is important for troubleshooting when TCM has detected no DTC and no abnormality has been noted in

“Visual Inspection”. Fo llow the flow carefully.

Step Action YesNo

1 Was “A/T System Check” preformed? Go to Step 2.Go to “A/T System

Check”.

2 Perform “Road Test”.

Is it OK? Go to Step 3.

Proceed to

“Troubleshooting” in

“Road Test”.

3 Perform “Manual Road Test”.

Is it OK? Go to Step 4.

Proceed to

“Troubleshooting” in

“Manual Road Test”.

4 Perform “Engine Brake Test”.

Is it OK? Go to Step 5.

Proceed to

“Troubleshooting” in

“Engine Brake Test”.

5 Perform “Stall Test”.

Is it OK? Go to Step 6.

Proceed to

“Troubleshooting” in

“Stall Test”.

6 Perform “Time Lag Test”.

Is it OK? Go to Step 7.

Proceed to

“Troubleshooting” in

“Time Lag Test”.

7 Perform “Line Pressure Test”.

Is it OK? Go to Step 8.

Proceed to

“Troubleshooting” in

“Line Pressure Test”.

8 Proceed to “Trouble Diag nosis 1” in “A/T Symptom

Diagnosis”.

Is trouble identified? Repair or replace faulty

parts.

Go to Step 9.

Page 671 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-27

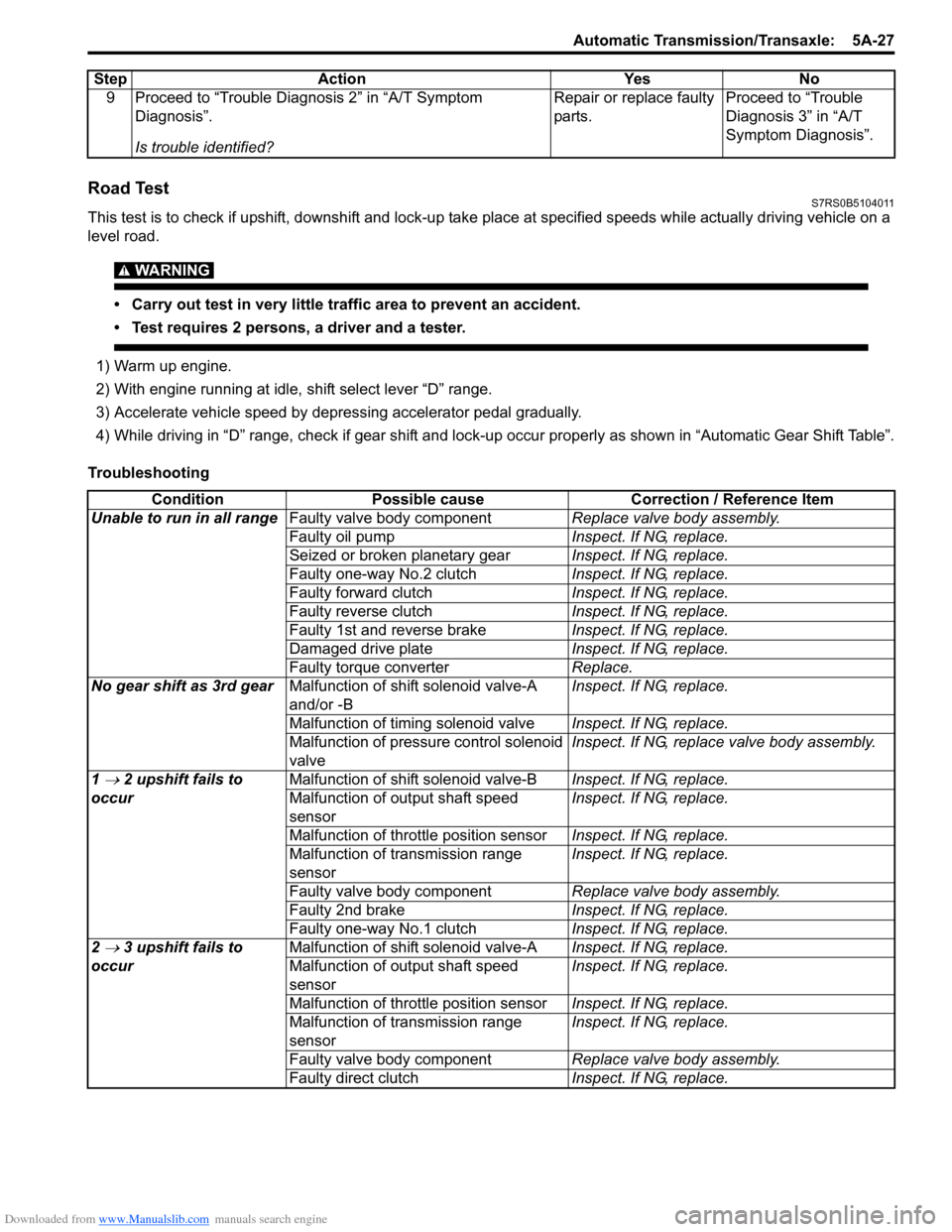

Road TestS7RS0B5104011

This test is to check if upshift, downshift and lock-up take place at specified speeds while actually driving vehicle on a

level road.

WARNING!

• Carry out test in very little traffic area to prevent an accident.

• Test requires 2 persons, a driver and a tester.

1) Warm up engine.

2) With engine running at idle, shift select lever “D” range.

3) Accelerate vehicle speed by depressing accelerator pedal gradually.

4) While driving in “D” range, check if gear shift and lock-up occur properly as shown in “Automatic Gear Shift Table”.

Troubleshooting 9 Proceed to “Trouble Diag

nosis 2” in “A/T Symptom

Diagnosis”.

Is trouble identified? Repair or replace faulty

parts.

Proceed to “Trouble

Diagnosis 3” in “A/T

Symptom Diagnosis”.

Step Action Yes No

Condition

Possible cause Correction / Reference Item

Unable to run in all range Faulty valve body component Replace valve body assembly.

Faulty oil pump Inspect. If NG, replace.

Seized or broken planetary gear Inspect. If NG, replace.

Faulty one-way No.2 clutch Inspect. If NG, replace.

Faulty forward clutch Inspect. If NG, replace.

Faulty reverse clutch Inspect. If NG, replace.

Faulty 1st and reverse brake Inspect. If NG, replace.

Damaged drive plate Inspect. If NG, replace.

Faulty torque converter Replace.

No gear shift as 3rd gear Malfunction of shift solenoid valve-A

and/or -B Inspect. If NG, replace.

Malfunction of timing solenoid valve Inspect. If NG, replace.

Malfunction of pressure control solenoid

valve Inspect. If NG, replace valve body assembly.

1

→ 2 upshift fails to

occur Malfunction of shif

t solenoid valve-B Inspect. If NG, replace.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of throttle position sensor Inspect. If NG, replace.

Malfunction of transmission range

sensor Inspect. If NG, replace.

Faulty valve body component Replace valve body assembly.

Faulty 2nd brake Inspect. If NG, replace.

Faulty one-way No.1 clutch Inspect. If NG, replace.

2

→ 3 upshift fails to

occur Malfunction of shif

t solenoid valve-A Inspect. If NG, replace.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of throttle position sensor Inspect. If NG, replace.

Malfunction of transmission range

sensor Inspect. If NG, replace.

Faulty valve body component Replace valve body assembly.

Faulty direct clutch Inspect. If NG, replace.

Page 672 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-28 Automatic Transmission/Transaxle:

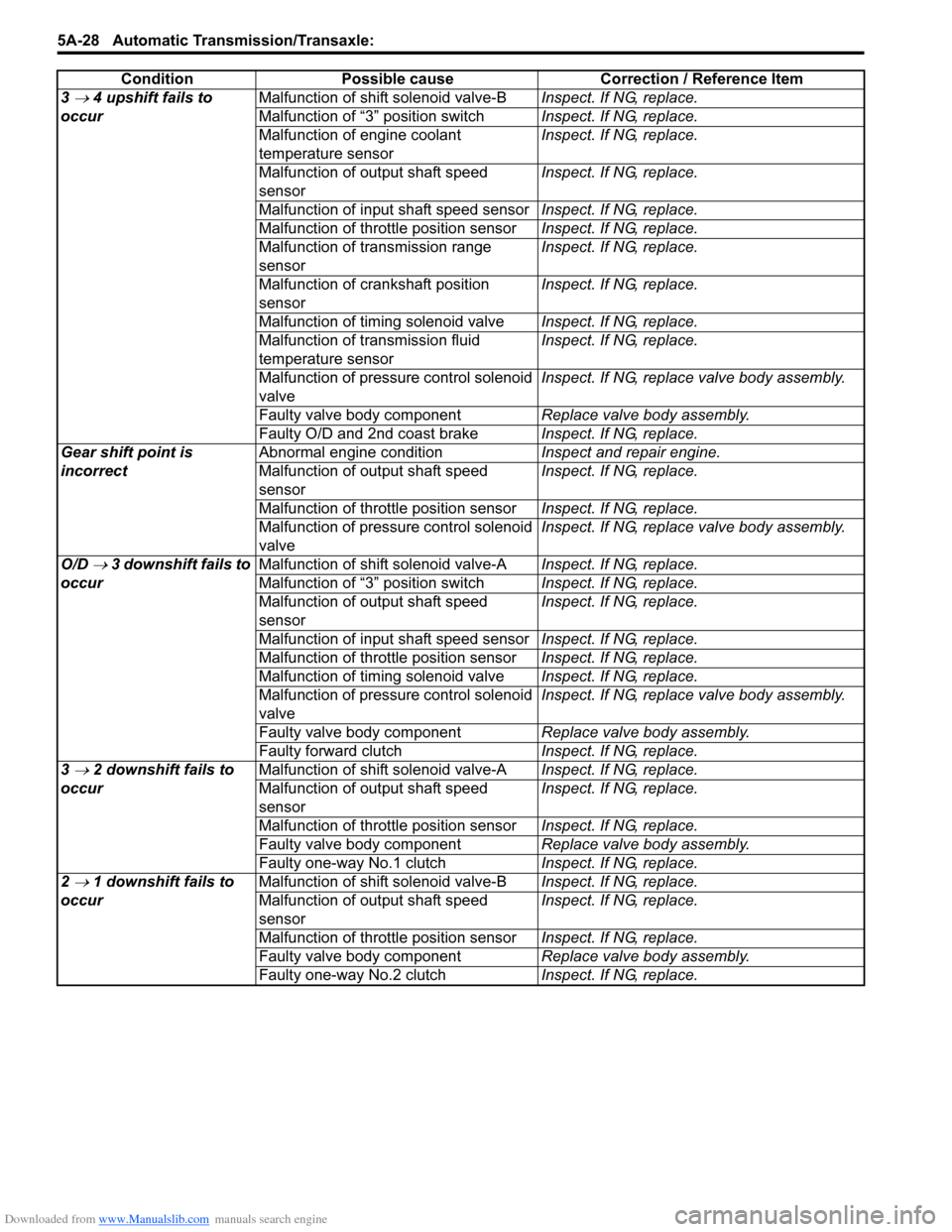

3 → 4 upshift fails to

occur Malfunction of shift solenoid valve-B

Inspect. If NG, replace.

Malfunction of “3” position switch Inspect. If NG, replace.

Malfunction of engine coolant

temperature sensor Inspect. If NG, replace.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of input shaft speed sensor Inspect. If NG, replace.

Malfunction of throttle position sensor Inspect. If NG, replace.

Malfunction of transmission range

sensor Inspect. If NG, replace.

Malfunction of crankshaft position

sensor Inspect. If NG, replace.

Malfunction of timing solenoid valve Inspect. If NG, replace.

Malfunction of transmission fluid

temperature sensor Inspect. If NG, replace.

Malfunction of pressure control solenoid

valve Inspect. If NG, replace valve body assembly.

Faulty valve body component Replace valve body assembly.

Faulty O/D and 2nd coast brake Inspect. If NG, replace.

Gear shift point is

incorrect Abnormal engine condition

Inspect and repair engine.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of throttle position sensor Inspect. If NG, replace.

Malfunction of pressure control solenoid

valve Inspect. If NG, replace valve body assembly.

O/D

→ 3 downshift fails to

occur Malfunction of shift solenoid valve-A

Inspect. If NG, replace.

Malfunction of “3” position switch Inspect. If NG, replace.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of input shaft speed sensor Inspect. If NG, replace.

Malfunction of throttle position sensor Inspect. If NG, replace.

Malfunction of timing solenoid valve Inspect. If NG, replace.

Malfunction of pressure control solenoid

valve Inspect. If NG, replace valve body assembly.

Faulty valve body component Replace valve body assembly.

Faulty forward clutch Inspect. If NG, replace.

3

→ 2 downshift fails to

occur Malfunction of shift solenoid valve-A

Inspect. If NG, replace.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of throttle position sensor Inspect. If NG, replace.

Faulty valve body component Replace valve body assembly.

Faulty one-way No.1 clutch Inspect. If NG, replace.

2

→ 1 downshift fails to

occur Malfunction of shift solenoid valve-B

Inspect. If NG, replace.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of throttle position sensor Inspect. If NG, replace.

Faulty valve body component Replace valve body assembly.

Faulty one-way No.2 clutch Inspect. If NG, replace.

Condition Possible cause Correction / Reference Item