Wheel bolt SUZUKI SWIFT 2008 2.G Service Manual Online

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 880 of 1496

Downloaded from www.Manualslib.com manuals search engine 6B-9 Steering Wheel and Column:

Ignition Switch Cylinder Assembly Removal

and Installation (Non- Keyless Start Model)

S7RS0B6206008

Removal1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove steering column upper and lower covers.

4) Remove immobilizer co ntrol module referring to

“Immobilizer Control Modu le (ICM) Removal and

Installation in Section 10C”.

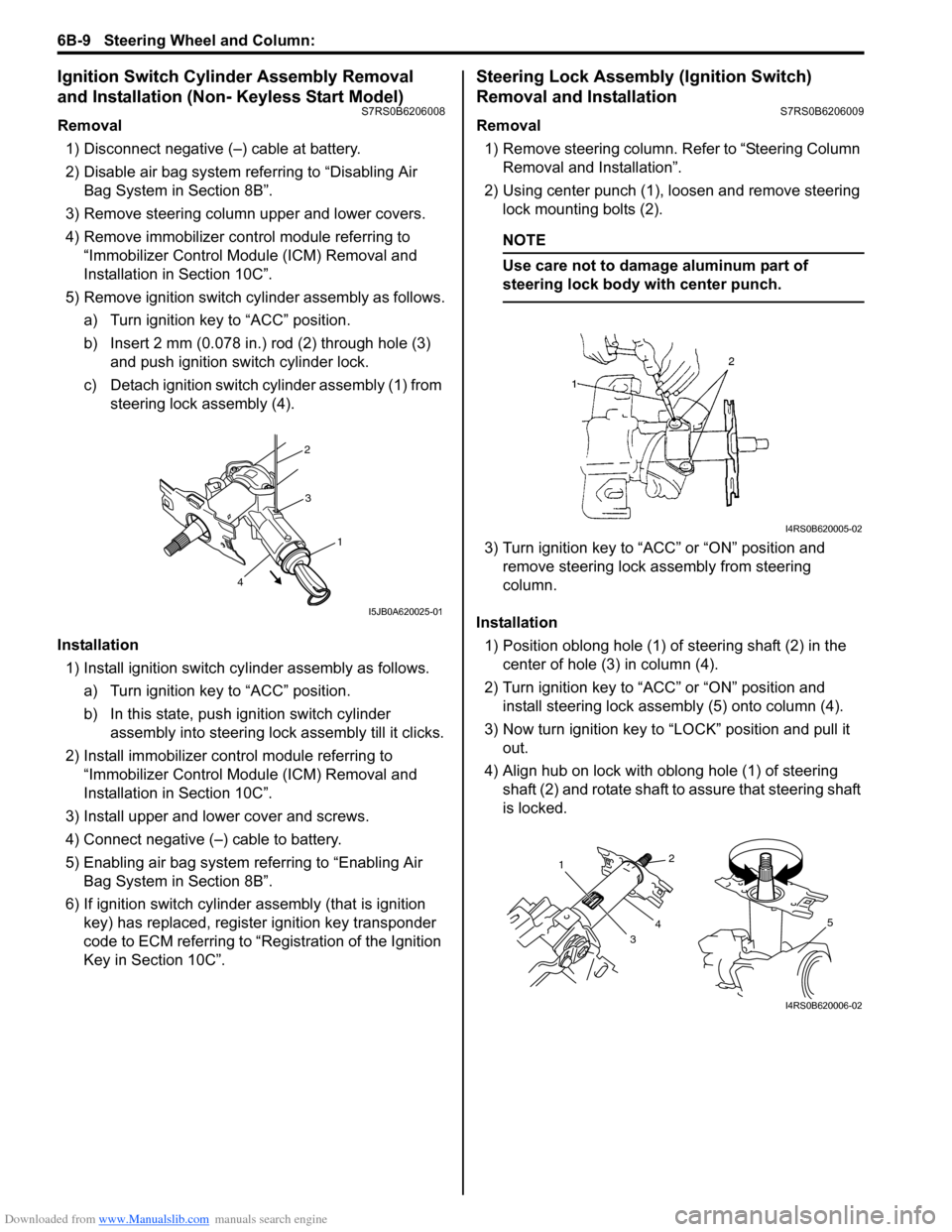

5) Remove ignition switch cy linder assembly as follows.

a) Turn ignition key to “ACC” position.

b) Insert 2 mm (0.078 in.) rod (2) through hole (3) and push ignition switch cylinder lock.

c) Detach ignition switch cylinder assembly (1) from steering lock assembly (4).

Installation 1) Install ignition switch cy linder assembly as follows.

a) Turn ignition key to “ACC” position.

b) In this state, push ignition switch cylinder assembly into steering lock assembly till it clicks.

2) Install immobilizer cont rol module referring to

“Immobilizer Control Modu le (ICM) Removal and

Installation in Section 10C”.

3) Install upper and lower cover and screws.

4) Connect negative (–) cable to battery.

5) Enabling air bag system referring to “Enabling Air Bag System in Section 8B”.

6) If ignition switch cylinder assembly (that is ignition

key) has replaced, register ignition key transponder

code to ECM referring to “R egistration of the Ignition

Key in Section 10C”.

Steering Lock Assembly (Ignition Switch)

Removal and Installation

S7RS0B6206009

Removal

1) Remove steering column. Refer to “Steering Column

Removal and Installation”.

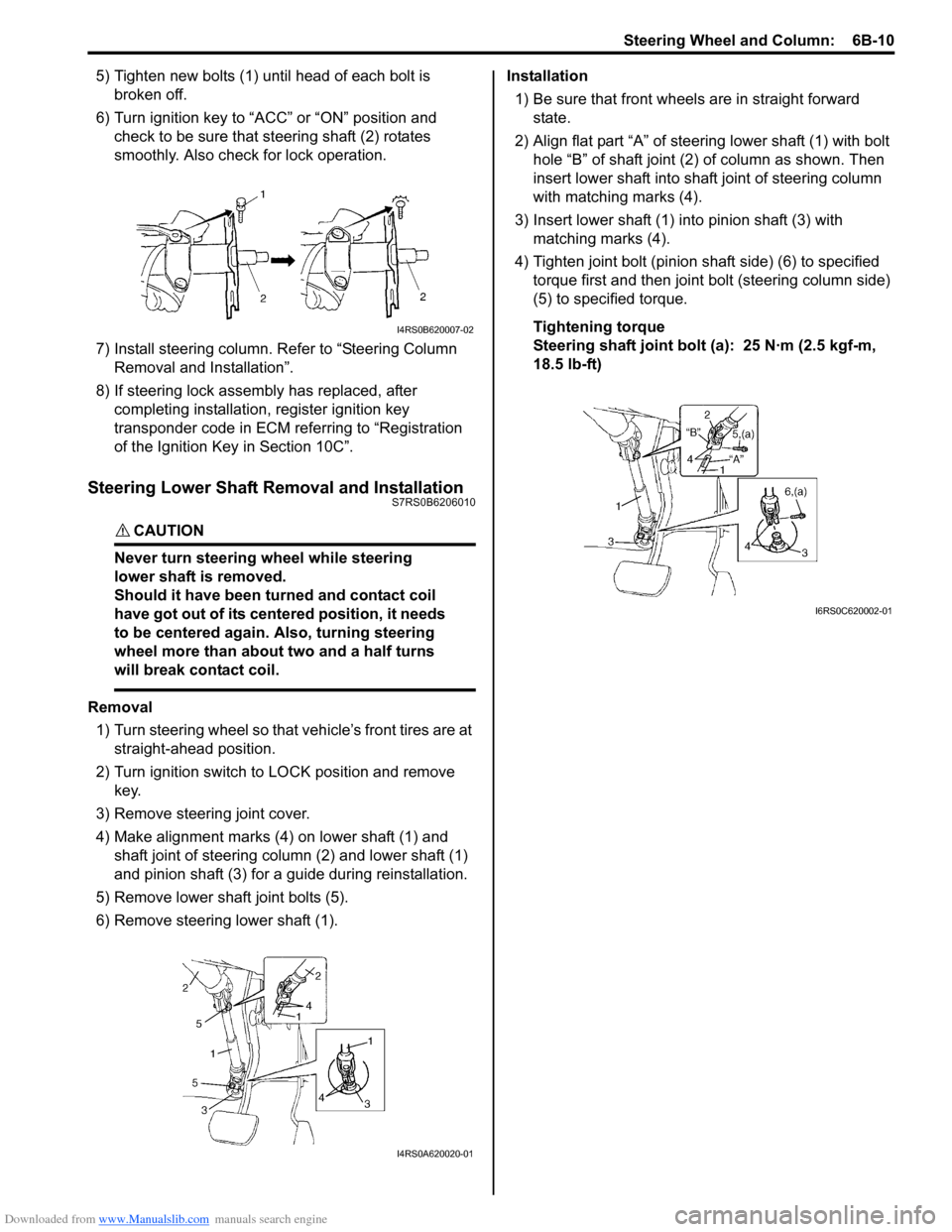

2) Using center punch (1), loosen and remove steering lock mounting bolts (2).

NOTE

Use care not to damage aluminum part of

steering lock body with center punch.

3) Turn ignition key to “ACC” or “ON” position and remove steering lock a ssembly from steering

column.

Installation 1) Position oblong hole (1) of steering shaft (2) in the center of hole (3) in column (4).

2) Turn ignition key to “ACC” or “ON” position and install steering lock assemb ly (5) onto column (4).

3) Now turn ignition key to “LOCK” position and pull it out.

4) Align hub on lock with oblong hole (1) of steering shaft (2) and rotate shaft to assure that steering shaft

is locked.

2

3

1

4

I5JB0A620025-01

I4RS0B620005-02

1

32

4

5

I4RS0B620006-02

Page 881 of 1496

Downloaded from www.Manualslib.com manuals search engine Steering Wheel and Column: 6B-10

5) Tighten new bolts (1) until head of each bolt is broken off.

6) Turn ignition key to “ACC” or “ON” position and check to be sure that st eering shaft (2) rotates

smoothly. Also check for lock operation.

7) Install steering column. Re fer to “Steering Column

Removal and Installation”.

8) If steering lock assembly has replaced, after completing installation, register ignition key

transponder code in ECM referring to “Registration

of the Ignition Key in Section 10C”.

Steering Lower Shaft Removal and InstallationS7RS0B6206010

CAUTION!

Never turn steering wheel while steering

lower shaft is removed.

Should it have been turned and contact coil

have got out of its centered position, it needs

to be centered again. Also, turning steering

wheel more than about two and a half turns

will break contact coil.

Removal

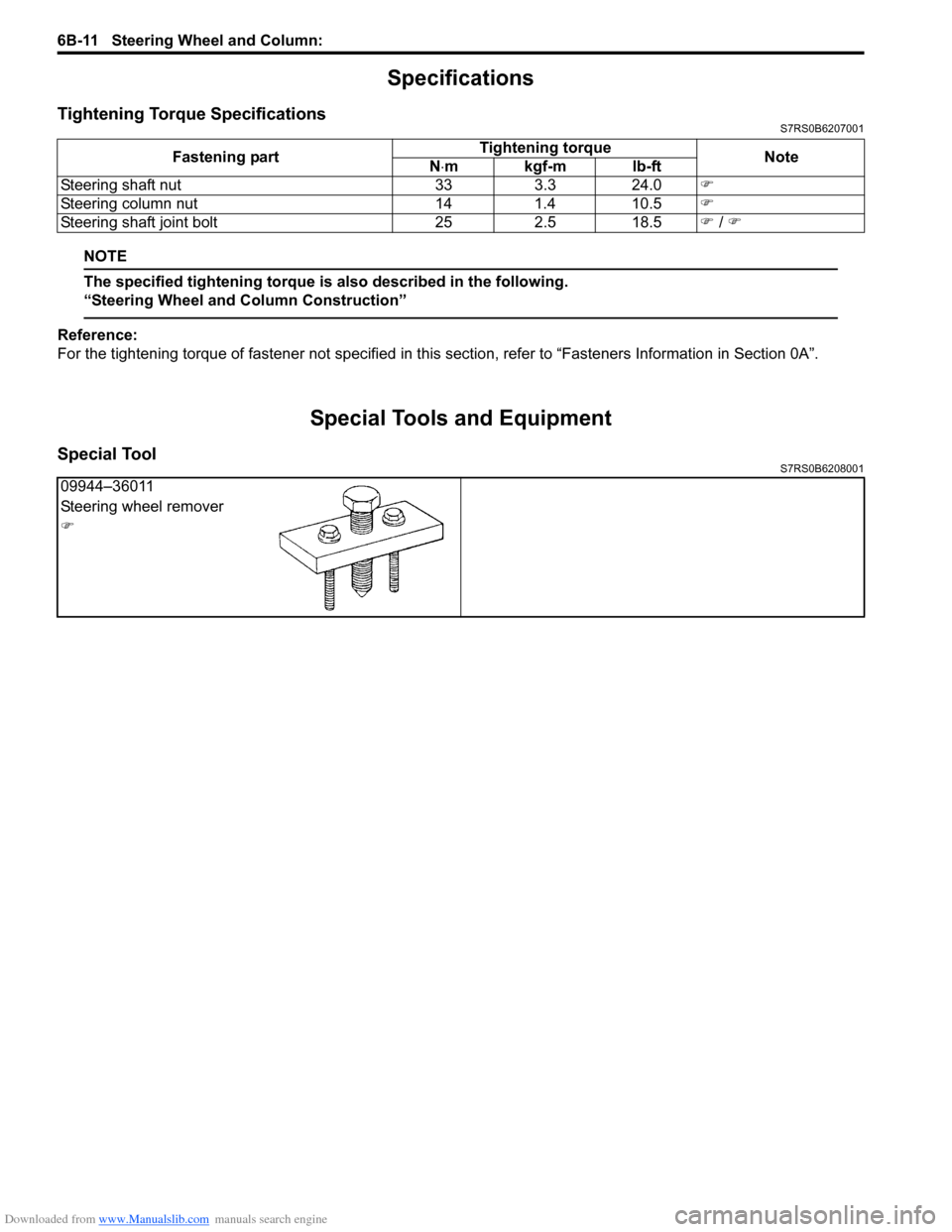

1) Turn steering wheel so that vehicle’s front tires are at straight-ahead position.

2) Turn ignition switch to LOCK position and remove key.

3) Remove steering joint cover.

4) Make alignment marks (4) on lower shaft (1) and shaft joint of steering colu mn (2) and lower shaft (1)

and pinion shaft (3) for a guide during reinstallation.

5) Remove lower shaf t joint bolts (5).

6) Remove steering lower shaft (1). Installation

1) Be sure that front wheels are in straight forward state.

2) Align flat part “A” of steering lower shaft (1) with bolt hole “B” of shaft joint (2) of column as shown. Then

insert lower shaft into shaf t joint of steering column

with matching marks (4).

3) Insert lower shaft (1) into pinion shaft (3) with matching marks (4).

4) Tighten joint bolt (pinion shaft side) (6) to specified

torque first and then joint bolt (steering column side)

(5) to specified torque.

Tightening torque

Steering shaft joint bolt (a ): 25 N·m (2.5 kgf-m,

18.5 lb-ft)

I4RS0B620007-02

I4RS0A620020-01

I6RS0C620002-01

Page 882 of 1496

Downloaded from www.Manualslib.com manuals search engine 6B-11 Steering Wheel and Column:

Specifications

Tightening Torque SpecificationsS7RS0B6207001

NOTE

The specified tightening torque is also described in the following.

“Steering Wheel and Column Construction”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Special ToolS7RS0B6208001

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Steering shaft nut 33 3.3 24.0 �)

Steering column nut 14 1.4 10.5 �)

Steering shaft joint bolt 25 2.5 18.5 �) / �)

09944–36011

Steering wheel remover

�)

Page 923 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-41

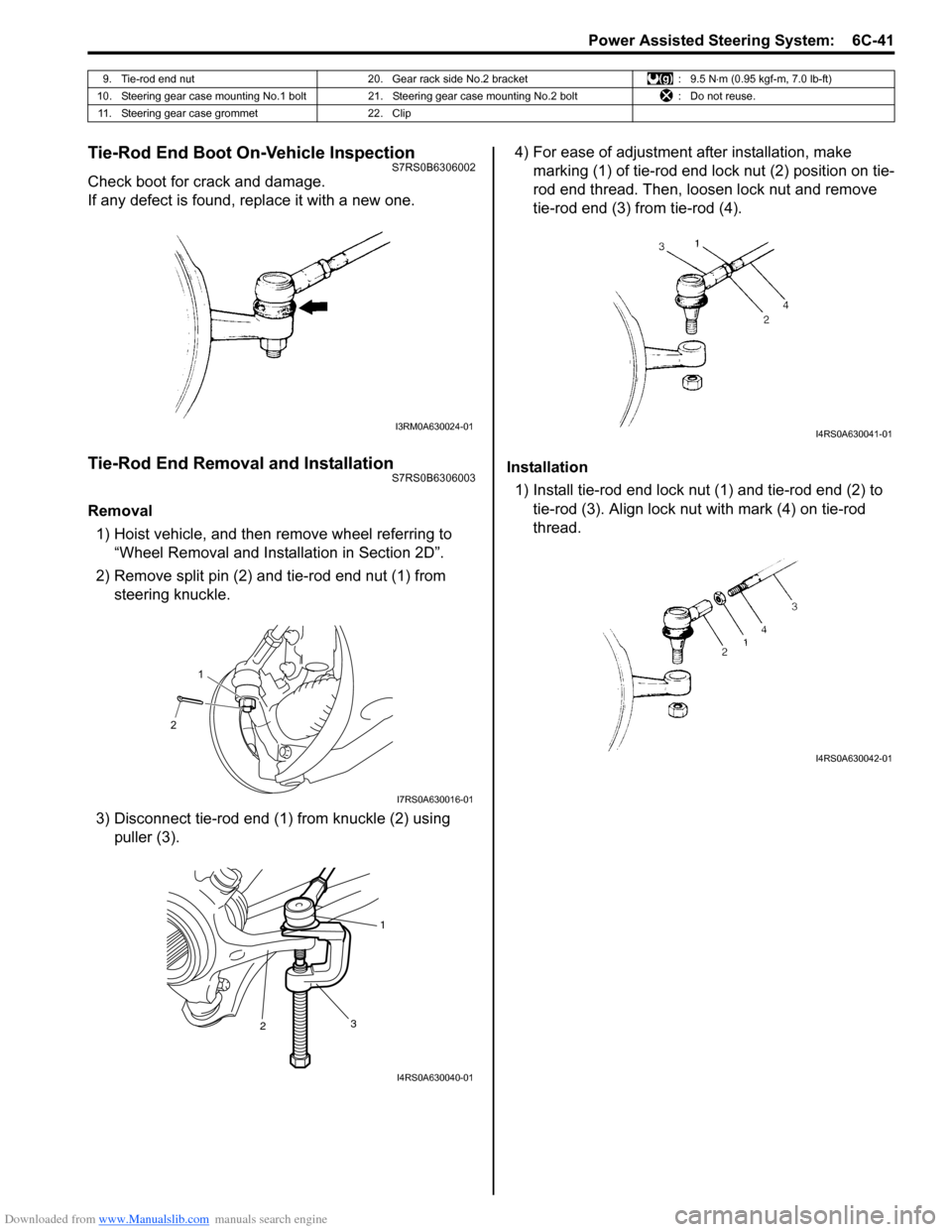

Tie-Rod End Boot On-Vehicle InspectionS7RS0B6306002

Check boot for crack and damage.

If any defect is found, replace it with a new one.

Tie-Rod End Removal and InstallationS7RS0B6306003

Removal1) Hoist vehicle, and then remove wheel referring to “Wheel Removal and Installation in Section 2D”.

2) Remove split pin (2) and tie-rod end nut (1) from steering knuckle.

3) Disconnect tie-rod end (1) from knuckle (2) using puller (3). 4) For ease of adjustment after installation, make

marking (1) of tie-rod end lock nut (2) position on tie-

rod end thread. Then, loosen lock nut and remove

tie-rod end (3) from tie-rod (4).

Installation 1) Install tie-rod end lock nut (1) and tie-rod end (2) to tie-rod (3). Align lock nut with mark (4) on tie-rod

thread.

9. Tie-rod end nut 20. Gear rack side No.2 bracket : 9.5 N⋅m (0.95 kgf-m, 7.0 lb-ft)

10. Steering gear case mounting No.1 bolt 21. Steering gear case mounting No.2 bolt : Do not reuse.

11. Steering gear case grommet 22. Clip

I3RM0A630024-01

21

I7RS0A630016-01

2 1

3

I4RS0A630040-01

I4RS0A630041-01

I4RS0A630042-01

Page 924 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-42 Power Assisted Steering System:

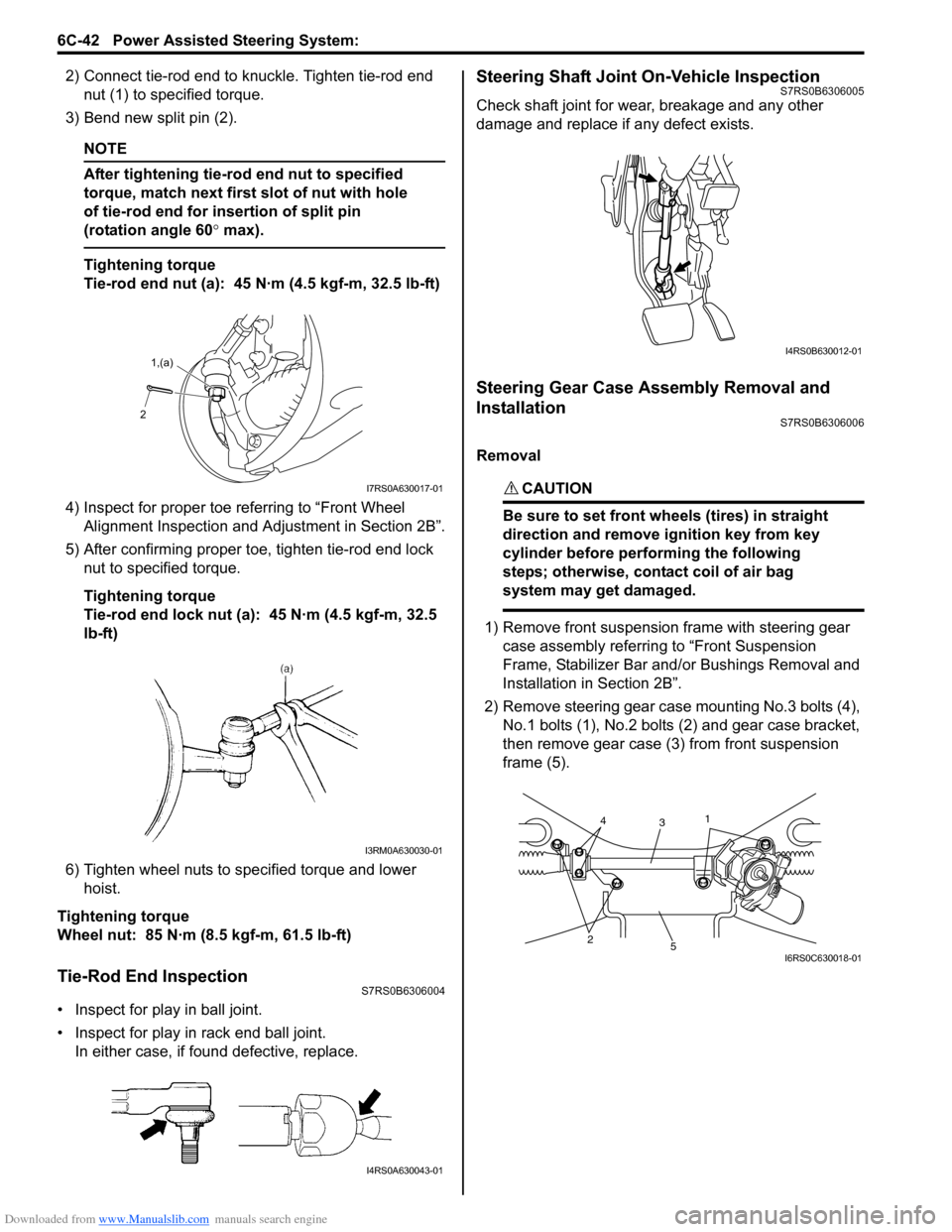

2) Connect tie-rod end to knuckle. Tighten tie-rod end nut (1) to spec ified torque.

3) Bend new split pin (2).

NOTE

After tightening tie-rod end nut to specified

torque, match next first slot of nut with hole

of tie-rod end for insertion of split pin

(rotation angle 60 ° max).

Tightening torque

Tie-rod end nut (a): 45 N·m (4.5 kgf-m, 32.5 lb-ft)

4) Inspect for proper toe re ferring to “Front Wheel

Alignment Inspection and Adjustment in Section 2B”.

5) After confirming proper toe, tighten tie-rod end lock nut to specified torque.

Tightening torque

Tie-rod end lock nut (a): 45 N·m (4.5 kgf-m, 32.5

lb-ft)

6) Tighten wheel nuts to specified torque and lower hoist.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

Tie-Rod End InspectionS7RS0B6306004

• Inspect for play in ball joint.

• Inspect for play in rack end ball joint. In either case, if found defective, replace.

Steering Shaft Joint On-Vehicle InspectionS7RS0B6306005

Check shaft joint for wear, breakage and any other

damage and replace if any defect exists.

Steering Gear Case Assembly Removal and

Installation

S7RS0B6306006

Removal

CAUTION!

Be sure to set front wheels (tires) in straight

direction and remove ignition key from key

cylinder before performing the following

steps; otherwise, contact coil of air bag

system may get damaged.

1) Remove front suspension frame with steering gear case assembly referrin g to “Front Suspension

Frame, Stabilizer Bar and/ or Bushings Removal and

Installation in Section 2B”.

2) Remove steering gear case mounting No.3 bolts (4), No.1 bolts (1), No.2 bolts (2) and gear case bracket,

then remove gear case (3) from front suspension

frame (5).

2 1,(a)

I7RS0A630017-01

I3RM0A630030-01

I4RS0A630043-01

I4RS0B630012-01

25

3

14

I6RS0C630018-01

Page 930 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-48 Power Assisted Steering System:

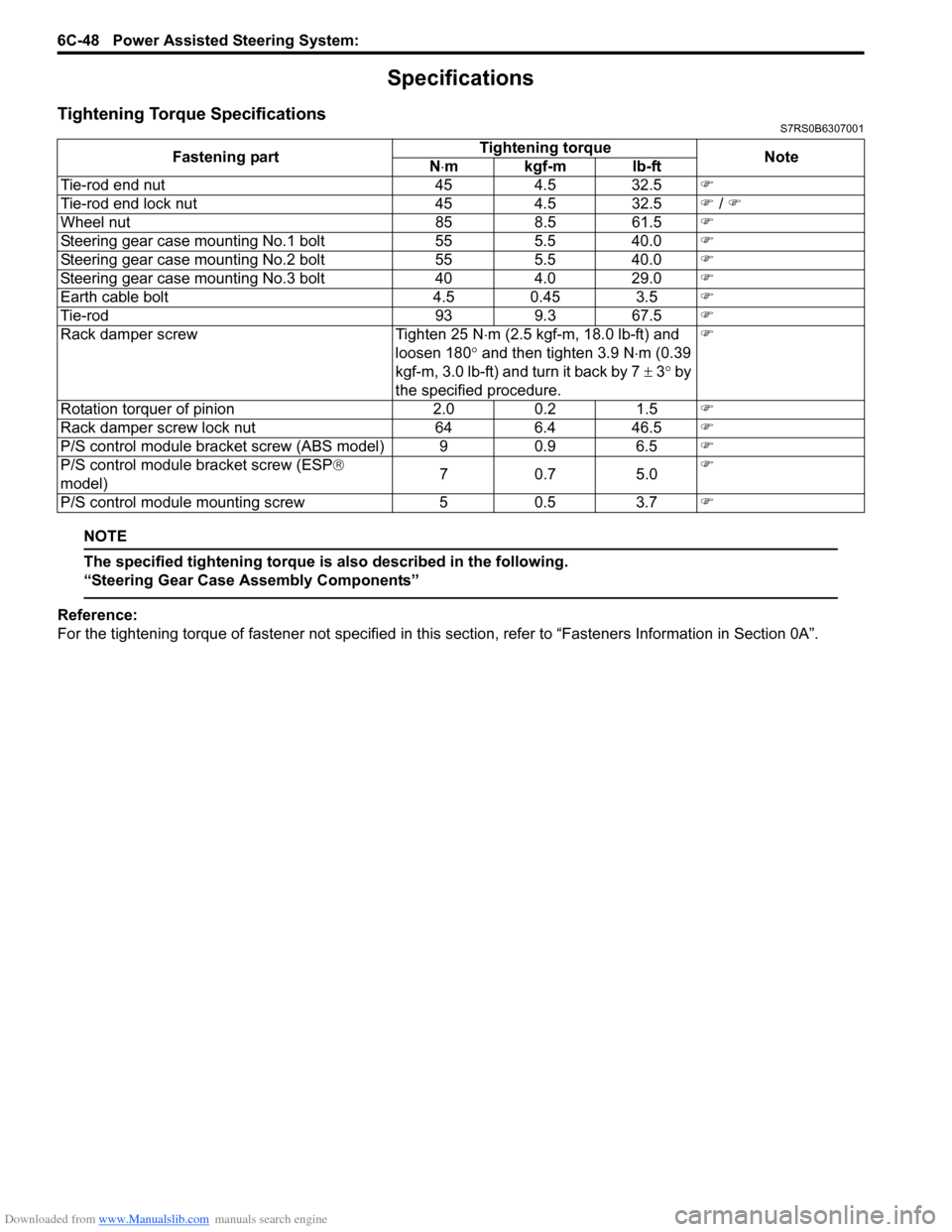

Specifications

Tightening Torque SpecificationsS7RS0B6307001

NOTE

The specified tightening torque is also described in the following.

“Steering Gear Case Assembly Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Tie-rod end nut 454.5 32.5 �)

Tie-rod end lock nut 454.5 32.5 �) / �)

Wheel nut 858.5 61.5 �)

Steering gear case mounting No.1 bolt 555.5 40.0 �)

Steering gear case mounting No.2 bolt 555.5 40.0 �)

Steering gear case mounting No.3 bolt 404.0 29.0 �)

Earth cable bolt 4.5 0.45 3.5�)

Tie-rod 939.3 67.5 �)

Rack damper screw Tighten 25 N⋅m (2.5 kgf-m, 18.0 lb-ft) and

loosen 180 ° and then tighten 3.9 N ⋅m (0.39

kgf-m, 3.0 lb-ft) and turn it back by 7 ± 3° by

the specified procedure. �)

Rotation torquer of pinion 2.00.2 1.5 �)

Rack damper screw lock nut 646.4 46.5 �)

P/S control module bracket screw (ABS model) 9 0.9 6.5�)

P/S control module bracket screw (ESP ®

model) 70

.7 5 .0 �)

P/S control module mounting screw 50.5 3.7 �)

Page 1140 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-102 Air Bag System:

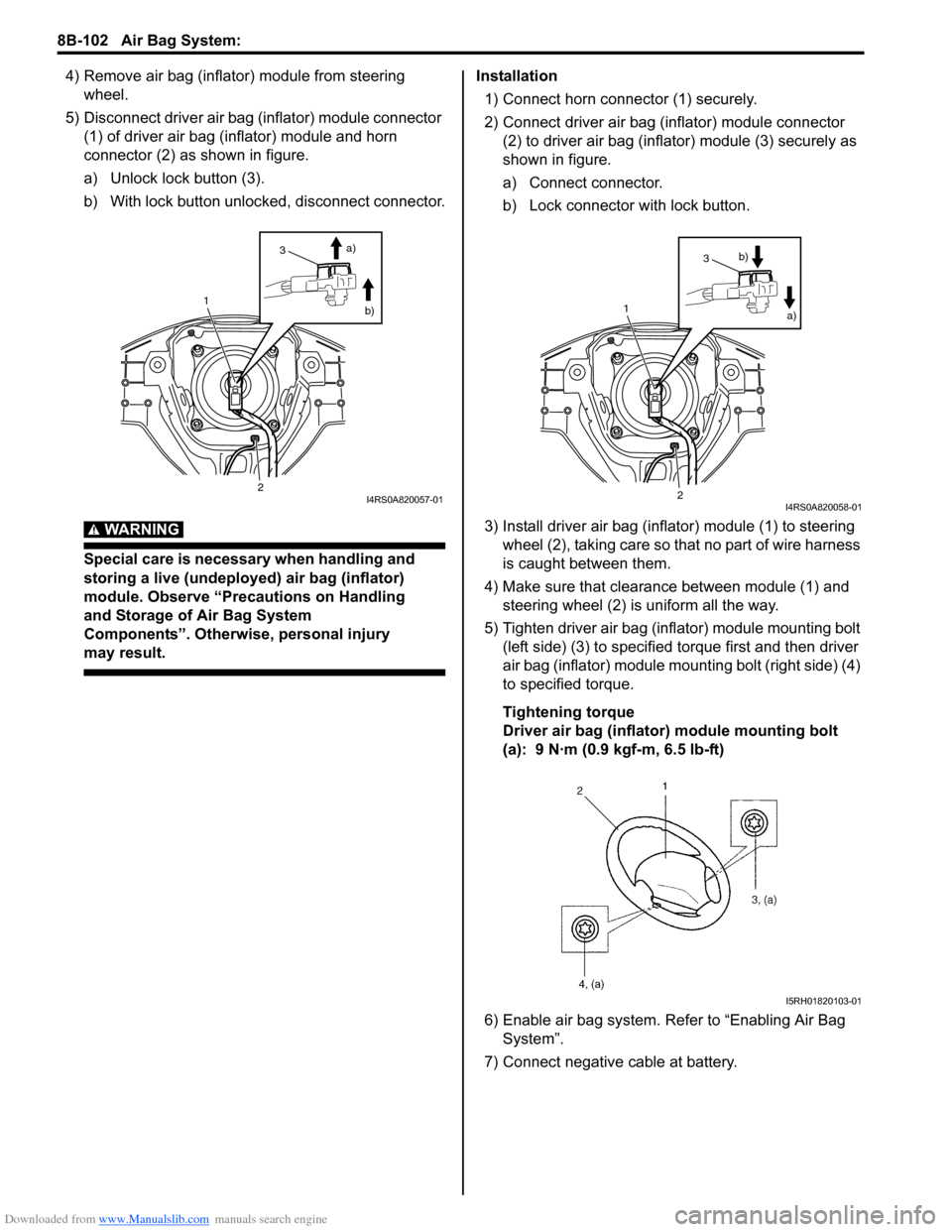

4) Remove air bag (inflator) module from steering wheel.

5) Disconnect driver air bag (inflator) module connector (1) of driver air bag (inflator) module and horn

connector (2) as shown in figure.

a) Unlock lock button (3).

b) With lock button unlocked, disconnect connector.

WARNING!

Special care is necessary when handling and

storing a live (undeployed) air bag (inflator)

module. Observe “Precautions on Handling

and Storage of Air Bag System

Components”. Otherwise, personal injury

may result.

Installation

1) Connect horn connector (1) securely.

2) Connect driver air bag (inflator) module connector (2) to driver air bag (inflator) module (3) securely as

shown in figure.

a) Connect connector.

b) Lock connector with lock button.

3) Install driver air bag (inflator) module (1) to steering wheel (2), taking care so t hat no part of wire harness

is caught between them.

4) Make sure that clearance between module (1) and steering wheel (2) is uniform all the way.

5) Tighten driver air bag (inflator) module mounting bolt (left side) (3) to specified torque first and then driver

air bag (inflator) module mounting bolt (right side) (4)

to specified torque.

Tightening torque

Driver air bag (inflator) module mounting bolt

(a): 9 N·m (0.9 kgf-m, 6.5 lb-ft)

6) Enable air bag system. Refer to “Enabling Air Bag System”.

7) Connect negative cable at battery.

1

2

3 a)

b)

I4RS0A820057-01

1

2

3 a)

b)

I4RS0A820058-01

I5RH01820103-01

Page 1313 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-18

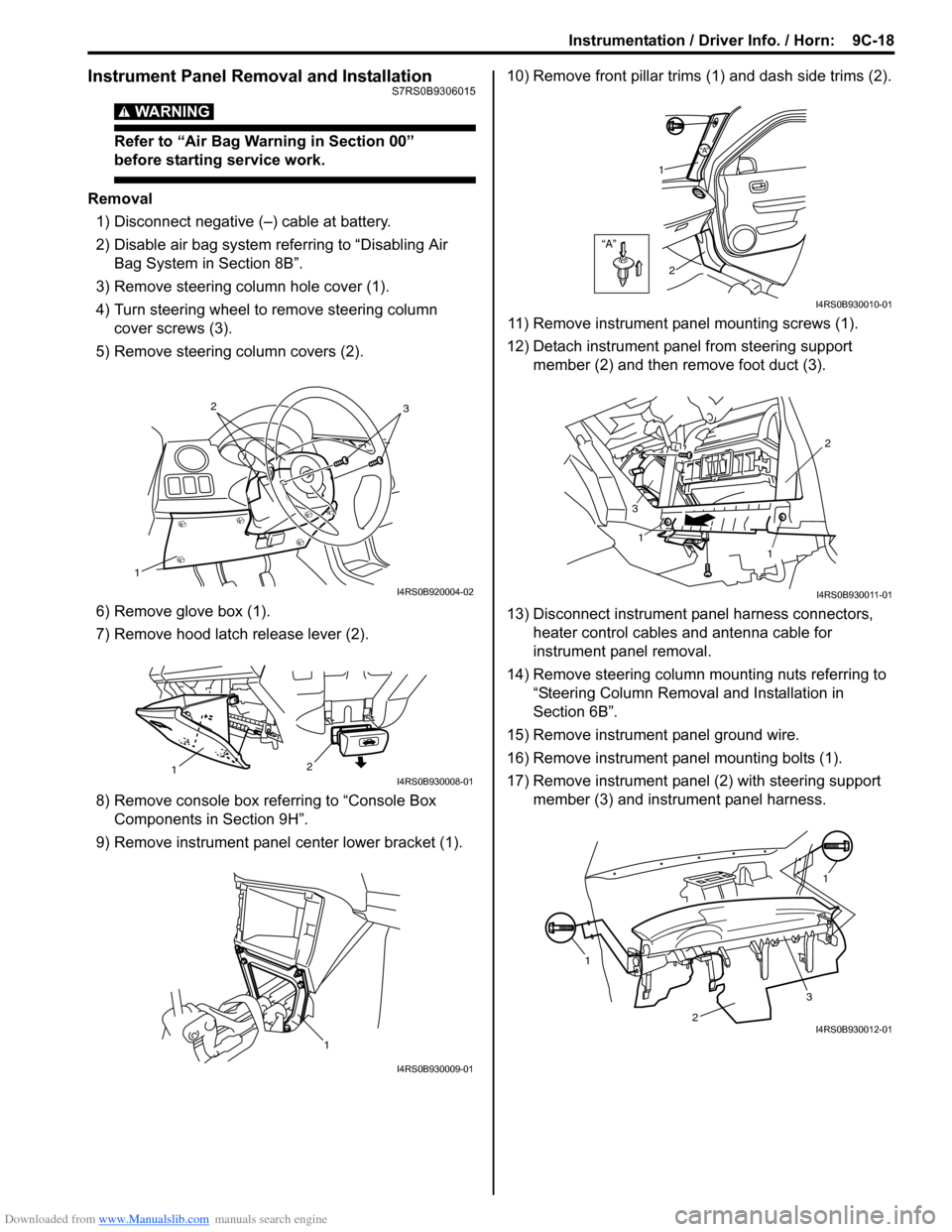

Instrument Panel Removal and InstallationS7RS0B9306015

WARNING!

Refer to “Air Bag Warning in Section 00”

before starting service work.

Removal

1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove steering column hole cover (1).

4) Turn steering wheel to remove steering column cover screws (3).

5) Remove steering column covers (2).

6) Remove glove box (1).

7) Remove hood latch release lever (2).

8) Remove console box referring to “Console Box Components in Section 9H”.

9) Remove instrument panel center lower bracket (1). 10) Remove front pillar trims

(1) and dash side trims (2).

11) Remove instrument panel mounting screws (1).

12) Detach instrument panel from steering support member (2) and then remove foot duct (3).

13) Disconnect instrument panel harness connectors, heater control cables and antenna cable for

instrument panel removal.

14) Remove steering column mounting nuts referring to “Steering Column Remova l and Installation in

Section 6B”.

15) Remove instrument panel ground wire.

16) Remove instrument panel mounting bolts (1).

17) Remove instrument panel (2) with steering support member (3) and instrument panel harness.

1

32

I4RS0B920004-02

2

1I4RS0B930008-01

1

I4RS0B930009-01

“A”

“A”

1

2

I4RS0B930010-01

1

1 2

3

I4RS0B930011-01

1 1

2

3I4RS0B930012-01