engine troubleshooting SUZUKI SWIFT 2008 2.G Service Manual Online

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 554 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-15 ABS:

EBD Warning Light (Brake Warning Light) Comes ON SteadyS7RS0B4504010

Wiring Diagram

Refer to “ABS Warning Light Does Not Come ON at Ignition Switch ON”.

Circuit Description

EBD warning light (brake warn ing light) is controlled by parking brake switch, brake fluid level switch and ABS

hydraulic unit / control module assembly throug h lamp driver module in combination meter.

EBD warning light turns ON when parki ng brake switch is ON and/or brake fluid level is lower than minimum level.

The information of parking brake switch and brake fluid leve l are transmitted from BCM to lamp driver module in

combination meter through CAN communication line.

Troubleshooting 5 1) Turn ignition switch to OFF and measure resistance

between each terminal of “E03-13”, “E03-26” and vehicle

body ground.

Is resistance less than 2

Ω? Go to Step 6. Ground circuit for ABS

hydraulic unit / control

module open or high

resistance.

6 Check CAN communication circuit between combination meter and ABS control module referring to “DTC U1073:

Control Module Communication Bus Off”.

Is CAN communication circuit in good condition? Substitute a known-

good combination meter

and recheck. If ABS

warning light remains

ON, substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.Repair or replace.

Step Action Yes No

Step

Action YesNo

1 1) Make sure that:

• Parking brake is completely released.

• Brake fluid level is upper than the minimum level.

Are the check results OK? Go to Step 2.

Release parking brake

completely and/or

replenish brake fluid.

2 1) Turn ignition switch to ON position. Does “ABS” warning light come on steady? Perform “ABS Warning

Light Comes ON

Steady” previously

outlined.Go to Step 3.

3 1) CAN communication circuit between combination meter, ABS hydraulic unit / control module and BCM referring to

“DTC U1073: Control Module Communication Bus Off”.

Is CAN communication circuit in good condition? Substitute a known-

good combination meter

and recheck. If ABS

warning light remains

ON, substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.Repair or replace.

Page 558 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-19 ABS:

DTC TroubleshootingStep Action Yes No 1 Was “ABS Check” performed? Go to Step 2. Go to “ABS Check”.

2 1) Disconnect applicable ABS wheel speed sensor coupler with ignition switch OFF.

2) Measure resistance betw een terminals of ABS wheel

speed sensor. Refer to “Front Wheel Speed Sensor

Inspection” and/or “Front Wheel Encoder On-Vehicle

Inspection”.

Is measured resistance value as specified? Go to Step 3. Replace ABS wheel

speed sensor assembly.

3 1) Turn ignition switch OFF. 2) Connect applicable ABS wh eel speed sensor coupler.

3) Disconnect ABS hydraulic unit / control module connector.

4) Check for proper connection to ABS control module at each sensor terminal.

5) If OK, then turn ignition switch ON and measure voltage between applicable sensor terminal of module connector

and body ground.

Is it 0 V? Go to Step 4. ABS wheel speed

sensor circuit shorted to

power.

4 1) Turn ignition switch OFF. 2) Measure resistance between the following points.• Both ABS hydraulic unit / control module connector terminals of the correspo nding sensor. This check

result should be the same as Step 2).

• Either terminal of wheel speed sensor coupler and body ground. This check result should be no

continuity.

Are both check results OK? Go to Step 5. Circuit open or shorted

to ground.

5 1) Remove applicable ABS wheel speed sensor. 2) Check sensor for damage or foreign material attached.

Is it in good condition? Go to Step 6. Clean, repair or replace.

6 Check front and/or rear sensor ring for the following (remove rear drum as necessary):

• Sensor ring serration (teeth) neither missing nor damaged

• No foreign material being attached

• Sensor ring not being eccentric

• Wheel bearing free from excessive play

Are they in good condition? Go to Step 7. Clean, repair or replace.

7 1) Install ABS wheel speed sensor to knuckle. 2) Tighten sensor bolt to specified torque and check that there is no clearance between sensor and knuckle.

Is it OK? Go to Step 8. Replace ABS wheel

speed sensor.

8 Refer to “Front / Rear Wheel Speed Sensor On-Vehicle Inspection” and/or “Rear Wheel Speed Sensor Removal and

Installation”, check output voltage or waveform.

Is specified voltage and/or waveform obtained? Substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.

Replace sensor and

recheck.

Page 559 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-20

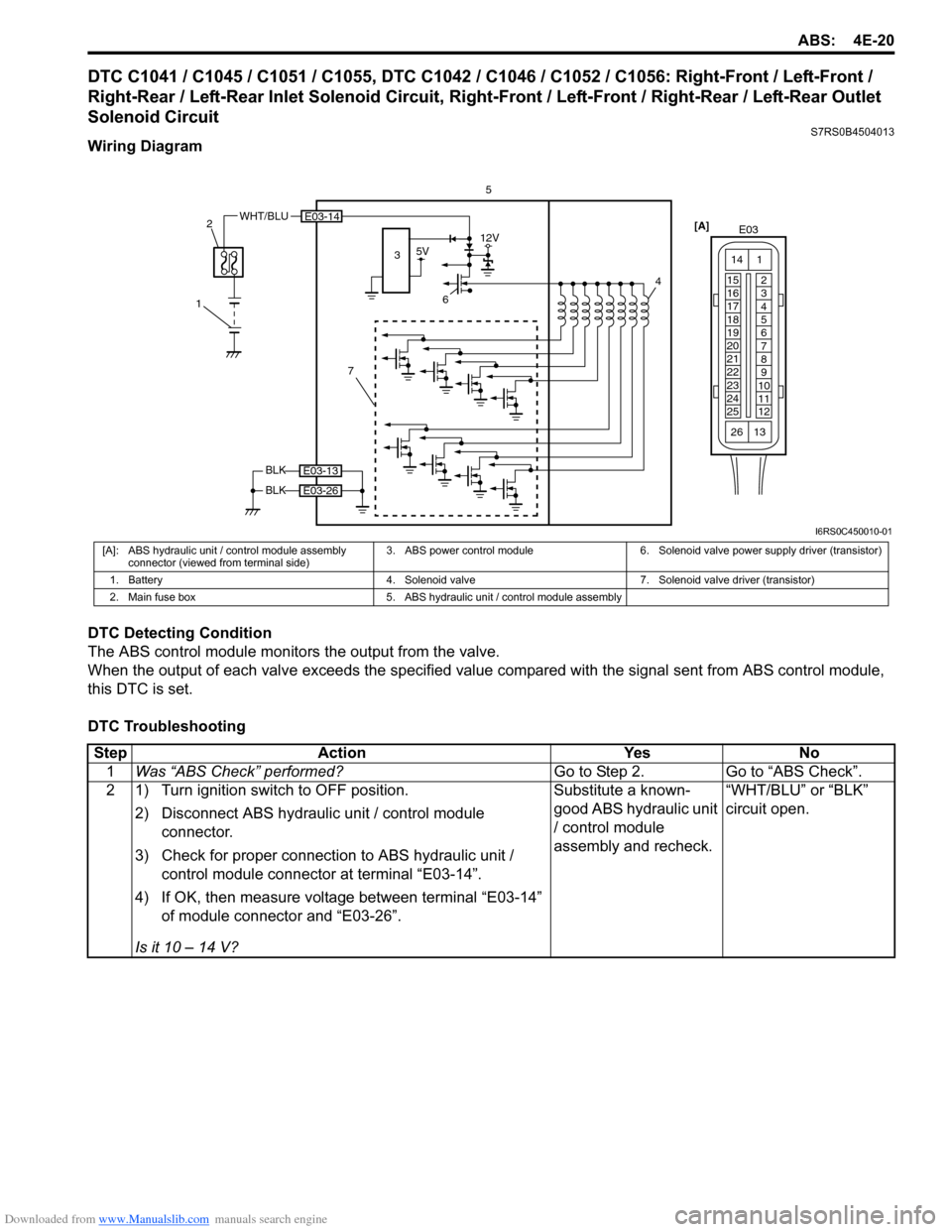

DTC C1041 / C1045 / C1051 / C1055, DTC C1042 / C1046 / C1052 / C1056: Right-Front / Left-Front /

Right-Rear / Left-Rear Inlet Solenoid Circuit, Right-Front / Left-Front / Right-Rear / Left-Rear Outlet

Solenoid Circuit

S7RS0B4504013

Wiring Diagram

DTC Detecting Condition

The ABS control module monitors the output from the valve.

When the output of each valve exceeds the specified value compared with the signal sent from ABS control module,

this DTC is set.

DTC Troubleshooting

6 4

E03-14

5V12V

7

3

WHT/BLU

1 2

5

BLK

BLK

E03-13

E03-26

[A]

E03

15

16

17

18

19

20

21

22

23

24

25 2

3

4

5

6

7

8

9

10

11

12

1

13

14

26

I6RS0C450010-01

[A]: ABS hydraulic unit / control module assembly

connector (viewed from terminal side) 3. ABS power control module 6. Solenoid valve power supply driver (transistor)

1. Battery 4. Solenoid valve 7. Solenoid valve driver (transistor)

2. Main fuse box 5. ABS hydraulic unit / control module assembly

Step Action YesNo

1 Was “ABS Check” performed? Go to Step 2.Go to “ABS Check”.

2 1) Turn ignition switch to OFF position.

2) Disconnect ABS hydraulic unit / control module connector.

3) Check for proper connection to ABS hydraulic unit / control module connector at terminal “E03-14”.

4) If OK, then measure voltage between terminal “E03-14” of module connector and “E03-26”.

Is it 10 – 14 V? Substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.

“WHT/BLU” or “BLK”

circuit open.

Page 560 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-21 ABS:

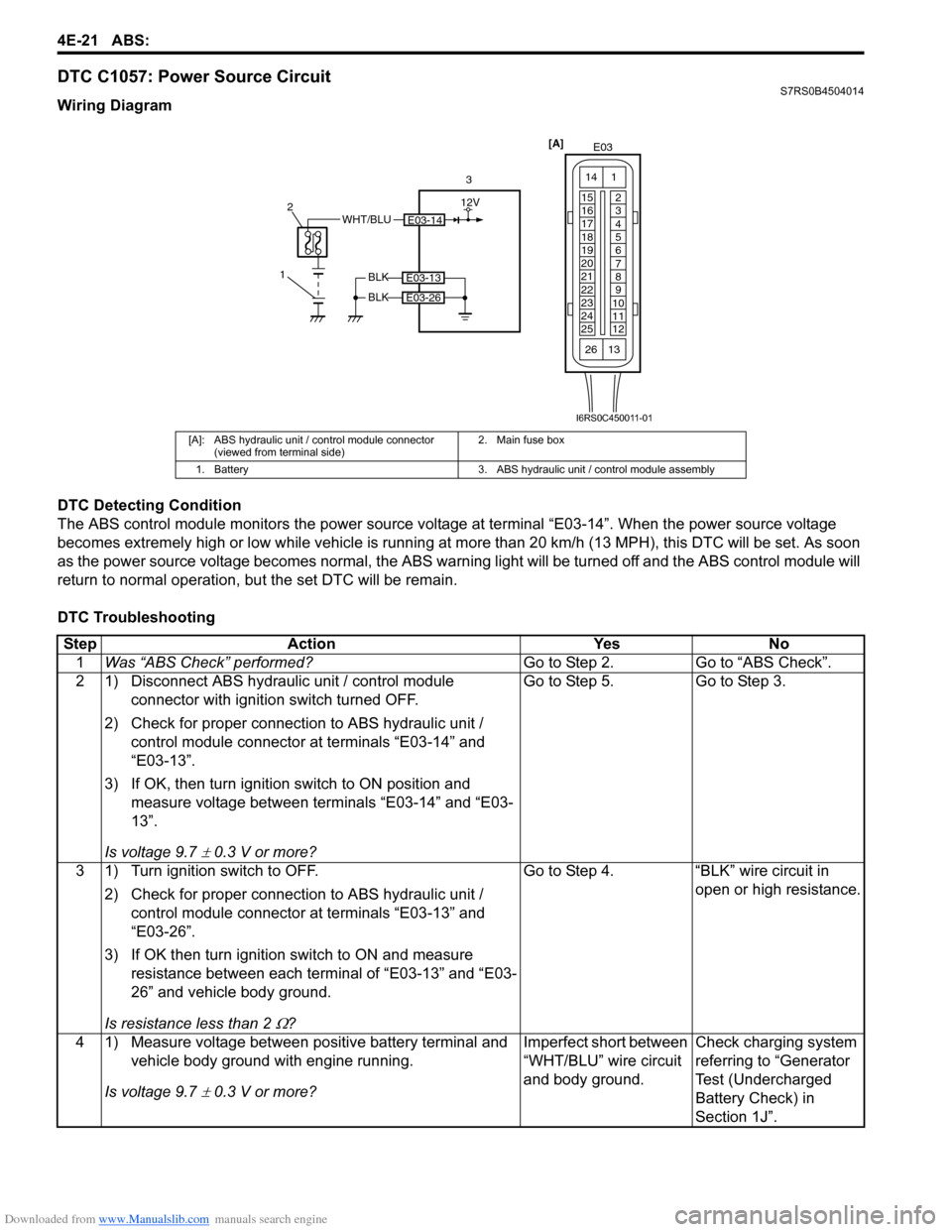

DTC C1057: Power Source CircuitS7RS0B4504014

Wiring Diagram

DTC Detecting Condition

The ABS control module monitors the power source voltage at terminal “E03-14”. When the power source voltage

becomes extremely high or low while vehicle is running at more than 20 km/h (13 MPH), this DTC will be set. As soon

as the power source volta ge becomes normal, the ABS warning light will be turned off and the ABS control module will

return to normal operation, bu t the set DTC will be remain.

DTC Troubleshooting

[A]: ABS hydraulic unit / control module connector (viewed from terminal side) 2. Main fuse box

1. Battery 3. ABS hydraulic unit / control module assembly

E03-14WHT/BLU

1 2

3

BLK

BLK

E03-13

E03-26

[A]

E03

15

16

17

18

19

20

21

22

23

24

25 2

3

4

5

6

7

8

9

10

11

12

1

13

14

26

12V

I6RS0C450011-01

Step

Action YesNo

1 Was “ABS Check” performed? Go to Step 2.Go to “ABS Check”.

2 1) Disconnect ABS hydraulic unit / control module connector with ignition switch turned OFF.

2) Check for proper connection to ABS hydraulic unit / control module connector at terminals “E03-14” and

“E03-13”.

3) If OK, then turn ignition switch to ON position and measure voltage between terminals “E03-14” and “E03-

13”.

Is voltage 9.7

± 0.3 V or more? Go to Step 5. Go to Step 3.

3 1) Turn ignition switch to OFF. 2) Check for proper connection to ABS hydraulic unit / control module connector at terminals “E03-13” and

“E03-26”.

3) If OK then turn ignition switch to ON and measure resistance between each terminal of “E03-13” and “E03-

26” and vehicle body ground.

Is resistance less than 2

Ω? Go to Step 4. “BLK” wire circuit in

open or high resistance.

4 1) Measure voltage between positive battery terminal and vehicle body ground with engine running.

Is voltage 9.7

± 0.3 V or more? Imperfect short between

“WHT/BLU” wire circuit

and body ground.

Check charging system

referring to “Generator

Test (Undercharged

Battery Check) in

Section 1J”.

Page 561 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-22

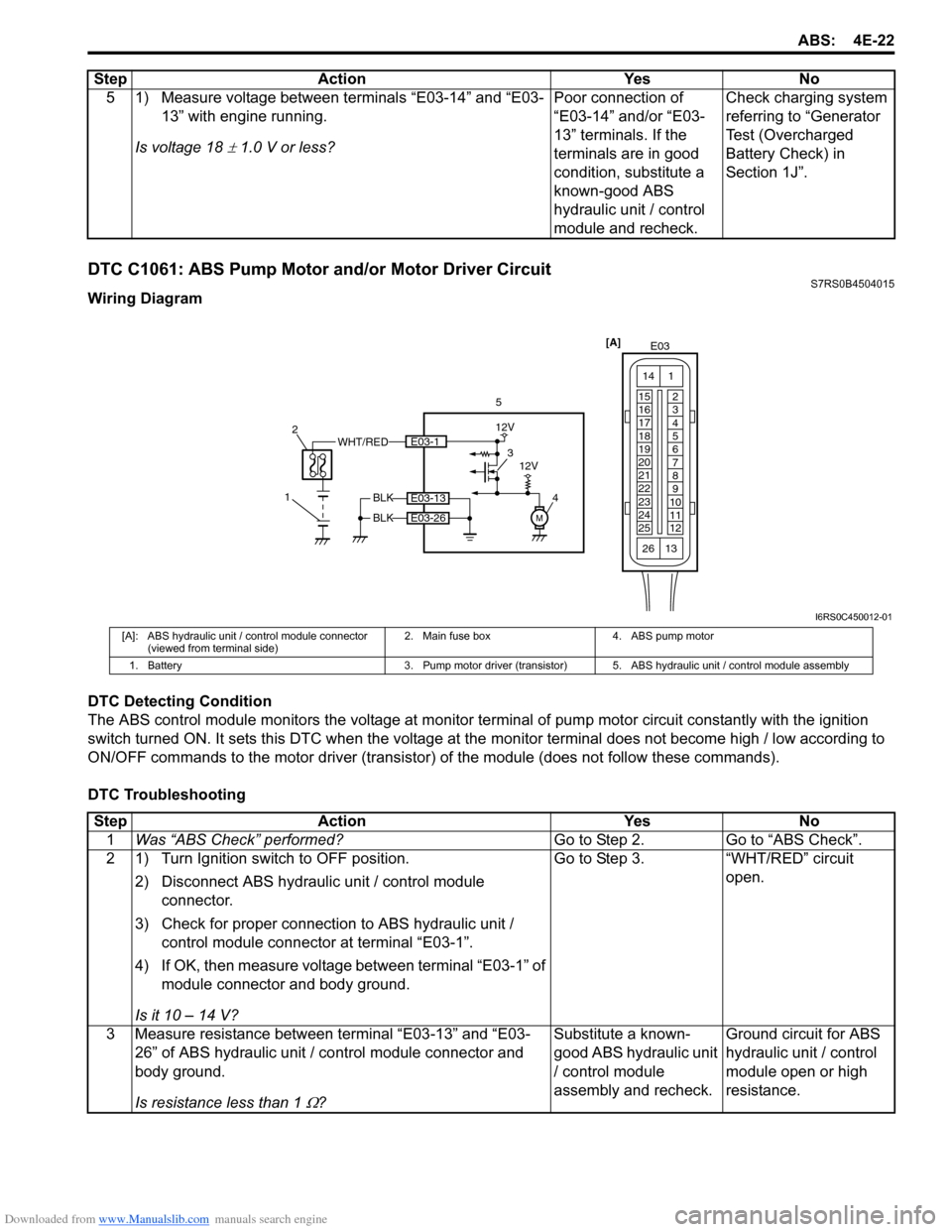

DTC C1061: ABS Pump Motor and/or Motor Driver CircuitS7RS0B4504015

Wiring Diagram

DTC Detecting Condition

The ABS control module monitors the voltage at monitor terminal of pump motor circuit constantly with the ignition

switch turned ON. It sets this DTC when the voltage at the monitor terminal does not become high / low according to

ON/OFF commands to the motor driver (transistor) of the module (does not follow these commands).

DTC Troubleshooting 5 1) Measure voltage between terminals “E03-14” and “E03-

13” with engine running.

Is voltage 18

± 1.0 V or less? Poor connection of

“E03-14” and/or “E03-

13” terminals. If the

terminals are in good

condition, substitute a

known-good ABS

hydraulic unit / control

module and recheck.Check charging system

referring to “Generator

Test (Overcharged

Battery Check) in

Section 1J”.

Step Action Yes No

WHT/RED

1 2

5

BLK

BLK

E03-13

E03-26

[A]

E03

15

16

17

18

19

20

21

22

23

24

25 2

3

4

5

6

7

8

9

10

11

12

1

13

14

26

M

3

4E03-1

12V

12V

I6RS0C450012-01

[A]: ABS hydraulic unit / control module connector (viewed from terminal side) 2. Main fuse box 4. ABS pump motor

1. Battery 3. Pump motor driver (transistor) 5. ABS hydraulic unit / control module assembly

StepAction YesNo

1 Was “ABS Check” performed? Go to Step 2.Go to “ABS Check”.

2 1) Turn Ignition switch to OFF position.

2) Disconnect ABS hydraulic unit / control module connector.

3) Check for proper connection to ABS hydraulic unit / control module connector at terminal “E03-1”.

4) If OK, then measure voltage between terminal “E03-1” of module connector and body ground.

Is it 10 – 14 V? Go to Step 3.

“WHT/RED” circuit

open.

3 Measure resistance between terminal “E03-13” and “E03- 26” of ABS hydraulic unit / co ntrol module connector and

body ground.

Is resistance less than 1

Ω? Substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.

Ground circuit for ABS

hydraulic unit / control

module open or high

resistance.

Page 562 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-23 ABS:

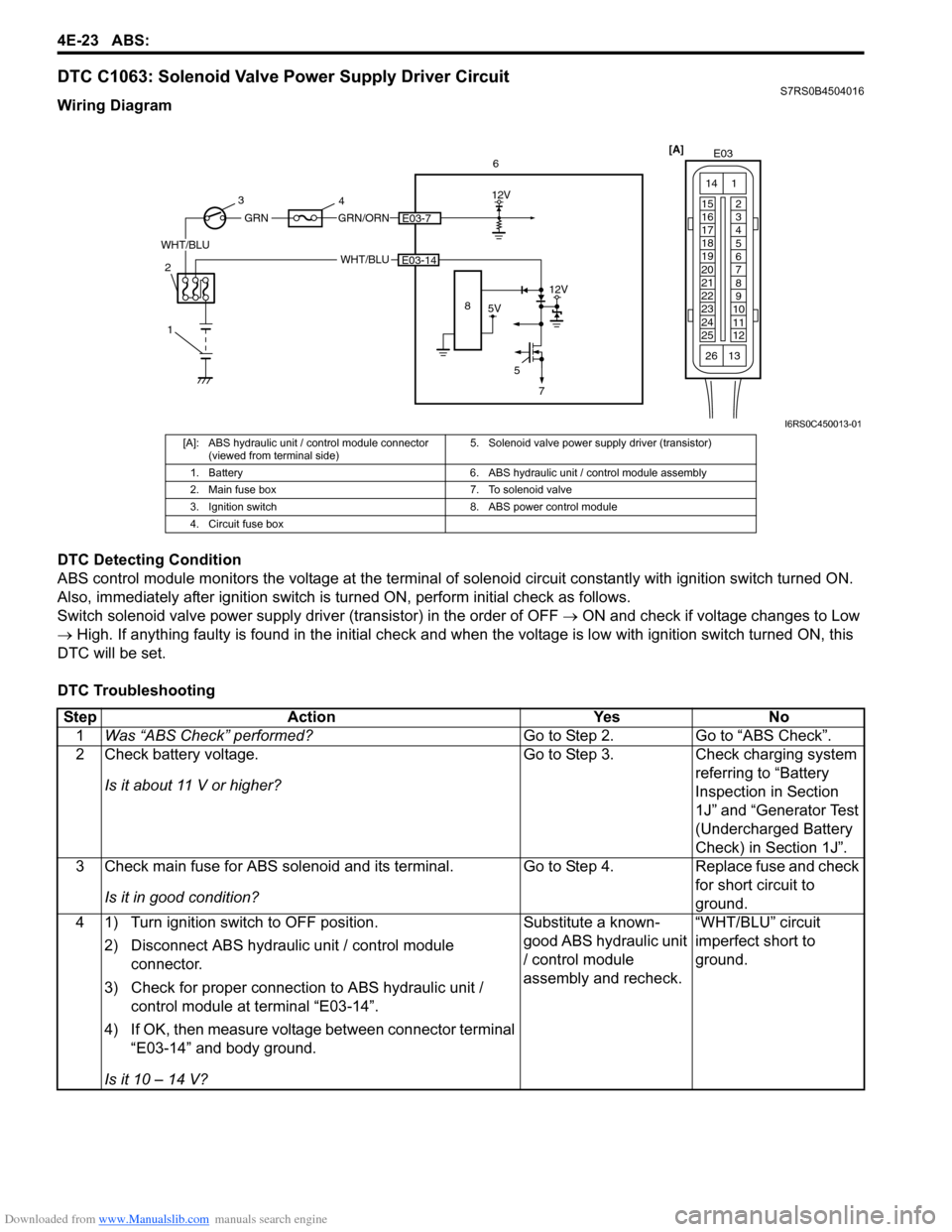

DTC C1063: Solenoid Valve Power Supply Driver CircuitS7RS0B4504016

Wiring Diagram

DTC Detecting Condition

ABS control module monitors the voltage at the terminal of solenoid circuit constantly with ignition switch turned ON.

Also, immediately after ignition switch is turned ON, perform initial check as follows.

Switch solenoid valve power supply driv er (transistor) in the order of OFF → ON and check if voltage changes to Low

→ High. If anything faulty is found in the initial check and when the voltage is low with ignition switch turned ON, this

DTC will be set.

DTC Troubleshooting

[A] E03

15

16

17

18

19

20

21

22

23

24

25 2

3

4

5

6

7

8

9

10

11

12

1

13

14

266

WHT/BLU

12V

5E03-14

5V

12V

8

GRN/ORNE03-7

WHT/BLU

GRN

1

2 3

4

7

I6RS0C450013-01

[A]: ABS hydraulic unit / control module connector

(viewed from terminal side) 5. Solenoid valve power supp

ly driver (transistor)

1. Battery 6. ABS hydraulic unit / control module assembly

2. Main fuse box 7. To solenoid valve

3. Ignition switch 8. ABS power control module

4. Circuit fuse box

Step Action YesNo

1 Was “ABS Check” performed? Go to Step 2.Go to “ABS Check”.

2 Check battery voltage.

Is it about 11 V or higher? Go to Step 3.

Check charging system

referring to “Battery

Inspection in Section

1J” and “Generator Test

(Undercharged Battery

Check) in Section 1J”.

3 Check main fuse for ABS solenoid and its terminal.

Is it in good condition? Go to Step 4.

Replace fuse and check

for short circuit to

ground.

4 1) Turn ignition switch to OFF position.

2) Disconnect ABS hydraulic unit / control module connector.

3) Check for proper connection to ABS hydraulic unit / control module at terminal “E03-14”.

4) If OK, then measure voltage between connector terminal “E03-14” and body ground.

Is it 10 – 14 V? Substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.

“WHT/BLU” circuit

imperfect short to

ground.

Page 563 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-24

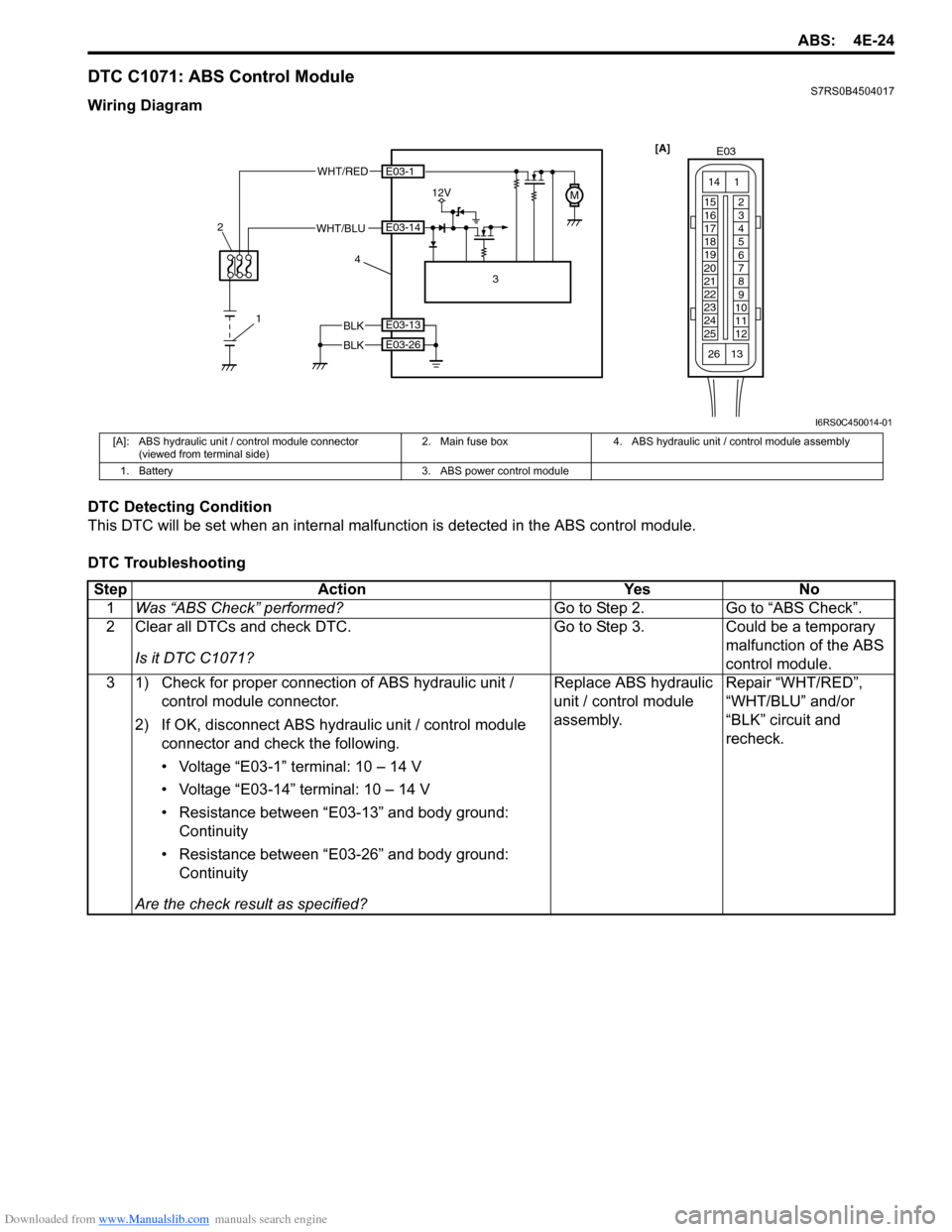

DTC C1071: ABS Control ModuleS7RS0B4504017

Wiring Diagram

DTC Detecting Condition

This DTC will be set when an internal malfunction is detected in the ABS control module.

DTC Troubleshooting

1

2

WHT/RED

12VM

3

4

E03-1

E03-14

BLK

BLK

E03-13

E03-26

WHT/BLU [A]

E03

15

16

17

18

19

20

21

22

23

24

25 2

3

4

5

6

7

8

9

10

11

12

1

13

14

26

I6RS0C450014-01

[A]: ABS hydraulic unit / control module connector

(viewed from terminal side) 2. Main fuse box 4. ABS hydraulic unit / control module assembly

1. Battery 3. ABS power control module

Step Action YesNo

1 Was “ABS Check” performed? Go to Step 2.Go to “ABS Check”.

2 Clear all DTCs and check DTC.

Is it DTC C1071? Go to Step 3.

Could be a temporary

malfunction of the ABS

control module.

3 1) Check for proper connection of ABS hydraulic unit / control module connector.

2) If OK, disconnect ABS hydr aulic unit / control module

connector and check the following.

• Voltage “E03-1” terminal: 10 – 14 V

• Voltage “E03-14” terminal: 10 – 14 V

• Resistance between “E03-13” and body ground: Continuity

• Resistance between “E03-26” and body ground: Continuity

Are the check result as specified? Replace ABS hydraulic

unit / control module

assembly.

Repair “WHT/RED”,

“WHT/BLU” and/or

“BLK” circuit and

recheck.

Page 565 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-26

DTC TroubleshootingStep Action Yes No 1 Was “ABS Check” performed? Go to Step 2. Go to “ABS Check”.

2 1) Check connection of connectors of all control modules communicating by means of CAN.

2) Recheck DTC.

Is DTC U1073 indicated? Go to Step 3. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00” in related manual.

3 1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules communicating by means of CAN.

3) Check CAN communication circuit between control modules for open, short and high resistance.

Is each CAN communication circuit in good condition? Go to Step 4. Repair insulation of

CAN communication

line circuit referring to

“Precaution for CAN

Communication System

in Section 00” in related

manual.

4 1) Turn ignition switch to OFF position.

2) Connect connector of disconnected control modules communicating by means of CAN.

3) Disconnect connector from any one of control modules other than BCM and ABS control module.

4) Recheck ABS contro l module for DTC.

IS DTC U1073 detected? Disconnected

connectors of control

modules other than the

one whose connector is

disconnected in Step 3)

one by one and check

that DTC U1073 is

detected by ABS control

module each time

connector is

disconnected.

When DTC U1073 is not

detected by ABS

module while checking

in this way, go to

description under “NO”

below. If DTC U1073 is

detected by ABS control

module, go to Step 5.Check power and

ground circuit of control

module disconnected in

Step 3) circuit is OK,

substitute a know-good

control module

disconnected in Step 3)

and recheck.

5 1) Substitute a know-good BCM and recheck ABS control module for DTC.

IS DTC U1073 detected? Substitute a know-good

ABS control module and

recheck.

End.

Page 566 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-27 ABS:

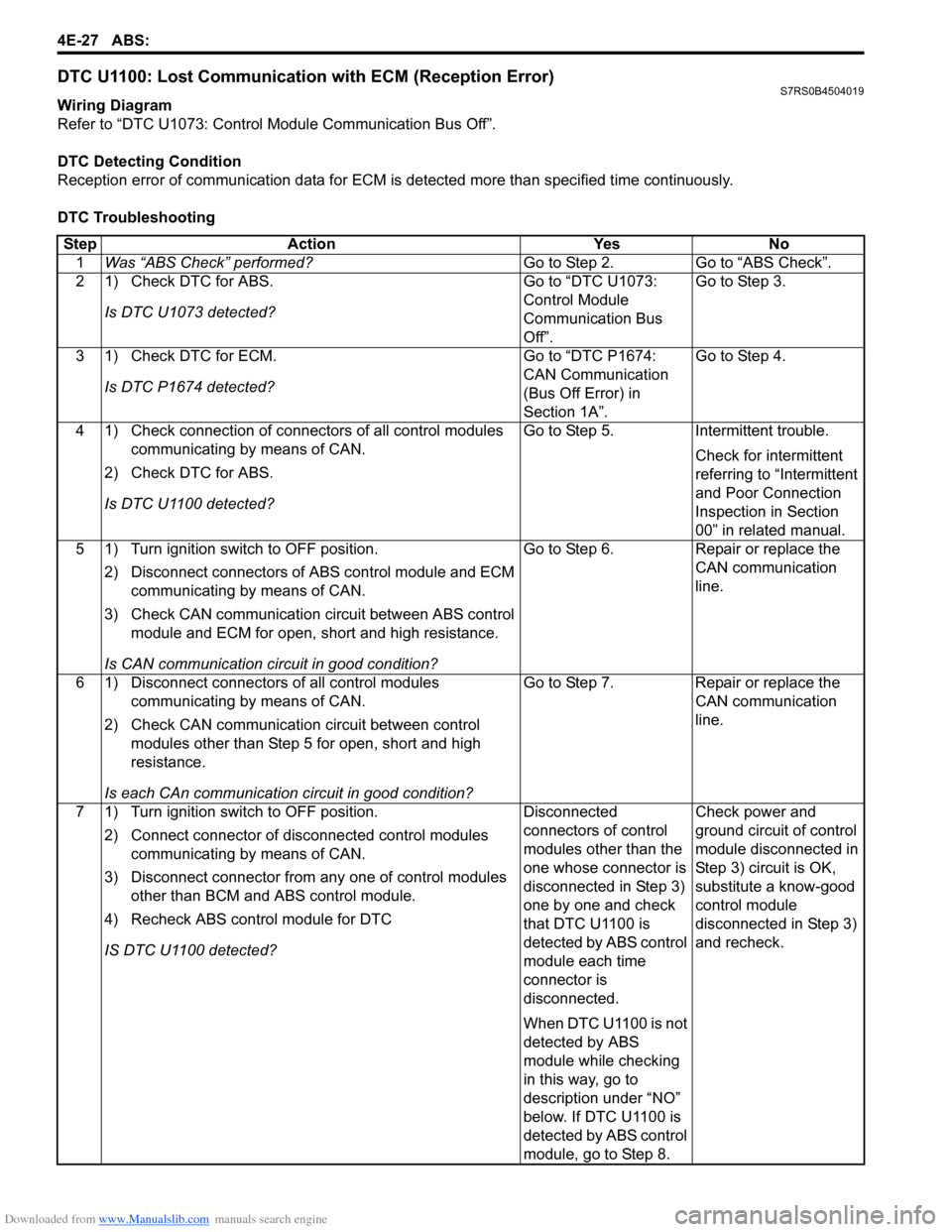

DTC U1100: Lost Communication with ECM (Reception Error)S7RS0B4504019

Wiring Diagram

Refer to “DTC U1073: Control Module Communication Bus Off”.

DTC Detecting Condition

Reception error of communication data for ECM is detected more than specified time continuously.

DTC Troubleshooting Step Action Yes No 1 Was “ABS Check” performed? Go to Step 2. Go to “ABS Check”.

2 1) Check DTC for ABS.

Is DTC U1073 detected? Go to “DTC U1073:

Control Module

Communication Bus

Off”.Go to Step 3.

3 1) Check DTC for ECM. Is DTC P1674 detected? Go to “DTC P1674:

CAN Communication

(Bus Off Error) in

Section 1A”.Go to Step 4.

4 1) Check connection of connectors of all control modules communicating by means of CAN.

2) Check DTC for ABS.

Is DTC U1100 detected? Go to Step 5. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00” in related manual.

5 1) Turn ignition switch to OFF position.

2) Disconnect connectors of ABS control module and ECM

communicating by means of CAN.

3) Check CAN communication circuit between ABS control module and ECM for open, short and high resistance.

Is CAN communication circuit in good condition? Go to Step 6. Repair or replace the

CAN communication

line.

6 1) Disconnect connectors of all control modules communicating by means of CAN.

2) Check CAN communication circuit between control modules other than Step 5 for open, short and high

resistance.

Is each CAn communication circuit in good condition? Go to Step 7. Repair or replace the

CAN communication

line.

7 1) Turn ignition switch to OFF position. 2) Connect connector of disconnected control modules communicating by means of CAN.

3) Disconnect connector from any one of control modules other than BCM and ABS control module.

4) Recheck ABS contro l module for DTC

IS DTC U1100 detected? Disconnected

connectors of control

modules other than the

one whose connector is

disconnected in Step 3)

one by one and check

that DTC U1100 is

detected by ABS control

module each time

connector is

disconnected.

When DTC U1100 is not

detected by ABS

module while checking

in this way, go to

description under “NO”

below. If DTC U1100 is

detected by ABS control

module, go to Step 8.Check power and

ground circuit of control

module disconnected in

Step 3) circuit is OK,

substitute a know-good

control module

disconnected in Step 3)

and recheck.

Page 596 of 1496

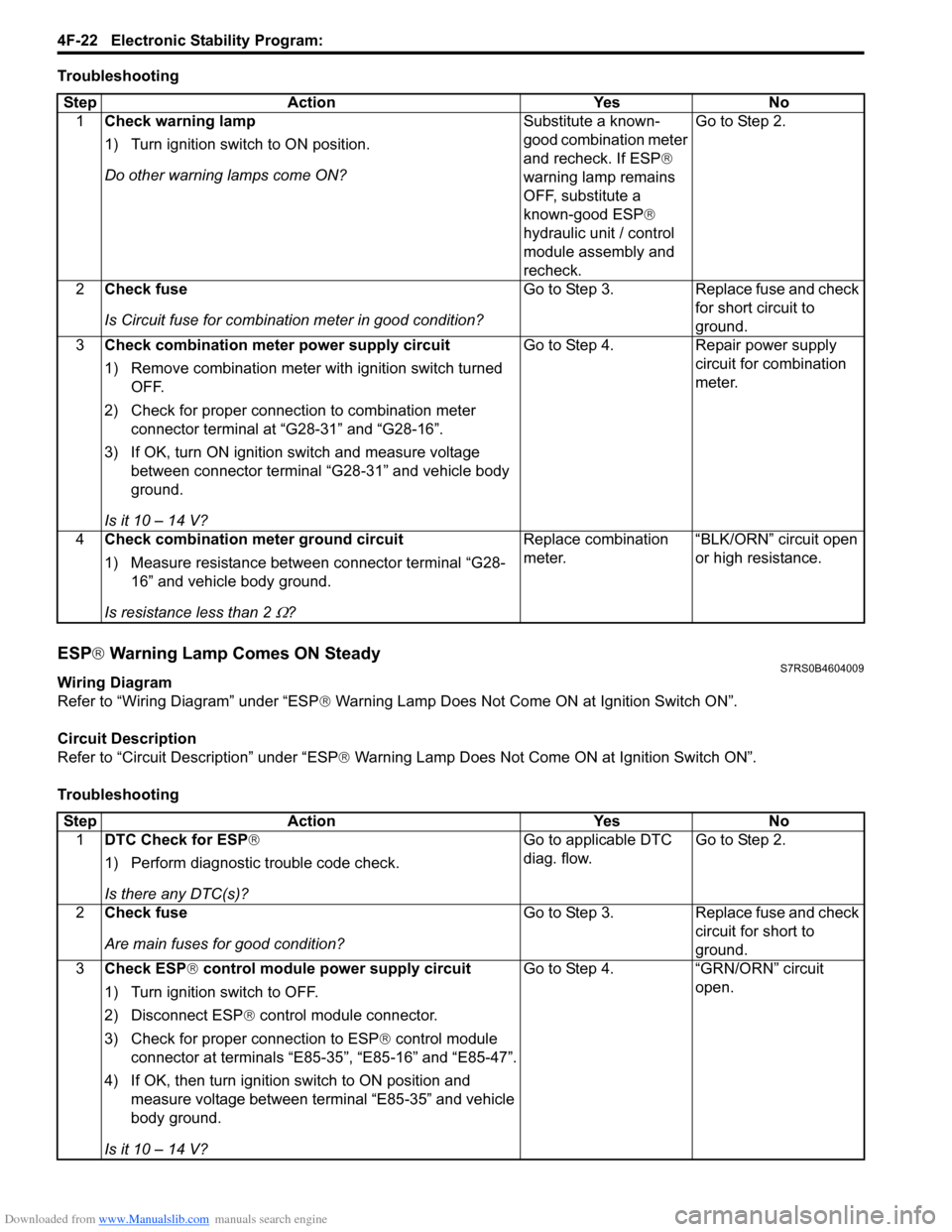

Downloaded from www.Manualslib.com manuals search engine 4F-22 Electronic Stability Program:

Troubleshooting

ESP® Warning Lamp Comes ON SteadyS7RS0B4604009

Wiring Diagram

Refer to “Wiring Diagram” under “ESP ® Warning Lamp Does Not Come ON at Ignition Switch ON”.

Circuit Description

Refer to “Circuit Description” under “ESP ® Warning Lamp Does Not Come ON at Ignition Switch ON”.

Troubleshooting Step Action Yes No

1 Check warning lamp

1) Turn ignition switch to ON position.

Do other warning lamps come ON? Substitute a known-

good combination meter

and recheck. If ESP®

warning lamp remains

OFF, substitute a

known-good ESP ®

hydraulic unit / control

module assembly and

recheck. Go to Step 2.

2 Check fuse

Is Circuit fuse fo r combination meter in good condition? Go to Step 3. Replace fuse and check

for short circuit to

ground.

3 Check combination meter power supply circuit

1) Remove combination meter wit h ignition switch turned

OFF.

2) Check for proper connection to combination meter connector terminal at “G28-31” and “G28-16”.

3) If OK, turn ON ignition switch and measure voltage between connector terminal “G28-31” and vehicle body

ground.

Is it 10 – 14 V? Go to Step 4. Repair power supply

circuit for combination

meter.

4 Check combination me ter ground circuit

1) Measure resistance between connector terminal “G28- 16” and vehicle body ground.

Is resistance less than 2

Ω? Replace combination

meter.

“BLK/ORN” circuit open

or high resistance.

Step

Action YesNo

1 DTC Check for ESP ®

1) Perform diagnostic trouble code check.

Is there any DTC(s)? Go to applicable DTC

diag. flow.

Go to Step 2.

2 Check fuse

Are main fuses for good condition? Go to Step 3.

Replace fuse and check

circuit for short to

ground.

3 Check ESP ® control module power supply circuit

1) Turn ignition switch to OFF.

2) Disconnect ESP ® control module connector.

3) Check for proper connection to ESP ® control module

connector at terminals “E85-35”, “E85-16” and “E85-47”.

4) If OK, then turn ignition switch to ON position and measure voltage between terminal “E85-35” and vehicle

body ground.

Is it 10 – 14 V? Go to Step 4.

“GRN/ORN” circuit

open.