electronic stability SUZUKI SWIFT 2008 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 629 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-55

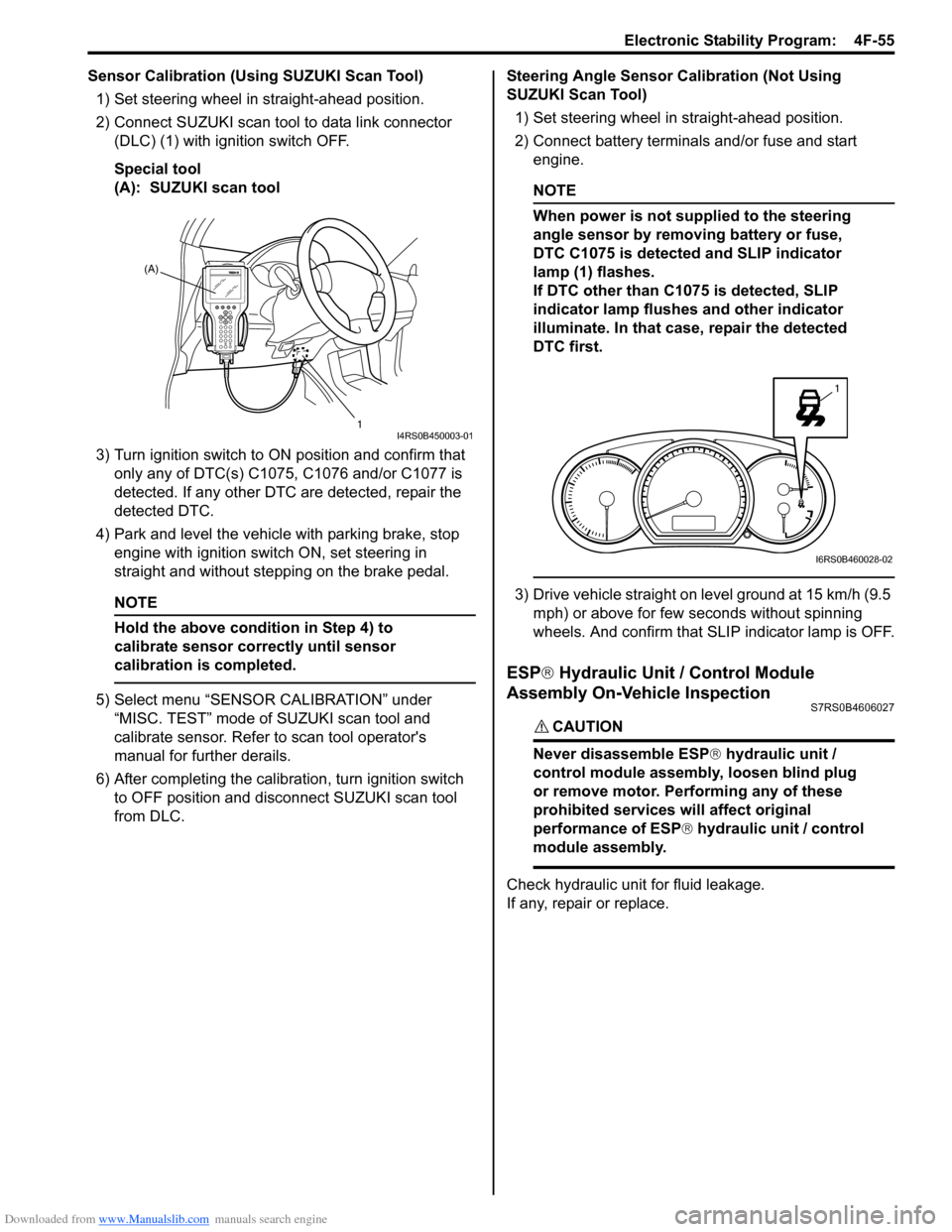

Sensor Calibration (Using SUZUKI Scan Tool)1) Set steering wheel in straight-ahead position.

2) Connect SUZUKI scan tool to data link connector (DLC) (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch to ON position and confirm that

only any of DTC(s) C1075, C1076 and/or C1077 is

detected. If any other DTC are detected, repair the

detected DTC.

4) Park and level the vehicle with parking brake, stop engine with ignition switch ON, set steering in

straight and without step ping on the brake pedal.

NOTE

Hold the above condition in Step 4) to

calibrate sensor correctly until sensor

calibration is completed.

5) Select menu “SENSOR CALIBRATION” under

“MISC. TEST” mode of SUZUKI scan tool and

calibrate sensor. Refer to scan tool operator's

manual for further derails.

6) After completing the calibra tion, turn ignition switch

to OFF position and disconnect SUZUKI scan tool

from DLC. Steering Angle Sensor Calibration (Not Using

SUZUKI Scan Tool)

1) Set steering wheel in straight-ahead position.

2) Connect battery terminals and/or fuse and start engine.

NOTE

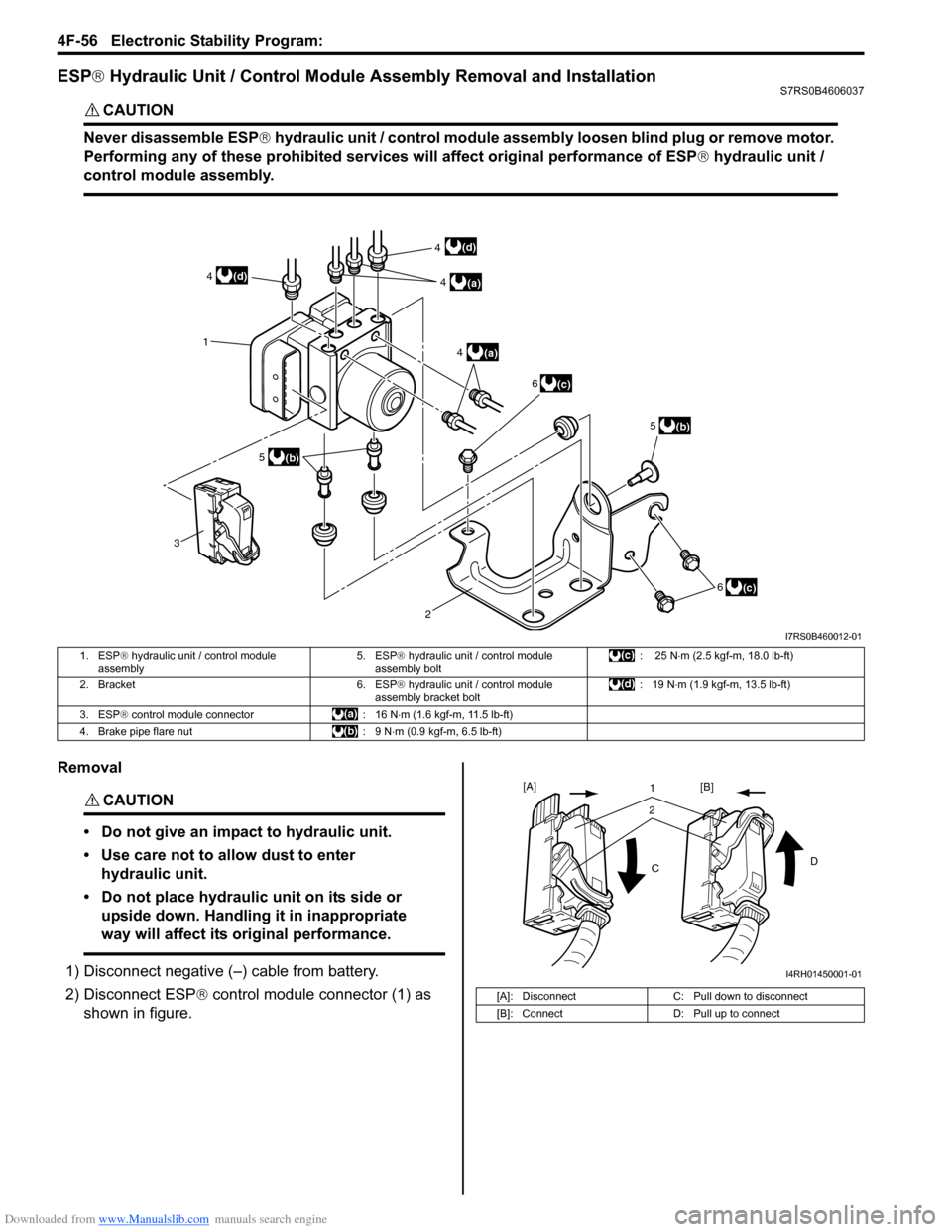

When power is not supplied to the steering

angle sensor by removing battery or fuse,

DTC C1075 is detected and SLIP indicator

lamp (1) flashes.

If DTC other than C1075 is detected, SLIP

indicator lamp flushes and other indicator

illuminate. In that case, repair the detected

DTC first.

3) Drive vehicle straight on level ground at 15 km/h (9.5 mph) or above for few seconds without spinning

wheels. And confirm that SLIP indicator lamp is OFF.

ESP ® Hydraulic Unit / Control Module

Assembly On-Vehicle Inspection

S7RS0B4606027

CAUTION!

Never disassemble ESP ® hydraulic unit /

control module assembly, loosen blind plug

or remove motor. Pe rforming any of these

prohibited services will affect original

performance of ESP ® hydraulic unit / control

module assembly.

Check hydraulic unit for fluid leakage.

If any, repair or replace.

(A)

1

I4RS0B450003-01

1

I6RS0B460028-02

Page 630 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-56 Electronic Stability Program:

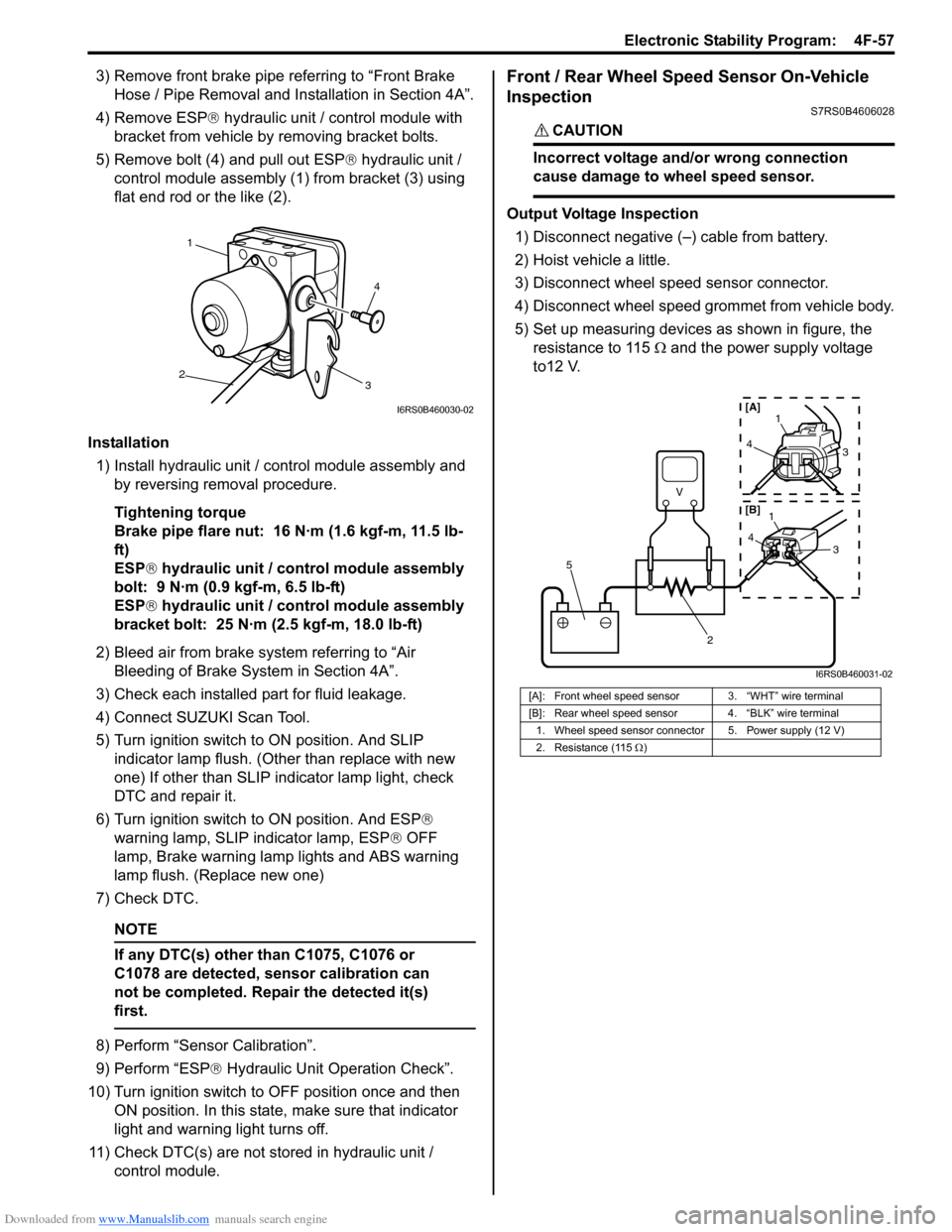

ESP® Hydraulic Unit / Control Module Assembly Removal and InstallationS7RS0B4606037

CAUTION!

Never disassemble ESP ® hydraulic unit / control module assembly loosen blind plug or remove motor.

Performing any of these proh ibited services will affect original performance of ESP ® hydraulic unit /

control module assembly.

Removal

CAUTION!

• Do not give an impact to hydraulic unit.

• Use care not to allow dust to enter hydraulic unit.

• Do not place hydraulic unit on its side or upside down. Handling it in inappropriate

way will affect its original performance.

1) Disconnect negative (–) cable from battery.

2) Disconnect ESP ® control module connector (1) as

shown in figure.

3 1

(c)

2

(b)

(a)4

(a)

4

5

6

(b)

5

(c)

6

(d)

(d) 4

4

I7RS0B460012-01

1. ESP ® hydraulic unit / control module

assembly 5. ESP

® hydraulic unit / control module

assembly bolt : 25 N

⋅m (2.5 kgf-m, 18.0 lb-ft)

2. Bracket 6. ESP ® hydraulic unit / control module

assembly bracket bolt : 19 N

⋅m (1.9 kgf-m, 13.5 lb-ft)

3. ESP ® control module connector : 16 N ⋅m (1.6 kgf-m, 11.5 lb-ft)

4. Brake pipe flare nut : 9 N ⋅m (0.9 kgf-m, 6.5 lb-ft)

[A]: DisconnectC: Pull down to disconnect

[B]: Connect D: Pull up to connect

21

C D

[A]

[B]

I4RH01450001-01

Page 631 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-57

3) Remove front brake pipe referring to “Front Brake Hose / Pipe Removal and In stallation in Section 4A”.

4) Remove ESP ® hydraulic unit / control module with

bracket from vehicle by removing bracket bolts.

5) Remove bolt (4) and pull out ESP ® hydraulic unit /

control module assembly (1) from bracket (3) using

flat end rod or the like (2).

Installation 1) Install hydraulic unit / co ntrol module assembly and

by reversing removal procedure.

Tightening torque

Brake pipe flare nut: 16 N·m (1.6 kgf-m, 11.5 lb-

ft)

ESP ® hydraulic unit / control module assembly

bolt: 9 N·m (0.9 kgf-m, 6.5 lb-ft)

ESP ® hydraulic unit / control module assembly

bracket bolt: 25 N·m (2.5 kgf-m, 18.0 lb-ft)

2) Bleed air from brake system referring to “Air Bleeding of Brake System in Section 4A”.

3) Check each installed part for fluid leakage.

4) Connect SUZUKI Scan Tool.

5) Turn ignition switch to ON position. And SLIP indicator lamp flush. (Other than replace with new

one) If other than SLIP indicator lamp light, check

DTC and repair it.

6) Turn ignition switch to ON position. And ESP®

warning lamp, SLIP indicator lamp, ESP ® OFF

lamp, Brake warning lamp lights and ABS warning

lamp flush. (Replace new one)

7) Check DTC.

NOTE

If any DTC(s) other than C1075, C1076 or

C1078 are detected, sensor calibration can

not be completed. Repair the detected it(s)

first.

8) Perform “Sensor Calibration”.

9) Perform “ESP ® Hydraulic Unit Operation Check”.

10) Turn ignition switch to OFF position once and then

ON position. In this state, make sure that indicator

light and warning light turns off.

11) Check DTC(s) are not stored in hydraulic unit / control module.

Front / Rear Wheel Speed Sensor On-Vehicle

Inspection

S7RS0B4606028

CAUTION!

Incorrect voltage and/or wrong connection

cause damage to wheel speed sensor.

Output Voltage Inspection

1) Disconnect negative (–) cable from battery.

2) Hoist vehicle a little.

3) Disconnect wheel speed sensor connector.

4) Disconnect wheel speed grommet from vehicle body.

5) Set up measuring devices as shown in figure, the resistance to 115 Ω and the power supply voltage

to12 V.

4

1

2 3

I6RS0B460030-02

[A]: Front wheel speed sensor 3. “WHT” wire terminal

[B]: Rear wheel speed sensor 4. “BLK” wire terminal

1. Wheel speed sensor connector 5. Power supply (12 V)

2. Resistance (115 Ω)

V

2

5

4 1

3

43

1

[A]

[B]

I6RS0B460031-02

Page 632 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-58 Electronic Stability Program:

6) Measure voltage at resistance without wheel rotation.

If voltage is out of specification, check sensor,

mating encoder and their installation conditions.

Voltage at the resistance (115

Ω) without wheel

rotation

680 to 960 mV

7) Measure voltage at resistance with wheel rotation and confirm voltage alternately changes between

high and low voltages.

If voltage does not change with wheel rotation, check

sensor, mating encoder and their installation

conditions.

Voltage at the resistance (115

Ω) with wheel

rotation

High voltage “a”: 1360 to 1930 mV

Low voltage “b”: 680 to 960 mV

Reference

When using oscilloscope for this check, check if peak-to-

peak voltage and waveform meet specification.

Peak-to-peak Voltage at the resistance (115

Ω) with

wheel rotation

High voltage “a”: 1360 to 1930 mV

Low voltage “b”: 680 to 960 mV

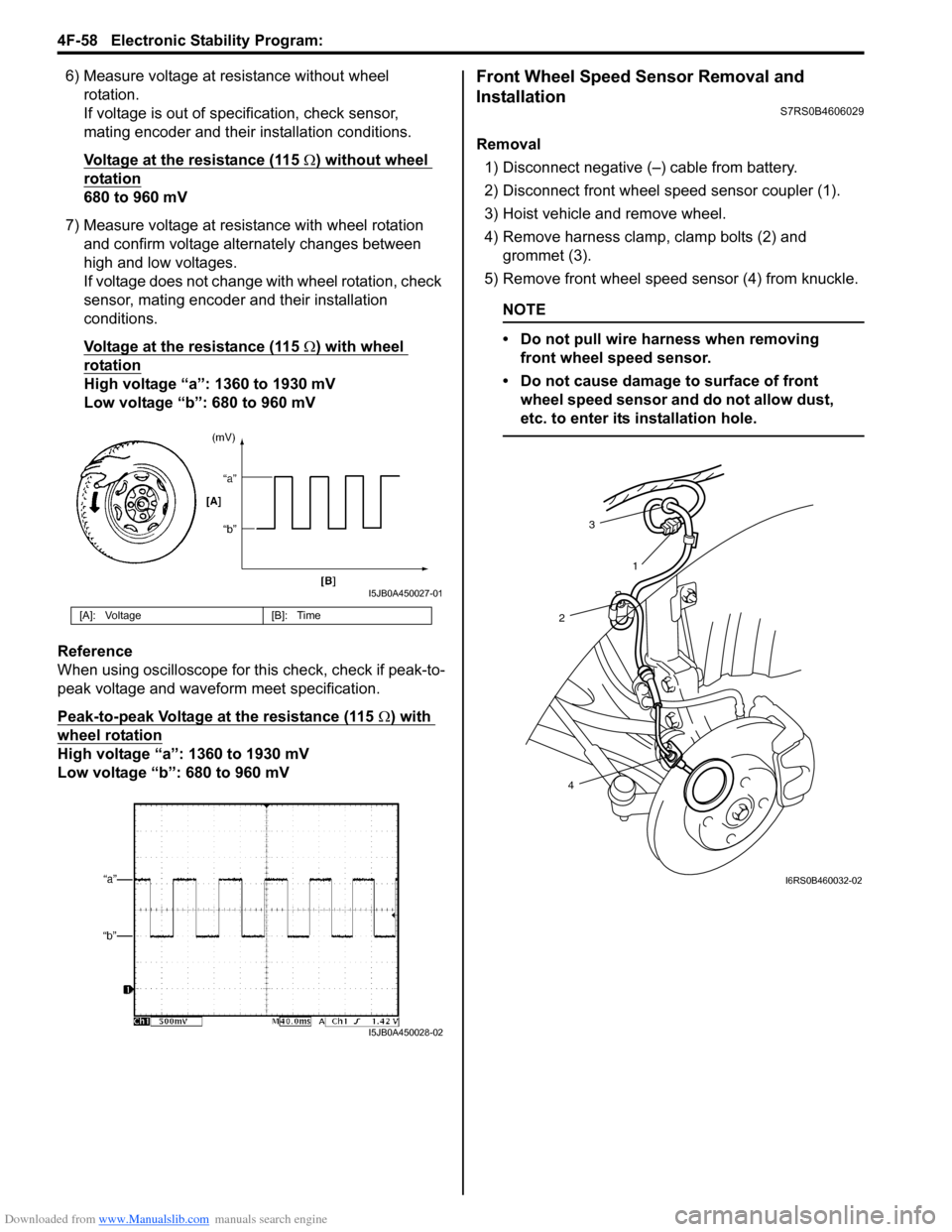

Front Wheel Speed Sensor Removal and

Installation

S7RS0B4606029

Removal

1) Disconnect negative (–) cable from battery.

2) Disconnect front wheel speed sensor coupler (1).

3) Hoist vehicle and remove wheel.

4) Remove harness clamp, clamp bolts (2) and grommet (3).

5) Remove front wheel speed sensor (4) from knuckle.

NOTE

• Do not pull wire harness when removing front wheel speed sensor.

• Do not cause damage to surface of front wheel speed sensor and do not allow dust,

etc. to enter its installation hole.

[A]: Voltage [B]: Time

I5JB0A450027-01

I5JB0A450028-02

3

2

4 1

I6RS0B460032-02

Page 633 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-59

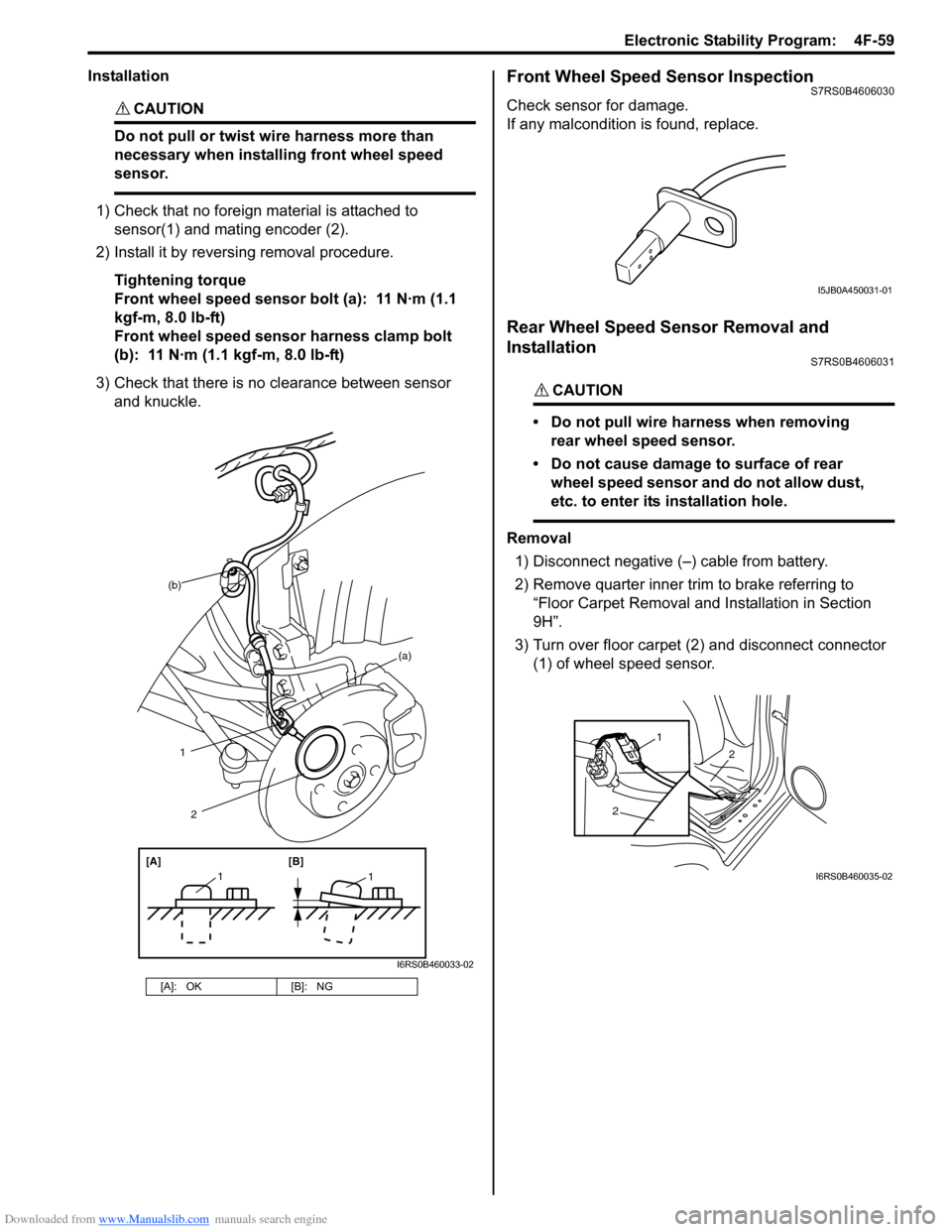

Installation

CAUTION!

Do not pull or twist wire harness more than

necessary when installing front wheel speed

sensor.

1) Check that no foreign material is attached to sensor(1) and mating encoder (2).

2) Install it by reversing removal procedure.

Tightening torque

Front wheel speed sensor bolt (a): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

Front wheel speed sensor harness clamp bolt

(b): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

3) Check that there is no clearance between sensor and knuckle.

Front Wheel Speed Sensor InspectionS7RS0B4606030

Check sensor for damage.

If any malcondition is found, replace.

Rear Wheel Speed Sensor Removal and

Installation

S7RS0B4606031

CAUTION!

• Do not pull wire harness when removing rear wheel speed sensor.

• Do not cause damage to surface of rear wheel speed sensor and do not allow dust,

etc. to enter its installation hole.

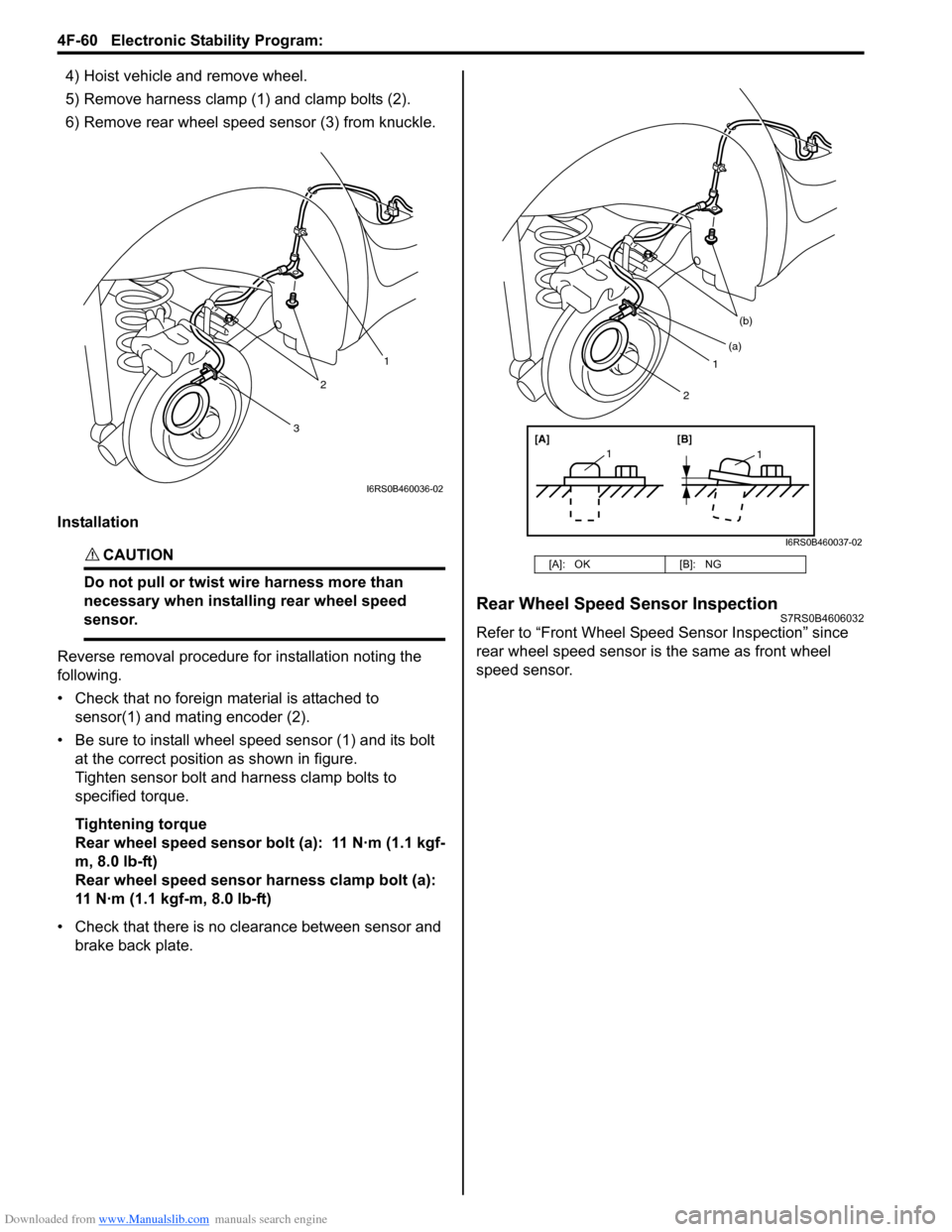

Removal

1) Disconnect negative (–) cable from battery.

2) Remove quarter inner trim to brake referring to

“Floor Carpet Removal and Installation in Section

9H”.

3) Turn over floor carpet (2) and disconnect connector (1) of wheel speed sensor.

[A]: OK [B]: NG

(b)

1

[A][B]

11

2

(a)

I6RS0B460033-02

I5JB0A450031-01

2

2

1

I6RS0B460035-02

Page 634 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-60 Electronic Stability Program:

4) Hoist vehicle and remove wheel.

5) Remove harness clamp (1) and clamp bolts (2).

6) Remove rear wheel speed sensor (3) from knuckle.

Installation

CAUTION!

Do not pull or twist wi re harness more than

necessary when installing rear wheel speed

sensor.

Reverse removal procedure for installation noting the

following.

• Check that no foreign material is attached to sensor(1) and mating encoder (2).

• Be sure to install wheel speed sensor (1) and its bolt at the correct position as shown in figure.

Tighten sensor bolt and harness clamp bolts to

specified torque.

Tightening torque

Rear wheel speed sensor bolt (a): 11 N·m (1.1 kgf-

m, 8.0 lb-ft)

Rear wheel speed sensor harness clamp bolt (a):

11 N·m (1.1 kgf-m, 8.0 lb-ft)

• Check that there is no clearance between sensor and brake back plate.

Rear Wheel Speed Sensor InspectionS7RS0B4606032

Refer to “Front Wheel Speed Sensor Inspection” since

rear wheel speed sensor is the same as front wheel

speed sensor.

3

2

1

I6RS0B460036-02

[A]: OK [B]: NG

1

(b)

[A][B]

11

(a)

2

I6RS0B460037-02

Page 635 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-61

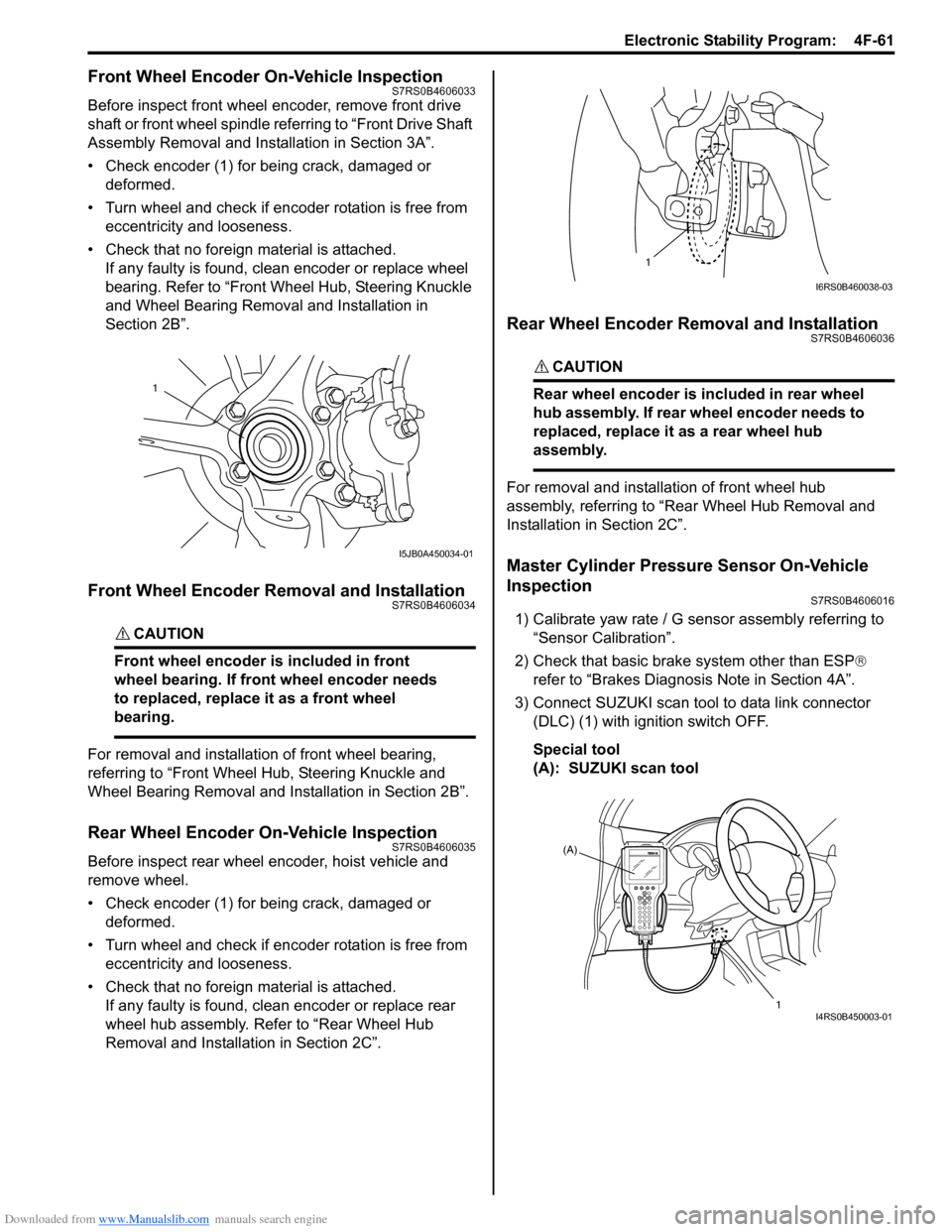

Front Wheel Encoder On-Vehicle InspectionS7RS0B4606033

Before inspect front wheel encoder, remove front drive

shaft or front wheel spindle referring to “Front Drive Shaft

Assembly Removal and Installation in Section 3A”.

• Check encoder (1) for being crack, damaged or deformed.

• Turn wheel and check if encoder rotation is free from eccentricity and looseness.

• Check that no foreign material is attached. If any faulty is found, cl ean encoder or replace wheel

bearing. Refer to “Front Wheel Hub, Steering Knuckle

and Wheel Bearing Removal and Installation in

Section 2B”.

Front Wheel Encoder Removal and InstallationS7RS0B4606034

CAUTION!

Front wheel encoder is included in front

wheel bearing. If front wheel encoder needs

to replaced, replace it as a front wheel

bearing.

For removal and installation of front wheel bearing,

referring to “Front Wheel Hub, Steering Knuckle and

Wheel Bearing Removal and Installation in Section 2B”.

Rear Wheel Encoder On-Vehicle InspectionS7RS0B4606035

Before inspect rear wheel encoder, hoist vehicle and

remove wheel.

• Check encoder (1) for being crack, damaged or deformed.

• Turn wheel and check if encoder rotation is free from eccentricity and looseness.

• Check that no foreign material is attached. If any faulty is found, cl ean encoder or replace rear

wheel hub assembly. Refer to “Rear Wheel Hub

Removal and Installati on in Section 2C”.

Rear Wheel Encoder Removal and InstallationS7RS0B4606036

CAUTION!

Rear wheel encoder is included in rear wheel

hub assembly. If rear wheel encoder needs to

replaced, replace it as a rear wheel hub

assembly.

For removal and installation of front wheel hub

assembly, referring to “Rear Wheel Hub Removal and

Installation in Section 2C”.

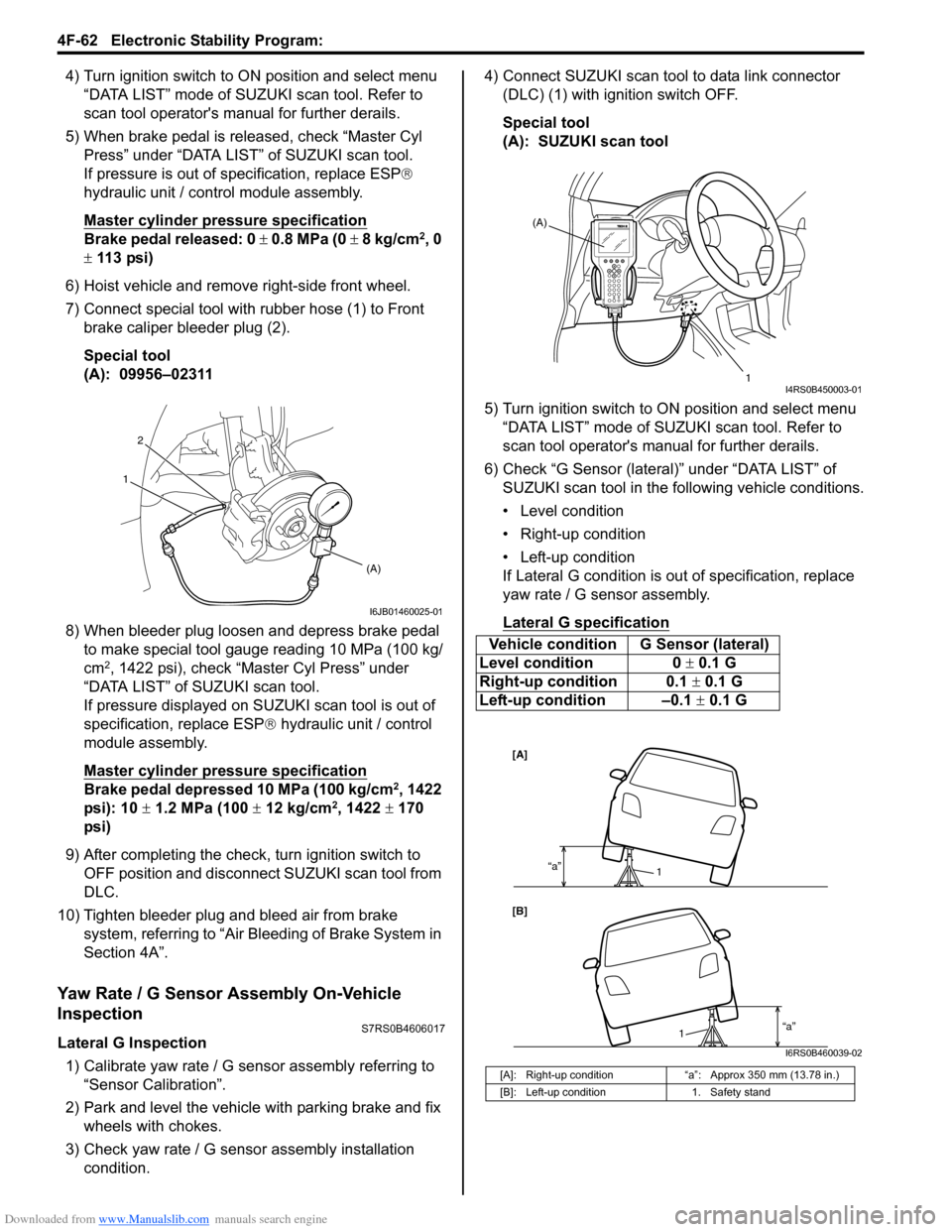

Master Cylinder Pressure Sensor On-Vehicle

Inspection

S7RS0B4606016

1) Calibrate yaw rate / G sens or assembly referring to

“Sensor Calibration”.

2) Check that basic brake system other than ESP ®

refer to “Brakes Diagnosi s Note in Section 4A”.

3) Connect SUZUKI scan tool to data link connector (DLC) (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

1

I5JB0A450034-01

1

I6RS0B460038-03

(A)

1

I4RS0B450003-01

Page 636 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-62 Electronic Stability Program:

4) Turn ignition switch to ON position and select menu “DATA LIST” mode of SUZUKI scan tool. Refer to

scan tool operator's manual for further derails.

5) When brake pedal is released, check “Master Cyl Press” under “DATA LIST” of SUZUKI scan tool.

If pressure is out of specification, replace ESP ®

hydraulic unit / cont rol module assembly.

Master cylinder pressure specification

Brake pedal released: 0 ± 0.8 MPa (0 ± 8 kg/cm2, 0

± 113 psi)

6) Hoist vehicle and remove right-side front wheel.

7) Connect special tool with rubber hose (1) to Front brake caliper bleeder plug (2).

Special tool

(A): 09956–02311

8) When bleeder plug loosen and depress brake pedal to make special tool gauge reading 10 MPa (100 kg/

cm

2, 1422 psi), check “Master Cyl Press” under

“DATA LIST” of SUZUKI scan tool.

If pressure displayed on SUZUKI scan tool is out of

specification, replace ESP ® hydraulic unit / control

module assembly.

Master cylinder pressure specification

Brake pedal depressed 10 MPa (100 kg/cm2, 1422

psi): 10 ± 1.2 MPa (100 ± 12 kg/cm2, 1422 ± 170

psi)

9) After completing the check, turn ignition switch to

OFF position and disconnect SUZUKI scan tool from

DLC.

10) Tighten bleeder plug and bleed air from brake system, referring to “Air Bleeding of Brake System in

Section 4A”.

Yaw Rate / G Sensor Assembly On-Vehicle

Inspection

S7RS0B4606017

Lateral G Inspection

1) Calibrate yaw rate / G sens or assembly referring to

“Sensor Calibration”.

2) Park and level the vehicle with parking brake and fix wheels with chokes.

3) Check yaw rate / G sensor assembly installation

condition. 4) Connect SUZUKI scan tool to data link connector

(DLC) (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

5) Turn ignition switch to ON position and select menu “DATA LIST” mode of SUZUKI scan tool. Refer to

scan tool operator's manual for further derails.

6) Check “G Sensor (lateral)” under “DATA LIST” of SUZUKI scan tool in the following vehicle conditions.

• Level condition

• Right-up condition

• Left-up condition

If Lateral G condition is ou t of specification, replace

yaw rate / G sensor assembly.

Lateral G sp ecification

2

(A)

1

I6JB01460025-01

Vehicle condition G Sensor (lateral)

Level condition 0 ± 0.1 G

Right-up condition 0.1 ± 0.1 G

Left-up condition –0.1 ± 0.1 G

[A]: Right-up condition “a”: Approx 350 mm (13.78 in.)

[B]: Left-up condition 1. Safety stand

(A)

1

I4RS0B450003-01

[A]

[B]“a”

1

“a”1

I6RS0B460039-02

Page 637 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-63

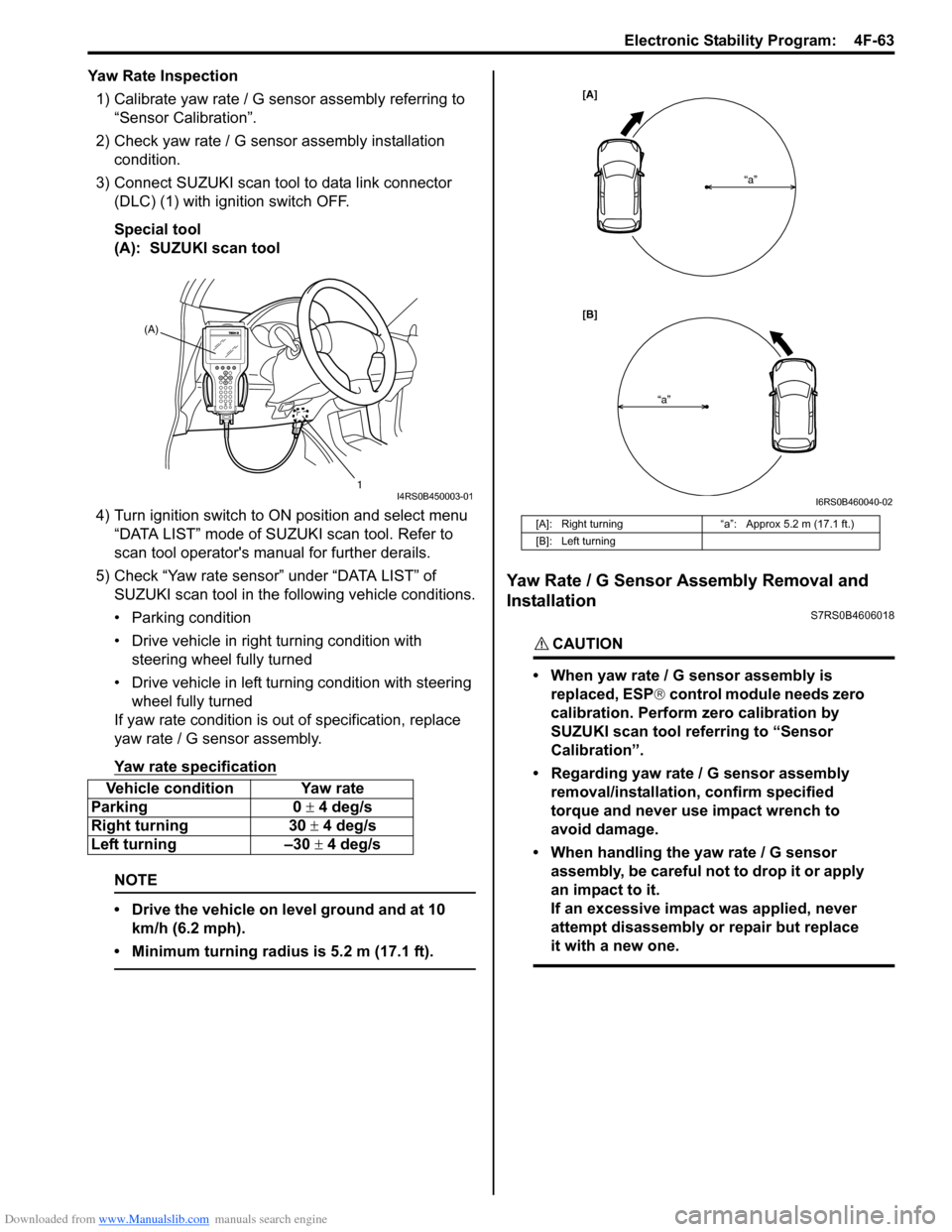

Yaw Rate Inspection1) Calibrate yaw rate / G sens or assembly referring to

“Sensor Calibration”.

2) Check yaw rate / G sensor assembly installation

condition.

3) Connect SUZUKI scan tool to data link connector (DLC) (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

4) Turn ignition switch to ON position and select menu

“DATA LIST” mode of SUZUKI scan tool. Refer to

scan tool operator's manual for further derails.

5) Check “Yaw rate sensor” under “DATA LIST” of SUZUKI scan tool in the following vehicle conditions.

• Parking condition

• Drive vehicle in right turning condition with steering wheel fully turned

• Drive vehicle in left tu rning condition with steering

wheel fully turned

If yaw rate condition is ou t of specification, replace

yaw rate / G sensor assembly.

Yaw rate specification

NOTE

• Drive the vehicle on level ground and at 10 km/h (6.2 mph).

• Minimum turning radius is 5.2 m (17.1 ft).

Yaw Rate / G Sensor Assembly Removal and

Installation

S7RS0B4606018

CAUTION!

• When yaw rate / G sensor assembly is replaced, ESP ® control module needs zero

calibration. Perform zero calibration by

SUZUKI scan tool referring to “Sensor

Calibration”.

• Regarding yaw rate / G sensor assembly removal/installation, confirm specified

torque and never use impact wrench to

avoid damage.

• When handling the yaw rate / G sensor assembly, be careful not to drop it or apply

an impact to it.

If an excessive impact was applied, never

attempt disassembly or repair but replace

it with a new one.

Vehicle condition Yaw rate

Parking 0 ± 4 deg/s

Right turning 30 ± 4 deg/s

Left turning –30 ± 4 deg/s

(A)

1

I4RS0B450003-01

[A]: Right turning“a”: Approx 5.2 m (17.1 ft.)

[B]: Left turning

[A]

[B] “a”

“a”

I6RS0B460040-02

Page 638 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-64 Electronic Stability Program:

Removal1) Disconnect negative (–) cable at battery.

2) Remove front console box referring to “Console Box Components in Section 9H”.

3) Disconnect connector from yaw rate / G sensor

assembly.

4) Remove yaw rate / G sens or assembly from sensor

bracket.

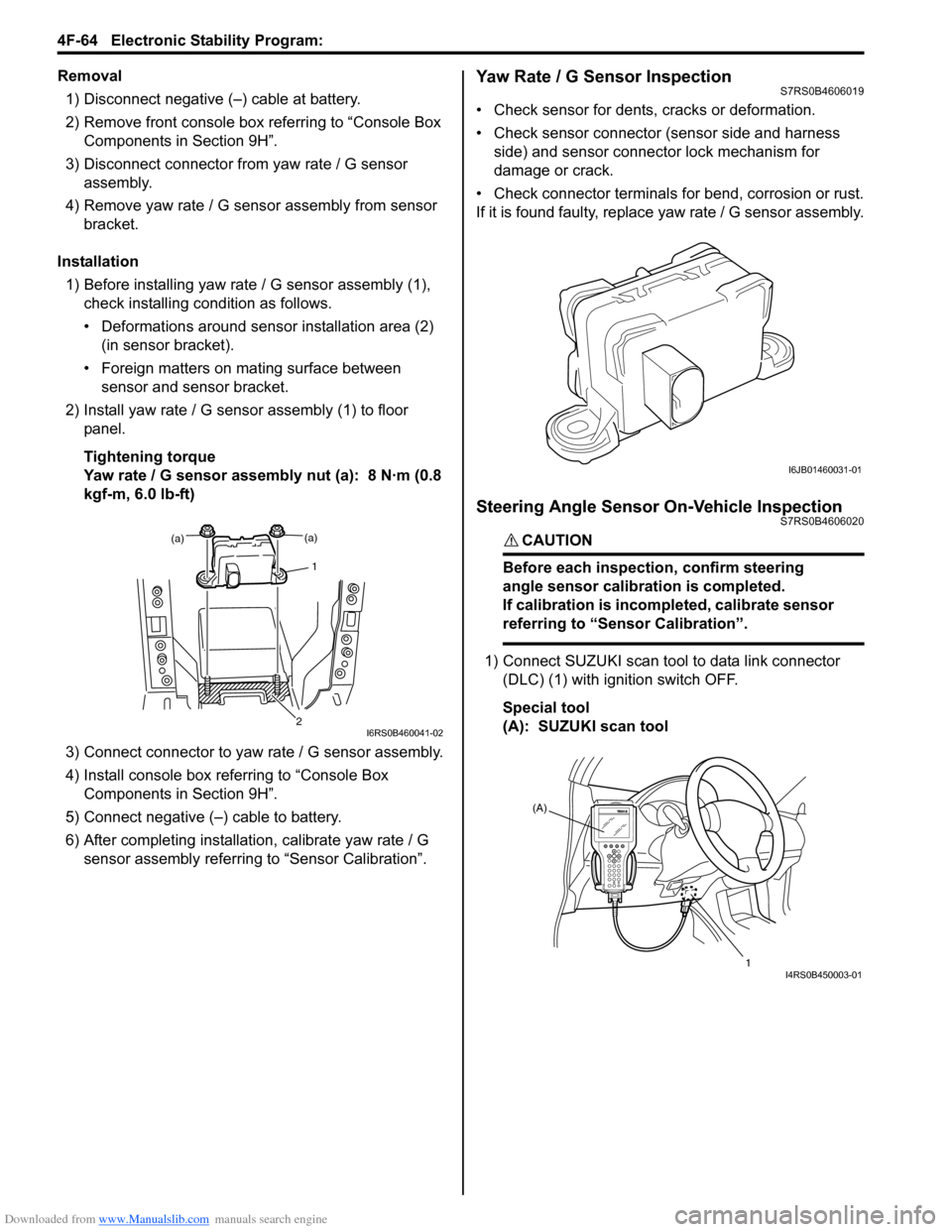

Installation 1) Before installing yaw rate / G sensor assembly (1),

check installing condition as follows.

• Deformations around sensor installation area (2) (in sensor bracket).

• Foreign matters on mating surface between sensor and sensor bracket.

2) Install yaw rate / G sensor assembly (1) to floor panel.

Tightening torque

Yaw rate / G sensor assembly nut (a): 8 N·m (0.8

kgf-m, 6.0 lb-ft)

3) Connect connector to yaw rate / G sensor assembly.

4) Install console box referring to “Console Box Components in Section 9H”.

5) Connect negative (–) cable to battery.

6) After completing installation, calibrate yaw rate / G

sensor assembly referring to “Sensor Calibration”.Yaw Rate / G Sensor InspectionS7RS0B4606019

• Check sensor for dents, cracks or deformation.

• Check sensor connector (sensor side and harness

side) and sensor connector lock mechanism for

damage or crack.

• Check connector terminals for bend, corrosion or rust.

If it is found faulty, replace yaw rate / G sensor assembly.

Steering Angle Sensor On-Vehicle InspectionS7RS0B4606020

CAUTION!

Before each inspection, confirm steering

angle sensor calibration is completed.

If calibration is incompleted, calibrate sensor

referring to “Sensor Calibration”.

1) Connect SUZUKI scan tool to data link connector

(DLC) (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

(a)

1

(a)

2I6RS0B460041-02

I6JB01460031-01

(A)

1

I4RS0B450003-01