water SUZUKI SWIFT 2008 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 527 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Brakes: 4C-3

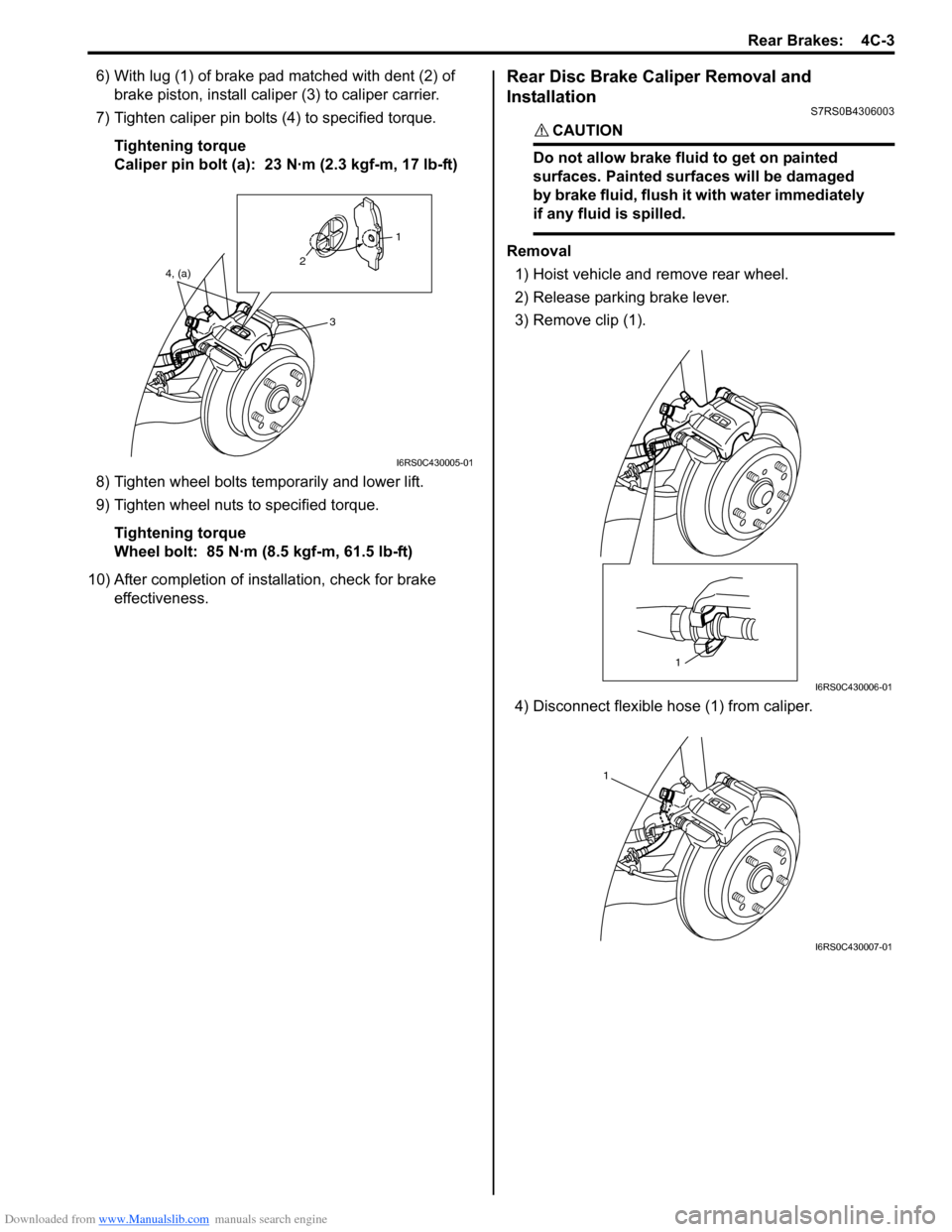

6) With lug (1) of brake pad matched with dent (2) of brake piston, install caliper (3) to caliper carrier.

7) Tighten caliper pin bolts (4) to specified torque.

Tightening torque

Caliper pin bolt (a): 23 N·m (2.3 kgf-m, 17 lb-ft)

8) Tighten wheel bolts temporarily and lower lift.

9) Tighten wheel nuts to specified torque. Tightening torque

Wheel bolt: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

10) After completion of installation, check for brake effectiveness.Rear Disc Brake Caliper Removal and

Installation

S7RS0B4306003

CAUTION!

Do not allow brake fluid to get on painted

surfaces. Painted surfaces will be damaged

by brake fluid, flush it with water immediately

if any fluid is spilled.

Removal

1) Hoist vehicle and remove rear wheel.

2) Release parking brake lever.

3) Remove clip (1).

4) Disconnect flexible hose (1) from caliper.

4, (a) 21

3

I6RS0C430005-01

1

I6RS0C430006-01

1

I6RS0C430007-01

Page 649 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-5

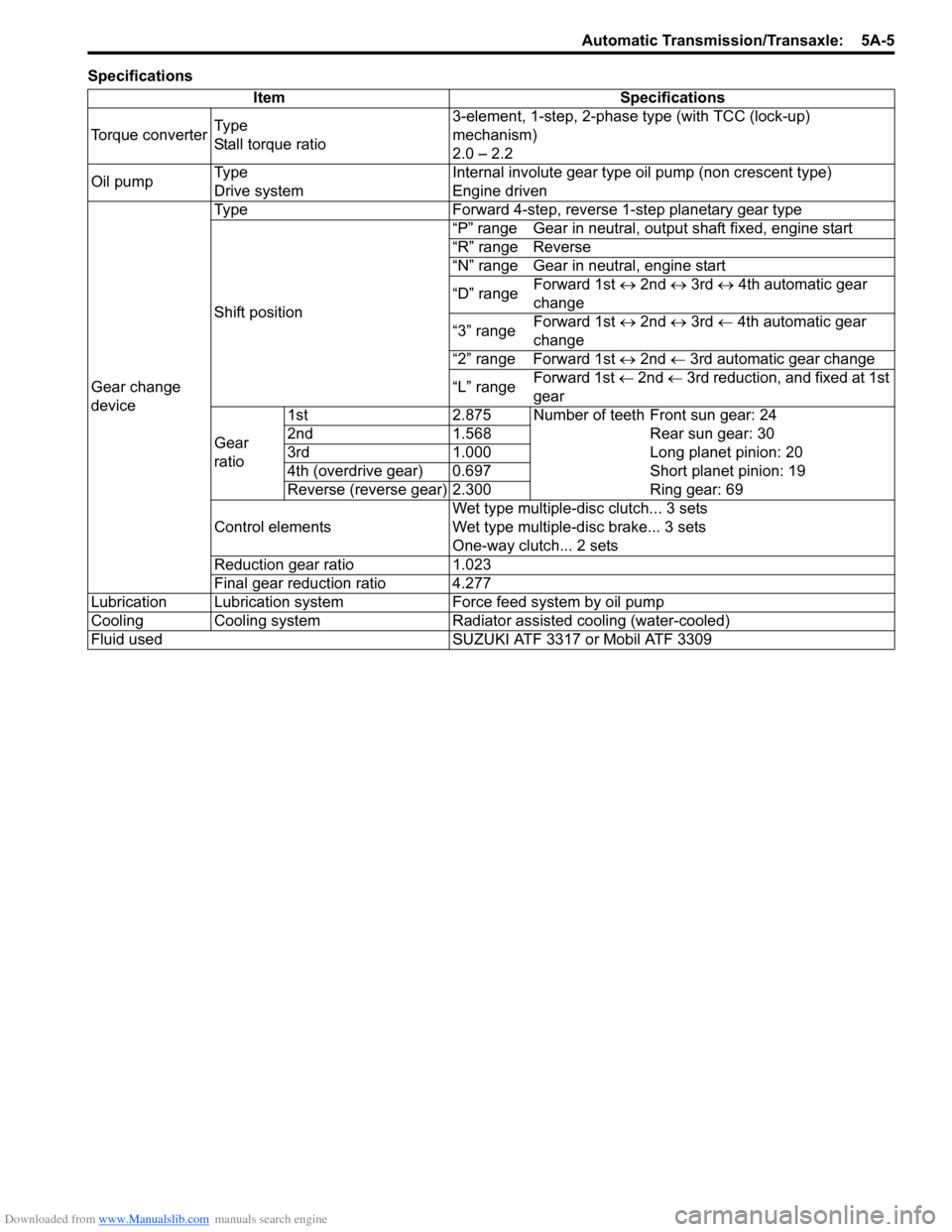

SpecificationsItem Specifications

Torque converter Ty p e

Stall torque ratio 3-element, 1-step, 2-phase type (with TCC (lock-up)

mechanism)

2.0 – 2.2

Oil pump Ty p e

Drive system Internal involute gear type oil pump (non crescent type)

Engine driven

Gear change

device Type Forward 4-step, reverse 1-step planetary gear type

Shift position

“P” range Gear in neutral, output shaft fixed, engine start

“R” range Reverse

“N” range Gear in neutral, engine start

“D” range

Forward 1st

↔ 2nd ↔ 3rd ↔ 4th automatic gear

change

“3” range Forward 1st

↔ 2nd ↔ 3rd ← 4th automatic gear

change

“2” range Forward 1st ↔ 2nd ← 3rd automatic gear change

“L” range Forward 1st

← 2nd ← 3rd reduction, and fixed at 1st

gear

Gear

ratio 1st 2.875 Number of teeth Front sun gear: 24

2nd 1.568 Rear sun gear: 30

3rd 1.000 Long planet pinion: 20

4th (overdrive gear) 0.697 Short planet pinion: 19

Reverse (reverse gear) 2.300 Ring gear: 69

Control elements Wet type multiple-disc clutch... 3 sets

Wet type multiple-d

isc brake... 3 sets

One-way clutch... 2 sets

Reduction gear ratio 1.023

Final gear reduction ratio 4.277

Lubrication Lubrication system Force feed system by oil pump

Cooling Cooling system Radiator assisted cooling (water-cooled)

Fluid used SUZUKI ATF 3317 or Mobil ATF 3309

Page 786 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-142 Automatic Transmission/Transaxle:

Differential Assembly Disassembly and

Reassembly

S7RS0B5106055

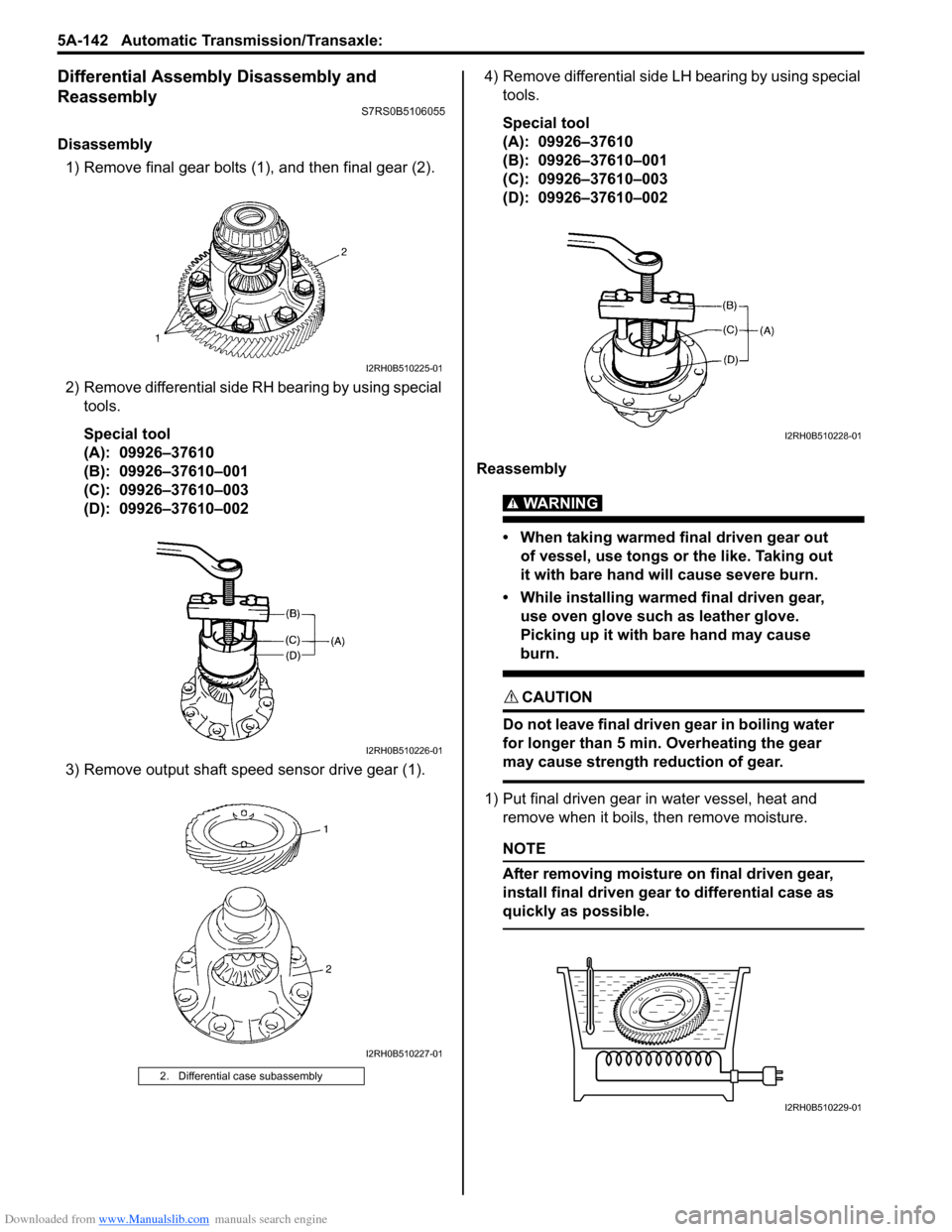

Disassembly1) Remove final gear bolts (1), and then final gear (2).

2) Remove differential side RH bearing by using special tools.

Special tool

(A): 09926–37610

(B): 09926–37610–001

(C): 09926–37610–003

(D): 09926–37610–002

3) Remove output shaft speed sensor drive gear (1). 4) Remove differential side LH bearing by using special

tools.

Special tool

(A): 09926–37610

(B): 09926–37610–001

(C): 09926–37610–003

(D): 09926–37610–002

Reassembly

WARNING!

• When taking warmed final driven gear out of vessel, use tongs or the like. Taking out

it with bare hand will cause severe burn.

• While installing warme d final driven gear,

use oven glove such as leather glove.

Picking up it with bare hand may cause

burn.

CAUTION!

Do not leave final driven gear in boiling water

for longer than 5 min. Overheating the gear

may cause strength reduction of gear.

1) Put final driven gear in water vessel, heat and remove when it boils, then remove moisture.

NOTE

After removing moisture on final driven gear,

install final driven gear to differential case as

quickly as possible.

2. Differential case subassembly

I2RH0B510225-01

I2RH0B510226-01

I2RH0B510227-01

I2RH0B510228-01

I2RH0B510229-01

Page 823 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-9

Manual Transaxle Unit Dismounting and

Remounting

S7RS0B5206009

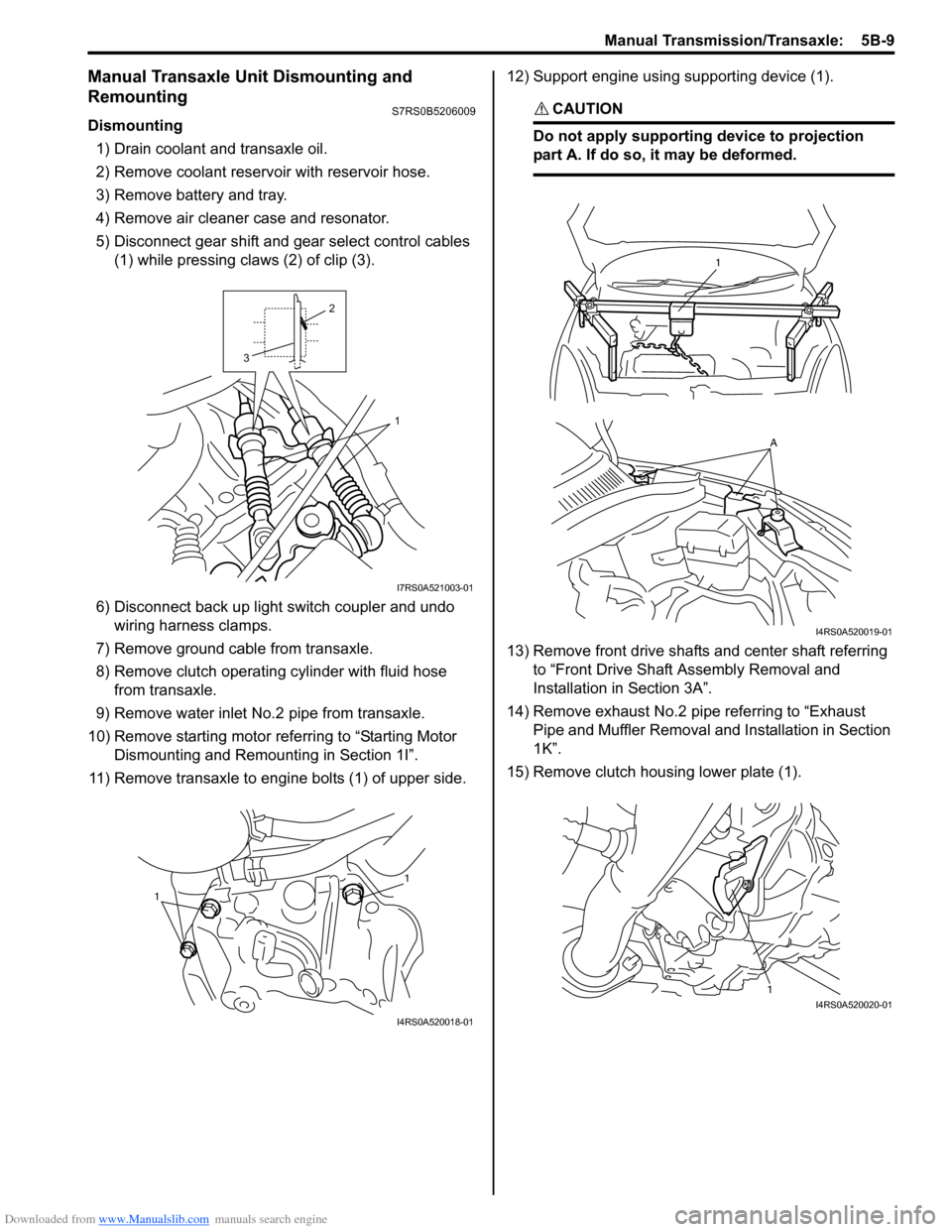

Dismounting1) Drain coolant and transaxle oil.

2) Remove coolant reservoir with reservoir hose.

3) Remove battery and tray.

4) Remove air cleaner case and resonator.

5) Disconnect gear shift and gear select control cables (1) while pressing claws (2) of clip (3).

6) Disconnect back up light switch coupler and undo wiring harness clamps.

7) Remove ground cable from transaxle.

8) Remove clutch operating cylinder with fluid hose from transaxle.

9) Remove water inlet No.2 pipe from transaxle.

10) Remove starting motor re ferring to “Starting Motor

Dismounting and Remounting in Section 1I”.

11) Remove transaxle to engine bolts (1) of upper side. 12) Support engine using supporting device (1).

CAUTION!

Do not apply supporting device to projection

part A. If do so, it may be deformed.

13) Remove front drive shafts and center shaft referring

to “Front Drive Shaft Assembly Removal and

Installation in Section 3A”.

14) Remove exhaust No.2 pipe referring to “Exhaust Pipe and Muffler Removal a nd Installation in Section

1K”.

15) Remove clutch housing lower plate (1).

1

2

3

I7RS0A521003-01

1

1

I4RS0A520018-01

1

A

I4RS0A520019-01

1I4RS0A520020-01

Page 925 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-43

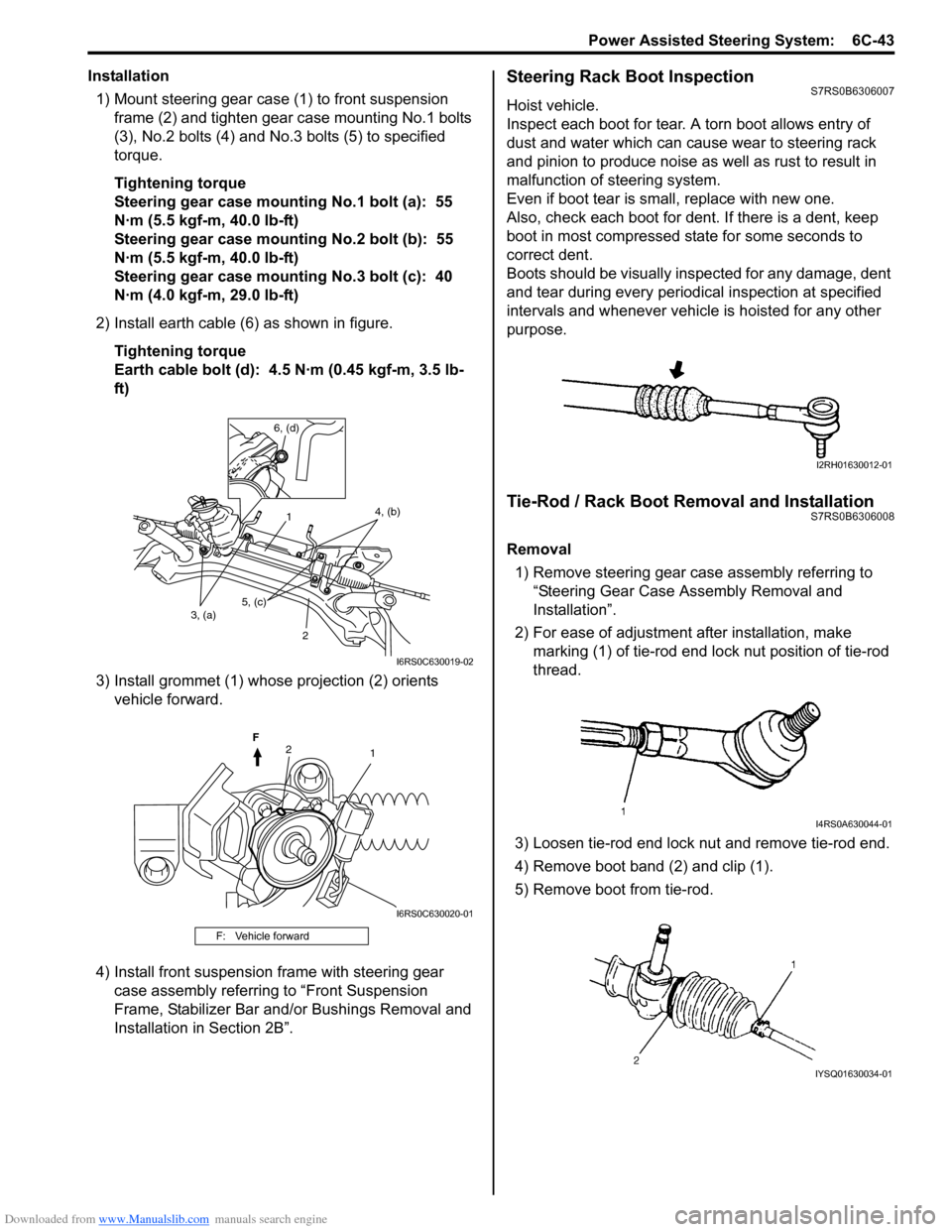

Installation1) Mount steering gear case (1) to front suspension frame (2) and tighten gear case mounting No.1 bolts

(3), No.2 bolts (4) and No .3 bolts (5) to specified

torque.

Tightening torque

Steering gear case mounting No.1 bolt (a): 55

N·m (5.5 kgf-m, 40.0 lb-ft)

Steering gear case mounting No.2 bolt (b): 55

N·m (5.5 kgf-m, 40.0 lb-ft)

Steering gear case mounting No.3 bolt (c): 40

N·m (4.0 kgf-m, 29.0 lb-ft)

2) Install earth cable (6) as shown in figure. Tightening torque

Earth cable bolt (d): 4.5 N·m (0.45 kgf-m, 3.5 lb-

ft)

3) Install grommet (1) whose projection (2) orients vehicle forward.

4) Install front suspension frame with steering gear case assembly referring to “Front Suspension

Frame, Stabilizer Bar and/or Bushings Removal and

Installation in Section 2B”.Steering Rack Boot InspectionS7RS0B6306007

Hoist vehicle.

Inspect each boot for tear. A torn boot allows entry of

dust and water which can cause wear to steering rack

and pinion to produce noise as well as rust to result in

malfunction of steering system.

Even if boot tear is small, replace with new one.

Also, check each boot for dent. If there is a dent, keep

boot in most compressed st ate for some seconds to

correct dent.

Boots should be visually inspected for any damage, dent

and tear during every periodical inspection at specified

intervals and whenever vehicle is hoisted for any other

purpose.

Tie-Rod / Rack Boot Removal and InstallationS7RS0B6306008

Removal

1) Remove steering gear case assembly referring to

“Steering Gear Case Assembly Removal and

Installation”.

2) For ease of adjustment after installation, make marking (1) of tie-rod end lock nut position of tie-rod

thread.

3) Loosen tie-rod end lock nut and remove tie-rod end.

4) Remove boot band (2) and clip (1).

5) Remove boot from tie-rod.

F: Vehicle forward

1 2

3, (a) 4, (b)

6, (d)

5, (c)

I6RS0C630019-02

12

F

I6RS0C630020-01

I2RH01630012-01

I4RS0A630044-01

IYSQ01630034-01

Page 949 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-1

HVAC

Air Conditioning System

Manual Type

Precautions

A/C System CautionS7RS0B7210001

CAUTION!

• The air conditioning system of this vehicle uses refrigerant HFC-134a (R-134a).

None of refrigerant, compressor oil and component parts is interchangeable between two types of

A/C: one using refrigerant HFC-134a (R-134a) and the other using refrigerant CFC-12 (R-12).

Be sure to check which refrigerant is used be fore any service work including inspection and

maintenance. For identification between these two types, refer to “Refrigerant Type Identification”.

When replenishing or changing refrigerant and comp ressor oil and when replacing parts, make sure

that the material or the part to be used is appropriate to the A/C installed in the vehicle being

serviced.

Use of incorrect one will result in leakage of refrigerant, damage in parts or other faulty condition.

• When servicing the compressor, keep dirt or foreign material away from getting on or into the compressor parts and system. Clean tools and a clean work area are important for proper service.

The compressor connection and the outside of the compressor should be cleaned before any “On

vehicle” repair or before removal of the compressor. The parts must be kept clean at all times and

any parts to be reassembled should be cleaned with trichloromethane, naphtha, kerosene or

equivalent solvent and dried with dry air. Use only lint free cloths to wipe parts.

• When compressor is removed from the vehicle for servicing, the oil remaining in the compressor

should be discarded and new refrigerant oil added to the compressor.

Minor repair procedures may be done on the vehicle without discharging the system. Major repair

procedures require that the system be discharged of refrigerant.

Precautions on Servicing A/C SystemS7RS0B7210002

WARNING!

Should refrigerant HFC-134a (R-134a) is exposed to your eye(s), consult a doctor immediately.

• Do not use your hand to rub affected eye(s). Instead, use fresh cold water to splash it over affected area to thus gradually raise its temperature above the freezing point.

• Obtain proper treatment as soon as possible from a doctor or eye specialist. Should liquid refrigerant HFC-134a (R-134a) is exposed to your skin, such affected part should be treated in the

same manner as when skin is frostbitten or frozen.

Handling Refrigerant HFC-134a (R-134a)

• Always wear goggles to protect your eyes.

• Avoid direct contact to liquid refrigerant.

• Do not heat refrigerant container higher than 40 °C (104 ° F).

• Do not discharge refrigerant into atmosphere.

• Do not expose bright metals to liquid refrigerant. Refrig erant combined with moisture is corrosive and tarnishes

surfaces of bright metals including chrome.

Page 950 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-2 Air Conditioning System: Manual Type

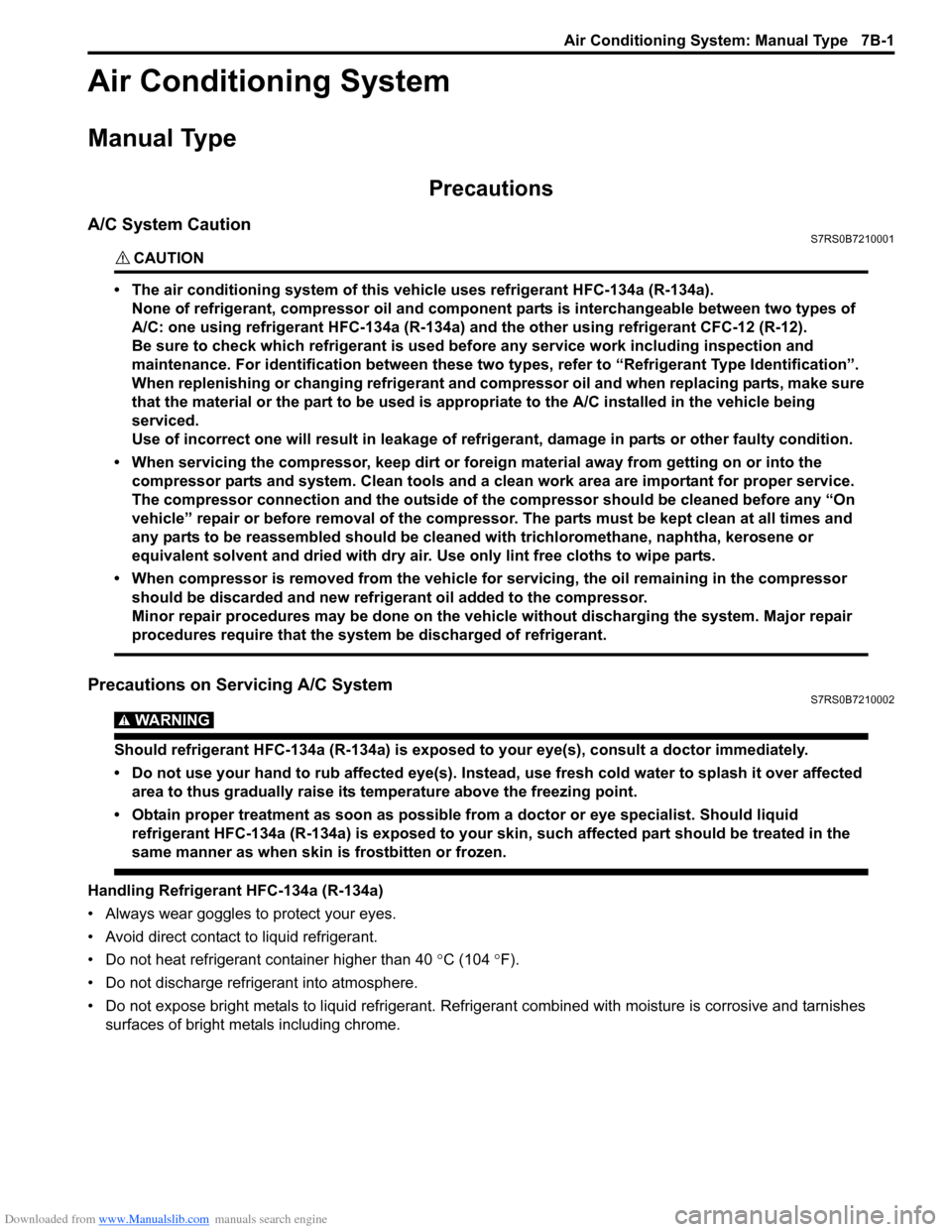

Refrigerant Line

• Never use heat for bending pipes. When bending a pipe , try to make its bending angle as smooth as possible.

• Keep internal parts of air conditioning free from moistu re and dirt. When disconnecting any line from system, install

a blind plug or cap to the fitting immediately.

• When connecting hoses and pipes, apply a few drops of compressor oil (refrigerant oil) to O-ring.

• When tightening or loosening a fitting, use two wrenches, one for turning and the other for support.

• When handling recovery and recycling equipment, be sure to follow the instruction manual for the equipment.

• Check local governmental regulations regarding working with refrigerator systems and its tooling.

• Route drain hose so that drained water does not make any contact to vehicle components.

• If pipes or hoses are replaced, replenish specified amount of compressor oil to compre ssor suction side referring to

“Replenishing Compressor Oil” in “Operation Procedure for Refrigerant Charge”.

Refrigerant Recovery

When discharging refrigerant out of A/C system, always recover it by using refrigerant recovery and recycling

equipment because discharging refrigerant HFC-134a (R-1 34a) into atmosphere would cause adverse effect to

environments.

NOTE

When handling recovery and recycling equipment, be sure to follow the instruction manual for the

equipment.

Refrigerant Charge

After performing compressor oil replenishment and evacuat ion, charge a proper amount of refrigerant to A/C system

referring to “Charge” in “Operation Procedure for Refrigerant Charge”.

3

1

2

4

5

I4RS0B720001-02

1. Suction hose : Apply compressor oil (refrigerant oil) to O-ring. 4. Expansion valve

: Apply compressor oil (refrigerant oil) to O-ring.

2. Discharge hose : Apply compressor oil (refrigerant oil) to O-ring. 5. A/C refrigerant pressure sensor

: Apply compressor oil (refrigerant oil) to O-ring.

3. Liquid pipe : Apply compressor oil (refrigerant oil) to O-ring.

Page 962 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-14 Air Conditioning System: Manual Type

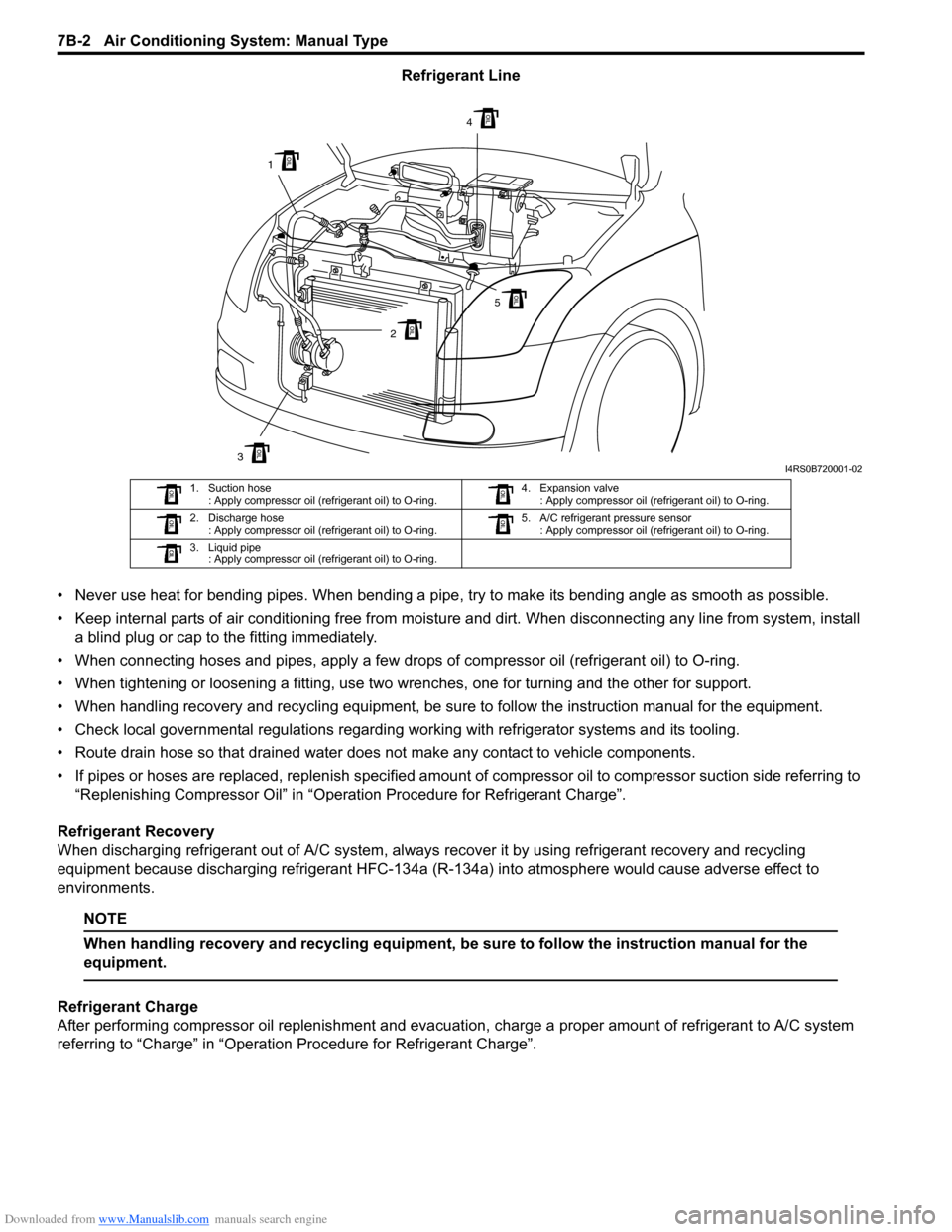

ConditionPossible cause Correction

Manifold gauge MPa (kg/cm2) (psi)

Detail

Lo Hi

0.27 – 0.43

(2.7 – 4.3)

(38 – 61) 1.59 – 1.94

(15.9 – 19.4)

(226 – 276)

Normal condition — —

Negative pressure 0.5 – 0.6

(5 – 6)

(71.2 – 85.3) The low pressure side

reads a negative

pressure, and the high

pressure side reads an

extremely low pressure.

Presence of frost around

tubing to and from

receiver/dryer and

expansion valve. Dust particles or water

droplets are either

stuck or frozen inside

expansion valve,

preventing the

refrigerant from

flowing.Clean expansion

valve.

Replace it if it cannot

be cleaned.

Replace receiver/

dryer.

Evacuate the A/C

system and recharge

with fresh refrigerant.

Normal:

0.27 – 0.43

(2.7 – 4.3)

(38 – 61)

↑ ↓

Abnormal:

Negative pressure Normal:

1.59 – 1.94

(15.9 – 19.4)

(226 – 276)

↑

↓

Abnormal:

0.7 – 1.0

(7 – 10)

(100 – 142) During A/C operation, the

low pressure side

sometimes indicates

negative pressure, and

sometimes normal

pressure. Also high

pressure side reading

fluctuates between the

abnormal and normal

pressure.

Expansion valve is

frozen due to

moisture in the

system, and

temporarily shuts off

the refrigeration cycle.

Replace expansion

valve.

Replace receiver/

dryer.

Evacuate A/C system

and recharge with

fresh refrigerant.

0.05 – 0.15

(0.5 – 1.5)

(4.2 – 21.3) 0.7 – 1.0

(7 – 10)

(100 – 142) Both low and high

pressure sides indicate

low readings.

Output air is slightly cold.

Insufficient refrigerant

in system

(Refrigerant leaking).Using leak detector,

check for leaks and

repair as necessary.

Recharge refrigerant

to a specified amount.

If the pressure reading

is almost 0 when the

manifold gauges are

attached, check for

any leaks, repair

them, and evacuate

the system.

0.4 – 0.6

(4 – 6)

(56.9 – 85.3) Pressure on low pressure

side is high.

Pressure on high

pressure side is low.

Both pressure becoming

equal right after A/C is

turned OFF.

Internal leak in

compressor.

Inspect compressor

and repair or replace

as necessary.

Page 964 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-16 Air Conditioning System: Manual Type

Repair Instructions

Operation Procedure for Refrigerant ChargeS7RS0B7216001

WARNING!

• Your eyes should not be exposed to refrigerant (liquid).Any liquid HFC-134a (R-134a) escaping by accident shows a temperature as low as approximately –

6 °C (21.2 ° F) below freezing point. Should liquid HFC-134a (R-134a) is exposed to your eyes, it may

cause a serious injury. To protect your eyes from such accident, it is necessary to always wear

goggles. Should it occur that HFC-134a (R-134a) is exposed to your eyes, consult a doctor

immediately.

– Do not use your hand to rub the affected eye(s). Instead, use fresh cold water to splash it over the affected area to gradually raise temperature of such area above freezing point.

– Obtain proper treatment as soon as possible from a doctor or eye specialist.

• Should the liquid refrigerant HFC-134a (R-134a) is exposed to your skin, the affected area should be treated in the same manner as when skin is frostbitten or frozen.

• Do not handle refrigerant near any place where welding or steam cleaning is performed.

• Refrigerant should be kept in a cold and dark pl ace. It should never be stored in any place where

temperature is high, e.g. where exposed to direct su n light, close to fire or inside vehicle (including

trunk room).

• Avoid breathing fume produced when HFC-134a (R-134a) is burned. Such fume may be hazardous to your health.

Recovery

When discharging refrigerant out of A/C system, always recover it by using refrigerant recovery and recycling

equipment because discharging refrigerant HFC-134a (R-1 34a) into atmosphere would cause adverse effect to

environments.

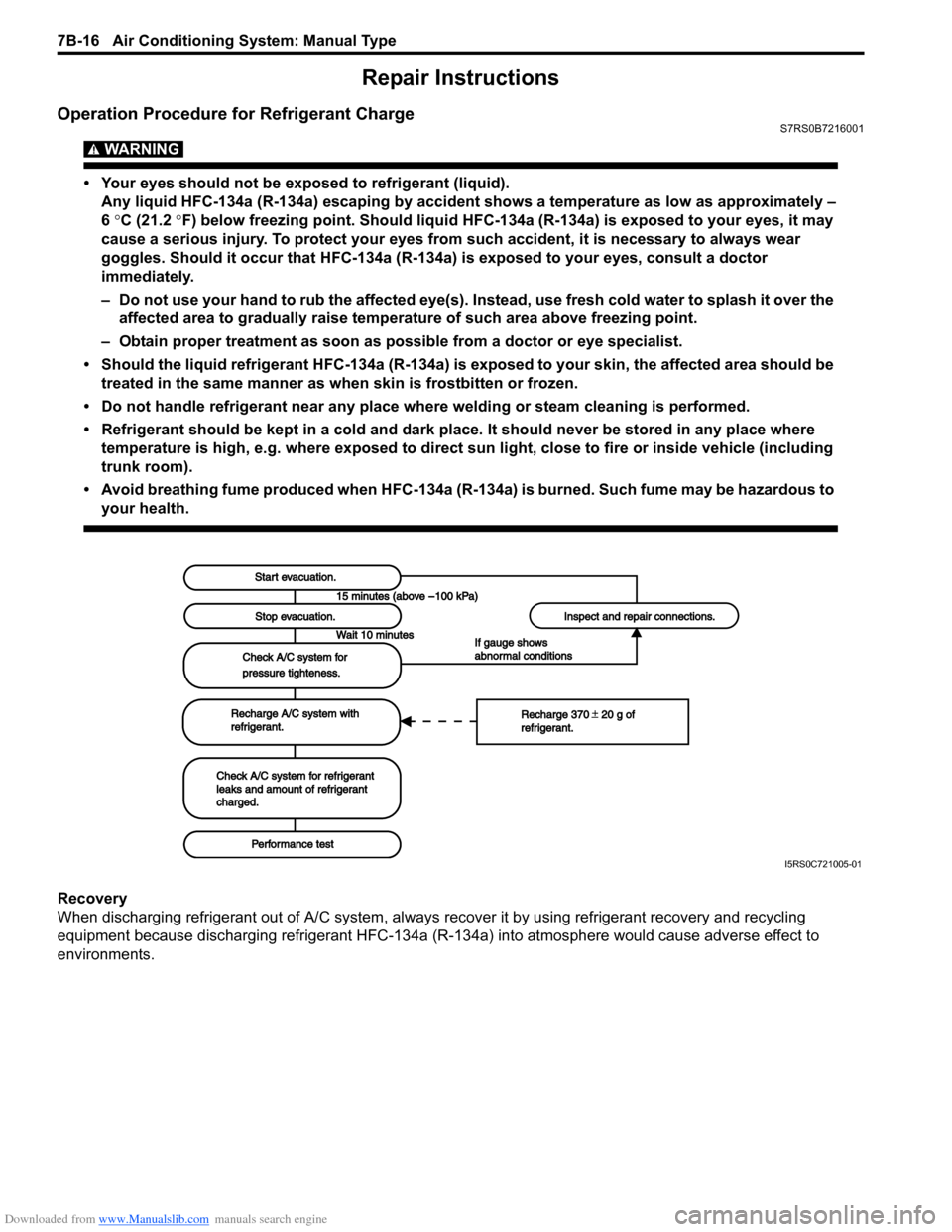

Start evacuation.Start evacuation.

Stop evacuation.Stop evacuation.

Wait 10 minutesWait 10 minutes

Check A/C system forCheck A/C system for

pressure tighteness.pressure tighteness.

Recharge A/C system withRecharge A/C system withrefrigerant.refrigerant.

Check A/C system for refrigerantCheck A/C system for refrigerantleaks and amount of refrigerantleaks and amount of refrigerantcharged.charged.

Performance testPerformance test

Inspect and repair connections.Inspect and repair connections.

If gauge showsIf gauge showsabnormal conditionsabnormal conditions

Recharge 370 20 g ofRecharge 370 20 g ofrefrigerant.refrigerant.

I5RS0C721005-01

Page 969 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-21

Removal of Manifold Gauge Set

WARNING!

High pressure side is under high pressure.

Therefore, be careful not to get injured

especially on your eyes and skin.

For the A/C system charged with the specified amount of

refrigerant, remove manifold gauge set as follows:

1) Close low pressure side valve of manifold gauge set. (The high pressure side valve is closed continuously

during the process of charging.)

2) Close refrigerant container valve.

3) Stop engine.

4) Using shop rag, remove charging hoses from service valves. This operation must be performed quickly.

5) Put caps on service valves.

Check A/C System for Refrigerant Leaks

Whenever a refrigerant leak is suspected in the system

or any service operation has been performed which may

result in malfunction of lines and connections, it is

advisable to check for leaks.

Common sense should be used during refrigerant leak

test, since the need and extent of any such test will, in

general, depend upon the nature of a complaint and the

type of a service performed on the system.

Liquid leak detector

WARNING!

• To prevent explosions and fires, make sure that there are no flammables in the vicinity.

• When the refrigerant exposed to fire, it turns into a poisonous gas (phosgene). Do

not inhale this gas.

There is a number of fittings and places throughout the

A/C system where a liquid leak detector solution may be

used to pinpoint refrigerant leaks.

By merely applying the solution to the area in question

with a swab, such as attached to the cap of a vial,

bubbles will form within seconds if there is a leak.

For confined areas, such as sections of the evaporator

and condenser, an electronic (refrigerant) leak detector

is more practical fo r determining leaks.

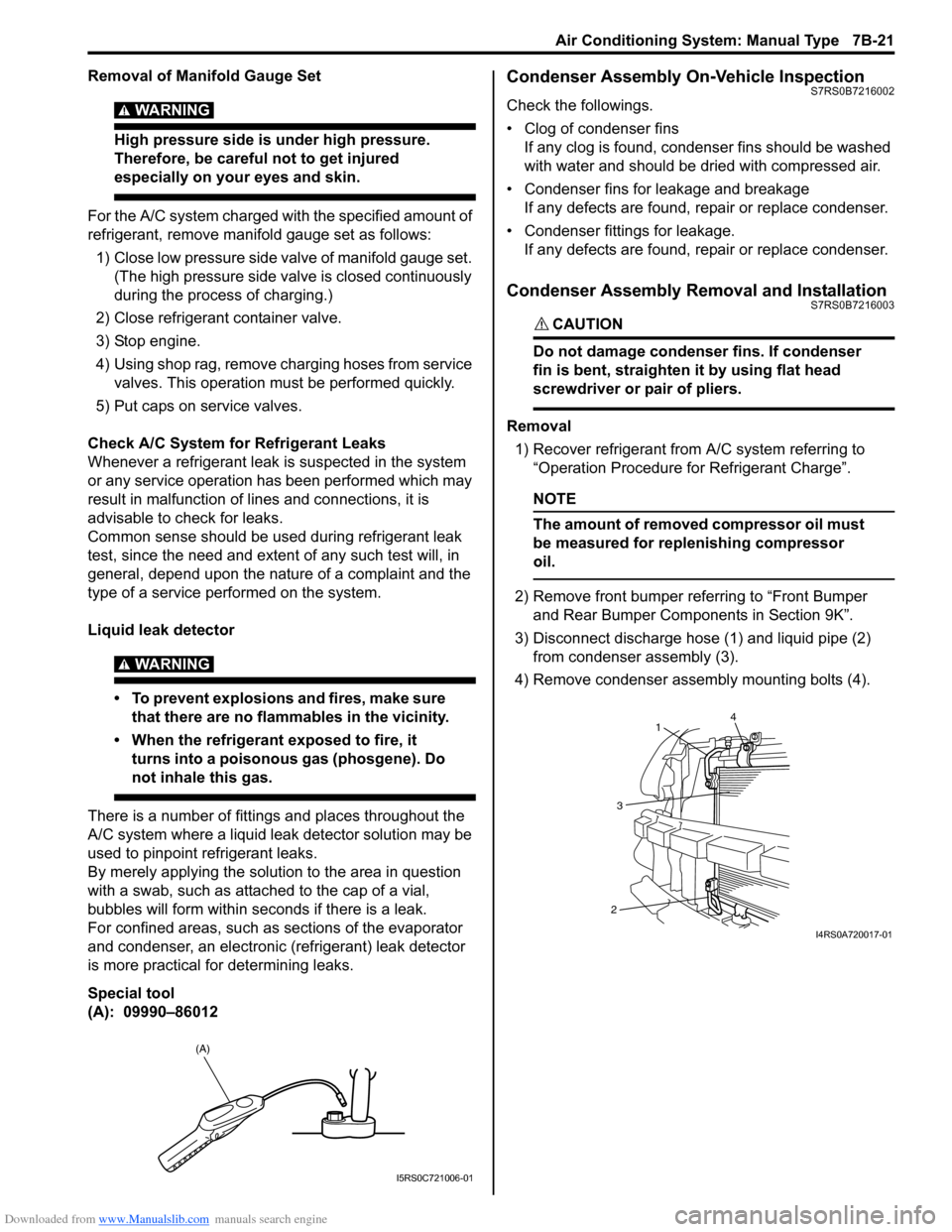

Special tool

(A): 09990–86012

Condenser Assembly On-Vehicle InspectionS7RS0B7216002

Check the followings.

• Clog of condenser fins If any clog is found, cond enser fins should be washed

with water and should be dried with compressed air.

• Condenser fins for leakage and breakage If any defects are found, repair or replace condenser.

• Condenser fittings for leakage. If any defects are found, repair or replace condenser.

Condenser Assembly Removal and InstallationS7RS0B7216003

CAUTION!

Do not damage condenser fins. If condenser

fin is bent, straighten it by using flat head

screwdriver or pair of pliers.

Removal

1) Recover refrigerant from A/C system referring to “Operation Procedure for Refrigerant Charge”.

NOTE

The amount of removed compressor oil must

be measured for replenishing compressor

oil.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Disconnect discharge hose (1) and liquid pipe (2) from condenser assembly (3).

4) Remove condenser assembly mounting bolts (4).

(A)

I5RS0C721006-01

4

1

3

2

I4RS0A720017-01