engine troubleshooting SUZUKI SWIFT 2008 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 206 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-156 Engine General Information and Diagnosis:

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC P2111 / P2112: Throttle Actuator Control System - Stuck Open / ClosedS7RS0B1104070

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Ignition switch turned OFF for 20 sec. or more.

4) Turn ON ignition switch and check DTC.

Step Action Yes No

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2 Throttle actuator cont rol relay circuit check

1) Remove throttle actuator co ntrol relay from individual

circuit fuse box No.1 with ignition switch turned OFF.

2) Check for proper connection to throttle actuator control relay “BLK/RED”, “YEL/BLU”, “BLU/ORN” and “RED/

YEL” wire terminals.

3) Turn ON ignition switch.

4) Measure voltage between engine ground and “E23-32” terminal of ECM connector.

Is voltage 0 V? Go to Step 3. “RED/YEL” wire is

shorted to other circuit.

3 Throttle actuator cont rol relay circuit check

1) Disconnect connectors from ECM with ignition switch turned OFF.

2) Measure resistance between engine ground and “E23- 45” terminal of ECM connector.

Is resistance infinity? Go to Step 4. “BLU/ORN” wire is

shorted to ground

circuit.

4 Throttle actuator control relay check

1) Check throttle actuator control relay referring to “Main Relay, Fuel Pump Relay an d Starting Motor Control

Relay Inspection in Section 1C”.

Is it in good condition? Substitute a known-

good ECM and recheck.

Replace throttle

actuator control relay.

DTC detecting condition

Trouble area

P2111:

Throttle valve default opening is greater than 6 ° from

complementary closed position when diagnosing throttle

valve at ignition switch turned OFF.

(1 driving detection logic)

P2112:

Throttle valve default opening is smaller than 6 ° from

complementary closed position when diagnosing throttle

valve at ignition switch turned OFF.

(1 driving detection logic) • Electric throttle body

•ECM

Page 207 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-157

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC P2119: Throttle Actuator Control Throttle Body Range / PerformanceS7RS0B1104071

Wiring Diagram

Refer to “DTC P2101: Throttle Actuator Control Motor Circuit Range / Performance”.

DTC Detecting Condition and Trouble Area Step Action Yes No

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2. Go to Step “Engine and

Emission Control

System Check”.

2 Throttle valve visual check

1) Check that there isn’t any foreign matter caught between

throttle valve and throttle body housing referring to

“Throttle Valve Visual Check” under “Electric Throttle

Body Assembly On-Vehicle Inspection in Section 1C”.

Is it in good condition? Go to Step 3. Take it out after

removing throttle body

and clean inside of

throttle body thoroughly.

3 Throttle valve operation check

1) Check operation of throttle valve referring to “Throttle

Valve Operation Check” under “Electric Throttle Body

Assembly On-Vehicle Inspection in Section 1C”.

Is check result satisfactory? Go to Step 4. Replace electric throttle

body.

4 Throttle actuator operation check

1) Check operation of throttle ac tuator referring to “Throttle

Actuator Operation Check” under “Electric Throttle Body

Assembly On-Vehicle Inspection in Section 1C”.

Is check result satisfactory? Go to Step 5. Replace electric throttle

body.

5 Throttle position sensor performance check

1) Check performance of throttle position sensor referring

to “Throttle Position Sensor Performance Check” under

“Electric Throttle Body Assembly On-Vehicle Inspection

in Section 1C”.

Is check result satisfactory? Substitute a known-

good ECM and recheck.

Replace electric throttle

body.

DTC detecting condition

Trouble area

Difference between the measured (actual) throttle valve

opening angle and the target throttle valve opening angle

which is calculated based on accelerator pedal opening

angle and engine condition is more than specification for

specified time continuously.

(1 driving detection logic) • Throttle actuator circuit

• Electric throttle body

•ECM

Page 208 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-158 Engine General Information and Diagnosis:

DTC Confirmation Procedure1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Keep the accelerator pedal at idle position for 2 seconds.

4) Keep the accelerator pedal at fully depressed position for 2 seconds.

5) Repeat Step 3) and 4) for 3 times.

6) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Electric throttle body assembly system check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch, check each voltage of “TP Sensor 1 Volt” and “TP Sensor 2 Volt” displayed on scan

tool when accelerator pedal is idle position and fully

depressed.

Is displayed each TP sensor value as described voltage in

“Scan Tool Data”? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 3.

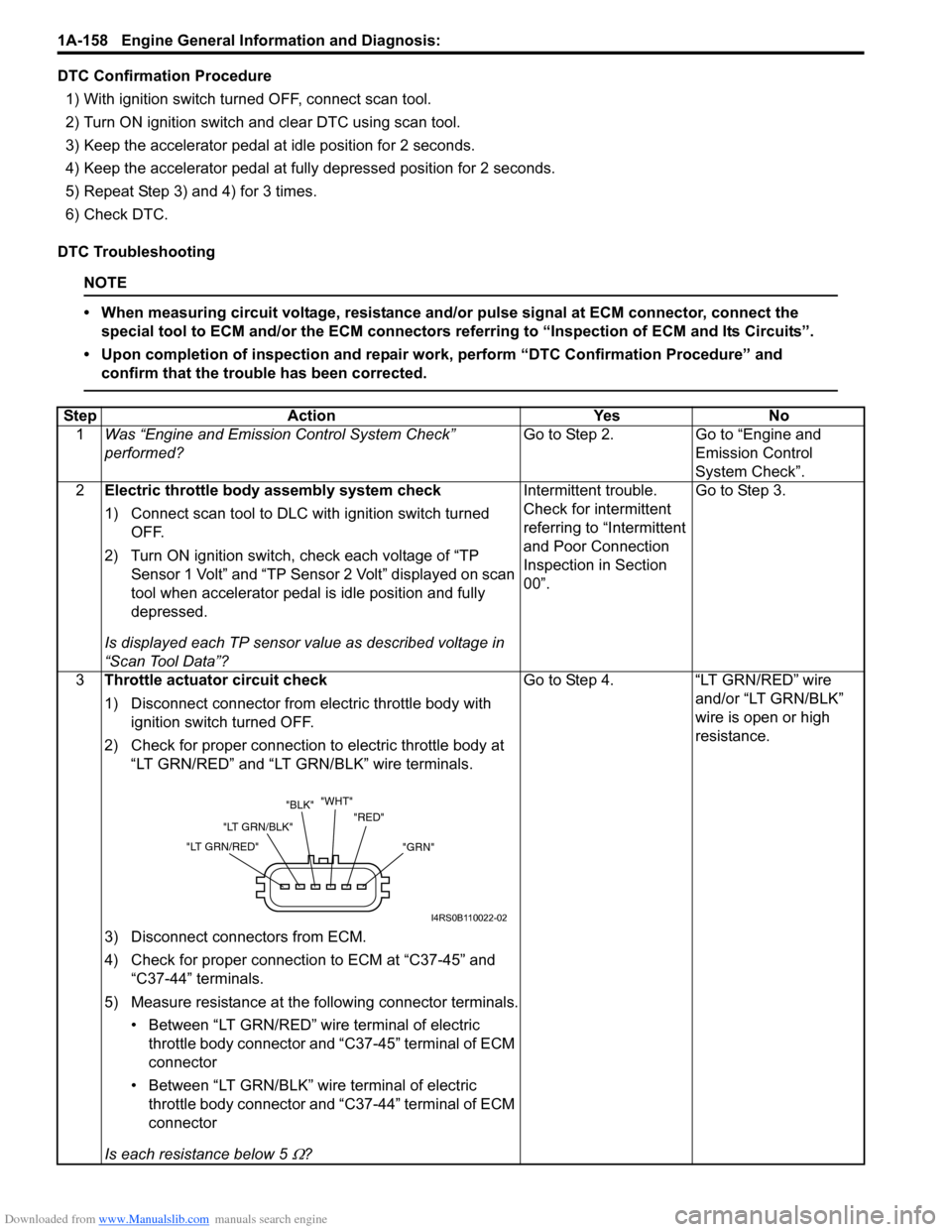

3 Throttle actuator circuit check

1) Disconnect connector from electric throttle body with

ignition switch turned OFF.

2) Check for proper connection to electric throttle body at “LT GRN/RED” and “LT G RN/BLK” wire terminals.

3) Disconnect connectors from ECM.

4) Check for proper connection to ECM at “C37-45” and “C37-44” terminals.

5) Measure resistance at the following connector terminals. • Between “LT GRN/RED” wire terminal of electric throttle body connector and “C37-45” terminal of ECM

connector

• Between “LT GRN/BLK” wire terminal of electric throttle body connector and “C37-44” terminal of ECM

connector

Is each resistance below 5

Ω? Go to Step 4. “LT GRN/RED” wire

and/or “LT GRN/BLK”

wire is open or high

resistance.

"GRN"

"RED"

"WHT"

"BLK"

"LT GRN/BLK"

"LT GRN/RED"

I4RS0B110022-02

Page 210 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-160 Engine General Information and Diagnosis:

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 APP sensor mounting check

1) Check that APP sensor has been mounted to vehicle

body properly (no pinched floor carpet, etc.).

It is OK? Go to Step 3.

Reinstall APP sensor

properly referring to

“APP Sensor Assembly

Removal and

Installation in Section

1C”.

3 APP sensor (main) and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch, check “APP Sensor 1 Volt” displayed on scan tool.

Is displayed voltage below 0.384 V? Go to Step 4.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

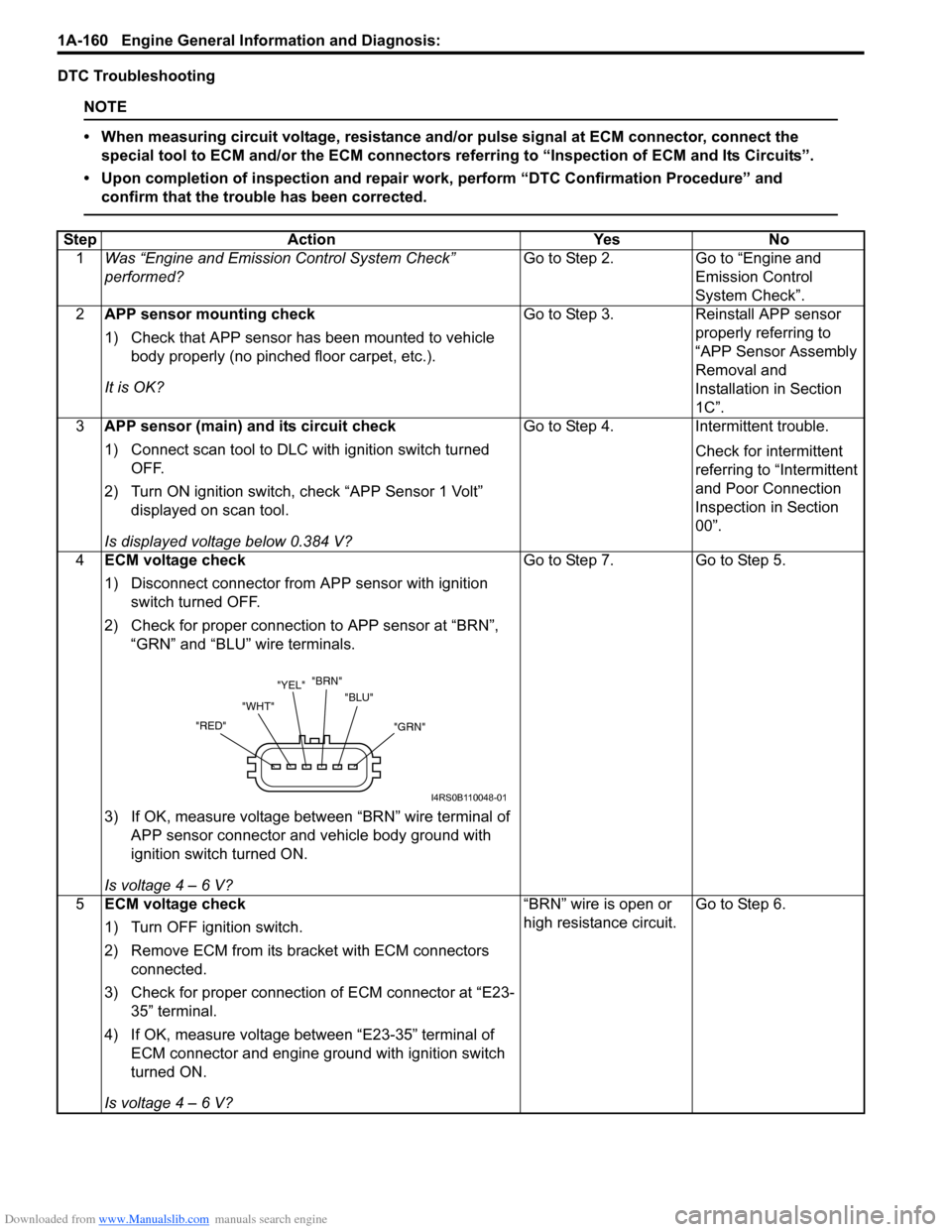

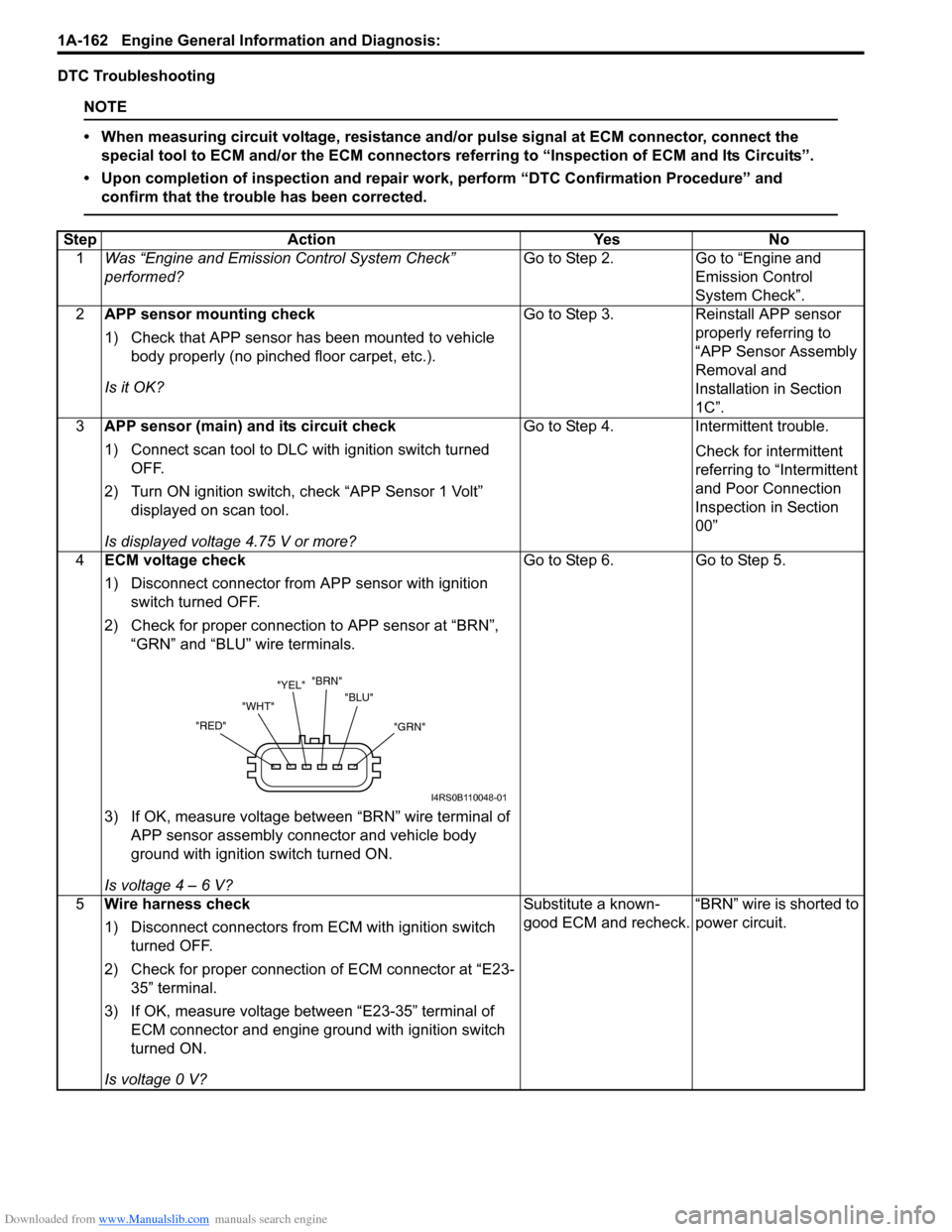

4 ECM voltage check

1) Disconnect connector from APP sensor with ignition

switch turned OFF.

2) Check for proper connection to APP sensor at “BRN”, “GRN” and “BLU” wire terminals.

3) If OK, measure voltage between “BRN” wire terminal of APP sensor connector and vehicle body ground with

ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 7.

Go to Step 5.

5 ECM voltage check

1) Turn OFF ignition switch.

2) Remove ECM from its br acket with ECM connectors

connected.

3) Check for proper connection of ECM connector at “E23- 35” terminal.

4) If OK, measure voltage between “E23-35” terminal of ECM connector and engine ground with ignition switch

turned ON.

Is voltage 4 – 6 V? “BRN” wire is open or

high resistance circuit.

Go to Step 6.

"GRN"

"BLU"

"BRN"

"YEL"

"WHT"

"RED"

I4RS0B110048-01

Page 212 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-162 Engine General Information and Diagnosis:

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 APP sensor mounting check

1) Check that APP sensor has been mounted to vehicle

body properly (no pinched floor carpet, etc.).

Is it OK? Go to Step 3.

Reinstall APP sensor

properly referring to

“APP Sensor Assembly

Removal and

Installation in Section

1C”.

3 APP sensor (main) and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch, check “APP Sensor 1 Volt” displayed on scan tool.

Is displayed voltage 4.75 V or more? Go to Step 4.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”

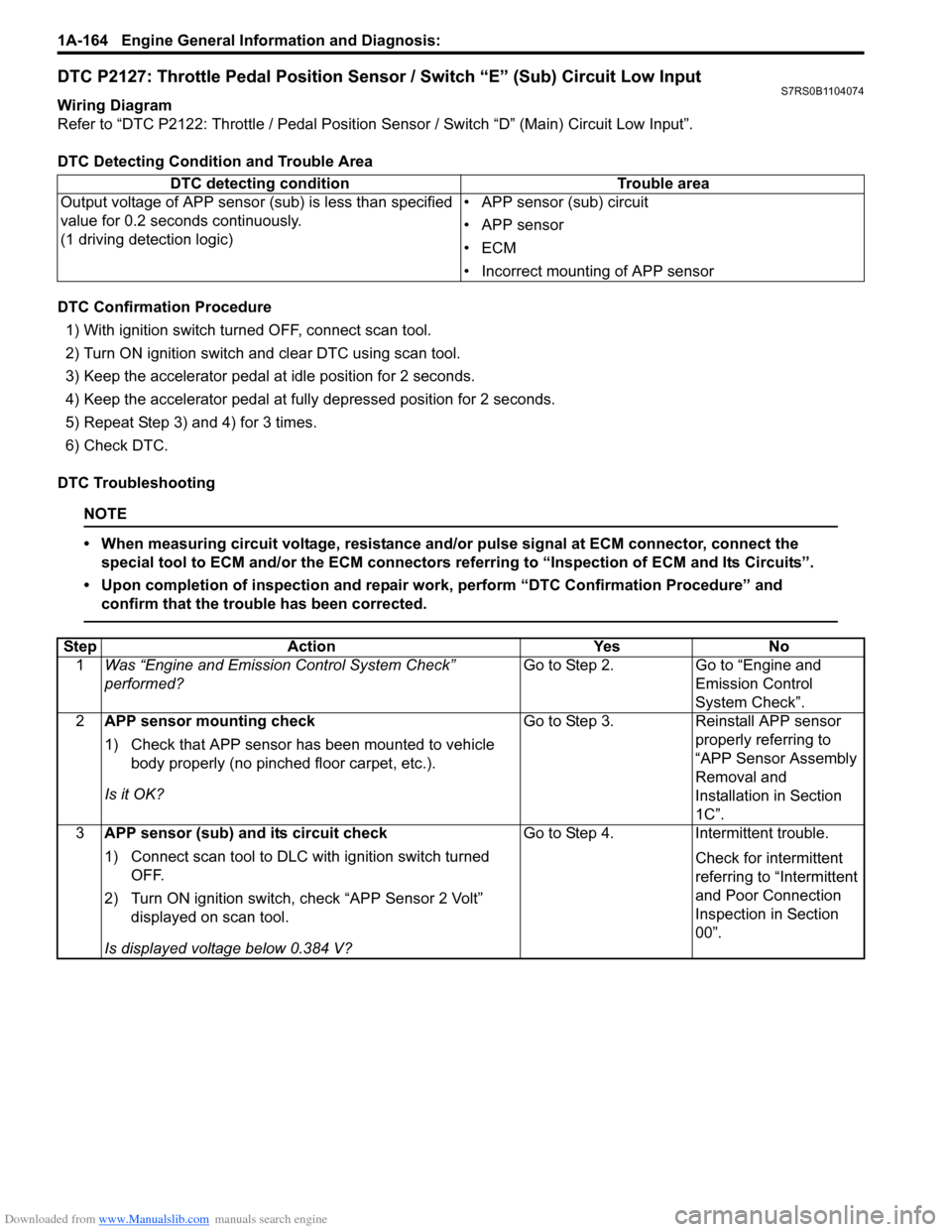

4 ECM voltage check

1) Disconnect connector from APP sensor with ignition

switch turned OFF.

2) Check for proper connection to APP sensor at “BRN”, “GRN” and “BLU” wire terminals.

3) If OK, measure voltage between “BRN” wire terminal of APP sensor assembly connector and vehicle body

ground with ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 6.

Go to Step 5.

5 Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection of ECM connector at “E23- 35” terminal.

3) If OK, measure voltage between “E23-35” terminal of ECM connector and engine ground with ignition switch

turned ON.

Is voltage 0 V? Substitute a known-

good ECM and recheck.

“BRN” wire is shorted to

power circuit.

"GRN"

"BLU"

"BRN"

"YEL"

"WHT"

"RED"

I4RS0B110048-01

Page 214 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-164 Engine General Information and Diagnosis:

DTC P2127: Throttle Pedal Position Sensor / Switch “E” (Sub) Circuit Low InputS7RS0B1104074

Wiring Diagram

Refer to “DTC P2122: Throttle / Pedal Position Sensor / Switch “D” (Main) Circuit Low Input”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure 1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Keep the accelerator pedal at idle position for 2 seconds.

4) Keep the accelerator pedal at fully depressed position for 2 seconds.

5) Repeat Step 3) and 4) for 3 times.

6) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC detecting condition Trouble area

Output voltage of APP sensor (sub) is less than specified

value for 0.2 seconds continuously.

(1 driving detection logic) • APP sensor (sub) circuit

• APP sensor

•ECM

• Incorrect mounting of APP sensor

Step

Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 APP sensor mounting check

1) Check that APP sensor has been mounted to vehicle

body properly (no pinched floor carpet, etc.).

Is it OK? Go to Step 3.

Reinstall APP sensor

properly referring to

“APP Sensor Assembly

Removal and

Installation in Section

1C”.

3 APP sensor (sub) and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch, check “APP Sensor 2 Volt” displayed on scan tool.

Is displayed voltage below 0.384 V? Go to Step 4.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Page 216 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-166 Engine General Information and Diagnosis:

DTC P2128: Throttle / Pedal Position Sensor / Switch “E” (Sub) Circuit High InputS7RS0B1104075

Wiring Diagram

Refer to “DTC P2122: Throttle / Pedal Position Sensor / Switch “D” (Main) Circuit Low Input”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure 1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Keep the accelerator pedal at idle position for 2 seconds.

4) Keep the accelerator pedal at fully depressed position for 2 seconds.

5) Repeat Step 3) and 4) for 3 times.

6) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

10 APP sensor check

1) Check APP sensor (sub) re ferring to “APP Sensor

Assembly Inspection in Section 1C”.

Is output voltage within specified value? Substitute a known-

good ECM and recheck.

Replace APP sensor.

Step Action Yes No

DTC detecting condition

Trouble area

Output voltage of APP sensor (s ub) is more than specified

value for 0.2 seconds continuously.

(1 driving detection logic) • APP sensor (sub) circuit

• APP sensor

•ECM

• Incorrect mounting of

accelerator APP sensor

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 APP sensor mounting check

1) Check that APP sensor has been mounted to vehicle

body properly (no pinched floor carpet, etc.).

Is it OK? Go to Step 3.

Reinstall APP sensor

properly referring to

“APP Sensor Assembly

Removal and

Installation in Section

1C”.

3 APP sensor (sub) and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch, check “APP Sensor 2 Volt” displayed on scan tool.

Is displayed voltage 4.75 V or more? Go to Step 4.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Page 219 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-169

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Keep the accelerator pedal at idle position for 2 seconds.

4) Keep the accelerator pedal at fully depressed position for 2 seconds.

5) Repeat Step 3) and 4) for 3 times.

6) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC detecting condition Trouble area

Difference between the opening angle based on TP

sensor (main) and the opening angle based on TP sensor

(sub) is more than specif ication for specified time

continuously.

(1 driving detection logic) • Throttle position sensor (main) and (sub) circuit

• Electric throttle body

•ECM

Step

Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Throttle position sensor and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch, check each voltage of “TP Sensor 1 Volt” and “TP Sensor 2 Volt” displayed on scan

tool when accelerator pedal is idle position and fully

depressed.

Is displayed each TP sensor value as described voltage in

“Scan Tool Data”? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 3.

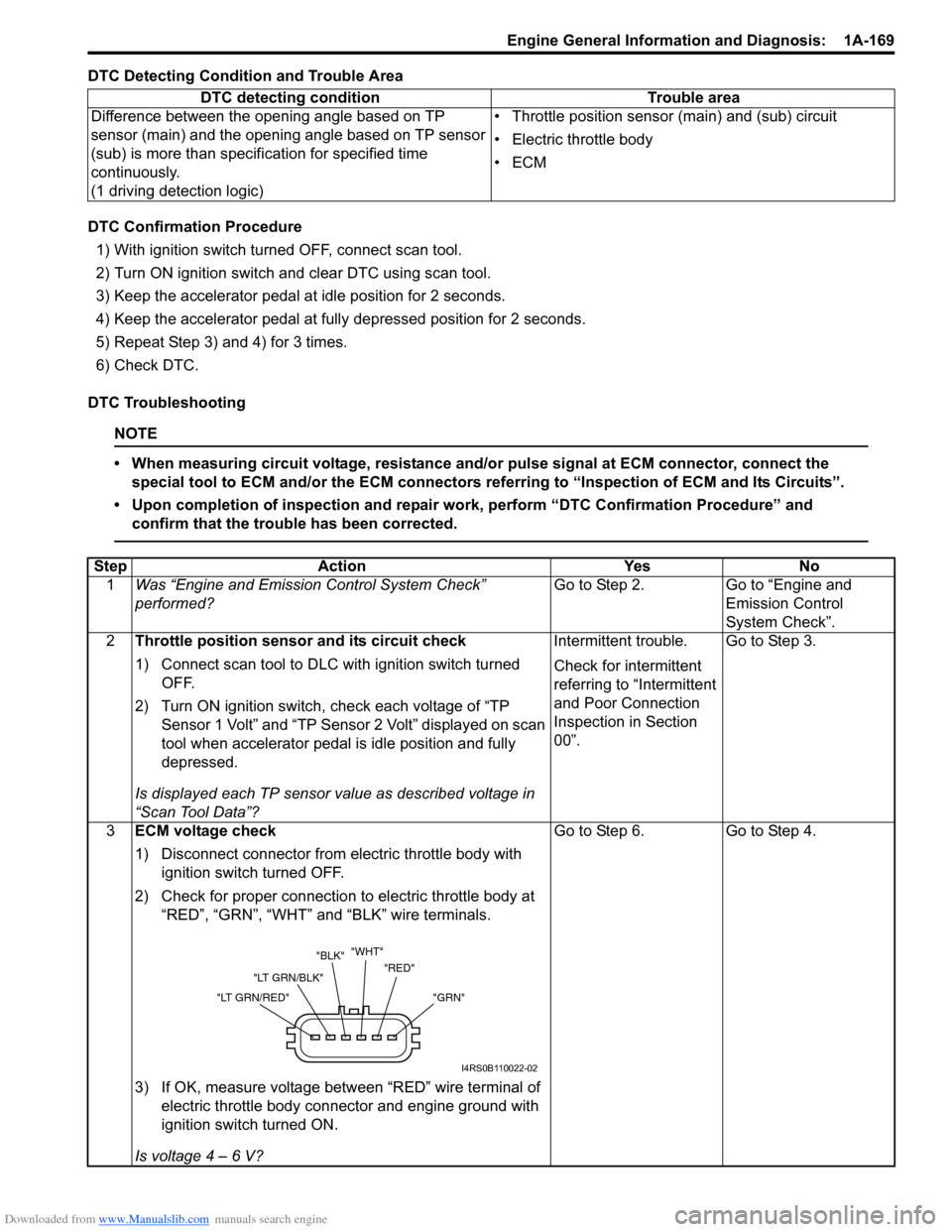

3 ECM voltage check

1) Disconnect connector from electric throttle body with

ignition switch turned OFF.

2) Check for proper connection to electric throttle body at “RED”, “GRN”, “WHT” and “BLK” wire terminals.

3) If OK, measure voltage between “RED” wire terminal of electric throttle body connector and engine ground with

ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 6.

Go to Step 4.

"GRN"

"RED"

"WHT"

"BLK"

"LT GRN/BLK"

"LT GRN/RED"

I4RS0B110022-02

Page 222 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-172 Engine General Information and Diagnosis:

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 APP sensor and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch.

3) Check each voltage of “APP Sensor 1 Volt” and “APP Sensor 2 Volt” displayed on scan tool when accelerator

pedal is idle position and fully depressed.

Is displayed each APP sensor value as described voltage in

“Scan Tool Data”? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 3.

3 ECM voltage check

1) Disconnect connector from APP sensor with ignition

switch turned OFF.

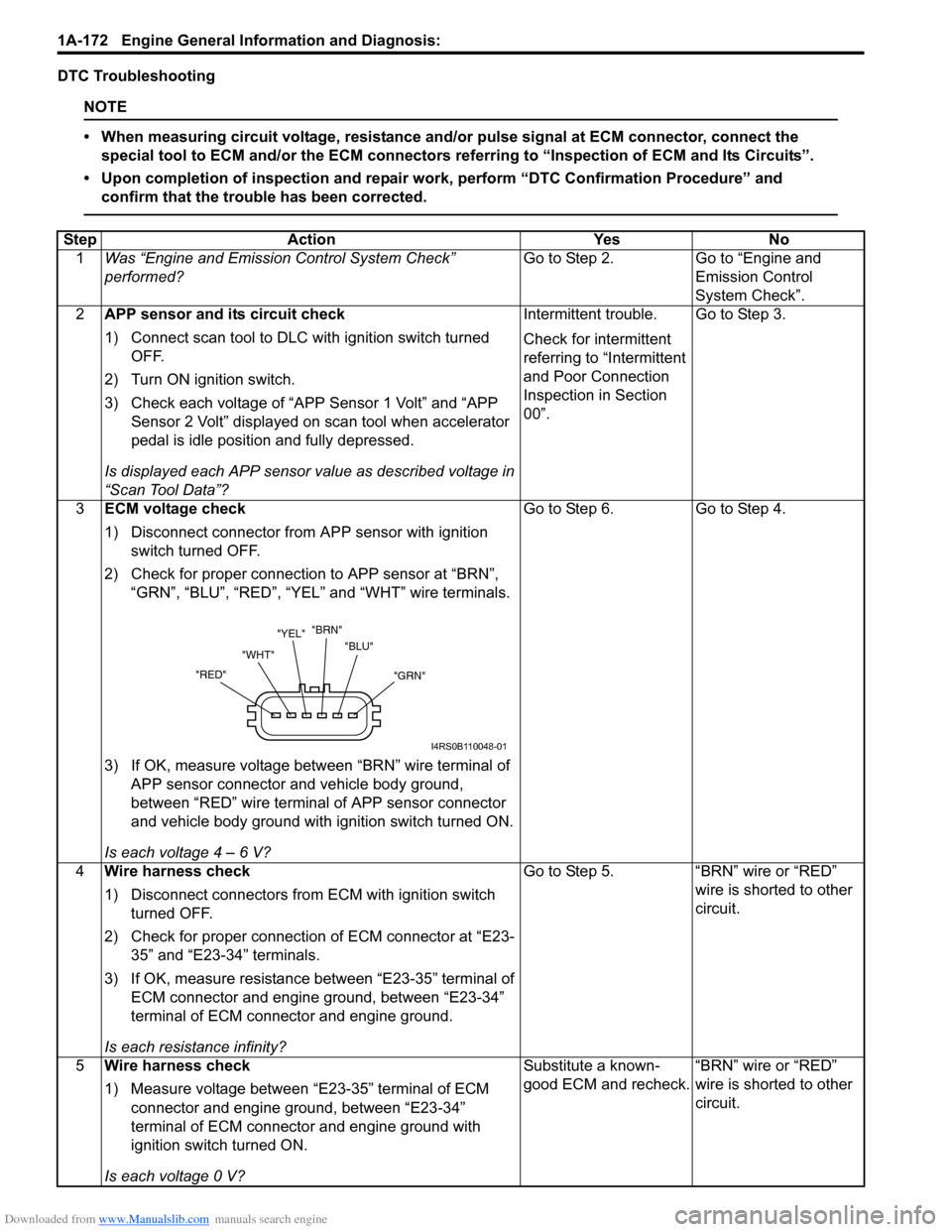

2) Check for proper connection to APP sensor at “BRN”, “GRN”, “BLU”, “RED”, “YEL” and “WHT” wire terminals.

3) If OK, measure voltage between “BRN” wire terminal of APP sensor connector and vehicle body ground,

between “RED” wire terminal of APP sensor connector

and vehicle body ground with ignition switch turned ON.

Is each voltage 4 – 6 V? Go to Step 6.

Go to Step 4.

4 Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection of ECM connector at “E23- 35” and “E23-34” terminals.

3) If OK, measure resistance between “E23-35” terminal of ECM connector and engine ground, between “E23-34”

terminal of ECM connector and engine ground.

Is each resistance infinity? Go to Step 5.

“BRN” wire or “RED”

wire is shorted to other

circuit.

5 Wire harness check

1) Measure voltage between “E23-35” terminal of ECM

connector and engine ground, between “E23-34”

terminal of ECM connector and engine ground with

ignition switch turned ON.

Is each voltage 0 V? Substitute a known-

good ECM and recheck.

“BRN” wire or “RED”

wire is shorted to other

circuit.

"GRN"

"BLU"

"BRN"

"YEL"

"WHT"

"RED"

I4RS0B110048-01

Page 224 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-174 Engine General Information and Diagnosis:

DTC Confirmation Procedure

DTC P2227:

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC, pending DTC and freeze frame data by using scan tool and warm up

engine to normal operating temperature.

3) Check DTC and pending DTC by using scan tool.

DTC P2228 / P2229: 1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch, clear DTC by using scan tool and run engine for 1 min.

3) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Is DTC P2227 set? Go to Step 3.Substitute a known-

good ECM and recheck.

3 MAP sensor check

1) Check MAP sensor and its circuit referring to “DTC

P0107: Manifold Absolute Pressure / Barometric

Pressure Circuit Low Input” and/or “DTC P0108:

Manifold Absolute Pressure / Barometric Pressure

Circuit High Input”.

Is check result satisfactory? Substitute a known-

good ECM and recheck.

MAP sensor or its circuit

malfunction.