battery voltage SUZUKI SWIFT 2008 2.G Service Manual PDF

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 918 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-36 Power Assisted Steering System:

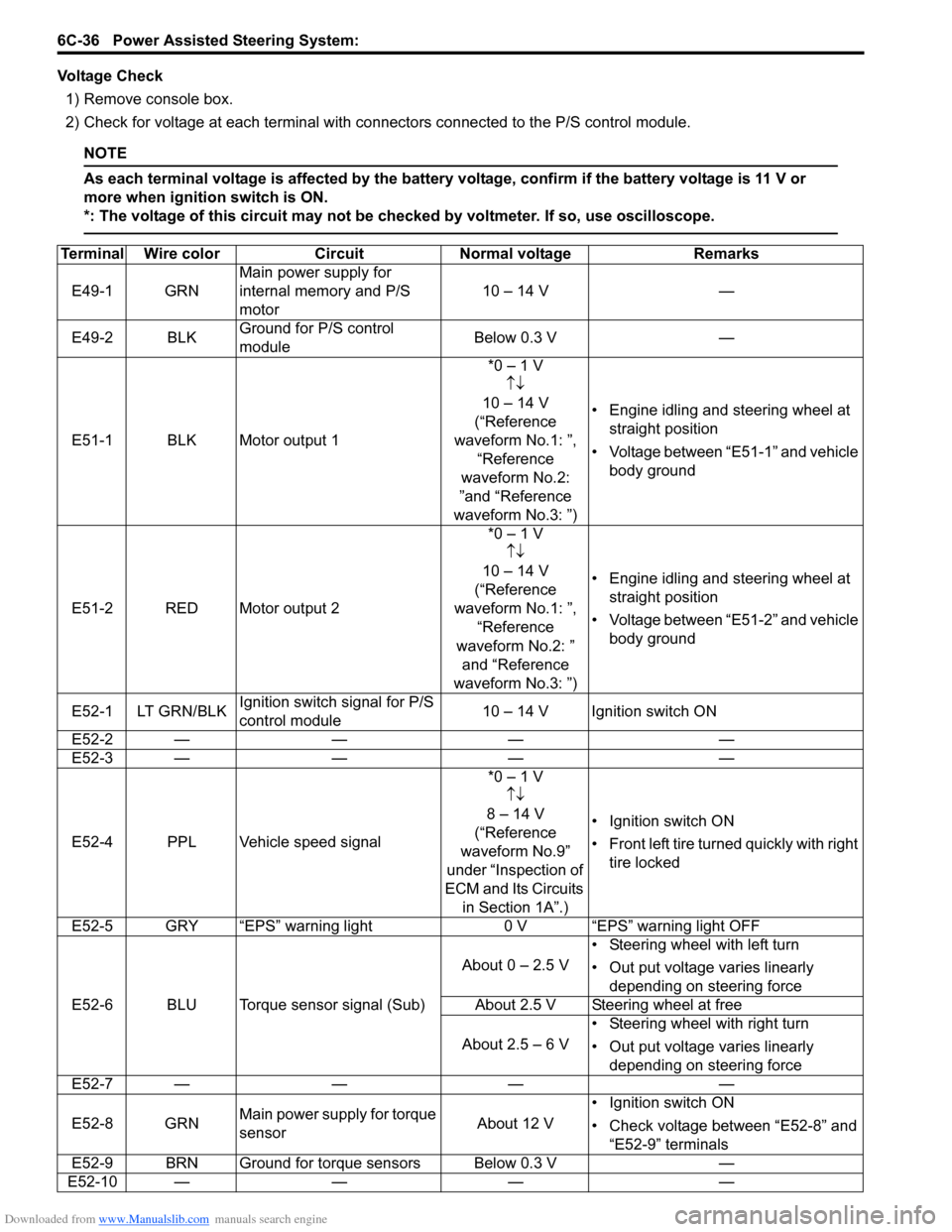

Voltage Check1) Remove console box.

2) Check for voltage at each terminal with co nnectors connected to the P/S control module.

NOTE

As each terminal voltage is affected by the battery voltage, confirm if the battery voltage is 11 V or

more when ignition switch is ON.

*: The voltage of this circuit may not be checked by voltmeter. If so, use oscilloscope.

Terminal Wire colorCircuit Normal voltage Remarks

E49-1 GRN Main power supply for

internal memory and P/S

motor 10 – 14 V

—

E49-2 BLK Ground for P/S control

module Below 0.3 V

—

E51-1 BLK Motor output 1 *0 – 1 V

↑↓

10 – 14 V

(“Reference

waveform No.1: ”, “Reference

waveform No.2:

”and “Reference

waveform No.3: ”) • Engine idling and steering wheel at

straight position

• Voltage between “E51-1” and vehicle body ground

E51-2 RED Motor output 2 *0 – 1 V

↑↓

10 – 14 V

(“Reference

waveform No.1: ”, “Reference

waveform No.2: ” and “Reference

waveform No.3: ”) • Engine idling and steering wheel at

straight position

• Voltage between “E51-2” and vehicle body ground

E52-1 LT GRN/BLK Ignition switch signal for P/S

control module 10 – 14 V Ignition switch ON

E52-2 — —— —

E52-3 — —— —

E52-4 PPL Vehicle speed signal *0 – 1 V

↑↓

8 – 14 V

(“Reference

waveform No.9”

under “Inspection of

ECM and Its Circuits in Section 1A”.) • Ignition switch ON

•Front left tire tu

rned quickly with right

tire locked

E52-5 GRY “EPS” warning light 0 V “EPS” warning light OFF

E52-6 BLU Torque sensor signal (Sub) About 0 – 2.5 V

• Steering wheel with left turn

• Out put voltage varies linearly

depending on steering force

About 2.5 V Steering wheel at free

About 2.5 – 6 V • Steering wheel with right turn

• Out put voltage varies linearly

depending on steering force

E52-7 — —— —

E52-8 GRN Main power supply for torque

sensor About 12 V• Ignition switch ON

• Check voltage between “E52-8” and

“E52-9” terminals

E52-9 BRN Ground for torque sensors Below 0.3 V —

E52-10 — —— —

Page 928 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-46 Power Assisted Steering System:

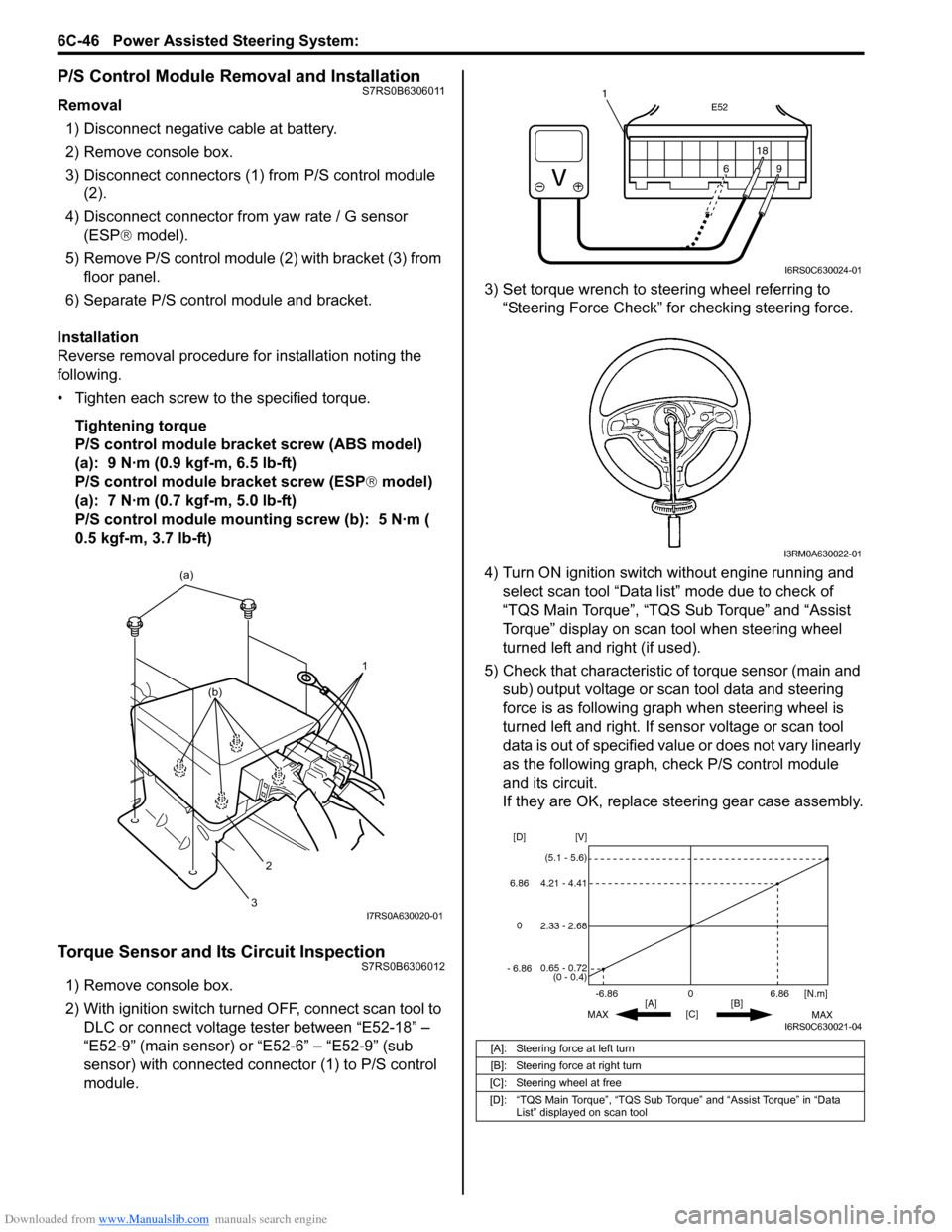

P/S Control Module Removal and InstallationS7RS0B6306011

Removal1) Disconnect negative cable at battery.

2) Remove console box.

3) Disconnect connectors (1) from P/S control module (2).

4) Disconnect connector from yaw rate / G sensor

(ESP ® model).

5) Remove P/S control module (2) with bracket (3) from floor panel.

6) Separate P/S control module and bracket.

Installation

Reverse removal procedure for installation noting the

following.

• Tighten each screw to the specified torque. Tightening torque

P/S control module bracket screw (ABS model)

(a): 9 N·m (0.9 kgf-m, 6.5 lb-ft)

P/S control module bracket screw (ESP ® model)

(a): 7 N·m (0.7 kgf-m, 5.0 lb-ft)

P/S control module mounting screw (b): 5 N·m (

0.5 kgf-m, 3.7 lb-ft)

Torque Sensor and Its Circuit InspectionS7RS0B6306012

1) Remove console box.

2) With ignition switch turned OFF, connect scan tool to DLC or connect voltage tester between “E52-18” –

“E52-9” (main sensor) or “E52-6” – “E52-9” (sub

sensor) with connected connector (1) to P/S control

module. 3) Set torque wrench to stee

ring wheel referring to

“Steering Force Check” for checking steering force.

4) Turn ON ignition switch without engine running and select scan tool “Data list” mode due to check of

“TQS Main Torque”, “TQS Sub Torque” and “Assist

Torque” display on scan tool when steering wheel

turned left and right (if used).

5) Check that characteristic of torque sensor (main and sub) output voltage or scan tool data and steering

force is as following graph when steering wheel is

turned left and right. If sensor voltage or scan tool

data is out of specified value or does not vary linearly

as the following graph, check P/S control module

and its circuit.

If they are OK, replace steering gear case assembly.

1

(a)

2

3

(b)

I7RS0A630020-01

[A]: Steering force at left turn

[B]: Steering force at right turn

[C]: Steering wheel at free

[D]: “TQS Main Torque”, “TQS Sub Torque” and “Assist Torque” in “Data List” displayed on scan tool

E52

18

9

6

9

6 18

1

I6RS0C630024-01

I3RM0A630022-01

0

[C] [N.m]

MAX MAX

[B]

[A]

2.33 - 2.68 [V]

[D]

0.65 - 0.72

(0 - 0.4)

4.21 - 4.41

(5.1 - 5.6)

6.86

-6.86

0

6.86

- 6.86

I6RS0C630021-04

Page 958 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-10 Air Conditioning System: Manual Type

Abnormal Noise from Tension Pulley

Abnormal Noise from A/C Evaporator

Abnormal Noise from Blower Motor

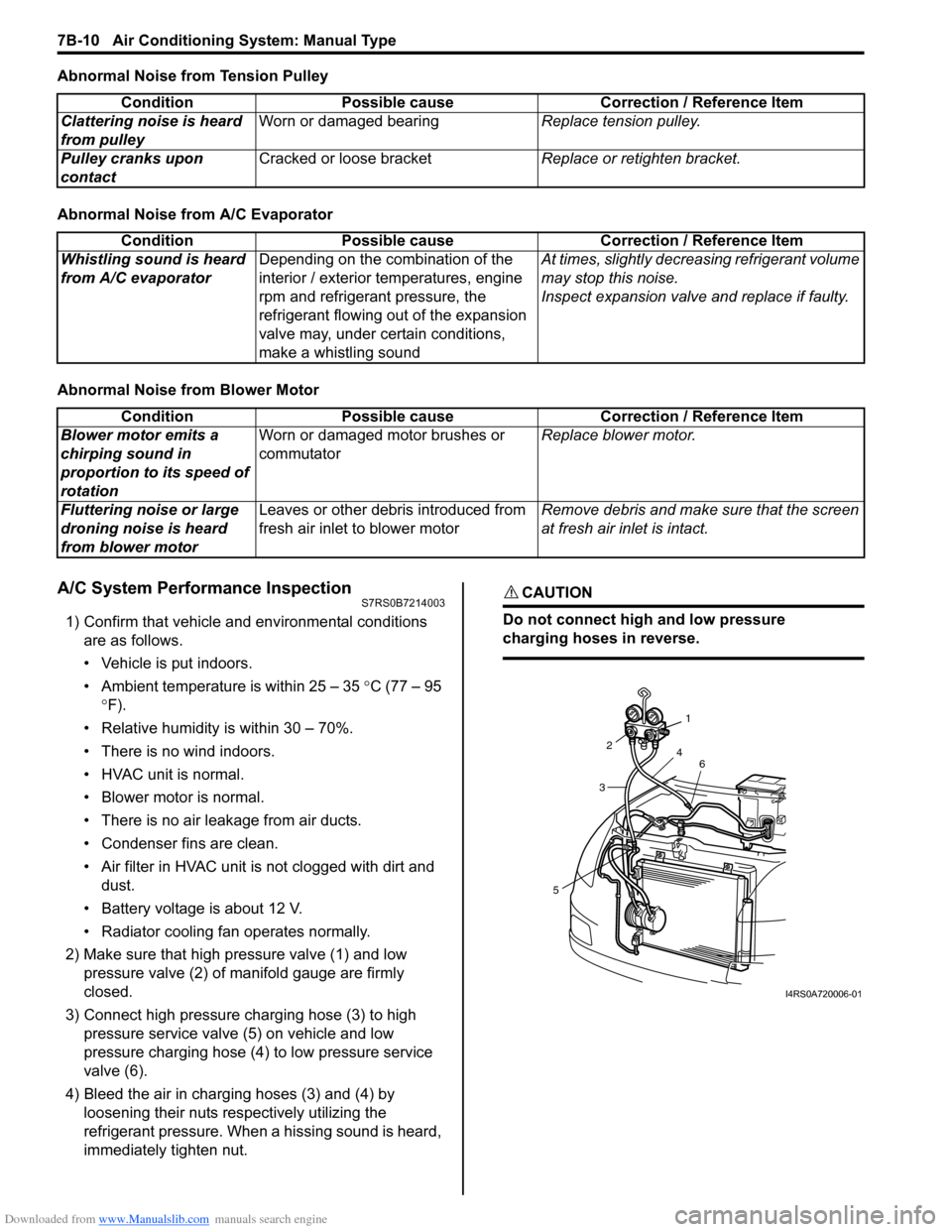

A/C System Performance InspectionS7RS0B7214003

1) Confirm that vehicle and environmental conditions are as follows.

• Vehicle is put indoors.

• Ambient temperature is within 25 – 35 °C (77 – 95

° F).

• Relative humidity is within 30 – 70%.

• There is no wind indoors.

• HVAC unit is normal.

• Blower motor is normal.

• There is no air leakage from air ducts.

• Condenser fins are clean.

• Air filter in HVAC unit is not clogged with dirt and

dust.

• Battery voltage is about 12 V.

• Radiator cooling fan operates normally.

2) Make sure that high pressure valve (1) and low pressure valve (2) of manifold gauge are firmly

closed.

3) Connect high pressure charging hose (3) to high pressure service valve (5) on vehicle and low

pressure charging hose (4) to low pressure service

valve (6).

4) Bleed the air in charging hoses (3) and (4) by loosening their nuts respectively utilizing the

refrigerant pressure. When a hissing sound is heard,

immediately tighten nut.

CAUTION!

Do not connect high and low pressure

charging hoses in reverse.

Condition Possible cause Correction / Reference Item

Clattering noise is heard

from pulley Worn or damaged bearing

Replace tension pulley.

Pulley cranks upon

contact Cracked or loose bracket

Replace or retighten bracket.

ConditionPossible cause Correction / Reference Item

Whistling sound is heard

from A/C evaporator Depending on the combination of the

interior / exterior temperatures, engine

rpm and refrigerant pressure, the

refrigerant flowing out of the expansion

valve may, under certain conditions,

make a whistling sound At times, slightly decrea

sing refrigerant volume

may stop this noise.

Inspect expansion valve and replace if faulty.

Condition Possible cause Correction / Reference Item

Blower motor emits a

chirping sound in

proportion to its speed of

rotation Worn or damaged motor brushes or

commutator

Replace blower motor.

Fluttering noise or large

droning noise is heard

from blower motor Leaves or other debris introduced from

fresh air inlet to blower motor

Remove debris and make sure that the screen

at fresh air inlet is intact.

53

2

1

4 6

I4RS0A720006-01

Page 974 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-26 Air Conditioning System: Manual Type

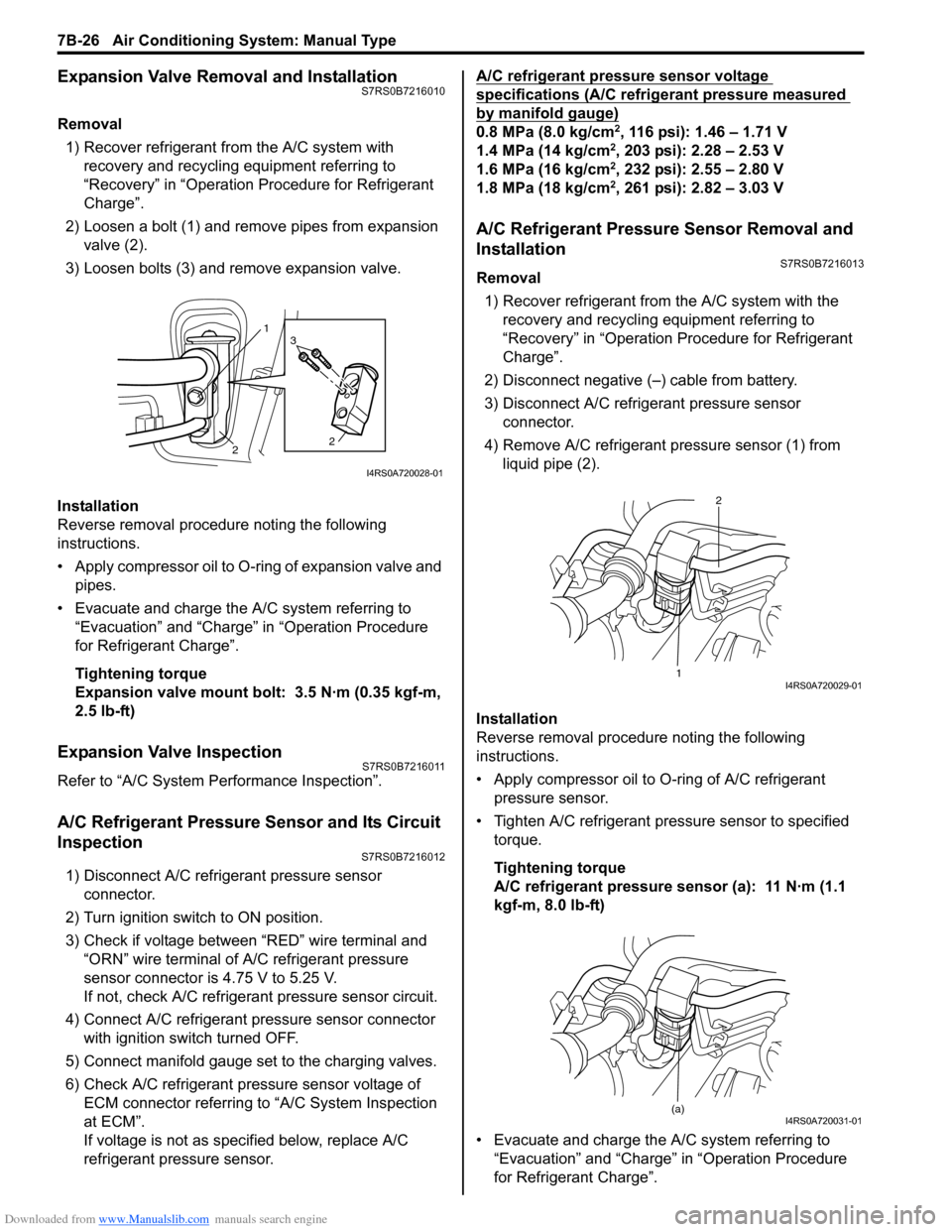

Expansion Valve Removal and InstallationS7RS0B7216010

Removal1) Recover refrigerant fr om the A/C system with

recovery and recycling equipment referring to

“Recovery” in “Operation Procedure for Refrigerant

Charge”.

2) Loosen a bolt (1) and remove pipes from expansion valve (2).

3) Loosen bolts (3) and remove expansion valve.

Installation

Reverse removal procedure noting the following

instructions.

• Apply compressor oil to O-ring of expansion valve and pipes.

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

Tightening torque

Expansion valve mount bolt: 3.5 N·m (0.35 kgf-m,

2.5 lb-ft)

Expansion Valve InspectionS7RS0B7216011

Refer to “A/C System Performance Inspection”.

A/C Refrigerant Pressure Sensor and Its Circuit

Inspection

S7RS0B7216012

1) Disconnect A/C refrigerant pressure sensor connector.

2) Turn ignition switch to ON position.

3) Check if voltage between “RED” wire terminal and “ORN” wire terminal of A/C refrigerant pressure

sensor connector is 4.75 V to 5.25 V.

If not, check A/C refrigerant pressure sensor circuit.

4) Connect A/C refrigerant pressure sensor connector with ignition switch turned OFF.

5) Connect manifold gauge set to the charging valves.

6) Check A/C refrigerant pressure sensor voltage of ECM connector referring to “A/C System Inspection

at ECM”.

If voltage is not as specified below, replace A/C

refrigerant pressure sensor. A/C refrigerant pressure sensor voltage

specifications (A/C refrigerant pressure measured

by manifold gauge)

0.8 MPa (8.0 kg/cm2, 116 psi): 1.46 – 1.71 V

1.4 MPa (14 kg/cm2, 203 psi): 2.28 – 2.53 V

1.6 MPa (16 kg/cm2, 232 psi): 2.55 – 2.80 V

1.8 MPa (18 kg/cm2, 261 psi): 2.82 – 3.03 V

A/C Refrigerant Pressure Sensor Removal and

Installation

S7RS0B7216013

Removal

1) Recover refrigerant from the A/C system with the recovery and recycling equipment referring to

“Recovery” in “Operation Procedure for Refrigerant

Charge”.

2) Disconnect negative (–) cable from battery.

3) Disconnect A/C refrigerant pressure sensor connector.

4) Remove A/C refrigerant pressure sensor (1) from liquid pipe (2).

Installation

Reverse removal procedure noting the following

instructions.

• Apply compressor oil to O-ring of A/C refrigerant

pressure sensor.

• Tighten A/C refrigerant pressure sensor to specified torque.

Tightening torque

A/C refrigerant pressure sensor (a): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

1

2 2

3

I4RS0A720028-01

1 2I4RS0A720029-01

(a)I4RS0A720031-01

Page 997 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-49

Step 7. Final confirmation test

Confirm if the problem symptom is troubleshoot and the A/C system is free from any abnormal conditions. If there

existed DTC, clear the DTC. Then , check if the DTC is still detected and if there is any other DTC.

Visual InspectionS7RS0B7224009

Check visually the following parts and systems.

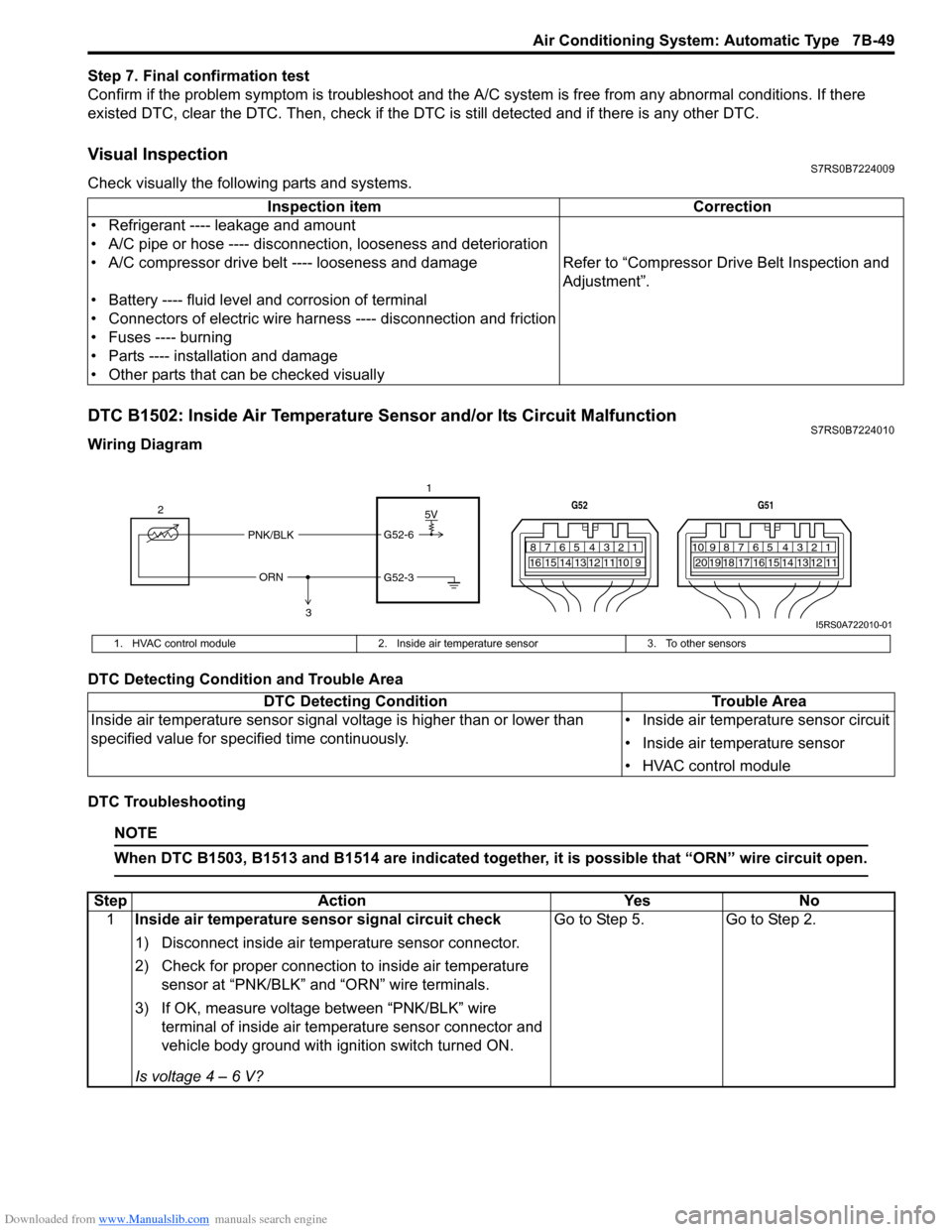

DTC B1502: Inside Air Temperature Sensor and/or Its Circuit MalfunctionS7RS0B7224010

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

NOTE

When DTC B1503, B1513 and B1514 are indicated together, it is possible that “ORN” wire circuit open.

Inspection item Correction

• Refrigerant ---- leakage and amount

• A/C pipe or hose ---- disconnection, looseness and deterioration

• A/C compressor drive belt ---- looseness and damage Refer to “Compressor Drive Belt Inspection and

Adjustment”.

• Battery ---- fluid level and corrosion of terminal

• Connectors of electric wire harn ess ---- disconnection and friction

• Fuses ---- burning

• Parts ---- installation and damage

• Other parts that can be checked visually

5V

PNK/BLK

ORN G52-6

G52-3

2

1

3

7812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

I5RS0A722010-01

1. HVAC control module

2. Inside air temperature sensor 3. To other sensors

DTC Detecting Condition Trouble Area

Inside air temperature sensor signal voltage is higher than or lower than

specified value for specified time continuously. • Inside air temperature sensor circuit

• Inside air temperature sensor

• HVAC control module

Step

Action YesNo

1 Inside air temperature sensor signal circuit check

1) Disconnect inside air temperature sensor connector.

2) Check for proper connection to inside air temperature

sensor at “PNK/BLK” and “ORN” wire terminals.

3) If OK, measure voltage between “PNK/BLK” wire terminal of inside air temp erature sensor connector and

vehicle body ground with ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 5.

Go to Step 2.

Page 1010 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-62 Air Conditioning System: Automatic Type

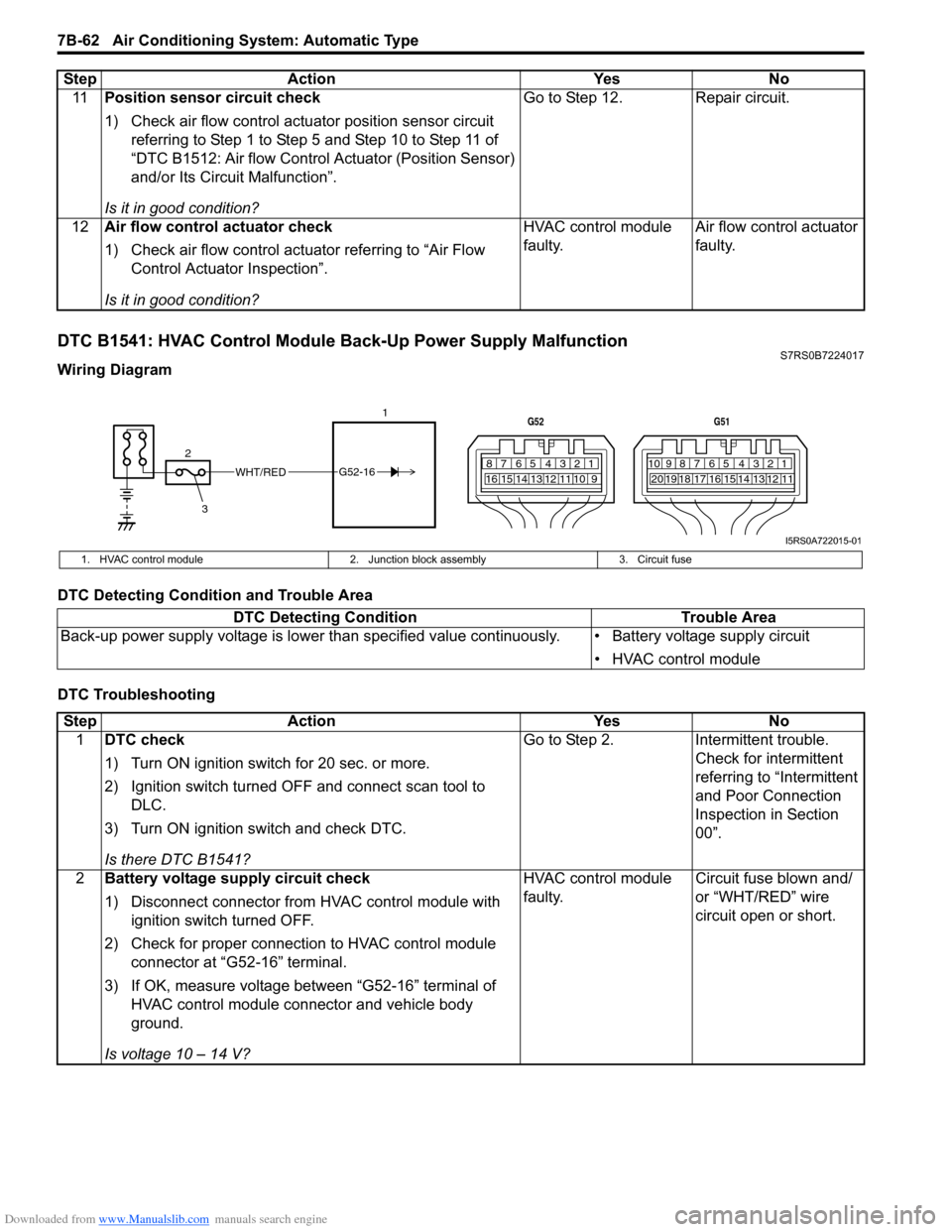

DTC B1541: HVAC Control Module Back-Up Power Supply MalfunctionS7RS0B7224017

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting11

Position sensor circuit check

1) Check air flow control actuator position sensor circuit

referring to Step 1 to Step 5 and Step 10 to Step 11 of

“DTC B1512: Air flow Control Actuator (Position Sensor)

and/or Its Circuit Malfunction”.

Is it in good condition? Go to Step 12. Repair circuit.

12 Air flow control actuator check

1) Check air flow control actuator referring to “Air Flow

Control Actuator Inspection”.

Is it in good condition? HVAC control module

faulty.

Air flow control actuator

faulty.

Step Action Yes No

WHT/RED

2 17812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

3

G52-16

I5RS0A722015-01

1. HVAC control module

2. Junction block assembly 3. Circuit fuse

DTC Detecting Condition Trouble Area

Back-up power supply voltage is lo wer than specified value continuously. • Battery voltage supply circuit

• HVAC control module

StepAction YesNo

1 DTC check

1) Turn ON ignition switch for 20 sec. or more.

2) Ignition switch turned OF F and connect scan tool to

DLC.

3) Turn ON ignition switch and check DTC.

Is there DTC B1541? Go to Step 2.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

2 Battery voltage supply circuit check

1) Disconnect connector from HVAC control module with

ignition switch turned OFF.

2) Check for proper connection to HVAC control module connector at “G52-16” terminal.

3) If OK, measure voltage between “G52-16” terminal of HVAC control module connector and vehicle body

ground.

Is voltage 10 – 14 V? HVAC control module

faulty.

Circuit fuse blown and/

or “WHT/RED” wire

circuit open or short.

Page 1015 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-67

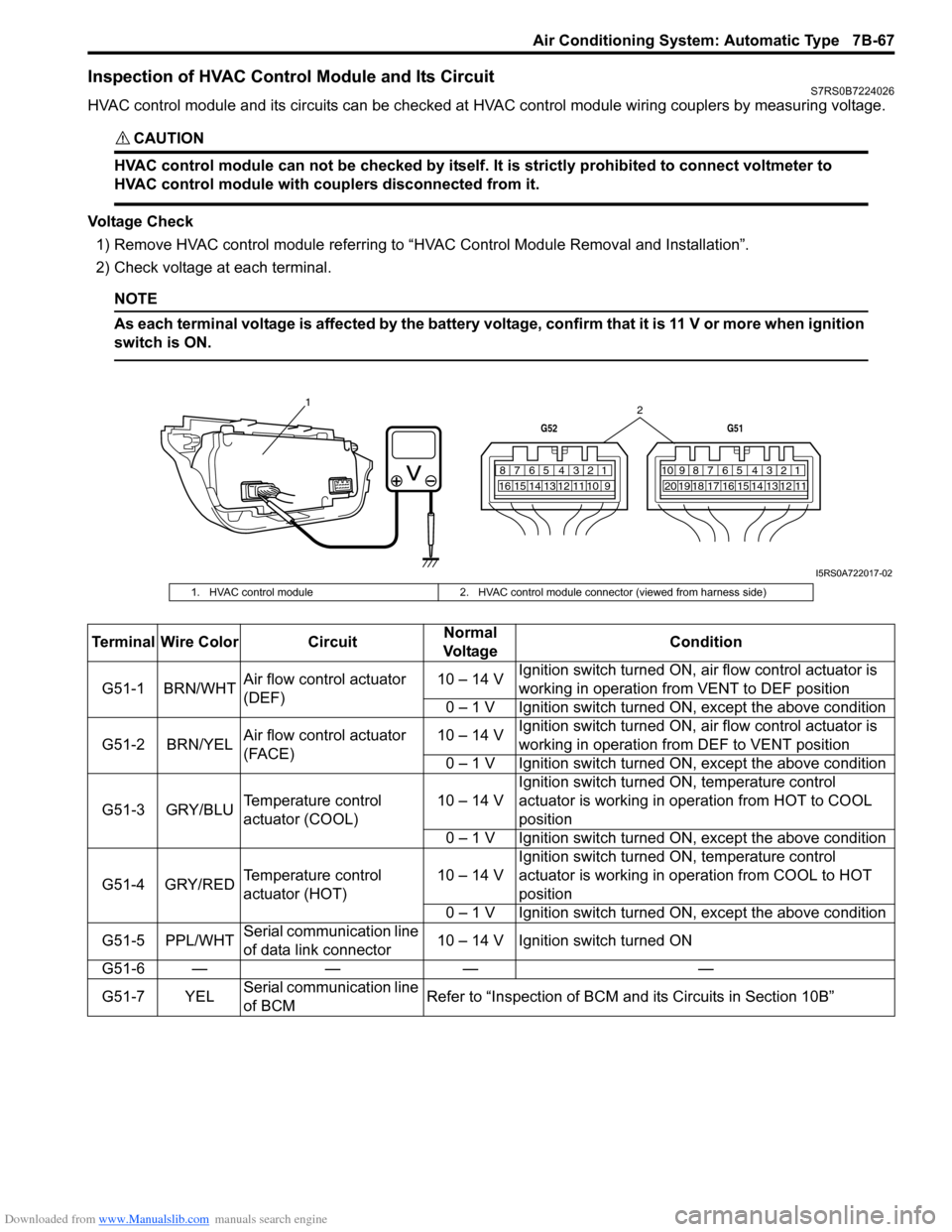

Inspection of HVAC Control Module and Its CircuitS7RS0B7224026

HVAC control module and its circuits can be checked at HVAC control module wiring couplers by measuring voltage.

CAUTION!

HVAC control module can not be checked by itself. It is strictly prohibited to connect voltmeter to

HVAC control module with couplers disconnected from it.

Voltage Check

1) Remove HVAC control module referring to “HVAC Control Module Removal and Installation”.

2) Check voltage at each terminal.

NOTE

As each terminal voltage is affected by the battery voltage, confirm that it is 11 V or more when ignition

switch is ON.

7812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

1

2

I5RS0A722017-02

1. HVAC control module2. HVAC control module connector (viewed from harness side)

Terminal Wire Color CircuitNormal

Vo l ta g e Condition

G51-1 BRN/WHT Air flow control actuator

(DEF) 10 – 14 V

Ignition switch turned ON, ai

r flow control actuator is

working in operation fr om VENT to DEF position

0 – 1 V Ignition switch turned ON, except the above condition

G51-2 BRN/YEL Air flow control actuator

(FACE) 10 – 14 V

Ignition switch turned ON, ai

r flow control actuator is

working in operation fr om DEF to VENT position

0 – 1 V Ignition switch turned ON, except the above condition

G51-3 GRY/BLU Temperature control

actuator (COOL) 10 – 14 VIgnition switch turned ON, temperature control

actuator is working in ope

ration from HOT to COOL

position

0 – 1 V Ignition switch turned ON, except the above condition

G51-4 GRY/RED Temperature control

actuator (HOT) 10 – 14 VIgnition switch turned ON, temperature control

actuator is working in operation from COOL to HOT

position

0 – 1 V Ignition switch turned ON, except the above condition

G51-5 PPL/WHT Serial communication line

of data link connector 10 – 14 V Ignition switch turned ON

G51-6 — — — —

G51-7 YEL Serial communication line

of BCM Refer to “Inspection of BCM a

nd its Circuits in Section 10B”

Page 1018 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-70 Air Conditioning System: Automatic Type

A/C System Performance InspectionS7RS0B7224027

Refer to “A/C System Performance Inspection”.

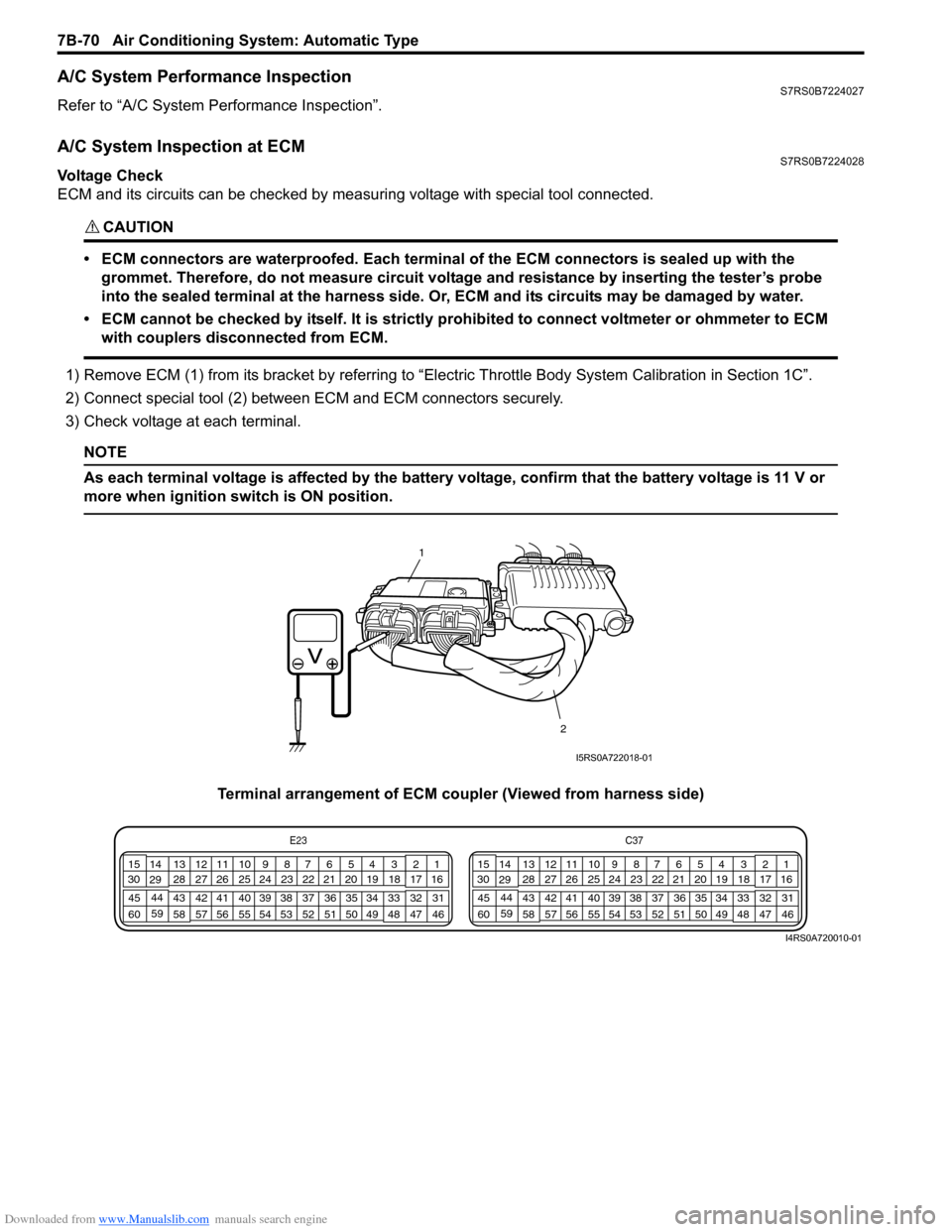

A/C System Inspection at ECMS7RS0B7224028

Voltage Check

ECM and its circuits can be checked by measuring voltage with special tool connected.

CAUTION!

• ECM connectors are waterproofed. Each terminal of the ECM connectors is sealed up with the

grommet. Therefore, do not measure circuit voltage and resistance by inserting the tester’s probe

into the sealed terminal at the harness side. Or, ECM and its circuits may be damaged by water.

• ECM cannot be checked by itself. It is strictly prohibited to connect voltmeter or ohmmeter to ECM with couplers disconnected from ECM.

1) Remove ECM (1) from its bracket by referring to “Electric Throttle Body System Calibration in Section 1C”.

2) Connect special tool (2) between ECM and ECM connectors securely.

3) Check voltage at each terminal.

NOTE

As each terminal voltage is affected by the battery voltage, confirm that the battery voltage is 11 V or

more when ignition sw itch is ON position.

Terminal arrangement of ECM coupler (Viewed from harness side)

1

2

I5RS0A722018-01

E23 C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

I4RS0A720010-01

Page 1024 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-76 Air Conditioning System: Automatic Type

Actuator Linkage InspectionS7RS0B7226010

• Check if each actuator linkage operates smoothly.

• Check actuator rod for bend.

• Check each actuator linkage for breakage.

• Make sure if there is not any obstruction in operating range of actuator linkage.

If any malfunction is found, repair or replace faulty

part(s).

Blower Motor Controller Removal and

Installation

S7RS0B7226011

Refer to “Blower Motor Resistor Removal and

Installation in Section 7A”.

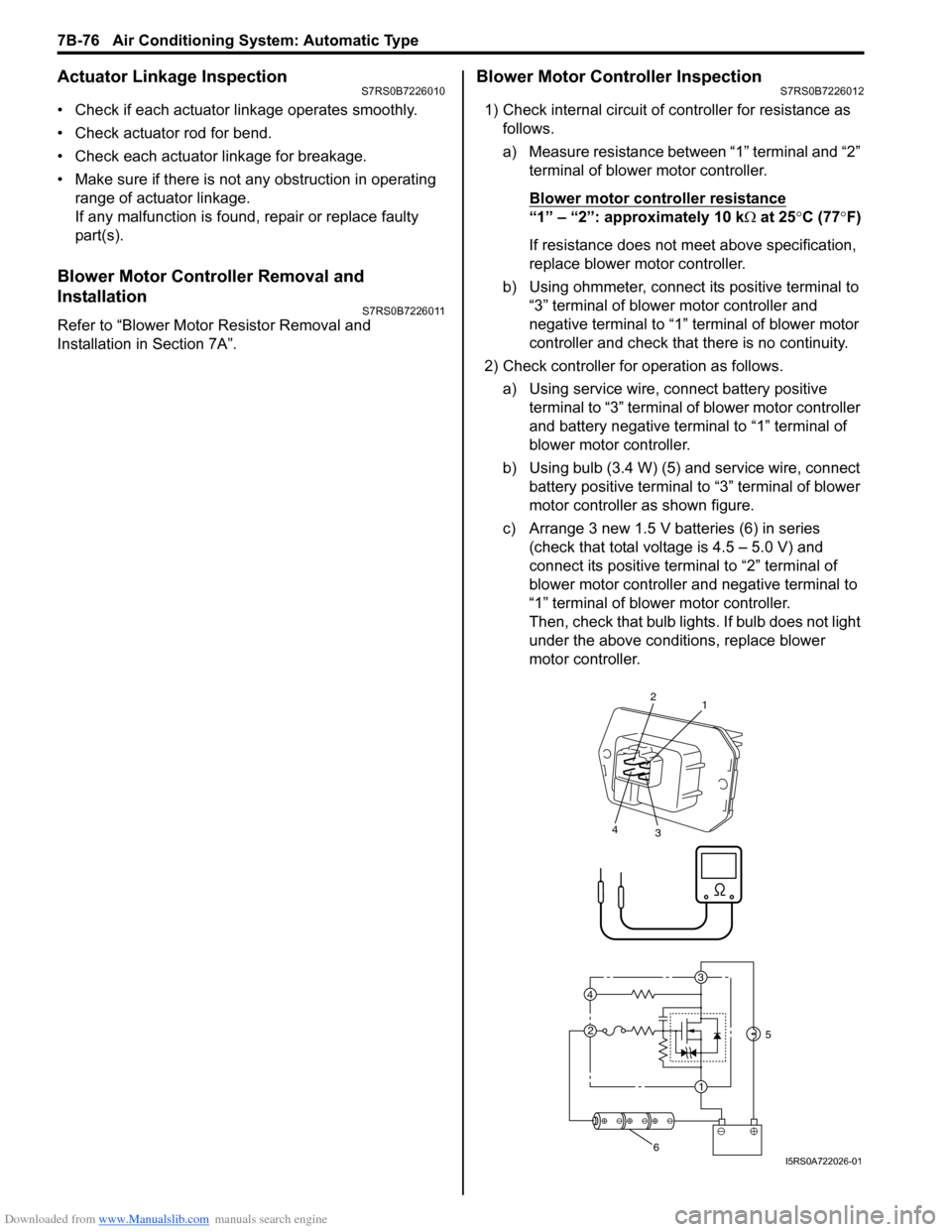

Blower Motor Controller InspectionS7RS0B7226012

1) Check internal circuit of controller for resistance as follows.

a) Measure resistance between “1” terminal and “2” terminal of blower motor controller.

Blower motor cont roller resistance

“1” – “2”: approximately 10 k Ω at 25 °C (77 °F)

If resistance does not meet above specification,

replace blower motor controller.

b) Using ohmmeter, connect its positive terminal to “3” terminal of blower motor controller and

negative terminal to “1” terminal of blower motor

controller and check that there is no continuity.

2) Check controller for operation as follows. a) Using service wire, connect battery positive terminal to “3” terminal of blower motor controller

and battery negative terminal to “1” terminal of

blower motor controller.

b) Using bulb (3.4 W) (5) and service wire, connect battery positive terminal to “3” terminal of blower

motor controller as shown figure.

c) Arrange 3 new 1.5 V batteries (6) in series (check that total voltage is 4.5 – 5.0 V) and

connect its positive term inal to “2” terminal of

blower motor controller and negative terminal to

“1” terminal of blower motor controller.

Then, check that bulb lights. If bulb does not light

under the above conditions, replace blower

motor controller.

3

1

2

4

2

1

3

4

5

6I5RS0A722026-01

Page 1025 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-77

HVAC Control Module Removal and InstallationS7RS0B7226013

Removal1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove passenger air bag module from instrument panel referring to “Passenger Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

4) Remove radio assembly from instrument panel referring to “Rear Speaker Removal and Installation

in Section 9C”.

5) Remove two connectors fr om HVAC control module.

6) Remove HVAC control modu le (1) from instrument

panel.

NOTE

Be careful not to damage HVAC control

module and instrument panel by using rag.

Installation

Reverse removal procedure noting the following

instructions.

Enable air bag system referring to “Enabling Air Bag

System in Section 8B”.

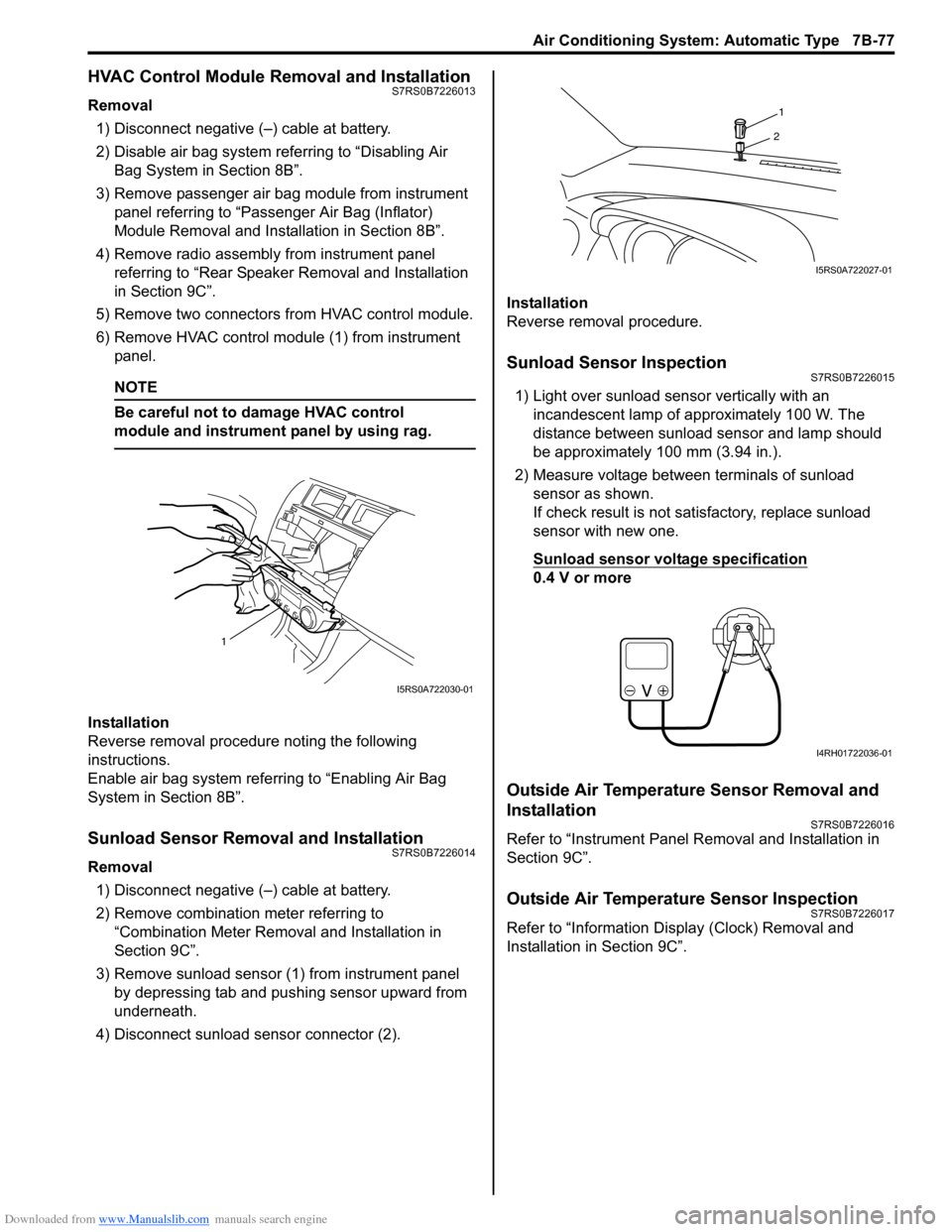

Sunload Sensor Removal and InstallationS7RS0B7226014

Removal

1) Disconnect negative (–) cable at battery.

2) Remove combination meter referring to “Combination Meter Removal and Installation in

Section 9C”.

3) Remove sunload sensor (1) from instrument panel by depressing tab and pushing sensor upward from

underneath.

4) Disconnect sunload sensor connector (2). Installation

Reverse removal procedure.

Sunload Sensor InspectionS7RS0B7226015

1) Light over sunload sensor vertically with an

incandescent lamp of approximately 100 W. The

distance between sunload sensor and lamp should

be approximately 100 mm (3.94 in.).

2) Measure voltage between terminals of sunload sensor as shown.

If check result is not satisfactory, replace sunload

sensor with new one.

Sunload sensor voltage specification

0.4 V or more

Outside Air Temperature Sensor Removal and

Installation

S7RS0B7226016

Refer to “Instrument Panel Re moval and Installation in

Section 9C”.

Outside Air Temperature Sensor InspectionS7RS0B7226017

Refer to “Information Display (Clock) Removal and

Installation in Section 9C”.

1

I5RS0A722030-01

1

2

I5RS0A722027-01

I4RH01722036-01