sus SUZUKI SWIFT 2008 2.G Service Manual Online

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 1384 of 1496

Downloaded from www.Manualslib.com manuals search engine 9K-7 Body Structure:

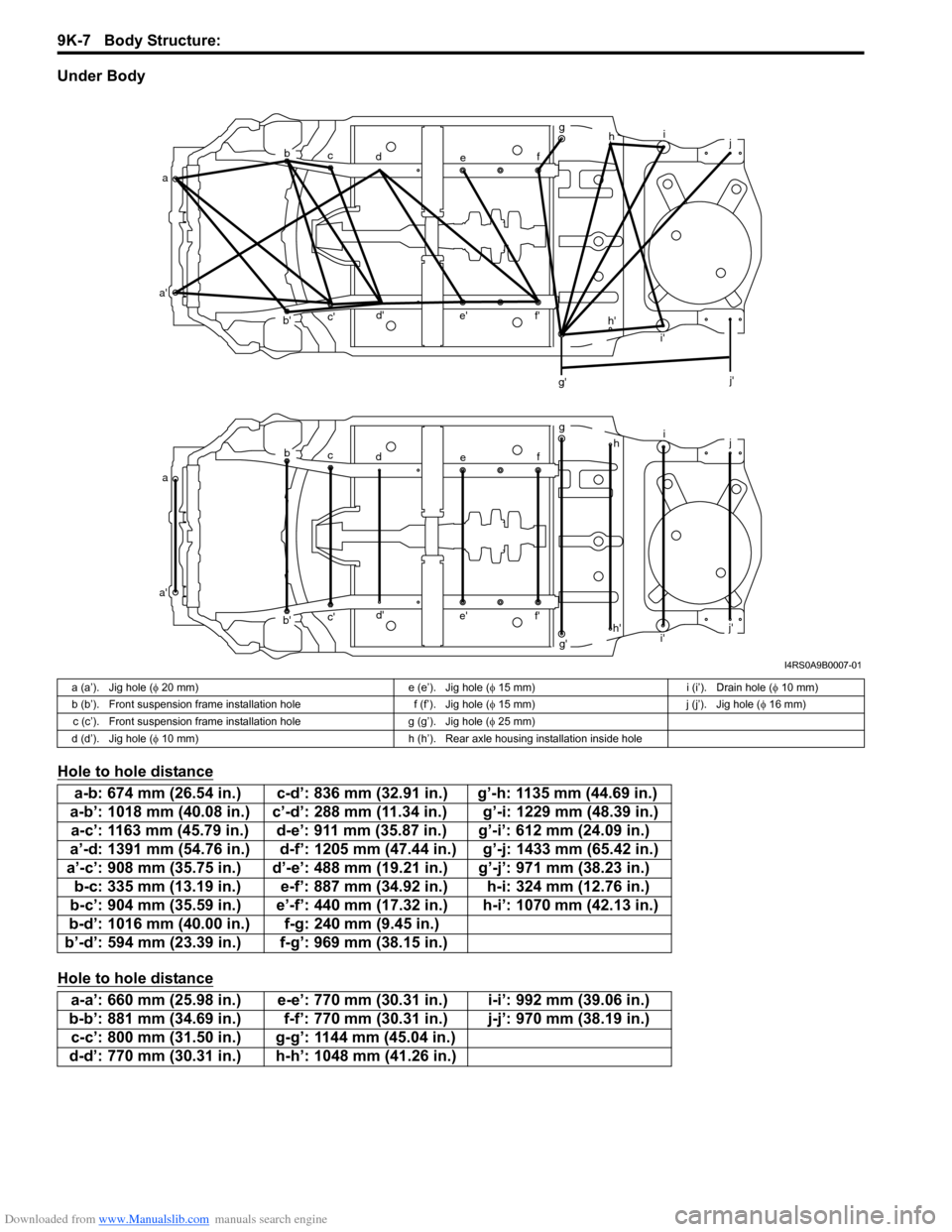

Under Body

Hole to hole distance

Hole to hole distance

ab

c d e fg

h i

j

a' b'c'

d'

e' f'

g' i'

j'

a b

c d e fg

hi

j

a' b'c'

d'

e' f'

g'h'

i' j'

h'

I4RS0A9B0007-01

a (a’). Jig hole (

φ 20 mm) e (e’). Jig hole ( φ 15 mm) i (i’). Drain hole ( φ 10 mm)

b (b’). Front suspension frame installation hole f (f’). Jig hole ( φ 15 mm) j (j’). Jig hole ( φ 16 mm)

c (c’). Front suspension frame installation hole g (g’). Jig hole (φ 25 mm)

d (d’). Jig hole ( φ 10 mm) h (h’). Rear axle housing installation inside hole

a-b: 674 mm (26.54 in.) c-d’: 836 mm (32.91 in.) g’-h: 1135 mm (44.69 in.)

a-b’: 1018 mm (40.08 in.) c’-d’: 288 mm (11.34 in.) g’-i: 1229 mm (48.39 in.) a-c’: 1163 mm (45.79 in.) d-e’: 911 mm (35.87 in.) g’-i’: 612 mm (24.09 in.)

a’-d: 1391 mm (54.76 in.) d-f’: 1205 mm (47.44 in.) g’-j: 1433 mm (65.42 in.)

a’-c’: 908 mm (35.75 in.) d’-e’: 488 mm (1 9.21 in.) g’-j’: 971 mm (38.23 in.)

b-c: 335 mm (13.19 in.) e-f’: 887 mm (34.92 in.) h-i: 324 mm (12.76 in.)

b-c’: 904 mm (35.59 in.) e’-f’: 440 mm (17.32 in.) h-i’: 1070 mm (42.13 in.)

b-d’: 1016 mm (40.00 in.) f-g: 240 mm (9.45 in.)

b’-d’: 594 mm (23.39 in.) f-g’: 969 mm (38.15 in.)

a-a’: 660 mm (25.98 in.) e-e’: 770 mm (30.31 in.) i-i’: 992 mm (39.06 in.)

b-b’: 881 mm (34.69 in.) f-f’: 770 mm (30.31 in.) j-j’: 970 mm (38.19 in.) c-c’: 800 mm (31.50 in.) g-g’: 1144 mm (45.04 in.)

d-d’: 770 mm (30.31 in.) h-h’: 1048 mm (41.26 in.)

Page 1385 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Structure: 9K-8

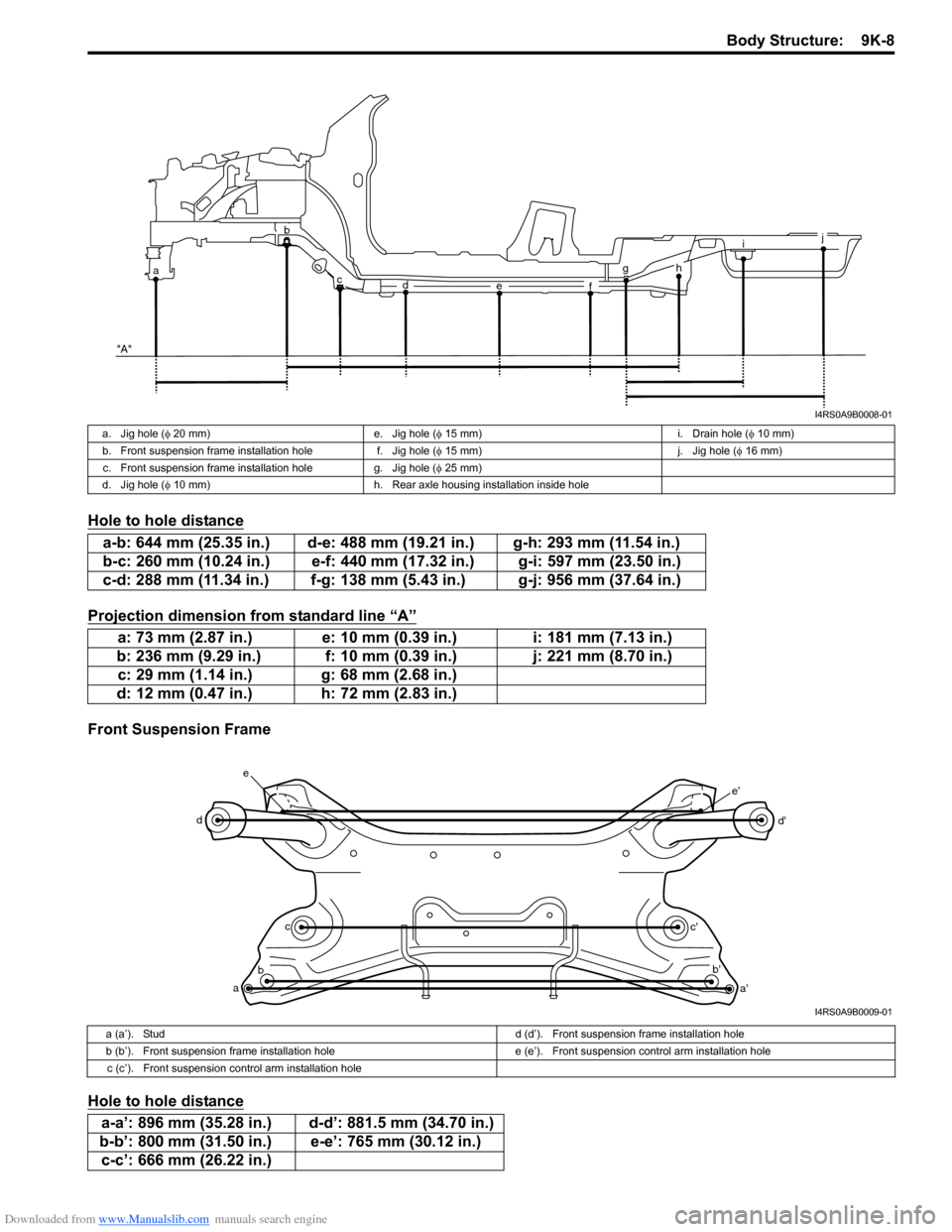

Hole to hole distance

Projection dimension from standard line “A”

Front Suspension Frame

Hole to hole distance

i

g

f

e

d

c

ab

"A"j

h

I4RS0A9B0008-01

a. Jig hole ( φ 20 mm) e. Jig hole ( φ 15 mm) i. Drain hole ( φ 10 mm)

b. Front suspension frame installation hole f. Jig hole (φ 15 mm) j. Jig hole (φ 16 mm)

c. Front suspension frame installation hole g. Jig hole ( φ 25 mm)

d. Jig hole ( φ 10 mm) h. Rear axle housing installation inside hole

a-b: 644 mm (25.35 in.) d-e: 488 mm (19.21 in.) g-h: 293 mm (11.54 in.)

b-c: 260 mm (10.24 in.) e-f: 440 mm (17.32 in.) g-i: 597 mm (23.50 in.)

c-d: 288 mm (11.34 in.) f-g: 138 mm (5.43 in.) g-j: 956 mm (37.64 in.)

a: 73 mm (2.87 in.) e: 10 mm (0.39 in.) i: 181 mm (7.13 in.)

b: 236 mm (9.29 in.) f: 10 mm (0.39 in.) j: 221 mm (8.70 in.) c: 29 mm (1.14 in.) g: 68 mm (2.68 in.)

d: 12 mm (0.47 in.) h: 72 mm (2.83 in.)

a b c

d

e

a'

b'

c' d'

e'

I4RS0A9B0009-01

a (a’). Stud

d (d’). Front suspension frame installation hole

b (b’). Front suspension frame installation hole e (e’). Front suspension control arm installation hole

c (c’). Front suspension control arm installation hole

a-a’: 896 mm (35.28 in.) d-d’: 881.5 mm (34.70 in.)

b-b’: 800 mm (31.50 in.) e-e’: 765 mm (30.12 in.) c-c’: 666 mm (26.22 in.)

Page 1386 of 1496

Downloaded from www.Manualslib.com manuals search engine 9K-9 Body Structure:

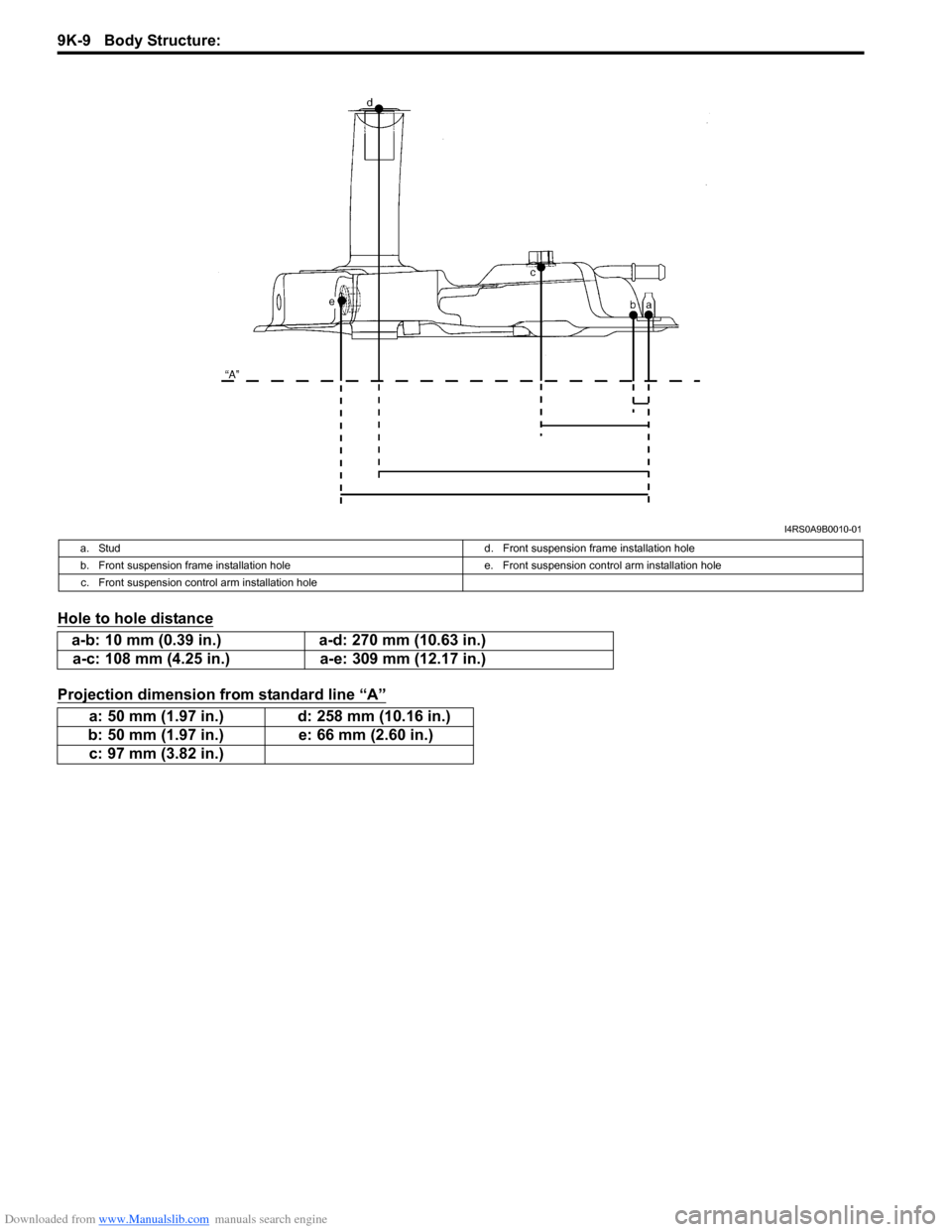

Hole to hole distance

Projection dimension from standard line “A”

I4RS0A9B0010-01

a. Studd. Front suspension frame installation hole

b. Front suspension frame installation hole e. Front suspension control arm installation hole

c. Front suspension control arm installation hole

a-b: 10 mm (0.39 in.) a-d: 270 mm (10.63 in.)

a-c: 108 mm (4.25 in.) a-e: 309 mm (12.17 in.)

a: 50 mm (1.97 in.) d: 258 mm (10.16 in.)

b: 50 mm (1.97 in.) e: 66 mm (2.60 in.)

c: 97 mm (3.82 in.)

Page 1389 of 1496

Downloaded from www.Manualslib.com manuals search engine Paint / Coatings: 9L-2

Plastic Parts FinishingS7RS0B9C01002

Paintable plastic parts are ABS plastic parts.

Painting

Rigid or hand ABS plastic needs no primer coating.

General acrylic lacquers can be painted properly over hard ABS plastic in terms of adherence.

1) Use cleaning solvent for paint finish to wash each part.

2) Apply conventional acrylic color lacquer to part surface.

3) Follow lacquer directions for required drying time. (Proper drying temperature range is 60 – 70 °C (140 – 158 ° F)).

Reference

Plastic parts employ not only ABS (Acrylonitrile Butadiene Styrene) plastic but also polypro pylene, vinyl, or the like

plastic. Burning test method to iden tify ABS plastic is described below.

1) Use a sharp blade to cut off a plastic sliver from the part at its hidden backside.

2) Hold sliver with pincer s and set it on fire.

3) Carefully observe condition of the burning plastic.

4) ABS plastic must raise readily dist inguishable back smoke while burning with its residue suspended in air

temporarily.

5) Polypropylene must raise no readily distinguishable smoke while burning.

Page 1414 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-11 Body Electrical Control System:

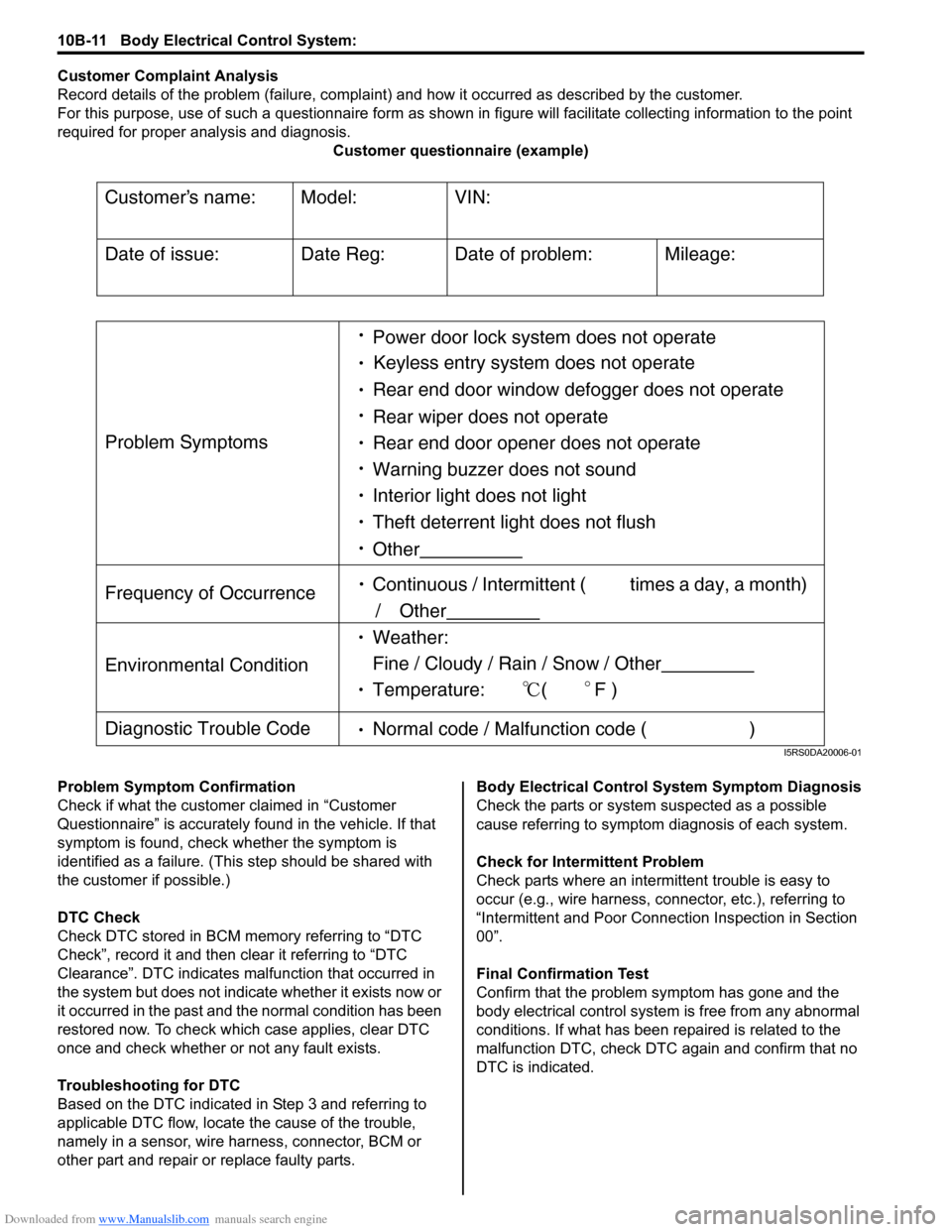

Customer Complaint Analysis

Record details of the problem (failure, complaint) and how it occurred as described by the customer.

For this purpose, use of such a questionnaire form as shown in figure will facilitate collectin g information to the point

required for proper analysis and diagnosis. Customer questionnaire (example)

Problem Symptom Confirmation

Check if what the custom er claimed in “Customer

Questionnaire” is accurately f ound in the vehicle. If that

symptom is found, check whether the symptom is

identified as a failure. (This step should be shared with

the customer if possible.)

DTC Check

Check DTC stored in BCM me mory referring to “DTC

Check”, record it and then clear it referring to “DTC

Clearance”. DTC indicates malfunction that occurred in

the system but does not indicate whether it exists now or

it occurred in the past and the normal condition has been

restored now. To check which case applies, clear DTC

once and check whether or not any fault exists.

Troubleshooting for DTC

Based on the DTC indicated in Step 3 and referring to

applicable DTC flow, locate the cause of the trouble,

namely in a sensor, wire harness, connector, BCM or

other part and repair or replace faulty parts. Body Electrical Control System Symptom Diagnosis

Check the parts or system

suspected as a possible

cause referring to symptom diagnosis of each system.

Check for Intermi ttent Problem

Check parts where an intermit tent trouble is easy to

occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connec tion Inspection in Section

00”.

Final Confirmation Test

Confirm that the problem symptom has gone and the

body electrical control system is free from any abnormal

conditions. If what has been repaired is related to the

malfunction DTC, check DTC again and confirm that no

DTC is indicated.

Customers name:

Model:

VIN:

Date of issue:

Date Reg:

Date of problem:

Mileage:

Problem Symptoms

Power door lock system does not operate

Keyless entry system does not operate

Rear end door window defogger does not operate

Rear wiper does not operate

Rear end door opener does not operate

Other

Frequency of Occurrence

Continuous / Intermittent ( times a day, a month)

/ Other

Environmental Condition

Weather:

Fine / Cloudy / Rain / Snow / Other

Temperature: (F )

Diagnostic Trouble Code Normal code / Malfunction code ( )

Warning buzzer does not sound

Interior light does not light

Theft deterrent light does not flush

I5RS0DA20006-01