Control system SUZUKI SWIFT 2008 2.G Service Manual PDF

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 147 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-97

DTC P0140: O2 Sensor (HO2S) Circuit No Activity Detected (Sensor-2)S7RS0B1104035

Wiring Diagram

Refer to “DTC P0137 / P0138: O2 Sensor (HO2S) Circuit Low Voltage / High Voltage (Sensor-2)”

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Start engine and warm up to normal operating temperature.

4) Increase vehicle speed to 60 – 80 km/h (37 – 50 mile/h) at 5th gear or D range.

5) Release accelerator pedal and with engine brake applied, ke ep vehicle coasting (with fuel cut for 4 sec. or more),

then stop vehicle and run engine at idle speed for 60 sec. or more.

6) Check DTC and pending DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC detecting condition Trouble area

HO2S-2 voltage is higher than specified value after warming up engine

(circuit open).

(2 driving cycle detection logic) •HO2S-2

• HO2S-2 circuit

•ECM

• Exhaust gas leakage

• Air intake system

Step

Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 HO2S-2 ground check

1) Disconnect connector from HO 2S-2 with ignition switch

turned OFF.

2) Check for proper connection to HO2S-2 connector at “RED/BLU”, “BRN”, “YEL” and “BLK/WHT” wire

terminals.

3) If connections are OK, m easure resistance between

“YEL” wire terminal of HO2S-2 connector and engine

ground.

Is resistance less than 5

Ω? Go to Step 3. “YEL” wire is open or

high resistance circuit.

Poor “C37-57” terminal

connection. Faulty ECM

ground.

If they are OK,

substitute a known-

good ECM and recheck.

Page 148 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-98 Engine General Information and Diagnosis:

DTC P0171 / P0172: Fuel System Too Lean / RichS7RS0B1104036

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

NOTE

Check to make sure that following conditions ar e satisfied when using this “DTC Confirmation

Procedure”.

• Intake air temperature at engine start: –10 °C (14 ° F) to 80 °C (176 °F)

• Intake air temperature: –10 °C (14 °F) to 70 °C (158 °F)

• Engine coolant temperature: 40 °C (104 °F) to 120 °C (248 °F)

• Altitude (barometric pressure): 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

3 Wire circuit check

1) Turn OFF ignition switch.

2) Remove ECM from its br acket with ECM connectors

connected.

3) Measure resistance between “BRN” wire terminal of HO2S-2 connector and “C37-11” terminal of ECM

connector.

Is resistance less than 5

Ω? Go to Step 4. “BRN” wire is high

resistance circuit or

open circuit. Poor “C37-

11” terminal connection.

If they are OK,

substitute a known-

good ECM and recheck.

4 HO2S-2 signal circuit check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Measure voltage between “BRN” wire terminal of HO2S- 2 connector and vehicle body ground.

Is voltage 0 V? Go to Step 5. “BRN” wire is shorted to

other circuit.

5 HO2S-2 heater circuit check

1) Check HO2S-2 heater circuit referring to “DTC P0037 /

P0038: HO2S Heater Control Circuit Low / High

(Sensor-2)”.

Is circuit in good condition? Go to Step 6. Repair HO2S-2 circuit. If

circuit is OK, substitute

a known-good ECM and

recheck.

6 HO2S-2 check

1) Check HO2S-2 referring to “HO2S-1 and HO2S-2

Heater On-Vehicle Inspection in Section 1C”.

Is it in good condition? Substitute a known-

good ECM and recheck.

Replace HO2S-2.

Step Action Yes No

DTC detecting condition

Trouble area

DTC P0171:

Total fuel trim is higher than 35% or short term fuel trim is higher

than 20% for more than 1 min. continuously.

(2 driving cycle detection logic)

DTC P0172:

Total fuel trim is lower than –35% or short term fuel trim is lower

than –20% for more than 1 min. continuously.

(2 driving cycle detection logic) • Vacuum leakage

• Exhaust gas leakage

• Fuel pressure out of specification

• Fuel injector malfunction

• Heated oxygen sensor-1 malfunction

• MAF sensor malfunction

• ECT sensor malfunction

Page 149 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-99

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and print Freeze Frame Data or write them down using scan tool.

3) Clear DTC using scan tool.

4) Start engine and warm up to normal operating temperature.

5) Operate vehicle with condition as noted freeze frame data for 5 min.

6) Stop vehicle and check DTC and pending DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Is there DTC(s) other than fuel system (DTC P0171 /

P0172)? Go to applicable DTC

diag. flow.Go to Step 3.

3 Intake system and exhaust system for leakage check

Are intake system and exhaust system in good condition? Go to Step 4.

Repair or replace

defective part.

4 Fuel pressure check

1) Check fuel pressure referring to “Fuel Pressure Check”.

Is check result satisfactory? Go to Step 5.

Repair or replace

defective part.

5 Fuel injectors and its circuit check

1) Check fuel injectors referring to “Fuel Injector Inspection

in Section 1G”.

Is check result satisfactory? Go to Step 6.

Faulty injector(s) or its

circuit.

6 Visual inspection

1) Check MAF sensor and air intake system.

• Objects which block measur ing duct and resistor of

MAF sensor.

• Other air flow which does not pass MAF sensor.

Are they in good condition? Go to Step 7.

Repair or replace

defective part.

7 MAF sensor for performance check

1) With ignition switch turn ed OFF, install scan tool.

2) Start engine and warm up to normal operating temperature.

3) Check MAF value using scan tool (Refer to “Scan Tool Data” for normal value.).

Is each value within specified range? Go to Step 8.

Go to “DTC P0101:

Mass or Volume Air

Flow Circuit Range /

Performance”.

8 ECT sensor for performance check

1) Check ECT sensor referring to Step 3 and 4 of “DTC

P0118: Engine Coolant Temperature Circuit High”.

Is check result satisfactory? Go to Step 9.

Faulty ECT sensor or its

circuit.

Page 151 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-101

NOTE

When DTC P0122 and P0222 are indicated together, it is possible that “RED” wire open circuit.

DTC Confirmation Procedure

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Keep the accelerator pedal at idle position for 2 seconds.

4) Keep the accelerator pedal at fully depressed position for 2 seconds.

5) Repeat Step 3) and 4) for 3 times.

6) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 TP sensor and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch, check “TP Sensor 2 Volt” displayed on scan tool when accelerator pedal is idle

position and fully depressed.

Is displayed TP sensor value as described voltage in “Scan

To o l D a t a ” ? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 3.

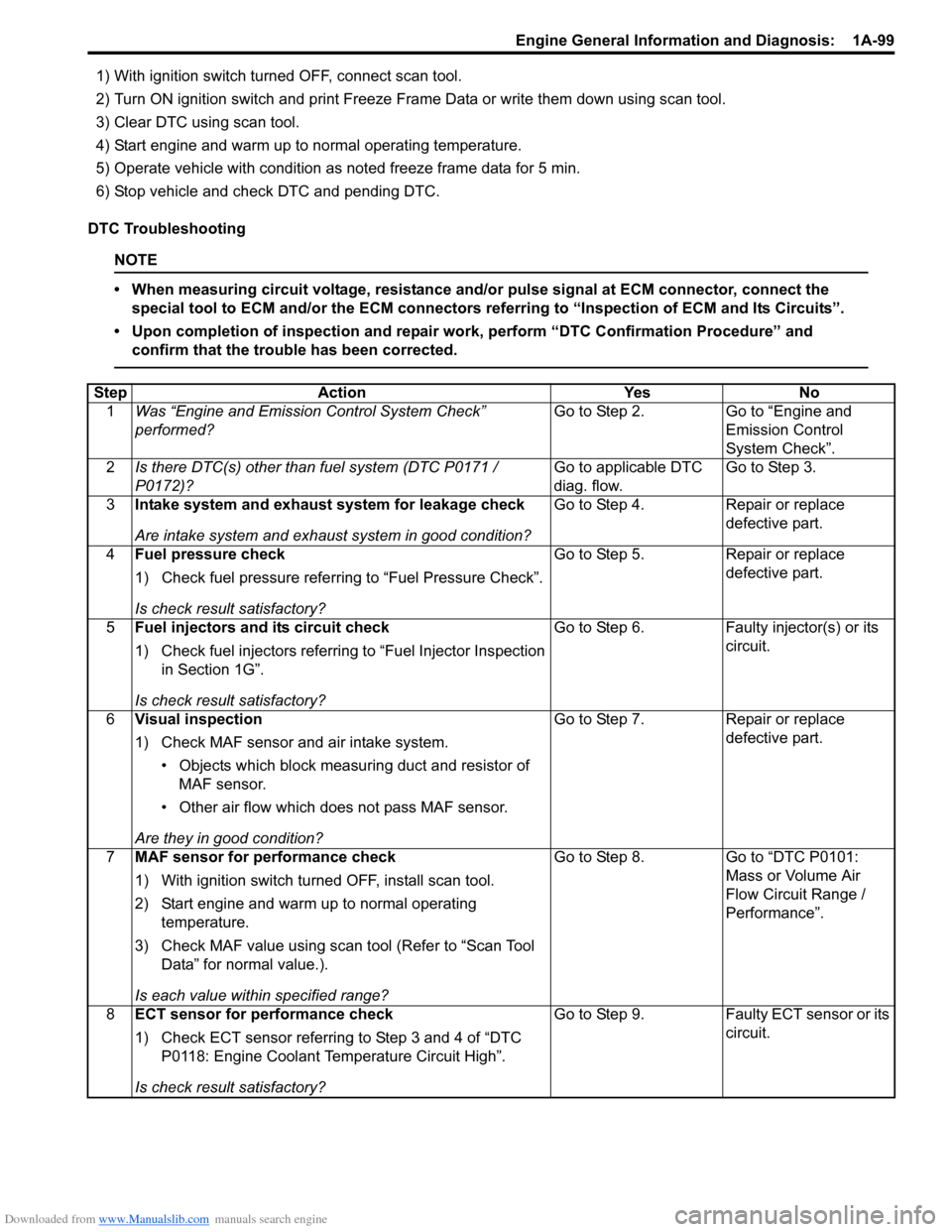

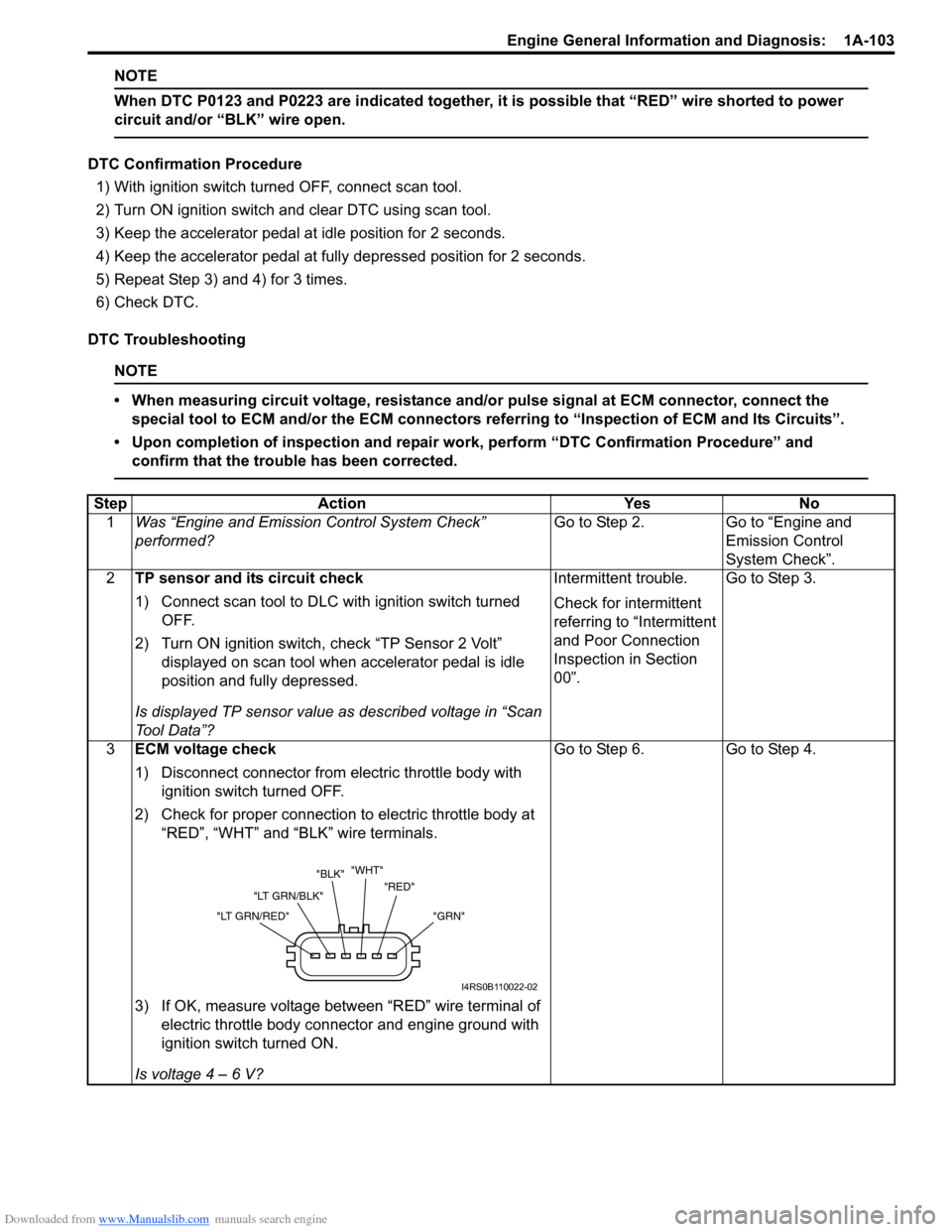

3 ECM voltage check

1) Disconnect connector from electric throttle body with

ignition switch turned OFF.

2) Check for proper connection to electric throttle body at “RED”, “WHT” and “BLK” wire terminals.

3) If OK, measure voltage between “RED” wire terminal of electric throttle body connector and engine ground with

ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 6.

Go to Step 4.

"GRN"

"RED"

"WHT"

"BLK"

"LT GRN/BLK"

"LT GRN/RED"

I4RS0B110022-02

Page 153 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-103

NOTE

When DTC P0123 and P0223 are indicated together, it is possible that “RED” wire shorted to power

circuit and/or “BLK” wire open.

DTC Confirmation Procedure

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Keep the accelerator pedal at idle position for 2 seconds.

4) Keep the accelerator pedal at fully depressed position for 2 seconds.

5) Repeat Step 3) and 4) for 3 times.

6) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 TP sensor and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch, check “TP Sensor 2 Volt” displayed on scan tool when accelerator pedal is idle

position and fully depressed.

Is displayed TP sensor value as described voltage in “Scan

To o l D a t a ” ? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 3.

3 ECM voltage check

1) Disconnect connector from electric throttle body with

ignition switch turned OFF.

2) Check for proper connection to electric throttle body at “RED”, “WHT” and “BLK” wire terminals.

3) If OK, measure voltage between “RED” wire terminal of electric throttle body connector and engine ground with

ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 6.

Go to Step 4.

"GRN"

"RED"

"WHT"

"BLK"

"LT GRN/BLK"

"LT GRN/RED"

I4RS0B110022-02

Page 156 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-106 Engine General Information and Diagnosis:

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Does fuel level meter in dicate “E” level (empty)? Add fuel and recheck. Go to Step 3.

3 Fuel quality check

1) Check that there is fuel of good quality in the fuel tank.

Is it OK? Go to Step 4.

Clean in fuel system

circuit and change fuel.

4 Ignition system check

1) Check spark plug and ignition spark of cylinder where

misfire occurs, referring to “Spark Plug Inspection in

Section 1H” and “Ignition Spark Test in Section 1H”.

Are they in good condition? Go to Step 5.

Faulty ignition coil, wire

harness, spark plug or

other system parts.

5 Fuel injector circuit check

1) Using sound scope, check each injector operating sound

at engine cranking or idling.

Do all injectors ma ke operating sound? Go to Step 6.

Check coupler

connection and wire

harness of injector not

making operating sound

and injector itself. If OK,

substitute a known-

good ECM and recheck.

6 Fuel pressure check

1) Check fuel pressure referring to “Fuel Pressure Check”.

Is check result satisfactory? Go to Step 7.

Repair or replace fuel

system.

7 Fuel injector check

1) Check fuel injector(s) re ferring to “Fuel Injector

Inspection in Section 1G”.

Is check result satisfactory? Go to Step 8.

Replace defective

injector.

8 Ignition timing check

1) Check ignition timing referring to “Ignition Timing

Inspection in Section 1H”.

Is check result satisfactory? Go to Step 9.

Check related sensors.

9 EGR system check

1) Check EGR system referring to “EGR System Inspection

in Section 1B”.

Is check result satisfactory? Go to Step 10. Repair or replace EGR

system.

10 Exhaust system check

1) Check exhaust system for exhaust gas clogged.

Is it OK? Go to Step 11. Repair clogged of

exhaust system.

Page 158 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-108 Engine General Information and Diagnosis:

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Knock sensor circuit check

1) Remove ECM from its br acket with ECM connectors

connected.

2) Measure voltage between “C37-56” terminal of ECM connector and vehicle body ground with engine running.

Is voltage within 1.23 – 3.91 V? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”. If OK, substitute a

known-good ECM and

recheck.Go to Step 3.

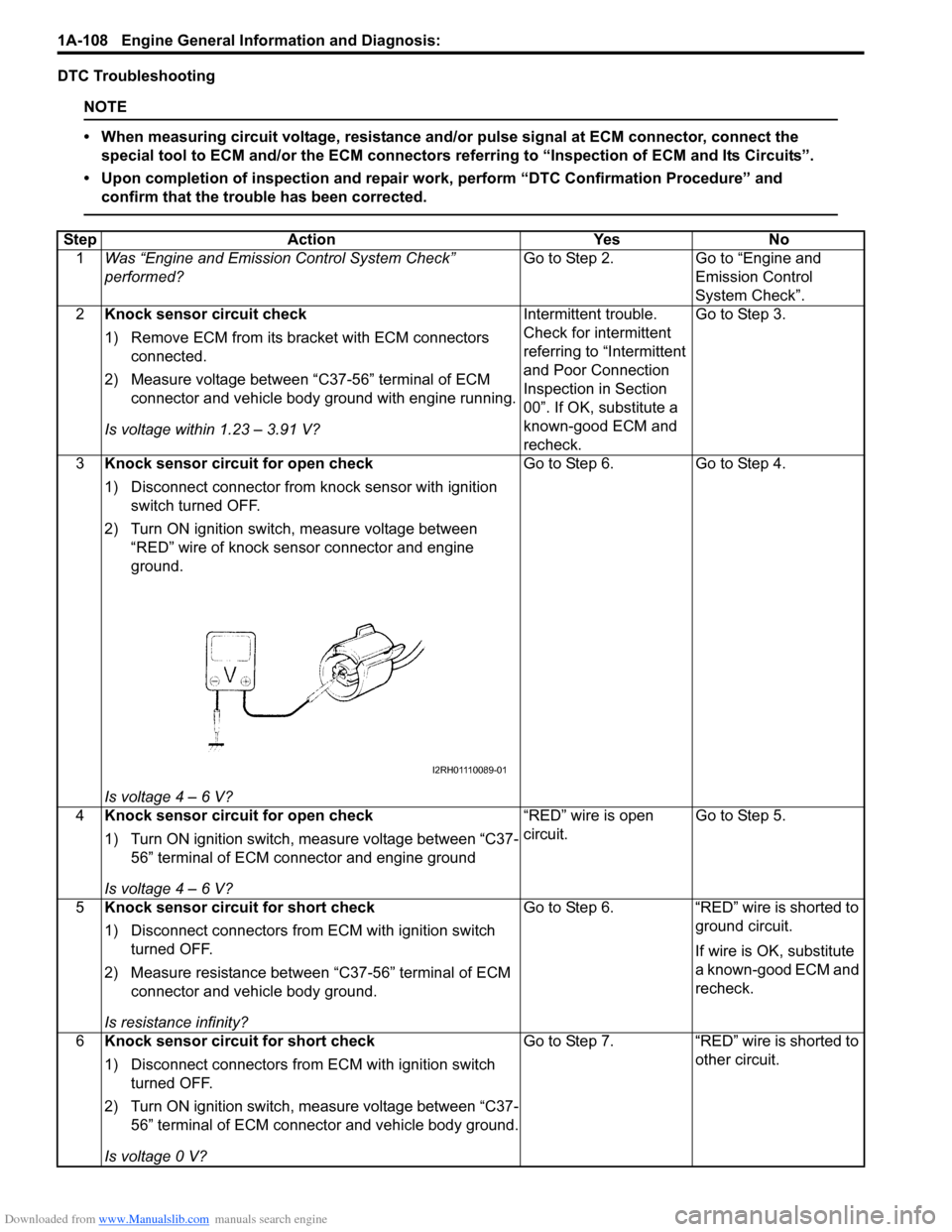

3 Knock sensor circuit for open check

1) Disconnect connector from knock sensor with ignition

switch turned OFF.

2) Turn ON ignition switch, measure voltage between “RED” wire of knock sensor connector and engine

ground.

Is voltage 4 – 6 V? Go to Step 6.

Go to Step 4.

4 Knock sensor circuit for open check

1) Turn ON ignition switch, measure voltage between “C37-

56” terminal of ECM connector and engine ground

Is voltage 4 – 6 V? “RED” wire is open

circuit.

Go to Step 5.

5 Knock sensor circuit for short check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Measure resistance between “C37-56” terminal of ECM connector and vehicle body ground.

Is resistance infinity? Go to Step 6.

“RED” wire is shorted to

ground circuit.

If wire is OK, substitute

a known-good ECM and

recheck.

6 Knock sensor circuit for short check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Turn ON ignition switch, measure voltage between “C37- 56” terminal of ECM connector and vehicle body ground.

Is voltage 0 V? Go to Step 7.

“RED” wire is shorted to

other circuit.

I2RH01110089-01

Page 160 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-110 Engine General Information and Diagnosis:

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 CKP sensor and connector for proper installation check

Is CKP sensor installed properly and connector connected

securely? Go to Step 3.

Correct.

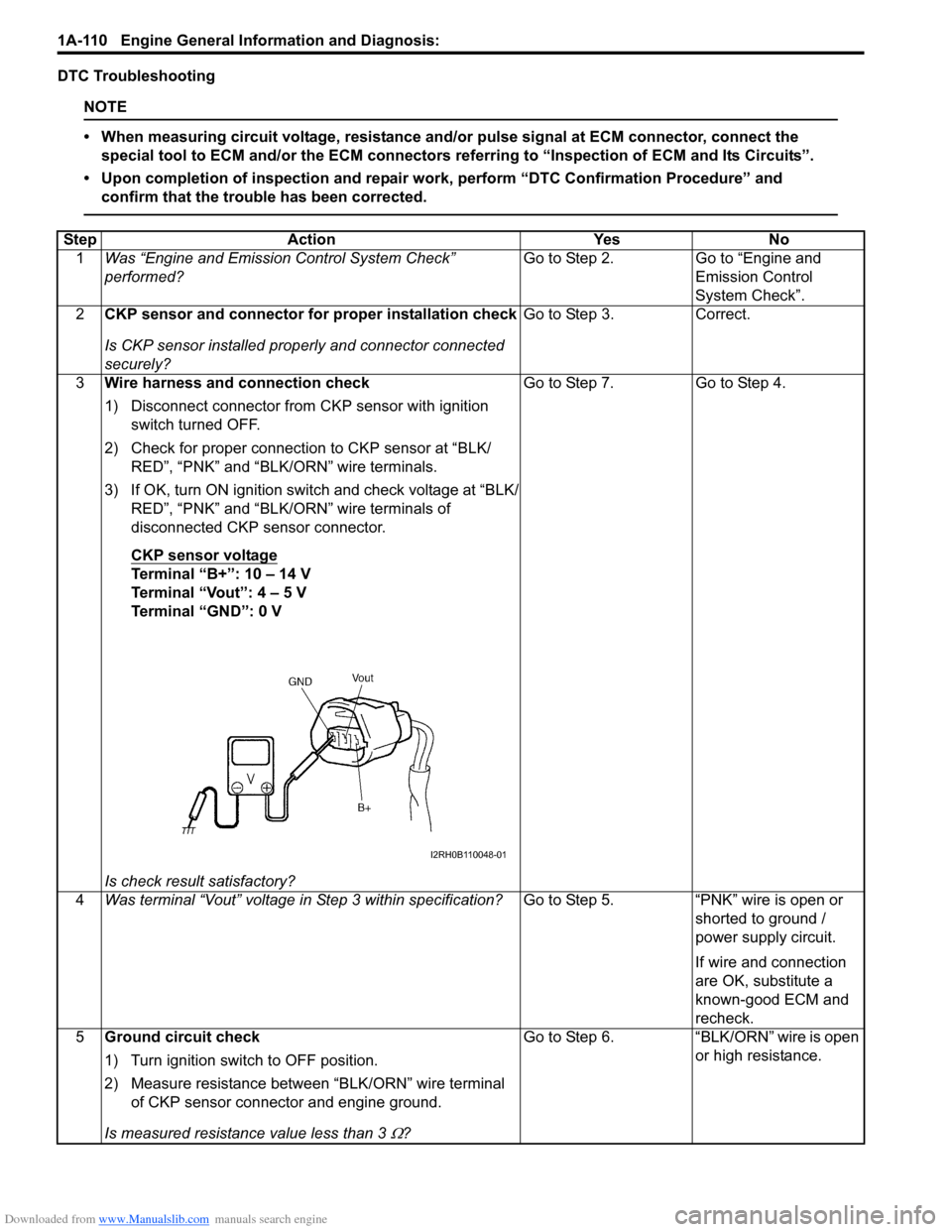

3 Wire harness and connection check

1) Disconnect connector from CKP sensor with ignition

switch turned OFF.

2) Check for proper connection to CKP sensor at “BLK/ RED”, “PNK” and “BLK/ORN” wire terminals.

3) If OK, turn ON ignition switch and check voltage at “BLK/ RED”, “PNK” and “BLK/ORN” wire terminals of

disconnected CKP sensor connector.

CKP sensor voltage

Terminal “B+”: 10 – 14 V

Terminal “Vout”: 4 – 5 V

Terminal “GND”: 0 V

Is check result satisfactory? Go to Step 7. Go to Step 4.

4 Was terminal “Vout” voltage in Step 3 within specification? Go to Step 5. “PNK” wire is open or

shorted to ground /

power supply circuit.

If wire and connection

are OK, substitute a

known-good ECM and

recheck.

5 Ground circuit check

1) Turn ignition switch to OFF position.

2) Measure resistance between “BLK/ORN” wire terminal

of CKP sensor connector and engine ground.

Is measured resistance value less than 3

Ω? Go to Step 6. “BLK/ORN” wire is open

or high resistance.

I2RH0B110048-01

Page 162 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-112 Engine General Information and Diagnosis:

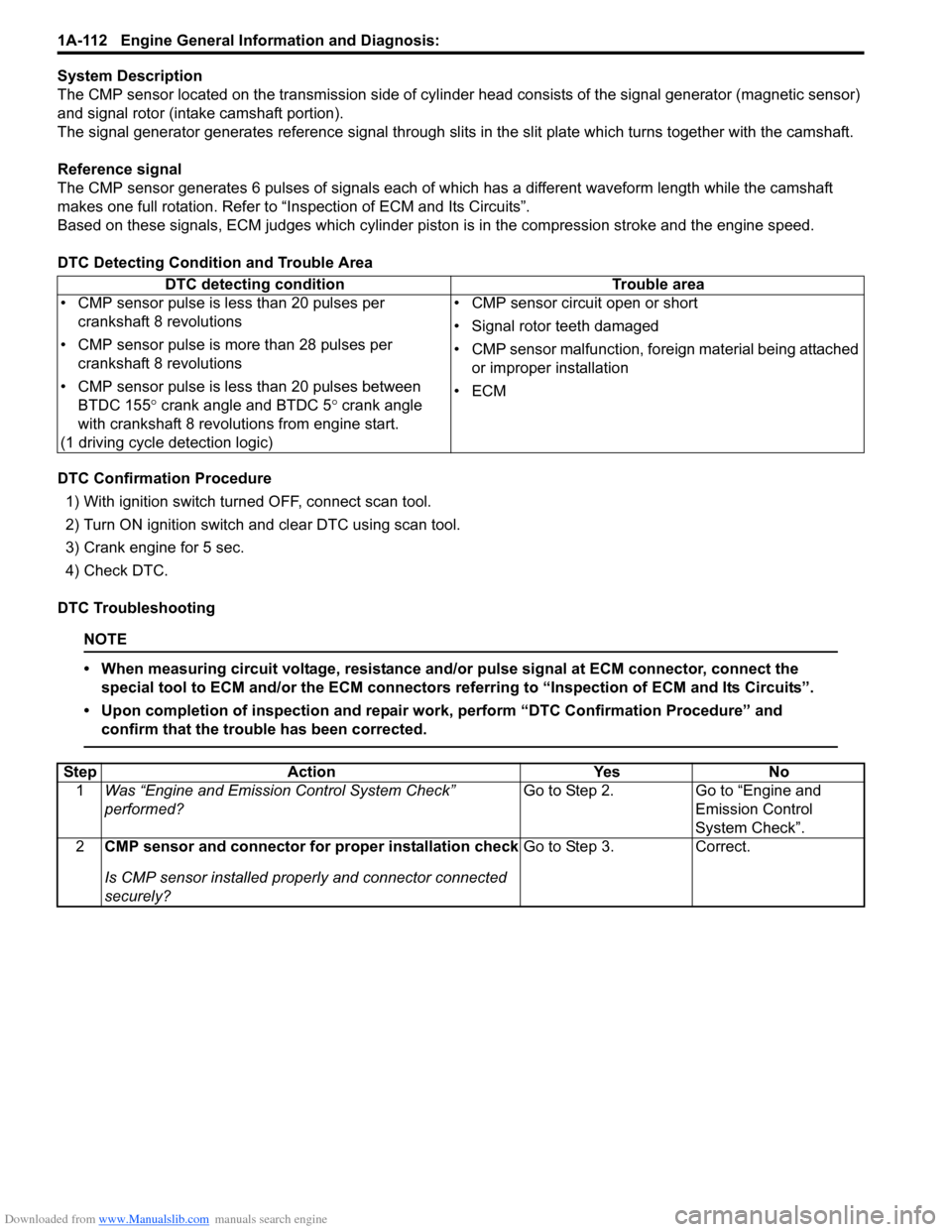

System Description

The CMP sensor located on the transmission side of cylinder head consists of the signal generator (magnetic sensor)

and signal rotor (intake camshaft portion).

The signal generator generates reference signal through slits in the slit plate which turns together with the camshaft.

Reference signal

The CMP sensor generates 6 pulses of si gnals each of which has a different waveform length while the camshaft

makes one full rotation. Refer to “Inspection of ECM and Its Circuits”.

Based on these signals, ECM judges which cylinder pist on is in the compression stroke and the engine speed.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure 1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Crank engine for 5 sec.

4) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC detecting condition Trouble area

• CMP sensor pulse is less than 20 pulses per crankshaft 8 revolutions

• CMP sensor pulse is more than 28 pulses per crankshaft 8 revolutions

• CMP sensor pulse is less than 20 pulses between BTDC 155 ° crank angle and BTDC 5 ° crank angle

with crankshaft 8 revolutions from engine start.

(1 driving cycle detection logic) • CMP sensor circuit open or short

• Signal rotor teeth damaged

• CMP sensor malfunction, foreign material being attached

or improper installation

•ECM

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 CMP sensor and connector for proper installation check

Is CMP sensor installed properly and connector connected

securely? Go to Step 3.

Correct.

Page 165 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-115

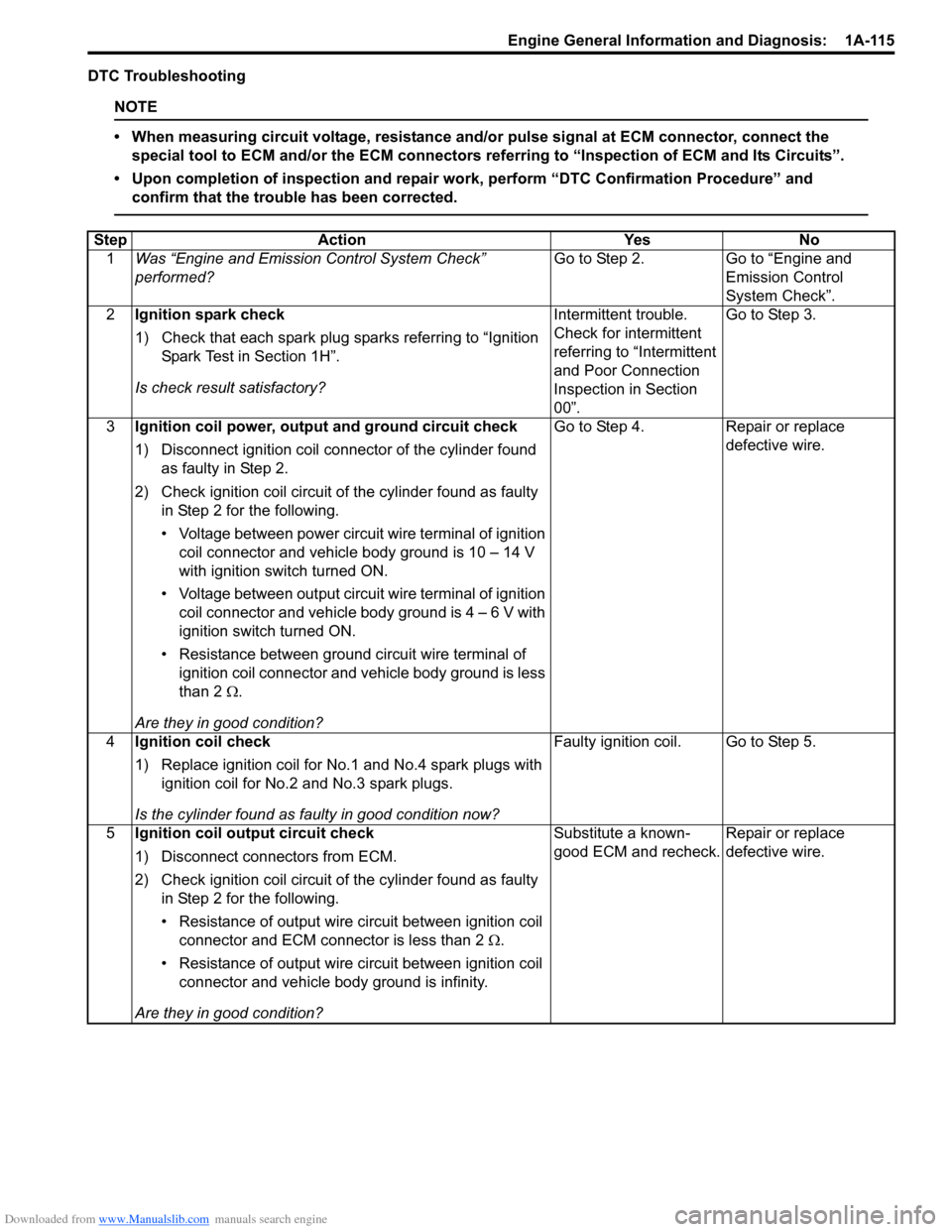

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Ignition spark check

1) Check that each spark plug sparks referring to “Ignition

Spark Test in Section 1H”.

Is check result satisfactory? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.Go to Step 3.

3 Ignition coil power, output and ground circuit check

1) Disconnect ignition coil connector of the cylinder found

as faulty in Step 2.

2) Check ignition coil circuit of the cylinder found as faulty in Step 2 for the following.

• Voltage between power circuit wire terminal of ignition coil connector and vehicle body ground is 10 – 14 V

with ignition switch turned ON.

• Voltage between output circuit wire terminal of ignition coil connector and vehicle body ground is 4 – 6 V with

ignition switch turned ON.

• Resistance between ground circuit wire terminal of ignition coil connector and vehicle body ground is less

than 2 Ω.

Are they in good condition? Go to Step 4.

Repair or replace

defective wire.

4 Ignition coil check

1) Replace ignition coil for No.1 and No.4 spark plugs with

ignition coil for No.2 and No.3 spark plugs.

Is the cylinder found as faulty in good condition now? Faulty ignition coil. Go to Step 5.

5 Ignition coil output circuit check

1) Disconnect connectors from ECM.

2) Check ignition coil circuit of the cylinder found as faulty

in Step 2 for the following.

• Resistance of output wire circuit between ignition coil

connector and ECM connector is less than 2 Ω.

• Resistance of output wire circuit between ignition coil connector and vehicle b ody ground is infinity.

Are they in good condition? Substitute a known-

good ECM and recheck.

Repair or replace

defective wire.