Check valve SUZUKI SWIFT 2008 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 307 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-22

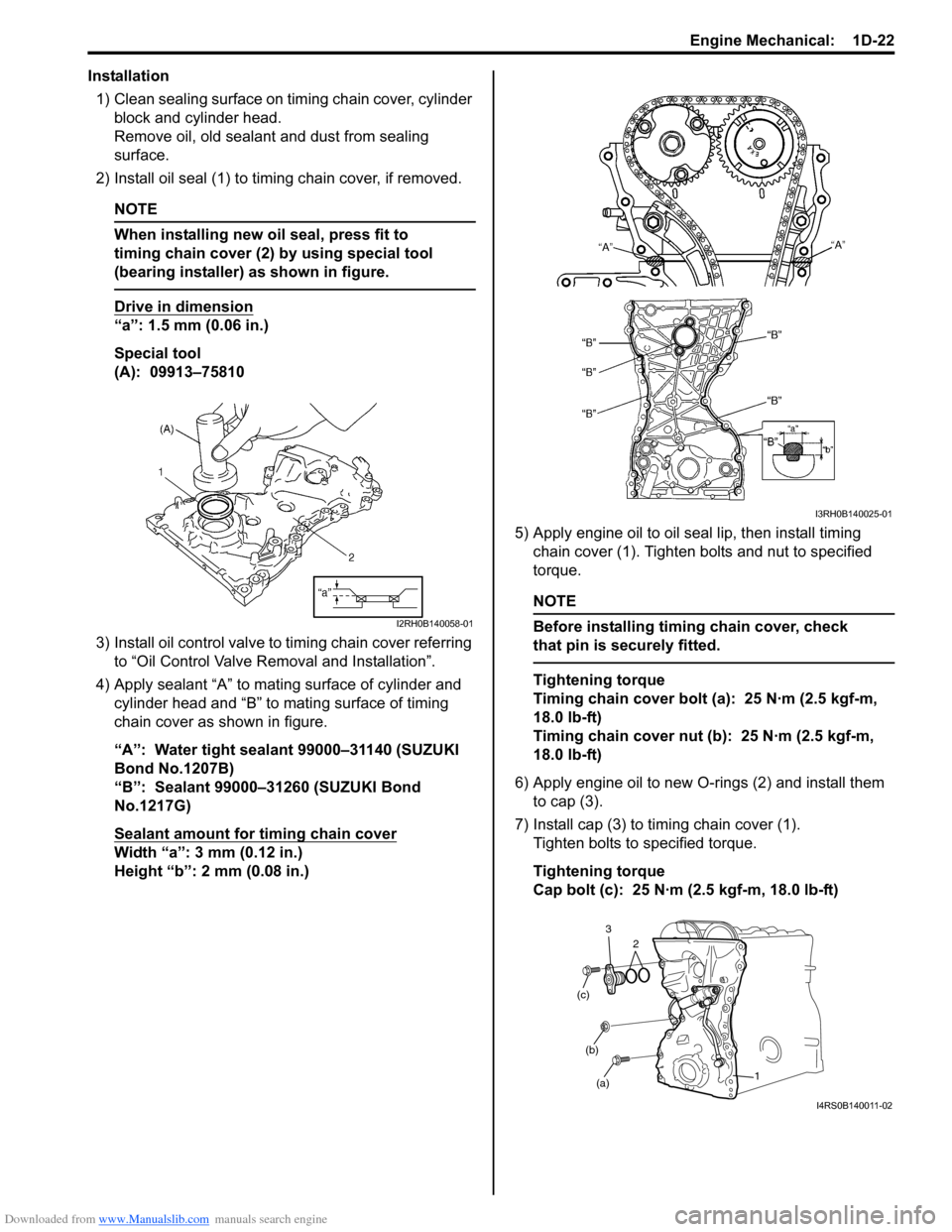

Installation1) Clean sealing surface on timing chain cover, cylinder block and cylinder head.

Remove oil, old sealant and dust from sealing

surface.

2) Install oil seal (1) to timi ng chain cover, if removed.

NOTE

When installing new oil seal, press fit to

timing chain cover (2) by using special tool

(bearing installer) as shown in figure.

Drive in dimension

“a”: 1.5 mm (0.06 in.)

Special tool

(A): 09913–75810

3) Install oil control valve to timing chain cover referring to “Oil Control Valve Removal and Installation”.

4) Apply sealant “A” to mating surface of cylinder and cylinder head and “B” to mating surface of timing

chain cover as shown in figure.

“A”: Water tight sealant 99000–31140 (SUZUKI

Bond No.1207B)

“B”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Sealant amount for timing chain cover

Width “a”: 3 mm (0.12 in.)

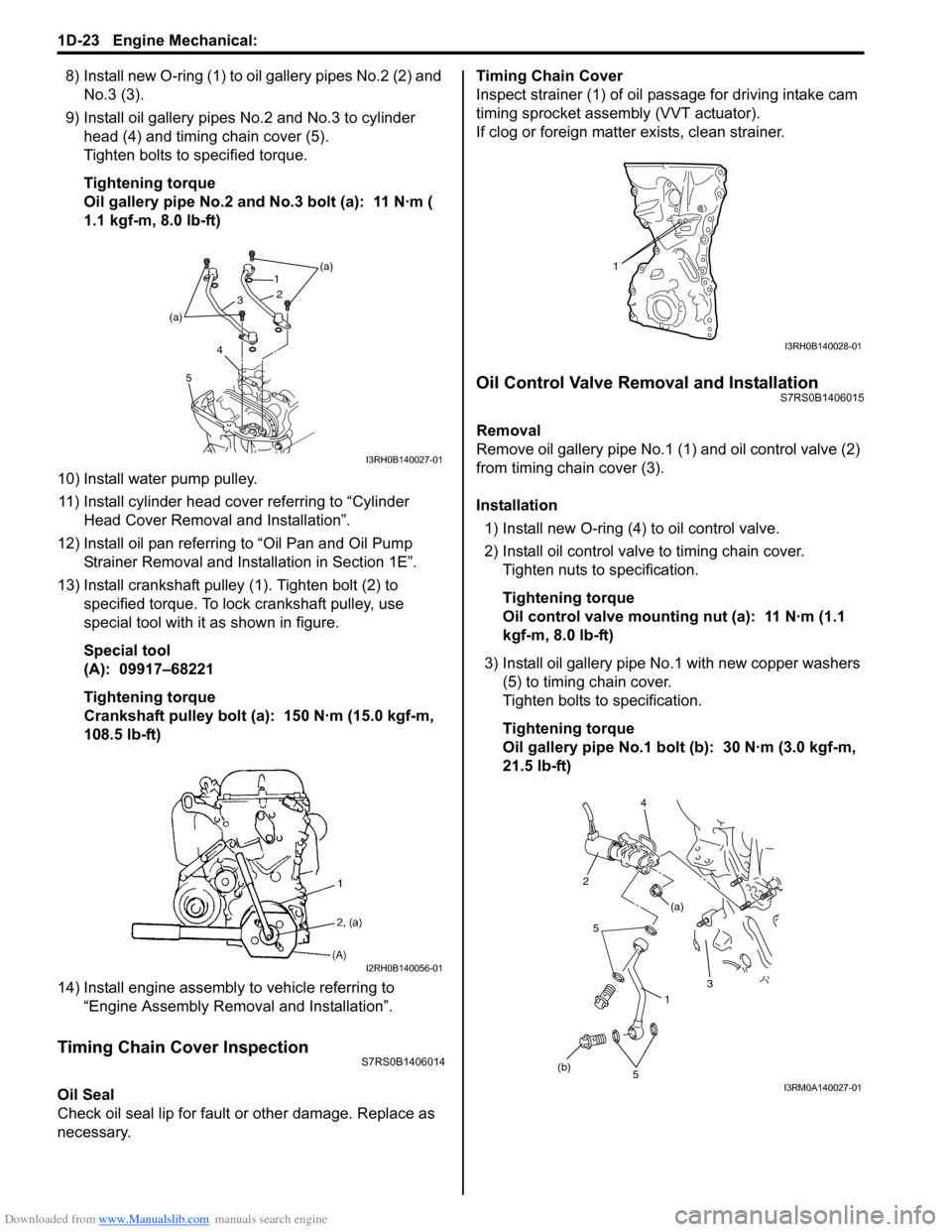

Height “b”: 2 mm (0.08 in.) 5) Apply engine oil to oil seal lip, then install timing

chain cover (1). Tighten bolts and nut to specified

torque.

NOTE

Before installing timing chain cover, check

that pin is securely fitted.

Tightening torque

Timing chain cover bolt (a): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

Timing chain cover nut (b): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

6) Apply engine oil to new O-rings (2) and install them to cap (3).

7) Install cap (3) to ti ming chain cover (1).

Tighten bolts to specified torque.

Tightening torque

Cap bolt (c): 25 N·m (2.5 kgf-m, 18.0 lb-ft)

I2RH0B140058-01

I3RH0B140025-01

(a)

(b)

(c)

1

2

3

I4RS0B140011-02

Page 308 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-23 Engine Mechanical:

8) Install new O-ring (1) to oil gallery pipes No.2 (2) and

No.3 (3).

9) Install oil gallery pipes No.2 and No.3 to cylinder

head (4) and timing chain cover (5).

Tighten bolts to specified torque.

Tightening torque

Oil gallery pipe No.2 and No.3 bolt (a): 11 N·m (

1.1 kgf-m, 8.0 lb-ft)

10) Install water pump pulley. 11) Install cylinder head cover referring to “Cylinder Head Cover Removal and Installation”.

12) Install oil pan referring to “Oil Pan and Oil Pump

Strainer Removal and Installation in Section 1E”.

13) Install crankshaft pulley (1). Tighten bolt (2) to specified torque. To lock crankshaft pulley, use

special tool with it as shown in figure.

Special tool

(A): 09917–68221

Tightening torque

Crankshaft pulley bolt (a): 150 N·m (15.0 kgf-m,

108.5 lb-ft)

14) Install engine assembly to vehicle referring to “Engine Assembly Removal and Installation”.

Timing Chain Cover InspectionS7RS0B1406014

Oil Seal

Check oil seal lip for fault or other damage. Replace as

necessary. Timing Chain Cover

Inspect strainer (1) of oil passage for driving intake cam

timing sprocket assembly (VVT actuator).

If clog or foreign matter exists, clean strainer.

Oil Control Valve Removal and InstallationS7RS0B1406015

Removal

Remove oil gallery pipe No.1

(1) and oil control valve (2)

from timing chain cover (3).

Installation

1) Install new O-ring (4) to oil control valve.

2) Install oil control valve to timing chain cover. Tighten nuts to specification.

Tightening torque

Oil control valve mounting nut (a): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

3) Install oil gallery pipe No .1 with new copper washers

(5) to timing chain cover.

Tighten bolts to specification.

Tightening torque

Oil gallery pipe No.1 bolt (b): 30 N·m (3.0 kgf-m,

21.5 lb-ft)

(a)

(a) 1

2

3

4

5

I3RH0B140027-01

I2RH0B140056-01

1

I3RH0B140028-01

1

5

(b) 3

(a)

2 4

5

I3RM0A140027-01

Page 309 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-24

Oil Control Valve InspectionS7RS0B1406016

Oil Control Valve1) Inspect strainer (1) and mating surface (2) of oil control valve for clog or damage. Clean oil control

valve if clog or foreign matter is present on strainer

or mating surface of oil control valve.

Replace oil control valve if its mating surface is

damaged.

2) Check resistance between terminals of oil control

valve.

Oil control valve resistance

6.7 – 7.7 Ω (at 20 °C (68 °F)) Oil Gallery Pipe

Inspect oil gallery pipes No

.1, No.2 (2) and No.3 (3).

Replace if crack, deformation or clog exists.

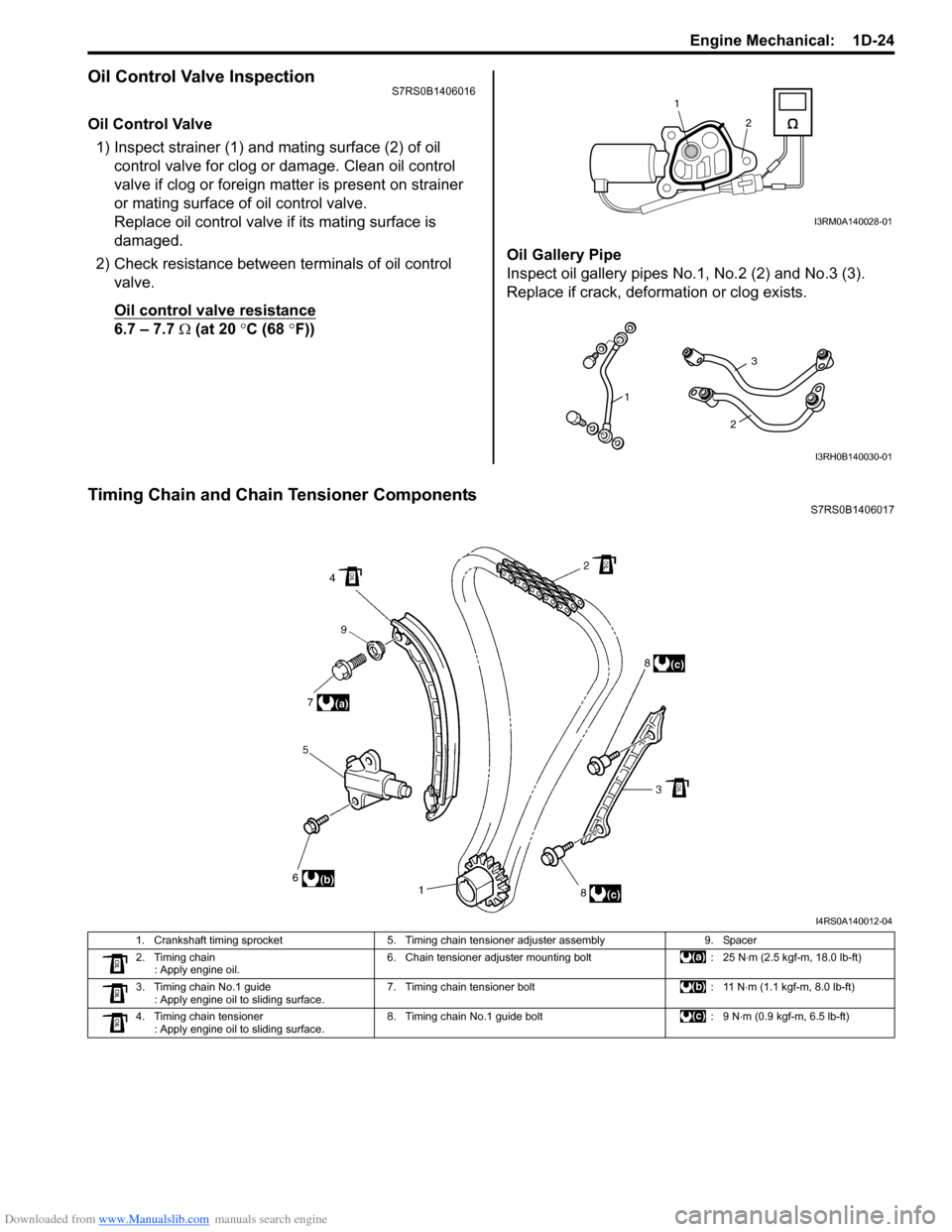

Timing Chain and Chain Tensioner ComponentsS7RS0B1406017

1

2

I3RM0A140028-01

1

3

2

I3RH0B140030-01

I4RS0A140012-04

1. Crankshaft timing sprocket 5. Timing chain tensioner adjuster assembly 9. Spacer

2. Timing chain : Apply engine oil. 6. Chain tensioner adjuster mounting bolt

: 25 N⋅m (2.5 kgf-m, 18.0 lb-ft)

3. Timing chain No.1 guide : Apply engine oil to sliding surface. 7. Timing chain tensioner bolt

: 11 N⋅m (1.1 kgf-m, 8.0 lb-ft)

4. Timing chain tensioner : Apply engine oil to sliding surface. 8. Timing chain No.1 guide bolt

: 9 N⋅m (0.9 kgf-m, 6.5 lb-ft)

Page 310 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-25 Engine Mechanical:

Timing Chain and Chain Tensioner Removal

and Installation

S7RS0B1406018

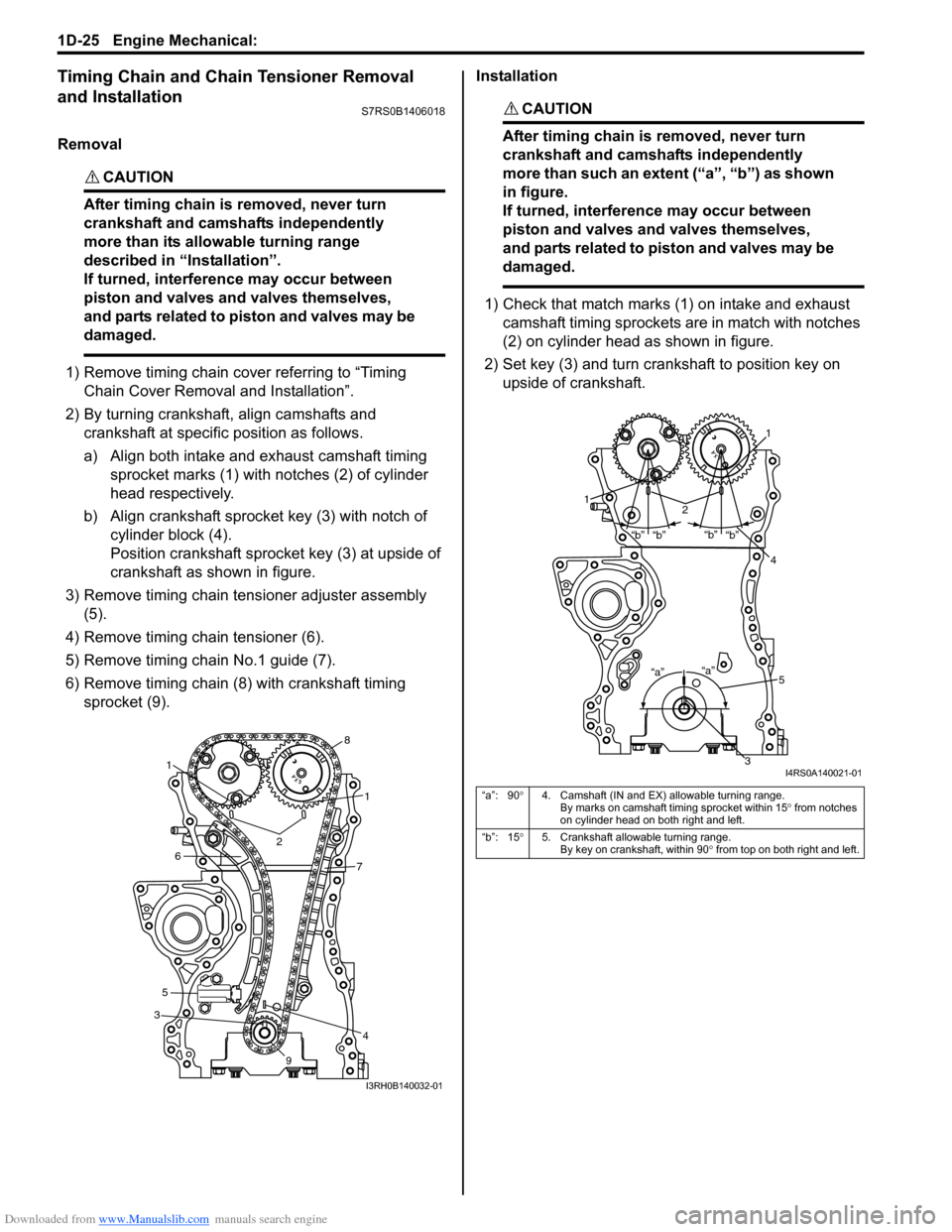

Removal

CAUTION!

After timing chain is removed, never turn

crankshaft and camshafts independently

more than its allowable turning range

described in “Installation”.

If turned, interferen ce may occur between

piston and valves and valves themselves,

and parts related to piston and valves may be

damaged.

1) Remove timing chain cover referring to “Timing Chain Cover Removal and Installation”.

2) By turning crankshaft, align camshafts and crankshaft at specific position as follows.

a) Align both intake and exhaust camshaft timing sprocket marks (1) with notches (2) of cylinder

head respectively.

b) Align crankshaft sprocket key (3) with notch of cylinder block (4).

Position crankshaft sprocke t key (3) at upside of

crankshaft as shown in figure.

3) Remove timing chain tensioner adjuster assembly (5).

4) Remove timing chain tensioner (6).

5) Remove timing chain No.1 guide (7).

6) Remove timing chain (8) with crankshaft timing sprocket (9). Installation

CAUTION!

After timing chain is removed, never turn

crankshaft and camshafts independently

more than such an extent (“a”, “b”) as shown

in figure.

If turned, interferen

ce may occur between

piston and valves and valves themselves,

and parts related to piston and valves may be

damaged.

1) Check that match marks (1) on intake and exhaust camshaft timing sprockets are in match with notches

(2) on cylinder head as shown in figure.

2) Set key (3) and turn crankshaft to position key on upside of crankshaft.

3

4

1

1

2

5

67

8

9

I3RH0B140032-01

“a”: 90 °4. Camshaft (IN and EX) allowable turning range.

By marks on camshaft timing sprocket within 15 ° from notches

on cylinder head on both right and left.

“b”: 15 °5. Crankshaft allowable turning range.

By key on crankshaft, within 90 ° from top on both right and left.

“a”

“b”

“b”“b”

“b”

“a”

1

12

4

3

5

I4RS0A140021-01

Page 316 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-31 Engine Mechanical:

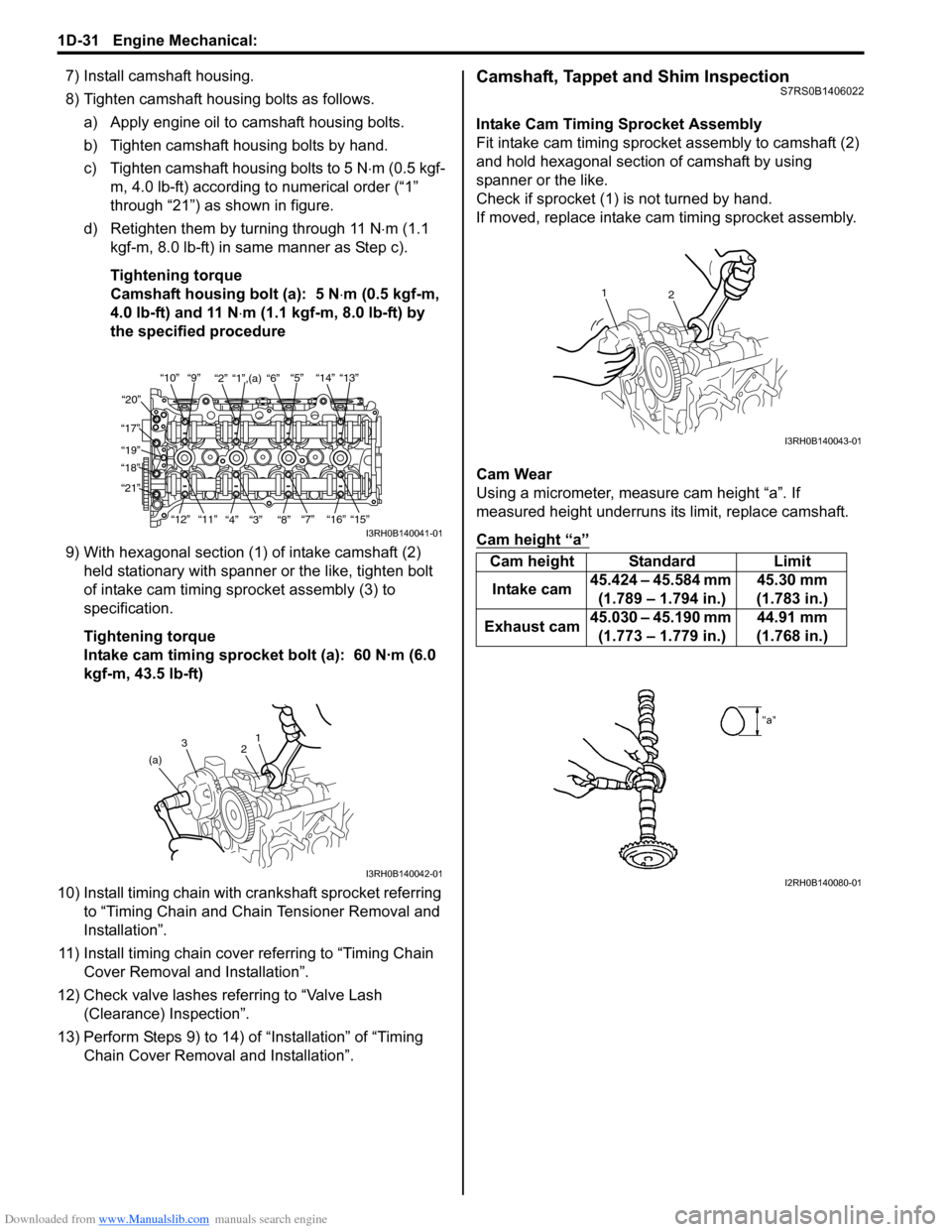

7) Install camshaft housing.

8) Tighten camshaft housing bolts as follows.a) Apply engine oil to camshaft housing bolts.

b) Tighten camshaft housing bolts by hand.

c) Tighten camshaft housing bolts to 5 N ⋅m (0.5 kgf-

m, 4.0 lb-ft) according to numerical order (“1”

through “21”) as shown in figure.

d) Retighten them by turning through 11 N⋅ m (1.1

kgf-m, 8.0 lb-ft) in same manner as Step c).

Tightening torque

Camshaft housing bolt (a): 5 N ⋅m (0.5 kgf-m,

4.0 lb-ft) and 11 N ⋅m (1.1 kgf-m, 8.0 lb-ft) by

the specified procedure

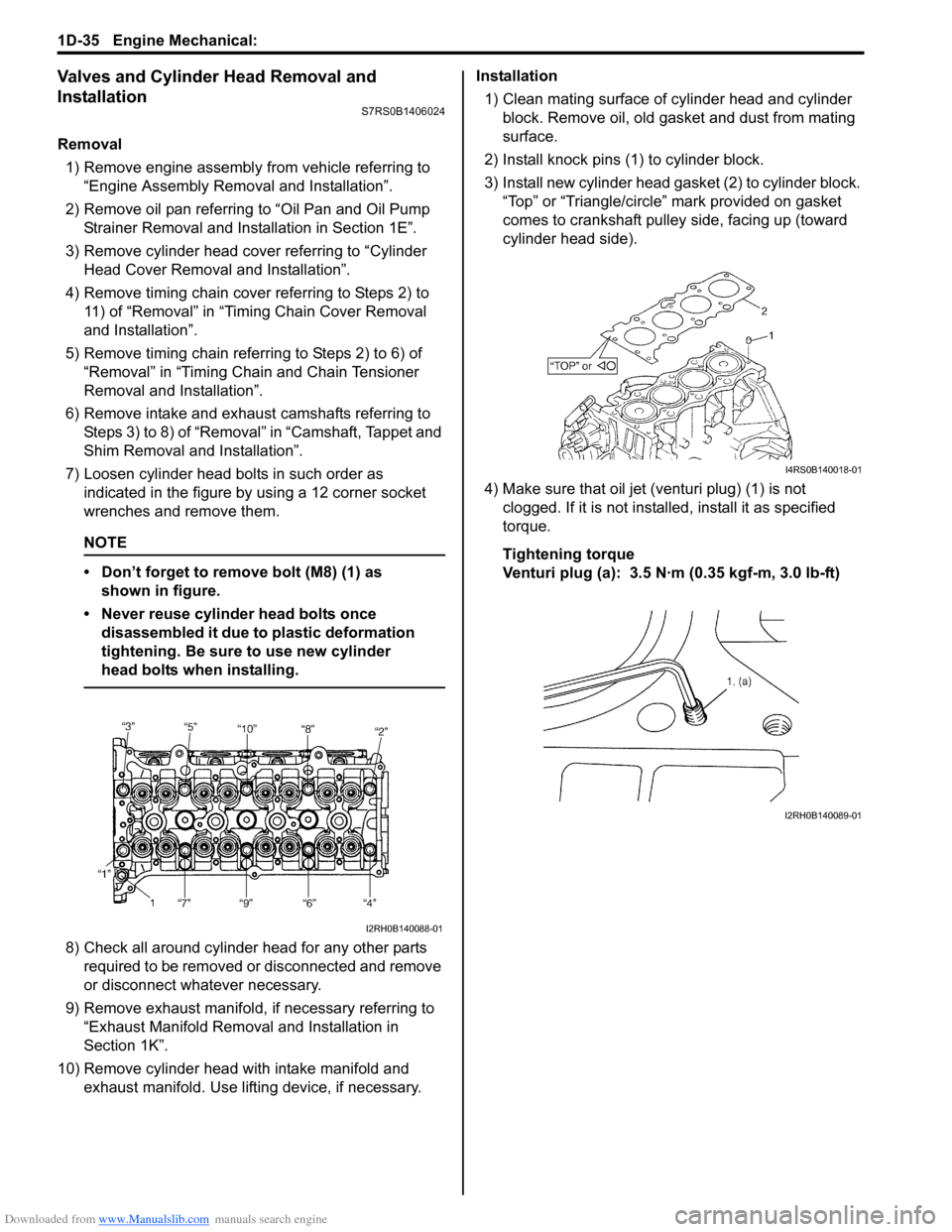

9) With hexagonal section (1) of intake camshaft (2) held stationary with spanner or the like, tighten bolt

of intake cam timing sp rocket assembly (3) to

specification.

Tightening torque

Intake cam timing sprocket bolt (a): 60 N·m (6.0

kgf-m, 43.5 lb-ft)

10) Install timing chain with cr ankshaft sprocket referring

to “Timing Chain and Chain Tensioner Removal and

Installation”.

11) Install timing chain cover referring to “Timing Chain Cover Removal and Installation”.

12) Check valve lashes referring to “Valve Lash (Clearance) Inspection”.

13) Perform Steps 9) to 14) of “Installation” of “Timing Chain Cover Removal and Installation”.Camshaft, Tappet and Shim InspectionS7RS0B1406022

Intake Cam Timing Sprocket Assembly

Fit intake cam timing sprocket assembly to camshaft (2)

and hold hexagonal section of camshaft by using

spanner or the like.

Check if sprocket (1) is not turned by hand.

If moved, replace intake ca m timing sprocket assembly.

Cam Wear

Using a micrometer, measure cam height “a”. If

measured height underruns its limit, replace camshaft.

Cam height “a”

“10”“9” “2” “1”,(a) “6” “5” “14” “13”

“20”

“17” “19”

“18”

“21”

“12”“11”

“4” “3” “8” “7” “16” “15”

I3RH0B140041-01

1

2

3

(a)

I3RH0B140042-01

Cam height Standard Limit

Intake cam 45.424 – 45.584 mm

(1.789 – 1.794 in.) 45.30 mm

(1.783 in.)

Exhaust cam 45.030 – 45.190 mm

(1.773 – 1.779 in.) 44.91 mm

(1.768 in.)

2

1

I3RH0B140043-01

I2RH0B140080-01

Page 320 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-35 Engine Mechanical:

Valves and Cylinder Head Removal and

Installation

S7RS0B1406024

Removal1) Remove engine assembly from vehicle referring to “Engine Assembly Removal and Installation”.

2) Remove oil pan referring to “Oil Pan and Oil Pump

Strainer Removal and Installation in Section 1E”.

3) Remove cylinder head cover referring to “Cylinder Head Cover Removal and Installation”.

4) Remove timing chain cover referring to Steps 2) to 11) of “Removal” in “Tim ing Chain Cover Removal

and Installation”.

5) Remove timing chain referring to Steps 2) to 6) of “Removal” in “Timing Chain and Chain Tensioner

Removal and Installation”.

6) Remove intake and exhaust camshafts referring to Steps 3) to 8) of “Removal” in “Camshaft, Tappet and

Shim Removal and Installation”.

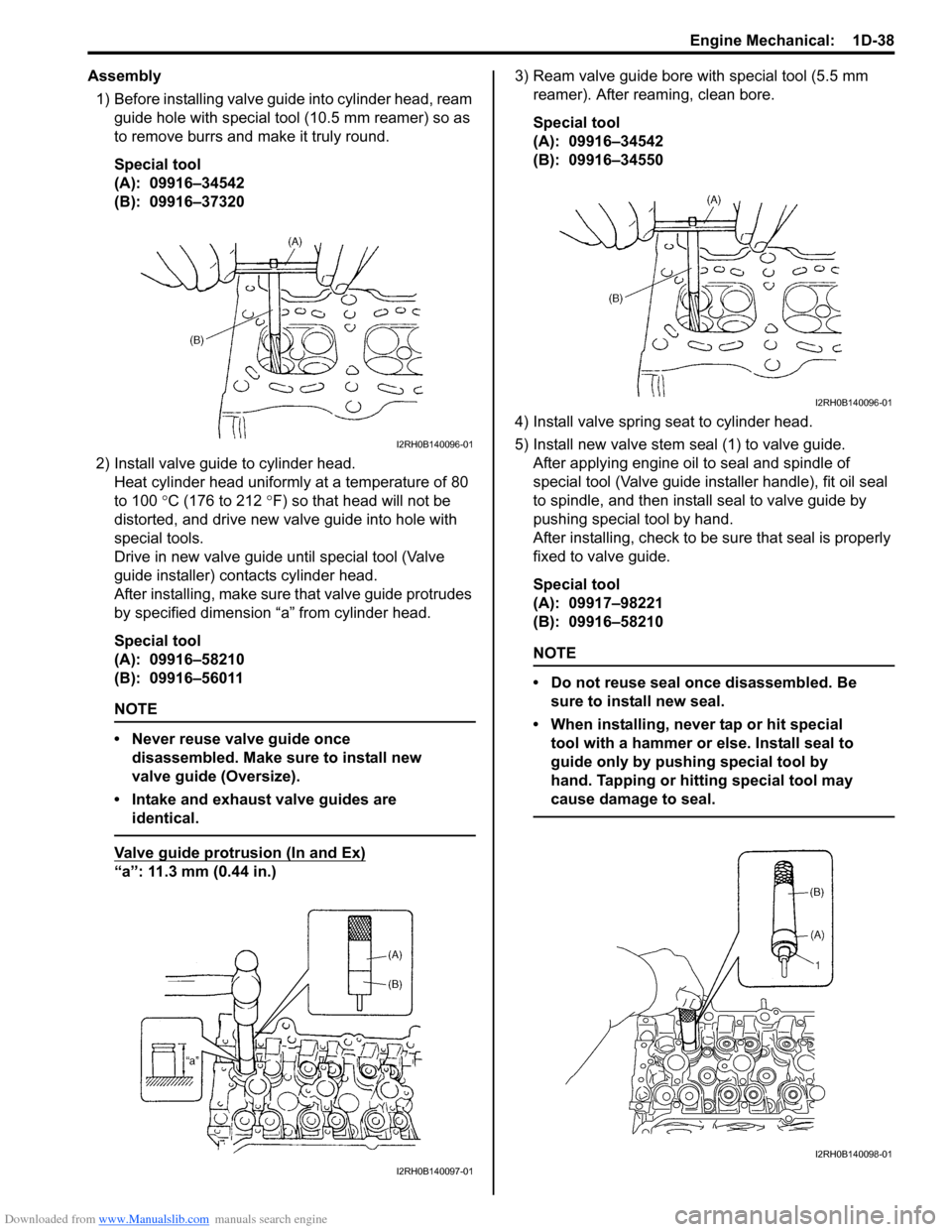

7) Loosen cylinder head bolts in such order as indicated in the figure by using a 12 corner socket

wrenches and remove them.

NOTE

• Don’t forget to remove bolt (M8) (1) as shown in figure.

• Never reuse cylinder head bolts once disassembled it due to plastic deformation

tightening. Be sure to use new cylinder

head bolts when installing.

8) Check all around cylinder head for any other parts required to be removed or disconnected and remove

or disconnect whatever necessary.

9) Remove exhaust manifold, if necessary referring to

“Exhaust Manifold Removal and Installation in

Section 1K”.

10) Remove cylinder head wi th intake manifold and

exhaust manifold. Use lifting device, if necessary. Installation

1) Clean mating surface of cylinder head and cylinder block. Remove oil, old gasket and dust from mating

surface.

2) Install knock pins (1) to cylinder block.

3) Install new cylinder head gasket (2) to cylinder block. “Top” or “Triangle/circle” mark provided on gasket

comes to crankshaft pulley side, facing up (toward

cylinder head side).

4) Make sure that oil jet (venturi plug) (1) is not clogged. If it is not install ed, install it as specified

torque.

Tightening torque

Venturi plug (a): 3.5 N·m (0.35 kgf-m, 3.0 lb-ft)

I2RH0B140088-01

I4RS0B140018-01

I2RH0B140089-01

Page 323 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-38

Assembly1) Before installing valve guide into cylinder head, ream

guide hole with special tool (10.5 mm reamer) so as

to remove burrs and make it truly round.

Special tool

(A): 09916–34542

(B): 09916–37320

2) Install valve guide to cylinder head. Heat cylinder head uniformly at a temperature of 80

to 100 °C (176 to 212 °F) so that head will not be

distorted, and drive new valve guide into hole with

special tools.

Drive in new valve guide until special tool (Valve

guide installer) contacts cylinder head.

After installing, ma ke sure that valve guide pr otrudes

by specified dimension “a” from cylinder head.

Special tool

(A): 09916–58210

(B): 09916–56011

NOTE

• Never reuse valve guide once disassembled. Make sure to install new

valve guide (Oversize).

• Intake and exhaust valve guides are identical.

Valve guide protrusion (In and Ex)

“a”: 11.3 mm (0.44 in.) 3) Ream valve guide bore with special tool (5.5 mm

reamer). After reaming, clean bore.

Special tool

(A): 09916–34542

(B): 09916–34550

4) Install valve spring seat to cylinder head.

5) Install new valve stem seal (1) to valve guide. After applying engine oil to seal and spindle of

special tool (Valve guide installer handle), fit oil seal

to spindle, and then install seal to valve guide by

pushing special tool by hand.

After installing, check to be sure that seal is properly

fixed to valve guide.

Special tool

(A): 09917–98221

(B): 09916–58210

NOTE

• Do not reuse seal once disassembled. Be sure to install new seal.

• When installing, never tap or hit special tool with a hammer or else. Install seal to

guide only by pushing special tool by

hand. Tapping or hitting special tool may

cause damage to seal.

I2RH0B140096-01

I2RH0B140097-01

I2RH0B140096-01

I2RH0B140098-01

Page 325 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-40

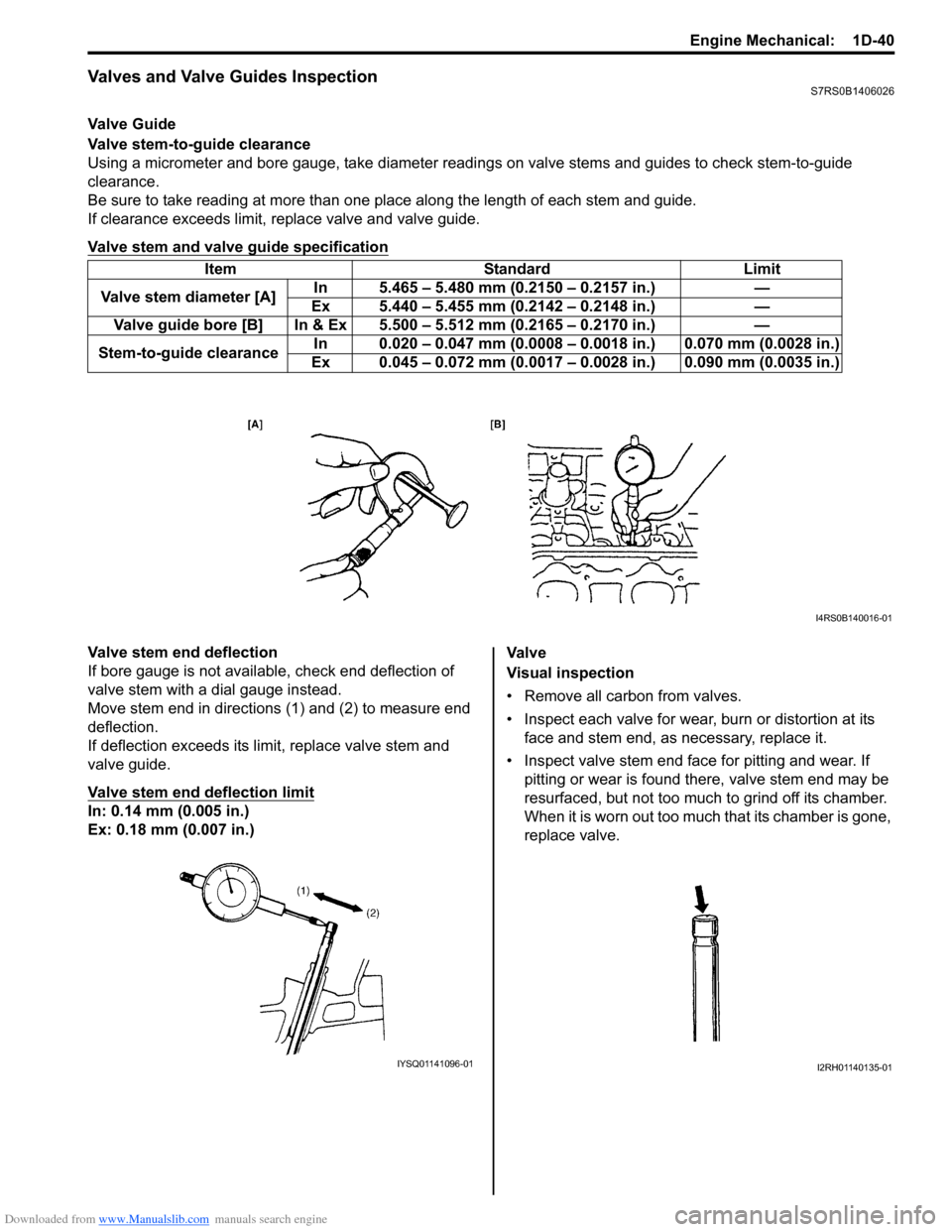

Valves and Valve Guides InspectionS7RS0B1406026

Valve Guide

Valve stem-to-guide clearance

Using a micrometer and bore gauge, take diameter readings on valve stems and guides to check stem-to-guide

clearance.

Be sure to take reading at more than one place along the length of each stem and guide.

If clearance exceeds limit, replace valve and valve guide.

Valve stem and valve guide specification

Valve stem end deflection

If bore gauge is not available, check end deflection of

valve stem with a dial gauge instead.

Move stem end in directions (1) and (2) to measure end

deflection.

If deflection exceeds its limit, replace valve stem and

valve guide.

Valve stem end deflection limit

In: 0.14 mm (0.005 in.)

Ex: 0.18 mm (0.007 in.) Va l v e

Visual inspection

• Remove all carbon from valves.

• Inspect each valve for wear, burn or distortion at its

face and stem end, as necessary, replace it.

• Inspect valve stem end face for pitting and wear. If pitting or wear is found there, valve stem end may be

resurfaced, but not too much to grind off its chamber.

When it is worn out too much that its chamber is gone,

replace valve.

Item Standard Limit

Valve stem diameter [A] In 5.465 – 5.480 mm (0.2150 – 0.2157 in.) —

Ex 5.440 – 5.455 mm (0.2142 – 0.2148 in.) —

Valve guide bore [B] In & Ex 5.500 – 5.512 mm (0.2165 – 0.2170 in.) —

Stem-to-guide clearance In 0.020 – 0.047 mm (0.0008 – 0.

0018 in.) 0.070 mm (0.0028 in.)

Ex 0.045 – 0.072 mm (0.0017 – 0. 0028 in.) 0.090 mm (0.0035 in.)

I4RS0B140016-01

IYSQ01141096-01I2RH01140135-01

Page 326 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-41 Engine Mechanical:

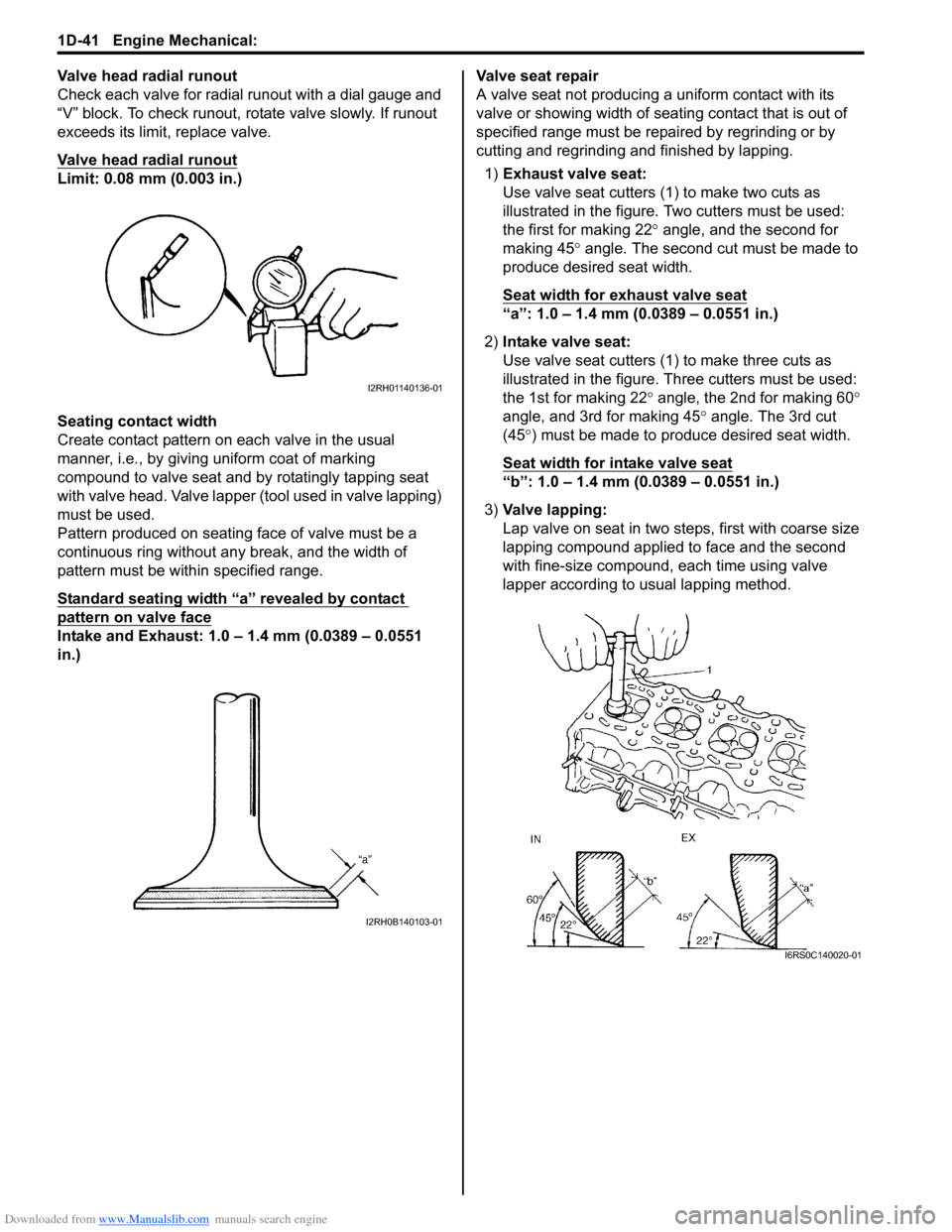

Valve head radial runout

Check each valve for radial runout with a dial gauge and

“V” block. To check runout, rotate valve slowly. If runout

exceeds its limit, replace valve.

Valve head radial runout

Limit: 0.08 mm (0.003 in.)

Seating contact width

Create contact pattern on each valve in the usual

manner, i.e., by giving uniform coat of marking

compound to valve seat and by rotatingly tapping seat

with valve head. Valve lapper (tool used in valve lapping)

must be used.

Pattern produced on seating face of valve must be a

continuous ring without any break, and the width of

pattern must be within specified range.

Standard seating width “a” revealed by contact

pattern on valve face

Intake and Exhaust: 1.0 – 1.4 mm (0.0389 – 0.0551

in.)Valve seat repair

A valve seat not producing

a uniform contact with its

valve or showing width of seating contact that is out of

specified range must be repaired by regrinding or by

cutting and regrinding and finished by lapping.

1) Exhaust valve seat:

Use valve seat cutters (1 ) to make two cuts as

illustrated in the figure. Two cutters must be used:

the first for making 22 ° angle, and the second for

making 45 ° angle. The second cut must be made to

produce desired seat width.

Seat width for exhaust valve seat

“a”: 1.0 – 1.4 mm (0.0389 – 0.0551 in.)

2) Intake valve seat:

Use valve seat cutters (1) to make three cuts as

illustrated in the figure. Th ree cutters must be used:

the 1st for making 22 ° angle, the 2nd for making 60 °

angle, and 3rd for making 45 ° angle. The 3rd cut

(45 °) must be made to produce desired seat width.

Seat width for intake valve seat

“b”: 1.0 – 1.4 mm (0.0389 – 0.0551 in.)

3) Valve lapping:

Lap valve on seat in two steps, first with coarse size

lapping compound applied to face and the second

with fine-size compound, each time using valve

lapper according to usual lapping method.

I2RH01140136-01

I2RH0B140103-01

I6RS0C140020-01

Page 327 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-42

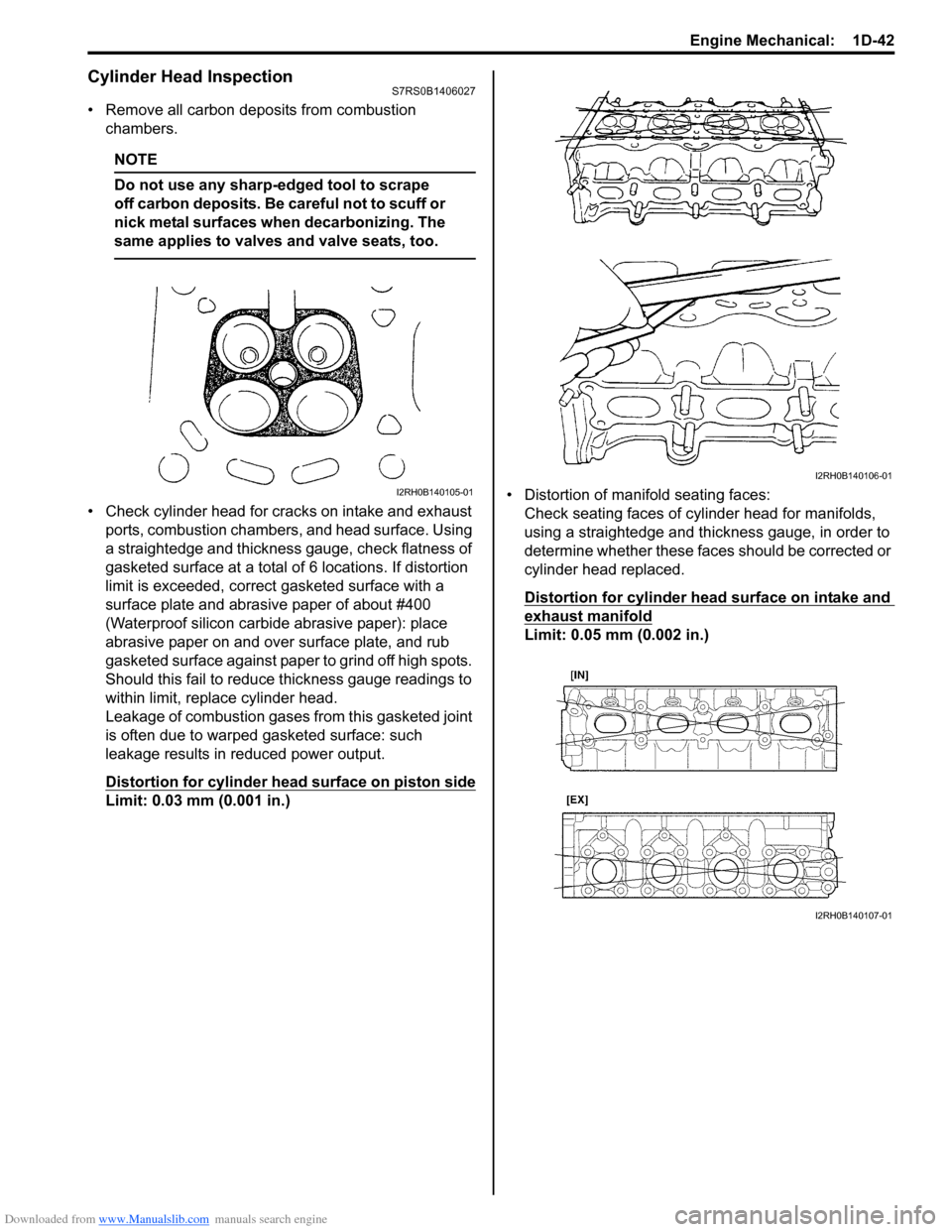

Cylinder Head InspectionS7RS0B1406027

• Remove all carbon deposits from combustion chambers.

NOTE

Do not use any sharp-edged tool to scrape

off carbon deposits. Be careful not to scuff or

nick metal surfaces when decarbonizing. The

same applies to valves and valve seats, too.

• Check cylinder head for cracks on intake and exhaust ports, combustion chambers, and head surface. Using

a straightedge and thickness gauge, check flatness of

gasketed surface at a total of 6 locations. If distortion

limit is exceeded, correct gasketed surface with a

surface plate and abrasive paper of about #400

(Waterproof silicon carbide abrasive paper): place

abrasive paper on and over surface plate, and rub

gasketed surface against paper to grind off high spots.

Should this fail to reduce thickness gauge readings to

within limit, replace cylinder head.

Leakage of combustion gases from this gasketed joint

is often due to warped gasketed surface: such

leakage results in reduced power output.

Distortion for cylinder head surface on piston side

Limit: 0.03 mm (0.001 in.) • Distortion of manifold seating faces:

Check seating faces of cylinder head for manifolds,

using a straightedge and thickness gauge, in order to

determine whether these faces should be corrected or

cylinder head replaced.

Distortion for cylinder head surface on intake and

exhaust manifold

Limit: 0.05 mm (0.002 in.)

I2RH0B140105-01

I2RH0B140106-01

I2RH0B140107-01