1A-85 SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 46 of 1496

Downloaded from www.Manualslib.com manuals search engine 1-ii Table of Contents

DTC P0123: Throttle / Pedal Position Sensor / Switch “A” (Main) Circuit High ....................... 1A-85

DTC P0131 / P0132: O2 Sensor (HO2S) Circuit Low Voltage / High Voltage (Sensor-

1) ..................................................................... 1A-88

DTC P0133: O2 Sensor (HO2S) Circuit Slow

Response (Sensor- 1) ...................................... 1A-91

DTC P0134: O2 Sensor (HO2S) Circuit No Activity Detected (Sensor -1) ........................... 1A-92

DTC P0137 / P0138: O2 Sensor (HO2S) Circuit Low Voltage / High Voltage (Sensor-

2) ..................................................................... 1A-94

DTC P0140: O2 Sensor (HO2S) Circuit No Activity Detected (Sensor -2) ........................... 1A-97

DTC P0171 / P0172: Fuel System Too Lean / Rich ................................................................. 1A-98

DTC P0222: Throttle / Pedal Position Sensor / Switch “B” (Sub) Circuit Low ....................... 1A-100

DTC P0223: Throttle / Pedal Position Sensor / Switch “B” (Sub) Circuit High ...................... 1A-102

DTC P0300 / P0301 / P0302 / P0303 / P0304: Random / Multiple Cylin der Misfire Detected

/ Cylinder 1 / Cylinder 2 / Cylinder 3 /

Cylinder 4 Misfire Detected ........................... 1A-105

DTC P0327 / P0328: Knoc k Sensor 1 Circuit

Low / High ..................................................... 1A-107

DTC P0335: Crankshaft Position (CKP) Sensor “A” Circuit .......................................... 1A-109

DTC P0340: Camshaft Position (CMP) Sensor “A” Circuit .......................................... 1A-111

DTC P0350: Ignition Coil Primary / Secondary Circuit ............................................................ 1A-114

DTC P0401 / P0402: Exhaust Gas Recirculation Flow Insufficient Detected /

Excessive Detected ...................................... 1A-116

DTC P0403: Exhaust Gas Recirculation Control Circuit ................... ............................ 1A-118

DTC P0420: Catalyst System Efficiency

below Threshold ................ ............................ 1A-120

DTC P0443: Evaporativ e Emission System

Purge Control Valve Circuit ........................... 1A-122

DTC P0480: Fan 1 (Radiator Cooling Fan) Control Circuit ................... ............................ 1A-124

DTC P0500: Vehicle Speed Sensor “A” Malfunction .................................................... 1A-128

DTC P0532: A/C Refrigerant Pressure Sensor “A” Circuit Low ... ............................... 1A-130

DTC P0533: A/C Refrigerant Pressure Sensor “A” Circuit High ................................. 1A-132

DTC P0601 / P0602 / P0607: Internal Control Module Memory Check Sum Error / Control

Module Programming Error / Control Module

Performance ................................................. 1A-134

DTC P0616: Starter Relay Circuit Low............ 1A-135

DTC P0617: Starter Relay Circuit High ........... 1A-136

DTC P0620: Generator Control Circuit ........... 1A-137

DTC P0625 / P0626: Generator Field Terminal Circuit Low / High . .......................... 1A-139

DTC P1501 / P1502: Electric Load Current Sensor Circuit Low / High . ............................ 1A-141 DTC P1510: ECM Back-Up Power Supply

Malfunction .................................................... 1A-143

DTC P1603: TCM Trouble Code Detected ..... 1A-144

DTC P1674: CAN Communication (Bus Off Error) ............................................................. 1A-145

DTC P1676: CAN Communication (Reception Error for TCM) ............................................... 1A-148

DTC P1678: CAN Communication (Reception Error for BCM) ............................................... 1A-149

DTC P1685: CAN Communication (Reception Error for ABS/ESP ® Control Module) ........... 1A-150

DTC P2101: Throttle Actuator Control Motor Circuit Range / Performance ......................... 1A-152

DTC P2102: Throttle Actuator Control Motor Circuit Low .................................................... 1A-154

DTC P2103: Throttle Actuator Control Motor Circuit High.................................................... 1A-155

DTC P2111 / P2112: Throttle Actuator Control System - Stuck Open / Closed ...................... 1A-156

DTC P2119: Throttle Actu ator Control Throttle

Body Range / Performance ........................... 1A-157

DTC P2122: Throttle / Pedal Position Sensor / Switch “D” (Main) Circuit Low Input............. 1A-159

DTC P2123: Throttle / Pedal Position Sensor / Switch “D” (Main) Circuit High Input ............ 1A-161

DTC P2127: Throttle Pedal Position Sensor / Switch “E” (Sub) Circuit Low Input ................ 1A-164

DTC P2128: Throttle / Pedal Position Sensor

/ Switc

h “E” (Sub) Circuit High Input ............. 1A-166

DTC P2135: Throttle / Pedal Position Sensor / Switch “A”/“B” (Main / Sub) Voltage

Correlation..................................................... 1A-168

DTC P2138: Throttle / Pedal Position Sensor / Switch “D”/“E” (Main / Sub) Voltage

Correlation..................................................... 1A-171

DTC P2227 / P2228 / P2229: Barometric Pressure Circuit Malfunction ......................... 1A-173

Inspection of ECM and Its Circuits .................. 1A-175

ECM Power and Ground Circuit Check........... 1A-194

Fuel Injector Circuit Check .............................. 1A-198

Fuel Pump and Its Circuit Check..................... 1A-200

Fuel Pressure Check....................................... 1A-203

A/C System Circuits Check ............................. 1A-205

Electric Load Signal Circuit Check .................. 1A-209

Radiator Cooling Fan Low Speed Control System Check ............................................... 1A-211

Radiator Cooling Fan High Speed Control System Check ............................................... 1A-213

Repair Instructions ......... .................................1A-216

Idle Speed and IAC Throttle Valve Opening Inspection ...................................................... 1A-216

Special Tools and Equipmen t .........................1A-217

Special Tool .................................................... 1A-217

Aux. Emission Control Devices ............. 1B-1

Diagnostic Information and Procedures ............1B-1

EGR System Inspection ...................................... 1B-1

Repair Instructions ............ ..................................1B-1

EVAP Canister Purge Inspec tion ........................ 1B-1

Page 135 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-85

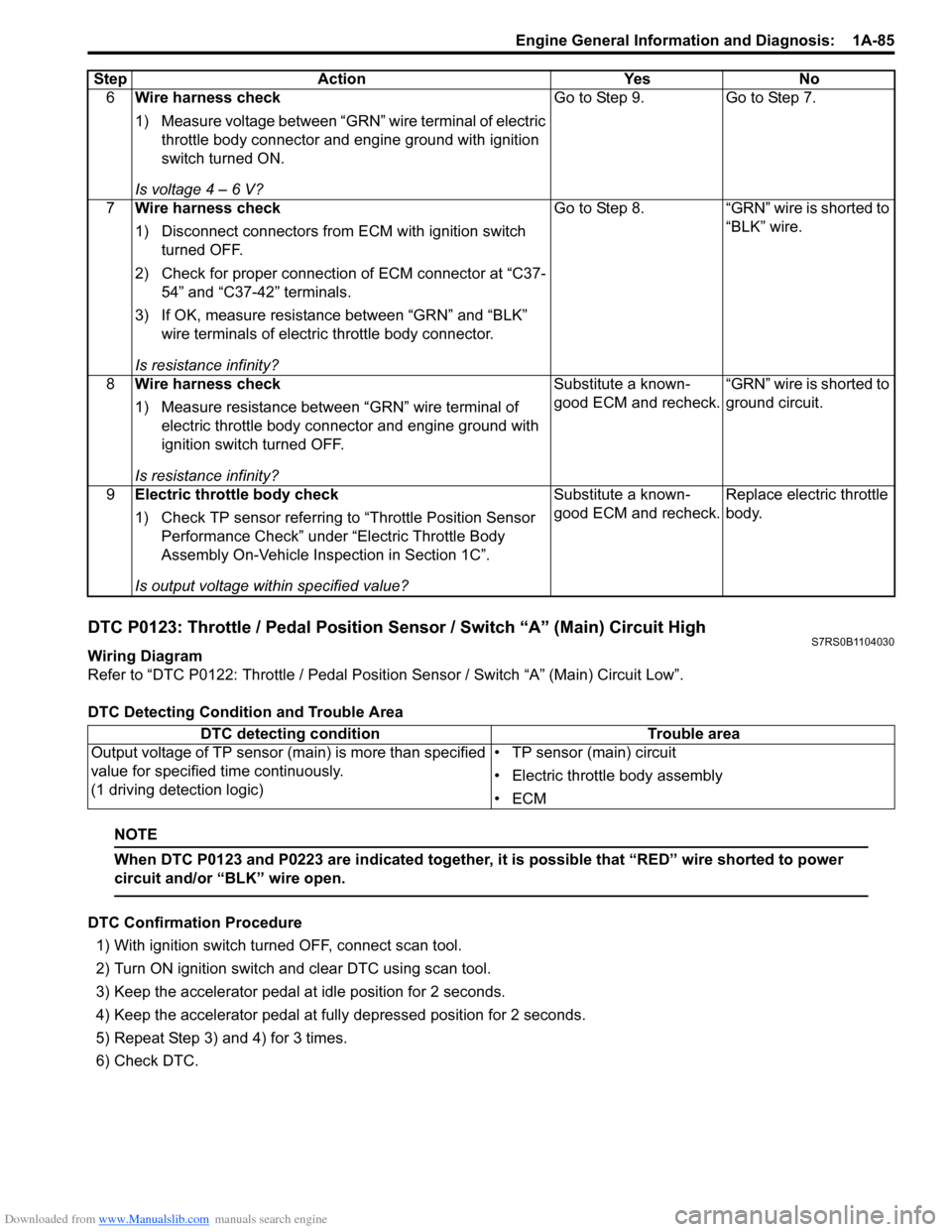

DTC P0123: Throttle / Pedal Position Sensor / Switch “A” (Main) Circuit HighS7RS0B1104030

Wiring Diagram

Refer to “DTC P0122: Throttle / Pedal Position Sensor / Switch “A” (Main) Circuit Low”.

DTC Detecting Condition and Trouble Area

NOTE

When DTC P0123 and P0223 are indicated together, it is possible that “RED” wire shorted to power

circuit and/or “BLK” wire open.

DTC Confirmation Procedure

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Keep the accelerator pedal at idle position for 2 seconds.

4) Keep the accelerator pedal at fully depressed position for 2 seconds.

5) Repeat Step 3) and 4) for 3 times.

6) Check DTC. 6

Wire harness check

1) Measure voltage between “GRN” wire terminal of electric

throttle body connector and engine ground with ignition

switch turned ON.

Is voltage 4 – 6 V? Go to Step 9. Go to Step 7.

7 Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection of ECM connector at “C37- 54” and “C37-42” terminals.

3) If OK, measure resistance between “GRN” and “BLK” wire terminals of electric throttle body connector.

Is resistance infinity? Go to Step 8. “GRN” wire is shorted to

“BLK” wire.

8 Wire harness check

1) Measure resistance between “GRN” wire terminal of

electric throttle body connector and engine ground with

ignition switch turned OFF.

Is resistance infinity? Substitute a known-

good ECM and recheck.

“GRN” wire is shorted to

ground circuit.

9 Electric throttle body check

1) Check TP sensor referring to “Throttle Position Sensor

Performance Check” under “Electric Throttle Body

Assembly On-Vehicle Inspection in Section 1C”.

Is output voltage within specified value? Substitute a known-

good ECM and recheck.

Replace electric throttle

body.

Step Action Yes No

DTC detecting condition

Trouble area

Output voltage of TP sensor (main) is more than specified

value for specified time continuously.

(1 driving detection logic) • TP sensor (main) circuit

• Electric throttle body assembly

•ECM