differential SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 23 of 1496

Downloaded from www.Manualslib.com manuals search engine General Information: 0A-2

SAS: Steering Angle Sensor

SDM: Sensing and Diagnostic Module (Air Bag Controller, Air bag Control Module)

SDT: Smart Diagnostic Tester

SFI: Sequential Multipor t Fuel Injection

SOHC: Single Over Head Camshaft

T:

TBI: Throttle Body Fuel Injection (Single-Point Fuel

Injection, SPI)

TCC: Torque Converter Clutch

TCM: Transmission Control Module (A/T Controller, A/T

Control Module)

TDC: Top Dead Center

TP Sensor: Throttle Position Sensor TVV:

Thermal Vacuum Valve (Thermal Vacuum

Switching Valve, TVSV, Bi metal Vacuum Switching

Valve, BVSV)

TWC: Three Way Catalytic Converter (Three Way

Catalyst)

2WD: 2 Wheel Drive

U:

USB: Universal Serial Bus

V:

VIN: Vehicle Identification Number

VSS: Vehicle Speed Sensor

VVT: Variable Valve Timing (Camshaft Position Control)

W:

WU-OC: Warm Up Oxidation Catalytic Converter

WU-TWC: Warm Up Three Way Catalytic Converter

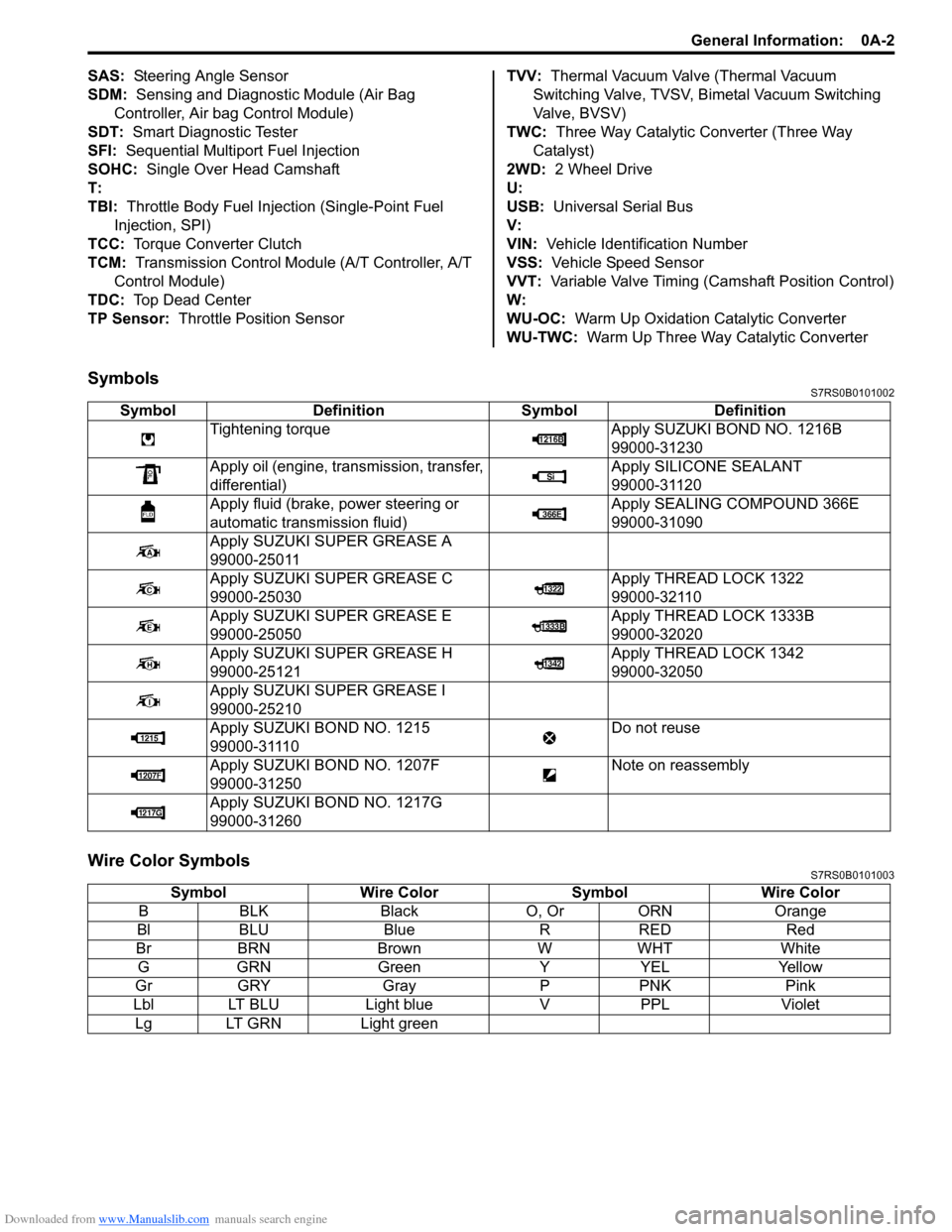

SymbolsS7RS0B0101002

Wire Color SymbolsS7RS0B0101003

Symbol Definition SymbolDefinition

Tightening torque Apply SUZUKI BOND NO. 1216B

99000-31230

Apply oil (engine, transmission, transfer,

differential) Apply SILICONE SEALANT

99000-31120

Apply fluid (brake, power steering or

automatic transmission fluid) Apply SEALING COMPOUND 366E

99000-31090

Apply SUZUKI SUPER GREASE A

99000-25011

Apply SUZUKI SUPER GREASE C

99000-25030 Apply THREAD LOCK 1322

99000-32110

Apply SUZUKI SUPER GREASE E

99000-25050 Apply THREAD LOCK 1333B

99000-32020

Apply SUZUKI SUPER GREASE H

99000-25121 Apply THREAD LOCK 1342

99000-32050

Apply SUZUKI SUPER GREASE I

99000-25210

Apply SUZUKI BOND NO. 1215

99000-31110 Do not reuse

Apply SUZUKI BO ND NO. 1207F

99000-31250 Note on reassembly

Apply SUZUKI BO ND NO. 1217G

99000-31260

Symbol Wire Color SymbolWire Color

B BLK Black O, Or ORN Orange

Bl BLU Blue RRED Red

Br BRN Brown WWHT White

G GRN Green YYEL Yellow

Gr GRY Gray PPNK Pink

Lbl LT BLU Light blueVPPL Violet

Lg LT GRN Light green

Page 40 of 1496

Downloaded from www.Manualslib.com manuals search engine 0B-10 Maintenance and Lubrication:

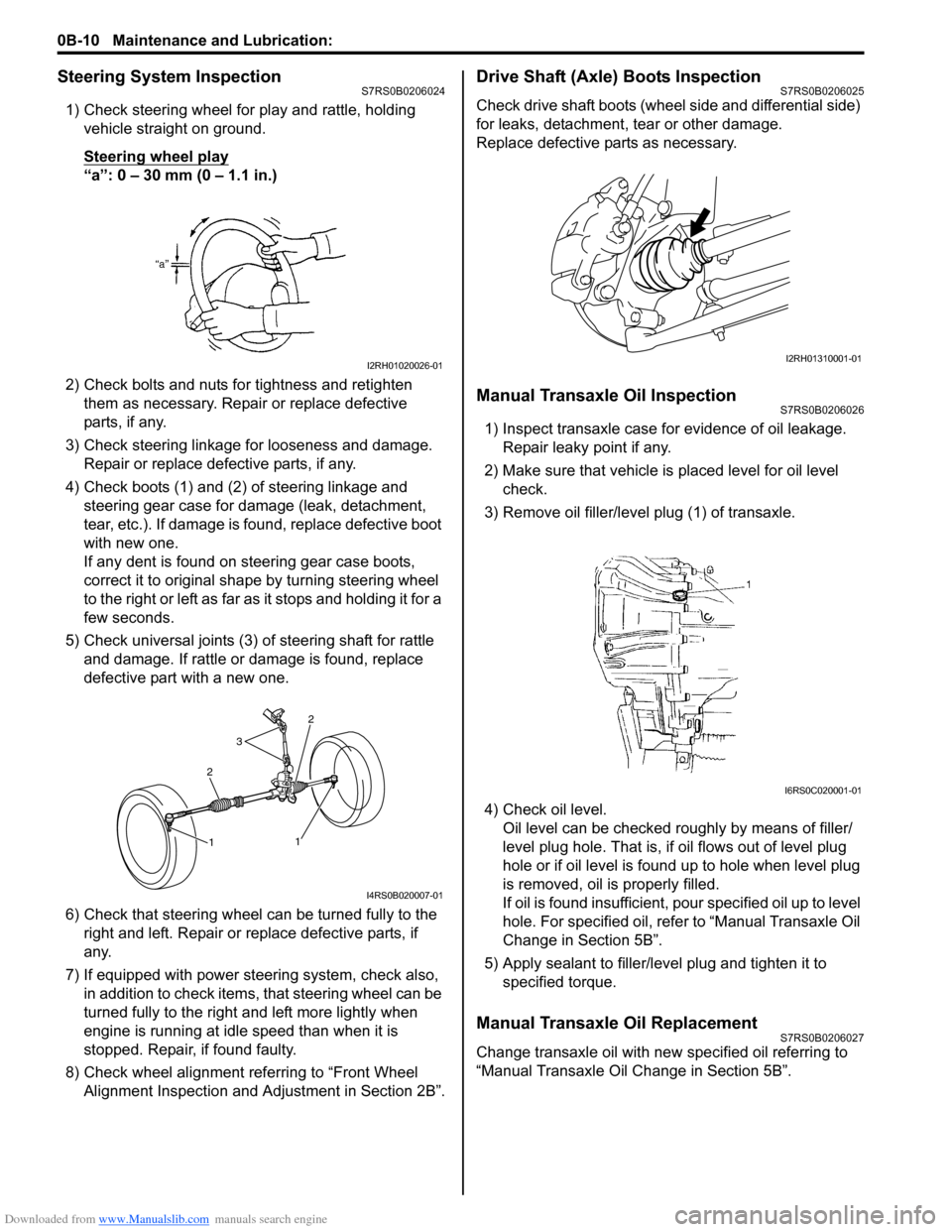

Steering System InspectionS7RS0B0206024

1) Check steering wheel for play and rattle, holding vehicle straight on ground.

Steering wheel play

“a”: 0 – 30 mm (0 – 1.1 in.)

2) Check bolts and nuts for tightness and retighten them as necessary. Repair or replace defective

parts, if any.

3) Check steering linkage for looseness and damage. Repair or replace defective parts, if any.

4) Check boots (1) and (2) of steering linkage and steering gear case for damage (leak, detachment,

tear, etc.). If damage is fo und, replace defective boot

with new one.

If any dent is found on steering gear case boots,

correct it to original shape by turning steering wheel

to the right or left as far as it stops and holding it for a

few seconds.

5) Check universal joints (3) of steering shaft for rattle and damage. If rattle or damage is found, replace

defective part with a new one.

6) Check that steering wheel can be turned fully to the

right and left. Repair or replace defective parts, if

any.

7) If equipped with power steering system, check also, in addition to check items, that steering wheel can be

turned fully to the right and left more lightly when

engine is running at idle speed than when it is

stopped. Repair, if found faulty.

8) Check wheel alignment referring to “Front Wheel Alignment Inspection and Adjustment in Section 2B”.

Drive Shaft (Axle) Boots InspectionS7RS0B0206025

Check drive shaft boots (wheel side and differential side)

for leaks, detachment, tear or other damage.

Replace defective parts as necessary.

Manual Transaxle Oil InspectionS7RS0B0206026

1) Inspect transaxle case for evidence of oil leakage. Repair leaky point if any.

2) Make sure that vehicle is placed level for oil level

check.

3) Remove oil filler/leve l plug (1) of transaxle.

4) Check oil level. Oil level can be checked roughly by means of filler/

level plug hole. That is, if oil flows out of level plug

hole or if oil level is found up to hole when level plug

is removed, oil is properly filled.

If oil is found insufficient, po ur specified oil up to level

hole. For specified oil, refe r to “Manual Transaxle Oil

Change in Section 5B”.

5) Apply sealant to filler/leve l plug and tighten it to

specified torque.

Manual Transaxle Oil ReplacementS7RS0B0206027

Change transaxle oil with new specified oil referring to

“Manual Transaxle Oil Change in Section 5B”.

I2RH01020026-01

2

3

2

1

1

I4RS0B020007-01

I2RH01310001-01

I6RS0C020001-01

Page 303 of 1496

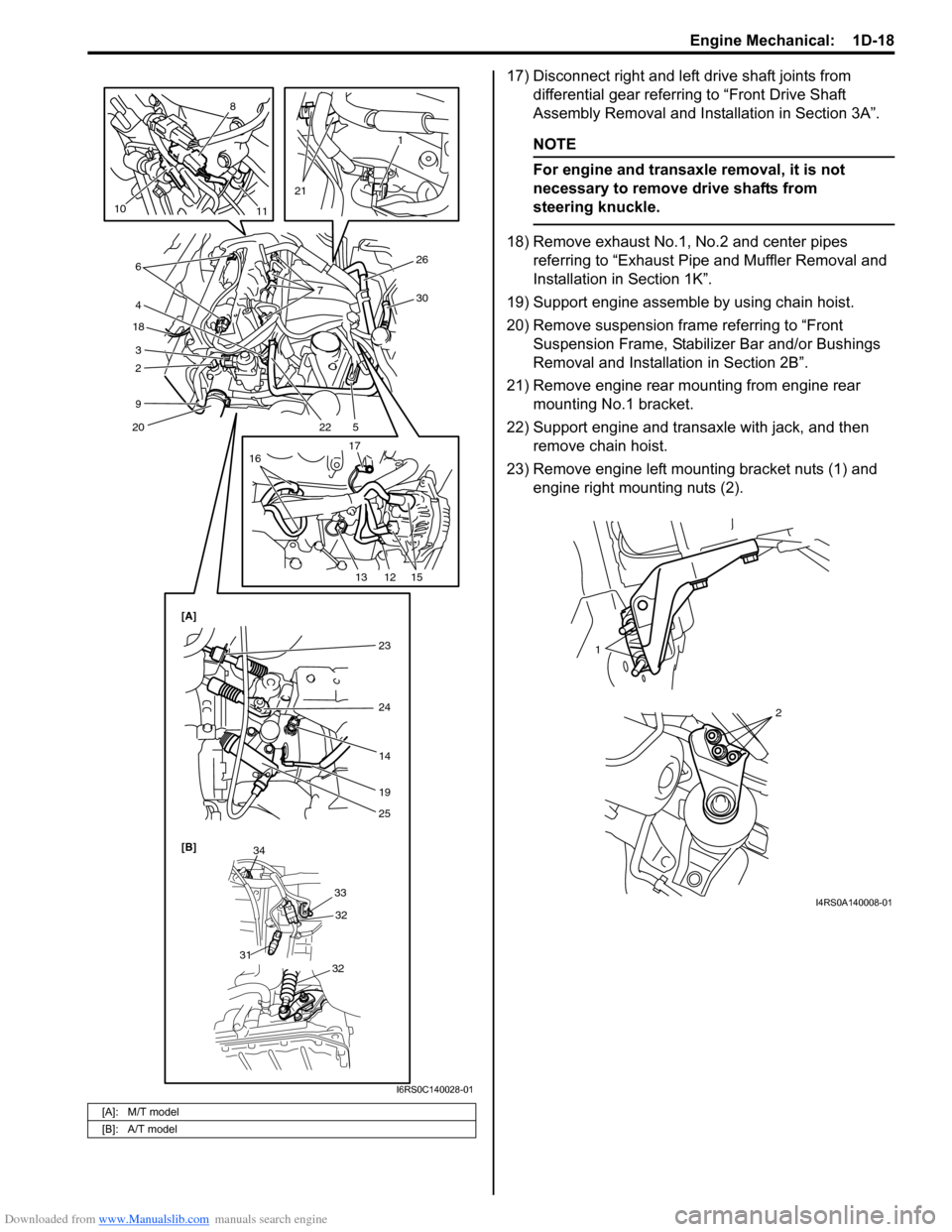

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-18

17) Disconnect right and left drive shaft joints from differential gear referring to “Front Drive Shaft

Assembly Removal and Installation in Section 3A”.

NOTE

For engine and transaxle removal, it is not

necessary to remove drive shafts from

steering knuckle.

18) Remove exhaust No.1, No.2 and center pipes referring to “Exhaust Pipe and Muffler Removal and

Installation in Section 1K”.

19) Support engine assemble by using chain hoist.

20) Remove suspension frame referring to “Front Suspension Frame, Stabiliz er Bar and/or Bushings

Removal and Installati on in Section 2B”.

21) Remove engine rear mounting from engine rear mounting No.1 bracket.

22) Support engine and transaxle with jack, and then remove chain hoist.

23) Remove engine left mounting bracket nuts (1) and engine right mounting nuts (2).

[A]: M/T model

[B]: A/T model

7

26

30

5

4

22

3

2

20

6

9

18

8

11

10

21 1

16

17

151213

[B]

23

24

14

25 19

34

33

32

32

31

[A]

I6RS0C140028-01

1

2

I4RS0A140008-01

Page 454 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-21 Front Suspension:

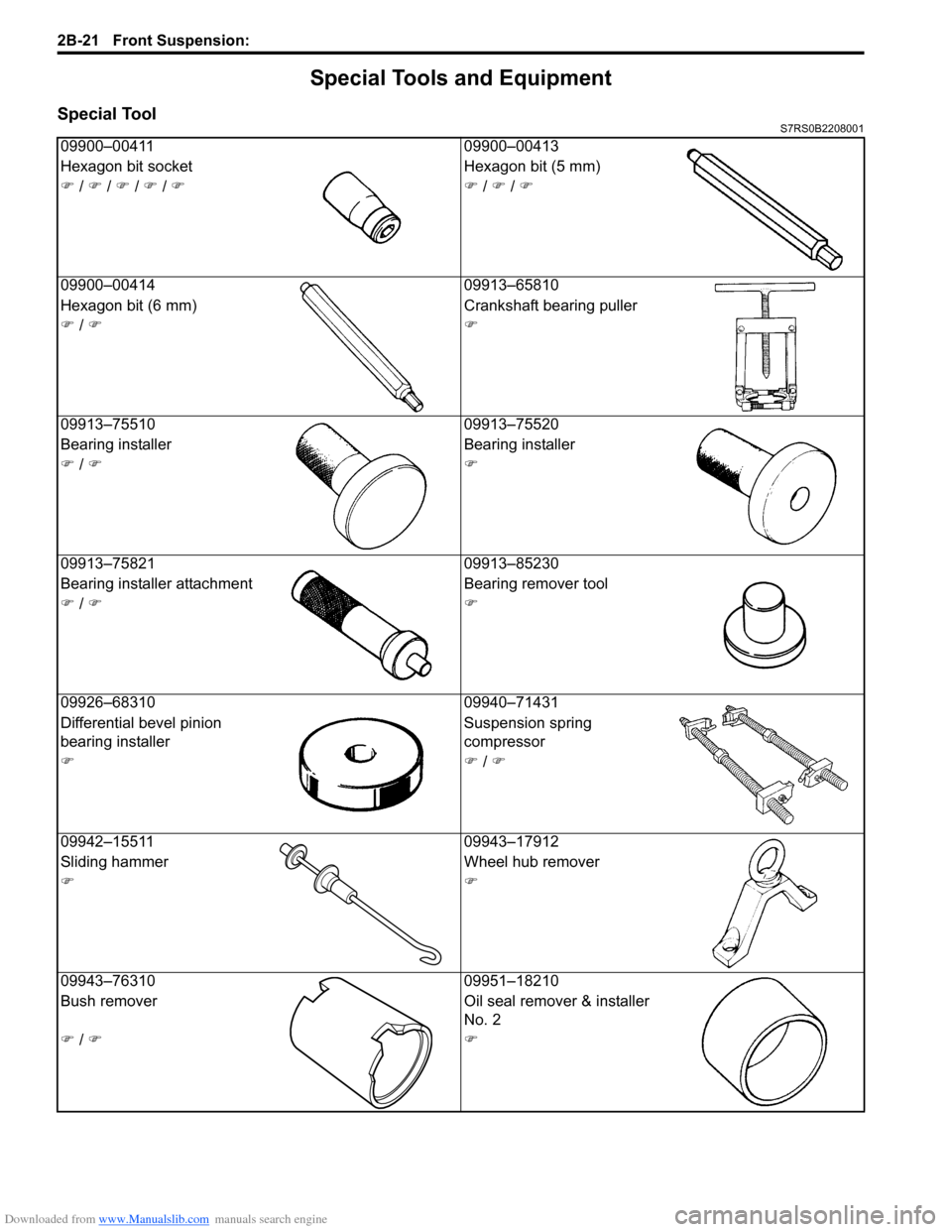

Special Tools and Equipment

Special ToolS7RS0B2208001

09900–0041109900–00413

Hexagon bit socket Hexagon bit (5 mm)

�) / �) / �) / �) / �)�) / �) / �)

09900–00414 09913–65810

Hexagon bit (6 mm) Crankshaft bearing puller

�) / �)�)

09913–75510 09913–75520

Bearing installer Bearing installer

�) / �)�)

09913–75821 09913–85230

Bearing installer attachment Bearing remover tool

�) / �)�)

09926–68310 09940–71431

Differential bevel pinion

bearing installer Suspension spring

compressor

�)�) / �)

09942–15511 09943–17912

Sliding hammer Wheel hub remover

�)�)

09943–76310 09951–18210

Bush remover Oil seal remover & installer

No. 2

�) / �)�)

Page 473 of 1496

Downloaded from www.Manualslib.com manuals search engine Wheels and Tires: 2D-6

Repair Instructions

General Balance ProceduresS7RS0B2406001

Deposits of mud, etc. must be cleaned from inside of rim.

WARNING!

Stones should be removed from the tread in

order to avoid operator injury during spin

balancing and to obtain good balance.

Each tire should be inspected for any damage, then

balanced according to equipment manufacturer’s

recommendation.

Off-Vehicle Balancing

Most electronic off-vehicle balancers are more accurate

than the on-vehicle spin balancers. They are easy to use

and give a dynamic (two plane) balance. Although they

do not correct for drum or disc unbalance as does on-

vehicle spin balancing, this is overcome by their

accuracy, usually to within 1/8 ounce.

On-Vehicle Balancing

On-vehicle balancing methods vary with equipment and

tool manufacturers. Be sure to follow each

manufacturer’s instructions during balancing operation.

WARNING!

Wheel spin should be limited to 55 km/h (35

mph) as indicated on speedometer.

This limit is necessary because speedometer

only indicates one-half of actual wheel speed

when one drive wheel is spinning and the

other drive wheel is stopped.

Unless care is taken in limiting drive wheel

spin, spinning wheel can reach excessive

speeds. This can result in possible tire

disintegration or differential failure, which

could cause serious personal injury or

extensive vehicle damage.

CAUTION!

Using on-vehicle balancing method with

ignition switch ON may set malfunction

diagnostic trouble code (DTC) of ESP® and

ABS even when system is in good condition.

Never turn ignition swit ch ON while spinning

wheel.

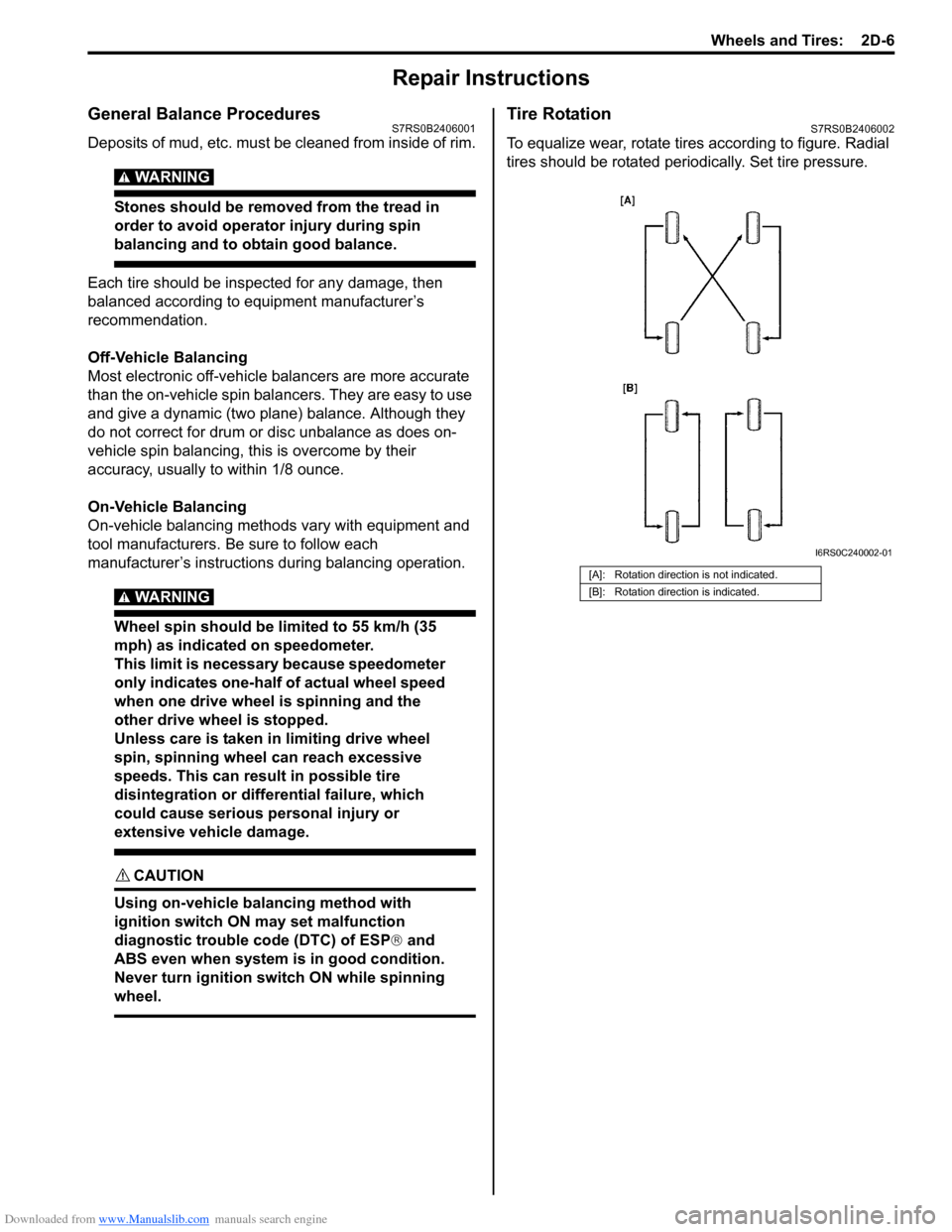

Tire RotationS7RS0B2406002

To equalize wear, rotate tires according to figure. Radial

tires should be rotated periodi cally. Set tire pressure.

[A]: Rotation direction is not indicated.

[B]: Rotation direction is indicated.

I6RS0C240002-01

Page 479 of 1496

Downloaded from www.Manualslib.com manuals search engine Drive Shaft / Axle: 3A-1

Driveline / Axle

Drive Shaft / Axle

General Description

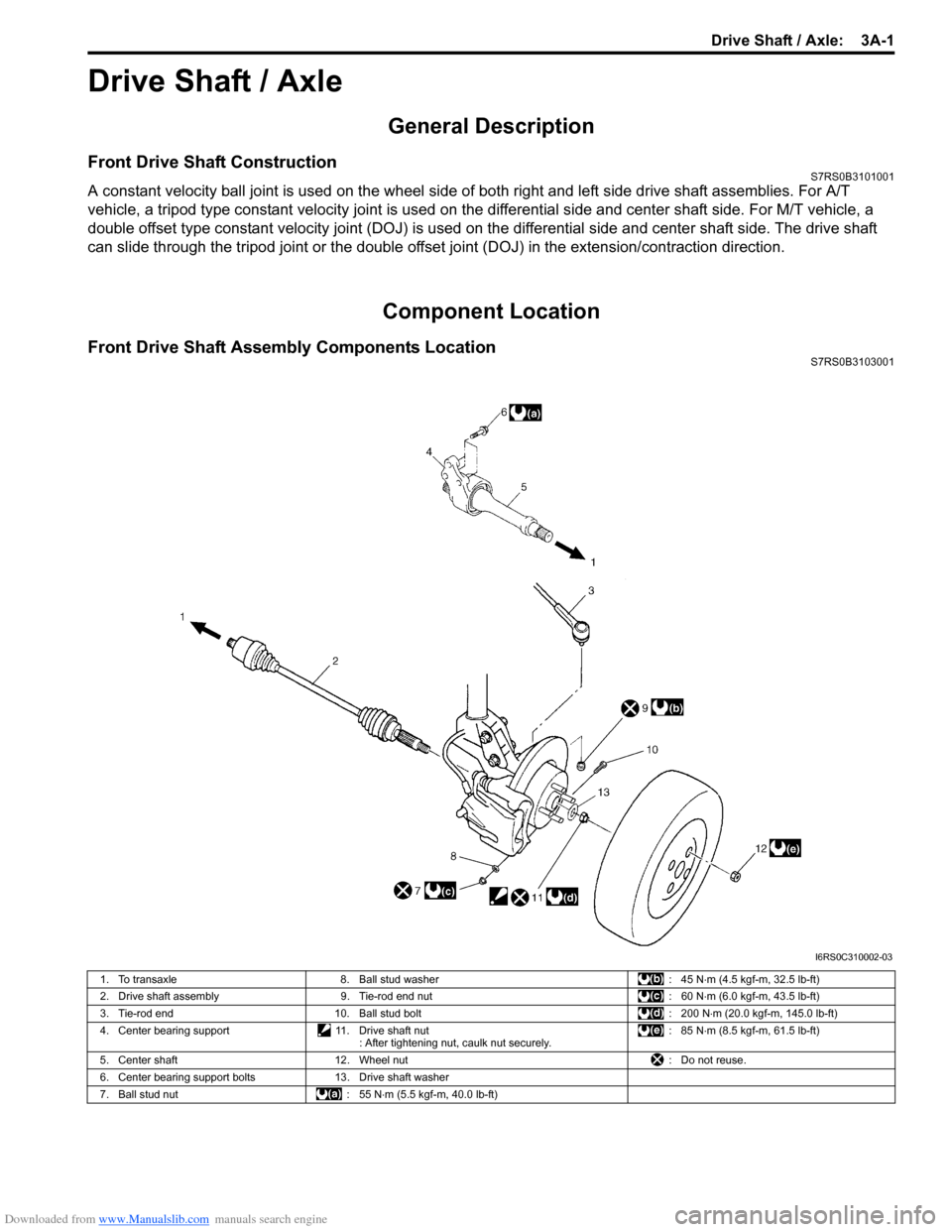

Front Drive Shaft ConstructionS7RS0B3101001

A constant velocity ball joint is used on the wheel side of both right and left side drive shaft assemblies. For A/T

vehicle, a tripod type constant velocity joint is used on the differential side and center shaft side. For M/T vehicle, a

double offset type constant velocity joint (DOJ) is used on the differential side and center shaft side. The drive shaft

can slide through the tripod joint or the double offset joint (DOJ) in the extension/contraction direction.

Component Location

Front Drive Shaft Assembly Components LocationS7RS0B3103001

I6RS0C310002-03

1. To transaxle 8. Ball stud washer : 45 N⋅m (4.5 kgf-m, 32.5 lb-ft)

2. Drive shaft assembly 9. Tie-rod end nut : 60 N⋅m (6.0 kgf-m, 43.5 lb-ft)

3. Tie-rod end 10. Ball stud bolt : 200 N⋅m (20.0 kgf-m, 145.0 lb-ft)

4. Center bearing support 11. Drive shaft nut

: After tightening nut, caulk nut securely. : 85 N

⋅m (8.5 kgf-m, 61.5 lb-ft)

5. Center shaft 12. Wheel nut : Do not reuse.

6. Center bearing support bolts 13. Drive shaft washer

7. Ball stud nut : 55 N⋅m (5.5 kgf-m, 40.0 lb-ft)

Page 482 of 1496

Downloaded from www.Manualslib.com manuals search engine 3A-4 Drive Shaft / Axle:

Front Drive Shaft Assembly On-Vehicle

Inspection

S7RS0B3106002

• Check boots for breakage or deterioration.

• Check wheel side joint for rattle or smooth rotation.

• Check differential side (or center shaft side) joint for smooth rotation.

If any abnormality is found, replace.

Front Drive Shaft Assembly Removal and

Installation

S7RS0B3106003

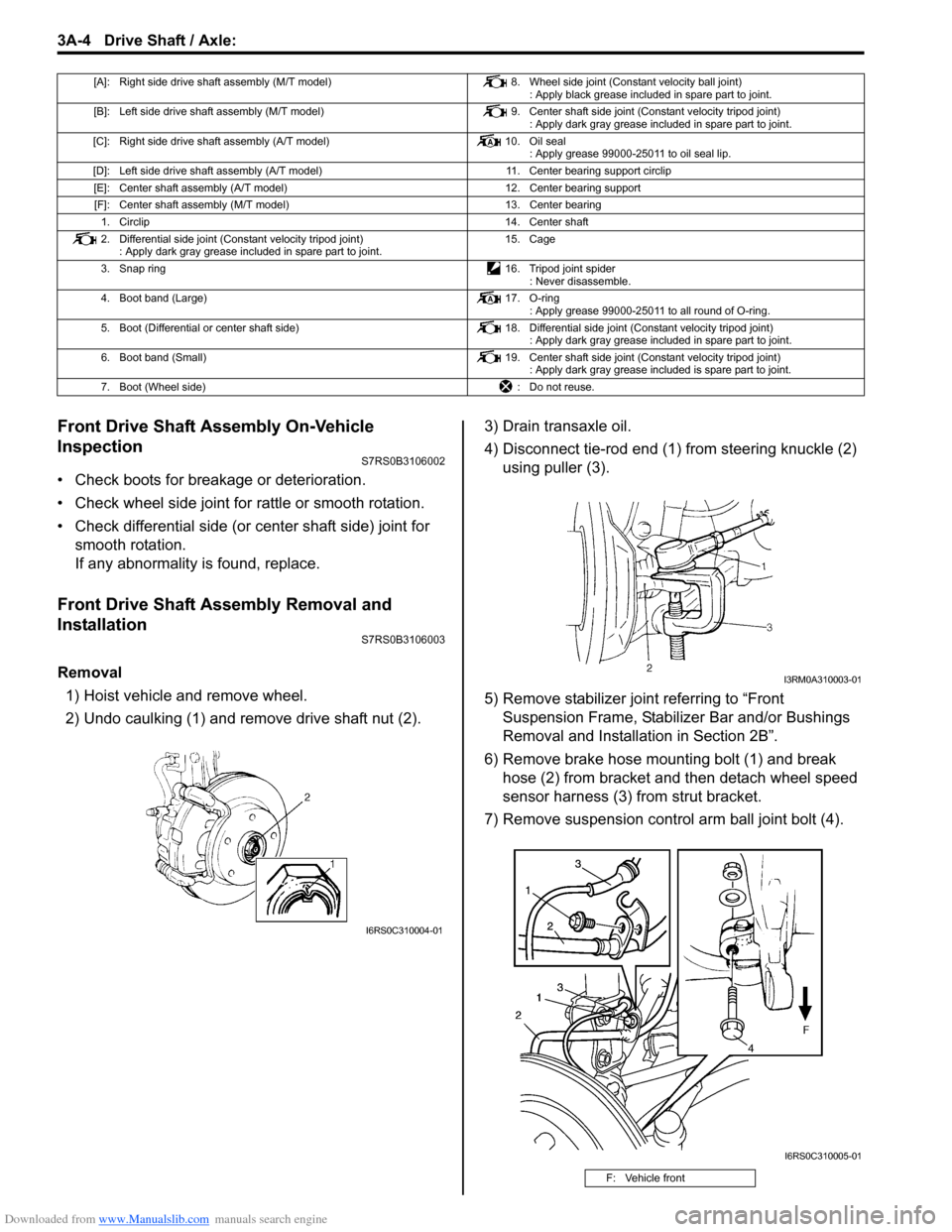

Removal

1) Hoist vehicle and remove wheel.

2) Undo caulking (1) and remove drive shaft nut (2). 3) Drain transaxle oil.

4) Disconnect tie-rod end (1) from steering knuckle (2)

using puller (3).

5) Remove stabilizer join t referring to “Front

Suspension Frame, Stabiliz er Bar and/or Bushings

Removal and Installati on in Section 2B”.

6) Remove brake hose mounting bolt (1) and break hose (2) from bracket and then detach wheel speed

sensor harness (3) from strut bracket.

7) Remove suspension contro l arm ball joint bolt (4).

[A]: Right side drive shaft assembly (M/T model) 8. Wheel side joint (Constant velocity ball joint)

: Apply black grease included in spare part to joint.

[B]: Left side drive shaft assembly (M/T model) 9. Center shaft side joint (Constant velocity tripod joint)

: Apply dark gray grease included in spare part to joint.

[C]: Right side drive shaft assembly (A/T model) 10. Oil seal

: Apply grease 99000-25011 to oil seal lip.

[D]: Left side drive shaft assembly (A/T model) 11. Center bearing support circlip

[E]: Center shaft assembly (A/T model) 12. Center bearing support

[F]: Center shaft assembly (M/T model) 13. Center bearing

1. Circlip 14. Center shaft

2. Differential side joint (Constant velocity tripod joint) : Apply dark gray grease included in spare part to joint. 15. Cage

3. Snap ring 16. Tripod joint spider

: Never disassemble.

4. Boot band (Large) 17. O-ring

: Apply grease 99000-25011 to all round of O-ring.

5. Boot (Differential or center shaft side) 18. Differential side joint (Constant velocity tripod joint)

: Apply dark gray grease included in spare part to joint.

6. Boot band (Small) 19. Center shaft side joint (Constant velocity tripod joint)

: Apply dark gray grease included is spare part to joint.

7. Boot (Wheel side) : Do not reuse.

I6RS0C310004-01

F: Vehicle front

I3RM0A310003-01

I6RS0C310005-01

Page 483 of 1496

Downloaded from www.Manualslib.com manuals search engine Drive Shaft / Axle: 3A-5

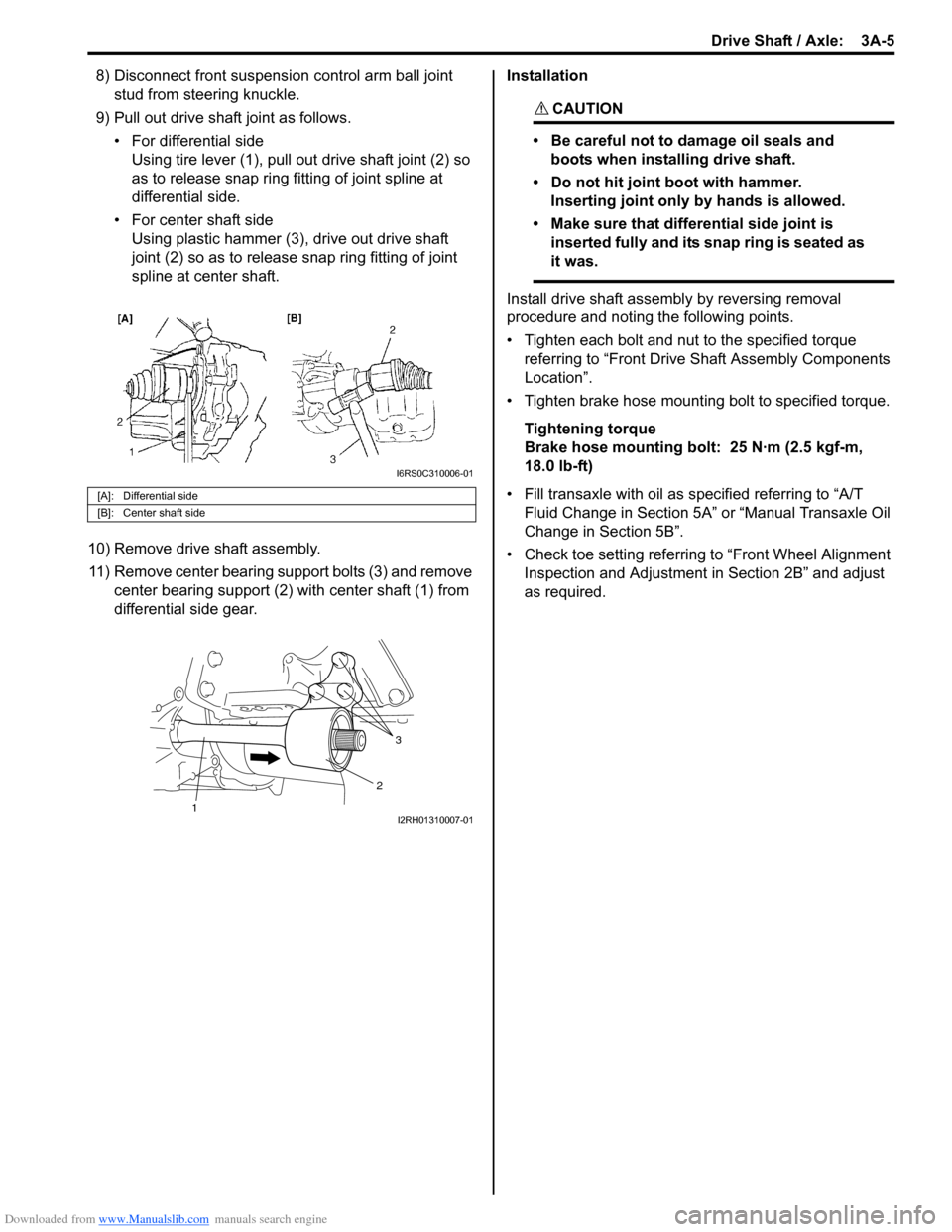

8) Disconnect front suspension control arm ball joint

stud from steering knuckle.

9) Pull out drive shaft joint as follows. • For differential sideUsing tire lever (1), pull out drive shaft joint (2) so

as to release snap ring fitting of joint spline at

differential side.

• For center shaft side Using plastic hammer (3), drive out drive shaft

joint (2) so as to release snap ring fitting of joint

spline at center shaft.

10) Remove drive shaft assembly. 11) Remove center bearing support bolts (3) and remove center bearing support (2) with center shaft (1) from

differential side gear. Installation

CAUTION!

• Be careful not to damage oil seals and

boots when installing drive shaft.

• Do not hit joint boot with hammer. Inserting joint only by hands is allowed.

• Make sure that differential side joint is inserted fully and its snap ring is seated as

it was.

Install drive shaft assemb ly by reversing removal

procedure and noting the following points.

• Tighten each bolt and nut to the specified torque referring to “Front Drive Shaft Assembly Components

Location”.

• Tighten brake hose mounting bolt to specified torque.

Tightening torque

Brake hose mounting bolt: 25 N·m (2.5 kgf-m,

18.0 lb-ft)

• Fill transaxle with oil as sp ecified referring to “A/T

Fluid Change in Section 5A” or “Manual Transaxle Oil

Change in Section 5B”.

• Check toe setting referring to “Front Wheel Alignment Inspection and Adjustment in Section 2B” and adjust

as required.

[A]: Differential side

[B]: Center shaft side

I6RS0C310006-01

3

2

1I2RH01310007-01

Page 484 of 1496

Downloaded from www.Manualslib.com manuals search engine 3A-6 Drive Shaft / Axle:

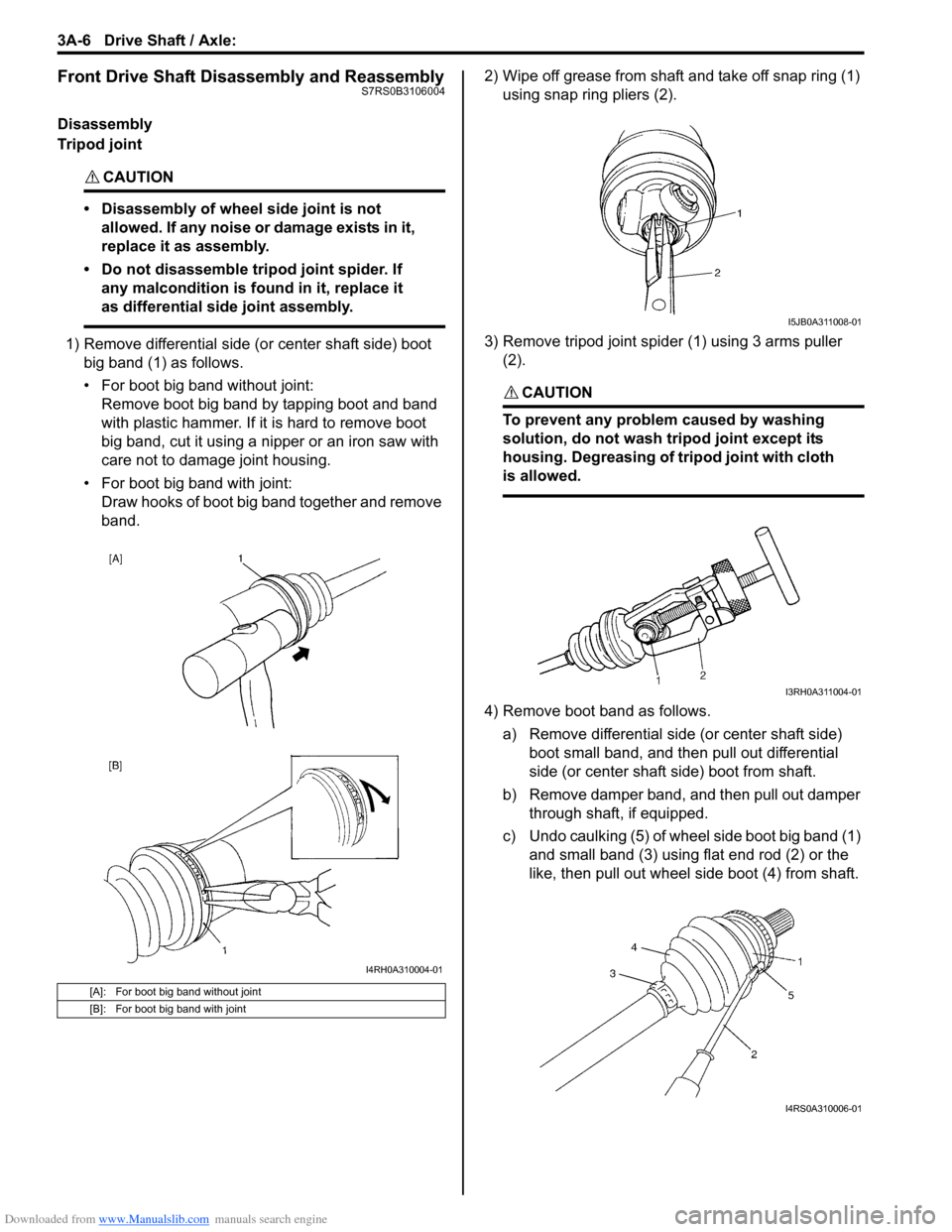

Front Drive Shaft Disassembly and ReassemblyS7RS0B3106004

Disassembly

Tripod joint

CAUTION!

• Disassembly of wheel side joint is not allowed. If any noise or damage exists in it,

replace it as assembly.

• Do not disassemble tripod joint spider. If any malcondition is found in it, replace it

as differential side joint assembly.

1) Remove differential side (or center shaft side) boot

big band (1) as follows.

• For boot big band without joint:Remove boot big band by tapping boot and band

with plastic hammer. If it is hard to remove boot

big band, cut it using a nipper or an iron saw with

care not to damage joint housing.

• For boot big band with joint: Draw hooks of boot big band together and remove

band. 2) Wipe off grease from shaft and take off snap ring (1)

using snap ring pliers (2).

3) Remove tripod joint spid er (1) using 3 arms puller

(2).

CAUTION!

To prevent any problem caused by washing

solution, do not wash tripod joint except its

housing. Degreasing of tr ipod joint with cloth

is allowed.

4) Remove boot band as follows.

a) Remove differential side (or center shaft side) boot small band, and then pull out differential

side (or center shaft side) boot from shaft.

b) Remove damper band, and then pull out damper through shaft, if equipped.

c) Undo caulking (5) of wheel side boot big band (1) and small band (3) using flat end rod (2) or the

like, then pull out wheel side boot (4) from shaft.

[A]: For boot big band without joint

[B]: For boot big band with joint

I4RH0A310004-01

I5JB0A311008-01

I3RH0A311004-01

I4RS0A310006-01

Page 485 of 1496

Downloaded from www.Manualslib.com manuals search engine Drive Shaft / Axle: 3A-7

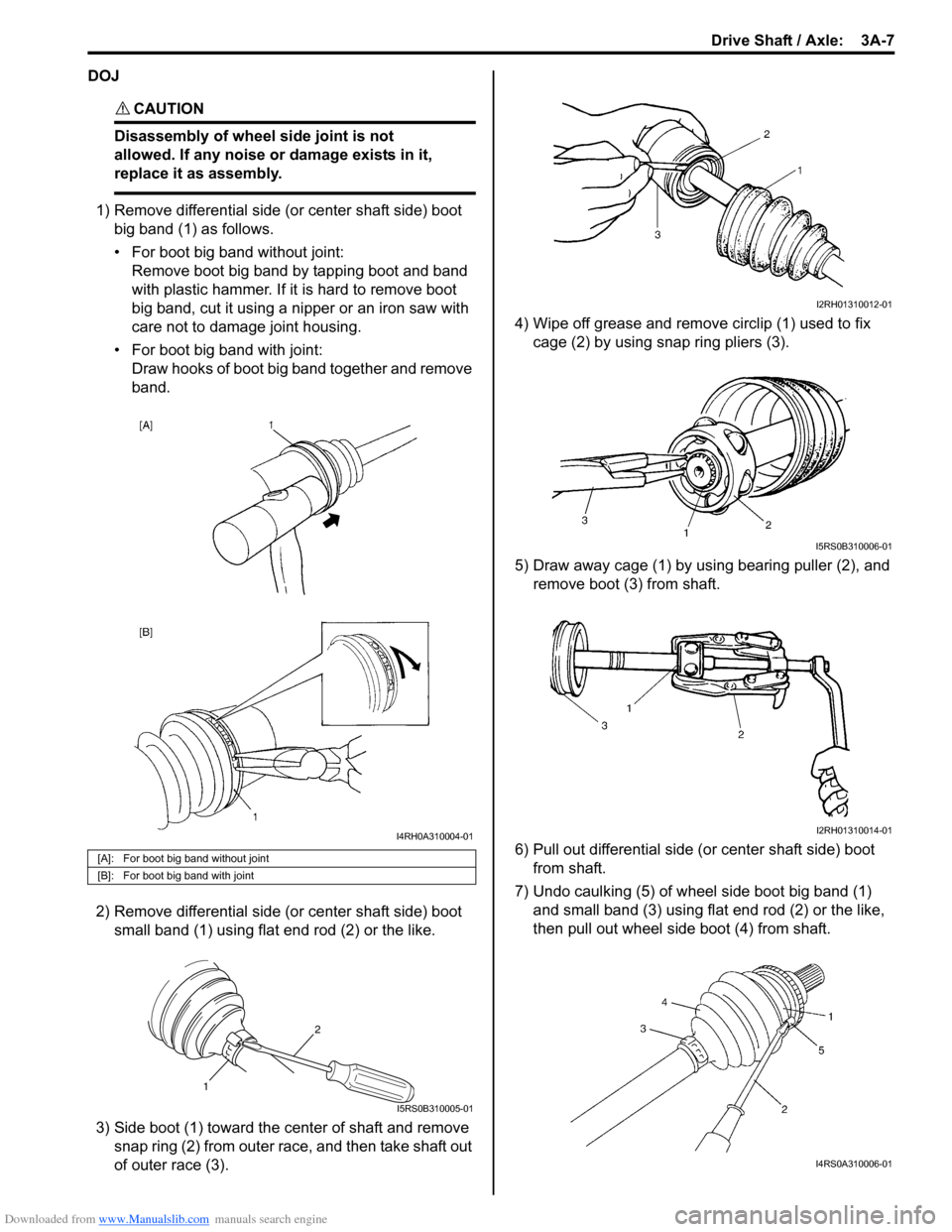

DOJ

CAUTION!

Disassembly of wheel side joint is not

allowed. If any noise or damage exists in it,

replace it as assembly.

1) Remove differential side (or center shaft side) boot big band (1) as follows.

• For boot big band without joint:Remove boot big band by tapping boot and band

with plastic hammer. If it is hard to remove boot

big band, cut it using a nipper or an iron saw with

care not to damage joint housing.

• For boot big band with joint: Draw hooks of boot big band together and remove

band.

2) Remove differential side (or center shaft side) boot small band (1) using flat end rod (2) or the like.

3) Side boot (1) toward the center of shaft and remove snap ring (2) from outer race, and then take shaft out

of outer race (3). 4) Wipe off grease and remove circlip (1) used to fix

cage (2) by using snap ring pliers (3).

5) Draw away cage (1) by using bearing puller (2), and remove boot (3) from shaft.

6) Pull out differential side (or center shaft side) boot from shaft.

7) Undo caulking (5) of wheel side boot big band (1) and small band (3) using flat end rod (2) or the like,

then pull out wheel side boot (4) from shaft.

[A]: For boot big band without joint

[B]: For boot big band with joint

I4RH0A310004-01

2

1

I5RS0B310005-01

I2RH01310012-01

I5RS0B310006-01

I2RH01310014-01

I4RS0A310006-01